manual transmission DODGE RAM SRT-10 2006 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2134 of 5267

BEARING-CRANKSHAFT PILOT

REMOVAL

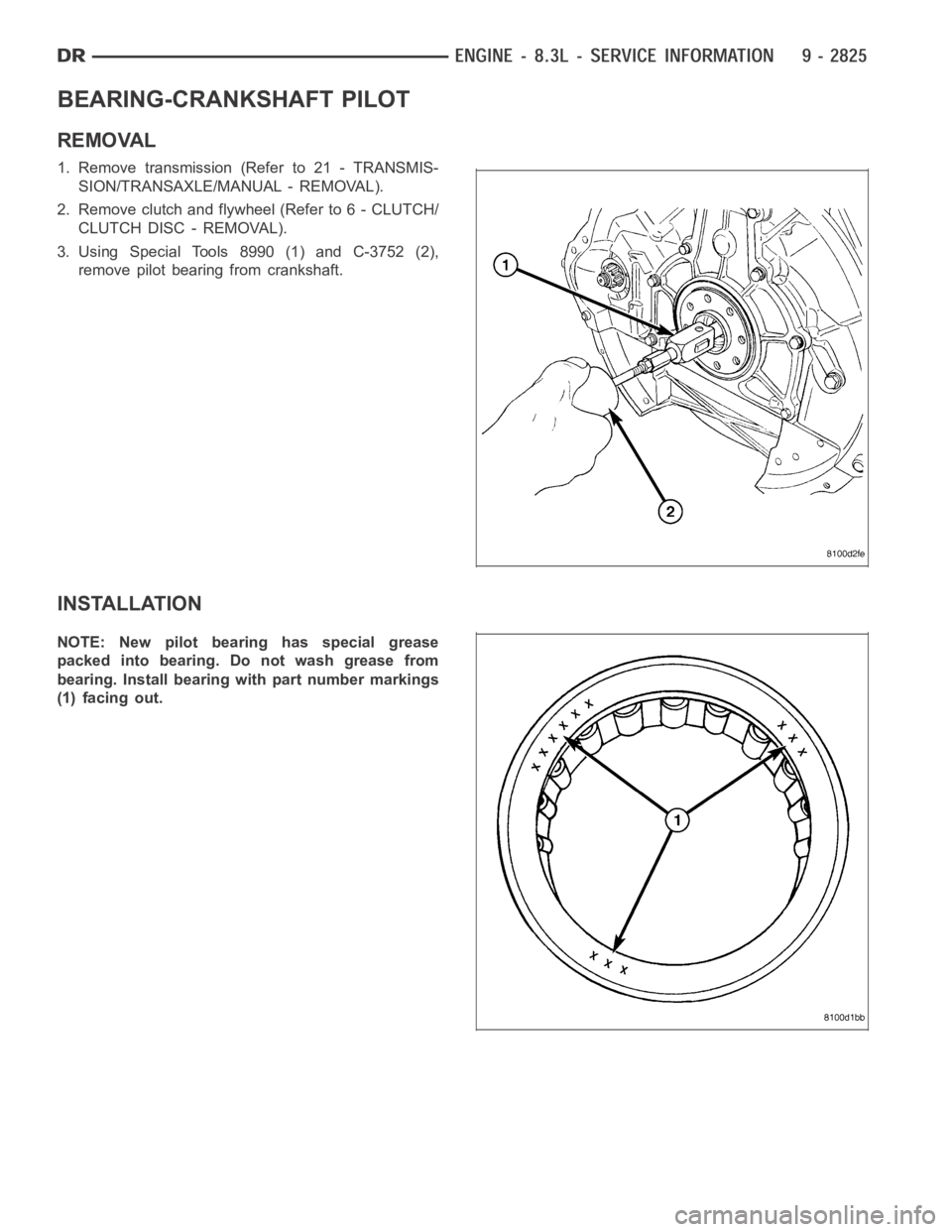

1. Remove transmission (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/MANUAL - REMOVAL).

2. Remove clutch and flywheel (Refer to 6 - CLUTCH/

CLUTCH DISC - REMOVAL).

3. Using Special Tools 8990 (1) and C-3752 (2),

remove pilot bearing from crankshaft.

INSTALLATION

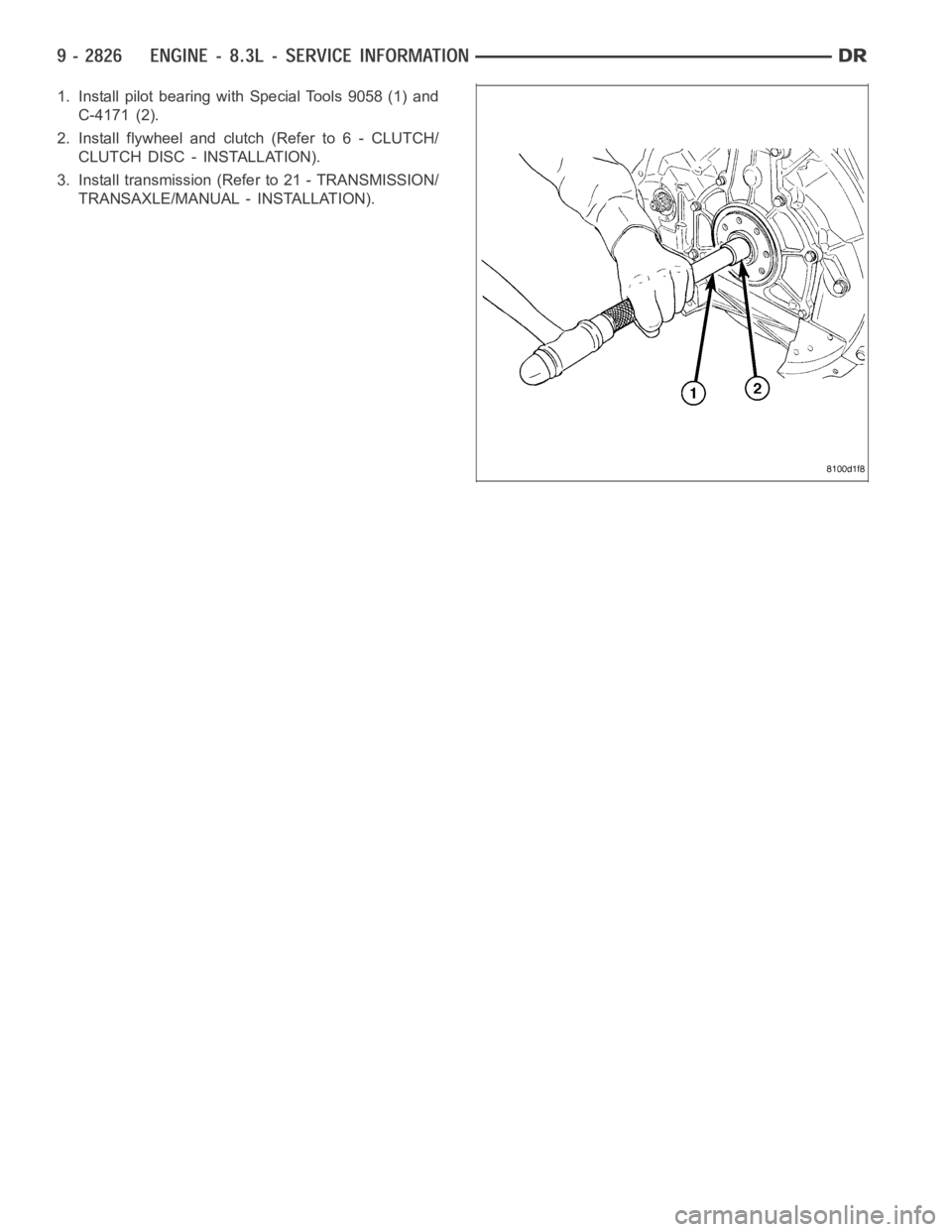

NOTE: New pilot bearing has special grease

packed into bearing. Do not wash grease from

bearing. Install bearing with part number markings

(1) facing out.

Page 2135 of 5267

1. Install pilot bearing with Special Tools 9058 (1) and

C-4171 (2).

2. Install flywheel and clutch (Refer to 6 - CLUTCH/

CLUTCH DISC - INSTALLATION).

3. Install transmission (Refer to 21 - TRANSMISSION/

TRANSAXLE/MANUAL - INSTALLATION).

Page 2414 of 5267

DESCRIPTION - SRT10

The SRT-10 column has noSTARTposition on the key cylinder. The push starter button switch is mounted on the

Instrument panel center stack. All SRT-10 columns are Tilt columns, Standard cab trucks come with manual trans-

missions, Quad cab trucks come equipped with automatic transmissions.

DIAGNOSIS AND TESTING

STEERING COLUMN

If the vehicle is involved in a front end collision/the air bag has deployedthe column must be inspected. This

inspection will determine if the Column has collapsed. Inspect the columnmounting capsules visually and manually

push and pull them to check for separation or fractures. If capsules are fractured or have moved the column MUST

be replaced.

REMOVAL

WARNING: Before servicing the steering column the airbag system must be disarmed. Refer to electrical

restraint system for service procedures. Failure to do so may result in accidental deployment of the airbag

and possible personal injury.

CAUTION: All fasteners must be torqued to specification to ensure proper operation of the steering column.

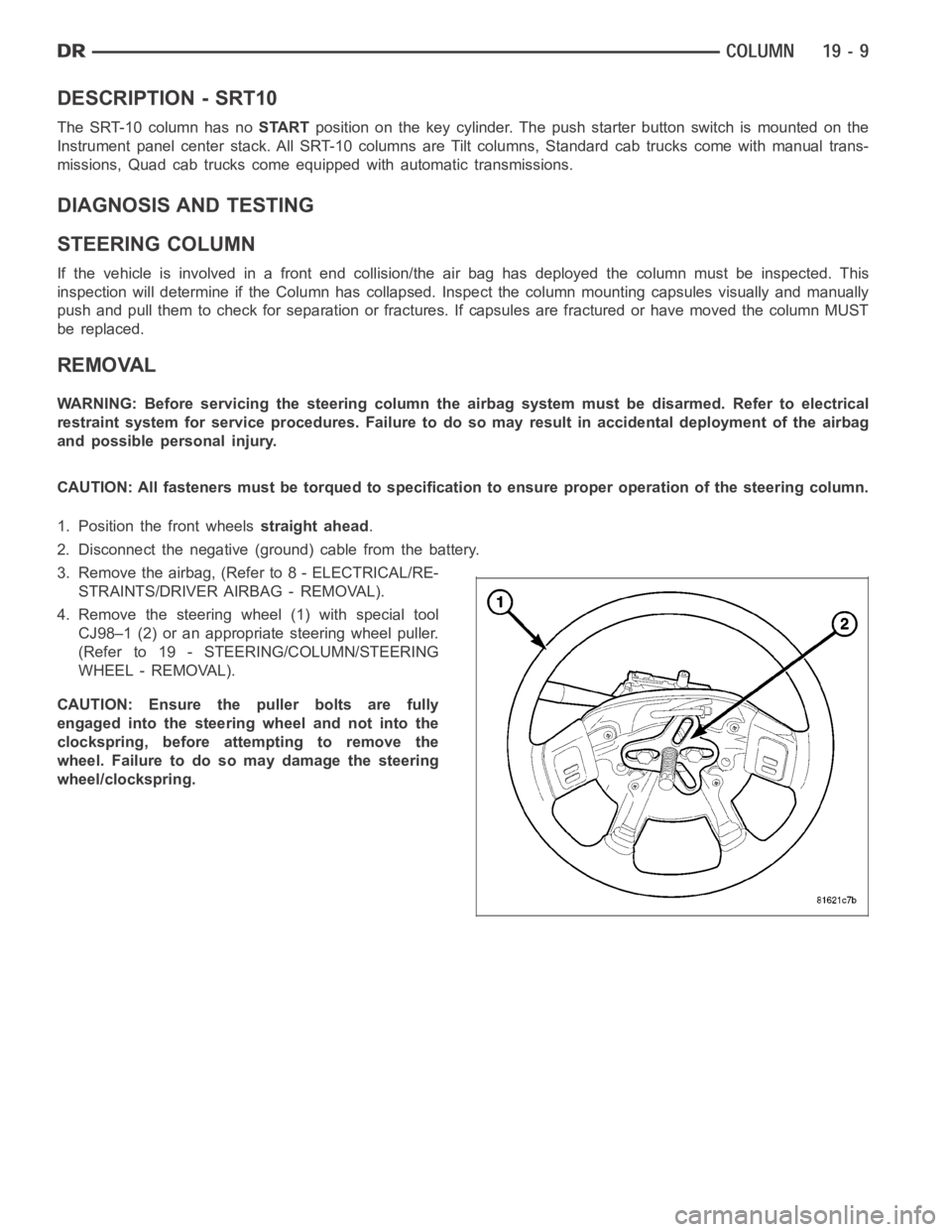

1. Position the front wheelsstraight ahead.

2. Disconnect the negative (ground) cable from the battery.

3. Remove the airbag, (Refer to 8 - ELECTRICAL/RE-

STRAINTS/DRIVER AIRBAG - REMOVAL).

4. Remove the steering wheel (1) with special tool

CJ98–1 (2) or an appropriate steering wheel puller.

(Refer to 19 - STEERING/COLUMN/STEERING

WHEEL - REMOVAL).

CAUTION: Ensure the puller bolts are fully

engaged into the steering wheel and not into the

clockspring, before attempting to remove the

wheel. Failure to do so may damage the steering

wheel/clockspring.

Page 2522 of 5267

TRANSMISSION AND TRANSFER CASE

TABLE OF CONTENTS

page page

MANUAL TRANSMISSION - G56 - SERVICE

INFORMATION...........................1

MANUAL TRANSMISSION - GETRAG 238 -

SERVICE INFORMATION..................70

MANUAL TRANSMISSION-T56 - SERVICE

INFORMATION.........................142

AUTOMATIC TRANSMISSION 42RLE -

ELECTRICAL DIAGNOSTICS..............203

AUTOMATIC TRANSMISSION 42RLE - SERVICE

INFORMATION.........................389

AUTOMATIC TRANSMISSION - 545RFE -

ELECTRICAL DIAGNOSTICS..............580

AUTOMATIC TRANSMISSION - 45RFE/545RFE -

SERVICE INFORMATION.................842

AUTOMATIC TRANSMISSION - 48RE - GAS -

ELECTRICAL DIAGNOSTICS..............987AUTOMATIC TRANSMISSION - 48RE - DIESEL -

ELECTRICAL DIAGNOSTICS.............1105

AUTOMATIC TRANSMISSION - 48RE - SERVICE

INFORMATION........................1266

TRANSFER CASE - ELECTRICAL

DIAGNOSTICS........................1499

TRANSFER CASE - NV241 GENII - SERVICE

INFORMATION........................1563

TRANSFER CASE - NV271 - SERVICE

INFORMATION........................1605

TRANSFER CASE - NV243 - SERVICE

INFORMATION........................1656

TRANSFER CASE - NV244 GENII - SERVICE

INFORMATION........................1700

TRANSFER CASE - NV273 - SERVICE

INFORMATION........................1743

page page

MANUAL TRANSMISSION - G56 - SERVICE

INFORMATION

DIAGNOSIS AND TESTING

MANUAL TRANSMISSION - G56 ............... 2

STANDARD PROCEDURE

DRAIN AND FILL ............................. 3

REMOVAL ..................................... 4

DISASSEMBLY ................................ 8

CLEANING ................................... 28INSPECTION ................................. 28

ASSEMBLY ................................... 29

INSTALLATION ............................... 58

ADJUSTMENTS

MAINSHAFT/COUNTERSHAFT BEARING

PRELOAD.................................. 62

SPECIFICATIONS

MANUAL TRANSMISSION-G56 ............... 65

SPECIAL TOOLS .............................. 67

Page 2523 of 5267

MANUAL TRANSMISSION - G56 - SERVICE INFORMATION

DIAGNOSIS AND TESTING

MANUAL TRANSMISSION - G56

LOW LUBRICANT LEVEL

A low transmission lubricant level is generally the result of a leak, inadequate lubricant fill or incorrect lubricant level

check.

Rear transmission leakswill be from the oil seals or component mating surfaces.

Front transmission leakswill be from the front input shaft retainer seal. Lubricant may drip from theclutchhousing

after extended operation. If leak is severe, it may contaminate the clutchdisc.

Lubricant level checkcan only be made when the vehicle is level and allowing the lubricant to settle for a minute

before checking. This will ensure an accurate check and avoid an under or overfill condition.

HARD SHIFTING

Hard shifting is usually caused by low lubricant level, improper or contaminated lubricants. This will cause noise,

excessive wear, internal bind, and hard shifting. Substantial lubricantleaks can result in gear, shift rail, synchro, and

bearing damage. The first indications of component damage is usually hardshifting and noise.

Shift component damage, clutch adjustment, worn pressure plate or disc are also causes of increased shift effort. If

clutch problem is advanced, gear clash during shifts can result. Worn or damaged synchronizer rings can cause

gear clash when shifting into any forward gear. In some new or rebuilt transmissions, new synchro rings may tend

to stick slightly causing hard or noisy shifts. In most cases, this condition will decline as the rings wear-in.

TRANSMISSION NOISE

Most manual transmissions make some noise during normal operation. Rotating gears generate a mild whine that is

audible, but generally only at extreme speeds.

Severe, highly audible transmission noise is generally the initial indicator of a lubricant problem. Insufficient,

improper or contaminated lubricant will promote rapid wear of gears, synchronizer rings, shift rails, forks and bear-

ings. The overheating caused by a lubricant problem, can also lead to gear and bearing damage.

Page 2586 of 5267

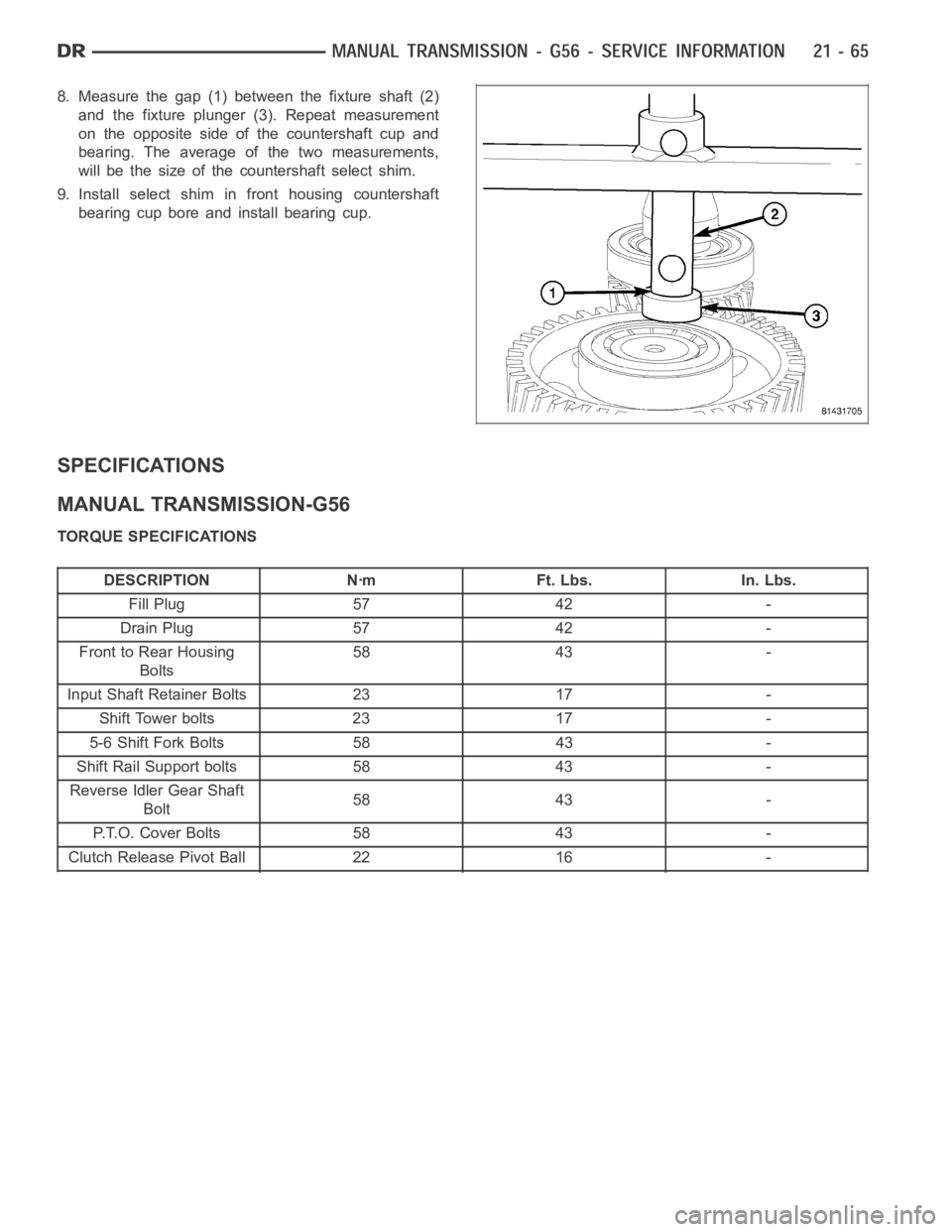

8. Measure the gap (1) between the fixture shaft (2)

and the fixture plunger (3). Repeat measurement

on the opposite side of the countershaft cup and

bearing. The average of the two measurements,

will be the size of the countershaft select shim.

9. Install select shim in front housing countershaft

bearing cup bore and install bearing cup.

SPECIFICATIONS

MANUAL TRANSMISSION-G56

TORQUE SPECIFICATIONS

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Fill Plug 57 42 -

Drain Plug 57 42 -

Front to Rear Housing

Bolts58 43 -

Input Shaft Retainer Bolts 23 17 -

Shift Tower bolts 23 17 -

5-6 Shift Fork Bolts 58 43 -

Shift Rail Support bolts 58 43 -

Reverse Idler Gear Shaft

Bolt58 43 -

P.T.O. Cover Bolts 58 43 -

Clutch Release Pivot Ball 22 16 -

Page 2591 of 5267

page page

MANUAL TRANSMISSION - GETRAG 238 -

SERVICE INFORMATION

DIAGNOSIS AND TESTING

MANUAL TRANSMISSION - GETRAG 238 . . . . . 71

STANDARD PROCEDURE

DRAIN AND FILL ............................ 71

REMOVAL .................................... 72

DISASSEMBLY ............................... 74CLEANING .................................. 100

INSPECTION . . .............................. 100

ASSEMBLY .................................. 103

INSTALLATION .............................. 135

SPECIFICATIONS

MANUAL TRANSMISSION - GETRAG 238 . . . . 136

SPECIAL TOOLS ............................ 138

Page 2592 of 5267

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

DIAGNOSIS AND TESTING

MANUAL TRANSMISSION - GETRAG 238

LOW LUBRICANT LEVEL

A low transmission lubricant level is generally the result of a leak, inadequate lubricant fill or incorrect lubricant level

check.

Rear transmission leakswill be from the oil seals or transfer case front seal on 4x4.

Front transmission leakswill be from the front input shaft retainer seal. Lubricant may drip from theclutchhousing

after extended operation. If leak is severe, it may contaminate the clutchdisc.

Lubricant level checkcan only be made when the vehicle is level and allowing the lubricant to settle for a minute

before checking. This will ensure an accurate check and avoid an under or overfill condition.

HARD SHIFTING

Hard shifting can be caused by low lubricant level, improper or contaminated lubricants. This will cause noise,

excessive wear, internal bind, and hard shifting. Substantial lubricantleaks can result in gear, shift rail, synchro, and

bearing damage. The first indications of component damage is usually hardshifting and noise.

Shift component damage, clutch adjustment, worn pressure plate or disc, can increased shift effort. If clutch problem

is advanced, gear clash during shifts can result. Worn or damaged synchronizer rings can cause gear clash when

shifting into any forward gear. In some new or rebuilt transmissions, new synchro rings may tend to stick slightly

causing hard or noisy shifts. In most cases, this condition will decline asthe rings wear-in.

TRANSMISSION NOISE

Most manual transmissions make some noise during normal operation. Rotating gears generate a mild whine that is

audible, but generally only at extreme speeds.

Severe, highly audible transmission noise is generally the initial indicator of a lubricant problem. Insufficient,

improper or contaminated lubricant will promote rapid wear of gears, synchronizer rings, shift rails, forks and bear-

ings. The overheating caused by a lubricant problem, can also lead to gear and bearing damage.

STANDARD PROCEDURE

DRAIN AND FILL

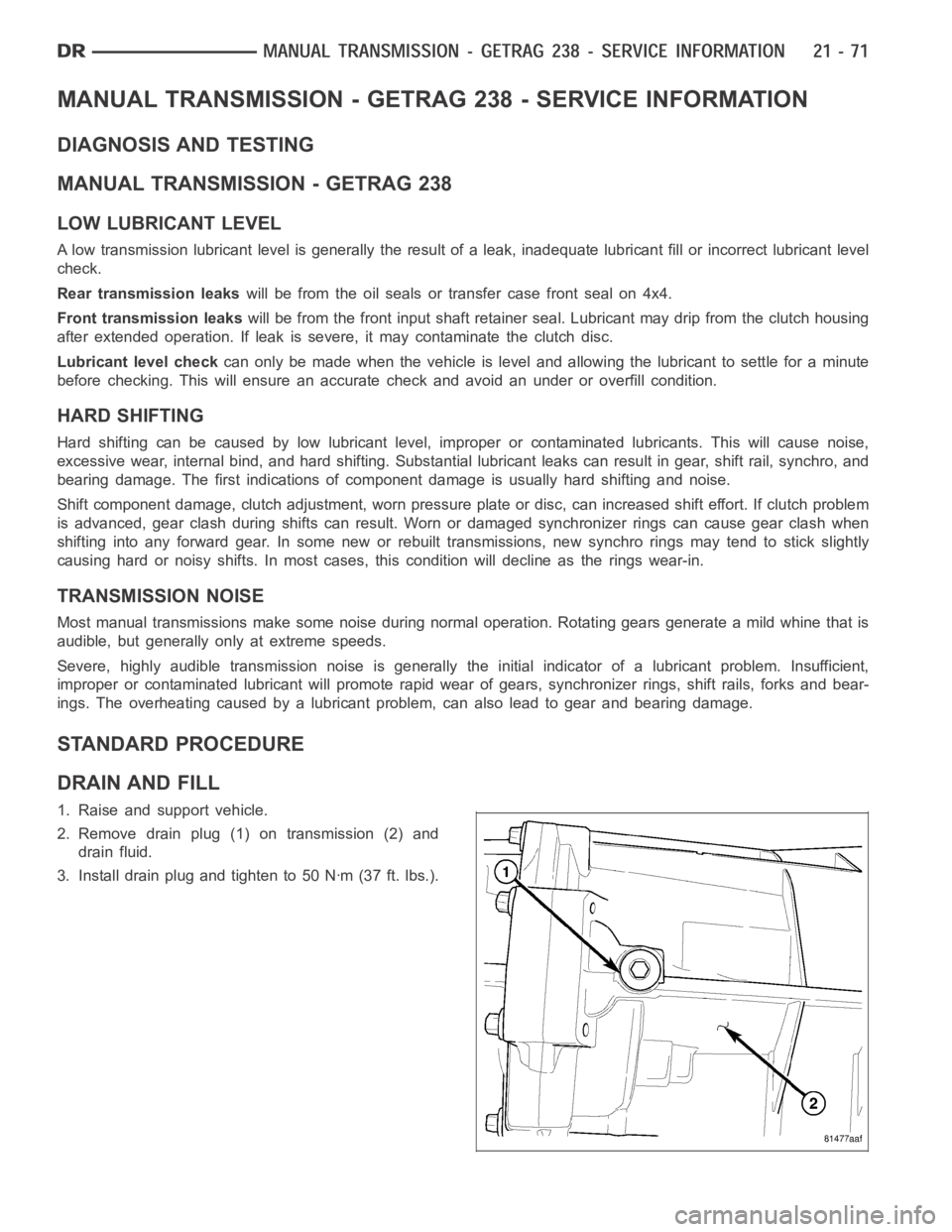

1. Raise and support vehicle.

2. Remove drain plug (1) on transmission (2) and

drain fluid.

3. Install drain plug and tighten to 50 Nꞏm (37 ft. lbs.).

Page 2657 of 5267

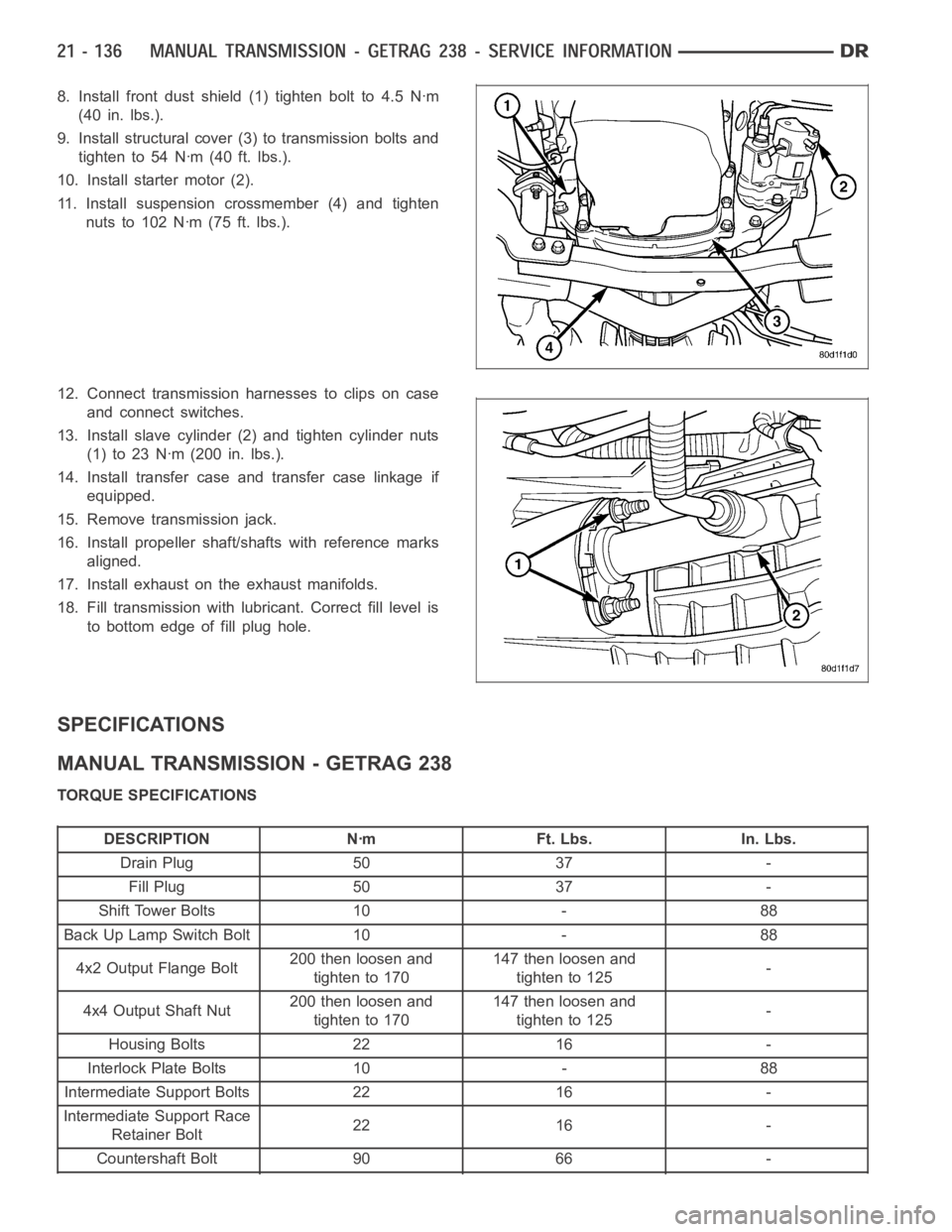

8. Install front dust shield (1) tighten bolt to 4.5 Nꞏm

(40 in. lbs.).

9. Install structural cover (3) to transmission bolts and

tighten to 54 Nꞏm (40 ft. lbs.).

10. Install starter motor (2).

11. Install suspension crossmember (4) and tighten

nuts to 102 Nꞏm (75 ft. lbs.).

12. Connect transmission harnesses to clips on case

and connect switches.

13. Install slave cylinder (2) and tighten cylinder nuts

(1)to23Nꞏm(200in.lbs.).

14. Install transfer case and transfer case linkage if

equipped.

15. Remove transmission jack.

16. Install propeller shaft/shafts with reference marks

aligned.

17. Install exhaust on the exhaust manifolds.

18. Fill transmission with lubricant. Correct fill level is

to bottom edge of fill plug hole.

SPECIFICATIONS

MANUAL TRANSMISSION - GETRAG 238

TORQUE SPECIFICATIONS

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Drain Plug 50 37 -

Fill Plug 50 37 -

Shift Tower Bolts 10 - 88

Back Up Lamp Switch Bolt 10 - 88

4x2 Output Flange Bolt200 then loosen and

tighten to 170147 then loosen and

tighten to 125-

4x4 Output Shaft Nut200 then loosen and

tighten to 170147 then loosen and

tighten to 125-

Housing Bolts 22 16 -

Interlock Plate Bolts 10 - 88

Intermediate Support Bolts 22 16 -

Intermediate Support Race

Retainer Bolt22 16 -

Countershaft Bolt 90 66 -

Page 2663 of 5267

page page

MANUAL TRANSMISSION-T56 - SERVICE

INFORMATION

DIAGNOSIS AND TESTING

MANUAL TRANSMISSION - T56 ............. 143

STANDARD PROCEDURE - DRAIN AND FILL . . 143

REMOVAL ................................... 144

DISASSEMBLY .............................. 146

CLEANING .................................. 168

INSPECTION ................................ 168

ASSEMBLY .................................. 169

INSTALLATION .............................. 189

ADJUSTMENTS

ADUSTMENTS ............................ 191

SPECIFICATIONS

MANUAL TRANSMISSION - T56 ............. 192SPECIAL TOOLS ............................ 194

SEAL-EXTENSION HOUSING

REMOVAL ................................... 198

INSTALLATION .............................. 198

SHAFT-INPUT

REMOVAL ................................... 199

INSTALLATION .............................. 200

SOLENOID-REVERSE LOCKOUT

DESCRIPTION ............................... 201

OPERATION ................................. 201

SOLENOID-REVERSE LOCK-OUT

DESCRIPTION ............................... 202

OPERATION ................................. 202