boot DODGE RAM SRT-10 2006 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4088 of 5267

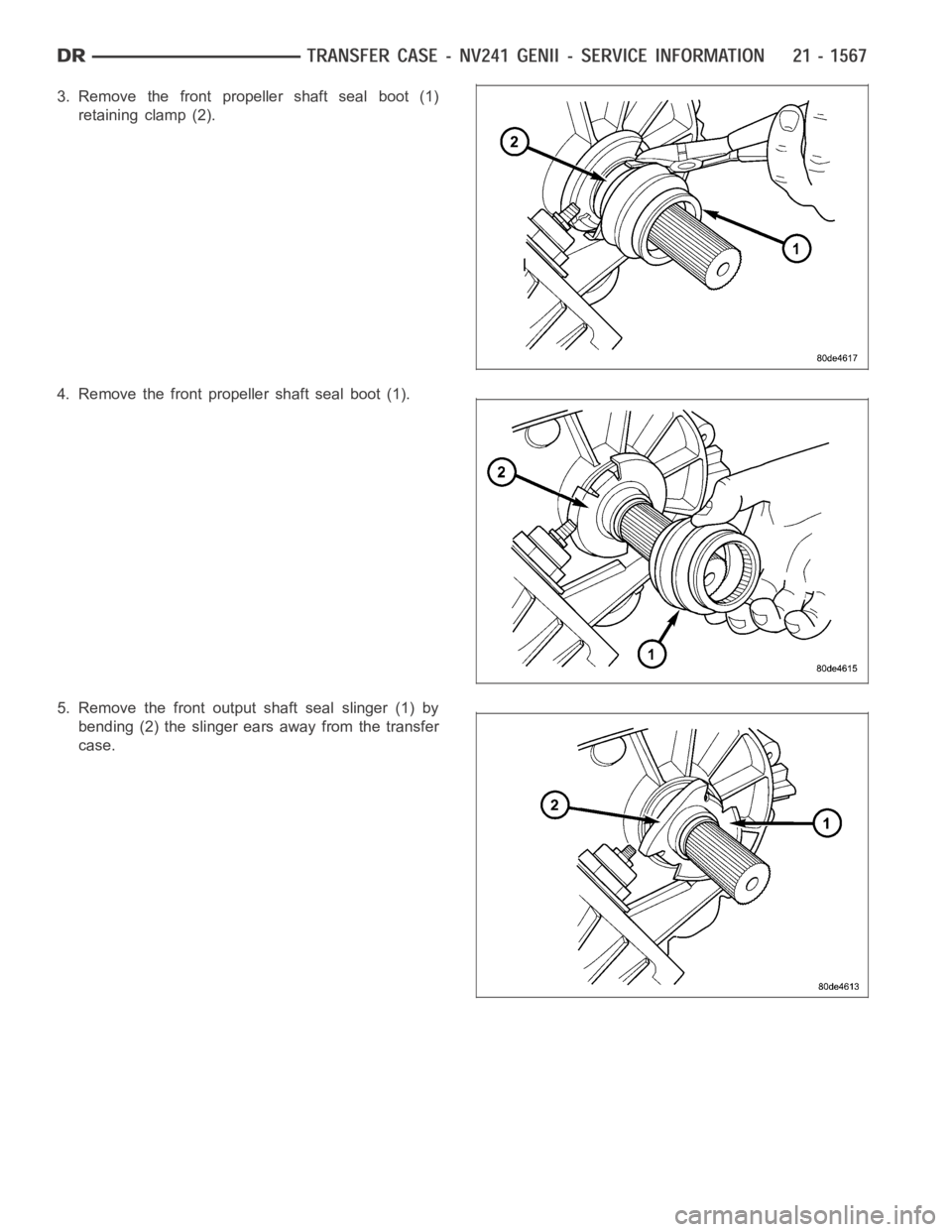

3. Remove the front propeller shaft seal boot (1)

retaining clamp (2).

4. Remove the front propeller shaft seal boot (1).

5. Remove the front output shaft seal slinger (1) by

bending (2) the slinger ears away from the transfer

case.

Page 4115 of 5267

SEAL BOOT

1. Install the front output shaft seal slinger with Oil Slinger Installer 8840. Install the slinger onto the shaft until the

tool contacts the rear of the output shaft.

2. Install a new seal boot clamp onto the seal boot.

3. Install the seal boot and clamp onto the slinger hub and tighten the clampwith Crimp Tool C-4975-A.

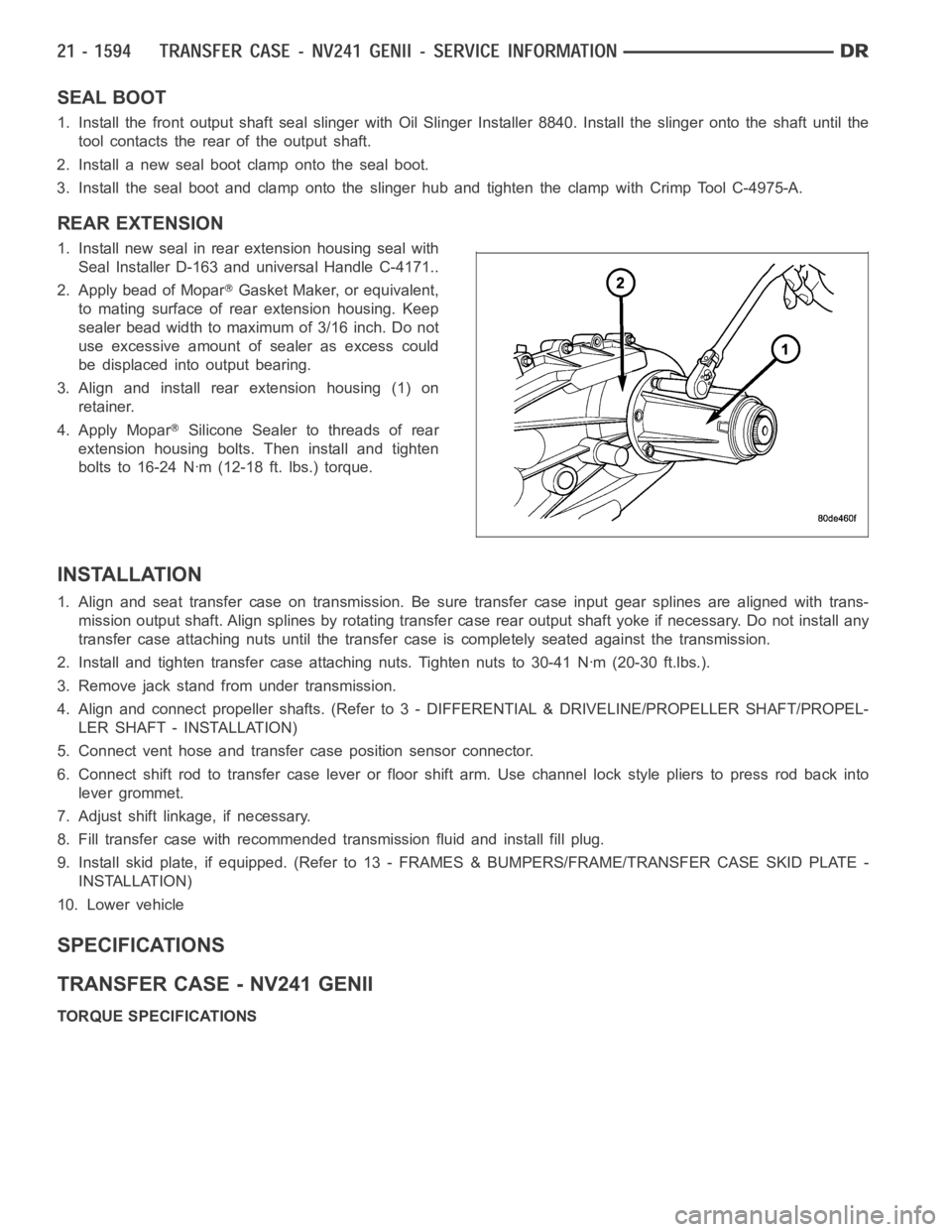

REAR EXTENSION

1. Install new seal in rear extension housing seal with

Seal Installer D-163 and universal Handle C-4171..

2. Apply bead of Mopar

Gasket Maker, or equivalent,

to mating surface of rear extension housing. Keep

sealer bead width to maximum of 3/16 inch. Do not

use excessive amount of sealer as excess could

be displaced into output bearing.

3. Align and install rear extension housing (1) on

retainer.

4. Apply Mopar

Silicone Sealer to threads of rear

extension housing bolts. Then install and tighten

bolts to 16-24 Nꞏm (12-18 ft. lbs.) torque.

INSTALLATION

1. Align and seat transfer case on transmission. Be sure transfer case input gear splines are aligned with trans-

mission output shaft. Align splines by rotating transfer case rear outputshaft yoke if necessary. Do not install any

transfer case attaching nuts until the transfer case is completely seatedagainst the transmission.

2. Install and tighten transfer case attaching nuts. Tighten nuts to 30-41Nꞏm (20-30 ft.lbs.).

3. Remove jack stand from under transmission.

4. Align and connect propeller shafts. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/PROPEL-

LER SHAFT - INSTALLATION)

5. Connect vent hose and transfer case position sensor connector.

6. Connect shift rod to transfer case lever or floor shift arm. Use channel lock style pliers to press rod back into

lever grommet.

7. Adjust shift linkage, if necessary.

8. Fill transfer case with recommended transmission fluid and install fillplug.

9. Install skid plate, if equipped. (Refer to 13 - FRAMES & BUMPERS/FRAME/TRANSFER CASE SKID PLATE -

INSTALLATION)

10. Lower vehicle

SPECIFICATIONS

TRANSFER CASE - NV241 GENII

TORQUE SPECIFICATIONS

Page 4121 of 5267

FRONT OUTPUT SHAFT SEAL

REMOVAL

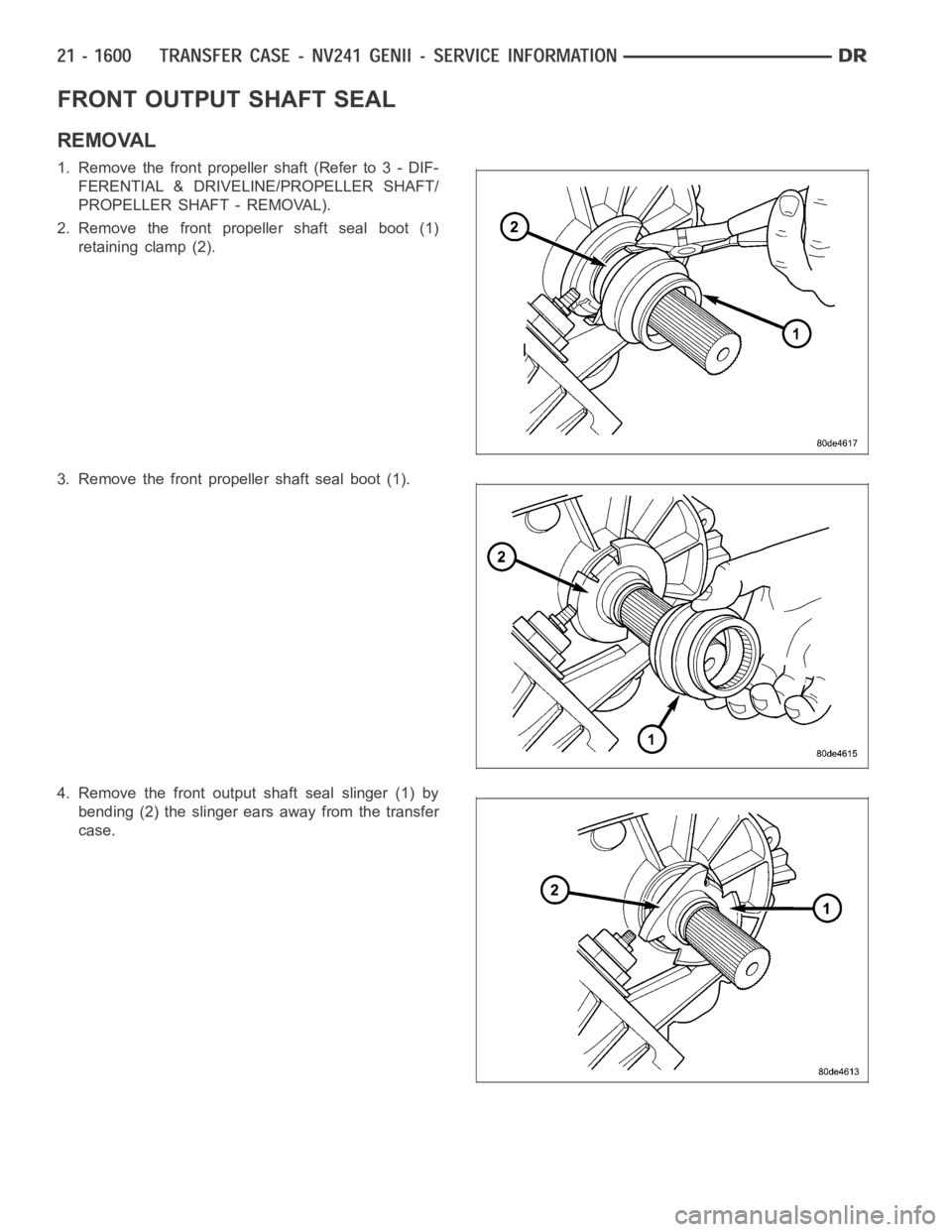

1. Remove the front propeller shaft (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL).

2. Remove the front propeller shaft seal boot (1)

retaining clamp (2).

3. Remove the front propeller shaft seal boot (1).

4. Remove the front output shaft seal slinger (1) by

bending (2) the slinger ears away from the transfer

case.

Page 4122 of 5267

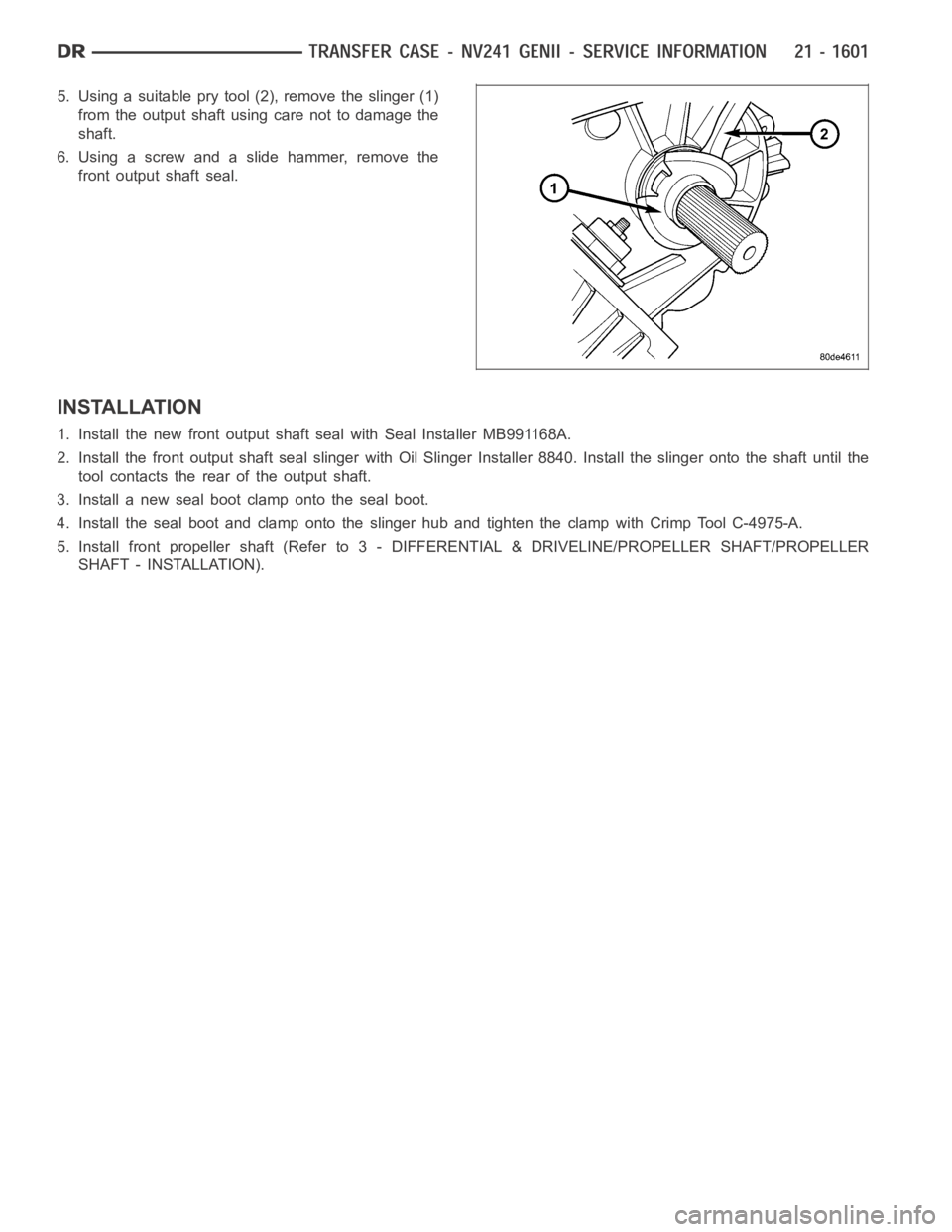

5. Using a suitable pry tool (2), remove the slinger (1)

from the output shaft using care not to damage the

shaft.

6. Using a screw and a slide hammer, remove the

front output shaft seal.

INSTALLATION

1. Install the new front output shaft seal with Seal Installer MB991168A.

2. Install the front output shaft seal slinger with Oil Slinger Installer 8840. Install the slinger onto the shaft until the

tool contacts the rear of the output shaft.

3. Install a new seal boot clamp onto the seal boot.

4. Install the seal boot and clamp onto the slinger hub and tighten the clampwith Crimp Tool C-4975-A.

5. Install front propeller shaft (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/PROPELLER

SHAFT - INSTALLATION).

Page 4123 of 5267

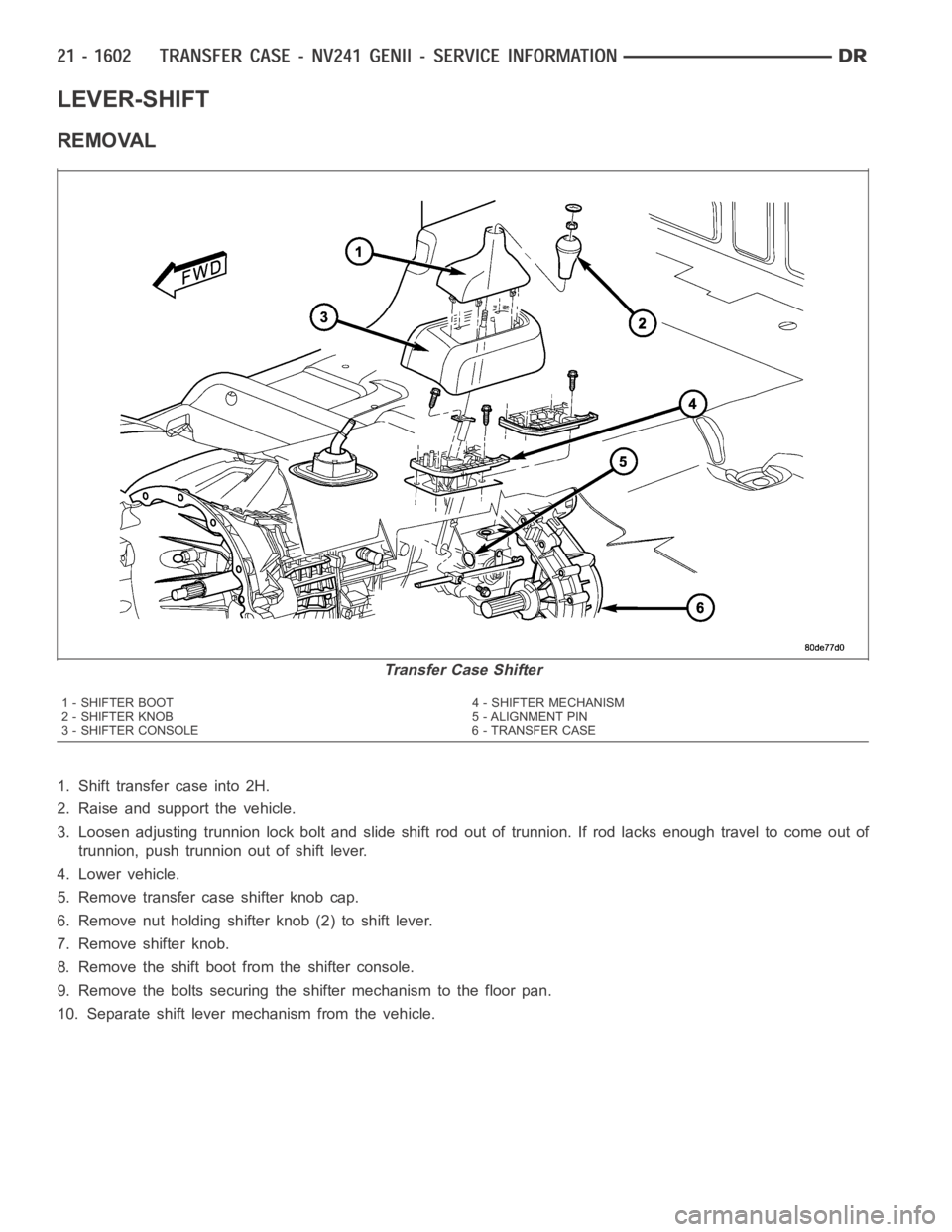

LEVER-SHIFT

REMOVAL

1. Shift transfer case into 2H.

2. Raise and support the vehicle.

3. Loosen adjusting trunnion lock bolt and slide shift rod out of trunnion.If rod lacks enough travel to come out of

trunnion, push trunnion out of shift lever.

4. Lower vehicle.

5. Remove transfer case shifter knob cap.

6. Remove nut holding shifter knob (2) to shift lever.

7. Remove shifter knob.

8. Remove the shift boot from the shifter console.

9. Remove the bolts securing the shifter mechanism to the floor pan.

10. Separate shift lever mechanism from the vehicle.

Transfer Case Shifter

1 - SHIFTER BOOT 4 - SHIFTER MECHANISM

2-SHIFTERKNOB 5-ALIGNMENTPIN

3 - SHIFTER CONSOLE 6 - TRANSFER CASE

Page 4124 of 5267

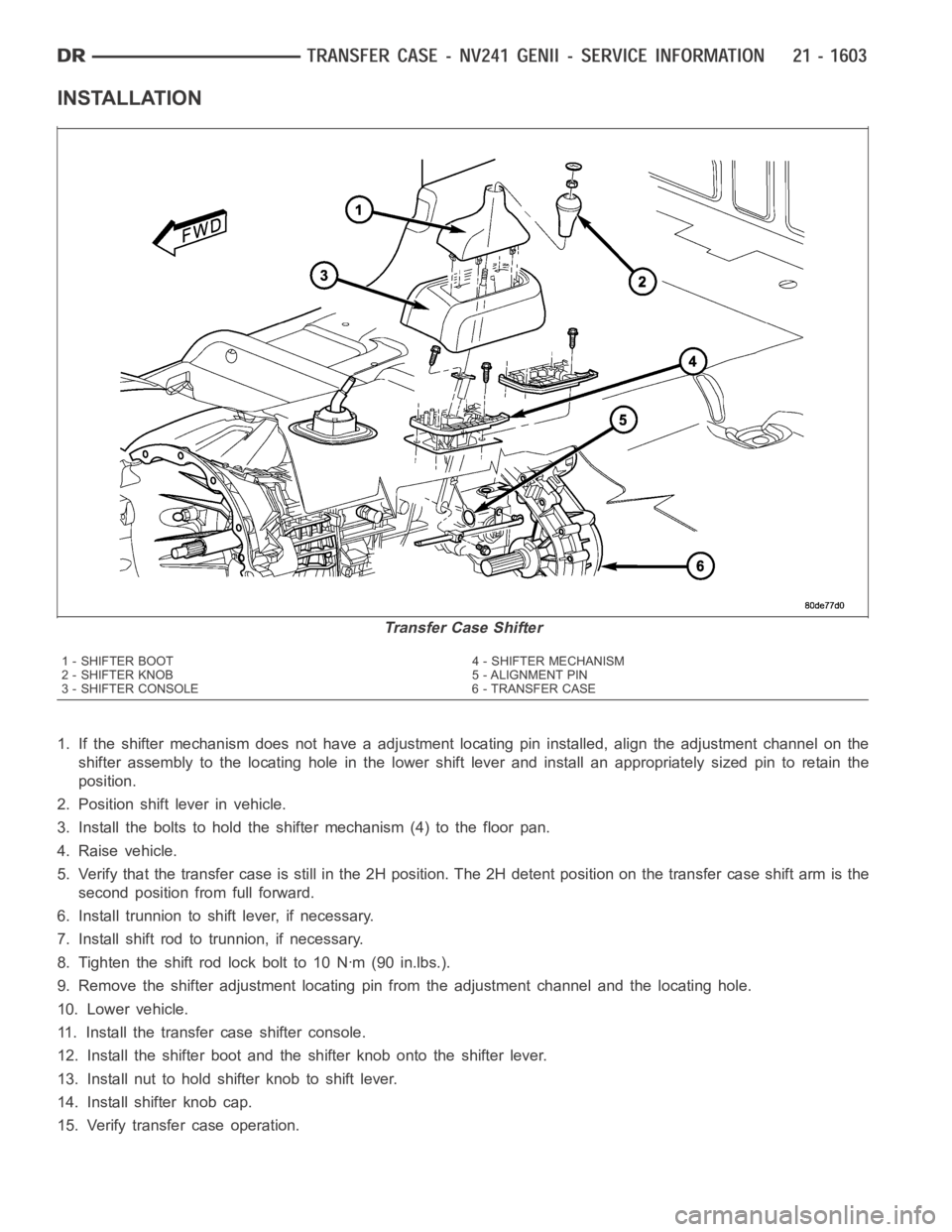

INSTALLATION

1. If the shifter mechanism does not have a adjustment locating pin installed, align the adjustment channel on the

shifter assembly to the locating hole in the lower shift lever and install an appropriately sized pin to retain the

position.

2. Position shift lever in vehicle.

3. Install the bolts to hold the shifter mechanism (4) to the floor pan.

4. Raise vehicle.

5. Verify that the transfer case is still in the 2H position. The 2H detent position on the transfer case shift arm is the

second position from full forward.

6. Install trunnion to shift lever, if necessary.

7. Install shift rod to trunnion, if necessary.

8. Tighten the shift rod lock bolt to 10 Nꞏm (90 in.lbs.).

9. Remove the shifter adjustment locating pin from the adjustment channeland the locating hole.

10. Lower vehicle.

11. Install the transfer case shifter console.

12. Install the shifter boot and the shifter knob onto the shifter lever.

13. Install nut to hold shifter knob to shift lever.

14. Install shifter knob cap.

15. Verify transfer case operation.

Transfer Case Shifter

1 - SHIFTER BOOT 4 - SHIFTER MECHANISM

2-SHIFTERKNOB 5-ALIGNMENTPIN

3 - SHIFTER CONSOLE 6 - TRANSFER CASE

Page 4125 of 5267

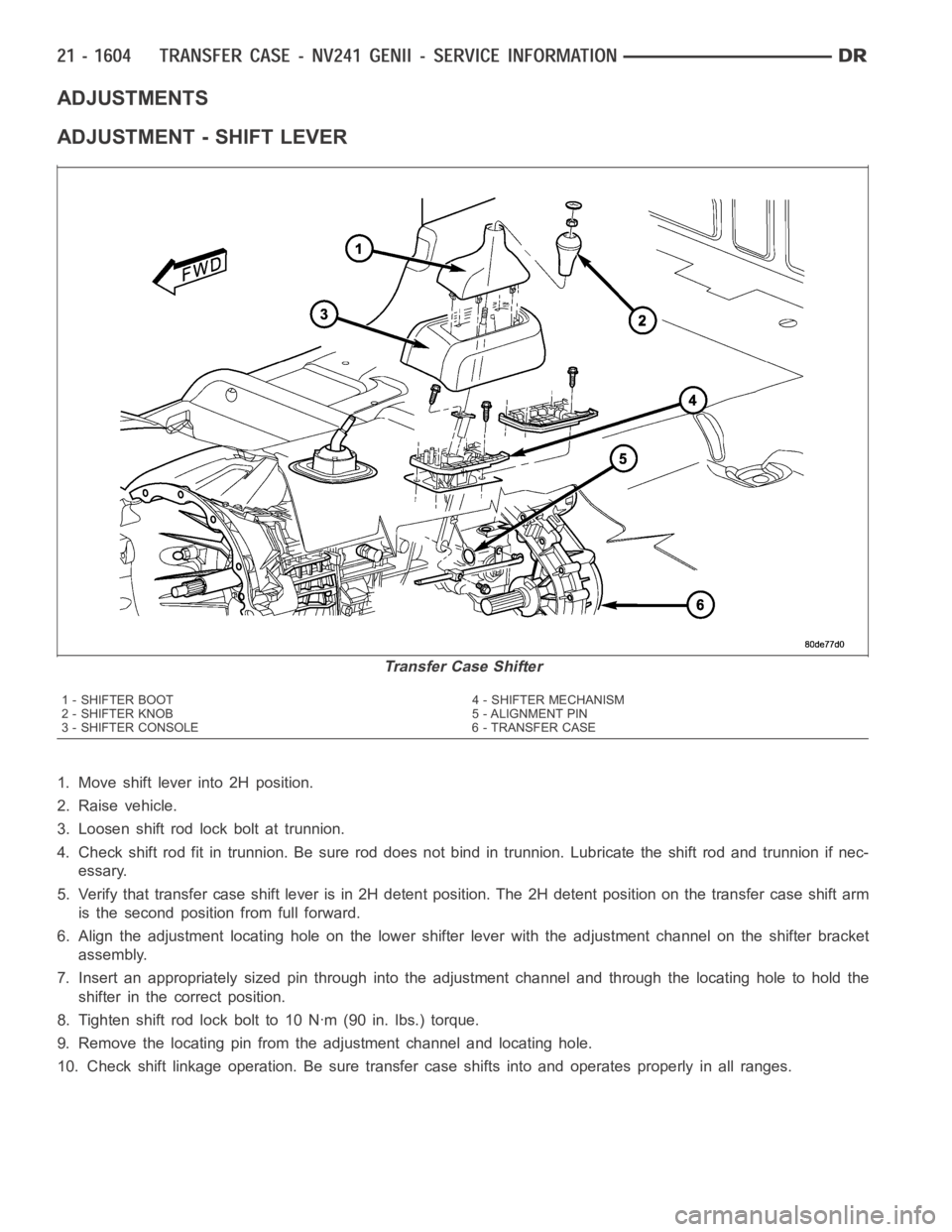

ADJUSTMENTS

ADJUSTMENT - SHIFT LEVER

1. Move shift lever into 2H position.

2. Raise vehicle.

3. Loosen shift rod lock bolt at trunnion.

4. Check shift rod fit in trunnion. Be sure rod does not bind in trunnion. Lubricate the shift rod and trunnion if nec-

essary.

5. Verify that transfer case shift lever is in 2H detent position. The 2H detent position on the transfer case shift arm

is the second position from full forward.

6. Align the adjustment locating hole on the lower shifter lever with the adjustment channel on the shifter bracket

assembly.

7. Insert an appropriately sized pin through into the adjustment channel and through the locating hole to hold the

shifter in the correct position.

8. Tighten shift rod lock bolt to 10 Nꞏm (90 in. lbs.) torque.

9. Remove the locating pin from the adjustment channel and locating hole.

10. Check shift linkage operation. Be sure transfer case shifts into and operates properly in all ranges.

Transfer Case Shifter

1 - SHIFTER BOOT 4 - SHIFTER MECHANISM

2-SHIFTERKNOB 5-ALIGNMENTPIN

3 - SHIFTER CONSOLE 6 - TRANSFER CASE

Page 4126 of 5267

page page

TRANSFER CASE - NV271 - SERVICE

INFORMATION

DESCRIPTION ............................. 1606

OPERATION ............................... 1606

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV271 ............................ 1607

REMOVAL ................................. 1608

DISASSEMBLY ............................. 1608

CLEANING ................................. 1623

INSPECTION ............................... 1623

ASSEMBLY . ............................... 1626

INSTALLATION ............................. 1644

SPECIFICATIONS

TRANSFER CASE - NV271 ................ 1645

SPECIAL TOOLS

TRANSFER CASE NV271/NV273 ........... 1646

BOOT-EXTENSION HOUSING SEAL AND DUST

REMOVAL ................................. 1648INSTALLATION ............................. 1648

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL ................................... 1649

SEAL-FRONT OUTPUT SHAFT

REMOVAL ................................. 1650

INSTALLATION ............................. 1650

SENSOR-POSITION

DESCRIPTION ............................. 1651

OPERATION ............................... 1651

REMOVAL ................................. 1651

INSTALLATION ............................. 1652

LEVER-SHIFT

REMOVAL ................................. 1653

INSTALLATION ............................. 1654

ADJUSTMENTS

ADJUSTMENT - SHIFT LEVER............. 1655

Page 4130 of 5267

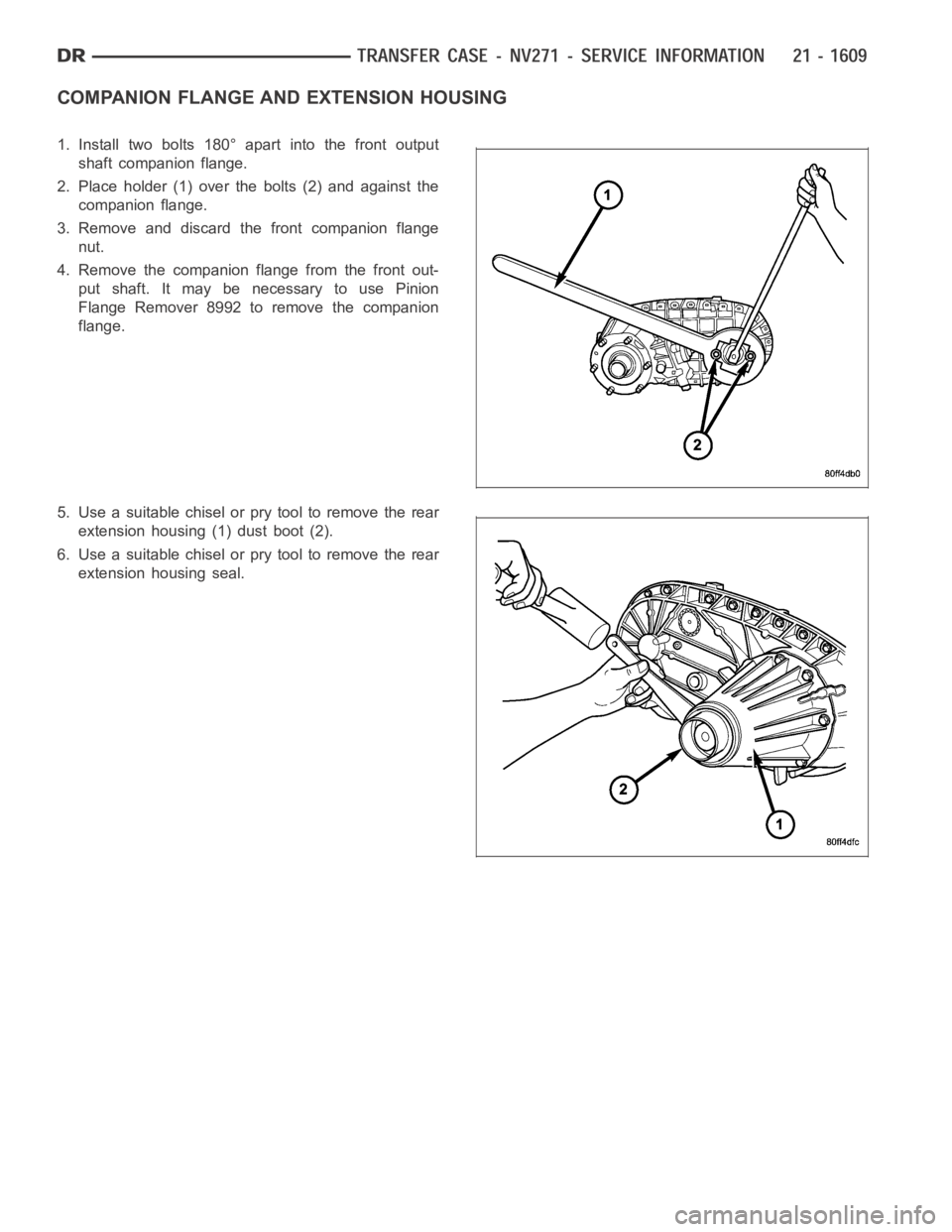

COMPANION FLANGE AND EXTENSION HOUSING

1. Install two bolts 180° apart into the front output

shaft companion flange.

2. Place holder (1) over the bolts (2) and against the

companion flange.

3. Remove and discard the front companion flange

nut.

4. Remove the companion flange from the front out-

put shaft. It may be necessary to use Pinion

Flange Remover 8992 to remove the companion

flange.

5. Use a suitable chisel or pry tool to remove the rear

extension housing (1) dust boot (2).

6. Use a suitable chisel or pry tool to remove the rear

extension housing seal.

Page 4165 of 5267

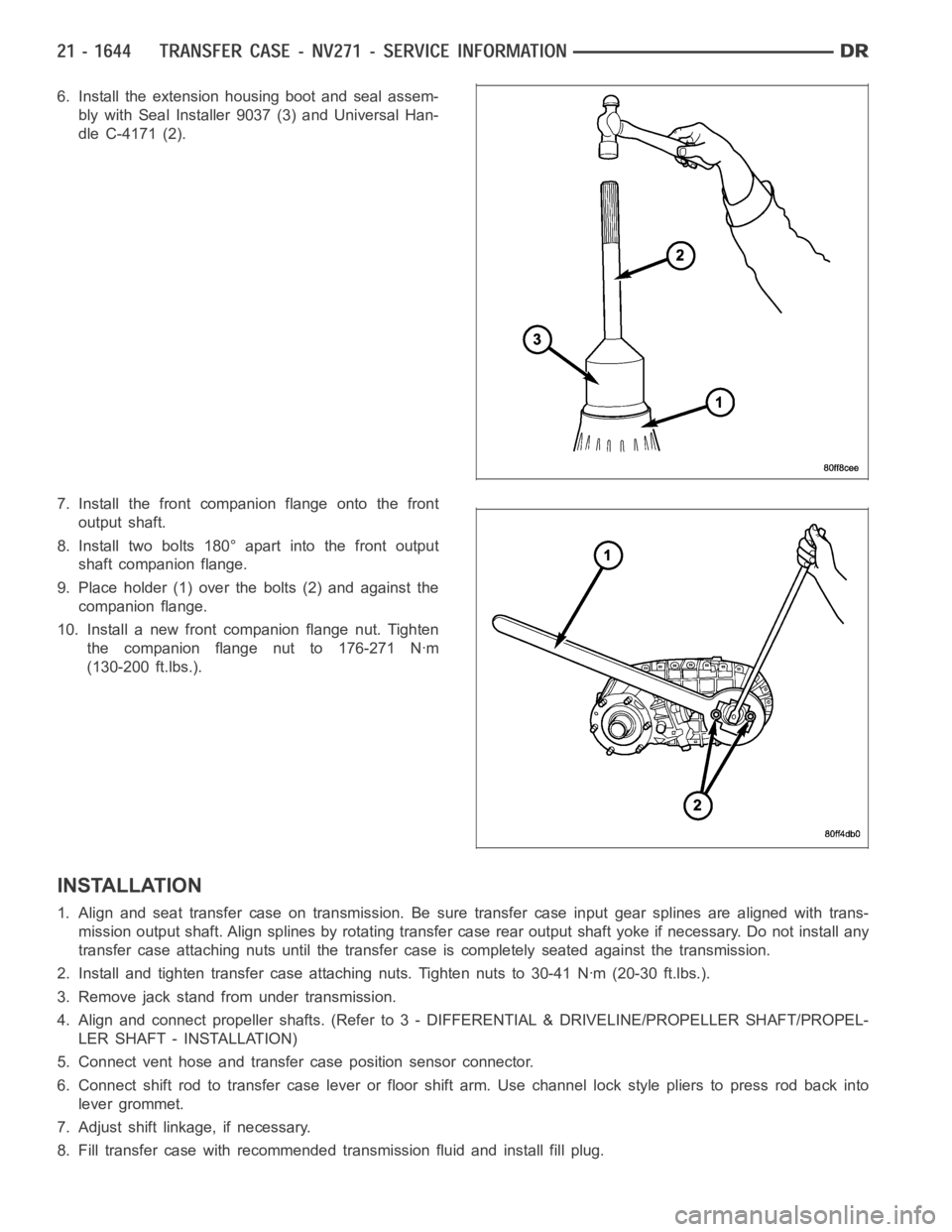

6. Install the extension housing boot and seal assem-

bly with Seal Installer 9037 (3) and Universal Han-

dle C-4171 (2).

7. Install the front companion flange onto the front

output shaft.

8. Install two bolts 180° apart into the front output

shaft companion flange.

9. Place holder (1) over the bolts (2) and against the

companion flange.

10. Install a new front companion flange nut. Tighten

the companion flange nut to 176-271 Nꞏm

(130-200 ft.lbs.).

INSTALLATION

1. Align and seat transfer case on transmission. Be sure transfer case input gear splines are aligned with trans-

mission output shaft. Align splines by rotating transfer case rear outputshaft yoke if necessary. Do not install any

transfer case attaching nuts until the transfer case is completely seatedagainst the transmission.

2. Install and tighten transfer case attaching nuts. Tighten nuts to 30-41Nꞏm (20-30 ft.lbs.).

3. Remove jack stand from under transmission.

4. Align and connect propeller shafts. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/PROPEL-

LER SHAFT - INSTALLATION)

5. Connect vent hose and transfer case position sensor connector.

6. Connect shift rod to transfer case lever or floor shift arm. Use channel lock style pliers to press rod back into

lever grommet.

7. Adjust shift linkage, if necessary.

8. Fill transfer case with recommended transmission fluid and install fillplug.