tow DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4609 of 5267

1 - MECHANISM COVERS (2) 10 - MOTOR FASTENERS (3)

2 - RIGHT HAND GLASS GUIDE 11 - SUNROOF MOTOR/MODULE ASSEMBLY

3 - GLASS FASTENERS (4) 12 - ALIGNMENT HOLE

4 - GLASS ASSEMBLY 13 - TRIM RING

5 - DRAIN CHANNEL 14 - ASSEMBLY FASTENERS (8)

6 - SUNSHADE 15 - ALIGNMENT HOLE

7 - LEFT SUNROOF GLASS GUIDE 16 - WIND DEFLECTOR

8 - WIRE HARNESS 17 - GLASS GUIDE FOOT

9 - SUNROOF ASSEMBLY 18 - WIND DEFLECTOR STRAP SCREWS (2)

The power sunroof system allows the sunroof to be opened, closed or placed in the vent position electrically by

actuating a switch in the overhead console. The sunroof system receives battery feed through a fuse in the Power

Distribution Center (PDC). The sunroof will operate normally with the keyin any position while the Accessory Delay

system is active.

The sunroof glass panel tilts upward at the rear for ventilation and slidesrearward under the roof when open. The

panel seals flush with the roof in the closed position to eliminate wind noise. The sunroof includes a manual-sliding

sunshade to cover the deep-tinted glass panel.

In addition to the standard power sunroof operation, this vehicle offers several additional features. There is an

express (one-touch) opening and closing feature as well as Excessive Force Limitation (EFL). The EFL function

detects obstacles trapped between the glass and the vehicle roof during a closing motion. Upon sensing an obstacle

the EFL function will reverse direction of the glass to allow removal of theobstacle.

The main components of thepower sunroof system are:

The motor/module assembly

The power sunroof glass and frame assembly

The power sunroof switch

The manual-sliding sunshade

OPERATION

This vehicle has a vent, tilt and slide power sunroof system with express (one-touch) open and closing feature. The

sunroof system receives constant battery feed through a fuse in the Power Distribution Center (PDC). The sunroof

will operate normally with the key in any position while the Accessory Delay system is active. If the sunroof is mov-

ing when the key is turned to the START position (crank engine), all motionsstop until the key is released, then the

previously requested sunroof motion will resume. The sunroof will also complete a requested motion if the Acces-

sory Delay system goes inactivewhile the motion is in progress.

A combination push-button and rocker switch module mounted in the overhead console controls sunroof operation.

The sunroof switch is a rocker design with a push button in the center of the two halves of the rocker. Pressing the

rocker towards the front of the car commands the sunroof closed. Pressing the rocker towards the rear of the car

commands the sunroof open. Pressing the center push button commands the sunroof up into the vent position

(Rear of sunroof glass raises above the vehicle roof with glass still covering the sunroof opening). All switch com-

mands operate with the glass startingin any position. (Refer to 8 - ELECTRICAL/POWER TOP/SWITCH - OPER-

ATION) for additional information.

An electronic control system, integralto the motor/module assembly, provides the express open and close functions.

Pressing the

openorcloseend of the rocker switch moves the sunroof glass panel to the full open or fullclosed

position, respectively. During express closing, anytime an obstacle is detected in the way of the glass, the motor will

stop and reverse travel to avoid pinching an occupant’s finger, ice in the track, etc. This function is called Excessive

Force Limitation (EFL). There are two methods of overriding the EFL function.

1. When three EFL events occur without the glass being allowed to fully close, the next close attempt will only

move while the close switch is continuously actuated. This allows the sunrooftobeforcedclosedifmultipleclose

attempts fail.

2. If the sunroof close switch is continuously actuated during an EFL event, through the reversal, and during a two

second wait time, then continuing to hold the close switch will cause the roof to move towards close with the EFL

protection disabled. This allows the sunroof to be forced closed if it is known that a reversal will occur.

While in EFL override, the closing motion will cease if the sunroof switch is released at any time.

Page 4610 of 5267

The motor/module is programmed to learn the speed required to drive the panel based on position and recalibrates

itself as needed. If the sunroof becomes uncalibrated, it will only respond to the vent switch. If the vent switch is

pressed, the glass will move toward vent; if the switch is released, all motion stops. In the event that the sunroof

system becomes uncalibrated performthe sunroof position calibration procedure, (Refer to 8 - ELECTRICAL/

POWER TOP/MOTOR - STANDARD PROCEDURE -SUNROOF POSITION CALIBRATION).

DIAGNOSIS AND TESTING

POWER TOP - SUNROOF

Any diagnosis of the power sunroof system should begin with the use of a scantool and the proper Diagnostic

Procedures Information. The scan tool can provide confirmation that the Controller Area Network (CAN) Data Bus is

functional, that all of the electronic modules are sending and receiving the proper messages on the CAN Data Bus,

and that the power sunroof motor is being sent the proper hard wired output by the sunroof switch.

For complete circuit diagrams, refer to the appropriate wiring information. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures, details of wire harness routing and retention, connector pin-out

information and location views for the various wire harness connectors, splices and grounds.

Refer to the appropriate diagnostic information.

SUNROOF

Refer to SUNROOF DIAGNOSIS CHART for possible causes. Before beginning sunroof diagnostics verify that all

other power accessories are in proper operating condition. If not, a common electrical problem may exist. Refer to

Wiring Diagrams, in this publication for circuit, splice and component descriptions. Check the condition of the circuit

protection (20 amp circuit breaker in the Junction Block). Inspect all wiring connector pins for proper engagement

and continuity. Check for battery voltage at the power sunroof controller, refer to Wiring Diagrams, for circuit infor-

mation. If battery voltage of more than 10 volts is detected at the controller, proceed with the following tests (the

controller will not operate at less than 10 volts).

Before beginning diagnosis for wind noise or water leaks, verify that the problem was not caused by releasing the

control switch before the sunroof was fully closed. The sunroof module hasa water-management system. If how-

ever, the sunroof glass is in a partial closed position, high pressure water may be forced beyond the water man-

agement system boundariesand onto the headlining.

Every time the sunroof module loses power it must be initialized. This is done by connecting power to the sunroof

and moving the sunroof toward the closed position. When initialization occurs a slight “kick” in the sunroof module

will be seen and heard. This is the indication that the sunroof module is initialized

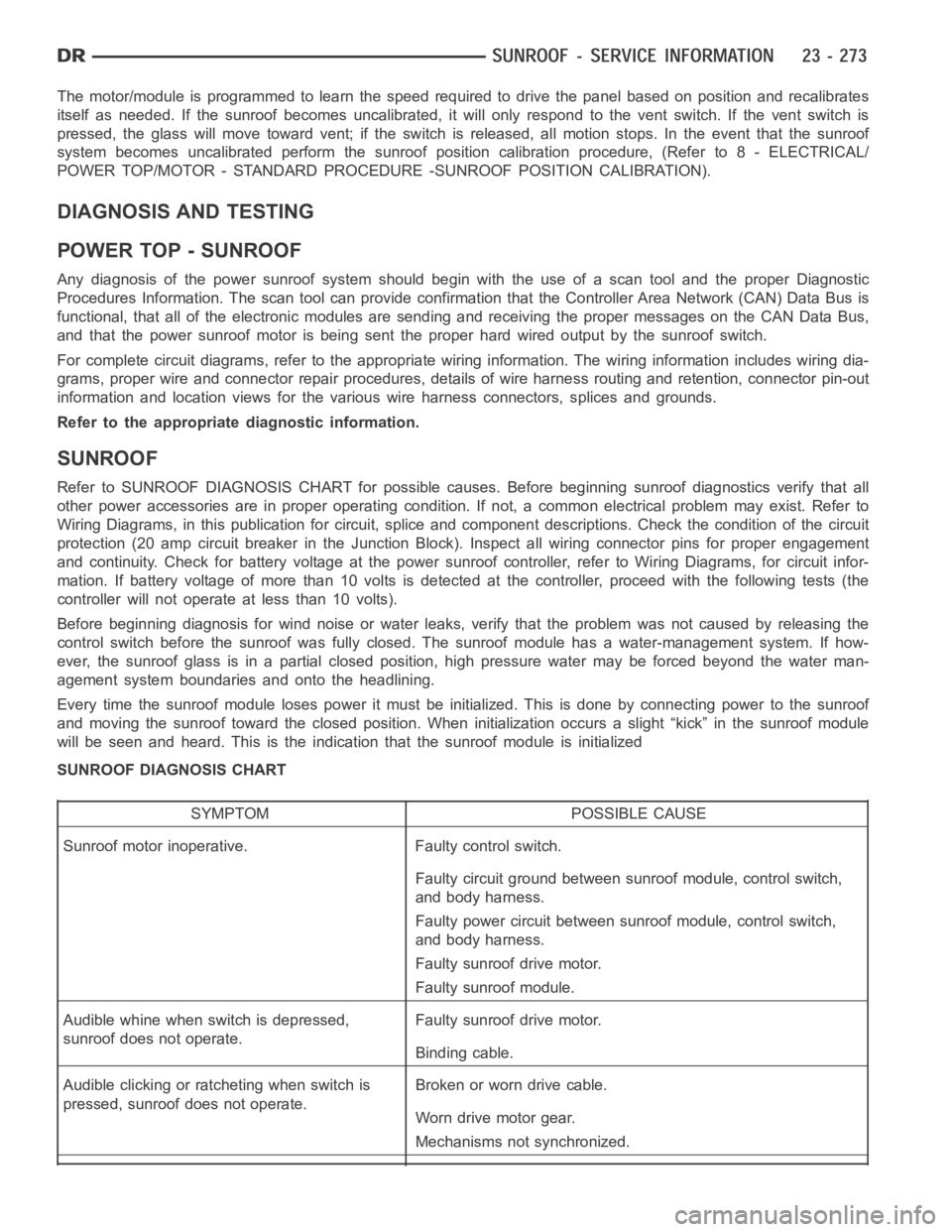

SUNROOF DIAGNOSIS CHART

SYMPTOM POSSIBLE CAUSE

Sunroof motor inoperative. Faulty control switch.

Faulty circuit ground between sunroof module, control switch,

and body harness.

Faulty power circuit between sunroof module, control switch,

and body harness.

Faulty sunroof drive motor.

Faulty sunroof module.

Audible whine when switch is depressed,

sunroof does not operate.Faulty sunroof drive motor.

Binding cable.

Audible clicking or ratcheting when switch is

pressed, sunroof does not operate.Broken or worn drive cable.

Worn drive motor gear.

Mechanisms not synchronized.

Page 4693 of 5267

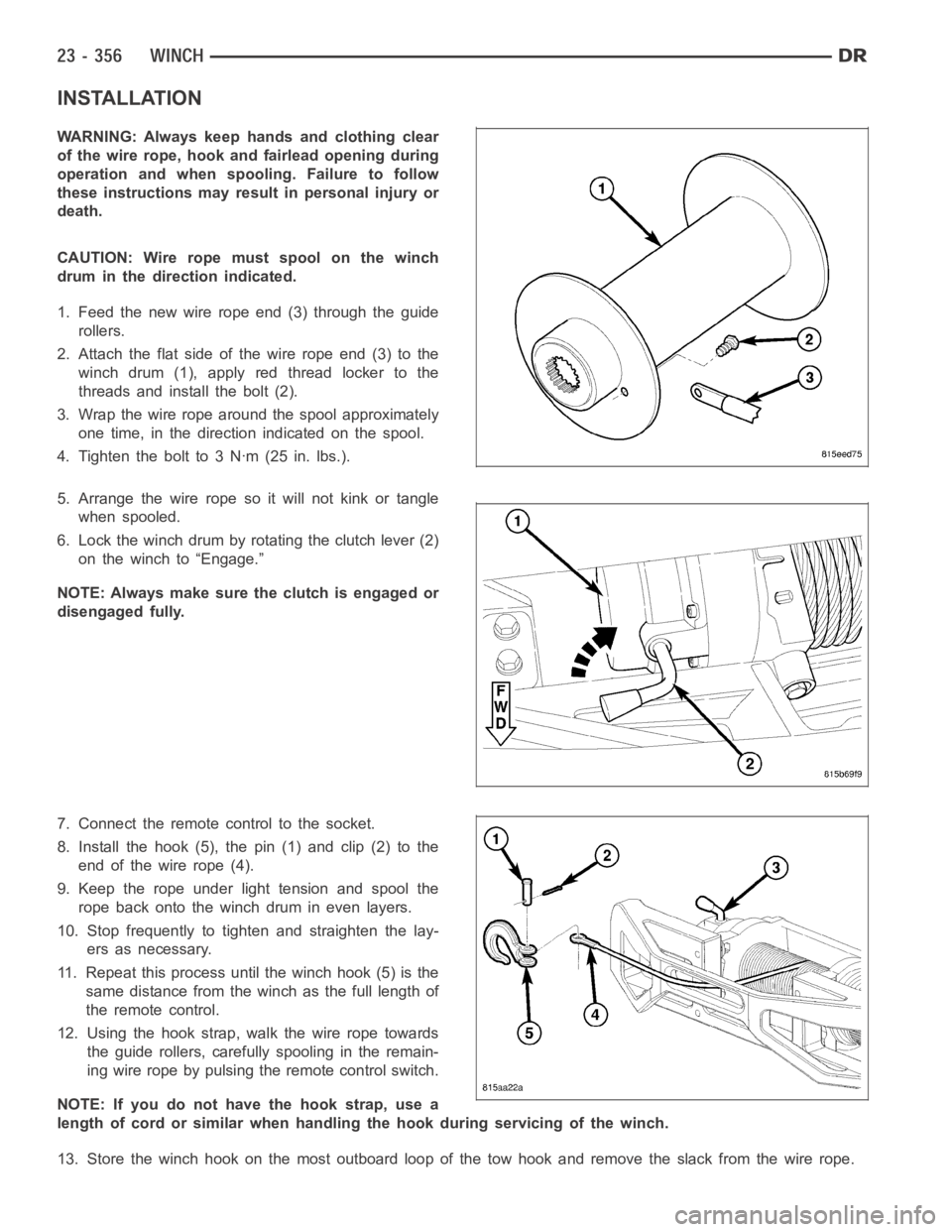

INSTALLATION

WARNING: Always keep hands and clothing clear

of the wire rope, hook and fairlead opening during

operation and when spooling. Failure to follow

these instructions may result in personal injury or

death.

CAUTION: Wire rope must spool on the winch

drum in the direction indicated.

1. Feed the new wire rope end (3) through the guide

rollers.

2. Attach the flat side of the wire rope end (3) to the

winch drum (1), apply red thread locker to the

threads and install the bolt (2).

3. Wrap the wire rope around the spool approximately

one time, in the direction indicated on the spool.

4. Tighten the bolt to 3 Nꞏm (25 in. lbs.).

5. Arrange the wire rope so it will not kink or tangle

when spooled.

6. Lock the winch drum by rotating the clutch lever (2)

on the winch to “Engage.”

NOTE: Always make sure the clutch is engaged or

disengaged fully.

7. Connect the remote control to the socket.

8. Install the hook (5), the pin (1) and clip (2) to the

end of the wire rope (4).

9. Keep the rope under light tension and spool the

rope back onto the winch drum in even layers.

10. Stop frequently to tighten and straighten the lay-

ers as necessary.

11. Repeat this process until the winch hook (5) is the

same distance from the winch as the full length of

theremotecontrol.

12. Using the hook strap, walk the wire rope towards

the guide rollers, carefully spooling in the remain-

ing wire rope by pulsing the remote control switch.

NOTE: If you do not have the hook strap, use a

length of cord or similar when handling the hook during servicing of the winch.

13. Store the winch hook on the most outboard loop of the tow hook and remove the slack from the wire rope.

Page 4697 of 5267

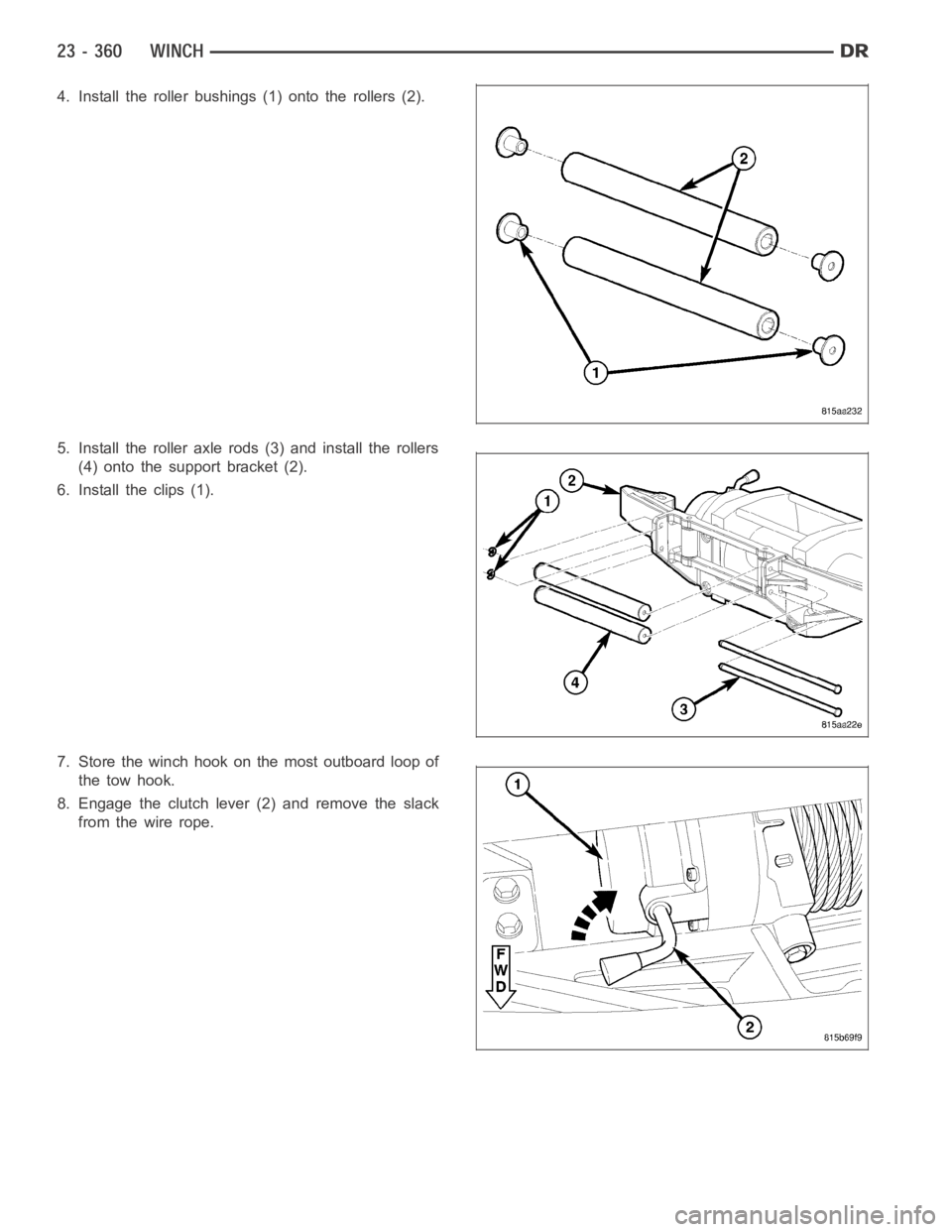

4. Install the roller bushings (1) onto the rollers (2).

5. Install the roller axle rods (3) and install the rollers

(4) onto the support bracket (2).

6. Install the clips (1).

7. Store the winch hook on the most outboard loop of

the tow hook.

8. Engage the clutch lever (2) and remove the slack

fromthewirerope.

Page 4949 of 5267

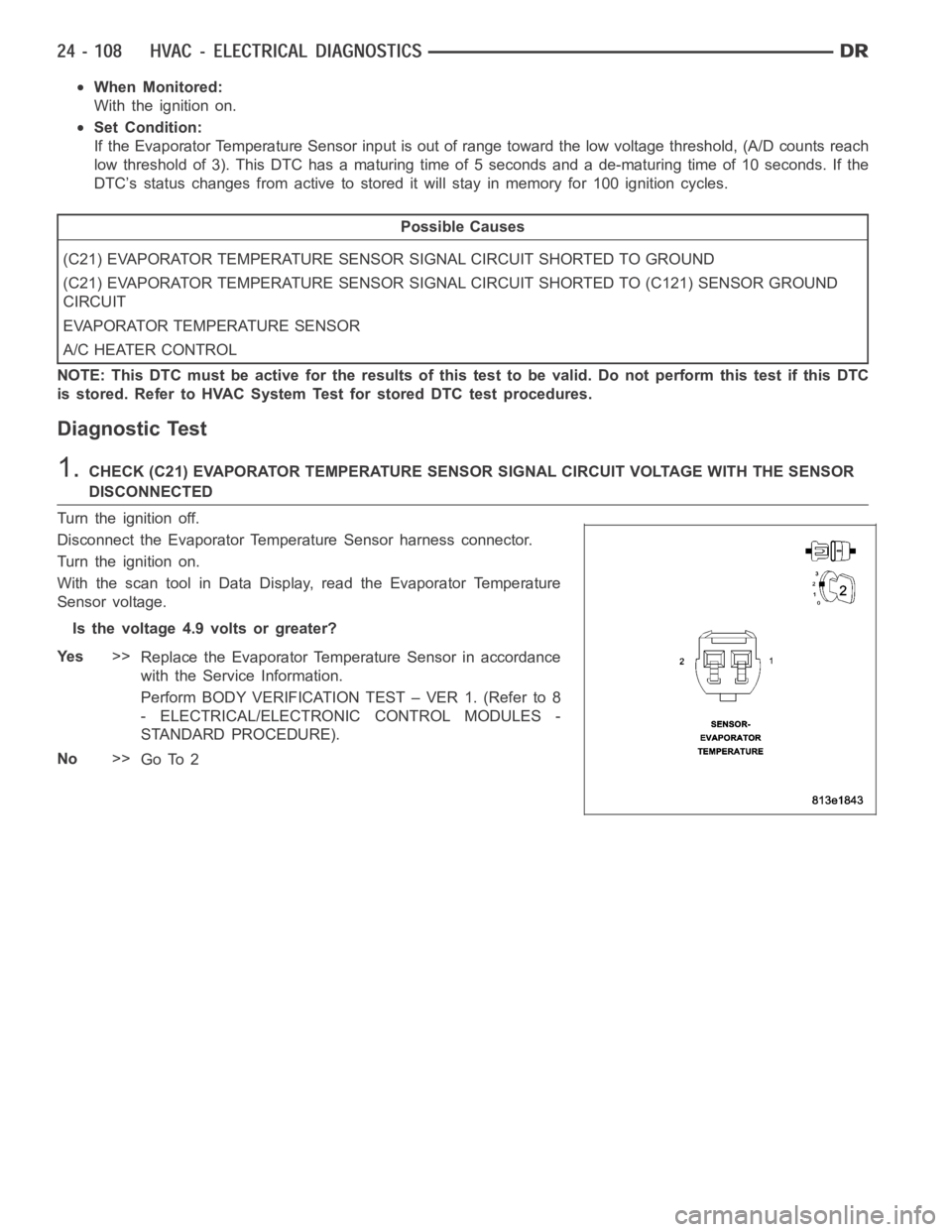

When Monitored:

With the ignition on.

Set Condition:

If the Evaporator Temperature Sensor input is out of range toward the low voltage threshold, (A/D counts reach

low threshold of 3). This DTC has a maturing time of 5 seconds and a de-maturing time of 10 seconds. If the

DTC’s status changes from active to stored it will stay in memory for 100 ignition cycles.

Possible Causes

(C21) EVAPORATOR TEMPERATURE SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

(C21) EVAPORATOR TEMPERATURE SENSOR SIGNAL CIRCUIT SHORTED TO (C121) SENSOR GROUND

CIRCUIT

EVAPORATOR TEMPERATURE SENSOR

A/C HEATER CONTROL

NOTE: This DTC must be active for the results of this test to be valid. Do not perform this test if this DTC

is stored. Refer to HVAC System Test for stored DTC test procedures.

Diagnostic Test

1.CHECK (C21) EVAPORATOR TEMPERATURE SENSOR SIGNAL CIRCUIT VOLTAGE WITH THE SENSOR

DISCONNECTED

Turn the ignition off.

Disconnect the Evaporator Temperature Sensor harness connector.

Turn the ignition on.

With the scan tool in Data Display, read the Evaporator Temperature

Sensor voltage.

Is the voltage 4.9 volts or greater?

Ye s>>

Replace the Evaporator Temperature Sensor in accordance

with the Service Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

No>>

Go To 2

Page 4952 of 5267

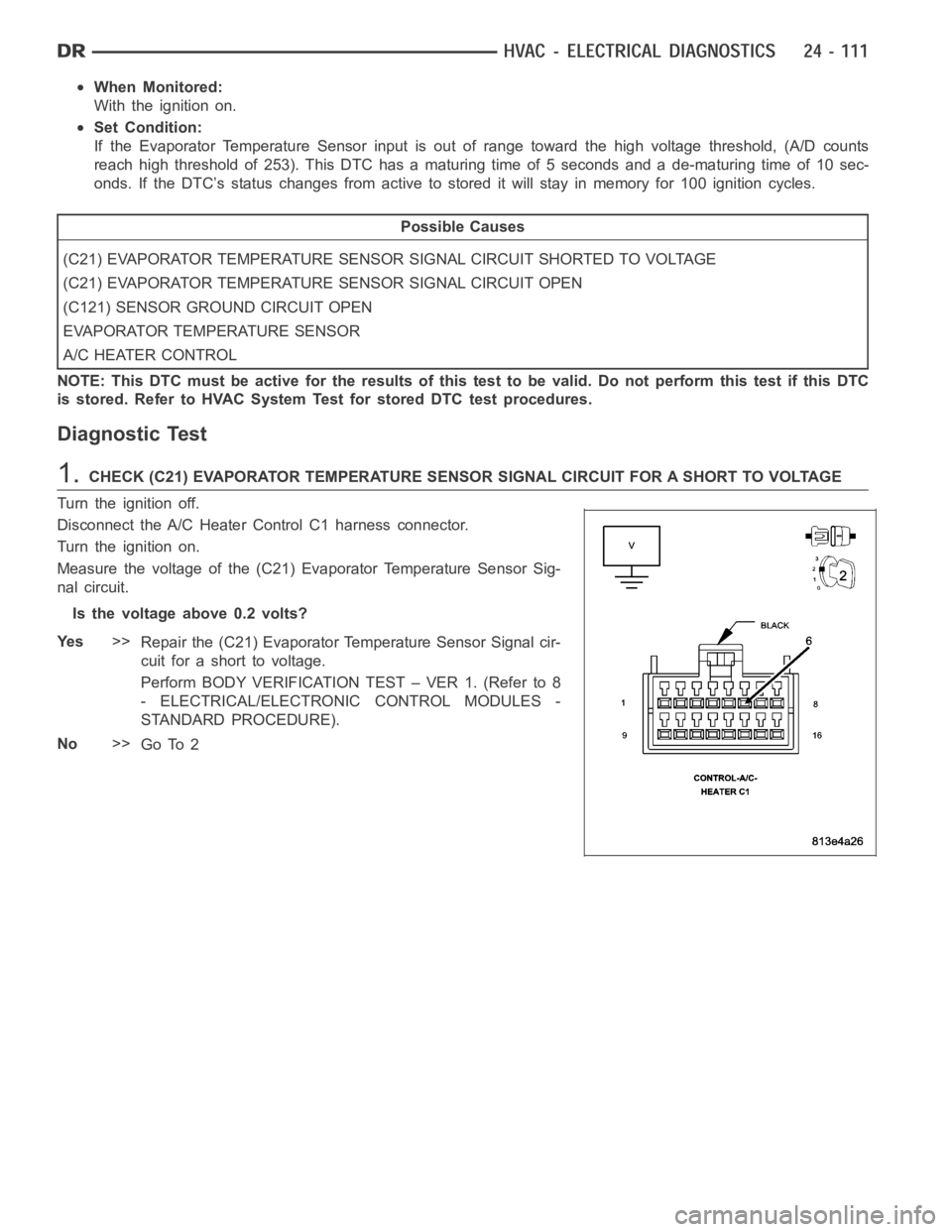

When Monitored:

With the ignition on.

Set Condition:

If the Evaporator Temperature Sensor input is out of range toward the high voltage threshold, (A/D counts

reach high threshold of 253). This DTC has a maturing time of 5 seconds and a de-maturing time of 10 sec-

onds. If the DTC’s status changes from active to stored it will stay in memory for 100 ignition cycles.

Possible Causes

(C21) EVAPORATOR TEMPERATURE SENSOR SIGNAL CIRCUIT SHORTED TO VOLTAGE

(C21) EVAPORATOR TEMPERATURE SENSOR SIGNAL CIRCUIT OPEN

(C121) SENSOR GROUND CIRCUIT OPEN

EVAPORATOR TEMPERATURE SENSOR

A/C HEATER CONTROL

NOTE: This DTC must be active for the results of this test to be valid. Do not perform this test if this DTC

is stored. Refer to HVAC System Test for stored DTC test procedures.

Diagnostic Test

1.CHECK (C21) EVAPORATOR TEMPERATURE SENSOR SIGNAL CIRCUIT FOR A SHORT TO VOLTA G E

Turn the ignition off.

Disconnect the A/C Heater Control C1 harness connector.

Turn the ignition on.

Measure the voltage of the (C21) Evaporator Temperature Sensor Sig-

nal circuit.

Is the voltage above 0.2 volts?

Ye s>>

Repair the (C21) Evaporator Temperature Sensor Signal cir-

cuit for a short to voltage.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

No>>

Go To 2

Page 5224 of 5267

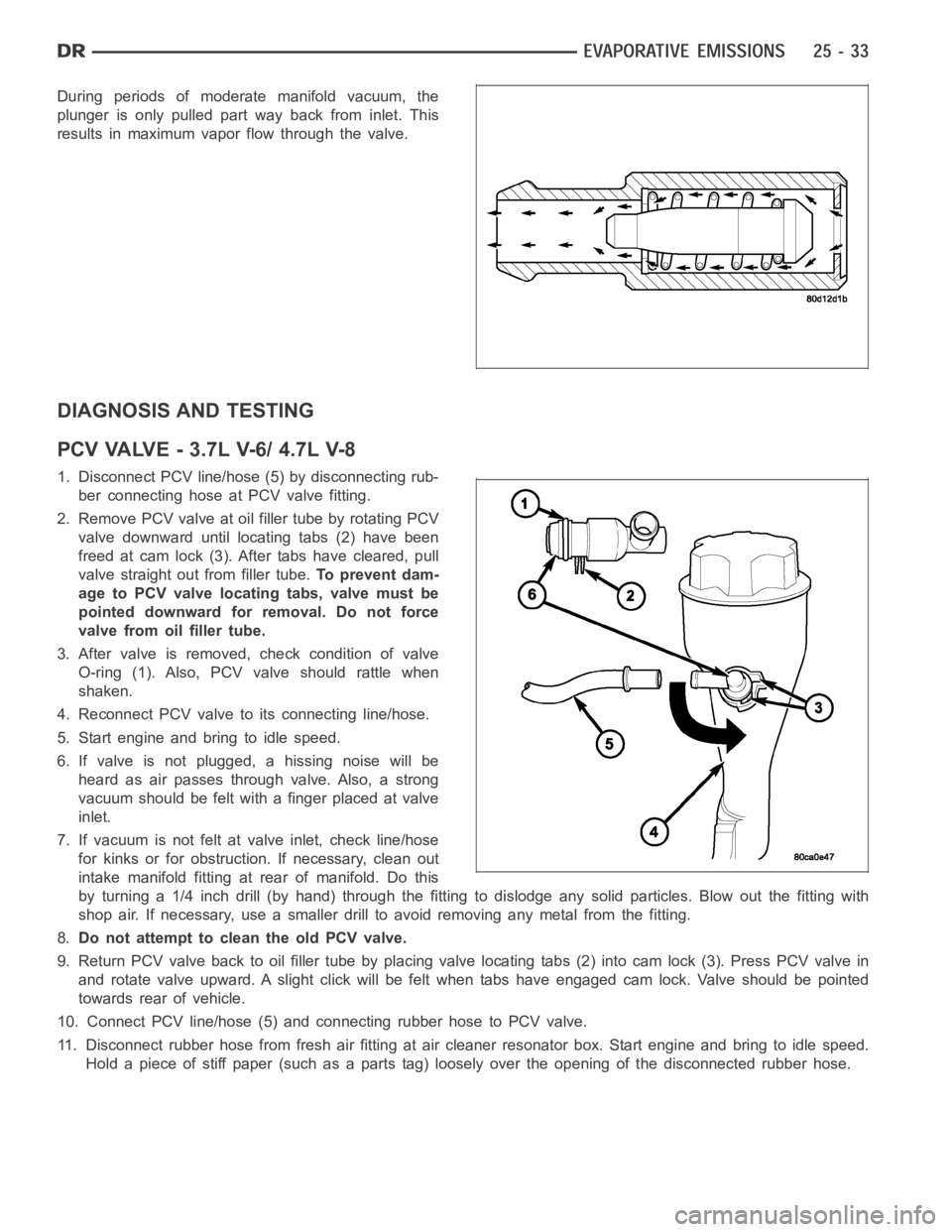

During periods of moderate manifold vacuum, the

plunger is only pulled part way back from inlet. This

results in maximum vapor flow through the valve.

DIAGNOSIS AND TESTING

PCVVALVE-3.7LV-6/4.7LV-8

1. Disconnect PCV line/hose (5) by disconnecting rub-

ber connecting hose at PCV valve fitting.

2. Remove PCV valve at oil filler tube by rotating PCV

valve downward until locating tabs (2) have been

freed at cam lock (3). After tabs have cleared, pull

valve straight out from filler tube.To prevent dam-

age to PCV valve locating tabs, valve must be

pointed downward for removal. Do not force

valve from oil filler tube.

3. After valve is removed, check condition of valve

O-ring (1). Also, PCV valve should rattle when

shaken.

4. Reconnect PCV valve to its connecting line/hose.

5. Start engine and bring to idle speed.

6. If valve is not plugged, a hissing noise will be

heard as air passes through valve. Also, a strong

vacuum should be felt with a finger placed at valve

inlet.

7. If vacuum is not felt at valve inlet, check line/hose

for kinks or for obstruction. If necessary, clean out

intake manifold fitting at rear of manifold. Do this

byturninga1/4inchdrill(byhand)throughthefittingtodislodgeanysolid particles. Blow out the fitting with

shop air. If necessary, use a smaller drill to avoid removing any metal fromthe fitting.

8.Do not attempt to clean the old PCV valve.

9. Return PCV valve back to oil filler tube by placing valve locating tabs (2) into cam lock (3). Press PCV valve in

and rotate valve upward. A slight click will be felt when tabs have engaged cam lock. Valve should be pointed

towards rear of vehicle.

10. Connect PCV line/hose (5) and connecting rubber hose to PCV valve.

11. Disconnect rubber hose from fresh air fitting at air cleaner resonatorbox. Start engine and bring to idle speed.

Hold a piece of stiff paper (such as a parts tag) loosely over the opening of the disconnected rubber hose.

Page 5227 of 5267

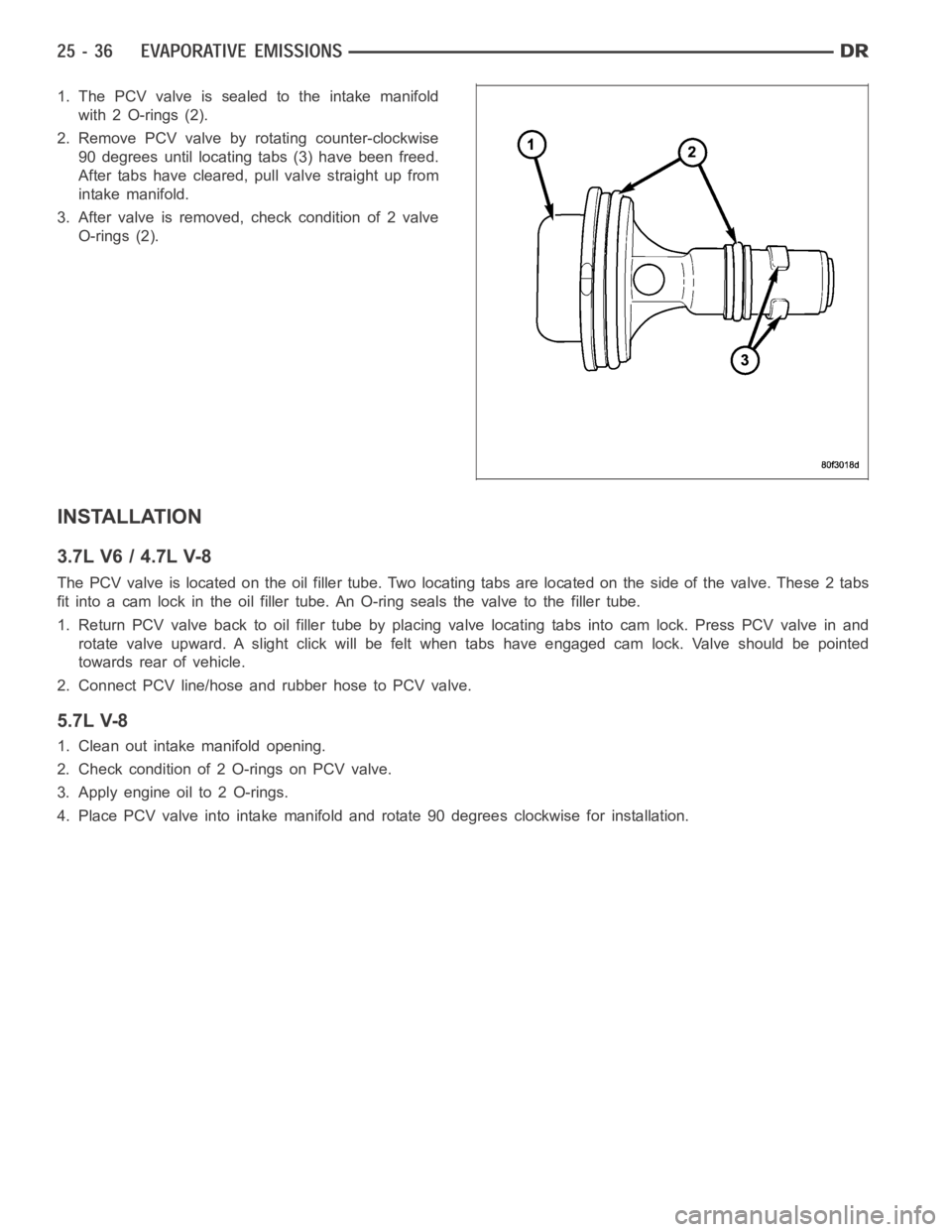

1. The PCV valve is sealed to the intake manifold

with 2 O-rings (2).

2. Remove PCV valve by rotating counter-clockwise

90 degrees until locating tabs (3) have been freed.

After tabs have cleared, pull valve straight up from

intake manifold.

3. After valve is removed, check condition of 2 valve

O-rings (2).

INSTALLATION

3.7L V6 / 4.7L V-8

The PCV valve is located on the oil filler tube. Two locating tabs are locatedonthesideofthevalve.These2tabs

fit into a cam lock in the oil filler tube.An O-ring seals the valve to the filler tube.

1. Return PCV valve back to oil filler tube by placing valve locating tabs into cam lock. Press PCV valve in and

rotate valve upward. A slight click will be felt when tabs have engaged cam lock. Valve should be pointed

towards rear of vehicle.

2. Connect PCV line/hose and rubber hose to PCV valve.

5.7L V-8

1. Clean out intake manifold opening.

2. Check condition of 2 O-rings on PCV valve.

3. Apply engine oil to 2 O-rings.

4. Place PCV valve into intake manifold and rotate 90 degrees clockwise forinstallation.