ignition DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 5037 of 5267

When Monitored:

Continuously

Set Condition:

If the CAN B Bus (+) or CAN B Bus (-) circuit is open, shorted to voltage, or shorted to ground.

Possible Causes

ACTIVE U0019 CAN B BUS DTC IN THE TOTALLY INTEGRATED POWER MODULE (TIPM)

(D55) CAN B BUS (+) CIRCUIT OPEN

(D54) CAN B BUS (-) CIRCUIT OPEN

A/C HEATER CONTROL

Diagnostic Test

1.VERIFY DTC U0019–CAN B BUS IS ACTIVE

Turn the ignition on.

With the scan tool, read HVAC DTCs.

Does the scan tool display active: U0019–CAN B BUS?

Ye s>>

Go To 2

No>>

If the DTC is stored, check for an intermittent condition by inspecting therelated wiring harness for

chafed, pierced, pinched, and partially broken wires. Also, inspect the related connectors for broken,

bent, pushed out, spread, corroded, or contaminated terminals.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

2.CHECK FOR ACTIVE CAN B BUS RELATED DTCS IN THE TOTALLY INTEGRATED POWER MODULE

(TIPM)

With the scan tool, read Totally Integrated Power Module (TIPM) DTCs.

Does the scan tool display any active CAN B BUS related DTCs?

Ye s>>

Diagnose and repair the DTC(s). (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES -

DIAGNOSIS AND TESTING).

No>>

Go To 3

Page 5038 of 5267

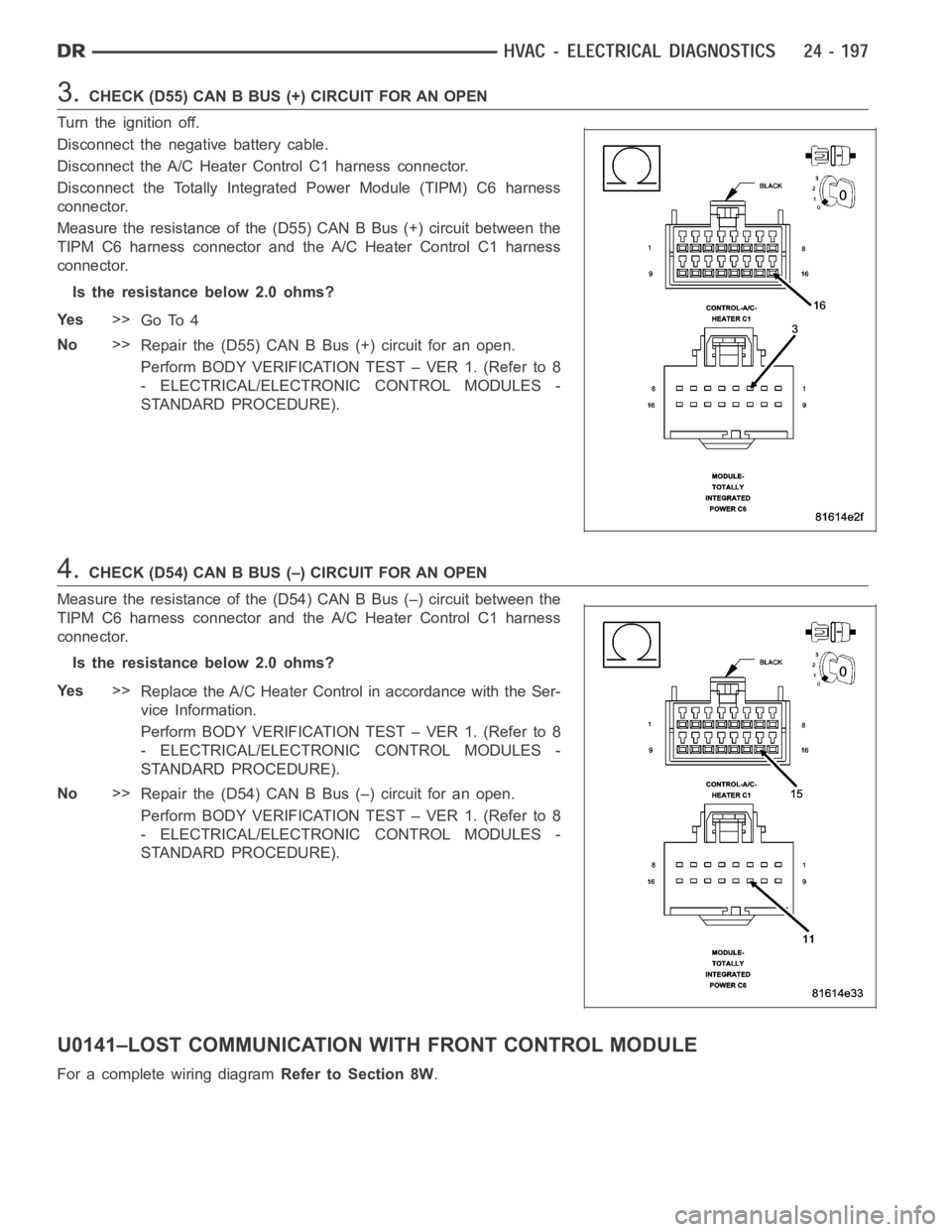

3.CHECK(D55)CANBBUS(+)CIRCUITFORANOPEN

Turn the ignition off.

Disconnect the negative battery cable.

Disconnect the A/C Heater Control C1 harness connector.

Disconnect the Totally Integrated Power Module (TIPM) C6 harness

connector.

Measure the resistance of the (D55) CAN B Bus (+) circuit between the

TIPM C6 harness connector and the A/C Heater Control C1 harness

connector.

Is the resistance below 2.0 ohms?

Ye s>>

Go To 4

No>>

Repair the (D55) CAN B Bus (+) circuit for an open.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

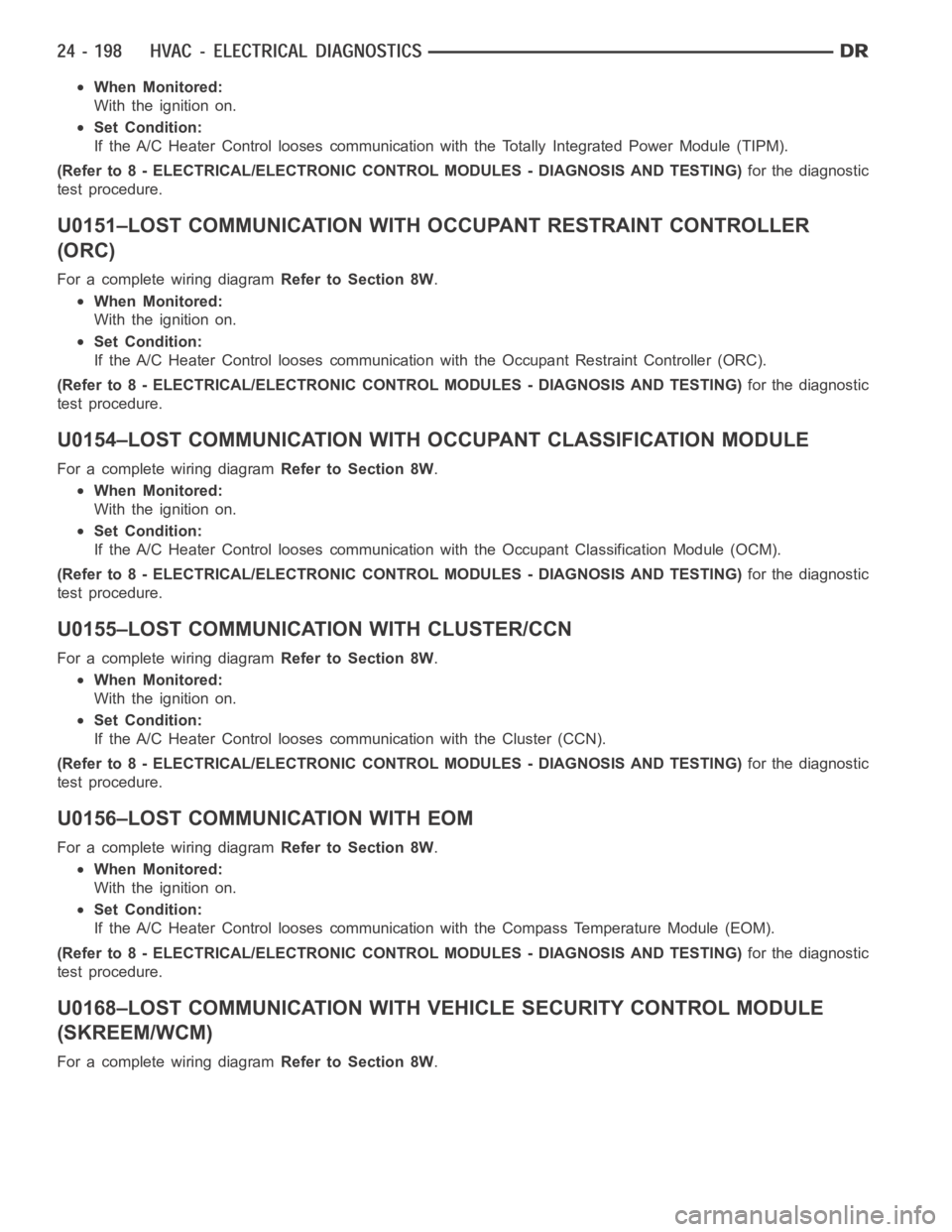

4.CHECK (D54) CAN B BUS (–) CIRCUIT FOR AN OPEN

Measure the resistance of the (D54) CAN B Bus (–) circuit between the

TIPM C6 harness connector and the A/C Heater Control C1 harness

connector.

Is the resistance below 2.0 ohms?

Ye s>>

Replace the A/C Heater Control in accordance with the Ser-

vice Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

No>>

Repair the (D54) CAN B Bus (–) circuit for an open.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

U0141–LOST COMMUNICATION WITH FRONT CONTROL MODULE

For a complete wiring diagramRefer to Section 8W.

Page 5039 of 5267

When Monitored:

With the ignition on.

Set Condition:

If the A/C Heater Control looses communication with the Totally Integrated Power Module (TIPM).

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING)for the diagnostic

test procedure.

U0151–LOST COMMUNICATION WITHOCCUPANT RESTRAINT CONTROLLER

(ORC)

For a complete wiring diagramRefer to Section 8W.

When Monitored:

With the ignition on.

Set Condition:

If the A/C Heater Control looses communication with the Occupant Restraint Controller (ORC).

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING)for the diagnostic

test procedure.

U0154–LOST COMMUNICATION WITH OCCUPANT CLASSIFICATION MODULE

For a complete wiring diagramRefer to Section 8W.

When Monitored:

With the ignition on.

Set Condition:

If the A/C Heater Control looses communication with the Occupant Classification Module (OCM).

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING)for the diagnostic

test procedure.

U0155–LOST COMMUNICATION WITH CLUSTER/CCN

For a complete wiring diagramRefer to Section 8W.

When Monitored:

With the ignition on.

Set Condition:

If the A/C Heater Control looses communication with the Cluster (CCN).

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING)for the diagnostic

test procedure.

U0156–LOST COMMUNICATION WITH EOM

For a complete wiring diagramRefer to Section 8W.

When Monitored:

With the ignition on.

Set Condition:

If the A/C Heater Control looses communication with the Compass Temperature Module (EOM).

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING)for the diagnostic

test procedure.

U0168–LOST COMMUNICATION WITHVEHICLE SECURITY CONTROL MODULE

(SKREEM/WCM)

For a complete wiring diagramRefer to Section 8W.

Page 5040 of 5267

When Monitored:

With the ignition on.

Set Condition:

If the A/C Heater Control looses communication with the Vehicle Security Control Module (SKREEM/WCM).

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING)for the diagnostic

test procedure.

U0169–LOST COMMUNICATION WITH SUNROOF CONTROL MODULE

For a complete wiring diagramRefer to Section 8W.

When Monitored:

With the ignition on.

Set Condition:

If the A/C Heater Control looses communication with the Sunroof Control Module (SCM).

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING)for the diagnostic

test procedure.

U0184–LOST COMMUNICATION WITH RADIO

For a complete wiring diagramRefer to Section 8W.

When Monitored:

With the ignition on.

Set Condition:

If the A/C Heater Control looses communication with the Radio.

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING)for the diagnostic

test procedure.

U0186–LOST COMMUNICATION WITH AUDIO AMPLIFIER

For a complete wiring diagramRefer to Section 8W.

When Monitored:

With the ignition on.

Set Condition:

If the A/C Heater Control looses communication with the Amplifier (AMP).

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING)for the diagnostic

test procedure.

U0195–LOST COMMUNICATION WITH SDARS

For a complete wiring diagramRefer to Section 8W.

When Monitored:

With the ignition on.

Set Condition:

If the A/C Heater Control looses communication with the Satellite Audio Receiver (SDARS).

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING)for the diagnostic

test procedure.

U0196–LOST COMMUNICATION WITHVEHICLE ENTERTAINMENT CONTROL

MODULE

For a complete wiring diagramRefer to Section 8W.

Page 5041 of 5267

When Monitored:

With the ignition on.

Set Condition:

If the A/C Heater Control looses communication with the Vehicle Entertainment System (VES).

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING)for the diagnostic

test procedure.

U0197–LOST COMMUNICATION WITH HANDS FREE PHONE MODULE

For a complete wiring diagramRefer to Section 8W.

When Monitored:

With the ignition on.

Set Condition:

If the A/C Heater Control looses communication with the Hands Free Phone Module (HFM).

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING)for the diagnostic

test procedure.

DTC SET DURING ROUTINE - TEST NOT PASSED

For a complete wiring diagramRefer to Section 8W.

When Monitored:

When the Cooldown Test is executed.

Set Condition:

If the A/C system is unable to lower the evaporator temperature 11.11°C (20°F) within one minute.

For dual-zone HVAC systems,refer to B10B2-A/C COOL DOWN TEST PERFORMANCEfor the diagnostic test

procedure. For single-zone HVAC systems,refer to B1079–CLIMATE CONTROL COOL DOWN TEST EXCESSIVE

TIMEfor the diagnostic test procedure.

BLOWERS NOT ON HIGH - TEST NOT RUN

For a complete wiring diagramRefer to Section 8W.

When Monitored:

When the Cooldown Test is executed.

Set Condition:

If either the blower speed was not set to high speed prior to starting the Cooldown Test or the blower speed

was changed from high speed to another setting after starting the Cooldowntest.

For dual-zone HVAC systems,refer to B10B2-A/C COOL DOWN TEST PERFORMANCEfor the diagnostic test

procedure. For single-zone HVAC systems,refer to B1079–CLIMATE CONTROL COOL DOWN TEST EXCESSIVE

TIMEfor the diagnostic test procedure.

REFRIGERANT TEMPERATURE SENSOR ERROR

For a complete wiring diagramRefer to Section 8W.

When Monitored:

When the Cooldown Test is executed.

Set Condition:

If a fault occurred with the Evaporator Temperature Sensor/sensor circuits.

For dual-zone HVAC systems,refer to B10B2-A/C COOL DOWN TEST PERFORMANCEfor the diagnostic test

procedure. For single-zone HVAC systems,refer to B1079–CLIMATE CONTROL COOL DOWN TEST EXCESSIVE

TIMEfor the diagnostic test procedure.

Page 5043 of 5267

Possible Causes

(F942) FUSED IGNITION SWITCH OUTPUT (RUN-START) CIRCUIT OPEN

(C70) BLOWER MOTOR HIGH DRIVER CIRCUIT OPEN

(Z134) GROUND CIRCUIT OPEN

BLOWER MOTOR

A/C HEATER CONTROL

TIPM

Diagnostic Test

1.CHECK FOR DTCs IN THE TIPM

Turn the ignition on.

With the scan tool, read TIPM DTCs.

Does the scan tool display any DTCs?

Ye s>>

Diagnose and repair the DTC(s). Refer to the Table of Contents in the applicable section for the diag-

nostic procedure.

No>>

Go To 2

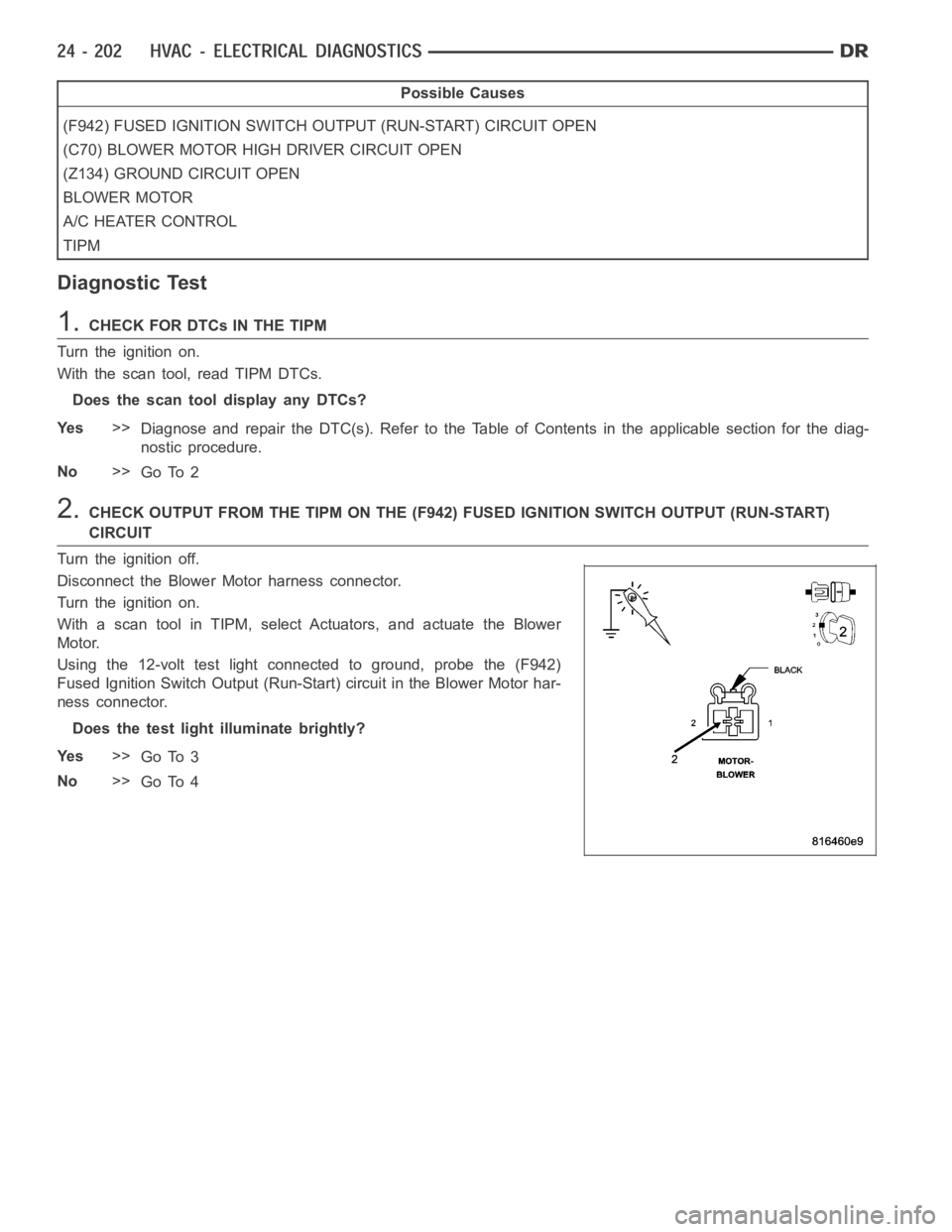

2.CHECK OUTPUT FROM THE TIPM ON THE (F942) FUSED IGNITION SWITCH OUTPUT (RUN-START)

CIRCUIT

Turn the ignition off.

Disconnect the Blower Motor harness connector.

Turn the ignition on.

With a scan tool in TIPM, select Actuators, and actuate the Blower

Motor.

Using the 12-volt test light connected to ground, probe the (F942)

Fused Ignition Switch Output (Run-Start) circuit in the Blower Motor har-

ness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Go To 4

Page 5044 of 5267

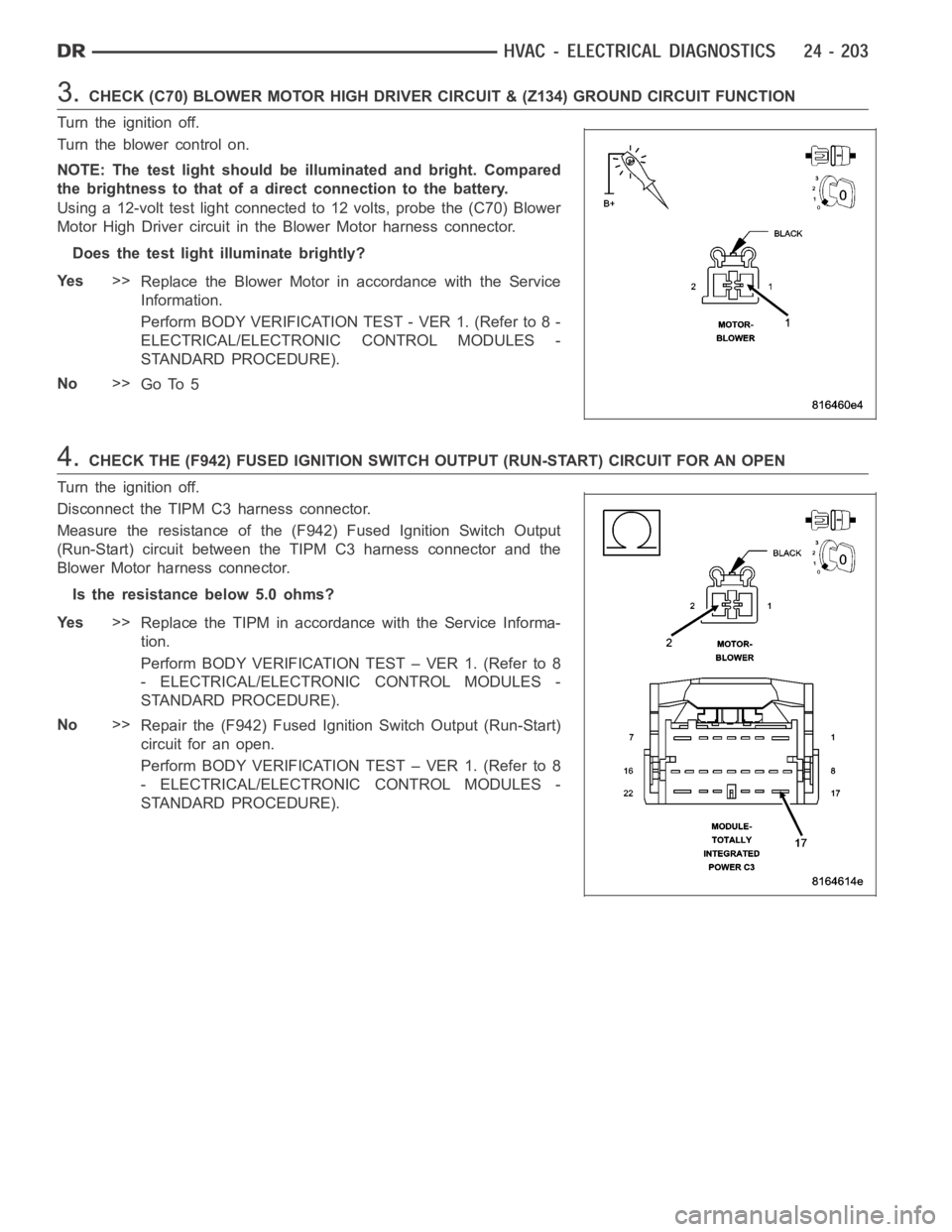

3.CHECK (C70) BLOWER MOTOR HIGH DRIVER CIRCUIT & (Z134) GROUND CIRCUIT FUNCTION

Turn the ignition off.

Turn the blower control on.

NOTE: The test light should be illuminated and bright. Compared

the brightness to that of a direct connection to the battery.

Using a 12-volt test light connected to 12 volts, probe the (C70) Blower

Motor High Driver circuit in the Blower Motor harness connector.

Does the test light illuminate brightly?

Ye s>>

Replace the Blower Motor in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

No>>

Go To 5

4.CHECK THE (F942) FUSED IGNITION SWITCH OUTPUT (RUN-START) CIRCUIT FOR AN OPEN

Turn the ignition off.

Disconnect the TIPM C3 harness connector.

Measure the resistance of the (F942) Fused Ignition Switch Output

(Run-Start) circuit between the TIPM C3 harness connector and the

Blower Motor harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Replace the TIPM in accordance with the Service Informa-

tion.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

No>>

Repair the (F942) Fused Ignition Switch Output (Run-Start)

circuit for an open.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

Page 5053 of 5267

ACTUATOR DTC DETECTION TEST — DUAL-ZONE

The Actuator DTC Detection Test:

is actuated with a scan tool.

clears all actuator related DTCs when the test is actuated.

supplements the continuous diagnostics on the actuator drive system.

monitors for shorted actuator circuits allowing service to easily diagnose and troubleshoot up to three simul-

taneous shorts. Shorted actuator circuit faults (XXX Control Circuit High or XXX Control Circuit Low) will only

display after running the Actuator DTC Detection Test.

After repairing each DTC, cycle the ignition switch, and then run the Actuator DTC Detection Test again to ensure

that no new DTCs exist. If multiple DTCs are present, beginning with the passenger blend door, diagnose and repair

all short high faults and then short low faults. When the test returns passed, clear all faults and run the Actuator

Calibration function as a final check of system health.

ACTUATOR DTC DETECTION TEST — SINGLE-ZONE

The Actuator DTC Detection Test:

is actuated with a scan tool.

clears all actuator related DTCs when the test is actuated.

supplements the continuous diagnostics on the actuator drive system.

monitors for shorted actuator circuits allowing service to easily diagnose and troubleshoot up to three simul-

taneous shorts. Shorted actuator circuit faults (XXX Control Circuit High or XXX Control Circuit Low) will only

display after running the Actuator DTC Detection Test.

After repairing each DTC, cycle the ignition switch, and then run the Actuator DTC Detection Test again to ensure

that no new DTCs exist. If multiple DTCs are present, beginning with the common circuit, diagnose and repair all

short high faults and then short low faults. When the test returns passed, clear all faults and run the Actuator Cal-

ibration function as a final check of system health.

A/C PERFORMANCE

The A/C system is designed to provide the passenger compartment with low temperature and low humidity air. The

A/C evaporator, located in the HVAC housing is cooled to temperatures nearthe freezing point. As warm damp air

passes over the fins of the A/C evaporator, the air transfers its heat to therefrigerant in the evaporator coils and the

moisture in the air condenses on the evaporator fins. During periods of high heat and humidity, an A/C system will

be more effective in the Recirculation mode (max-A/C). With the system in the Recirculation mode, only air from the

passenger compartment passes through the A/C evaporator. As the passenger compartment air dehumidifies, the

A/C system performance levels rise.

Humidity has an important bearing on the temperature of the air delivered to the interior of the vehicle. It is impor-

tant to understand the effect that humidity has on the performance of the A/C system. When humidity is high, the

A/C evaporator has to perform a double duty. It must lower the air temperature, and it must lower the temperature

of the moisture in the air that condenses on the evaporator fins. Condensing the moisture in the air transfers heat

energy into the evaporator fins and coils. This reduces the amount of heat the A/C evaporator can absorb from the

air. High humidity greatly reduces the ability of the A/C evaporator to lower the temperature of the air.

However, evaporator capacity used to reduce the amount of moisture in the air is not wasted. Wringing some of the

moisture out of the air entering the vehicle adds to the comfort of the passengers. Although, an owner may expect

too much from their A/C system on humid days. A performance test is the best way to determine whether the sys-

tem is performing up to design standards. This test also provides valuableclues as to the possible cause of trouble

with the A/C system. The ambient air temperature in the location where the vehicle will be tested must be a mini-

mum of 21° C (70° F) for this test.

A/C PERFORMANCE TEST

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

Page 5121 of 5267

MOTOR-BLOWER

DESCRIPTION

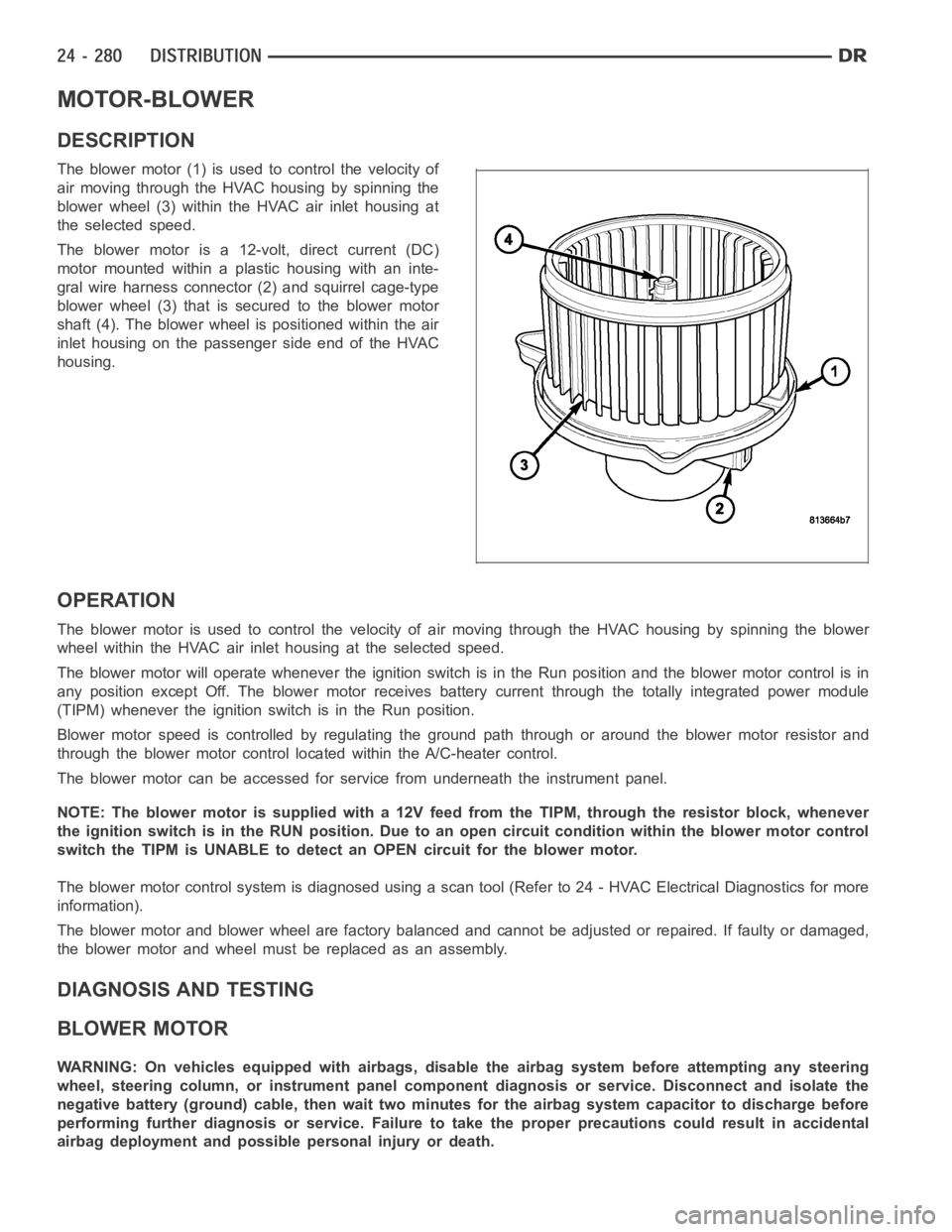

The blower motor (1) is used to control the velocity of

air moving through the HVAC housing by spinning the

blower wheel (3) within the HVAC air inlet housing at

the selected speed.

The blower motor is a 12-volt, direct current (DC)

motormountedwithinaplastichousingwithaninte-

gral wire harness connector (2) and squirrel cage-type

blower wheel (3) that is secured to the blower motor

shaft (4). The blower wheel is positioned within the air

inlet housing on the passenger side end of the HVAC

housing.

OPERATION

The blower motor is used to control the velocity of air moving through the HVAC housing by spinning the blower

wheel within the HVAC air inlet housing at the selected speed.

The blower motor will operate whenever the ignition switch is in the Run position and the blower motor control is in

any position except Off. The blower motor receives battery current through the totally integrated power module

(TIPM) whenever the ignition switch is in the Run position.

Blower motor speed is controlled by regulating the ground path through or around the blower motor resistor and

through the blower motor control located within the A/C-heater control.

The blower motor can be accessed for service from underneath the instrument panel.

NOTE: The blower motor is supplied with a 12V feed from the TIPM, through theresistor block, whenever

the ignition switch is in the RUN position. Due to an open circuit conditionwithin the blower motor control

switch the TIPM is UNABLE to detect an OPEN circuit for the blower motor.

The blower motor control system is diagnosed using a scan tool (Refer to 24 -HVAC Electrical Diagnostics for more

information).

The blower motor and blower wheel are factory balanced and cannot be adjusted or repaired. If faulty or damaged,

the blower motor and wheel must be replaced as an assembly.

DIAGNOSIS AND TESTING

BLOWER MOTOR

WARNING: On vehicles equipped with airbags, disable the airbag system before attempting any steering

wheel, steering column, or instrument panel component diagnosis or service. Disconnect and isolate the

negative battery (ground) cable, then wait two minutes for the airbag system capacitor to discharge before

performing further diagnosis or service. Failure to take the proper precautions could result in accidental

airbag deployment and possible personal injury or death.

Page 5122 of 5267

NOTE: The blower motor is supplied with a 12V feed from the TIPM, through theresistor block, whenever

the ignition switch is in the RUN position. Due to an open circuit conditionwithin the blower motor control

switch the TIPM is UNABLE to detect an OPEN circuit for the blower motor.

To determine if an open condition exists within the blower motor circuit wiring, it is necessary to disconnect the

negative battery cable and check for continuity within the blower motor circuits using an ohmmeter. For circuit

descriptions and diagrams, refer to Air Conditioning/Heater in Group 8W -Wiring Diagrams.

OPERATION

Possible causes of the blower motor not operating include:

Faulty blower motor

Faulty blower motor circuit wiring or wire harness connectors

Faulty blower motor control

Possible causes of the blower motor not operating in one or more speeds include:

Faulty blower motor resistor

Faulty blower motor circuit wiring or wire harness connectors

Faulty blower motor control

VIBRATION

Possible causes of blower motor vibration include:

Improper blower motor mounting

Improper blower wheel mounting

Deformed blower wheel

Out of balance blower wheel due to foreign material in the wheel

Faulty blower motor

NOISE

To determine if the blower motor is the source of the noise, simply switch the blower motor from Off to On. To verify

that the blower motor is the source of the noise, unplug the blower motor wire harness connector and operate the

heating-A/C system. If the noise goes away, possible causes include:

Foreign material in the HVAC air inlet housing

Improper blower motor mounting

Improper blower wheel mounting

Faulty blower motor