differential DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2033 of 5267

5. Identify the fluid in the cylinder(s) (i.e., coolant, fuel, oil or other).

6. Make sure all fluid has been removed from the cylinders. Inspect engine for damage (i.e., connecting rods, pis-

tons, valves, etc.)

7. Repair engine or components as necessary to prevent this problem from re-occurring.

CAUTION: Squirt approximately one teaspoon of oil into the cylinders, rotateenginetolubricatethecylin-

der walls to prevent damage on restart.

8. Install new spark plugs.

9. Drain engine oil and remove oil filter.

10. Fill engine with specified amount of approved oil and install new oil filter.

11. Connect negative battery cable.

12. Start engine and check for any leaks.

REMOVAL - ENGINE ASSEMBLY

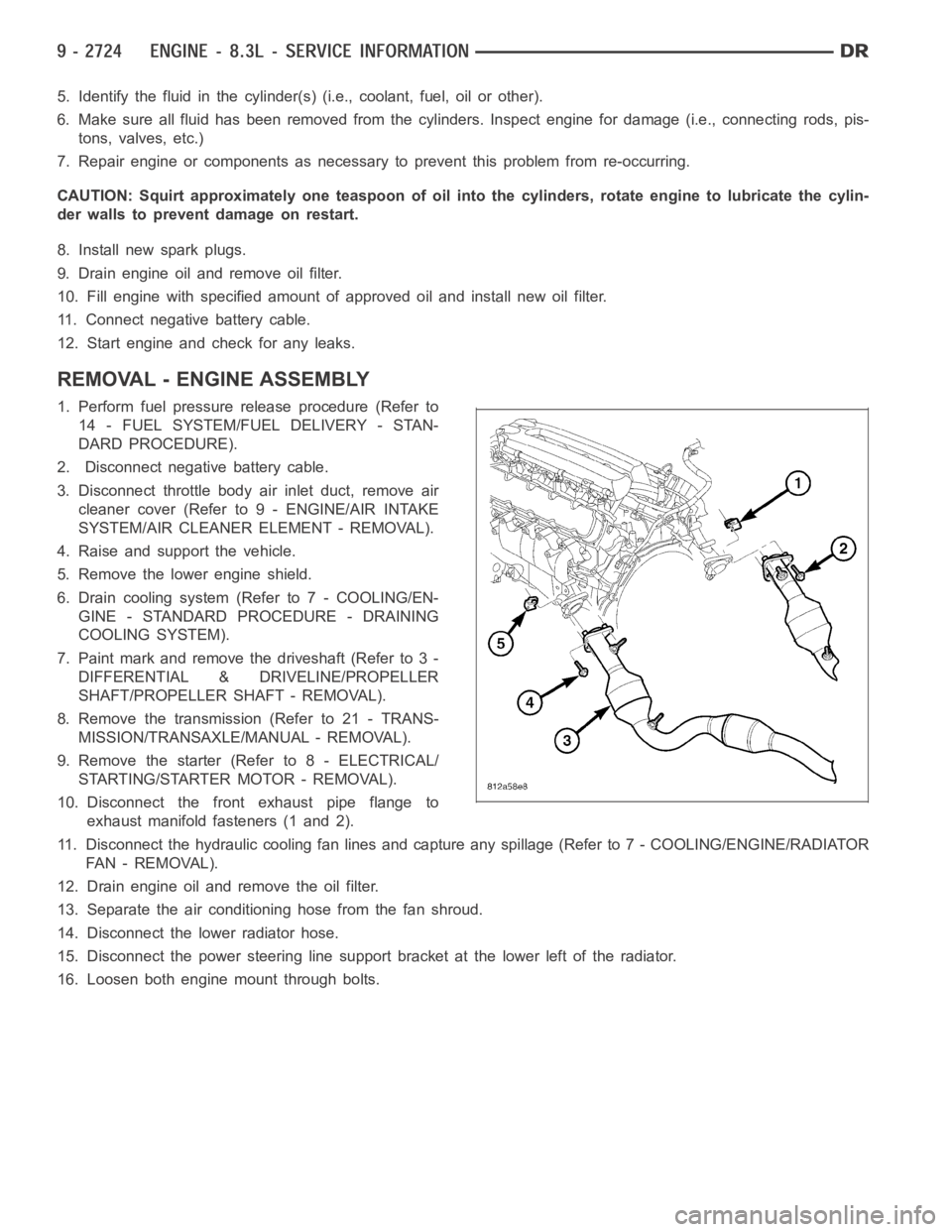

1. Perform fuel pressure release procedure (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY - STAN-

DARD PROCEDURE).

2. Disconnect negative battery cable.

3. Disconnect throttle body air inlet duct, remove air

cleaner cover (Refer to 9 - ENGINE/AIR INTAKE

SYSTEM/AIR CLEANER ELEMENT - REMOVAL).

4. Raise and support the vehicle.

5. Remove the lower engine shield.

6. Drain cooling system (Refer to 7 - COOLING/EN-

GINE - STANDARD PROCEDURE - DRAINING

COOLING SYSTEM).

7. Paint mark and remove the driveshaft (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL).

8.Removethetransmission(Referto21-TRANS-

MISSION/TRANSAXLE/MANUAL - REMOVAL).

9. Remove the starter (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - REMOVAL).

10. Disconnect the front exhaust pipe flange to

exhaust manifold fasteners (1 and 2).

11. Disconnect the hydraulic cooling fan lines and capture any spillage (Refer to 7 - COOLING/ENGINE/RADIATOR

FA N - R E M O VA L ) .

12. Drain engine oil and remove the oil filter.

13. Separate the air conditioning hose from the fan shroud.

14. Disconnect the lower radiator hose.

15. Disconnect the power steering line support bracket at the lower left ofthe radiator.

16. Loosen both engine mount through bolts.

Page 2925 of 5267

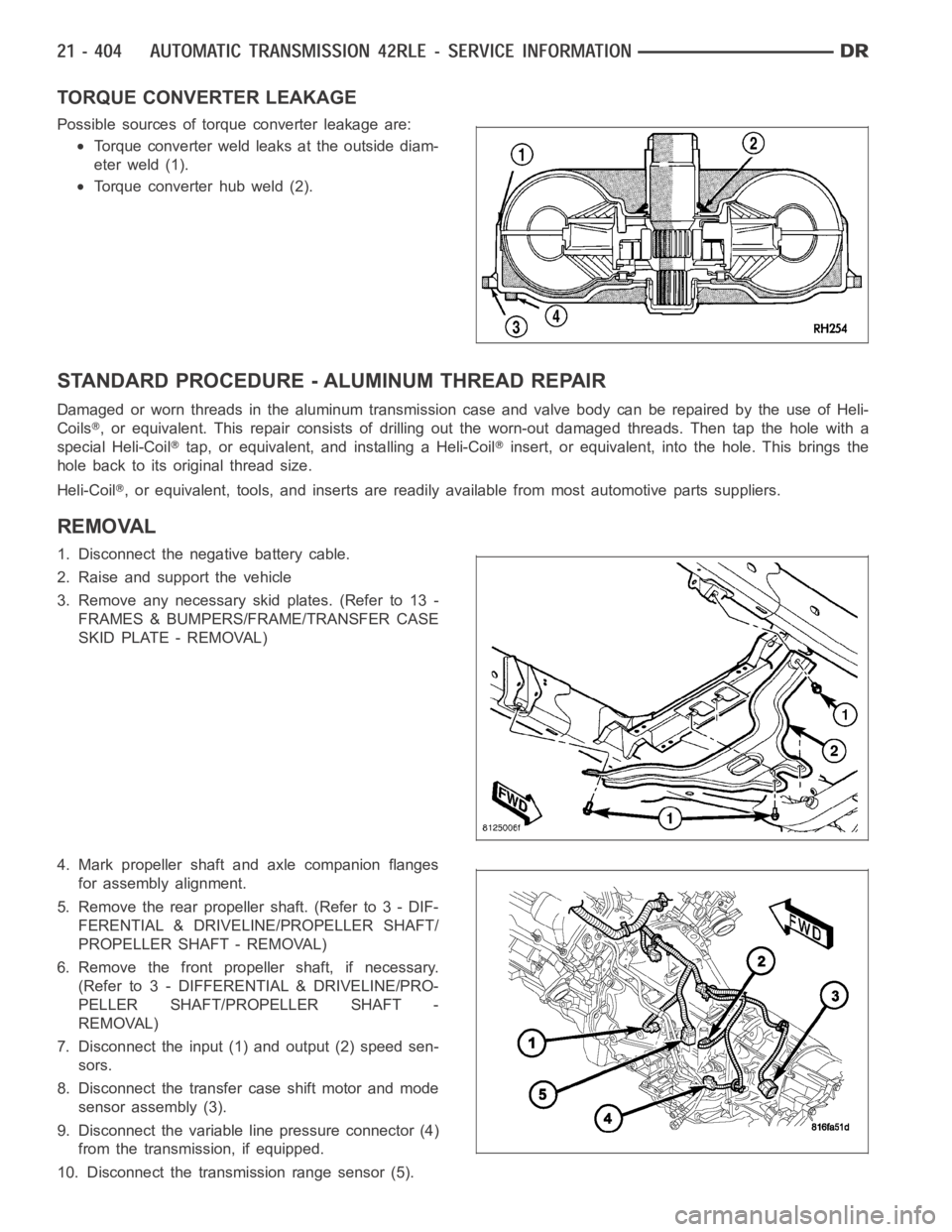

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

Torque converter weld leaks at the outside diam-

eter weld (1).

Torque converter hub weld (2).

STANDARD PROCEDURE - ALUMINUM THREAD REPAIR

DamagedorwornthreadsinthealuminumtransmissioncaseandvalvebodycanberepairedbytheuseofHeli-

Coils

, or equivalent. This repair consists of drilling out the worn-out damagedthreads. Then tap the hole with a

special Heli-Coil

tap, or equivalent, and installing a Heli-Coilinsert, or equivalent, into the hole. This brings the

hole back to its original thread size.

Heli-Coil

, or equivalent, tools, and inserts are readily available from most automotive parts suppliers.

REMOVAL

1. Disconnect the negative battery cable.

2. Raise and support the vehicle

3. Remove any necessary skid plates. (Refer to 13 -

FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - REMOVAL)

4. Mark propeller shaft and axle companion flanges

for assembly alignment.

5. Remove the rear propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

6. Remove the front propeller shaft, if necessary.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/PRO-

PELLER SHAFT/PROPELLER SHAFT -

REMOVAL)

7. Disconnect the input (1) and output (2) speed sen-

sors.

8. Disconnect the transfer case shift motor and mode

sensor assembly (3).

9. Disconnect the variable line pressure connector (4)

from the transmission, if equipped.

10. Disconnect the transmission range sensor (5).

Page 3367 of 5267

Improper adjustments

Hydraulic malfunctions

Mechanical malfunctions

Electronic malfunctions

Diagnosis of these problems should always begin by checking the easily accessible variables: fluid level and con-

dition, gearshift cable adjustment. Then perform a road test to determineif the problem has been corrected or if

more diagnosis is necessary. If the problem persists after the preliminary tests and corrections are completed,

hydraulic pressure checks should be performed.

PRELIMINARY

Two basic procedures are required. One procedure for vehicles that are drivable and an alternate procedure for

disabled vehicles (will not back up or move forward).

VEHICLE IS DRIVABLE

1. Check for transmission fault codes using scan tool.

2. Check fluid level and condition.

3. Adjust gearshift cable if complaint was based on delayed, erratic, or harsh shifts.

4. Road test and note how transmission upshifts, downshifts, and engages.

5. Perform hydraulic pressure test if shift problems were noted during roadtest.

6. Perform air-pressure test to check clutch operation.

VEHICLE IS DISABLED

1. Check fluid level and condition.

2. Check for broken or disconnected gearshift cable.

3. Check for cracked, leaking cooler lines, or loose or missing pressure-port plugs.

4. Raise and support vehicle on safety stands, start engine, shift transmission into gear, and note following:

a. If propeller shaft turns but wheels do not, problem is with differentialor axle shafts.

b. If propeller shaft does not turn and transmission is noisy, stop engine.Remove oil pan, and check for debris.

If pan is clear, remove transmission and check for damaged driveplate, converter, oil pump, or input shaft.

c. If propeller shaft does not turn and transmission is not noisy, perform hydraulic-pressure test to determine if

problem is hydraulic or mechanical.

ROAD TESTING

Before road testing, be sure the fluid level and control cable adjustmentshave been checked and adjusted if nec-

essary. Verify that all diagnostic trouble codes have been resolved.

Observe engine performance during the road test. A poorly tuned engine will not allow accurate analysis of trans-

mission operation.

Operate the transmission in all gear ranges. Check for shift variations and engine flare which indicates slippage.

Note if shifts are harsh, spongy, delayed, early, or if part throttle downshifts are sensitive.

Slippage indicated by engine flare, usually means clutch, overrunning clutch, or line pressure problems.

A slipping clutch can often be determined by comparing which internal units are applied in the various gear ranges.

The Clutch Application charts provide a basis for analyzing road test results.

45RFE CLUTCH APPLICATION CHART

Page 3798 of 5267

pressure to the overdrive clutch during 3-4 upshifts, and when accelerating in fourth gear. The 3-4 accumulator

cushions overdrive clutch engagement to smooth 3-4 upshifts. The accumulator is charged at the same time as

apply pressure acts against the overdrive piston.

DIAGNOSIS AND TESTING

AUTOMATIC TRANSMISSION

Automatic transmission problems can be a result of poor engine performance, incorrect fluid level, incorrect linkage

or cable adjustment, band or hydraulic control pressure adjustments, hydraulic system malfunctions or electrical/

mechanical component malfunctions. Begin diagnosis by checking the easily accessible items such as: fluid level

and condition, linkage adjustments and electrical connections. A road test will determine if further diagnosis is nec-

essary.

PRELIMINARY

Two basic procedures are required. One procedure for vehicles that are drivable and an alternate procedure for

disabled vehicles (will not back up or move forward).

VEHICLE IS DRIVEABLE

1. Check for transmission fault codes using DRBscan tool.

2. Check fluid level and condition.

3. Adjust throttle and gearshift linkage if complaint was based on delayed, erratic, or harsh shifts.

4. Road test and note how transmission upshifts, downshifts, and engages.

5. Perform hydraulic pressure test if shift problems were noted during roadtest.

6. Perform air-pressure test to check clutch-band operation.

VEHICLE IS DISABLED

1. Check fluid level and condition.

2. Check for broken or disconnected gearshift or throttle linkage.

3. Check for cracked, leaking cooler lines, or loose or missing pressure-port plugs.

4. Raise and support vehicle on safety stands, start engine, shift transmission into gear, and note following:

a. If propeller shaft turns but wheels do not, problem is with differentialor axle shafts.

b. If propeller shaft does not turn and transmission is noisy, stop engine.Remove oil pan, and check for debris.

If pan is clear, remove transmission and check for damaged drive plate, converter, oil pump, or input shaft.

c. If propeller shaft does not turn and transmission is not noisy, perform hydraulic-pressure test to determine if

problem is hydraulic or mechanical.

ROAD TESTING

Before road testing, be sure the fluid level and control cable adjustmentshave been checked and adjusted if nec-

essary. Verify that diagnostic trouble codes have been resolved.

Observe engine performance during the road test. A poorly tuned engine will not allow accurate analysis of trans-

mission operation.

Operate the transmission in all gear ranges. Check for shift variations and engine flare which indicates slippage.

Note if shifts are harsh, spongy, delayed, early, or if part throttle downshifts are sensitive.

Slippage indicated by engine flare, usually means clutch, band or overrunning clutch problems. If the condition is

advanced, an overhaul will be necessary to restore normal operation.

A slipping clutch or band can often be determined by comparing which internal units are applied in the various gear

ranges. The Clutch and Band Application chart provides a basis for analyzing road test results.

Clutch and Band Application Chart

Page 3815 of 5267

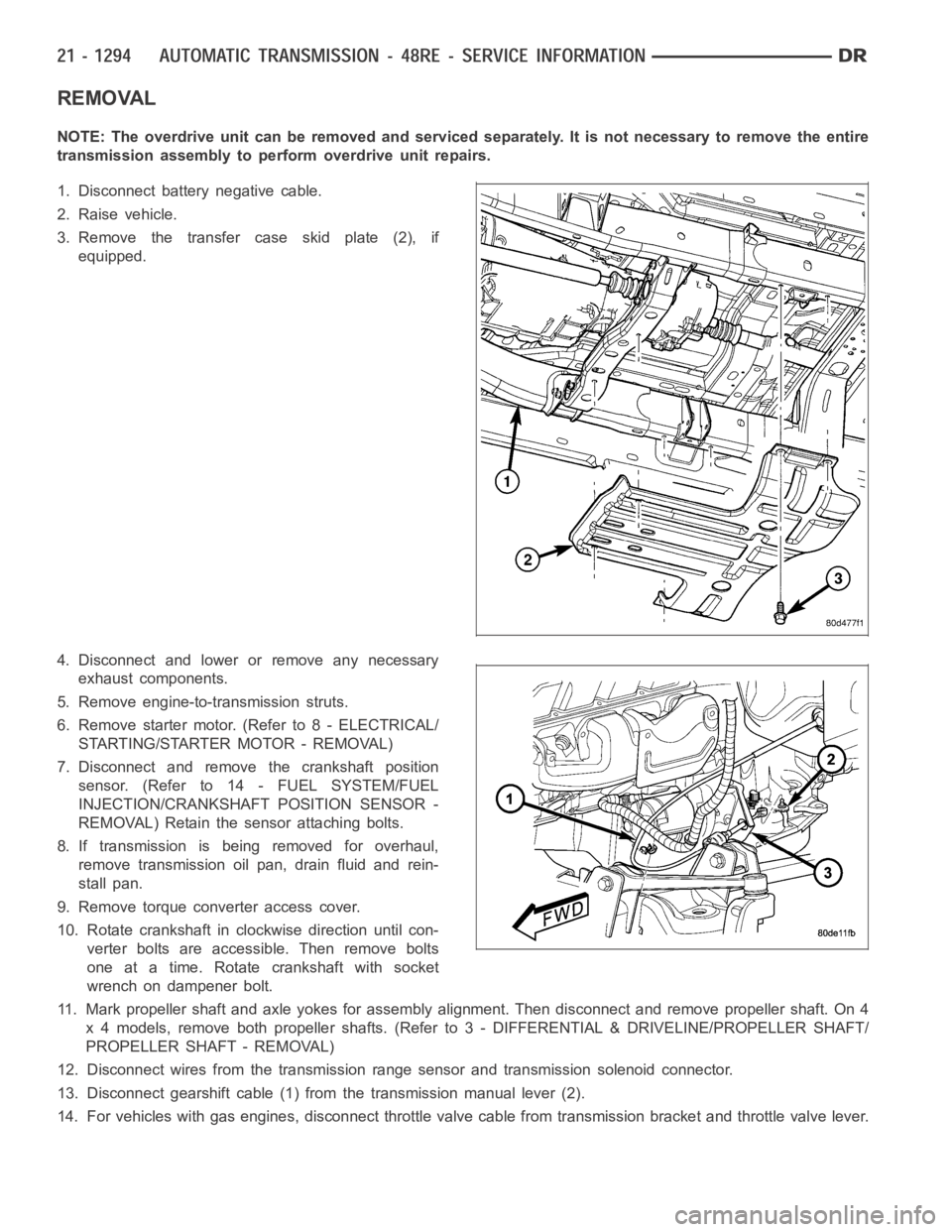

REMOVAL

NOTE: The overdrive unit can be removed and serviced separately. It is not necessary to remove the entire

transmission assembly to perform overdrive unit repairs.

1. Disconnect battery negative cable.

2. Raise vehicle.

3. Remove the transfer case skid plate (2), if

equipped.

4. Disconnect and lower or remove any necessary

exhaust components.

5. Remove engine-to-transmission struts.

6. Remove starter motor. (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - REMOVAL)

7. Disconnect and remove the crankshaft position

sensor. (Refer to 14 - FUEL SYSTEM/FUEL

INJECTION/CRANKSHAFT POSITION SENSOR -

REMOVAL) Retain the sensor attaching bolts.

8. If transmission is being removed for overhaul,

remove transmission oil pan, drain fluid and rein-

stall pan.

9. Remove torque converter access cover.

10. Rotate crankshaft in clockwise direction until con-

verter bolts are accessible. Then remove bolts

one at a time. Rotate crankshaft with socket

wrench on dampener bolt.

11. Mark propeller shaft and axle yokes for assembly alignment. Then disconnect and remove propeller shaft. On 4

x 4 models, remove both propeller shafts. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

12. Disconnect wires from the transmission range sensor and transmissionsolenoid connector.

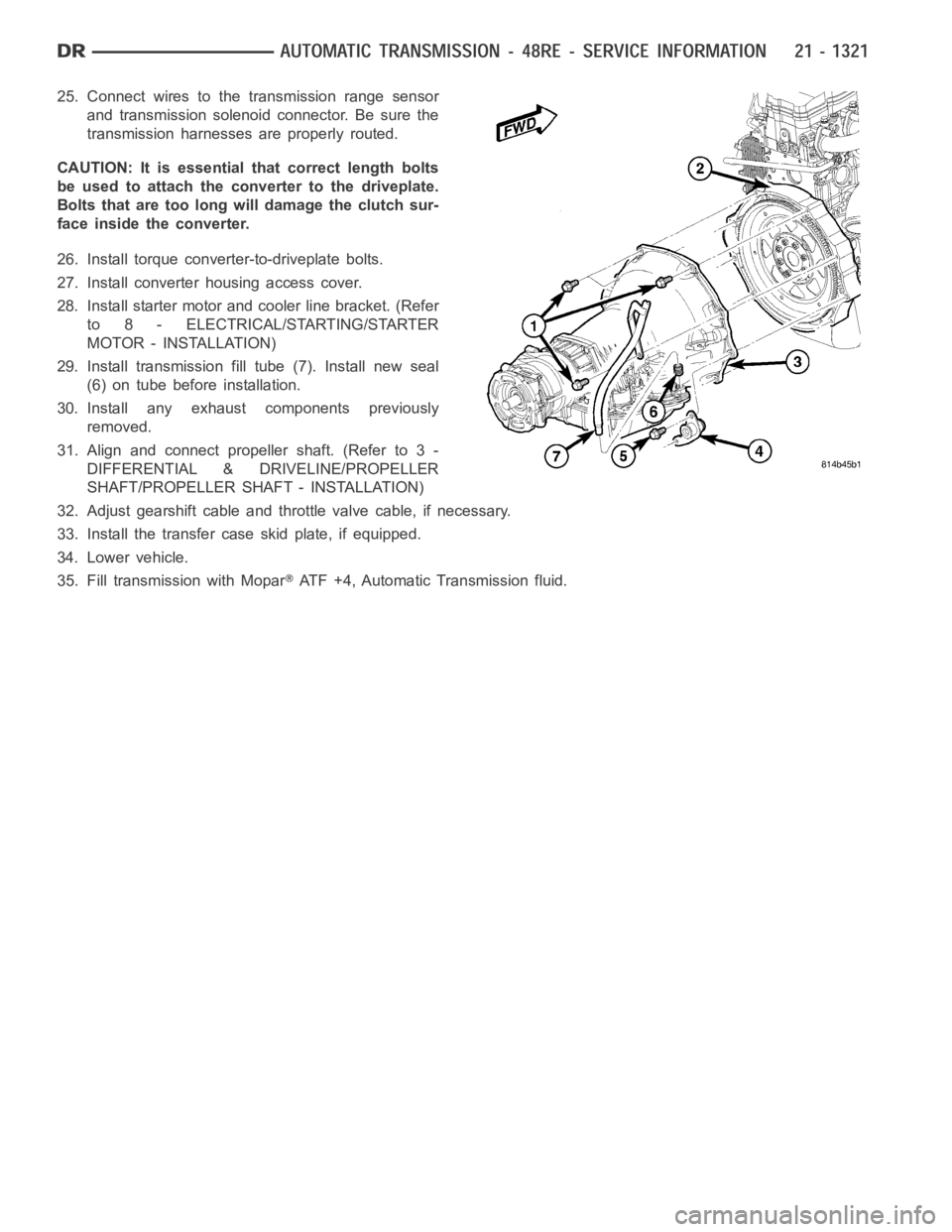

13. Disconnect gearshift cable (1) from the transmission manual lever (2).

14. For vehicles with gas engines, disconnect throttle valve cable from transmission bracket andthrottle valve lever.

Page 3842 of 5267

25. Connect wires to the transmission range sensor

and transmission solenoid connector. Be sure the

transmission harnesses are properly routed.

CAUTION: It is essential that correct length bolts

be used to attach the converter to the driveplate.

Bolts that are too long will damage the clutch sur-

face inside the converter.

26. Install torque converter-to-driveplate bolts.

27. Install converter housing access cover.

28. Install starter motor and cooler line bracket. (Refer

to 8 - ELECTRICAL/STARTING/STARTER

MOTOR - INSTALLATION)

29. Install transmission fill tube (7). Install new seal

(6) on tube before installation.

30. Install any exhaust components previously

removed.

31. Align and connect propeller shaft. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

32. Adjust gearshift cable and throttle valve cable, if necessary.

33. Install the transfer case skid plate, if equipped.

34. Lower vehicle.

35. Fill transmission with Mopar

ATF +4, Automatic Transmission fluid.

Page 3899 of 5267

UNIT-OVERDRIVE

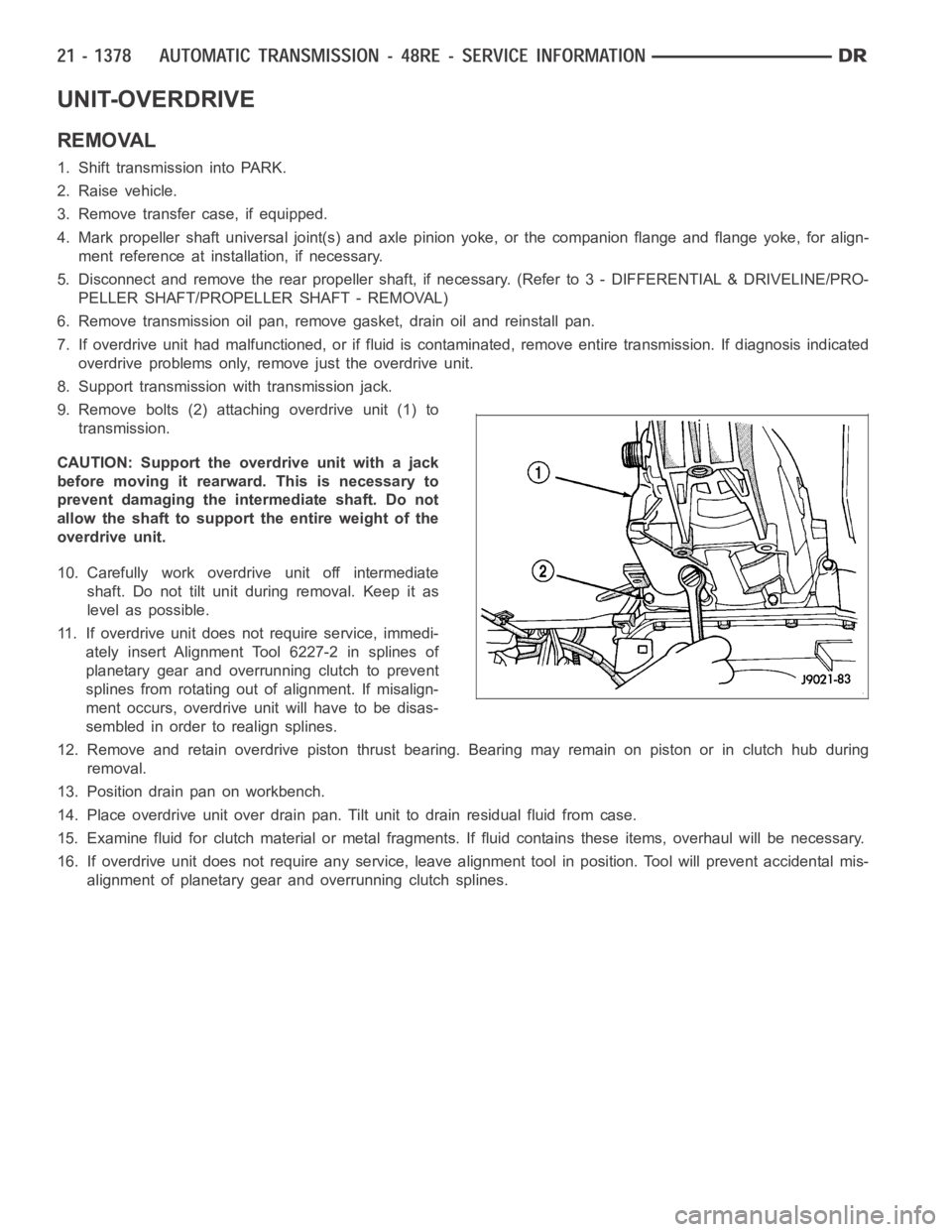

REMOVAL

1. Shift transmission into PARK.

2. Raise vehicle.

3. Remove transfer case, if equipped.

4. Mark propeller shaft universal joint(s) and axle pinion yoke, or the companion flange and flange yoke, for align-

ment reference at installation, if necessary.

5. Disconnect and remove the rear propeller shaft, if necessary. (Refer to3 - DIFFERENTIAL & DRIVELINE/PRO-

PELLER SHAFT/PROPELLER SHAFT - REMOVAL)

6. Remove transmission oil pan, remove gasket, drain oil and reinstall pan.

7. If overdrive unit had malfunctioned, or if fluid is contaminated, remove entire transmission. If diagnosis indicated

overdrive problems only, remove just the overdrive unit.

8. Support transmission with transmission jack.

9. Remove bolts (2) attaching overdrive unit (1) to

transmission.

CAUTION: Support the overdrive unit with a jack

before moving it rearward. This is necessary to

prevent damaging the intermediate shaft. Do not

allow the shaft to support the entire weight of the

overdrive unit.

10. Carefully work overdrive unit off intermediate

shaft. Do not tilt unit during removal. Keep it as

level as possible.

11. If overdrive unit does not require service, immedi-

ately insert Alignment Tool 6227-2 in splines of

planetary gear and overrunning clutch to prevent

splines from rotating out of alignment. If misalign-

ment occurs, overdrive unit will have to be disas-

sembled in order to realign splines.

12. Remove and retain overdrive piston thrust bearing. Bearing may remainon piston or in clutch hub during

removal.

13. Position drain pan on workbench.

14. Place overdrive unit over drain pan. Tilt unit to drain residual fluid from case.

15. Examine fluid for clutch material or metal fragments. If fluid contains these items, overhaul will be necessary.

16. If overdrive unit does not require any service, leave alignment tool inposition. Tool will prevent accidental mis-

alignment of planetary gear and overrunning clutch splines.

Page 3922 of 5267

15. Align and install rear propeller shaft, if necessary. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

Page 3991 of 5267

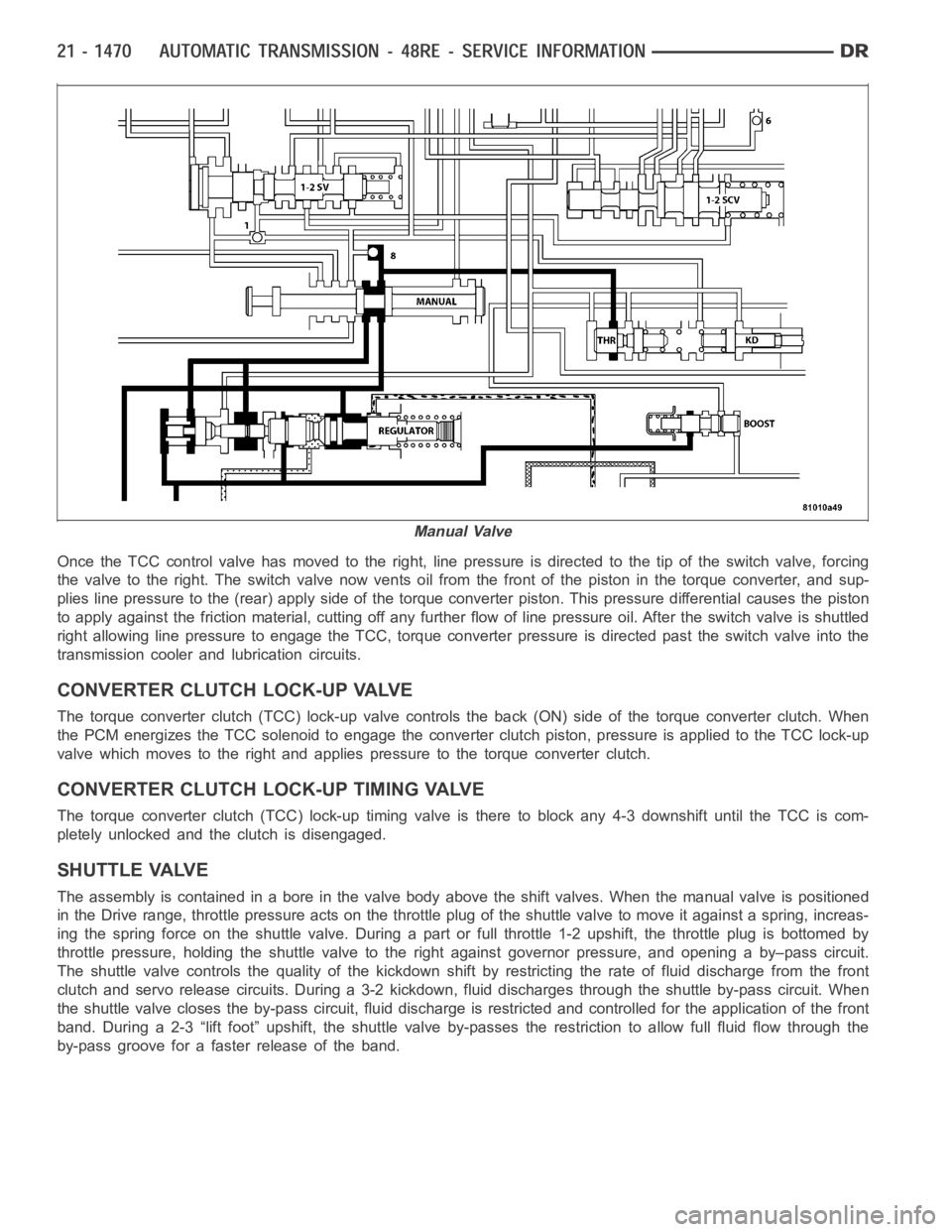

Once the TCC control valve has moved to the right, line pressure is directedto the tip of the switch valve, forcing

the valve to the right. The switch valve now vents oil from the front of the piston in the torque converter, and sup-

plies line pressure to the (rear) apply side of the torque converter piston. This pressure differential causes the piston

to apply against the friction material, cutting off any further flow of line pressure oil. After the switch valve is shuttled

right allowing line pressure to engage the TCC, torque converter pressureis directed past the switch valve into the

transmission cooler and lubrication circuits.

CONVERTER CLUTCH LOCK-UP VALVE

The torque converter clutch (TCC) lock-up valve controls the back (ON) side of the torque converter clutch. When

the PCM energizes the TCC solenoid to engage the converter clutch piston, pressure is applied to the TCC lock-up

valve which moves to the right and applies pressure to the torque converterclutch.

CONVERTER CLUTCH LOCK-UP TIMING VALVE

The torque converter clutch (TCC) lock-up timing valve is there to block any 4-3 downshift until the TCC is com-

pletely unlocked and the clutch is disengaged.

SHUTTLE VALVE

The assembly is contained in a bore in the valve body above the shift valves.When the manual valve is positioned

in the Drive range, throttle pressure acts on the throttle plug of the shuttle valve to move it against a spring, increas-

ing the spring force on the shuttle valve. During a part or full throttle 1-2upshift, the throttle plug is bottomed by

throttle pressure, holding the shuttle valve to the right against governor pressure, and opening a by–pass circuit.

The shuttle valve controls the quality of the kickdown shift by restricting the rate of fluid discharge from the front

clutch and servo release circuits. During a 3-2 kickdown, fluid discharges through the shuttle by-pass circuit. When

the shuttle valve closes the by-pass circuit, fluid discharge is restricted and controlled for the application of the front

band. During a 2-3 “lift foot” upshift, the shuttle valve by-passes the restriction to allow full fluid flow through the

by-pass groove for a faster release of the band.

Manual Valve

Page 4087 of 5267

Condition Possible Cause Correction

Lubricant leaking from output shaft

seal or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Vent closed or restricted. 2) Clear or replace vent as

necessary.

3) Output shaft seals damaged or

installed incorrectly.3) Replace seal as necessary.

Check to ensure that another

component, the propeller shaft slip

yoke for example, is not causing

damage to seal.

Abnormal tire wear. 1) Extended operation on hard, dry

surfaces in the 4H position.1) Operate vehicle in the 2H

position on hard, dry surfaces.

REMOVAL

1. Raise and support vehicle.

2. Remove skid plate, if equipped. (Refer to 13 - FRAMES & BUMPERS/FRAME/TRANSFER CASE SKID PLATE

- REMOVAL)

3. Position drain oil container under transfer case.

4. Remove transfer case drain plug and drain lubricant into container.

5. Disconnect vent hose and transfer case position sensor connector.

6. Disconnect shift rod from grommet in transfer case shift lever, or from floor shift arm whichever provides easy

access. Use channel lock style pliers to press rod out of lever grommet.

7. Support transmission with jack stand.

8. Mark front and rear propeller shafts for assembly reference.

9. Remove front and rear propeller shafts. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - REMOVAL)

10. Support transfer case with suitable jack. Secure transfer case to jackwith safety chains.

11. Remove nuts attaching transfer case to transmission.

12. Move transfer case assembly rearward until free of transmission outputshaft.

13. Lower jack and move transfer case from under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan. Remove drain plug and drain any remaining lubricant remaining in

case.

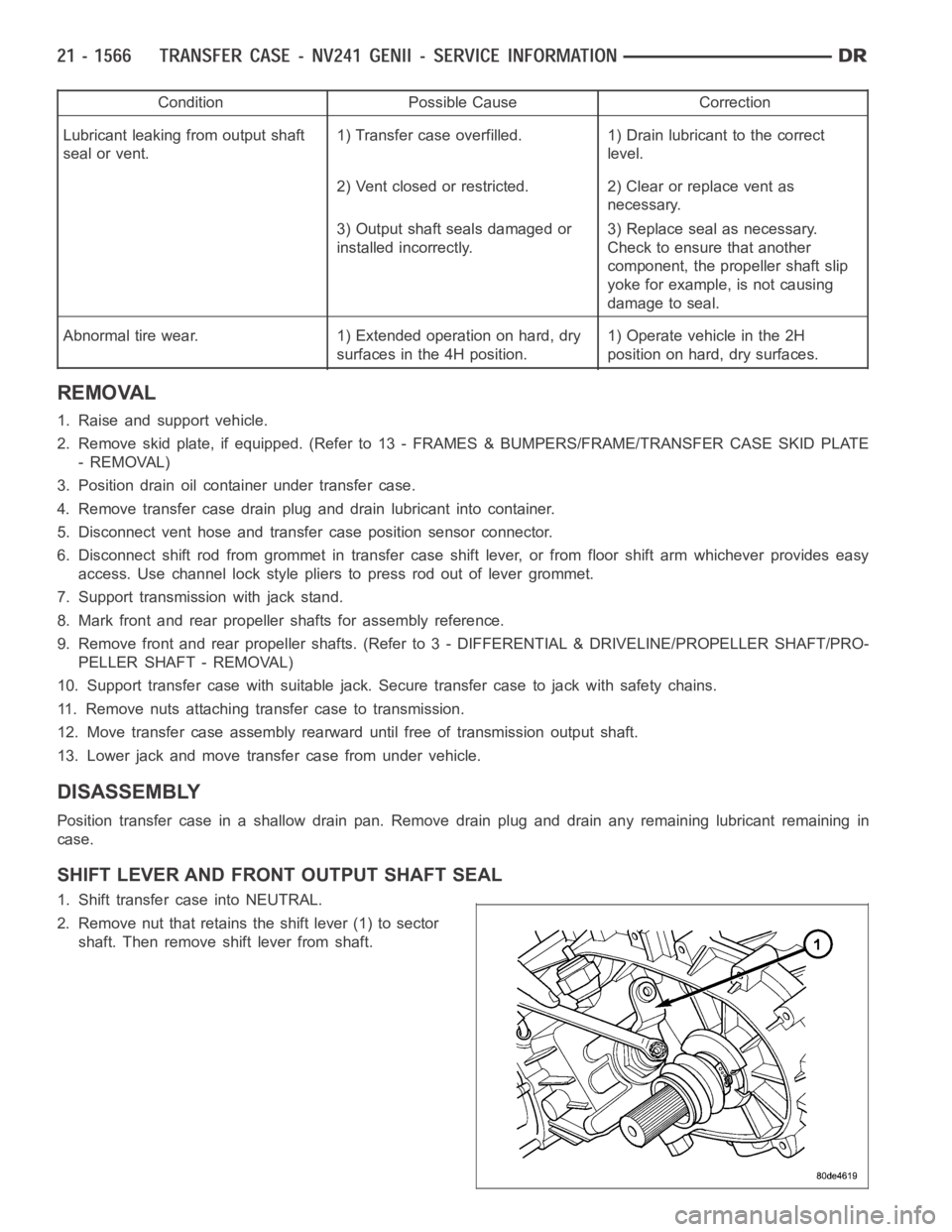

SHIFT LEVER AND FRONT OUTPUT SHAFT SEAL

1. Shift transfer case into NEUTRAL.

2. Remove nut that retains the shift lever (1) to sector

shaft. Then remove shift lever from shaft.