heating DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 5132 of 5267

degree of vacuum possible (approximately -88 kPa (- 26 in. Hg) or greater) for 30 minutes, close all valves and

turn off vacuum pump. If the system failsto reach specified vacuum, the refrigerant system likely has a leak that

must be corrected. If the refrigerantsystem maintains specified vacuum for at least 30 minutes, start the vacuum

pump, open the suction and discharge valves. Then allow the system to evacuate an additional 10 minutes.

4. Close all valves. Turn off and disconnect the vacuum pump.

5. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

REFRIGERANT SYSTEM CHARGE

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

NOTE: Always refer to the Underhood HVAC Specification Label for the refrigerant fill specification of the

vehicle being serviced.

After all refrigerant system leaks have been repaired and the refrigerantsystem has been evacuated, a refrigerant

charge can be injected into the system. For the proper amount of the refrigerant charge, refer to the Underhood

HVAC Specification Label.

An R-134a refrigerant recovery/recycling/charging station that meets SAE Standard J2210 must be used to charge

the refrigerant system with R-134a refrigerant. Refer to the operating instructions supplied by the equipment man-

ufacturer for proper care and use of this equipment.

CHARGING PROCEDURE

CAUTION: A small amount of refrigerant oil is removed from the A/C system each time the refrigerant sys-

tem is recovered and evacuated. Before charging the A/C system, you MUST replenish any oil lost during

the recovery process. Refer the equipment manufacturer instructions formore information.

1. Evacuate the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM EVACUATE).

2. A manifold gauge set and an R-134a refrigerant recovery/recycling/charging station that meets SAE standard

J2210 should be connected to the refrigerant system.

3. Measure the proper amount of refrigerant and heat it to 52° C (125° F) withthe charging station. See the oper-

ating instructions supplied by the equipment manufacturer for proper useof this equipment.

4. Open both the suction and discharge valves, then open the charge valve toallow the heated refrigerant to flow

into the system.

5. When the transfer of refrigerant has stopped, close both the suction anddischarge valves.

6. If all of the refrigerant charge did not transfer from the dispensing device, open all of the windows in the vehicle

and set the heating-A/C system controls so that the A/C compressor is engaged and the blower motor is oper-

ating at its lowest speed setting. Run the engine at a steady high idle (about 1400 rpm). If the A/C compressor

does not engage, test the compressor clutch control circuit and repair as required.

7. Open the low-side valve to allow the remaining refrigerant to transfer to the refrigerant system.

WARNING: Take care not to open the discharge (high pressure) valve at this time. Failure to follow this

warning could result in possible personal injury or death.

8. Disconnect the charging station and manifold gauge set from the refrigerant system service ports.

9. Reinstall the caps onto the refrigerant system service ports.

Page 5133 of 5267

ACCUMULATOR-A/C

DESCRIPTION

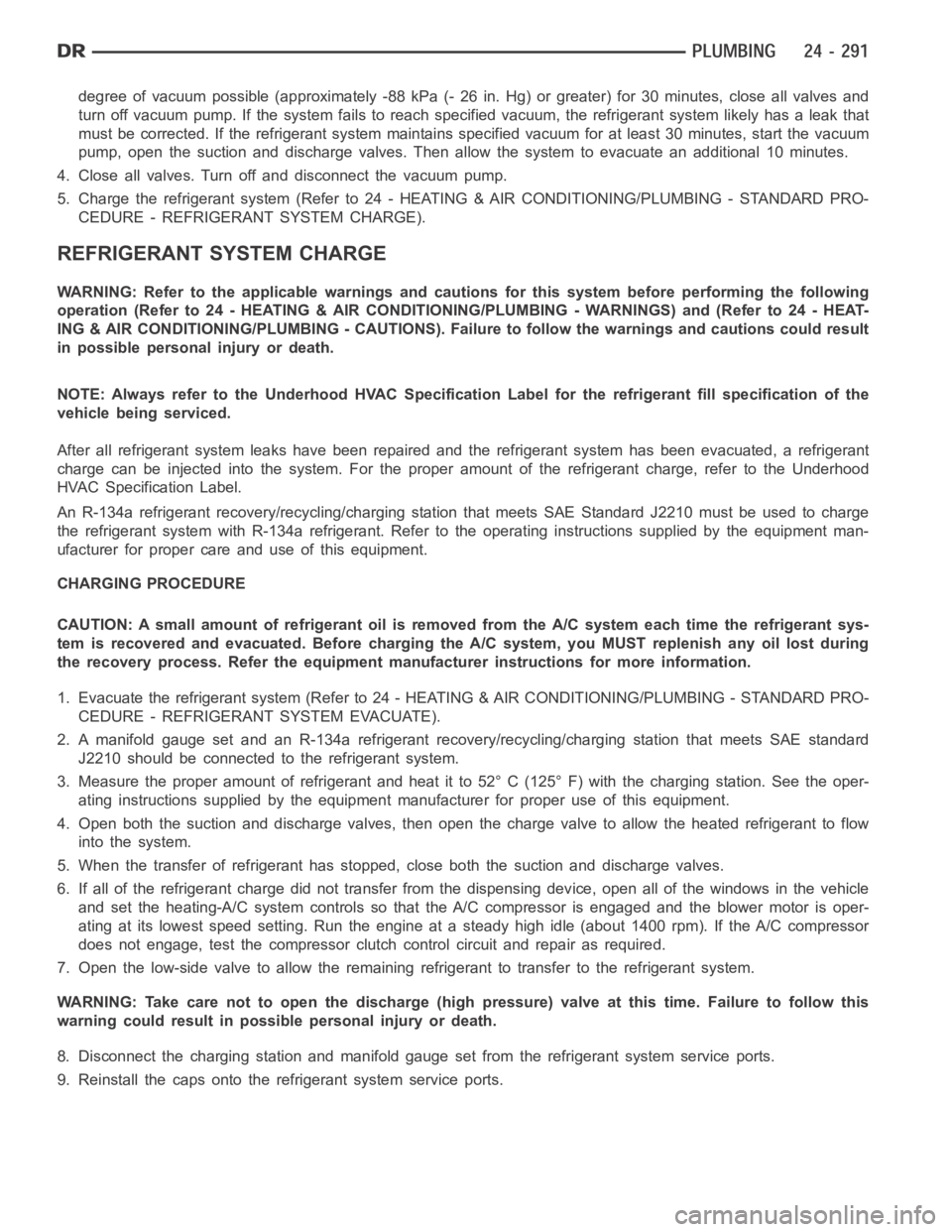

The A/C accumulator (5) is mounted in the engine

compartment between the evaporator outlet tube (2)

and the A/C suction line (6). An integral mounting

bracket (4) is used to secure the accumulator to the

dash panel (3). The A/C low side service port (1) is

mountedtothetopoftheA/Caccumulator.

CAUTION: Use only O-ring seals specified for the

vehicle. Failure to use the correct O-ring seal will

cause the refrigerant system connections to leak.

The A/C accumulator has no serviceable parts except

for the rubber O-ring seals, low side service port

valve, cap and secondary retaining clips. The O-ring

seals used on the connections are made from a spe-

cial type of rubber not affected by R-134a refrigerant.

The O-ring seals must be replaced whenever the A/C

accumulator is removed and installed.

The A/C accumulator cannot be repaired and, if faulty

or damaged, it must be replaced.

OPERATION

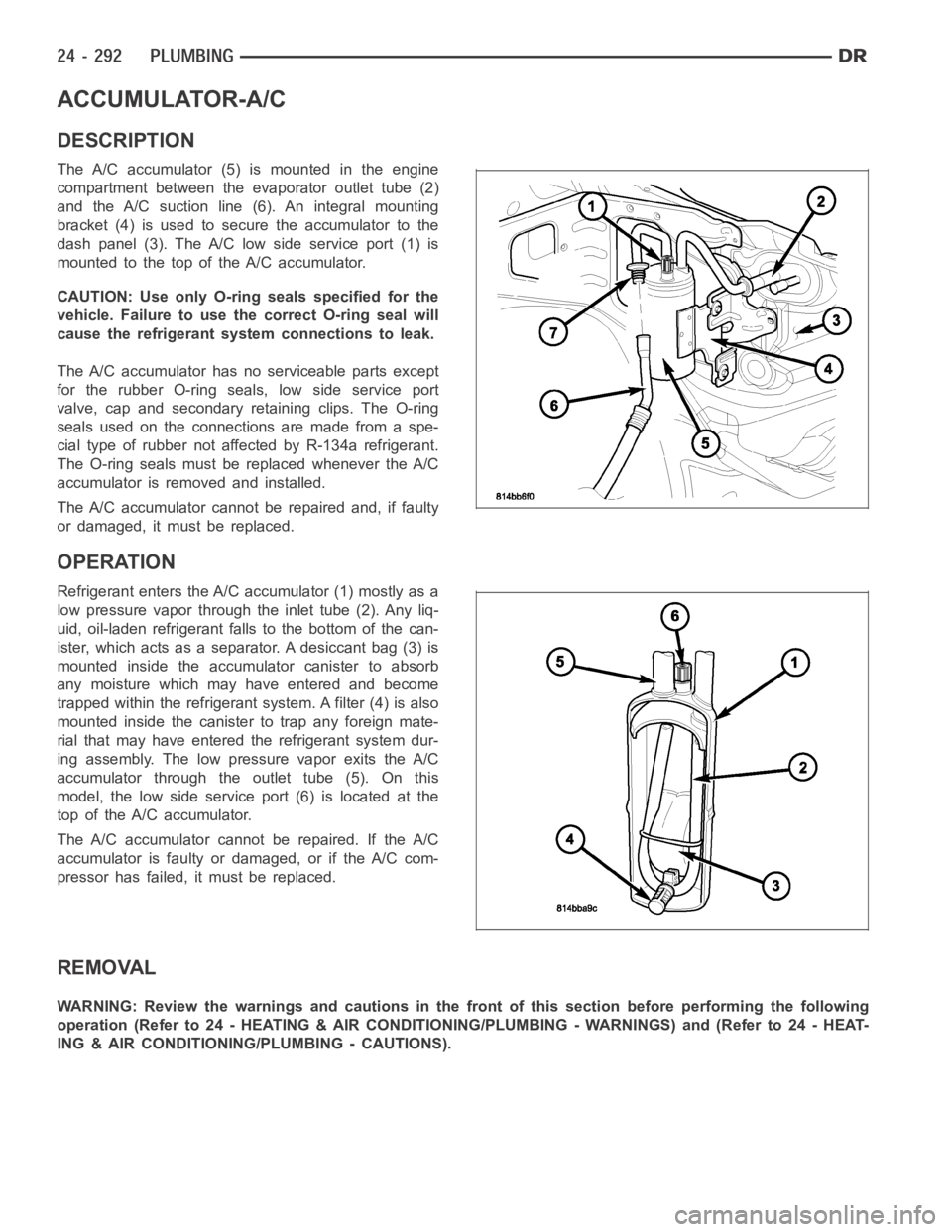

Refrigerant enters the A/C accumulator (1) mostly as a

low pressure vapor through the inlet tube (2). Any liq-

uid, oil-laden refrigerant falls to the bottom of the can-

ister, which acts as a separator. A desiccant bag (3) is

mounted inside the accumulator canister to absorb

any moisture which may have entered and become

trapped within the refrigerant system. A filter (4) is also

mounted inside the canister to trap any foreign mate-

rial that may have entered the refrigerant system dur-

ing assembly. The low pressure vapor exits the A/C

accumulator through the outlet tube (5). On this

model, the low side service port (6) is located at the

top of the A/C accumulator.

The A/C accumulator cannot be repaired. If the A/C

accumulator is faulty or damaged, or if the A/C com-

pressor has failed, it must be replaced.

REMOVAL

WARNING: Review the warnings and cautions in the front of this section before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS).

Page 5134 of 5267

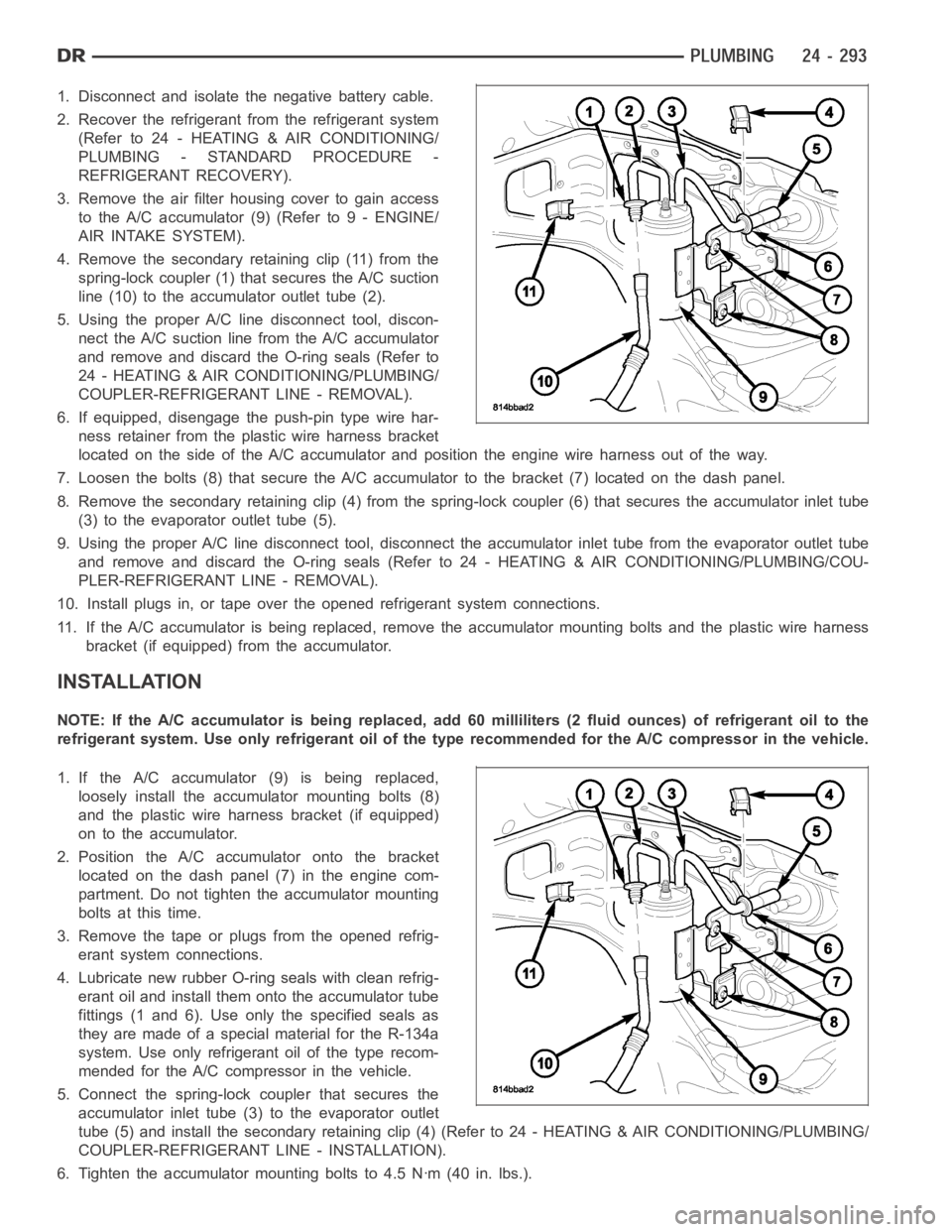

1. Disconnect and isolate the negative battery cable.

2. Recover the refrigerant from the refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

3. Remove the air filter housing cover to gain access

to the A/C accumulator (9) (Refer to 9 - ENGINE/

AIR INTAKE SYSTEM).

4. Remove the secondary retaining clip (11) from the

spring-lock coupler (1) that secures the A/C suction

line (10) to the accumulator outlet tube (2).

5. Using the proper A/C line disconnect tool, discon-

nect the A/C suction line from the A/C accumulator

and remove and discard the O-ring seals (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING/

COUPLER-REFRIGERANT LINE - REMOVAL).

6. If equipped, disengage the push-pin type wire har-

ness retainer from the plastic wire harness bracket

located on the side of the A/C accumulator and position the engine wire harness out of the way.

7. Loosen the bolts (8) that secure the A/C accumulator to the bracket (7) located on the dash panel.

8. Remove the secondary retaining clip (4) from the spring-lock coupler (6) that secures the accumulator inlet tube

(3) to the evaporator outlet tube (5).

9. Using the proper A/C line disconnect tool, disconnect the accumulator inlet tube from the evaporator outlet tube

and remove and discard the O-ring seals (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING/COU-

PLER-REFRIGERANT LINE - REMOVAL).

10. Install plugs in, or tape over the opened refrigerant system connections.

11. If the A/C accumulator is being replaced, remove the accumulator mounting bolts and the plastic wire harness

bracket (if equipped) from the accumulator.

INSTALLATION

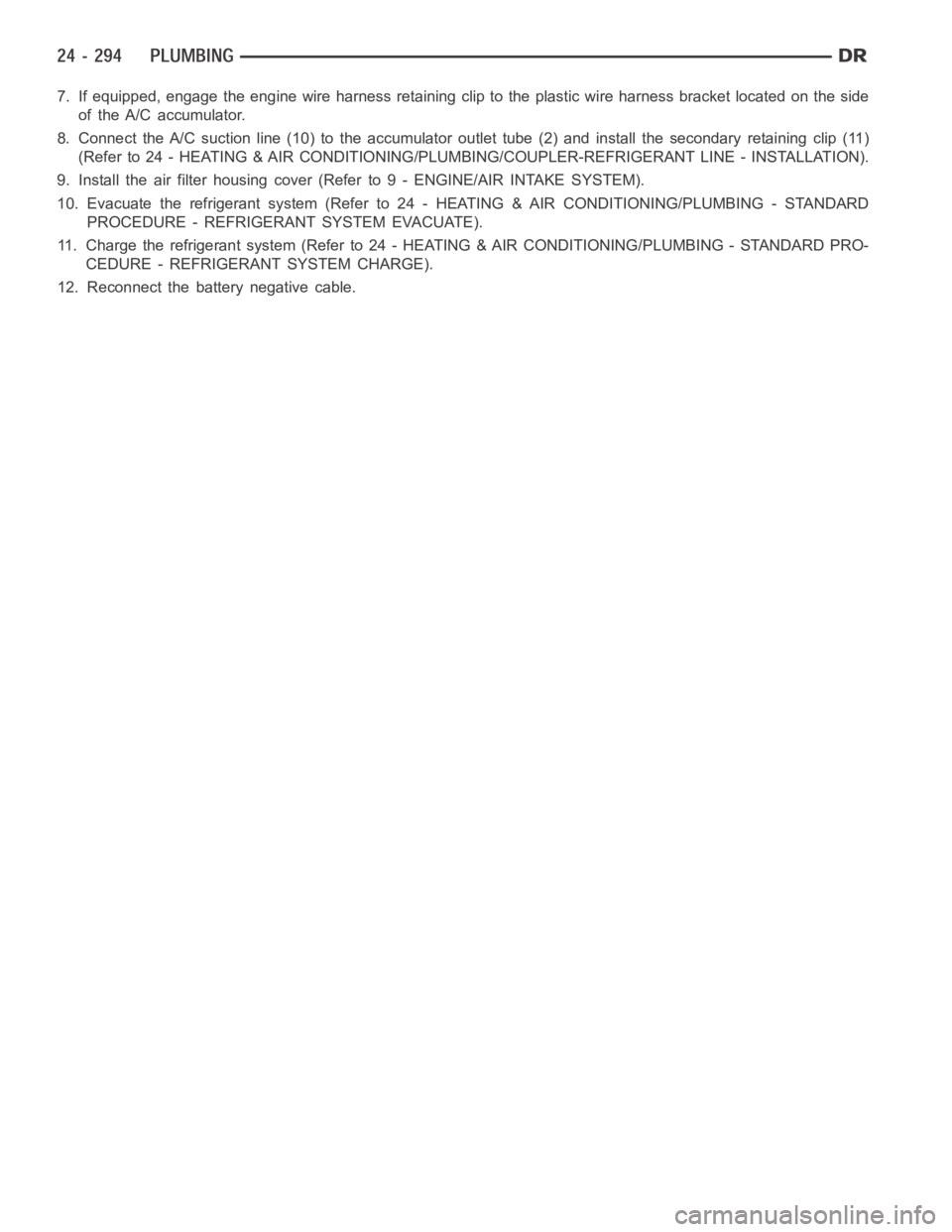

NOTE: If the A/C accumulator is being replaced, add 60 milliliters (2 fluidounces) of refrigerant oil to the

refrigerant system. Use only refrigerant oil of the type recommended for the A/C compressor in the vehicle.

1. If the A/C accumulator (9) is being replaced,

loosely install the accumulator mounting bolts (8)

and the plastic wire harness bracket (if equipped)

on to the accumulator.

2. Position the A/C accumulator onto the bracket

located on the dash panel (7) in the engine com-

partment. Do not tighten the accumulator mounting

bolts at this time.

3. Remove the tape or plugs from the opened refrig-

erant system connections.

4. Lubricate new rubber O-ring seals with clean refrig-

erant oil and install them onto the accumulator tube

fittings (1 and 6). Use only the specified seals as

they are made of a special material for the R-134a

system. Use only refrigerant oil of the type recom-

mended for the A/C compressor in the vehicle.

5. Connect the spring-lock coupler that secures the

accumulator inlet tube (3) to the evaporator outlet

tube (5) and install the secondary retaining clip (4) (Refer to 24 - HEATING& AIR CONDITIONING/PLUMBING/

COUPLER-REFRIGERANT LINE - INSTALLATION).

6. Tighten the accumulator mounting bolts to 4.5 Nꞏm (40 in. lbs.).

Page 5135 of 5267

7. If equipped, engage the engine wire harness retaining clip to the plastic wire harness bracket located on the side

of the A/C accumulator.

8. Connect the A/C suction line (10) to the accumulator outlet tube (2) and install the secondaryretaining clip (11)

(Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING/COUPLER-REFRIGERANTLINE - INSTALLATION).

9. Install the air filter housing cover (Refer to 9 - ENGINE/AIR INTAKE SYSTEM).

10. Evacuate the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE - REFRIGERANT SYSTEM EVACUATE).

11. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

12. Reconnect the battery negative cable.

Page 5137 of 5267

DIAGNOSIS AND TESTING

A/C COMPRESSOR

When investigating an A/C system related noise, you must first know the conditions under which the noise occurs.

These conditions include: weather, vehicle speed, transmission in gear or neutral, engine speed, engine tempera-

ture, and any other special conditions. Noises that develop during A/C operation can often be misleading. For exam-

ple: What sounds like a failed front engine bearing or connecting rod, may be caused by loose bolts, nuts, mounting

brackets or a loose compressor clutch assembly.

Drive belts are speed sensitive. At different engine speeds and dependingupon drive belt tension, drive belts can

develop noises that are mistaken for an A/C compressor noise. Improper drive belt tension can cause a misleading

noise when the compressor clutch is engaged, which may not occur when the compressor clutch is disengaged.

Check the accessory drive belt condition and tension as described in Cooling before beginning this procedure.

1. Select a quiet area for testing. Duplicate the complaint conditions as much as possible. Turn the A/C compressor

On and Off several times to clearly identify the compressor noise. Listen to the A/C compressor while the clutch

is engaged and disengaged. Probe the A/C compressor with an engine stethoscope or a long screwdriver with

the handle held to your ear to better localize the source of the noise.

2. Loosen all of the compressor mounting hardware and retighten. Check thecompressor clutch retainer. Be certain

that the clutch field coil is mounted securely to the A/C compressor, and that the clutch plate and pulley are

properly aligned and have the correct air gap (Refer to 24 - HEATING & AIR CONDITIONING/CONTROLS/

CLUTCH-A/C COMPRESSOR - INSTALLATION).

3. To duplicate high-ambient temperature conditions (high head pressure), restrict the air flow through the A/C con-

denser. Install a manifold gauge set or a scan tool to be certain that the discharge pressure does not exceed

2760 kPa (400 psi).

4. Check the refrigerant system plumbing for incorrect routing, rubbing or interference, which can cause unusual

noises. Also check the refrigerant lines and hoses for kinks or sharp bendsthat will restrict refrigerant flow, which

can cause noises (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - DESCRIPTION - REFRIGER-

ANT LINES).

5. If the noise is from opening and closing of the high pressure relief valve, recover, evacuate and recharge the

refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM RECOVERY), (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE - REFRIGERANT SYSTEM EVACUATE) and (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE - REFRIGERANT SYSTEM CHARGE). If the high pressure relief

valve still does not seat properly, replace the A/C compressor (Refer to 24- HEATING & AIR CONDITIONING/

PLUMBING/COMPRESSOR-A/C - REMOVAL).

6. If the noise is from liquid refrigerant slugging in the A/C suction line,replace the A/C accumulator (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/ACCUMULATOR-A/C - REMOVAL) and check the refrigerant oil

level and the refrigerant system charge (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING/REFRIG-

ERANT OIL - STANDARD PROCEDURE - REFRIGERANT OIL LEVEL) (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING- STANDARD PROCEDURE - REFRIGERANT SYSTEM CHARGE).

7. If a slugging condition still exists after replacing the A/C accumulator, then replace the A/C compressor (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING/COMPRESSOR-A/C - REMOVAL) and repeat Step 1.

REMOVAL

3.7L/4.7L ENGINES

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

NOTE: The A/C compressor may be removed and repositioned without disconnecting the refrigerant lines or

discharging the refrigerant system. Discharging is not necessary if servicing the compressor clutch, clutch

coil, engine, engine cylinder head or the generator.

Page 5138 of 5267

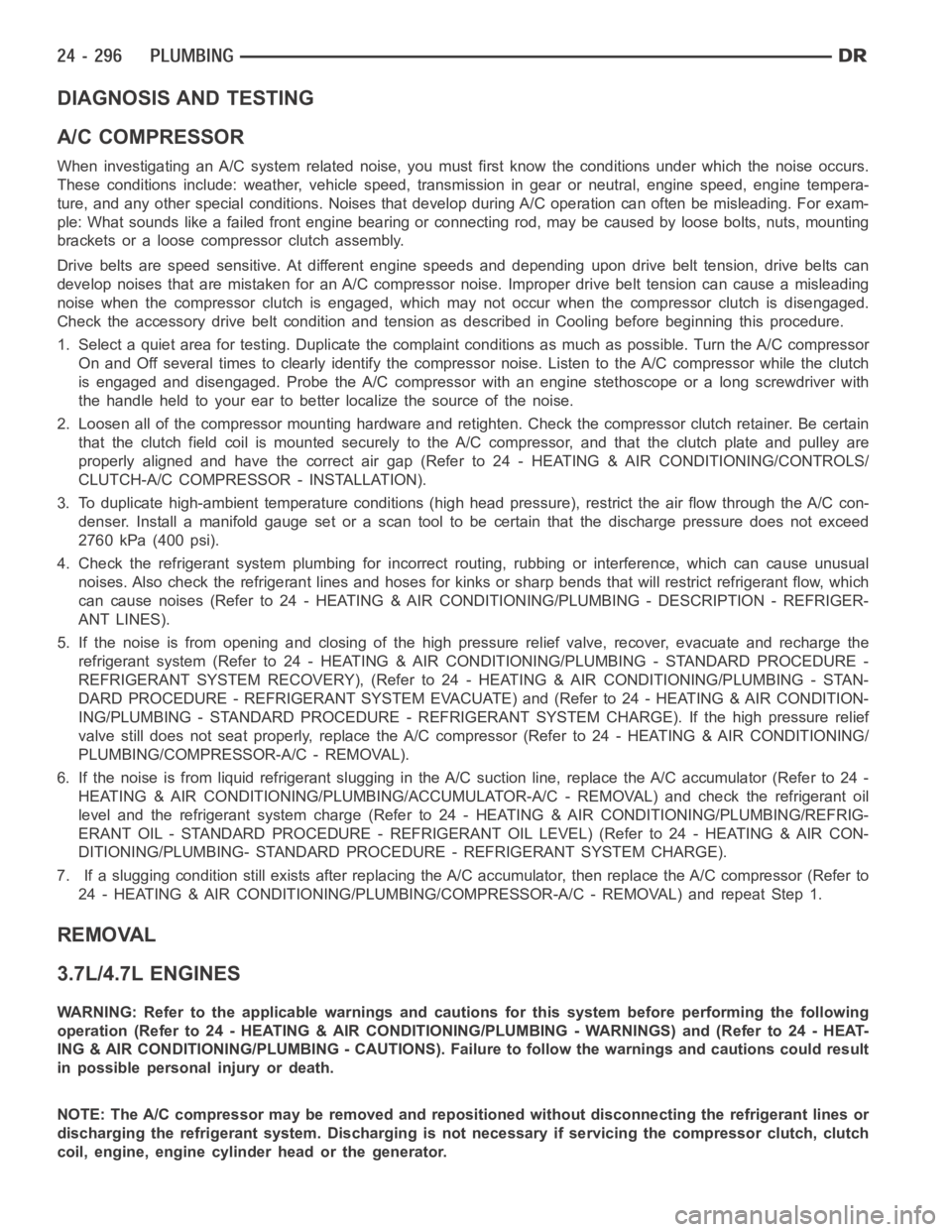

1. Recover the refrigerant from the refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM RECOVERY).

2. Disconnect and isolate the negative battery cable.

3. Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/BELTS-DRIVE -

REMOVAL).

4. Remove the nuts (4) that secure the A/C suction

line (5) and the A/C discharge line (9) to the A/C

compressor (6).

5. Disconnect the refrigerant lines from the A/C com-

pressor and remove and discard the seals.

6. Install plugs in, or tape over all of the opened

refrigerant line fittings and the compressor ports.

7. Loosen the bolt (5) that secures the bracket (7) to

the accessory mounting bracket (4).

8. Remove the three bolts (1, 6 and 3) that secure the

A/C compressor (2) to the accessory mounting

bracket.

9. Remove the A/C compressor from the engine

compartment.

5.7L ENGINE

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

NOTE: The A/C compressor may be removed and repositioned without disconnecting the refrigerant lines or

discharging the refrigerant system. Discharging is not necessary if servicing the compressor clutch, clutch

coil, engine, engine cylinder head or the generator.

Page 5139 of 5267

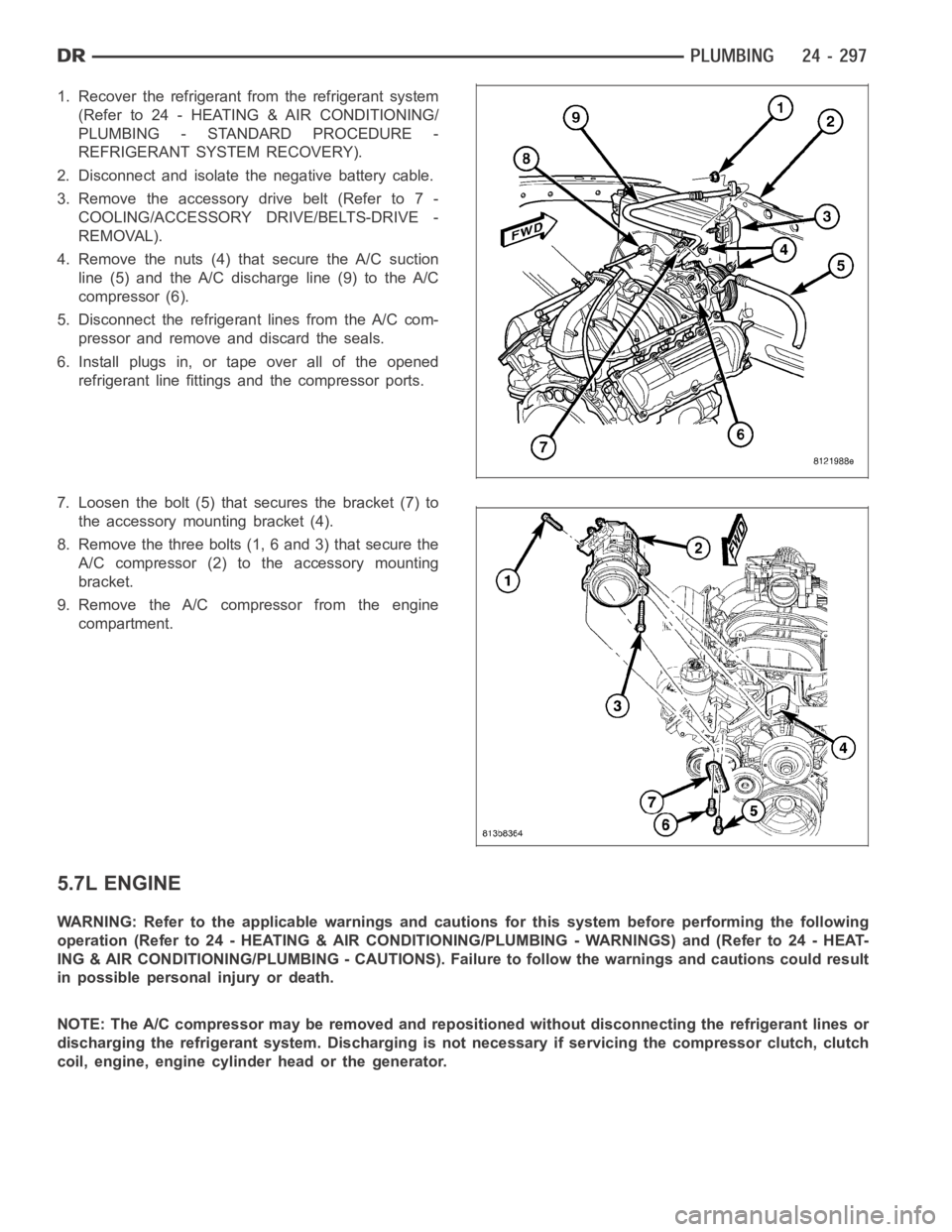

1. Recover the refrigerant from the refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM RECOVERY).

2. Disconnect and isolate the negative battery cable.

3. Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/BELTS-DRIVE -

REMOVAL).

4. Disconnect the wire harness connector from the

clutch field coil connector on top of the A/C com-

pressor (6) and the A/C pressure transducer (8) on

the A/C discharge line (1).

5. Remove the nuts (4 and 7) that secure the A/C dis-

charge line and the A/C suction line (5) to the A/C

compressor.

6. Disconnect the refrigerant lines from the A/C com-

pressor and remove and discard the O-rings and

dual plane seals.

7. Install plugs in, or tape over all of the opened

refrigerant line fittings and the compressor ports.

8. Remove the generator support bracket from the

front of the engine (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - REMOVAL).

9. Remove the three bolts (1 and 3) that secure the

A/C compressor (2) to the mounting bracket (4).

10. Remove the A/C compressor from the engine

compartment.

5.9L DIESEL ENGINE

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

NOTE: The A/C compressor may be removed and repositioned without disconnecting the refrigerant lines or

discharging the refrigerant system. Discharging is not necessary if servicing the compressor clutch, clutch

coil or engine.

Page 5140 of 5267

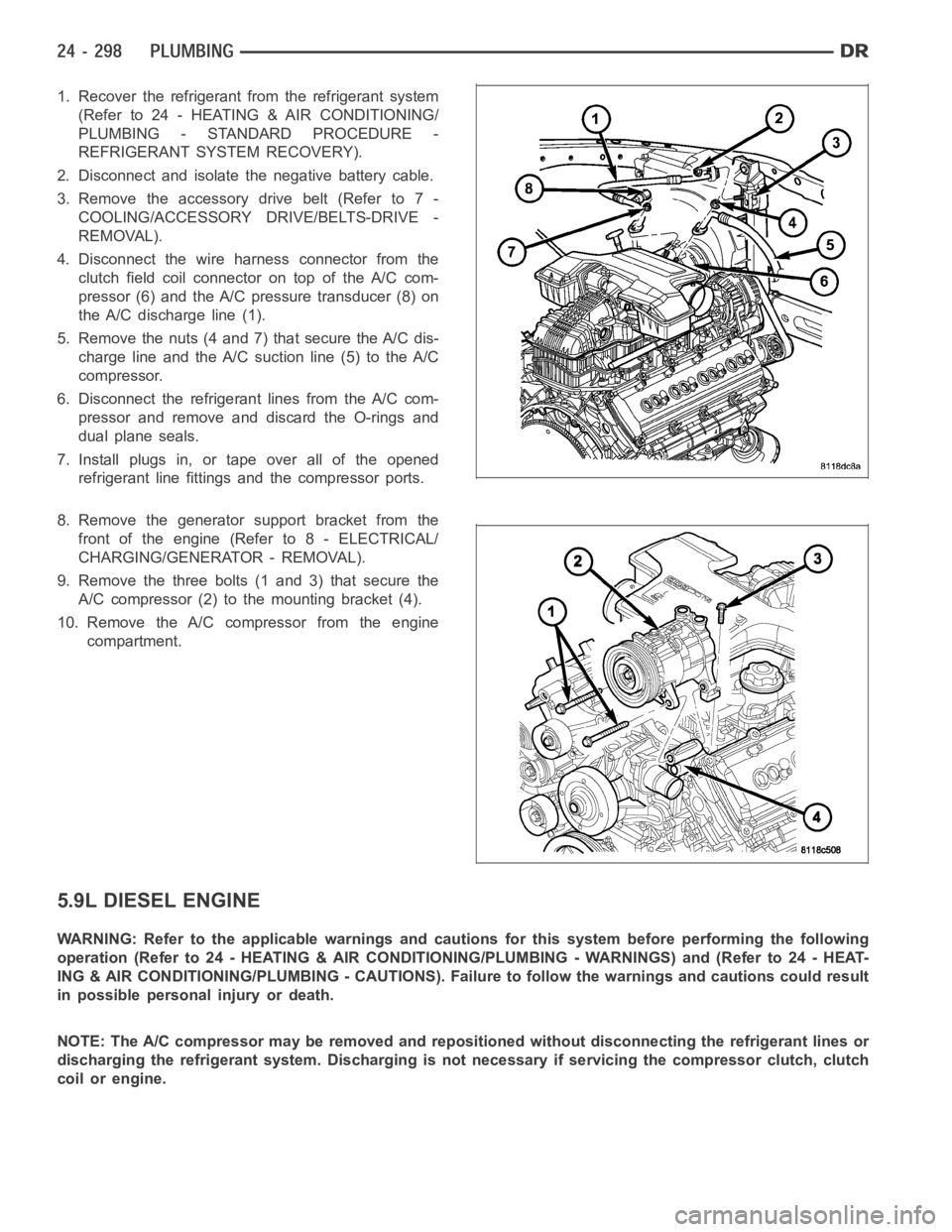

1. Recover the refrigerant from the refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM RECOVERY).

2. Disconnect and isolate the negative battery cable.

3. Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/BELTS-DRIVE -

REMOVAL).

4. Remove the bolt (1) that secures the A/C suction

and discharge line assembly (2) to the A/C com-

pressor (3).

5. Disconnect the refrigerant line assembly from the

A/C compressor and remove and discard the seals.

6. Install plugs in, or tape over all of the opened

refrigerant line fittings and compressor ports.

7. Disconnect the wire harness from the clutch field

coil wire lead connector (4).

8. Remove the four bolts (1) that secure the A/C com-

pressor (2) to the mounting bracket (3) located on

the right side of the cylinder block (4).

9. Remove the A/C compressor from the engine

compartment.

8.3L ENGINE

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

NOTE: The A/C compressor may be removed and repositioned without disconnecting the refrigerant lines or

discharging the refrigerant system. Discharging is not necessary if servicing the compressor clutch, clutch

coil or the engine.

Page 5141 of 5267

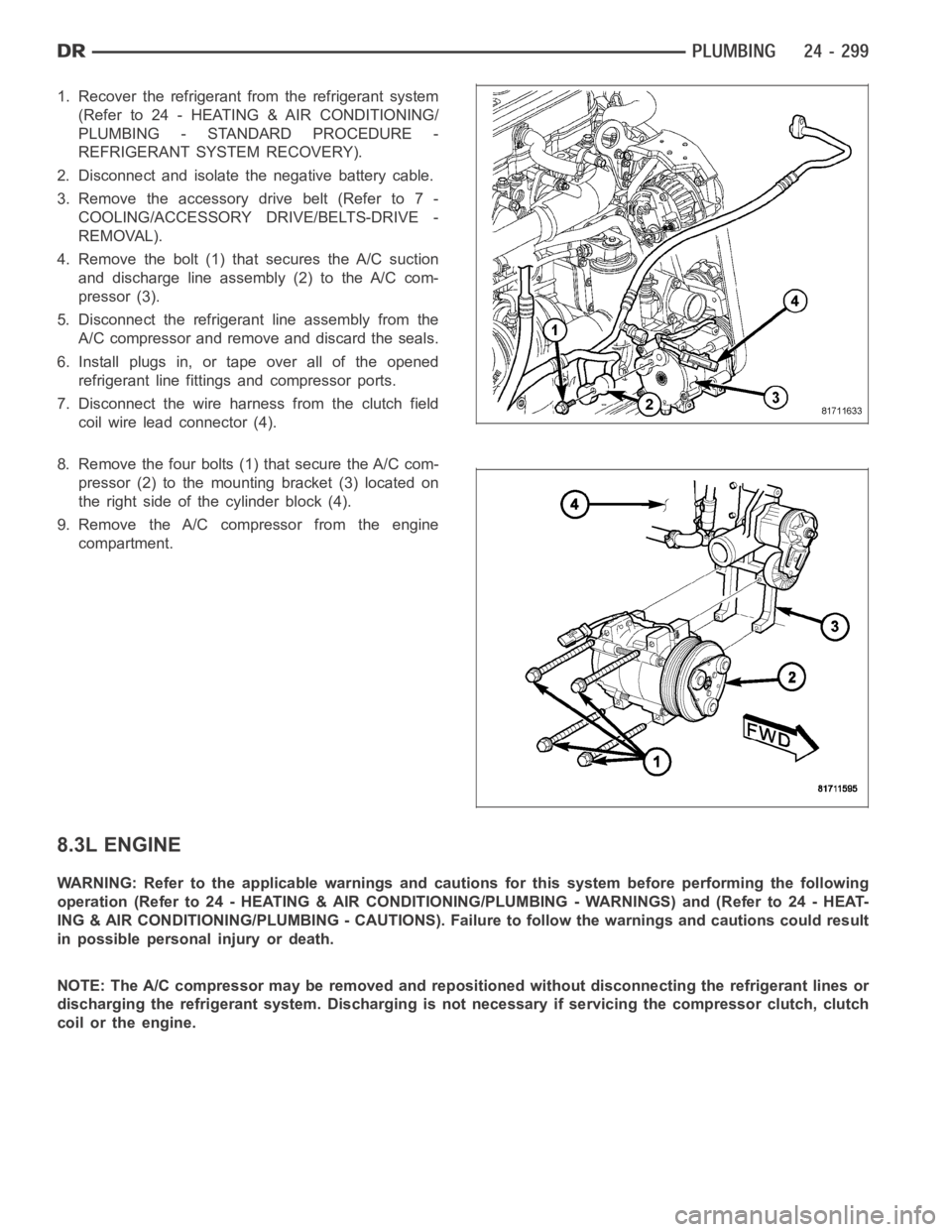

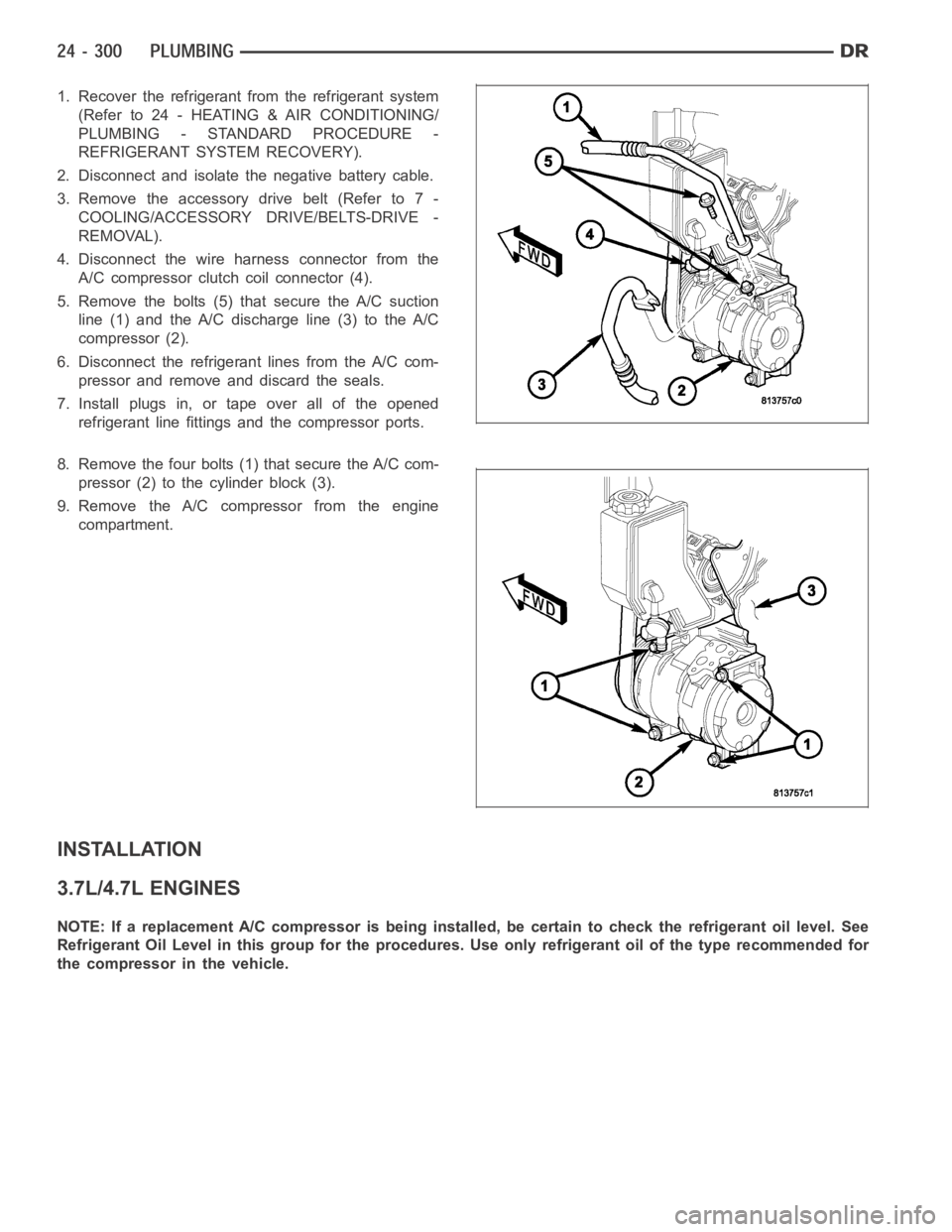

1. Recover the refrigerant from the refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM RECOVERY).

2. Disconnect and isolate the negative battery cable.

3. Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/BELTS-DRIVE -

REMOVAL).

4. Disconnect the wire harness connector from the

A/C compressor clutch coil connector (4).

5. Remove the bolts (5) that secure the A/C suction

line (1) and the A/C discharge line (3) to the A/C

compressor (2).

6. Disconnect the refrigerant lines from the A/C com-

pressor and remove and discard the seals.

7. Install plugs in, or tape over all of the opened

refrigerant line fittings and the compressor ports.

8. Remove the four bolts (1) that secure the A/C com-

pressor (2) to the cylinder block (3).

9. Remove the A/C compressor from the engine

compartment.

INSTALLATION

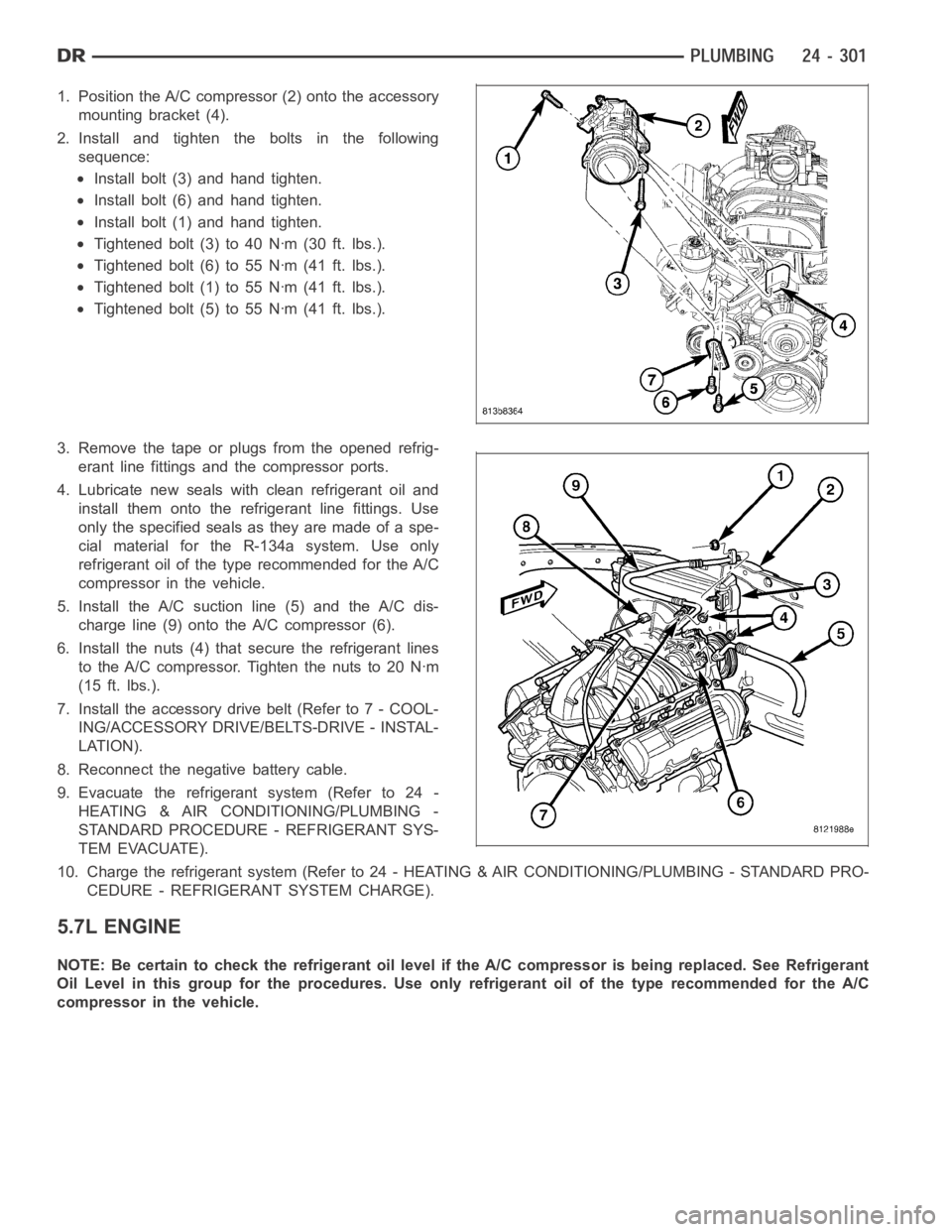

3.7L/4.7L ENGINES

NOTE: If a replacement A/C compressor is being installed, be certain to check the refrigerant oil level. See

Refrigerant Oil Level in this group for the procedures. Use only refrigerant oil of the type recommended for

the compressor in the vehicle.

Page 5142 of 5267

1. Position the A/C compressor (2) onto the accessory

mounting bracket (4).

2. Install and tighten the bolts in the following

sequence:

Install bolt (3) and hand tighten.

Install bolt (6) and hand tighten.

Install bolt (1) and hand tighten.

Tightened bolt (3) to 40 Nꞏm (30 ft. lbs.).

Tightened bolt (6) to 55 Nꞏm (41 ft. lbs.).

Tightened bolt (1) to 55 Nꞏm (41 ft. lbs.).

Tightened bolt (5) to 55 Nꞏm (41 ft. lbs.).

3. Remove the tape or plugs from the opened refrig-

erant line fittings and the compressor ports.

4. Lubricate new seals with clean refrigerant oil and

install them onto the refrigerant line fittings. Use

only the specified seals as they are made of a spe-

cial material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

5. Install the A/C suction line (5) and the A/C dis-

charge line (9) onto the A/C compressor (6).

6. Install the nuts (4) that secure the refrigerant lines

to the A/C compressor. Tighten the nuts to 20 Nꞏm

(15 ft. lbs.).

7. Install the accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/BELTS-DRIVE - INSTAL-

LATION).

8. Reconnect the negative battery cable.

9. Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

10. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

5.7L ENGINE

NOTE: Be certain to check the refrigerant oil level if the A/C compressor isbeing replaced. See Refrigerant

Oil Level in this group for the procedures. Use only refrigerant oil of the type recommended for the A/C

compressor in the vehicle.