steering DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2512 of 5267

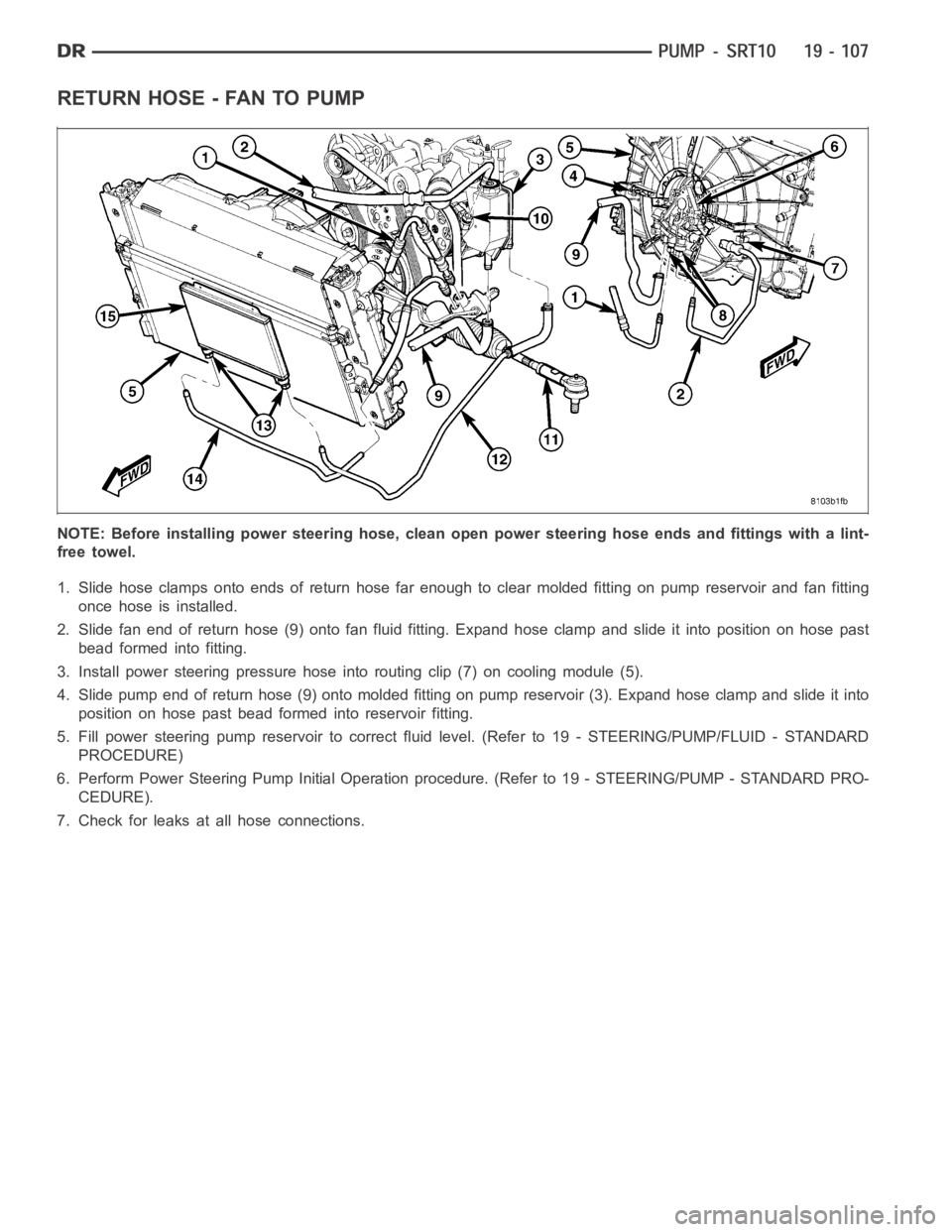

RETURN HOSE - FAN TO PUMP

NOTE: Before installing power steering hose, clean open power steering hose ends and fittings with a lint-

free towel.

1. Slide hose clamps onto ends of return hose far enough to clear molded fitting on pump reservoir and fan fitting

once hose is installed.

2. Slidefanendofreturnhose(9)ontofanfluidfitting.Expandhoseclampandslideitintopositiononhosepast

bead formed into fitting.

3. Install power steering pressure hose into routing clip (7) on cooling module (5).

4. Slide pump end of return hose (9) onto molded fitting on pump reservoir (3). Expand hose clamp and slide it into

position on hose past bead formed into reservoir fitting.

5. Fill power steering pump reservoir to correct fluid level. (Refer to 19 -STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

6. Perform Power Steering Pump Initial Operation procedure. (Refer to 19 -STEERING/PUMP - STANDARD PRO-

CEDURE).

7. Check for leaks at all hose connections.

Page 2513 of 5267

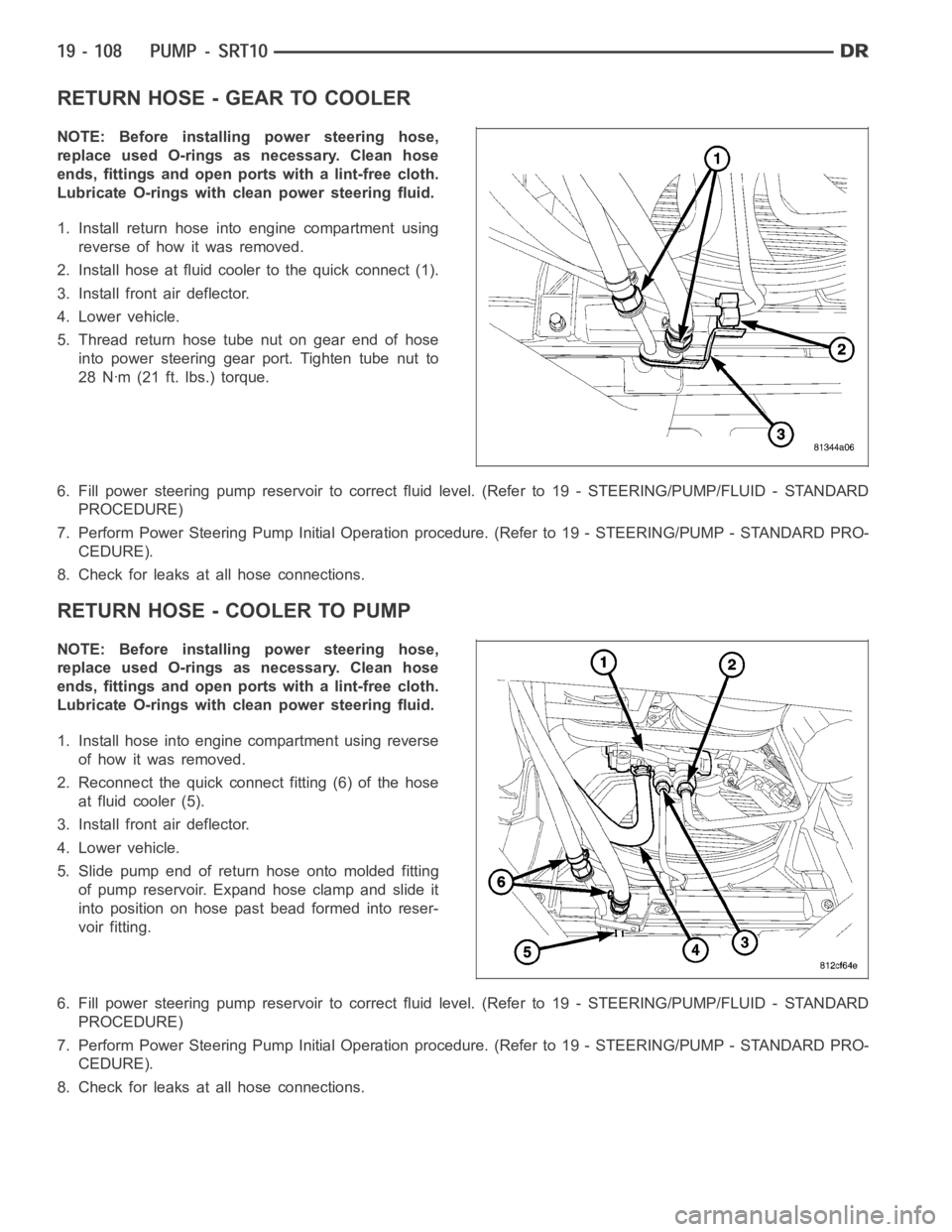

RETURN HOSE - GEAR TO COOLER

NOTE: Before installing power steering hose,

replace used O-rings as necessary. Clean hose

ends, fittings and open ports with a lint-free cloth.

Lubricate O-rings with clean power steering fluid.

1. Install return hose into engine compartment using

reverse of how it was removed.

2. Install hose at fluid cooler to the quick connect (1).

3. Install front air deflector.

4. Lower vehicle.

5. Thread return hose tube nut on gear end of hose

into power steering gear port. Tighten tube nut to

28 Nꞏm (21 ft. lbs.) torque.

6. Fill power steering pump reservoir to correct fluid level. (Refer to 19 -STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

7. Perform Power Steering Pump Initial Operation procedure. (Refer to 19 -STEERING/PUMP - STANDARD PRO-

CEDURE).

8. Check for leaks at all hose connections.

RETURN HOSE - COOLER TO PUMP

NOTE: Before installing power steering hose,

replace used O-rings as necessary. Clean hose

ends, fittings and open ports with a lint-free cloth.

Lubricate O-rings with clean power steering fluid.

1. Install hose into engine compartment using reverse

of how it was removed.

2. Reconnect the quick connect fitting (6) of the hose

at fluid cooler (5).

3. Install front air deflector.

4. Lower vehicle.

5. Slide pump end of return hose onto molded fitting

of pump reservoir. Expand hose clamp and slide it

into position on hose past bead formed into reser-

voir fitting.

6. Fill power steering pump reservoir to correct fluid level. (Refer to 19 -STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

7. Perform Power Steering Pump Initial Operation procedure. (Refer to 19 -STEERING/PUMP - STANDARD PRO-

CEDURE).

8. Check for leaks at all hose connections.

Page 2514 of 5267

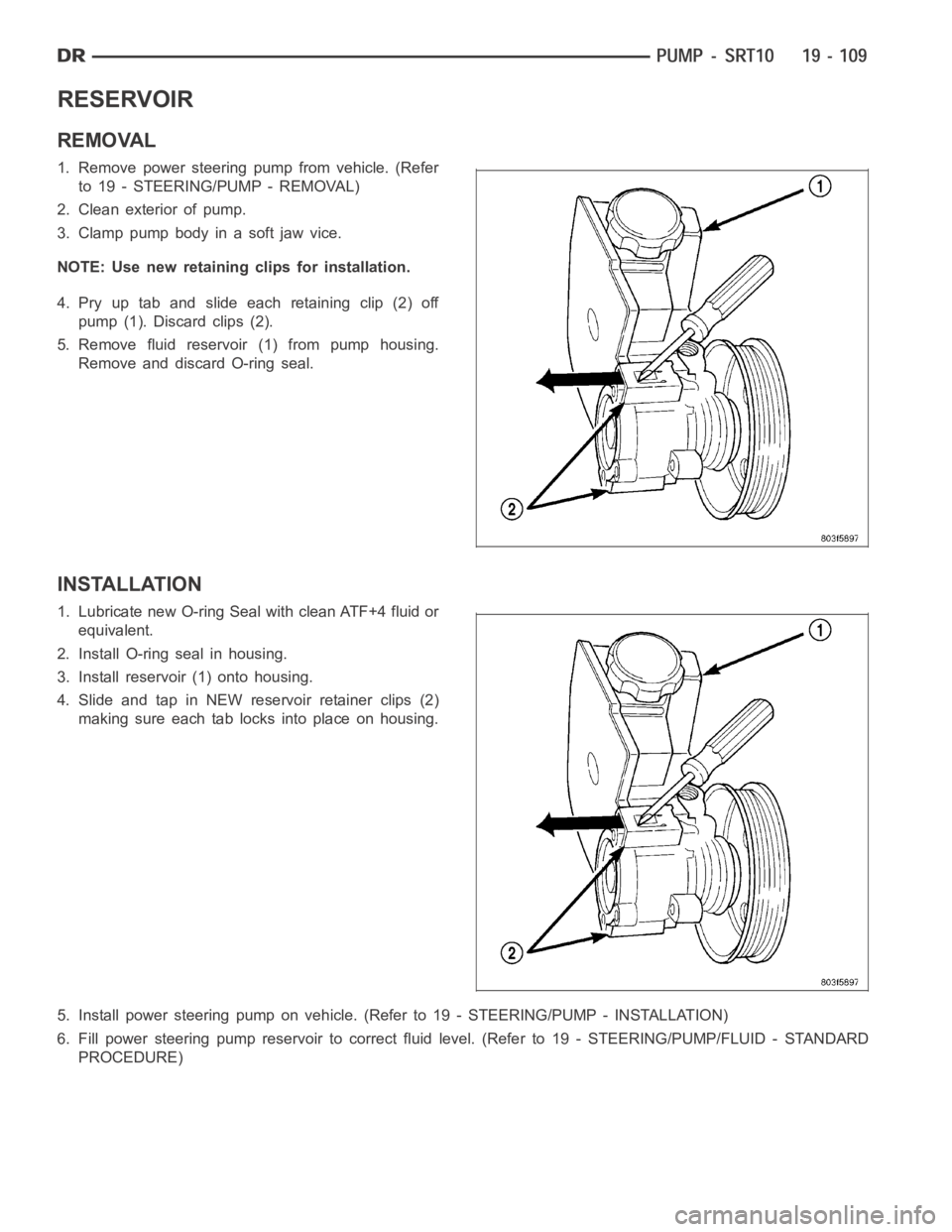

RESERVOIR

REMOVAL

1. Remove power steering pump from vehicle. (Refer

to 19 - STEERING/PUMP - REMOVAL)

2. Clean exterior of pump.

3. Clamp pump body in a soft jaw vice.

NOTE: Use new retaining clips for installation.

4. Pry up tab and slide each retaining clip (2) off

pump (1). Discard clips (2).

5. Remove fluid reservoir (1) from pump housing.

Remove and discard O-ring seal.

INSTALLATION

1. Lubricate new O-ring Seal with clean ATF+4 fluid or

equivalent.

2. Install O-ring seal in housing.

3. Install reservoir (1) onto housing.

4. Slide and tap in NEW reservoir retainer clips (2)

making sure each tab locks into place on housing.

5. Install power steering pump on vehicle. (Refer to 19 - STEERING/PUMP - INSTALLATION)

6. Fill power steering pump reservoir to correct fluid level. (Refer to 19 -STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

Page 2515 of 5267

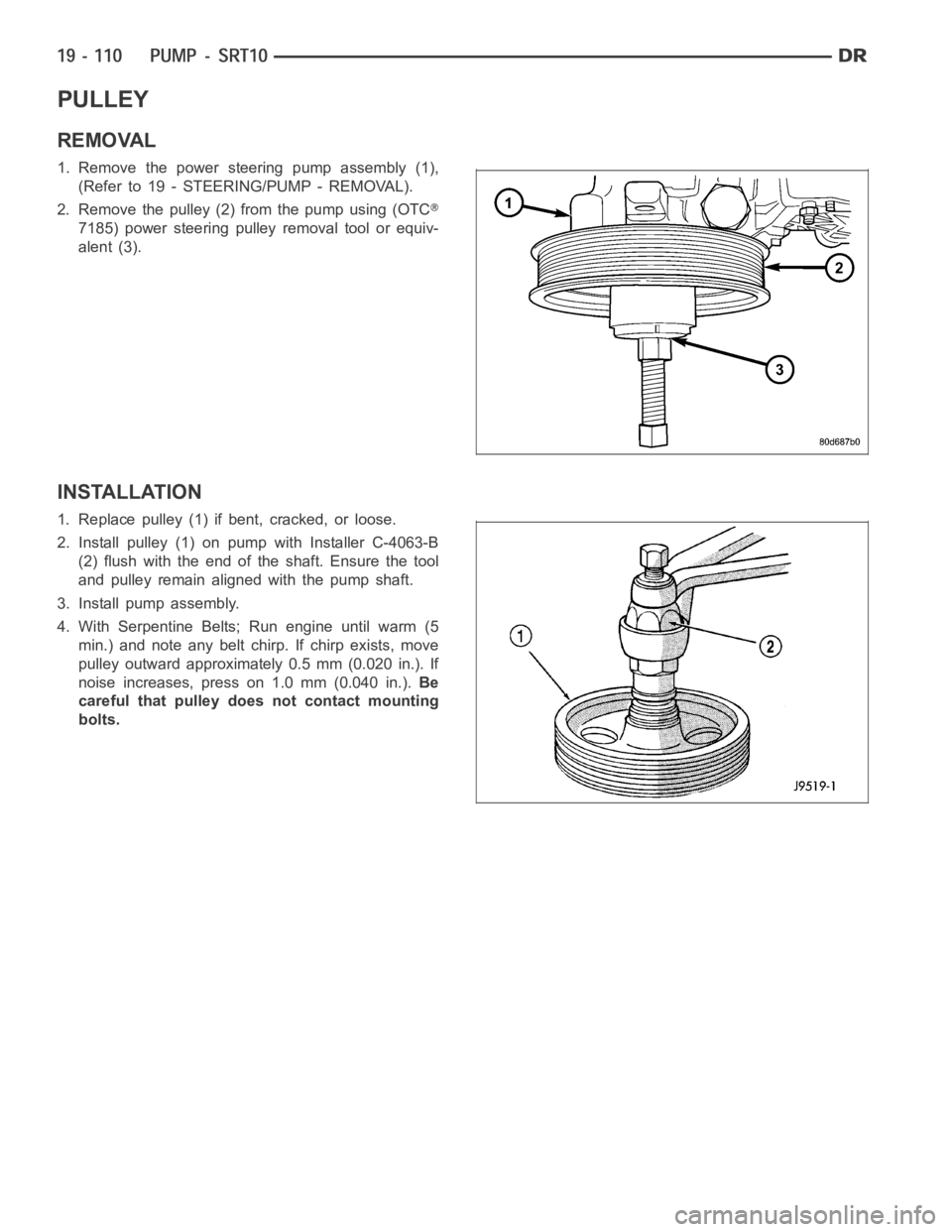

PULLEY

REMOVAL

1. Remove the power steering pump assembly (1),

(Refer to 19 - STEERING/PUMP - REMOVAL).

2. Remove the pulley (2) from the pump using (OTC

7185) power steering pulley removal tool or equiv-

alent (3).

INSTALLATION

1. Replace pulley (1) if bent, cracked, or loose.

2. Install pulley (1) on pump with Installer C-4063-B

(2) flush with the end of the shaft. Ensure the tool

and pulley remain aligned with the pump shaft.

3. Install pump assembly.

4. With Serpentine Belts; Run engine until warm (5

min.) and note any belt chirp. If chirp exists, move

pulley outward approximately 0.5 mm (0.020 in.). If

noise increases, press on 1.0 mm (0.040 in.).Be

careful that pulley does not contact mounting

bolts.

Page 2516 of 5267

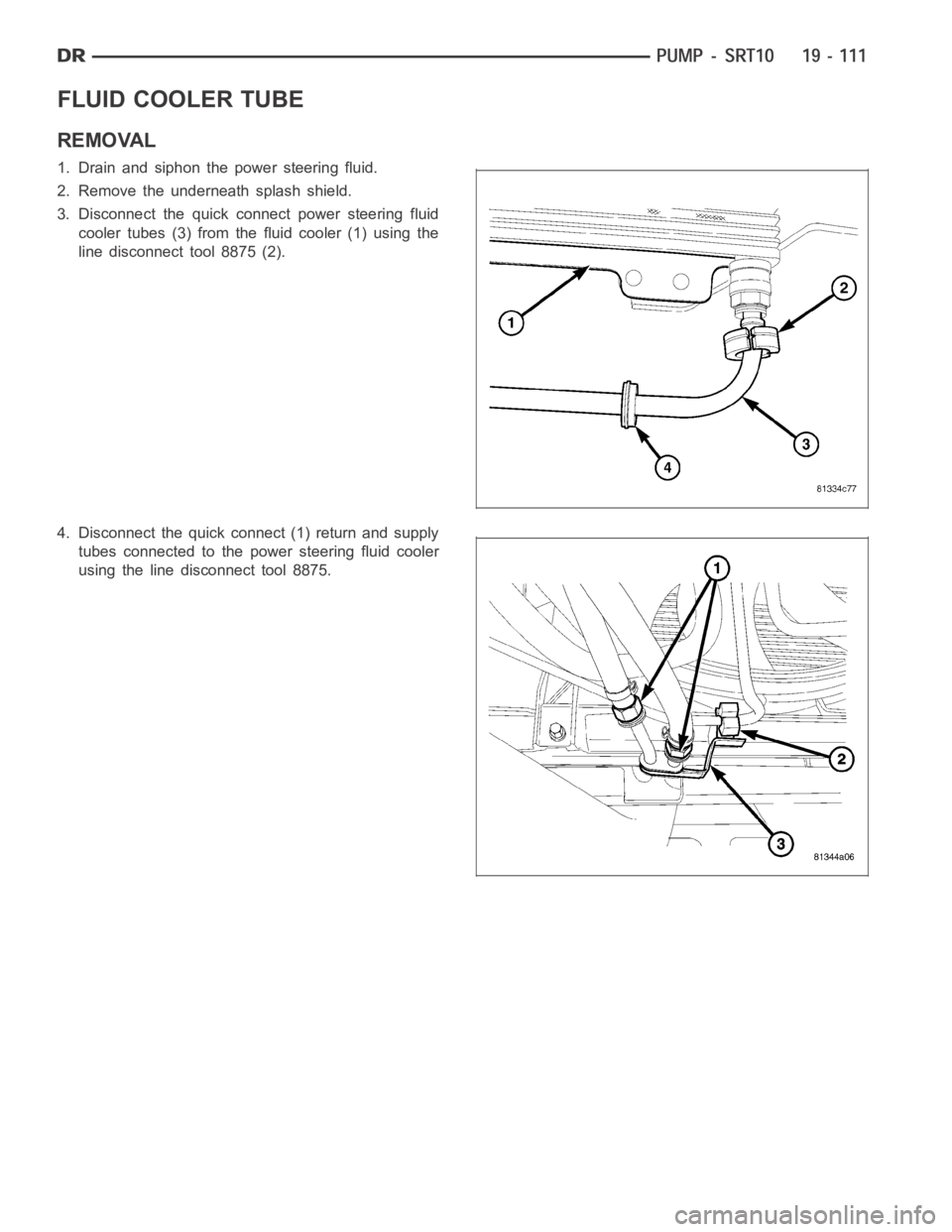

FLUID COOLER TUBE

REMOVAL

1. Drain and siphon the power steering fluid.

2. Remove the underneath splash shield.

3. Disconnect the quick connect power steering fluid

cooler tubes (3) from the fluid cooler (1) using the

line disconnect tool 8875 (2).

4. Disconnect the quick connect (1) return and supply

tubes connected to the power steering fluid cooler

using the line disconnect tool 8875.

Page 2517 of 5267

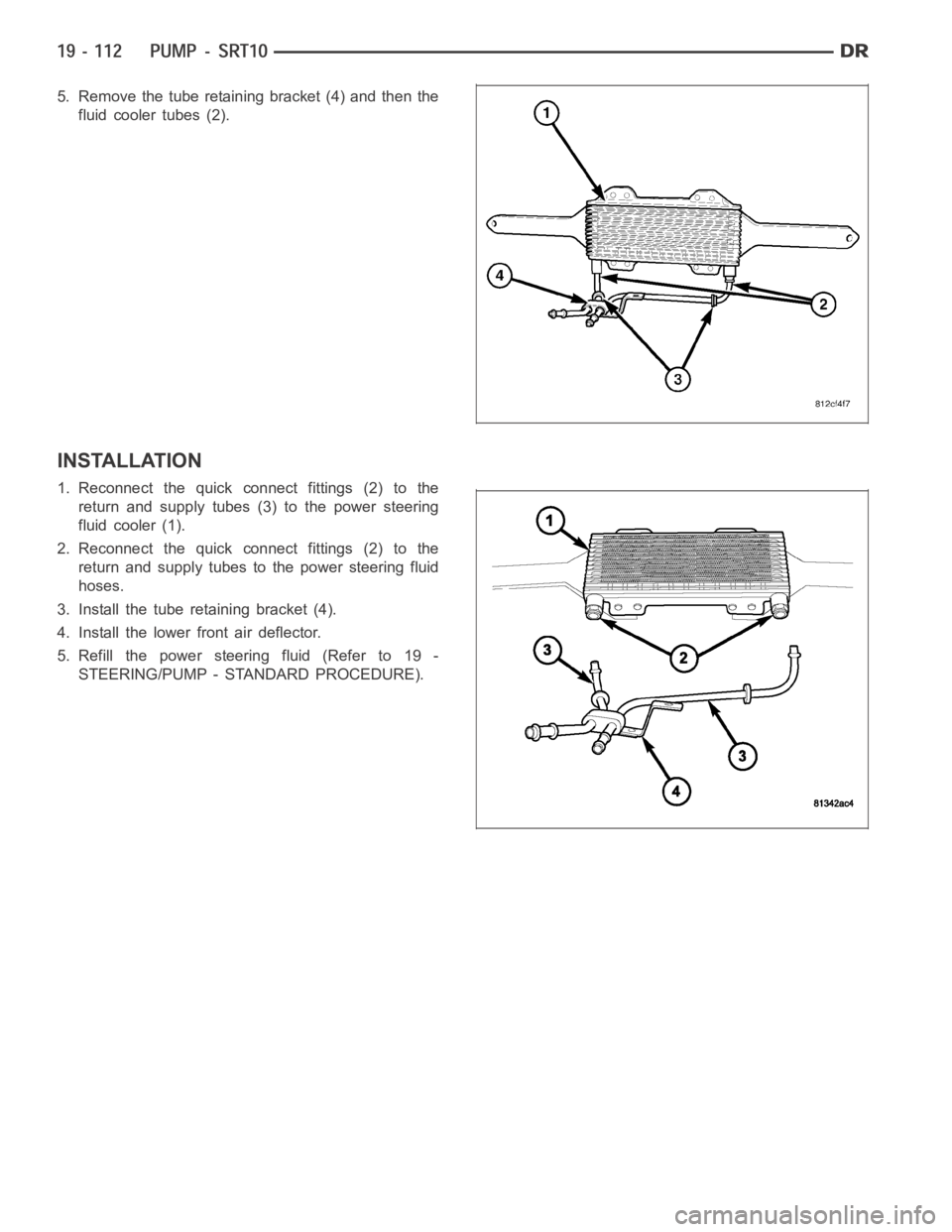

5. Remove the tube retaining bracket (4) and then the

fluid cooler tubes (2).

INSTALLATION

1. Reconnect the quick connect fittings (2) to the

return and supply tubes (3) to the power steering

fluid cooler (1).

2. Reconnect the quick connect fittings (2) to the

return and supply tubes to the power steering fluid

hoses.

3. Install the tube retaining bracket (4).

4. Install the lower front air deflector.

5. Refill the power steering fluid (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

Page 2518 of 5267

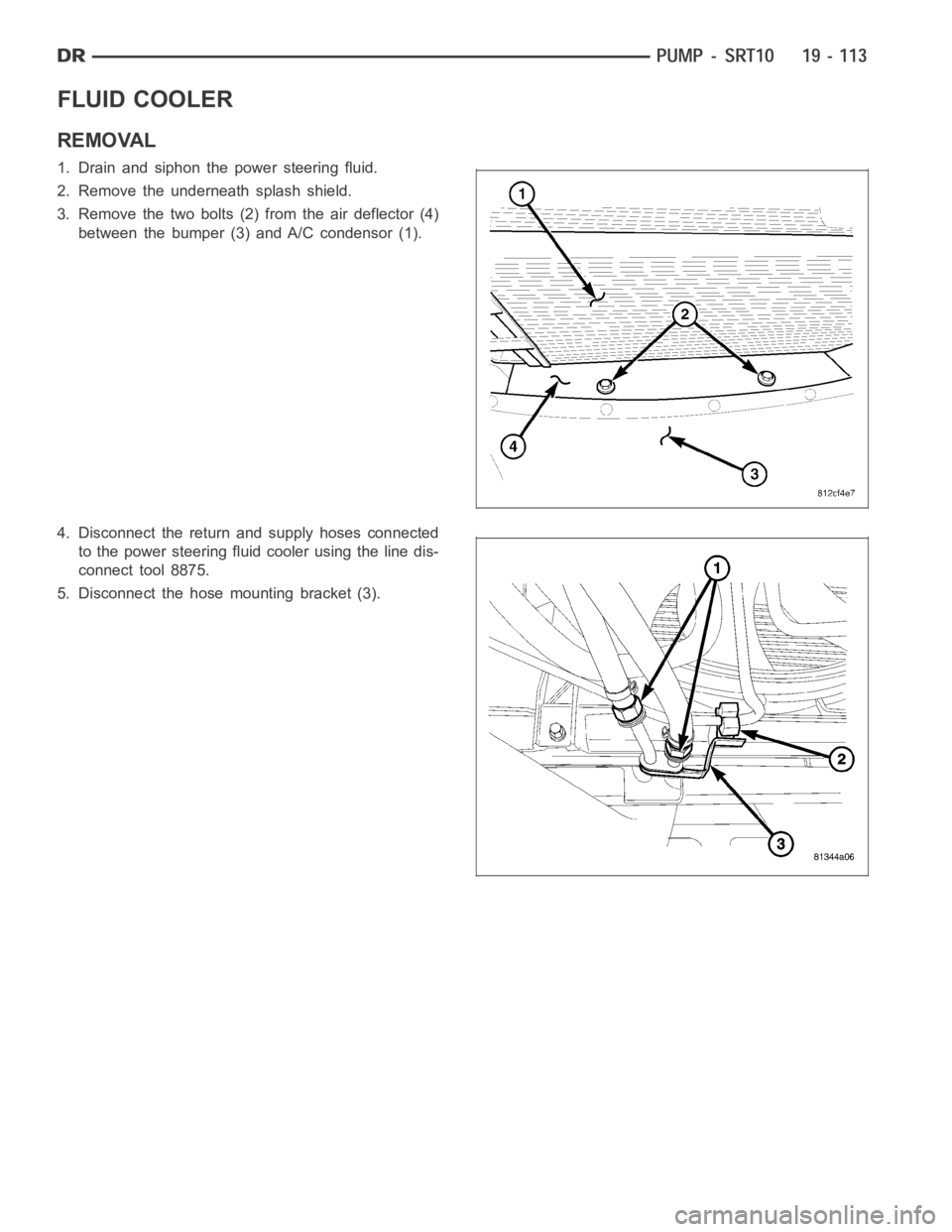

FLUID COOLER

REMOVAL

1. Drain and siphon the power steering fluid.

2. Remove the underneath splash shield.

3. Remove the two bolts (2) from the air deflector (4)

between the bumper (3) and A/C condensor (1).

4. Disconnect the return and supply hoses connected

to the power steering fluid cooler using the line dis-

connect tool 8875.

5. Disconnect the hose mounting bracket (3).

Page 2519 of 5267

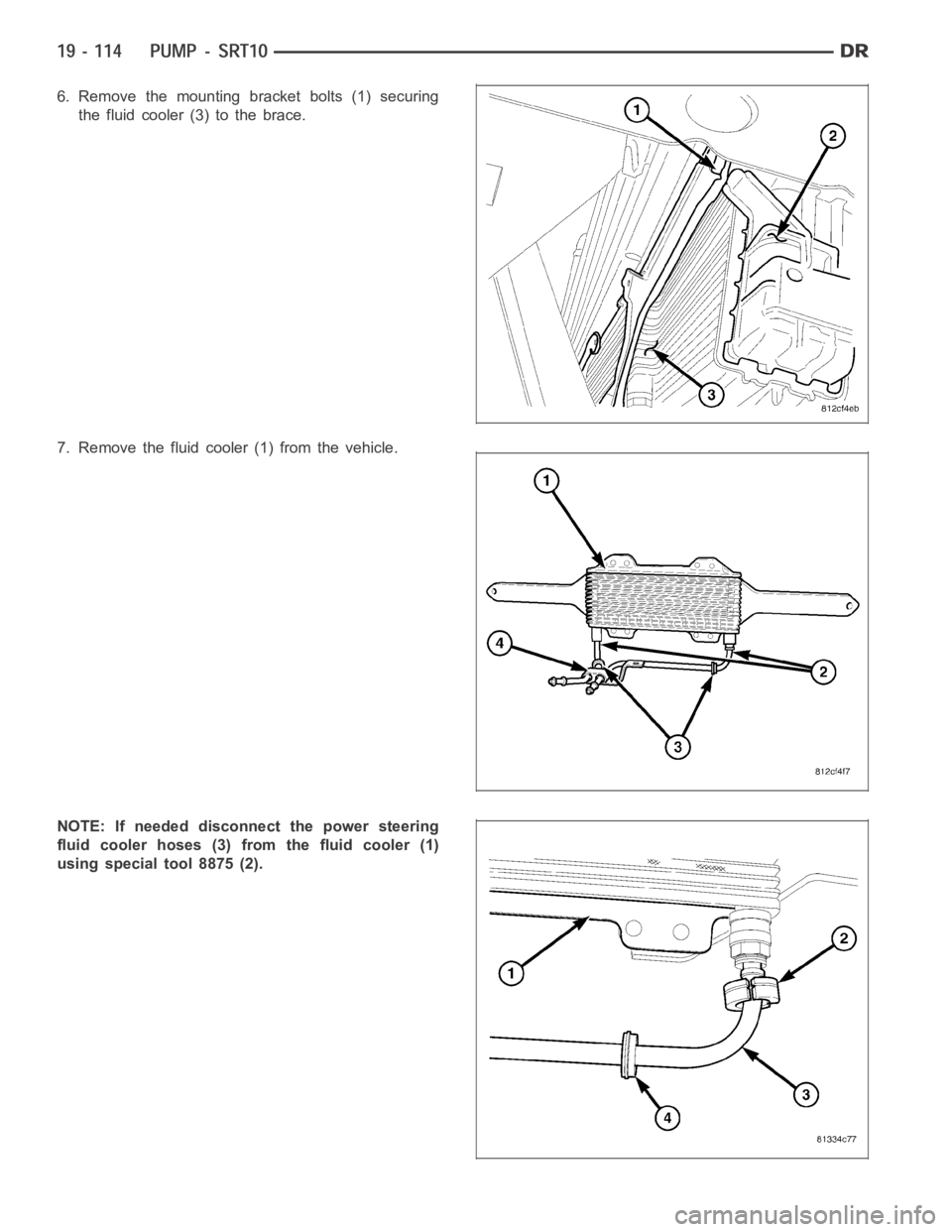

6. Remove the mounting bracket bolts (1) securing

the fluid cooler (3) to the brace.

7. Remove the fluid cooler (1) from the vehicle.

NOTE: If needed disconnect the power steering

fluid cooler hoses (3) from the fluid cooler (1)

using special tool 8875 (2).

Page 2521 of 5267

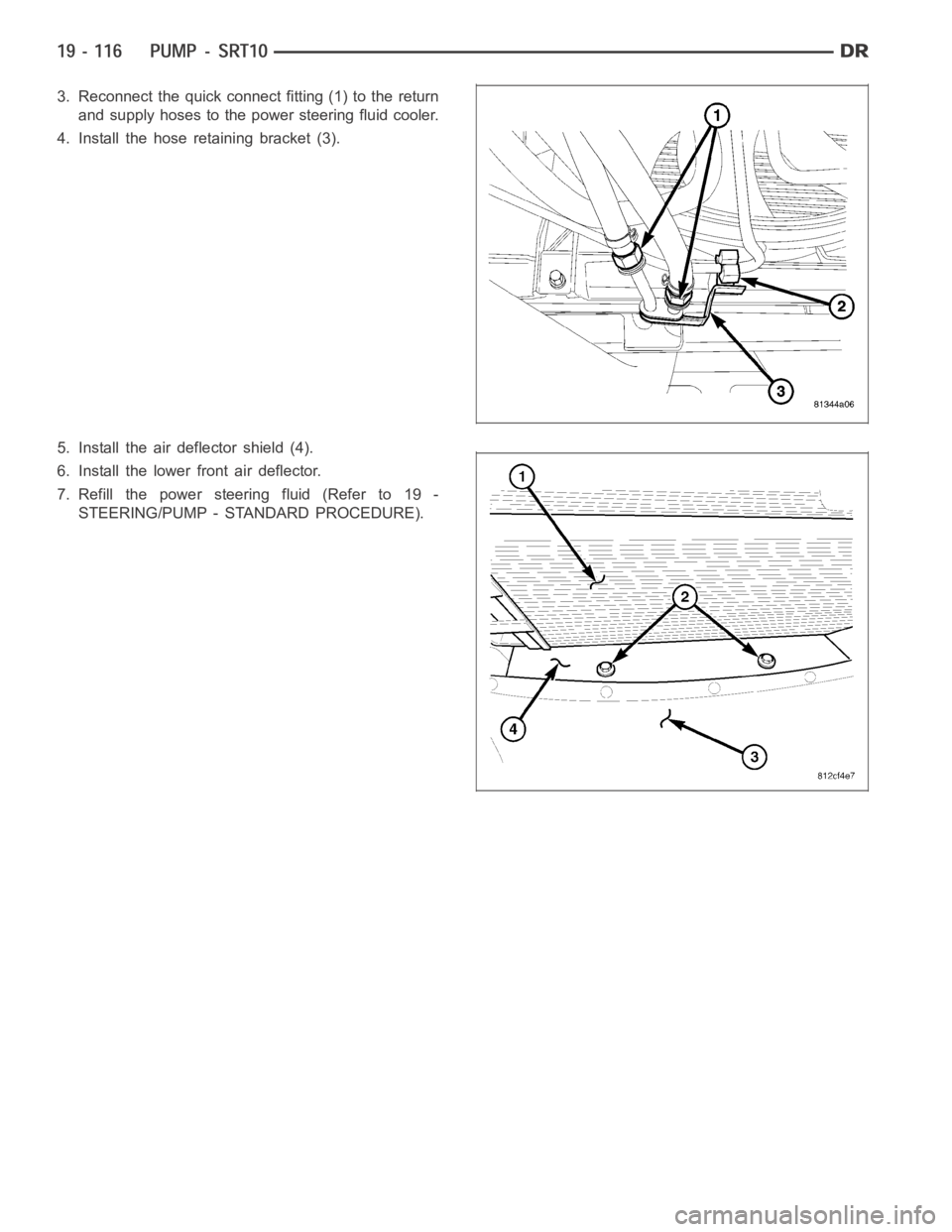

3. Reconnect the quick connect fitting (1) to the return

and supply hoses to the power steering fluid cooler.

4. Install the hose retaining bracket (3).

5. Install the air deflector shield (4).

6. Install the lower front air deflector.

7. Refill the power steering fluid (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

Page 3011 of 5267

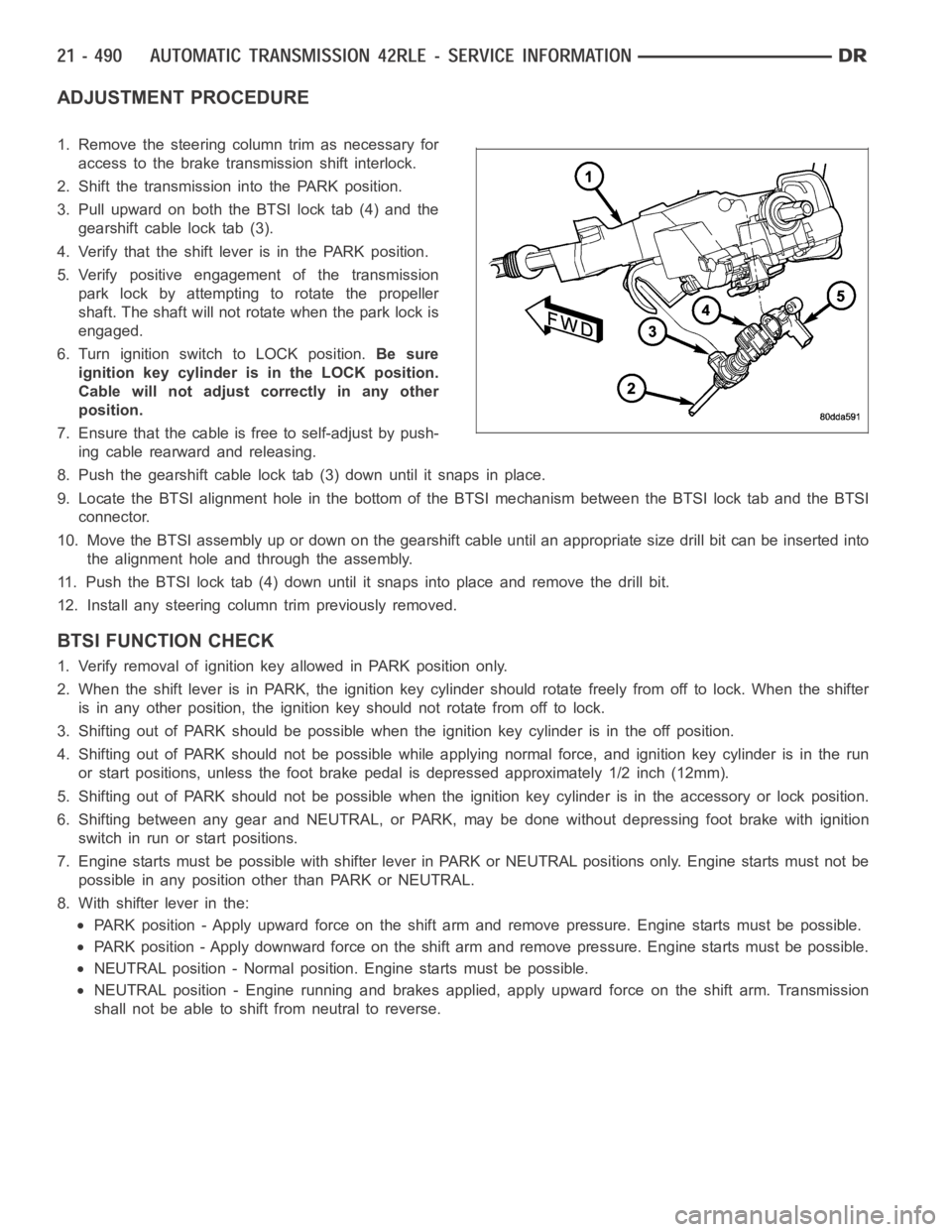

ADJUSTMENT PROCEDURE

1. Remove the steering column trim as necessary for

access to the brake transmission shift interlock.

2. Shift the transmission into the PARK position.

3. Pull upward on both the BTSI lock tab (4) and the

gearshift cable lock tab (3).

4. Verify that the shift lever is in the PARK position.

5. Verify positive engagement of the transmission

park lock by attempting to rotate the propeller

shaft. The shaft will not rotate when the park lock is

engaged.

6. Turn ignition switch to LOCK position.Be sure

ignition key cylinder is in the LOCK position.

Cable will not adjust correctly in any other

position.

7. Ensure that the cable is free to self-adjust by push-

ing cable rearward and releasing.

8. Push the gearshift cable lock tab (3) down until it snaps in place.

9. Locate the BTSI alignment hole in the bottom of the BTSI mechanism betweentheBTSIlocktabandtheBTSI

connector.

10. Move the BTSI assembly up or down on the gearshift cable until an appropriate size drill bit can be inserted into

the alignment hole and through the assembly.

11. Push the BTSI lock tab (4) down until it snaps into place and remove the drill bit.

12. Install any steering column trim previously removed.

BTSI FUNCTION CHECK

1. Verify removal of ignition key allowed in PARK position only.

2. When the shift lever is in PARK, the ignition key cylinder should rotate freely from off to lock. When the shifter

is in any other position, the ignition key should not rotate from off to lock.

3. Shifting out of PARK should be possible when the ignition key cylinder isin the off position.

4. Shifting out of PARK should not be possible while applying normal force,and ignition key cylinder is in the run

or start positions, unless the foot brake pedal is depressed approximately1/2inch(12mm).

5. Shifting out of PARK should not be possible when the ignition key cylinder is in the accessory or lock position.

6. Shifting between any gear and NEUTRAL, or PARK, may be done without depressing foot brake with ignition

switch in run or start positions.

7. Engine starts must be possible with shifter lever in PARK or NEUTRAL positions only. Engine starts must not be

possible in any position other than PARK or NEUTRAL.

8. With shifter lever in the:

PARK position - Apply upward force on the shift arm and remove pressure. Enginestartsmustbepossible.

PARK position - Apply downward force on the shift arm and remove pressure. Engine starts must be possible.

NEUTRAL position - Normal position. Engine starts must be possible.

NEUTRAL position - Engine running and brakes applied, apply upward force on the shift arm. Transmission

shall not be able to shift from neutral to reverse.