check engine light DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2351 of 5267

a. Install new o-ring seal to WIF sensor.

b. Apply a light film of clean oil to o-ring seal.

c. Install sensor into housing.

d. Tighten sensor to 2.5 Nꞏm (25 in. lbs.) torque.

e. Connect electrical connector to WIF sensor.

4.Fuel Heater Element:

a. Install fuel heater into fuel filter housing.

b. Install fuel heater thermostat onto the outside of the fuel filter housing.

c. Install fuel heater mounting screws and tighten to 1-1.5 Nꞏm (8 - 13 in. lbs.) torque.

d. Connect electrical connector to fuel heater thermostat.

e. Install new filter cover O-ring onto fuel filter housing cover and lubricate with clean engine oil.

f. Tighten fuel filter housing cover (lid) to 34 Nꞏm (25 ft. lbs.).

5.Drain Valve:

a. Install 2 new O-rings to valve.

b. Lubricate with silicon grease.

c. Installfueldrainvalve.

d. Install 4 mounting screws and tighten to 1–1.5 Nꞏm (8–13 in. lbs.) torque.

e. Connect drain hose to drain valve.

6. Install two new sealing washers to bolt.

7. Install screened banjo bolt Tighten to 24 Nꞏm (18 ft. lbs.)

8. Start engine and check for leaks.

Page 2487 of 5267

FLUID

DESCRIPTION

NOTE: It is normal that some pressure will build up inside the reservoir, especially, with a warm vehicle. A

slight popping noise upon removal ofthe cap is normal. The fluid level should read between the ADD and

the FULL COLD marks. When the fluid is hotit should read between ADD and FULLHOT marks. Only add

fluid when the vehicle is cold.

The recommended fluid for the power steering system is Mopar

AT F + 4 .

Mopar

ATF+4, when new is red in color. The ATF+4 is dyed red so it can be identified from other fluids used in the

vehicle such as engine oil or antifreeze. The red color is not permanent andis not an indicator of fluid condition, As

the vehicle is driven, the ATF+4 will begin to look darker in color and may eventually become brown.THIS IS NOR-

MAL.ATF+4 also has a unique odor that may change with age. Consequently, odor and color cannot be used to

indicate the fluid condition or the need for a fluid change.

STANDARD PROCEDURE

POWER STEERING FLUID LEVEL CHECKING

WARNING: FLUID LEVEL SHOULD BE CHECKED WITH THE ENGINE OFF TO PREVENT PERSONAL INJURY

FROM MOVING PARTS.

CAUTION: MOPAR

ATF+4 is to be used in the power steering system. No other power steering or auto-

matic transmission fluid is to be used in the system. Damage may result to the power steering pump and

system if any other fluid is used, and do not overfill.

The power steering fluid level can be viewed on the dipstick attached to thefiller cap. There are two ranges listed

on the dipstick, COLD and HOT. Before opening power steering system, wipe the reservoir filler cap free of dirt and

debris. Remove the cap and check the fluid level on its dipstick. When the fluid is at normal ambient temperature,

approximately 21°C to 27°C (70°F to 80°F), the fluid level should read between the minimum and maximum area of

the cold range. When the fluid is hot, fluid level is allowed to read up to thehighest end of the HOT range. Only add

fluid when the vehicle is cold.

Use only Mopar

AT F + 4 .Do not overfill the power steering system.

Page 2500 of 5267

STANDARD PROCEDURE

INITIAL OPERATION

WARNING: The fluid level should be checked with engine off to prevent injury from moving components.

NOTE: Remove as much of the old fluid out of the system as possible with a suction tool or by removing

a hose, when a component has failed. Then refill it with fresh fluid until itis clean. This may have to be

done more than once.

CAUTION: MOPAR

ATF+4 is to be used in the power steering system. No other power steering or auto-

matic transmission fluid is to be used in the system. Damage may result to the power steering pump and

system if any other fluid is used, and do not overfill.

Wipe filler cap clean, then check the fluid level. The dipstick should indicateCOLDwhen the fluid is at normal

ambient temperature.

1. Fill the pump fluid reservoir to the proper level and let the fluid settlefor at least two minutes.

2. Start the engine and let run for a few seconds then turn engine off.

3. Add fluid if necessary. Repeat the above procedure until the fluid levelremains constant after running the engine.

4. Raise the front wheels off the ground.

5. Slowly turn the steering wheel right and left, lightly contacting the wheel stops at least 20 times.

6. Check the fluid level add if necessary.

7. Lower the vehicle, start the engine, and use the DRB III to activate the hydraulic fan on full fan operation.

8. Turn the steering wheel slowly from lock to lock.

9. Stop the engine, check the fluid level and refill as required and repeat the process

CAUTION: Do not run a vehicle with foamy fluid for an extended period. This may cause pump damage.

10. If the fluid is extremely foamy or milky looking, allow the vehicle to stand a few minutes and repeat the pro-

cedure.

11. While the vehicle is in park, use the DRB III to activate the hydraulic fan to full fan operation and briefly rev the

engine up to 3000 rpm to fully engage the hydraulic fan.

12. Check the fluid level add if necessary.

Page 2737 of 5267

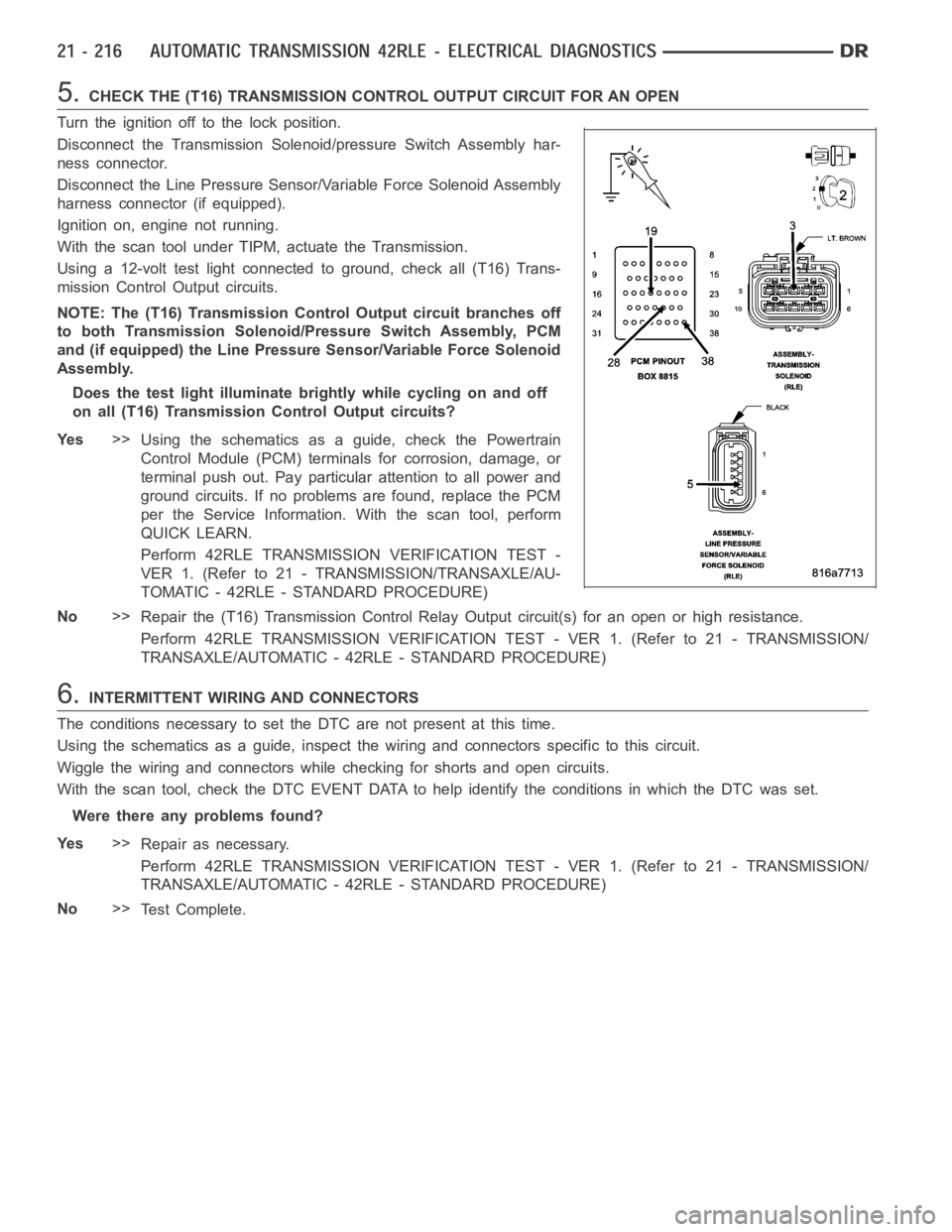

5.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the Transmission Solenoid/pressure Switch Assembly har-

ness connector.

Disconnect the Line Pressure Sensor/Variable Force Solenoid Assembly

harness connector (if equipped).

Ignition on, engine not running.

With the scan tool under TIPM, actuate the Transmission.

Using a 12-volt test light connected to ground, check all (T16) Trans-

mission Control Output circuits.

NOTE: The (T16) Transmission Control Output circuit branches off

to both Transmission Solenoid/Pressure Switch Assembly, PCM

and (if equipped) the Line Pressure Sensor/Variable Force Solenoid

Assembly.

Does the test light illuminate brightly while cycling on and off

on all (T16) Transmission Control Output circuits?

Ye s>>

Using the schematics as a guide, check the Powertrain

Control Module (PCM) terminals for corrosion, damage, or

terminal push out. Pay particular attention to all power and

ground circuits. If no problems are found, replace the PCM

per the Service Information.With the scan tool, perform

QUICK LEARN.

Perform 42RLE TRANSMISSION VERIFICATION TEST -

VER 1. (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Repair the (T16) Transmission Control Relay Output circuit(s) for an openor high resistance.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

6.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set the DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specifictothiscircuit.

Wiggle the wiring and connectors while checking for shorts and open circuits.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 2745 of 5267

4.TRS SENSE CIRCUIT SHORT TO GROUND

Measure the resistance between ground and the identified (T1, T3, T41, or T42) TRS Sense circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the identified (T1, T3, T41, or T42) TRS Sense circuit for a short to ground.

Perform the PRNDL Fault Clearing Procedure – Go To 7

No>>

Go To 5

5.TRS SENSE CIRCUIT SHORT TO OTHER CIRCUITS

Measure the resistance between the identified (T1, T3, T41, or T42) TRS Sense circuit and all other circuits in the

Transmission Solenoid/TRS Assembly harness connector.

Is the resistance below 100k ohms between the identified (T1, T3, T41, or T42) TRS Sense circuit and

any other circuit(s) in the Transmission Solenoid/TRS Assembly harness connector?

Ye s>>

Repair the identified (T1, T3, T41, or T42) TRS Sense circuit for a short to other circuit(s).

Perform the PRNDL Fault Clearing Procedure – Go To 7

No>>

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion,

damage, or terminal push out. Pay particular attention to all power and ground circuits. If no problems

are found, replace the PCM per the Service Information. With the scan tool,perform QUICK LEARN.

Perform the PRNDL Fault Clearing Procedure – Go To 7

6.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set the DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specifictothiscircuit.

Wiggle the wiring and connectors while checking for shorted and open circuits.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the PRNDL Fault Clearing Procedure – Go To 7

No>>

Te s t C o m p l e t e .

7.PRNDL FAULT CLEARING PROCEDURE

With the scan tool, erase Transmission DTCs.

Cycle the ignition off, then start the vehicle.

Firmly apply the brakes and shift into Overdrive.

NOTE: Vehicle must remain in Overdrive for at least 3.0 seconds.

With the brakes firmly applied, shift slowly through all gears (PRNDL) as least three times, pausing momentarily in

each gear.

NOTE: If all the PRNDL lights box individually then the error was cleared.

Shift into park and turn the ignition off to the lock position.

Ignition on, engine not running.

With the scan tool, read Transmission DTCs.

Does the DTC P0706 reset, or do all the PRNDL indicators remain boxed in parkor neutral?

Ye s>>

Return to the symptom list and perform diagnostics for P0706-TRANSMISSION RANGE SENSOR

RATIONALITY.

Go To 1

No>>

Te s t C o m p l e t e .

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Page 2869 of 5267

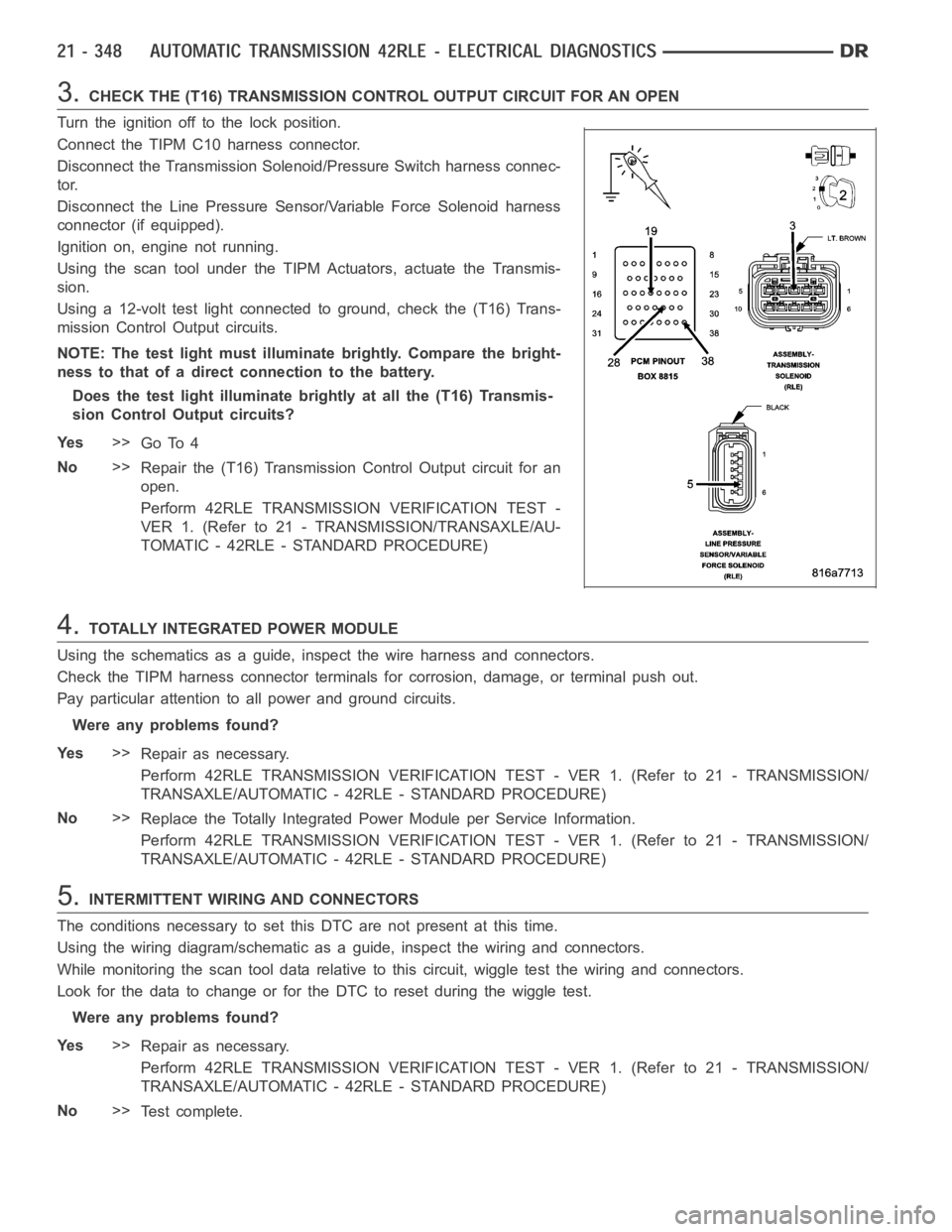

3.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Connect the TIPM C10 harness connector.

Disconnect the Transmission Solenoid/Pressure Switch harness connec-

tor.

Disconnect the Line Pressure Sensor/Variable Force Solenoid harness

connector (if equipped).

Ignition on, engine not running.

Using the scan tool under the TIPM Actuators, actuate the Transmis-

sion.

Using a 12-volt test light connected to ground, check the (T16) Trans-

mission Control Output circuits.

NOTE: The test light must illuminate brightly. Compare the bright-

ness to that of a direct connection to the battery.

Does the test light illuminate brightly at all the (T16) Transmis-

sion Control Output circuits?

Ye s>>

Go To 4

No>>

Repair the (T16) Transmission Control Output circuit for an

open.

Perform 42RLE TRANSMISSION VERIFICATION TEST -

VER 1. (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 42RLE - STANDARD PROCEDURE)

4.TOTALLY INTEGRATED POWER MODULE

Using the schematics as a guide, inspect the wire harness and connectors.

Check the TIPM harness connector terminals for corrosion, damage, or terminal push out.

Pay particular attention to all power and ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

5.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 2874 of 5267

When Monitored:

With the ignition on. Battery voltage greater than 10 volts.

Set Condition:

An open condition of the Transmission Control Output circuit is detected by the Totally Integrated Power Mod-

ule (TIPM).

Possible Causes

(T16) TRANSMISSION CONTROL OUTPUT CIRCUIT OPEN

TOTALLY INTEGRATED POWER MODULE (TIPM)

Diagnostic Test

1.CHECK IF THE DTC IS ACTIVE

Ignition on, engine not running.

With the scan tool, select View DTCs.

Is the status Active for this DTC?

Ye s>>

Go to 2

No>>

Go to 4

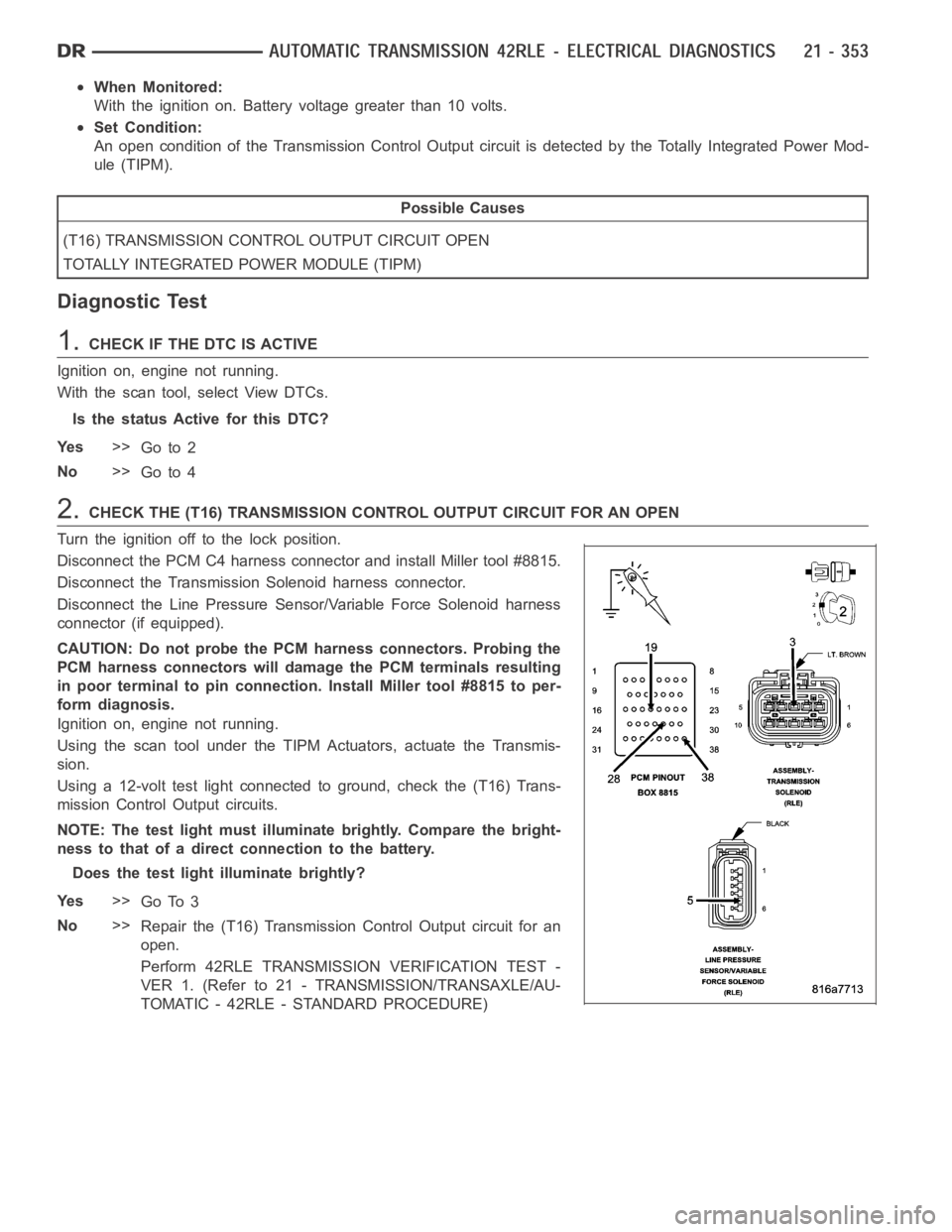

2.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the PCM C4 harness connector and install Miller tool #8815.

Disconnect the Transmission Solenoid harness connector.

Disconnect the Line Pressure Sensor/Variable Force Solenoid harness

connector (if equipped).

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Ignition on, engine not running.

Using the scan tool under the TIPM Actuators, actuate the Transmis-

sion.

Using a 12-volt test light connected to ground, check the (T16) Trans-

mission Control Output circuits.

NOTE: The test light must illuminate brightly. Compare the bright-

ness to that of a direct connection to the battery.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Repair the (T16) Transmission Control Output circuit for an

open.

Perform 42RLE TRANSMISSION VERIFICATION TEST -

VER 1. (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 42RLE - STANDARD PROCEDURE)

Page 2887 of 5267

3.PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator,Miller tool #8333 and the ElectronicTransmission Adapter kit.

Ignition on, engine not running.

With the Transmission Simulator, turn the Pressure Switch selector switchtoL/R.

With the scan tool, monitor the L/R Pressure Switch State while pressing the Pressure Switch Test button.

Did the Pressure Switch state change from open to closed when the test button was pressed?

Ye s>>

Repair internal transmission as necessary per the Service Information. Inspect the Solenoid Switch

Valve per the Service Information and repair or replace as necessary. If noproblems are found, replace

the Transmission Solenoid/Pressure Switch Assembly.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Go To 4

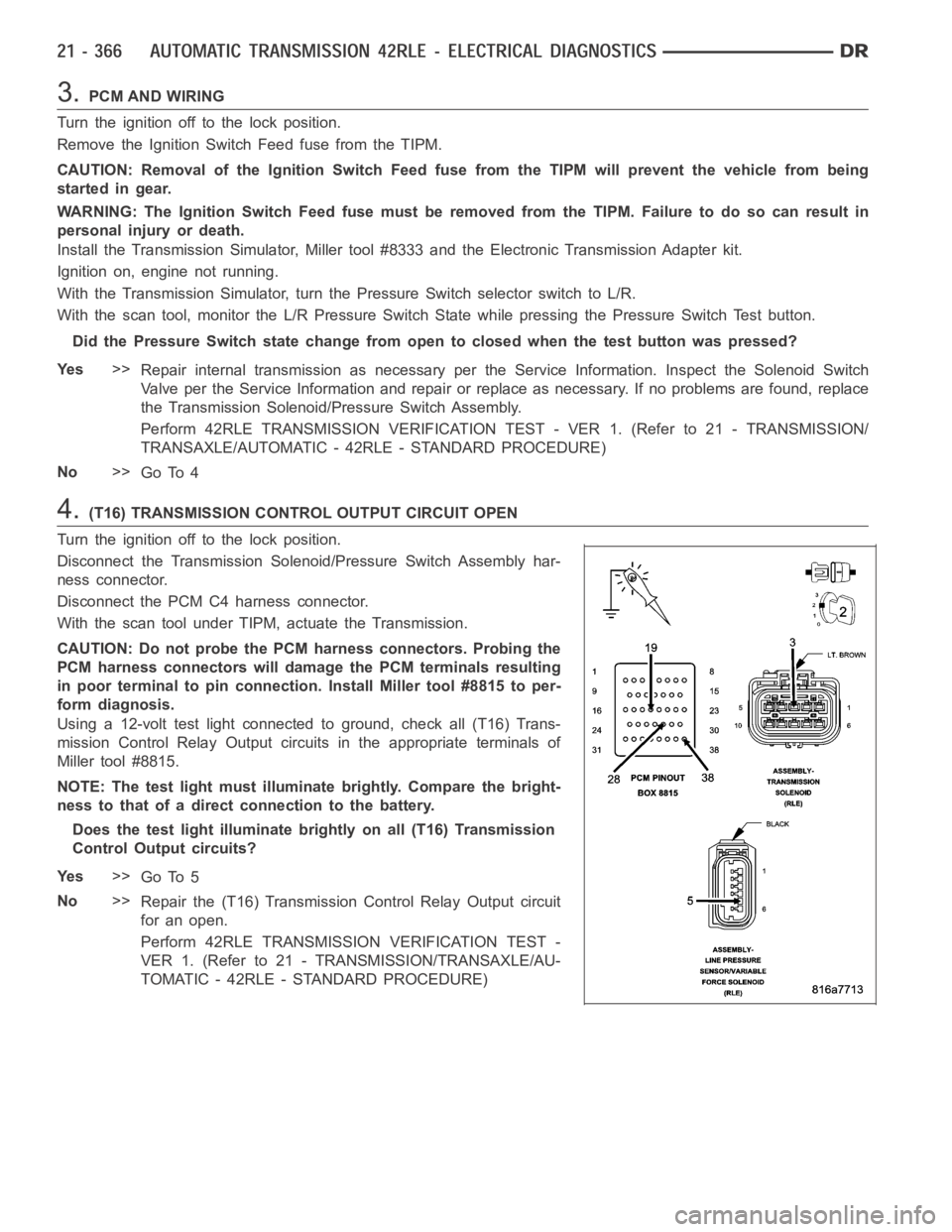

4.(T16) TRANSMISSION CONTROL OUTPUT CIRCUIT OPEN

Turn the ignition off to the lock position.

Disconnect the Transmission Solenoid/Pressure Switch Assembly har-

ness connector.

Disconnect the PCM C4 harness connector.

With the scan tool under TIPM, actuate the Transmission.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Using a 12-volt test light connected to ground, check all (T16) Trans-

mission Control Relay Output circuits in the appropriate terminals of

Miller tool #8815.

NOTE: The test light must illuminate brightly. Compare the bright-

ness to that of a direct connection to the battery.

Does the test light illuminate brightly on all (T16) Transmission

Control Output circuits?

Ye s>>

Go To 5

No>>

Repair the (T16) Transmission Control Relay Output circuit

for an open.

Perform 42RLE TRANSMISSION VERIFICATION TEST -

VER 1. (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 42RLE - STANDARD PROCEDURE)

Page 2972 of 5267

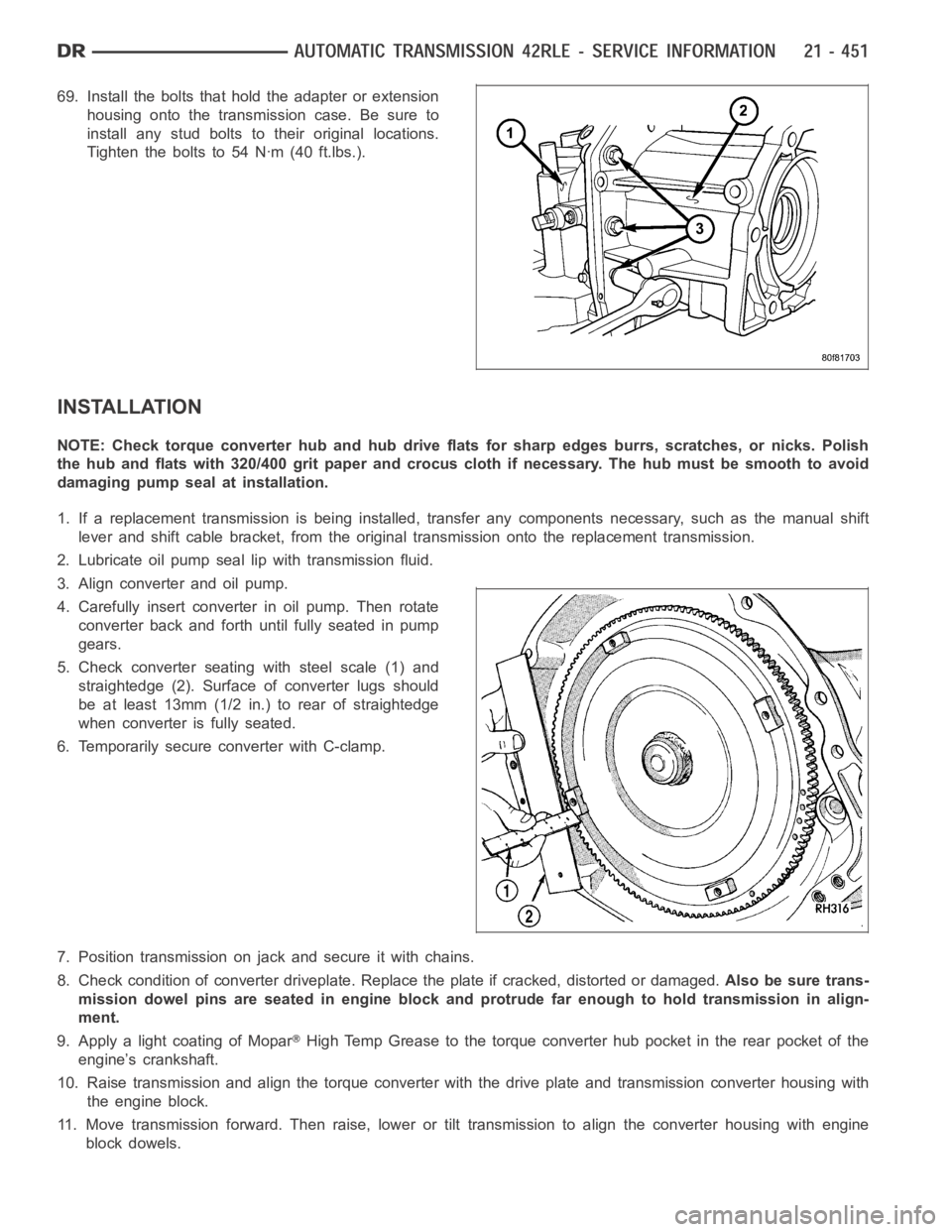

69. Install the bolts that hold the adapter or extension

housing onto the transmission case. Be sure to

install any stud bolts to their original locations.

Tighten the bolts to 54 Nꞏm (40 ft.lbs.).

INSTALLATION

NOTE: Check torque converter hub and hub drive flats for sharp edges burrs,scratches, or nicks. Polish

the hub and flats with 320/400 grit paper and crocus cloth if necessary. Thehub must be smooth to avoid

damaging pump seal at installation.

1. If a replacement transmission is being installed, transfer any components necessary, such as the manual shift

lever and shift cable bracket, from the original transmission onto the replacement transmission.

2. Lubricate oil pump seal lip with transmission fluid.

3. Align converter and oil pump.

4. Carefully insert converter in oil pump. Then rotate

converter back and forth until fully seated in pump

gears.

5. Check converter seating with steel scale (1) and

straightedge (2). Surface of converter lugs should

be at least 13mm (1/2 in.) to rear of straightedge

when converter is fully seated.

6. Temporarily secure converter with C-clamp.

7. Position transmission on jack and secure it with chains.

8. Check condition of converter driveplate. Replace the plate if cracked,distorted or damaged.Also be sure trans-

mission dowel pins are seated in engine block and protrude far enough to holdtransmissioninalign-

ment.

9. Apply a light coating of Mopar

High Temp Grease to the torque converter hub pocket in the rear pocket of the

engine’s crankshaft.

10. Raise transmission and align the torque converter with the drive plateand transmission converter housing with

the engine block.

11. Move transmission forward. Then raise, lower or tilt transmission to align the converter housing with engine

block dowels.

Page 3113 of 5267

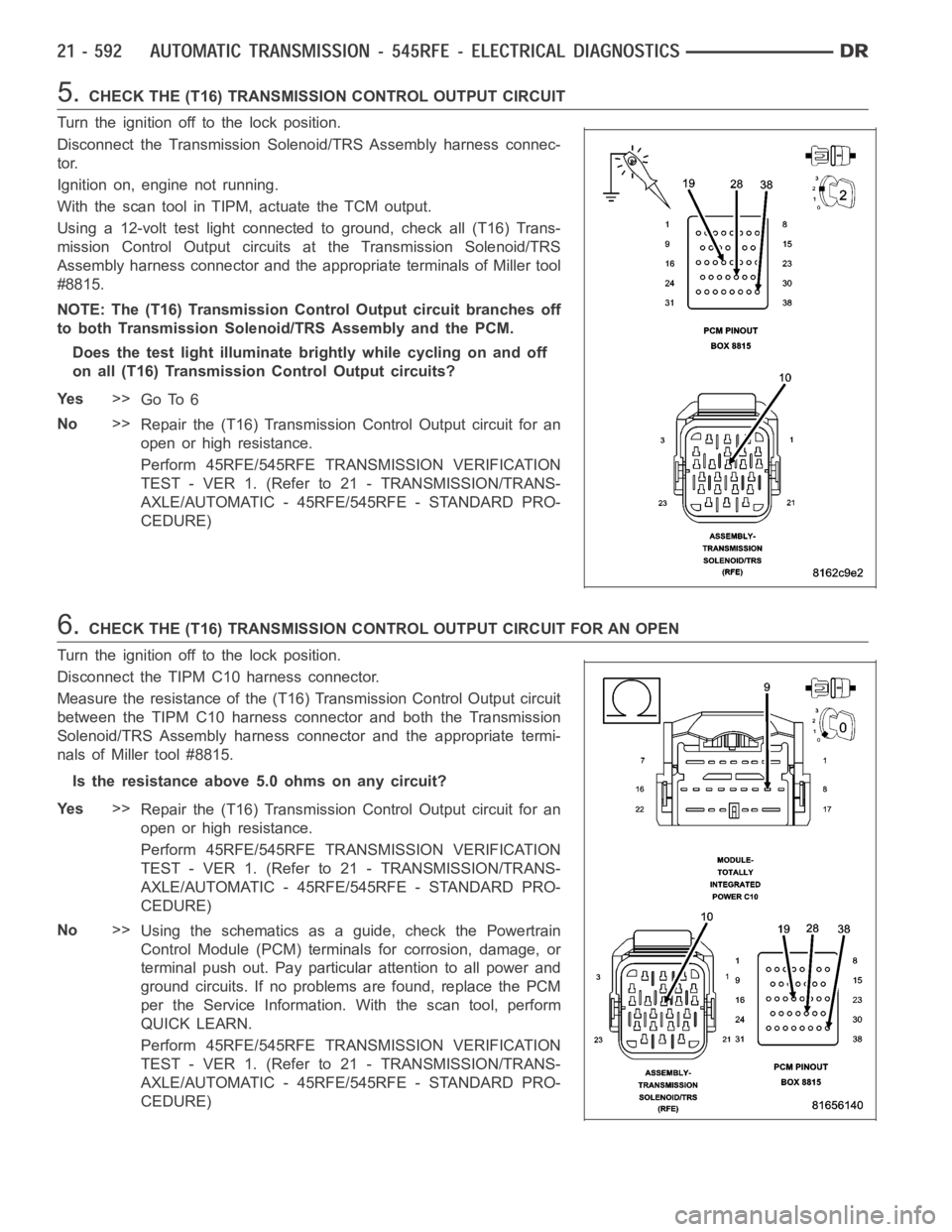

5.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT

Turn the ignition off to the lock position.

Disconnect the Transmission Solenoid/TRS Assembly harness connec-

tor.

Ignition on, engine not running.

With the scan tool in TIPM, actuate the TCM output.

Using a 12-volt test light connected to ground, check all (T16) Trans-

mission Control Output circuits at the Transmission Solenoid/TRS

Assembly harness connector and the appropriate terminals of Miller tool

#8815.

NOTE: The (T16) Transmission Control Output circuit branches off

to both Transmission Solenoid/TRS Assembly and the PCM.

Does the test light illuminate brightly while cycling on and off

on all (T16) Transmission Control Output circuits?

Ye s>>

Go To 6

No>>

Repair the (T16) Transmission Control Output circuit for an

open or high resistance.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

6.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the TIPM C10 harness connector.

Measure the resistance of the (T16) Transmission Control Output circuit

between the TIPM C10 harness connector and both the Transmission

Solenoid/TRS Assembly harness connector and the appropriate termi-

nals of Miller tool #8815.

Is the resistance above 5.0 ohms on any circuit?

Ye s>>

Repair the (T16) Transmission Control Output circuit for an

open or high resistance.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Using the schematics as a guide, check the Powertrain

Control Module (PCM) terminals for corrosion, damage, or

terminal push out. Pay particular attention to all power and

ground circuits. If no problems are found, replace the PCM

per the Service Information.With the scan tool, perform

QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)