heating DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 5112 of 5267

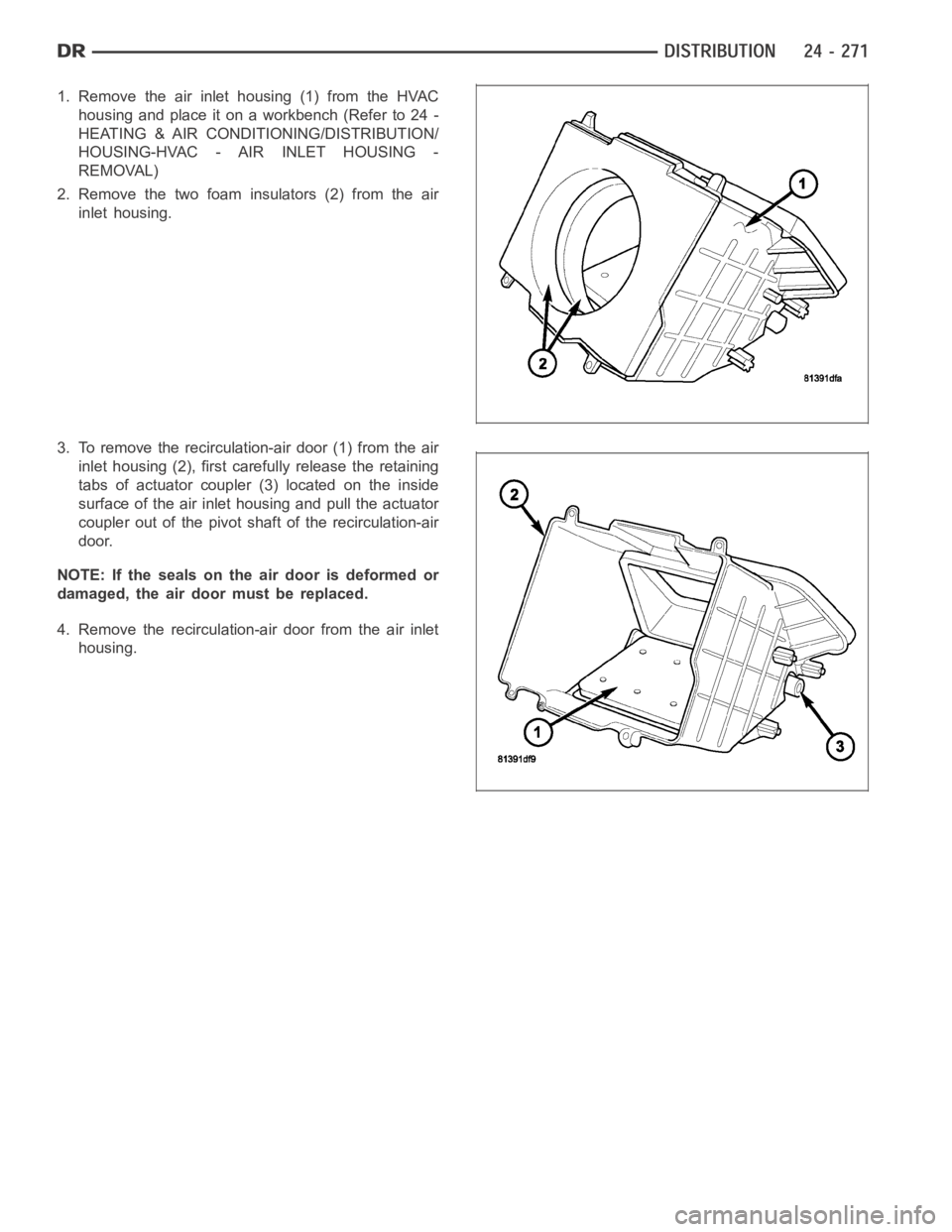

1. Remove the air inlet housing (1) from the HVAC

housing and place it on a workbench (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HOUSING-HVAC - AIR INLET HOUSING -

REMOVAL)

2. Remove the two foam insulators (2) from the air

inlet housing.

3. To remove the recirculation-air door (1) from the air

inlet housing (2), first carefully release the retaining

tabs of actuator coupler (3) located on the inside

surface of the air inlet housing and pull the actuator

coupler out of the pivot shaft of the recirculation-air

door.

NOTE: If the seals on the air door is deformed or

damaged, the air door must be replaced.

4. Remove the recirculation-air door from the air inlet

housing.

Page 5115 of 5267

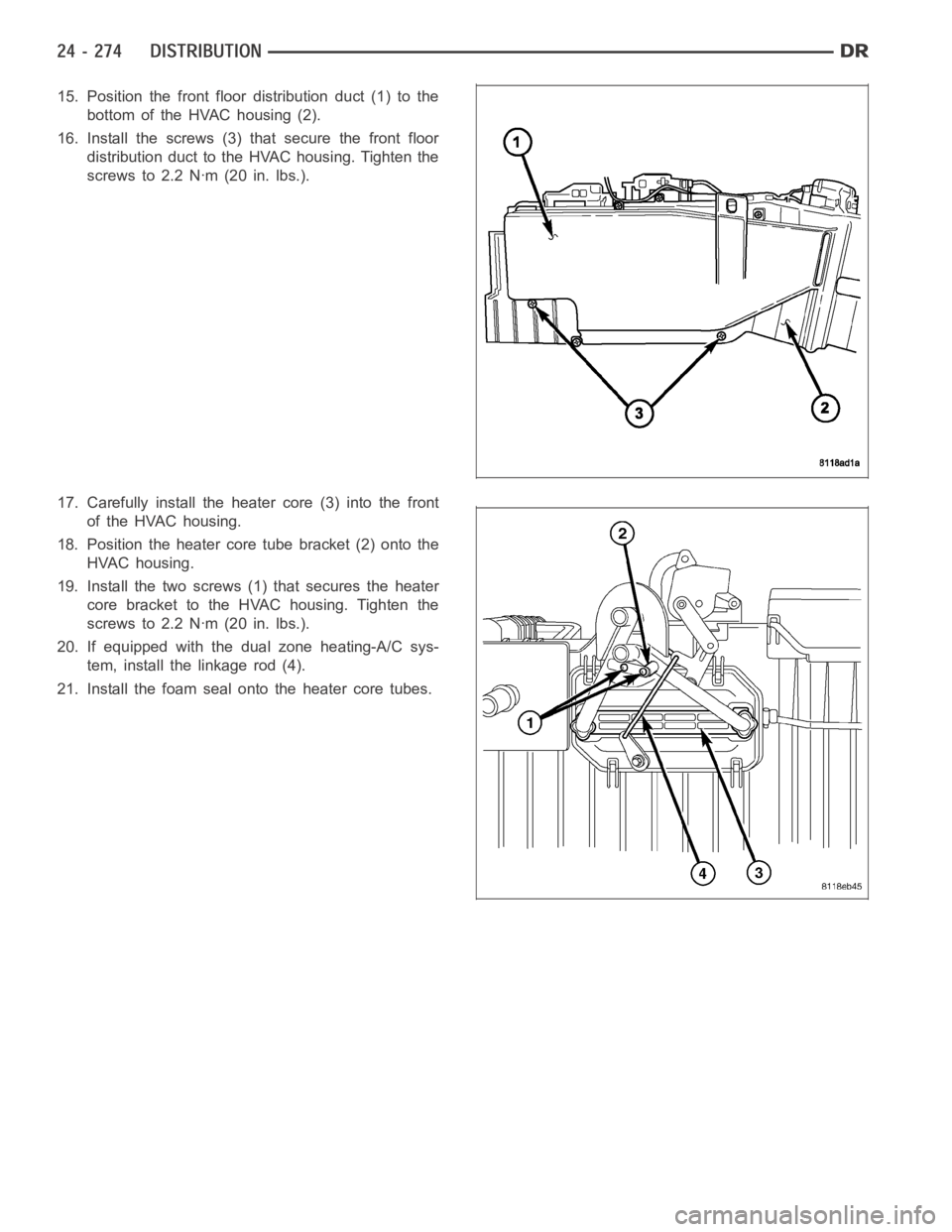

15. Position the front floor distribution duct (1) to the

bottom of the HVAC housing (2).

16. Install the screws (3) that secure the front floor

distribution duct to the HVAC housing. Tighten the

screws to 2.2 Nꞏm (20 in. lbs.).

17. Carefully install the heater core (3) into the front

of the HVAC housing.

18. Position the heater core tube bracket (2) onto the

HVAC housing.

19. Install the two screws (1) that secures the heater

core bracket to the HVAC housing. Tighten the

screws to 2.2 Nꞏm (20 in. lbs.).

20. If equipped with the dual zone heating-A/C sys-

tem, install the linkage rod (4).

21. Install the foam seal onto the heater core tubes.

Page 5117 of 5267

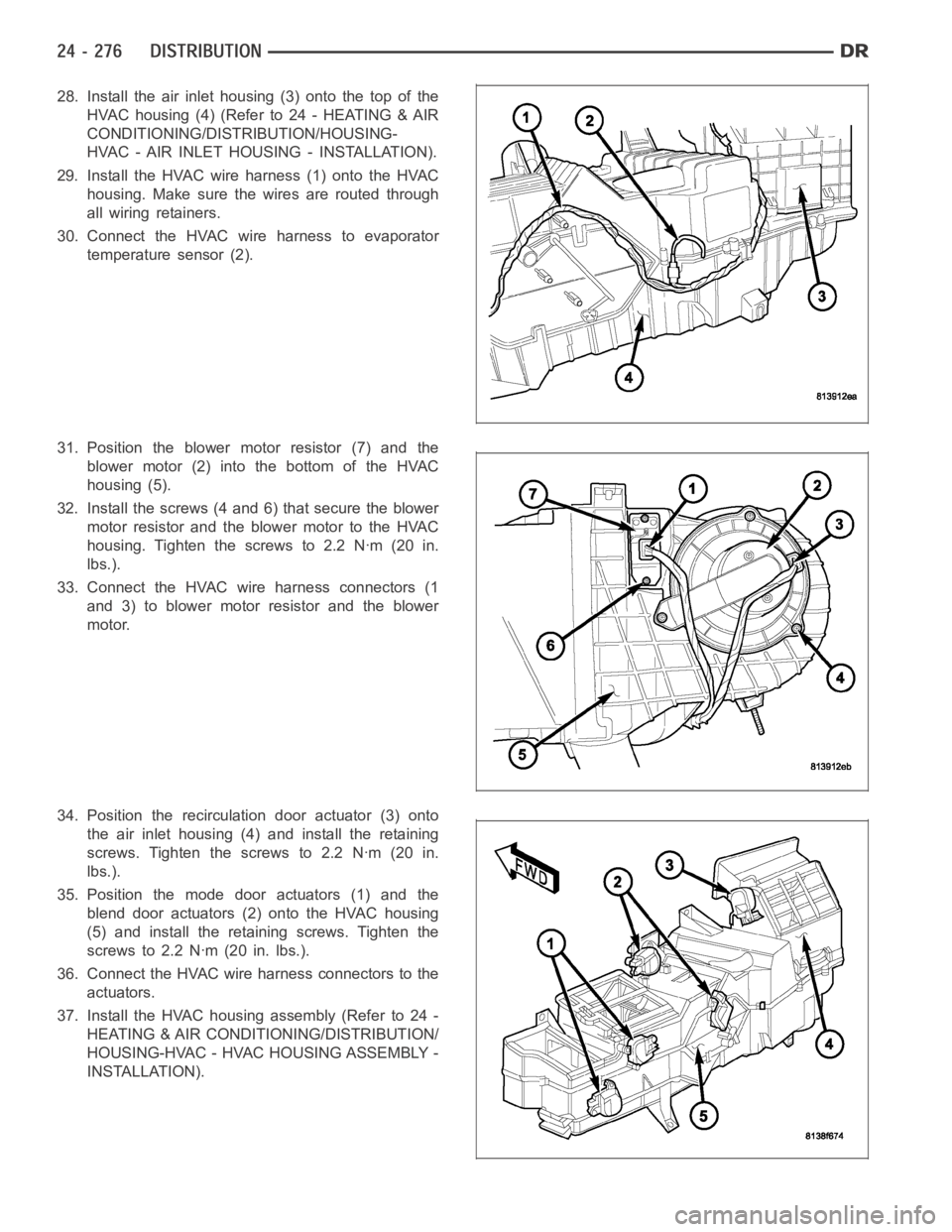

28. Install the air inlet housing (3) onto the top of the

HVAC housing (4) (Refer to 24 - HEATING & AIR

CONDITIONING/DISTRIBUTION/HOUSING-

HVAC - AIR INLET HOUSING - INSTALLATION).

29. Install the HVAC wire harness (1) onto the HVAC

housing. Make sure the wires are routed through

all wiring retainers.

30. Connect the HVAC wire harness to evaporator

temperature sensor (2).

31. Position the blower motor resistor (7) and the

blower motor (2) into the bottom of the HVAC

housing (5).

32. Install the screws (4 and 6) that secure the blower

motor resistor and the blower motor to the HVAC

housing. Tighten the screws to 2.2 Nꞏm (20 in.

lbs.).

33. Connect the HVAC wire harness connectors (1

and 3) to blower motor resistor and the blower

motor.

34. Position the recirculation door actuator (3) onto

the air inlet housing (4) and install the retaining

screws. Tighten the screws to 2.2 Nꞏm (20 in.

lbs.).

35. Position the mode door actuators (1) and the

blend door actuators (2) onto the HVAC housing

(5) and install the retaining screws. Tighten the

screws to 2.2 Nꞏm (20 in. lbs.).

36. Connect the HVAC wire harness connectors to the

actuators.

37. Install the HVAC housing assembly (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HOUSING-HVAC - HVAC HOUSING ASSEMBLY -

INSTALLATION).

Page 5118 of 5267

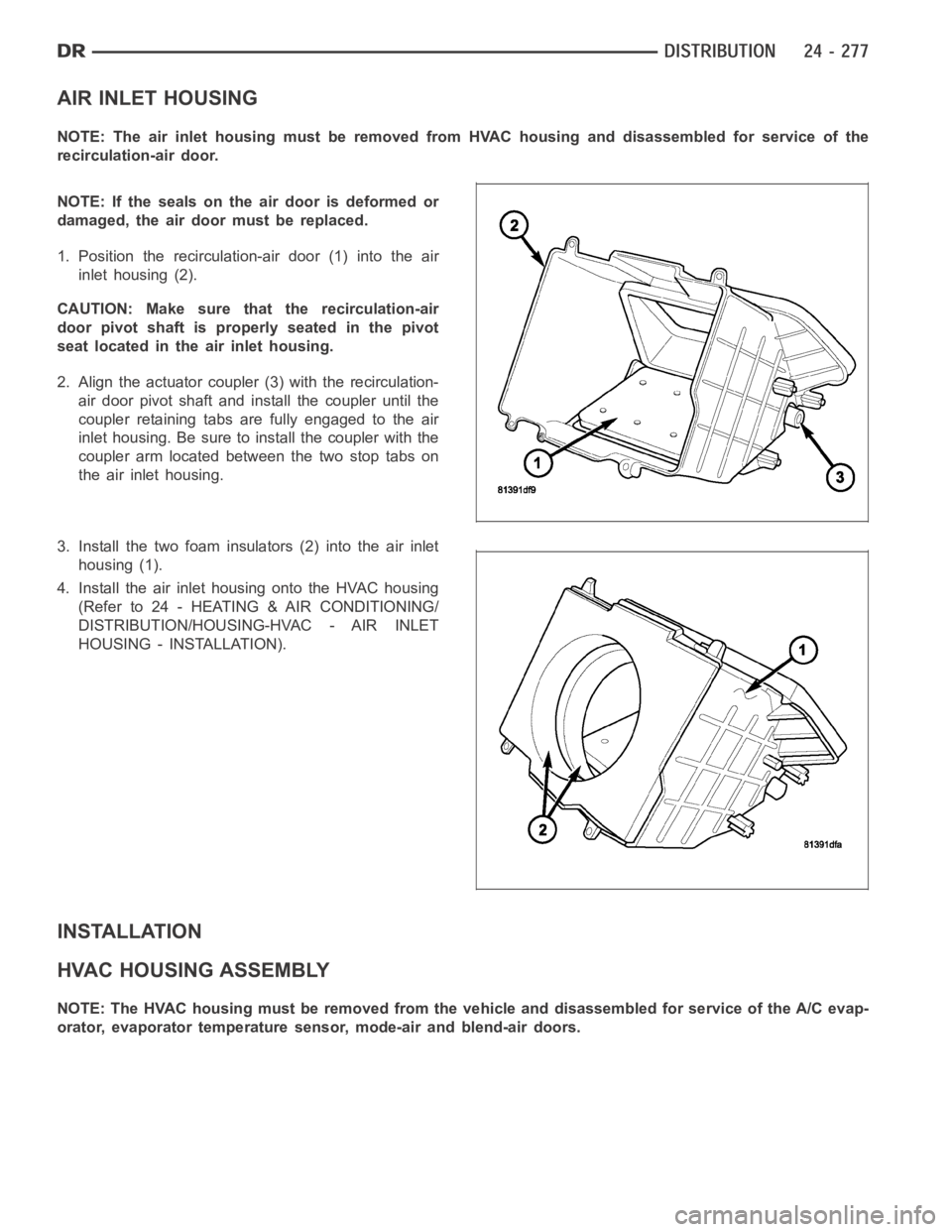

AIR INLET HOUSING

NOTE: The air inlet housing must be removed from HVAC housing and disassembled for service of the

recirculation-air door.

NOTE: If the seals on the air door is deformed or

damaged, the air door must be replaced.

1. Position the recirculation-air door (1) into the air

inlet housing (2).

CAUTION: Make sure that the recirculation-air

door pivot shaft is properly seated in the pivot

seat located in the air inlet housing.

2. Align the actuator coupler (3) with the recirculation-

air door pivot shaft and install the coupler until the

coupler retaining tabs are fully engaged to the air

inlet housing. Be sure to install the coupler with the

coupler arm located between the two stop tabs on

the air inlet housing.

3. Install the two foam insulators (2) into the air inlet

housing (1).

4. Install the air inlet housing onto the HVAC housing

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HOUSING-HVAC - AIR INLET

HOUSING - INSTALLATION).

INSTALLATION

HVAC HOUSING ASSEMBLY

NOTE: The HVAC housing must be removedfrom the vehicle and disassembled for service of the A/C evap-

orator, evaporator temperature sensor, mode-air and blend-air doors.

Page 5119 of 5267

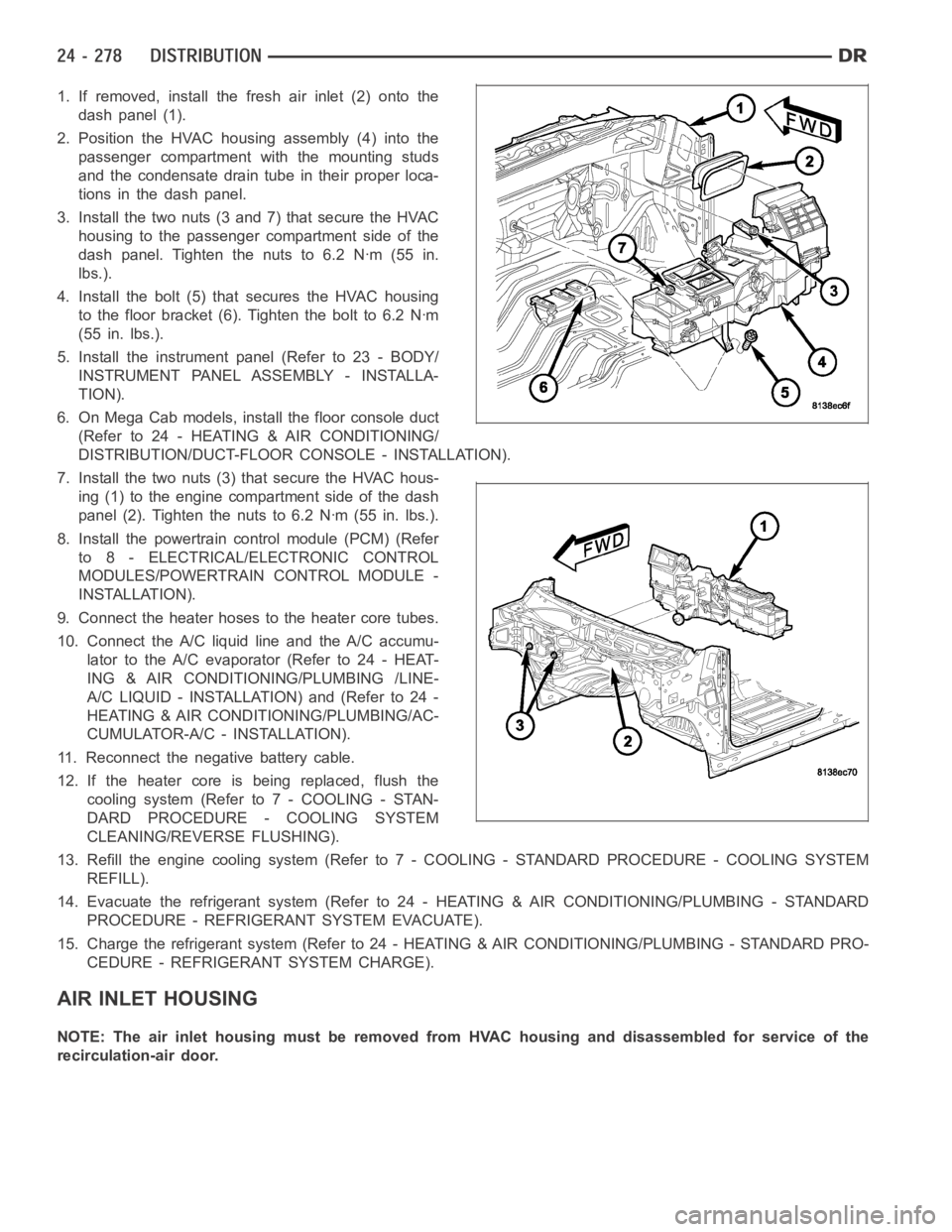

1. If removed, install the fresh air inlet (2) onto the

dash panel (1).

2. Position the HVAC housing assembly (4) into the

passenger compartment with the mounting studs

and the condensate drain tube in their proper loca-

tions in the dash panel.

3. Install the two nuts (3 and 7) that secure the HVAC

housing to the passenger compartment side of the

dash panel. Tighten the nuts to 6.2 Nꞏm (55 in.

lbs.).

4. Install the bolt (5) that secures the HVAC housing

to the floor bracket (6). Tighten the bolt to 6.2 Nꞏm

(55 in. lbs.).

5. Install the instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL ASSEMBLY - INSTALLA-

TION).

6. On Mega Cab models, install the floor console duct

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/DUCT-FLOOR CONSOLE - INSTALLATION).

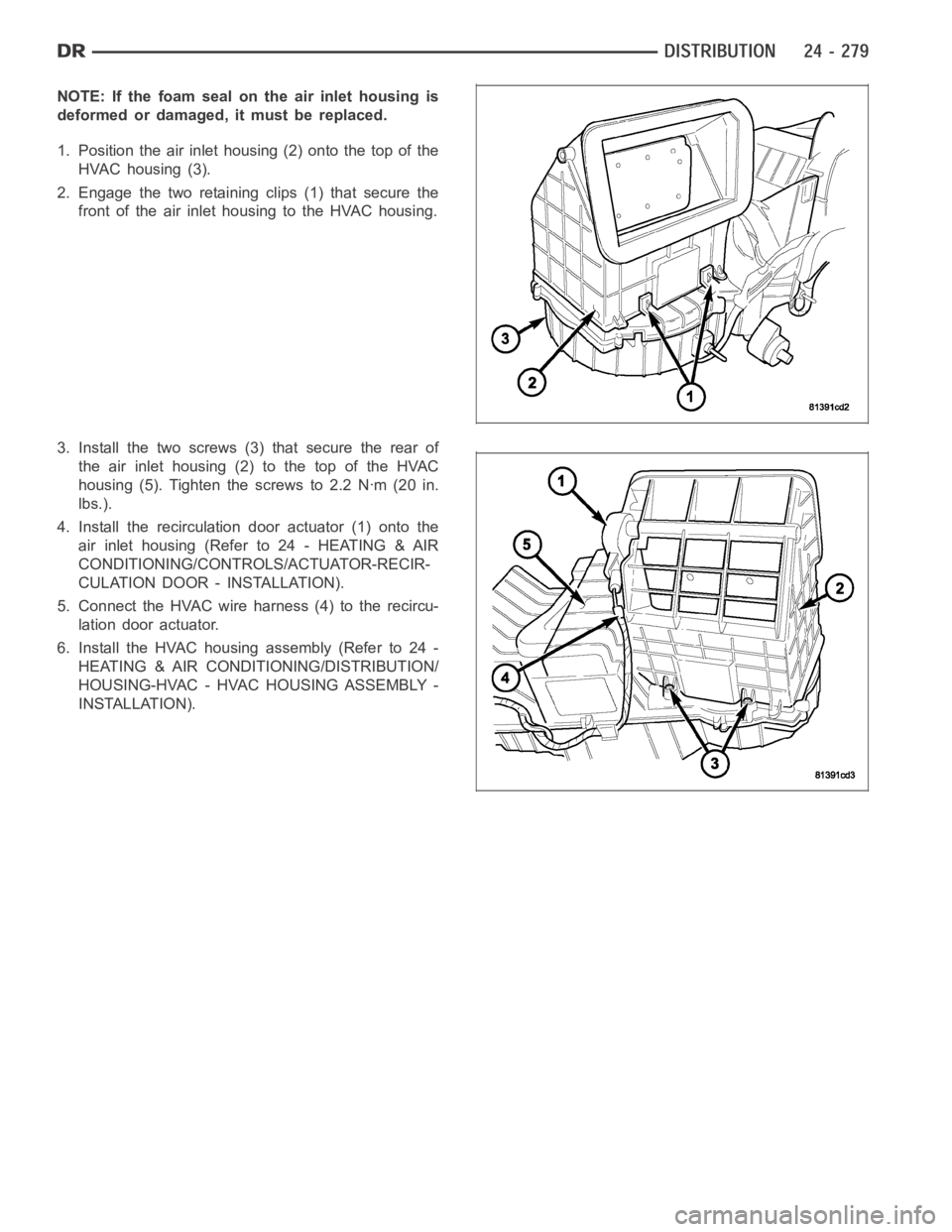

7. Install the two nuts (3) that secure the HVAC hous-

ing (1) to the engine compartment side of the dash

panel (2). Tighten the nuts to 6.2 Nꞏm (55 in. lbs.).

8. Install the powertrain control module (PCM) (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/POWERTRAIN CONTROL MODULE -

INSTALLATION).

9. Connect the heater hoses to the heater core tubes.

10. Connect the A/C liquid line and the A/C accumu-

lator to the A/C evaporator (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING /LINE-

A/C LIQUID - INSTALLATION) and (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/AC-

CUMULATOR-A/C - INSTALLATION).

11. Reconnect the negative battery cable.

12. If the heater core is being replaced, flush the

coolingsystem(Referto7-COOLING-STAN-

DARD PROCEDURE - COOLING SYSTEM

CLEANING/REVERSE FLUSHING).

13. Refill the engine cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE - COOLING SYSTEM

REFILL).

14. Evacuate the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE - REFRIGERANT SYSTEM EVACUATE).

15. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

AIR INLET HOUSING

NOTE: The air inlet housing must be removed from HVAC housing and disassembled for service of the

recirculation-air door.

Page 5120 of 5267

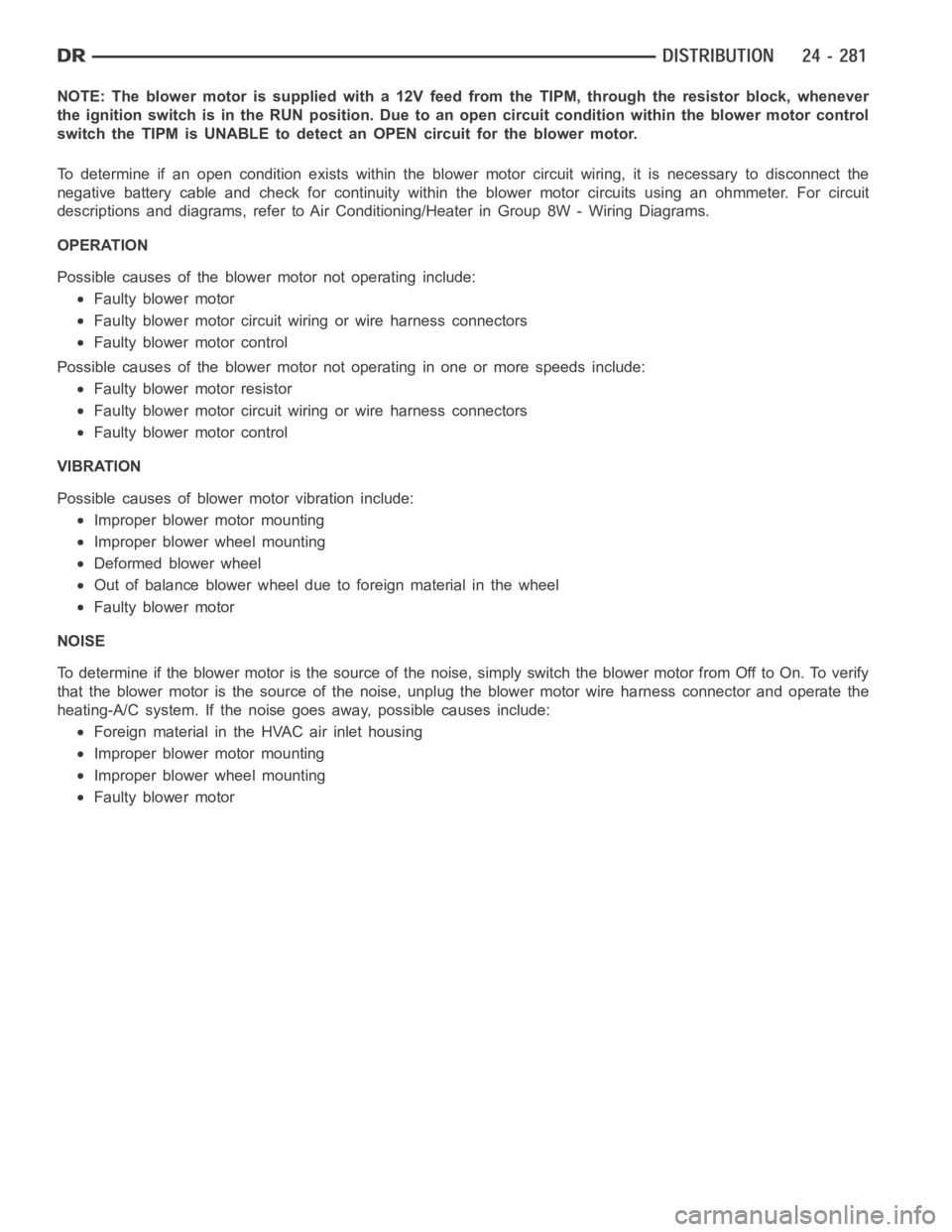

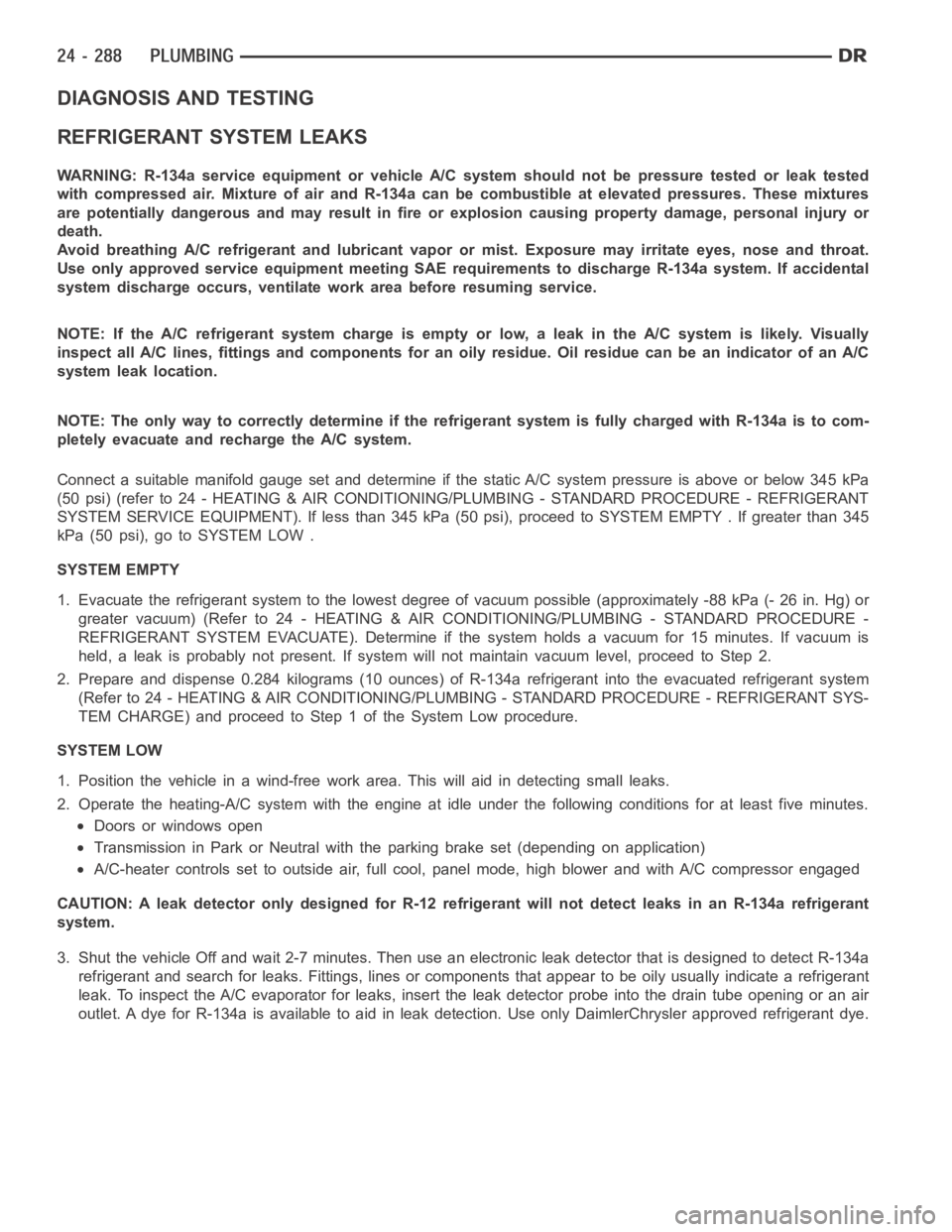

NOTE: If the foam seal on the air inlet housing is

deformed or damaged, it must be replaced.

1. Position the air inlet housing (2) onto the top of the

HVAC housing (3).

2. Engage the two retaining clips (1) that secure the

front of the air inlet housing to the HVAC housing.

3. Install the two screws (3) that secure the rear of

the air inlet housing (2) to the top of the HVAC

housing (5). Tighten the screws to 2.2 Nꞏm (20 in.

lbs.).

4. Install the recirculation door actuator (1) onto the

air inlet housing (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/ACTUATOR-RECIR-

CULATION DOOR - INSTALLATION).

5. Connect the HVAC wire harness (4) to the recircu-

lation door actuator.

6. Install the HVAC housing assembly (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HOUSING-HVAC - HVAC HOUSING ASSEMBLY -

INSTALLATION).

Page 5122 of 5267

NOTE: The blower motor is supplied with a 12V feed from the TIPM, through theresistor block, whenever

the ignition switch is in the RUN position. Due to an open circuit conditionwithin the blower motor control

switch the TIPM is UNABLE to detect an OPEN circuit for the blower motor.

To determine if an open condition exists within the blower motor circuit wiring, it is necessary to disconnect the

negative battery cable and check for continuity within the blower motor circuits using an ohmmeter. For circuit

descriptions and diagrams, refer to Air Conditioning/Heater in Group 8W -Wiring Diagrams.

OPERATION

Possible causes of the blower motor not operating include:

Faulty blower motor

Faulty blower motor circuit wiring or wire harness connectors

Faulty blower motor control

Possible causes of the blower motor not operating in one or more speeds include:

Faulty blower motor resistor

Faulty blower motor circuit wiring or wire harness connectors

Faulty blower motor control

VIBRATION

Possible causes of blower motor vibration include:

Improper blower motor mounting

Improper blower wheel mounting

Deformed blower wheel

Out of balance blower wheel due to foreign material in the wheel

Faulty blower motor

NOISE

To determine if the blower motor is the source of the noise, simply switch the blower motor from Off to On. To verify

that the blower motor is the source of the noise, unplug the blower motor wire harness connector and operate the

heating-A/C system. If the noise goes away, possible causes include:

Foreign material in the HVAC air inlet housing

Improper blower motor mounting

Improper blower wheel mounting

Faulty blower motor

Page 5129 of 5267

DIAGNOSIS AND TESTING

REFRIGERANT SYSTEM LEAKS

WARNING: R-134a service equipment or vehicle A/C system should not be pressure tested or leak tested

with compressed air. Mixture of air and R-134a can be combustible at elevated pressures. These mixtures

are potentially dangerous and may result in fire or explosion causing property damage, personal injury or

death.

Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure mayirritate eyes, nose and throat.

Use only approved service equipment meeting SAE requirements to discharge R-134a system. If accidental

system discharge occurs, ventilate work area before resuming service.

NOTE: If the A/C refrigerant system charge is empty or low, a leak in the A/C system is likely. Visually

inspect all A/C lines, fittings and components for an oily residue. Oil residue can be an indicator of an A/C

system leak location.

NOTE: The only way to correctly determine if the refrigerant system is fully charged with R-134a is to com-

pletely evacuate and recharge the A/C system.

Connect a suitable manifold gauge setand determine if the static A/C system pressure is above or below 345 kPa

(50 psi) (refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PROCEDURE - REFRIGERANT

SYSTEM SERVICE EQUIPMENT). If less than 345 kPa (50 psi), proceed to SYSTEMEMPTY . If greater than 345

kPa (50 psi), go to SYSTEM LOW .

SYSTEM EMPTY

1. Evacuate the refrigerant system to the lowest degree of vacuum possible(approximately -88 kPa (- 26 in. Hg) or

greater vacuum) (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM EVACUATE). Determine if the system holds a vacuum for 15 minutes. If vacuum is

held, a leak is probably not present. If system will not maintain vacuum level, proceed to Step 2.

2. Prepare and dispense 0.284 kilograms (10 ounces) of R-134a refrigerantinto the evacuated refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE) and proceed to Step 1 of the System Low procedure.

SYSTEM LOW

1. Position the vehicle in a wind-freework area. This will aid in detectingsmall leaks.

2. Operate the heating-A/C system with the engine at idle under the following conditions for at least five minutes.

Doors or windows open

Transmission in Park or Neutral with the parking brake set (depending on application)

A/C-heater controls set to outside air, full cool, panel mode, high blowerand with A/C compressor engaged

CAUTION: A leak detector only designed for R-12 refrigerant will not detect leaks in an R-134a refrigerant

system.

3. Shut the vehicle Off and wait 2-7 minutes. Then use an electronic leak detector that is designed to detect R-134a

refrigerant and search for leaks. Fittings, lines or components that appear to be oily usually indicate a refrigerant

leak. To inspect the A/C evaporator for leaks, insert the leak detector probe into the drain tube opening or an air

outlet. A dye for R-134a is available to aid in leak detection. Use only DaimlerChrysler approved refrigerant dye.

Page 5130 of 5267

STANDARD PROCEDURE

REFRIGERANT SYSTEM SERVICE EQUIPMENT

WARNING: Eye protection must be worn when servicing an A/C refrigerant system. Turn all valves off

(rotate clockwise) on the equipment being used before connecting or disconnecting service equipment from

the refrigerant system. Failure to observe these warnings may result in personal injury or death.

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

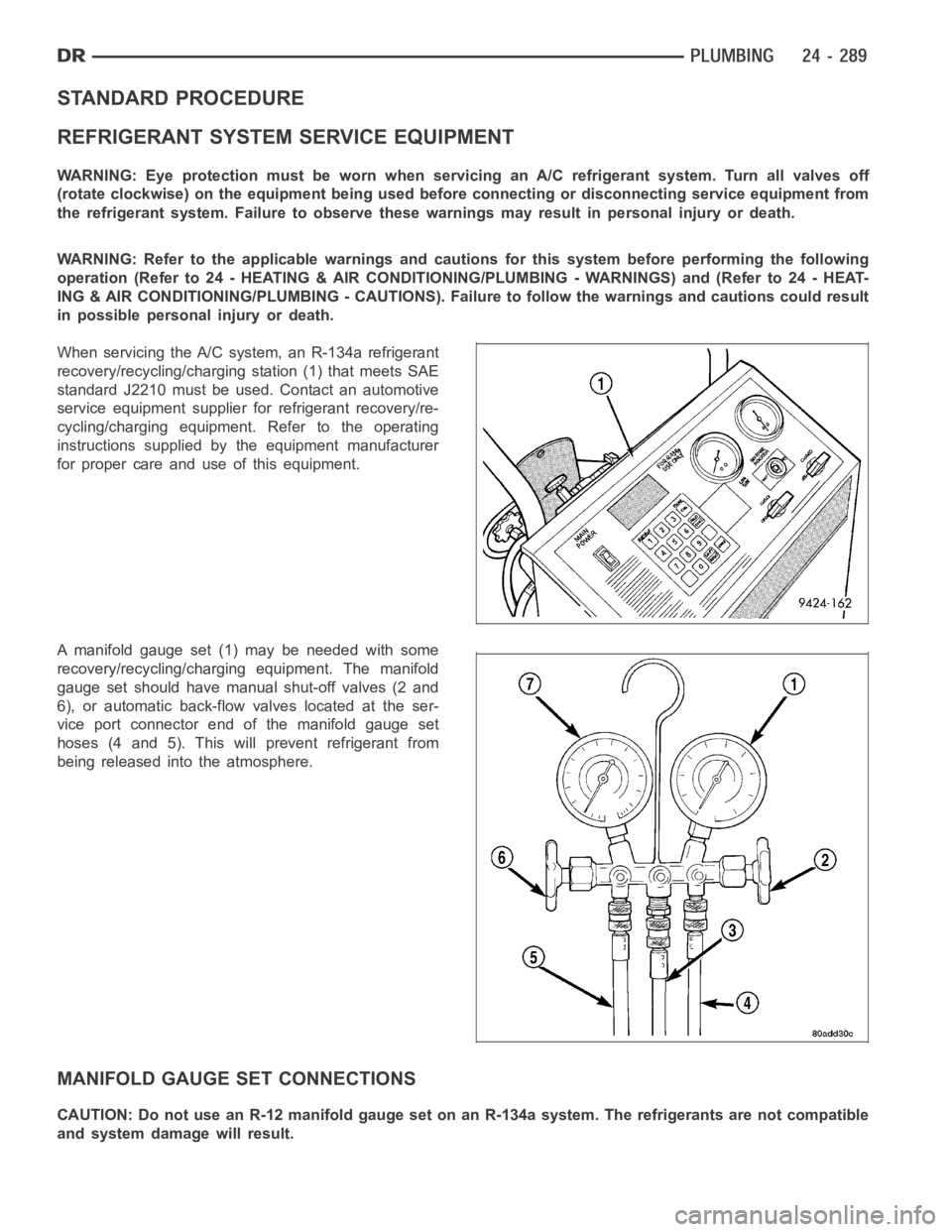

When servicing the A/C system, an R-134a refrigerant

recovery/recycling/charging station (1) that meets SAE

standard J2210 must be used. Contact an automotive

service equipment supplier for refrigerant recovery/re-

cycling/charging equipment. Refer to the operating

instructions supplied by the equipment manufacturer

for proper care and use of this equipment.

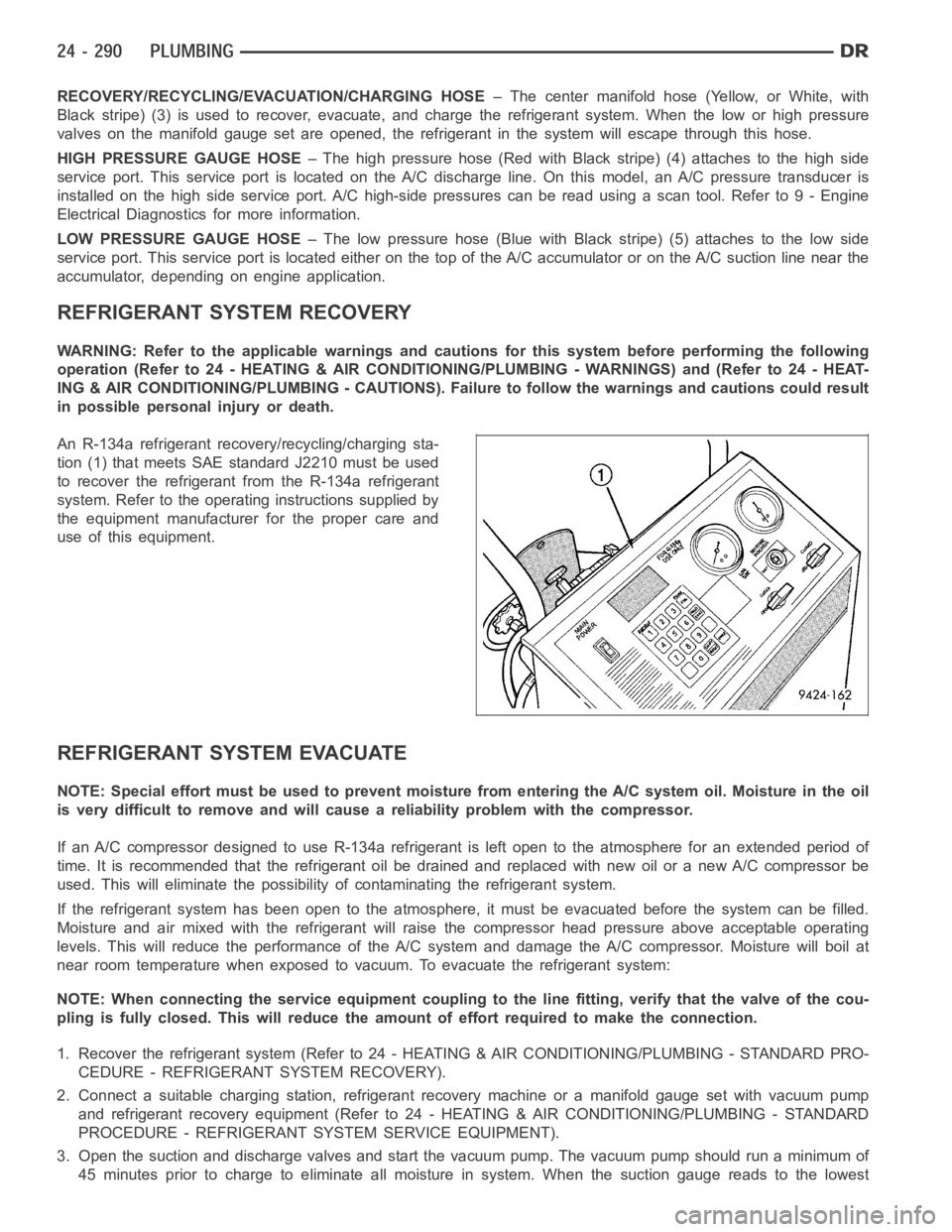

A manifold gauge set (1) may be needed with some

recovery/recycling/charging equipment. The manifold

gauge set should have manual shut-off valves (2 and

6), or automatic back-flow valves located at the ser-

vice port connector end of the manifold gauge set

hoses (4 and 5). This will prevent refrigerant from

being released into the atmosphere.

MANIFOLD GAUGE SET CONNECTIONS

CAUTION: Do not use an R-12 manifold gauge set on an R-134a system. The refrigerants are not compatible

and system damage will result.

Page 5131 of 5267

RECOVERY/RECYCLING/EVACUATION/CHARGING HOSE– The center manifold hose (Yellow, or White, with

Black stripe) (3) is used to recover, evacuate, and charge the refrigerantsystem. When the low or high pressure

valves on the manifold gauge set are opened, the refrigerant in the system will escape through this hose.

HIGH PRESSURE GAUGE HOSE– The high pressure hose (Red with Black stripe) (4) attaches to the high side

service port. This service port is located on the A/C discharge line. On this model, an A/C pressure transducer is

installed on the high side service port. A/C high-side pressures can be read using a scan tool. Refer to 9 - Engine

Electrical Diagnostics for more information.

LOW PRESSURE GAUGE HOSE– The low pressure hose (Blue with Black stripe) (5) attaches to the low side

service port. This service port is located either on the top of the A/C accumulator or on the A/C suction line near the

accumulator, depending on engine application.

REFRIGERANT SYSTEM RECOVERY

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

An R-134a refrigerant recovery/recycling/charging sta-

tion (1) that meets SAE standard J2210 must be used

to recover the refrigerant from the R-134a refrigerant

system. Refer to the operating instructions supplied by

the equipment manufacturer for the proper care and

use of this equipment.

REFRIGERANT SYSTEM EVACUATE

NOTE: Special effort must be used to prevent moisture from entering the A/Csystem oil. Moisture in the oil

is very difficult to remove and will cause a reliability problem with the compressor.

If an A/C compressor designed to use R-134a refrigerant is left open to the atmosphere for an extended period of

time. It is recommended that the refrigerant oil be drained and replaced with new oil or a new A/C compressor be

used. This will eliminate the possibility of contaminating the refrigerant system.

If the refrigerant system has been open to the atmosphere, it must be evacuated before the system can be filled.

Moisture and air mixed with the refrigerant will raise the compressor headpressure above acceptable operating

levels. This will reduce the performance of the A/C system and damage the A/C compressor. Moisture will boil at

near room temperature when exposed to vacuum. To evacuate the refrigerantsystem:

NOTE: When connecting the service equipment coupling to the line fitting,verify that the valve of the cou-

pling is fully closed. This will reduce the amount of effort required to make the connection.

1. Recover the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM RECOVERY).

2. Connect a suitable charging station, refrigerant recovery machine or amanifold gauge set with vacuum pump

and refrigerant recovery equipment (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE - REFRIGERANT SYSTEM SERVICE EQUIPMENT).

3. Open the suction and discharge valves and start the vacuum pump. The vacuum pump should run a minimum of

45minutespriortochargetoeliminateall moisture in system. When the suction gauge reads to the lowest