transmission DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4120 of 5267

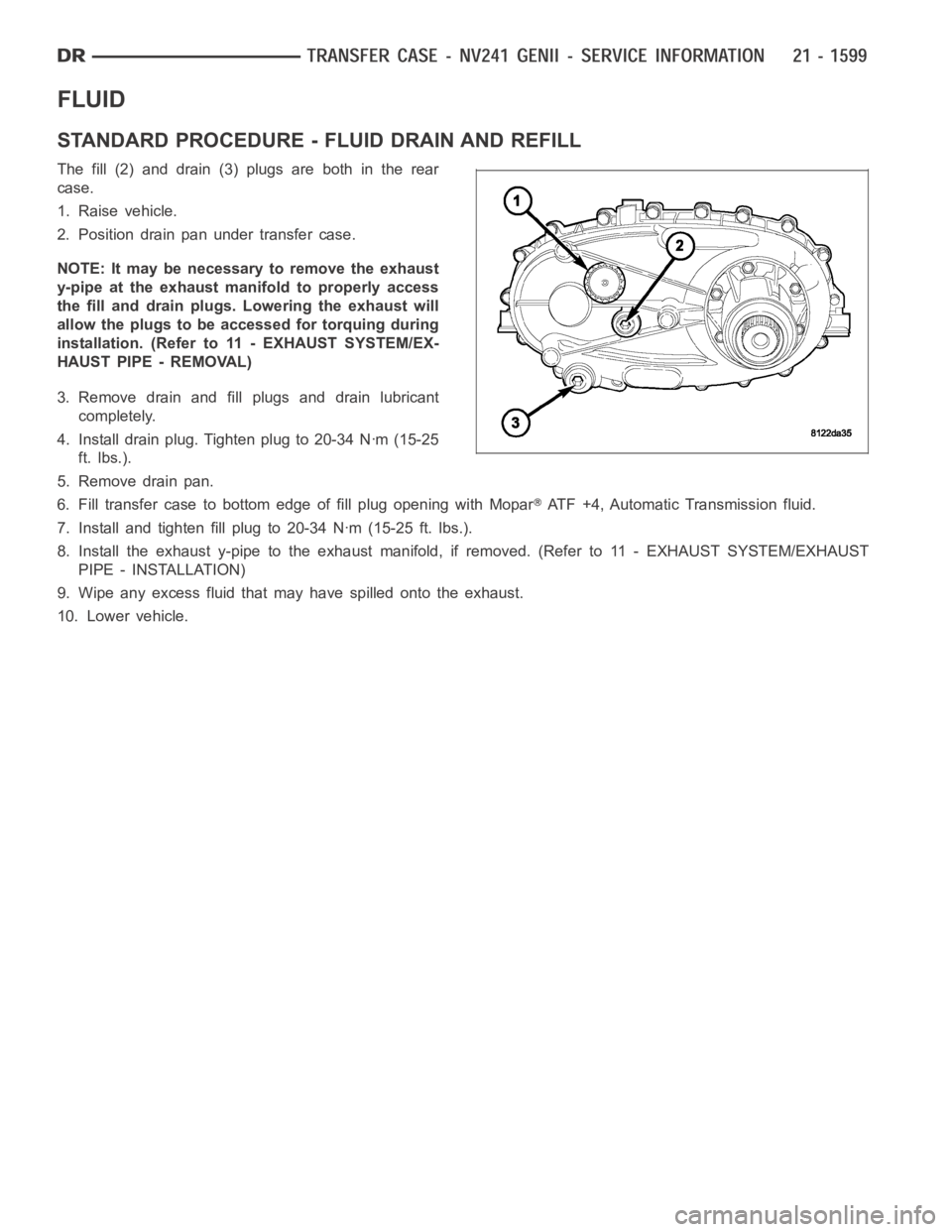

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND REFILL

The fill (2) and drain (3) plugs are both in the rear

case.

1. Raise vehicle.

2. Position drain pan under transfer case.

NOTE: It may be necessary to remove the exhaust

y-pipe at the exhaust manifold to properly access

the fill and drain plugs. Lowering the exhaust will

allow the plugs to be accessed for torquing during

installation. (Refer to 11 - EXHAUST SYSTEM/EX-

HAUST PIPE - REMOVAL)

3. Remove drain and fill plugs and drain lubricant

completely.

4. Install drain plug. Tighten plug to 20-34 Nꞏm (15-25

ft. lbs.).

5. Remove drain pan.

6. Fill transfer case to bottom edge of fill plug opening with Mopar

ATF +4, Automatic Transmission fluid.

7. Install and tighten fill plug to 20-34 Nꞏm (15-25 ft. lbs.).

8. Install the exhaust y-pipe to the exhaust manifold, if removed. (Refer to 11 - EXHAUST SYSTEM/EXHAUST

PIPE - INSTALLATION)

9. Wipe any excess fluid that mayhave spilled onto the exhaust.

10. Lower vehicle.

Page 4128 of 5267

A straight line shift pattern is used with a NEUTRAL detent. Lever range positions are imprinted in the shift knob.

SHIFTING

The transfer case can be shifted between the 2H and 4H operating ranges while the vehicle is in motion. The vehi-

cle must have the transmission placed in NEUTRAL, or the clutch depressed in the case of a manual transmission,

and be moving less than 2-3 MPH when shifting into and out of the 4L operatingrange.

DIAGNOSIS AND TESTING - TRANSFER CASE - NV271

Before beginning repair on a suspected transfer case malfunction, check all other driveline components beforehand.

The actual cause of a problem may be related to such items as: front hubs, axles, propeller shafts, wheels and tires,

transmission, or clutch instead. If all other driveline components are ingood condition and operating properly, refer

to the Diagnosis Chart for further information.

DIAGNOSIS CHART

Condition Possible Cause Correction

Transfer Case difficult to shift or will

not shift into desired range.1) Vehicle speed too great to permit

shifting.1) Stop vehicle and shift into

desired range. Or, reduce speed to

below 3-4 km/h (2-3 mph) before

attempting the shift.

2) If vehicle was operated for an

extended period in 4H on a dry

paved surface, the driveline torque

load may be causing a bind.2) Stop vehicle and shift the

transmission into neutral. Shift the

transfer case to 2H and operate

vehicle in 2H on dry paved

surfaces.

3) Transfer case external shift

linkage binding.3) Lubricate, repair, or replace

linkage bushings, or tighten loose

components as necessary.

4) Insufficient or incorrect lubricant. 4) Drain and refill to edge of fillhole

with Mopar

ATF +4, Automatic

Transmission fluid.

5) Internal components binding,

worn, or damaged.5) Disassemble the transfer case

and replace worn or damaged

components as necessary.

Transfer Case noisy in all operating

ranges.1) Insufficient or incorrect lubricant. 1) Drain and refill to edge of fillhole

with Mopar

ATF +4, Automatic

Transmission fluid.

Noisy in, or jumps out of, four wheel

drive low range.1) Transfer case not completely

engaged in 4L position.1) With the transmission in

NEUTRAL, or the clutch depressed

in the case of a manual

transmission and the vehicle moving

under 3-4 km/h (2-3 mph), shift the

transfer case to NEUTRAL and then

shift into the 4L position.

2) Shift linkage out of adjustment. 2) Adjust linkage.

3) Shift linkage loose or binding. 3) Tighten, lubricate, or repair

linkage as necessary.

4) Range fork damaged, inserts

worn, or fork is binding on the shift

rail.4) Disassemble unit and repair as

necessary.

5) Low range gear worn or

damaged.5) Disassemble unit and repair as

necessary.

Page 4129 of 5267

Condition Possible Cause Correction

Lubricant leaking from output shaft

seal or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Vent closed or restricted. 2) Clear or replace vent as

necessary.

3) Output shaft seals damaged or

installed incorrectly.3) Replace seal as necessary.

Check to ensure that another

component, the propeller shaft slip

yoke for example, is not causing

damage to seal.

Abnormal tire wear. 1) Extended operation on hard, dry

surfaces in the 4H position.1) Operate vehicle in the 2H

position on hard, dry surfaces.

REMOVAL

1. Raise and support vehicle.

2. Remove skid plate, if equipped. (Refer to 13 - FRAMES & BUMPERS/FRAME/TRANSFER CASE SKID PLATE

- REMOVAL)

3. Position drain oil container under transfer case.

4. Remove transfer case drain plug and drain lubricant into container.

5. Disconnect vent hose and transfer case position sensor connector.

6. Disconnect shift rod from grommet in transfer case shift lever, or from floor shift arm whichever provides easy

access. Use channel lock style pliers to press rod out of lever grommet.

7. Support transmission with jack stand.

8. Mark front and rear propeller shafts for assembly reference.

9. Remove front and rear propeller shafts. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - REMOVAL)

10. Support transfer case with suitable jack. Secure transfer case to jackwith safety chains.

11. Remove nuts attaching transfer case to transmission.

12. Move transfer case assembly rearward until free of transmission outputshaft.

13. Lower jack and move transfer case from under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan. Remove drain plug and drain any remaining lubricant remaining in

case.

Page 4152 of 5267

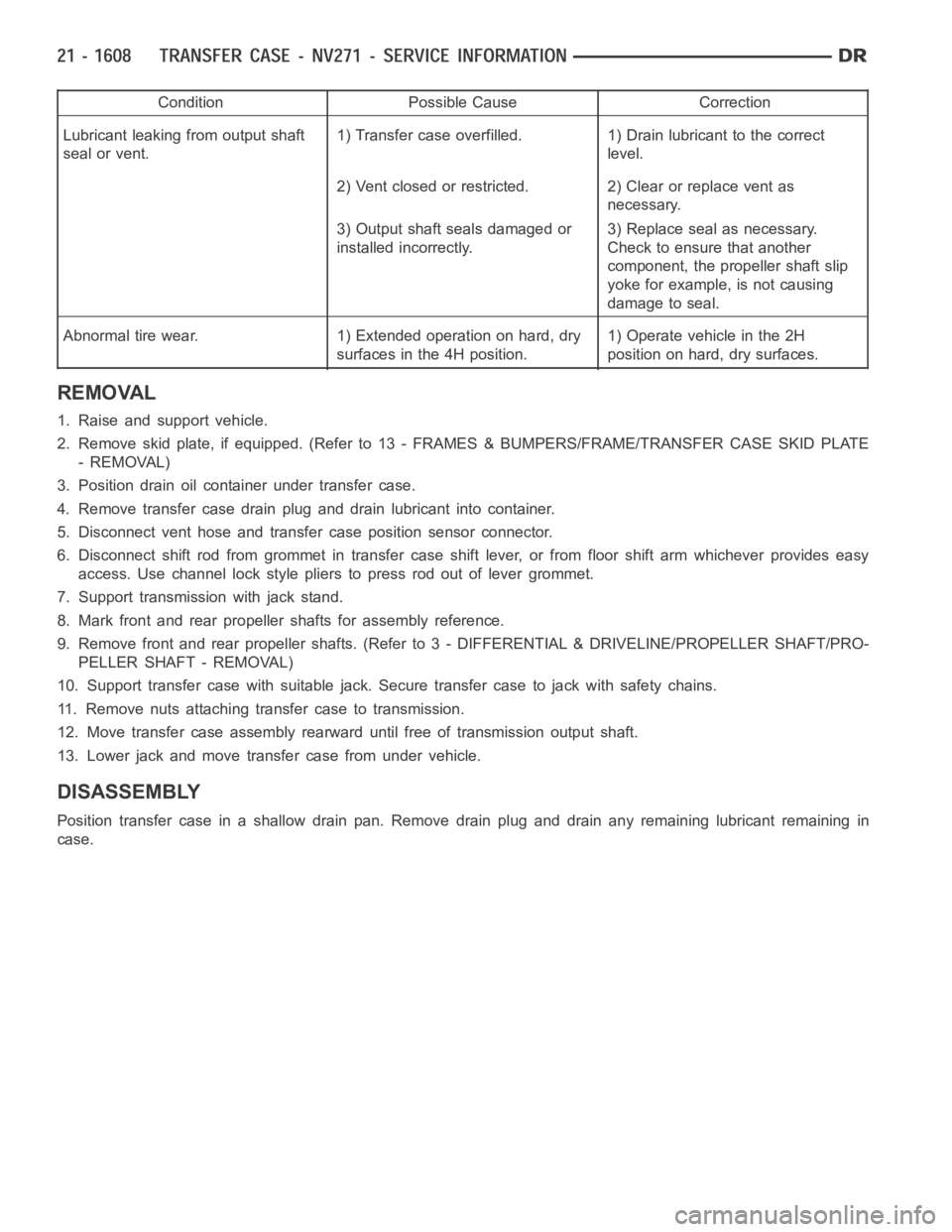

18. Install the rear output shaft bearing into the rear

case (1) using Seal Installer 8152 (3) and Univer-

sal Handle C-4171 (2).

19. Install the rear output shaft bearing snap-ring into

the rear case half.

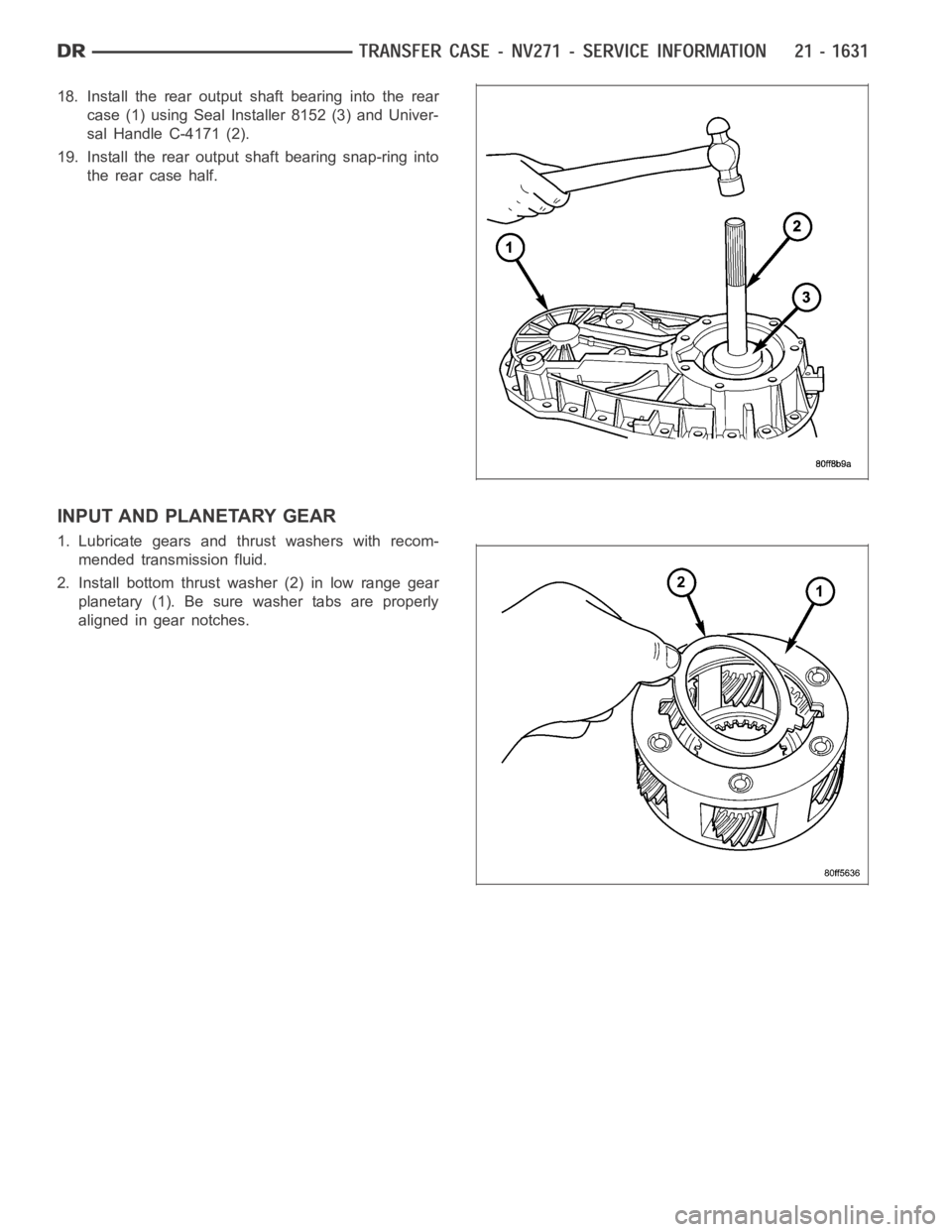

INPUT AND PLANETARY GEAR

1. Lubricate gears and thrust washers with recom-

mended transmission fluid.

2. Install bottom thrust washer (2) in low range gear

planetary (1). Be sure washer tabs are properly

aligned in gear notches.

Page 4155 of 5267

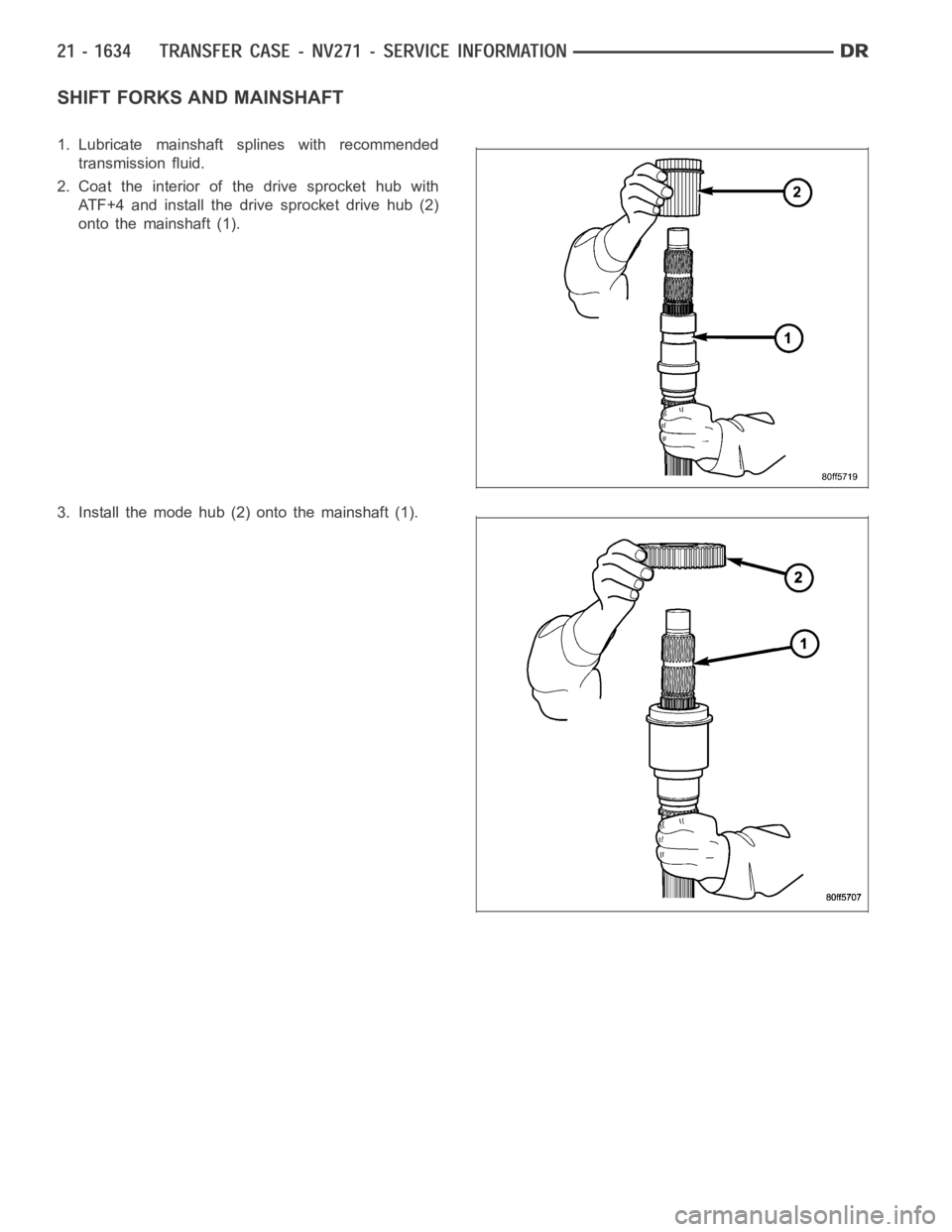

SHIFT FORKS AND MAINSHAFT

1. Lubricate mainshaft splines with recommended

transmission fluid.

2. Coat the interior of the drive sprocket hub with

ATF+4 and install the drive sprocket drive hub (2)

onto the mainshaft (1).

3. Install the mode hub (2) onto the mainshaft (1).

Page 4156 of 5267

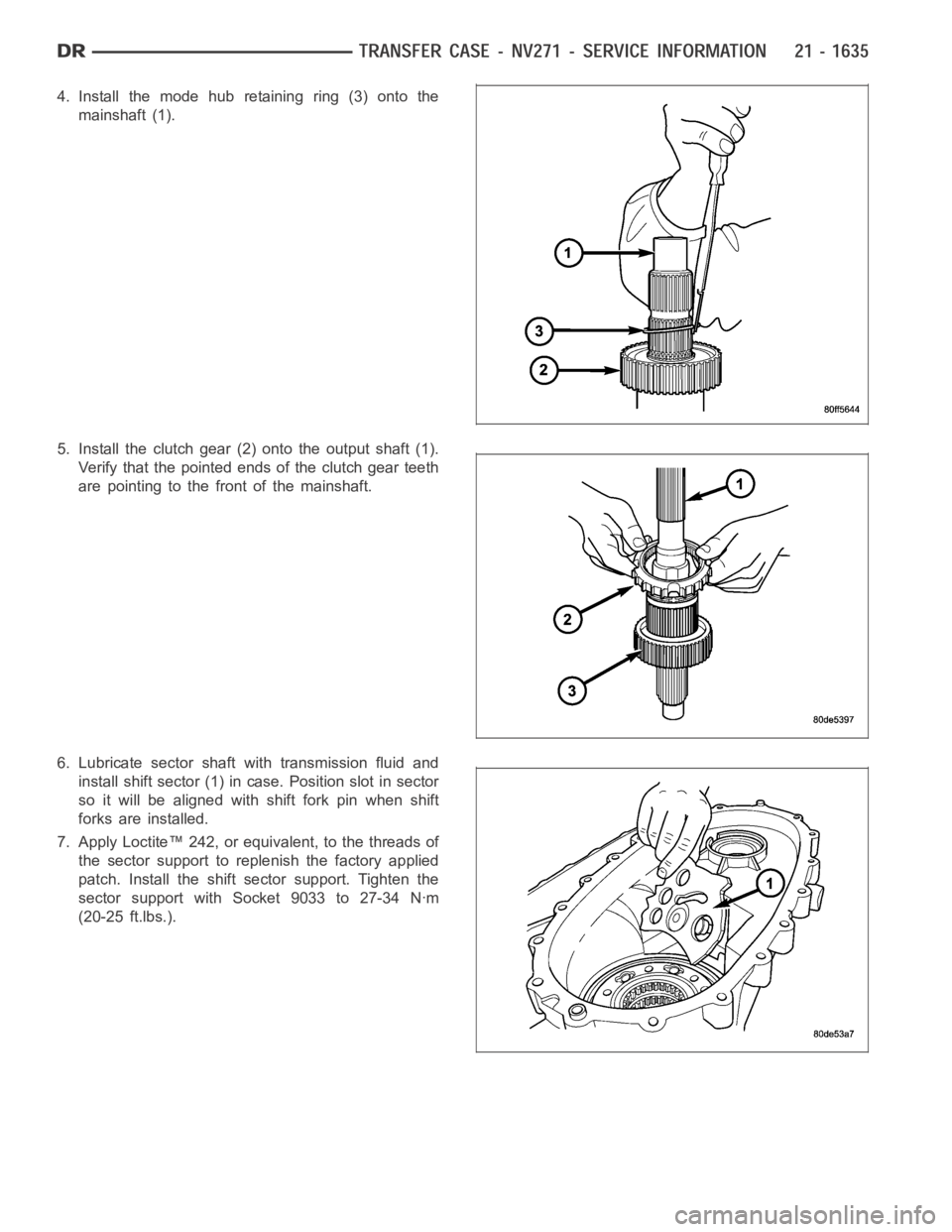

4. Install the mode hub retaining ring (3) onto the

mainshaft (1).

5. Install the clutch gear (2) onto the output shaft (1).

Verify that the pointed ends of the clutch gear teeth

are pointing to the front of the mainshaft.

6. Lubricate sector shaft with transmission fluid and

install shift sector (1) in case. Position slot in sector

so it will be aligned with shift fork pin when shift

forks are installed.

7. Apply Loctite™ 242, or equivalent, to the threads of

the sector support to replenish the factory applied

patch. Install the shift sector support. Tighten the

sector support with Socket 9033 to 27-34 Nꞏm

(20-25 ft.lbs.).

Page 4165 of 5267

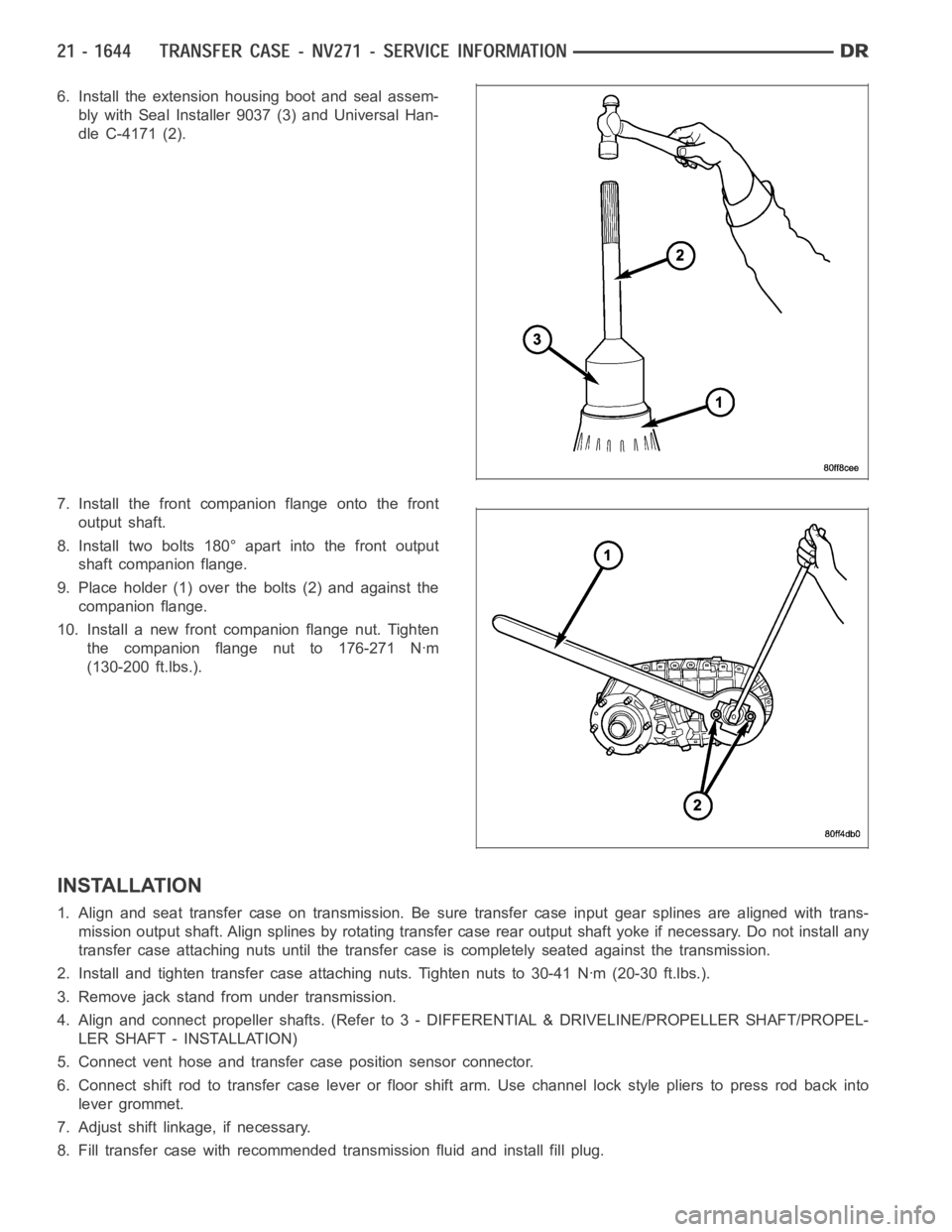

6. Install the extension housing boot and seal assem-

bly with Seal Installer 9037 (3) and Universal Han-

dle C-4171 (2).

7. Install the front companion flange onto the front

output shaft.

8. Install two bolts 180° apart into the front output

shaft companion flange.

9. Place holder (1) over the bolts (2) and against the

companion flange.

10. Install a new front companion flange nut. Tighten

the companion flange nut to 176-271 Nꞏm

(130-200 ft.lbs.).

INSTALLATION

1. Align and seat transfer case on transmission. Be sure transfer case input gear splines are aligned with trans-

mission output shaft. Align splines by rotating transfer case rear outputshaft yoke if necessary. Do not install any

transfer case attaching nuts until the transfer case is completely seatedagainst the transmission.

2. Install and tighten transfer case attaching nuts. Tighten nuts to 30-41Nꞏm (20-30 ft.lbs.).

3. Remove jack stand from under transmission.

4. Align and connect propeller shafts. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/PROPEL-

LER SHAFT - INSTALLATION)

5. Connect vent hose and transfer case position sensor connector.

6. Connect shift rod to transfer case lever or floor shift arm. Use channel lock style pliers to press rod back into

lever grommet.

7. Adjust shift linkage, if necessary.

8. Fill transfer case with recommended transmission fluid and install fillplug.

Page 4170 of 5267

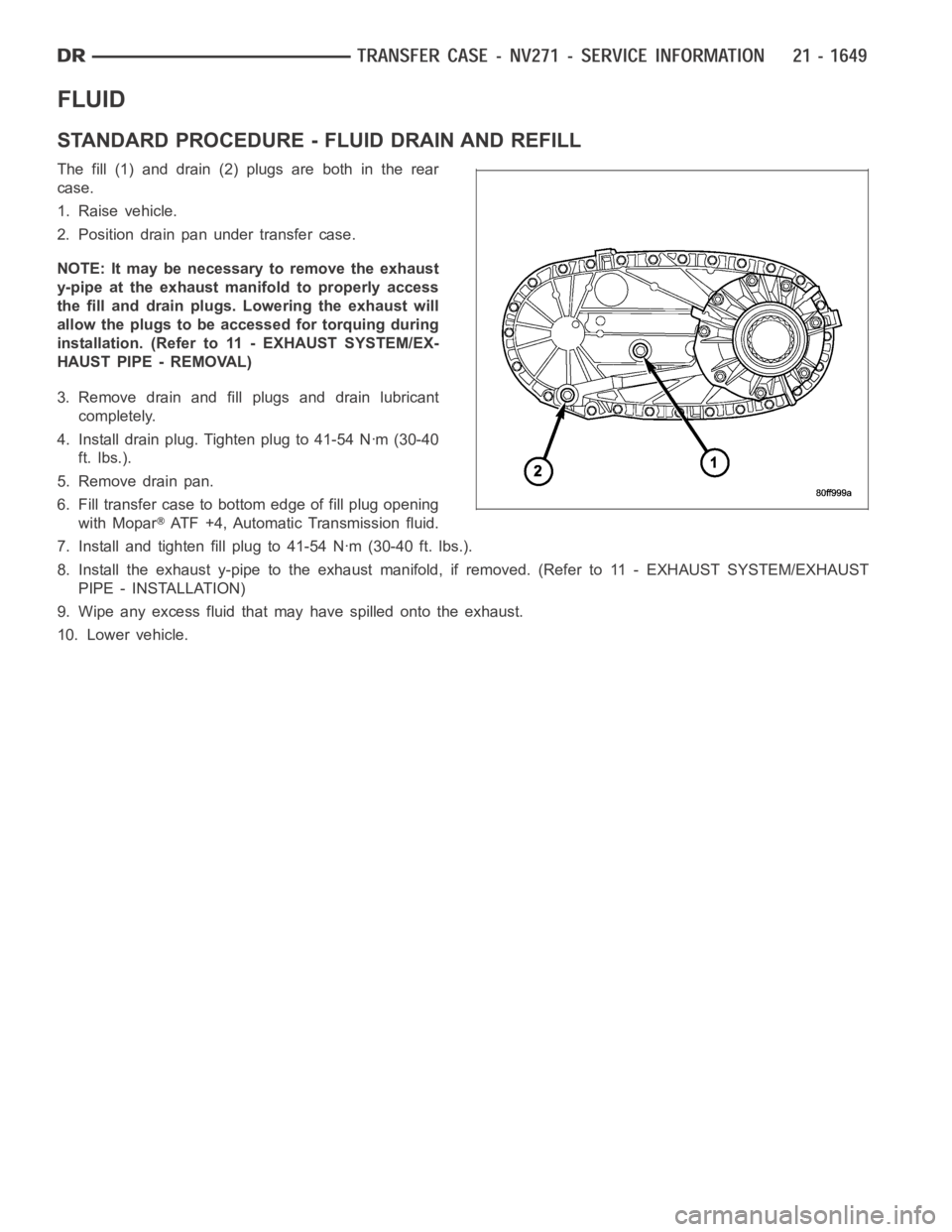

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND REFILL

The fill (1) and drain (2) plugs are both in the rear

case.

1. Raise vehicle.

2. Position drain pan under transfer case.

NOTE: It may be necessary to remove the exhaust

y-pipe at the exhaust manifold to properly access

the fill and drain plugs. Lowering the exhaust will

allow the plugs to be accessed for torquing during

installation. (Refer to 11 - EXHAUST SYSTEM/EX-

HAUST PIPE - REMOVAL)

3. Remove drain and fill plugs and drain lubricant

completely.

4. Install drain plug. Tighten plug to 41-54 Nꞏm (30-40

ft. lbs.).

5. Remove drain pan.

6. Fill transfer case to bottom edge of fill plug opening

with Mopar

ATF +4, Automatic Transmission fluid.

7. Install and tighten fill plug to 41-54 Nꞏm (30-40 ft. lbs.).

8. Install the exhaust y-pipe to the exhaust manifold, if removed. (Refer to 11 - EXHAUST SYSTEM/EXHAUST

PIPE - INSTALLATION)

9. Wipe any excess fluid that may have spilled onto the exhaust.

10. Lower vehicle.

Page 4178 of 5267

TRANSFER CASE - NV243 - SERVICE INFORMATION

DESCRIPTION

The NV243 is an electronically controlled part-time transfer case with a low range gear reduction system. The

NV243 has three operating ranges plus a NEUTRAL position. The low range system provides a gear reduction ratio

for increased low speed torque capability.

The geartrain is mounted in two aluminum case halves attached with bolts. The mainshaft front and rear bearings

are mounted in aluminum retainer housings bolted to the case halves.

OPERATING RANGES

Transfer case operating ranges are:

2WD (2-wheel drive).

4HI (4-wheel drive).

4LO (4-wheel drive low range).

NEUTRAL.

The 2WD range is for use on any road surface at any time.

The 4HI and 4LO ranges are for off road use only. They are not for use on hard surface roads. The only exception

being when the road surface is wet or slippery or covered by ice and snow.

The low range reduction gear system is operative in 4LO range only. This range is for extra pulling power in off road

situations. Low range reduction ratio is 2.72:1.

SHIFT MECHANISM

Operating ranges are selected with a dash mounted shift selector switch. The shift selector switch provides a input

to the Transfer Case Control Module (TCCM) to indicate the driver’s desireto change operating ranges. The TCCM

uses this input, along with input from the transfer case mounted mode sensor and information from the vehicle’s

bus, to determine if a shift is permitted. If the TCCM decides the shift is permitted, the TCCM controls the shift

motor, mounted to the exterior of the transfer case, to perform the shift.

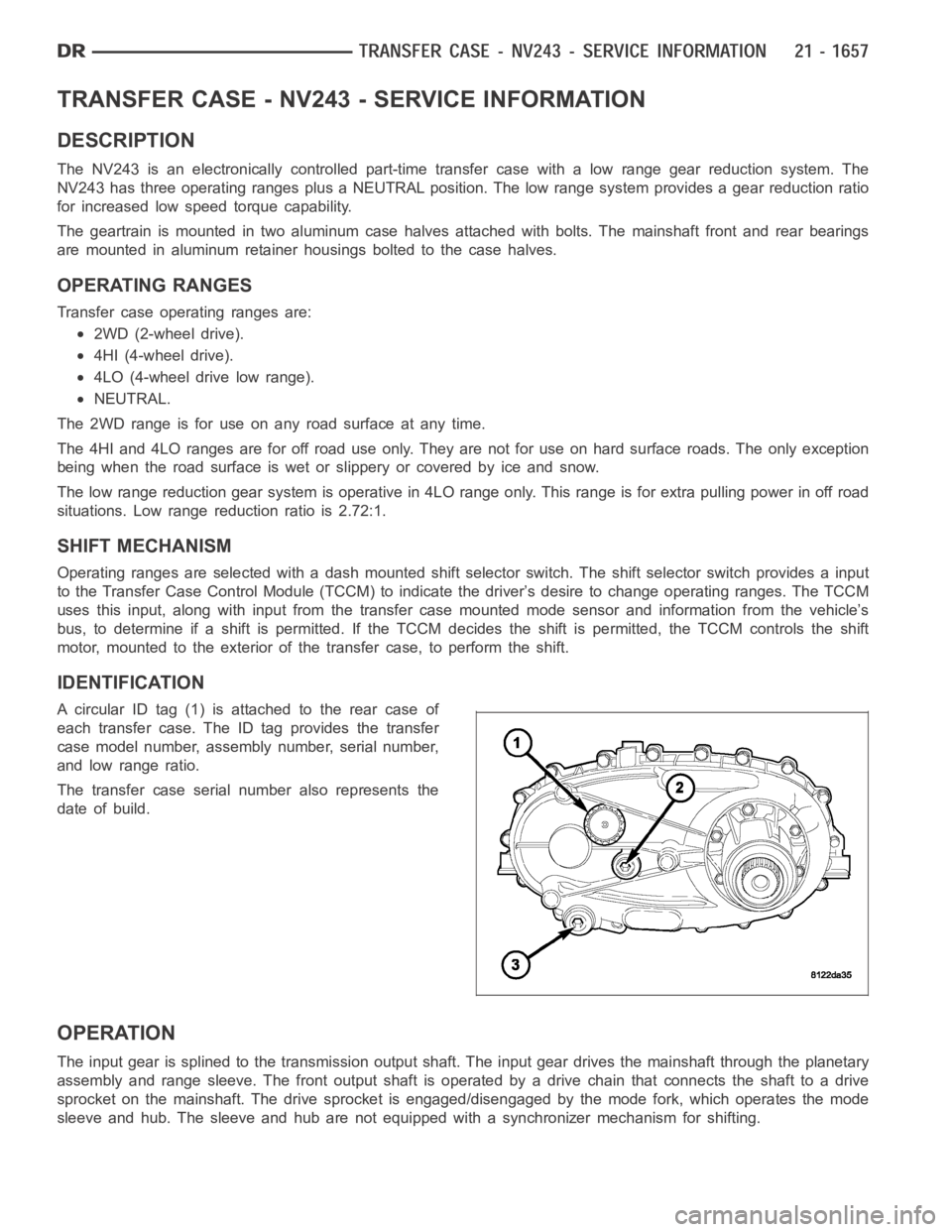

IDENTIFICATION

A circular ID tag (1) is attached to the rear case of

each transfer case. The ID tag provides the transfer

case model number, assembly number, serial number,

and low range ratio.

The transfer case serial number also represents the

date of build.

OPERATION

The input gear is splined to the transmission output shaft. The input gear drives the mainshaft through the planetary

assembly and range sleeve. The front output shaft is operated by a drive chain that connects the shaft to a drive

sprocket on the mainshaft. The drive sprocket is engaged/disengaged by themodefork,whichoperatesthemode

sleeve and hub. The sleeve and hub are not equipped with a synchronizer mechanism for shifting.

Page 4179 of 5267

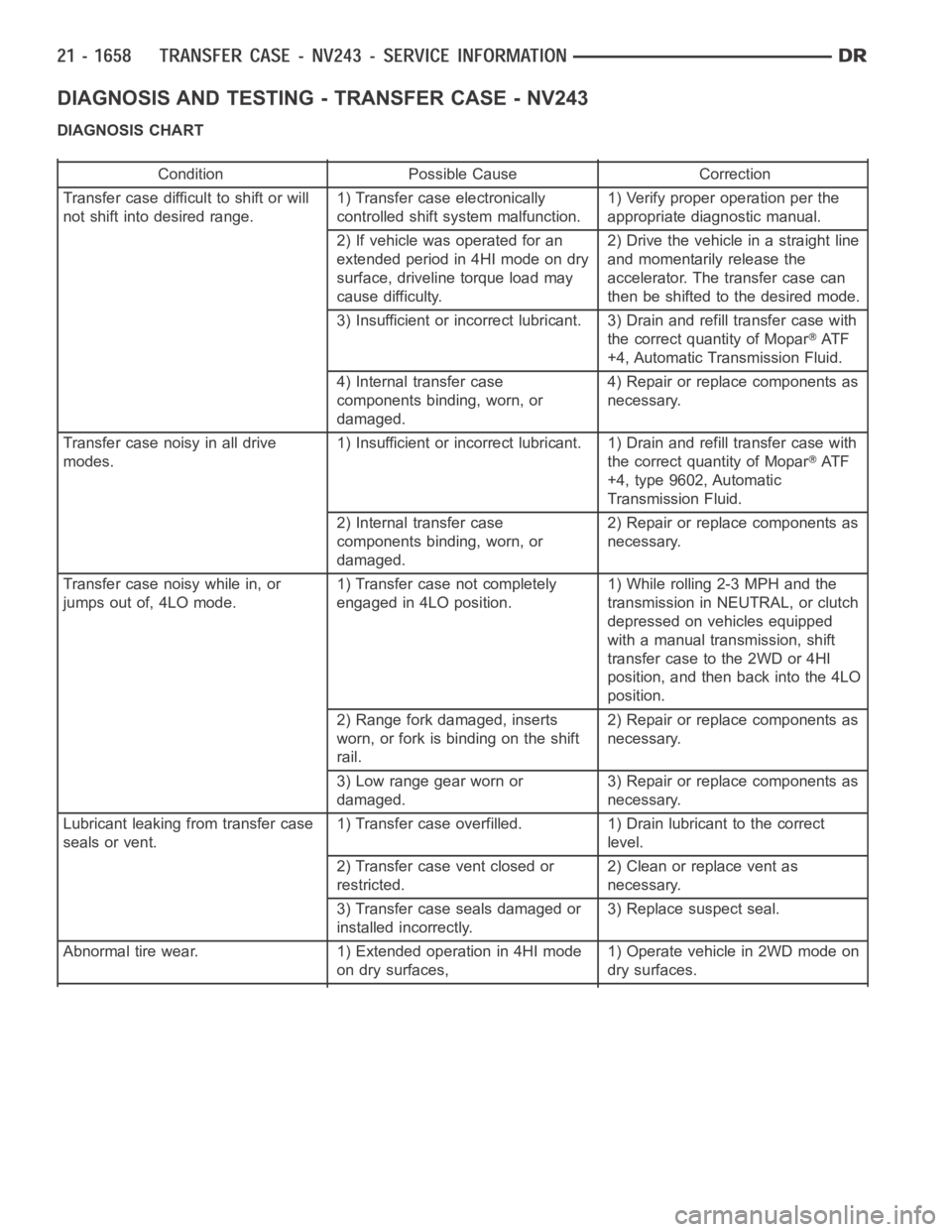

DIAGNOSIS AND TESTING - TRANSFER CASE - NV243

DIAGNOSIS CHART

Condition Possible Cause Correction

Transfer case difficult to shift or will

not shift into desired range.1) Transfer case electronically

controlled shift system malfunction.1) Verify proper operation per the

appropriate diagnostic manual.

2) If vehicle was operated for an

extended period in 4HI mode on dry

surface, driveline torque load may

cause difficulty.2) Drive the vehicle in a straight line

and momentarily release the

accelerator. The transfer case can

then be shifted to the desired mode.

3) Insufficient or incorrect lubricant. 3) Drain and refill transfer casewith

the correct quantity of Mopar

AT F

+4, Automatic Transmission Fluid.

4) Internal transfer case

components binding, worn, or

damaged.4) Repair or replace components as

necessary.

Transfer case noisy in all drive

modes.1) Insufficient or incorrect lubricant. 1) Drain and refill transfer casewith

the correct quantity of Mopar

AT F

+4, type 9602, Automatic

Transmission Fluid.

2) Internal transfer case

components binding, worn, or

damaged.2) Repair or replace components as

necessary.

Transfer case noisy while in, or

jumps out of, 4LO mode.1) Transfer case not completely

engaged in 4LO position.1) While rolling 2-3 MPH and the

transmission in NEUTRAL, or clutch

depressed on vehicles equipped

with a manual transmission, shift

transfer case to the 2WD or 4HI

position, and then back into the 4LO

position.

2) Range fork damaged, inserts

worn, or fork is binding on the shift

rail.2) Repair or replace components as

necessary.

3) Low range gear worn or

damaged.3) Repair or replace components as

necessary.

Lubricant leaking from transfer case

seals or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Transfer case vent closed or

restricted.2) Clean or replace vent as

necessary.

3) Transfer case seals damaged or

installed incorrectly.3) Replace suspect seal.

Abnormal tire wear. 1) Extended operation in 4HI mode

on dry surfaces,1) Operate vehicle in 2WD mode on

dry surfaces.