service DODGE RAM SRT-10 2006 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 44 of 5267

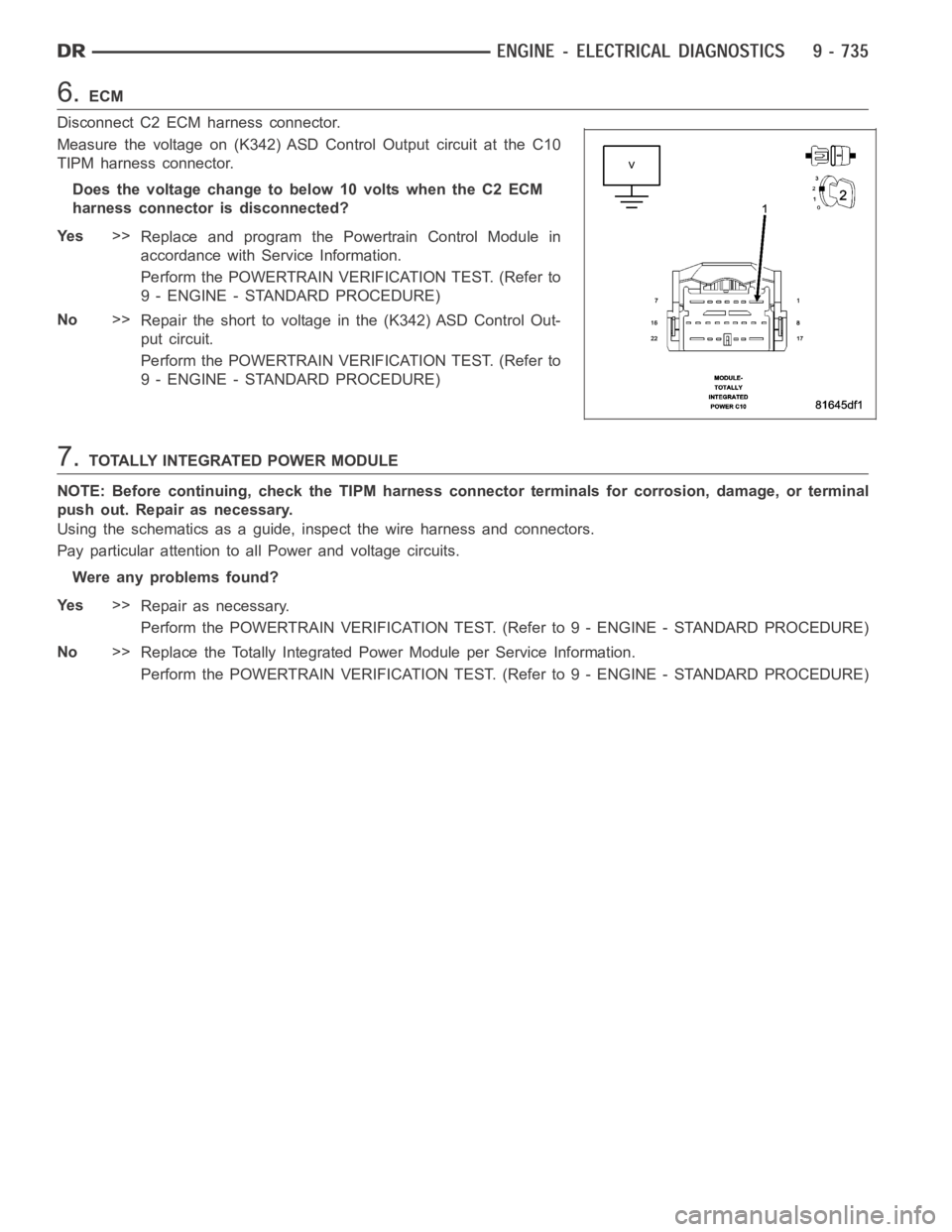

6.ECM

Disconnect C2 ECM harness connector.

Measure the voltage on (K342) ASD Control Output circuit at the C10

TIPM harness connector.

Does the voltage change to below 10 volts when the C2 ECM

harness connector is disconnected?

Ye s>>

Replace and program the Powertrain Control Module in

accordance with Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Repair the short to voltage in the (K342) ASD Control Out-

put circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

7.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to allPower and voltage circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 48 of 5267

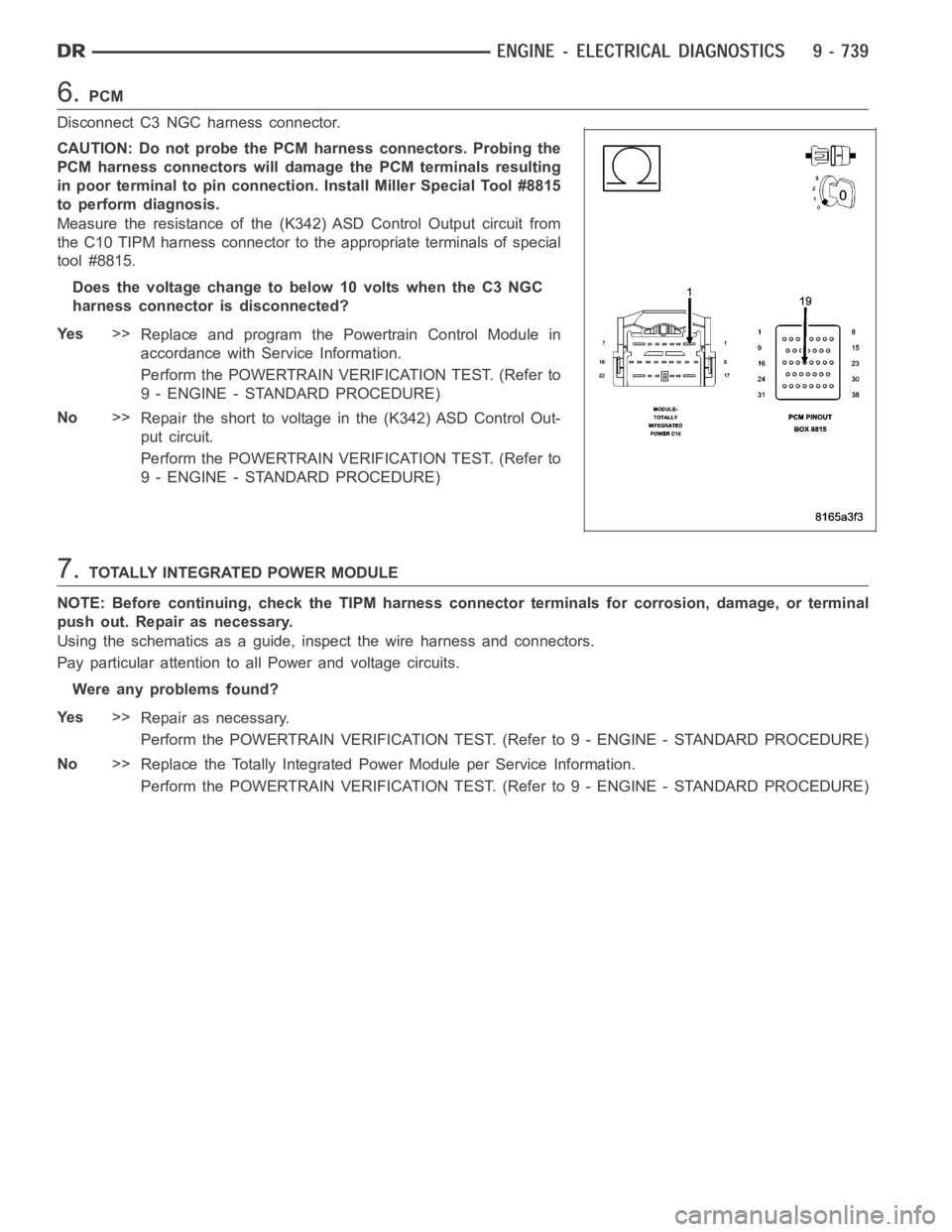

6.PCM

Disconnect C3 NGC harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

Measure the resistance of the (K342) ASD Control Output circuit from

the C10 TIPM harness connector to the appropriate terminals of special

tool #8815.

Does the voltage change to below 10 volts when the C3 NGC

harness connector is disconnected?

Ye s>>

Replace and program the Powertrain Control Module in

accordance with Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Repair the short to voltage in the (K342) ASD Control Out-

put circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

7.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to allPower and voltage circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 52 of 5267

6.PCM Turn the ignition off.

Disconnect C3 NGC harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the PCM harness connectors will damage

the PCM terminals resulting in poor terminal to pin connection. Install Miller Special Tool #8815 and #8815-1

to perform diagnosis.

With a voltmeter, use Negative lead of the voltmeter along with terminal probe tool #6801, probe the (K342) ASD

Control Output circuit at the appropriate terminals of special tool #8815.

With the Positive lead of the voltmeter along with terminal probe tool #6801, back probe the (K342) ASD Control

Output circuit at the C10 TIPM harness connector.

Start the engine and allow it to idle.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Measure the voltage of the (K342) ASD Control Output circuit.

Is the voltage above 0.001 of a volt (1.0mV) for any of the Ignition Coil ASD Control Output circuits?

Ye s>>

Repair the excessive resistance in the (K342) ASD Control Output circuit tothePCM.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module in accordance with Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

7.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to allPower and voltage circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 55 of 5267

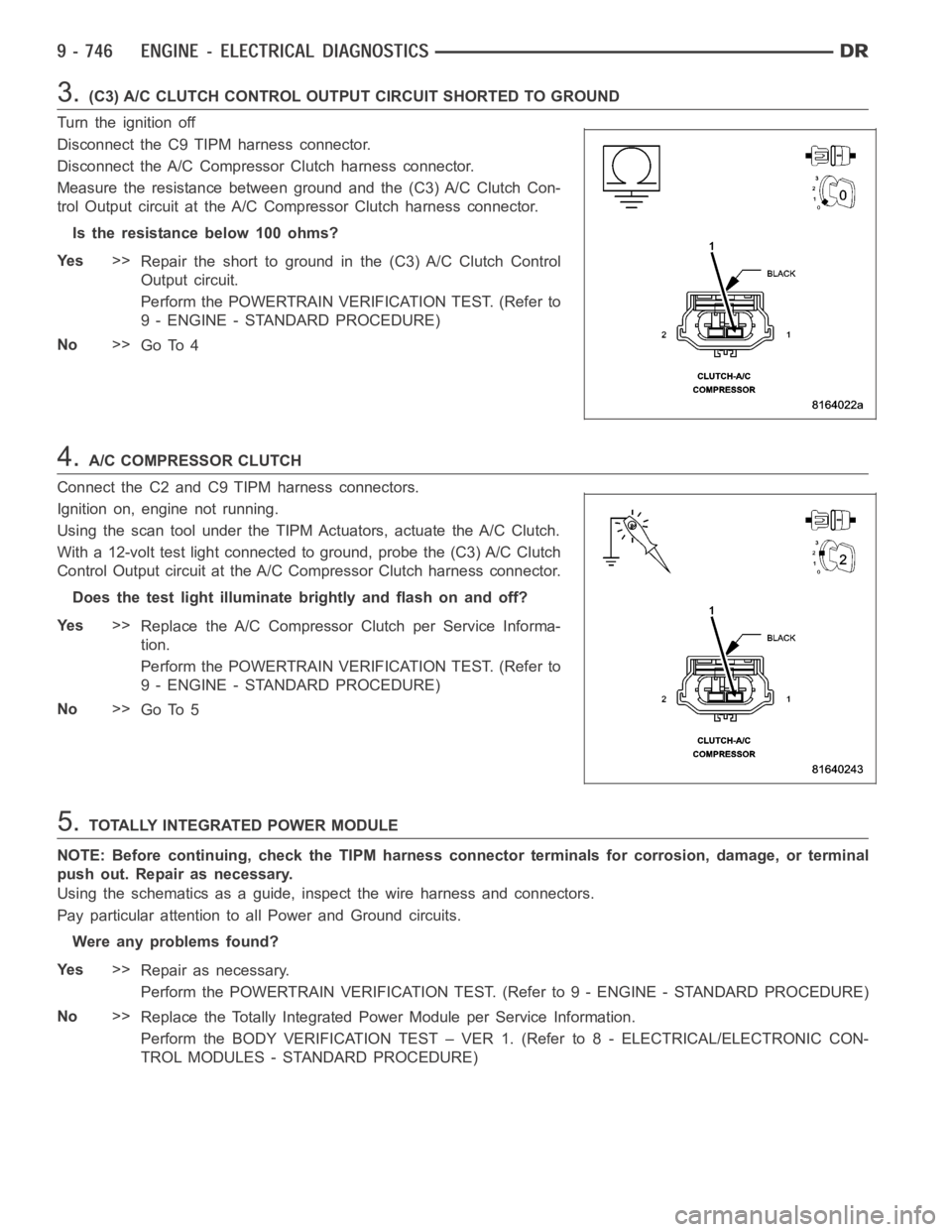

3.(C3) A/C CLUTCH CONTROL OUTPUT CIRCUIT SHORTED TO GROUND

Turn the ignition off

Disconnect the C9 TIPM harness connector.

Disconnect the A/C Compressor Clutch harness connector.

Measure the resistance between ground and the (C3) A/C Clutch Con-

trol Output circuit at the A/C Compressor Clutch harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (C3) A/C Clutch Control

Output circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.A/C COMPRESSOR CLUTCH

Connect the C2 and C9 TIPM harness connectors.

Ignition on, engine not running.

Using the scan tool under the TIPM Actuators, actuate the A/C Clutch.

With a 12-volt test light connected to ground, probe the (C3) A/C Clutch

Control Output circuit at the A/C Compressor Clutch harness connector.

Does the test light illuminate brightly and flash on and off?

Ye s>>

Replace the A/C Compressor Clutch per Service Informa-

tion.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to all Power and Ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform the BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES - STANDARD PROCEDURE)

Page 58 of 5267

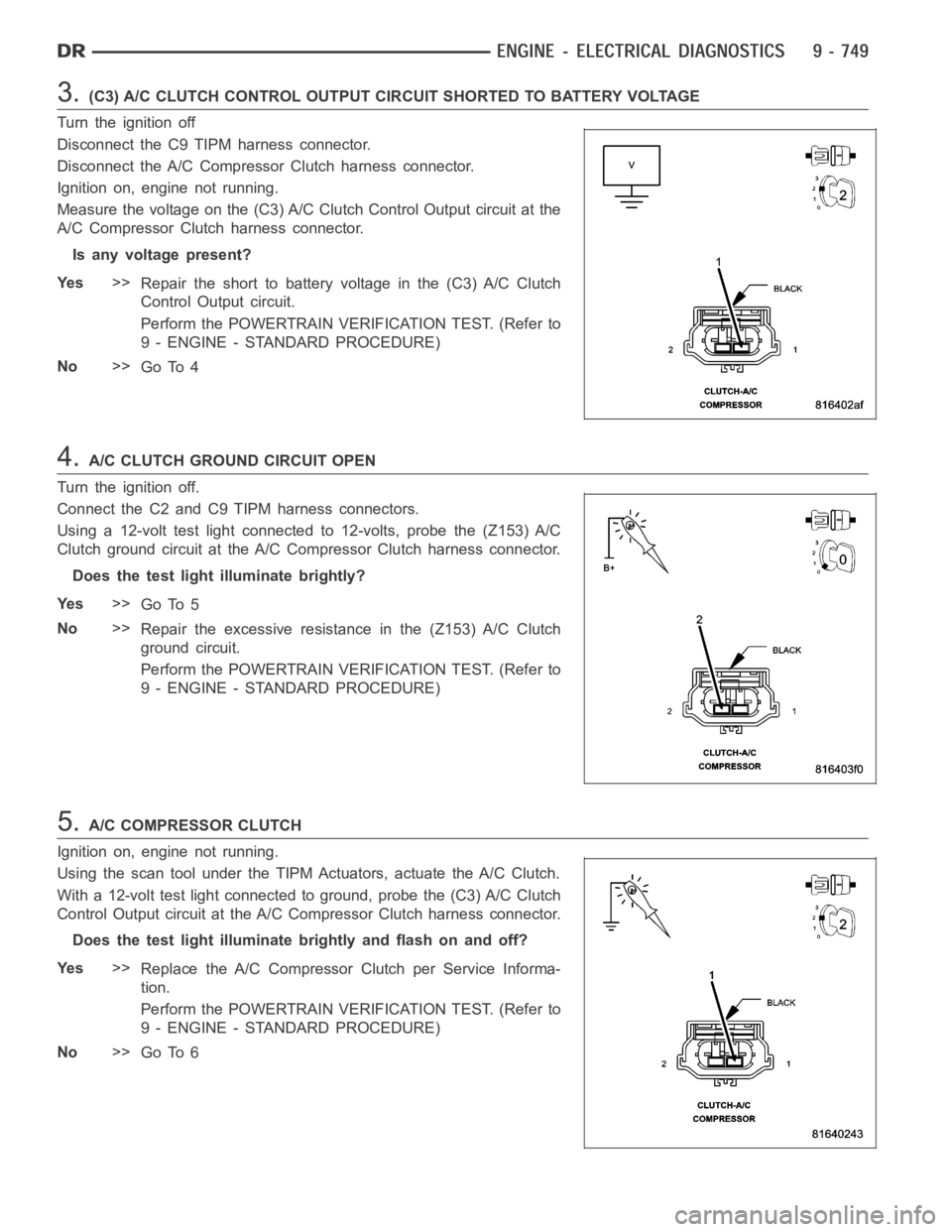

3.(C3) A/C CLUTCH CONTROL OUTPUT CIRCUIT SHORTED TO BATTERY VOLTAGE

Turn the ignition off

Disconnect the C9 TIPM harness connector.

Disconnect the A/C Compressor Clutch harness connector.

Ignition on, engine not running.

Measure the voltage on the (C3) A/C Clutch Control Output circuit at the

A/C Compressor Clutch harness connector.

Is any voltage present?

Ye s>>

Repair the short to battery voltage in the (C3) A/C Clutch

Control Output circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

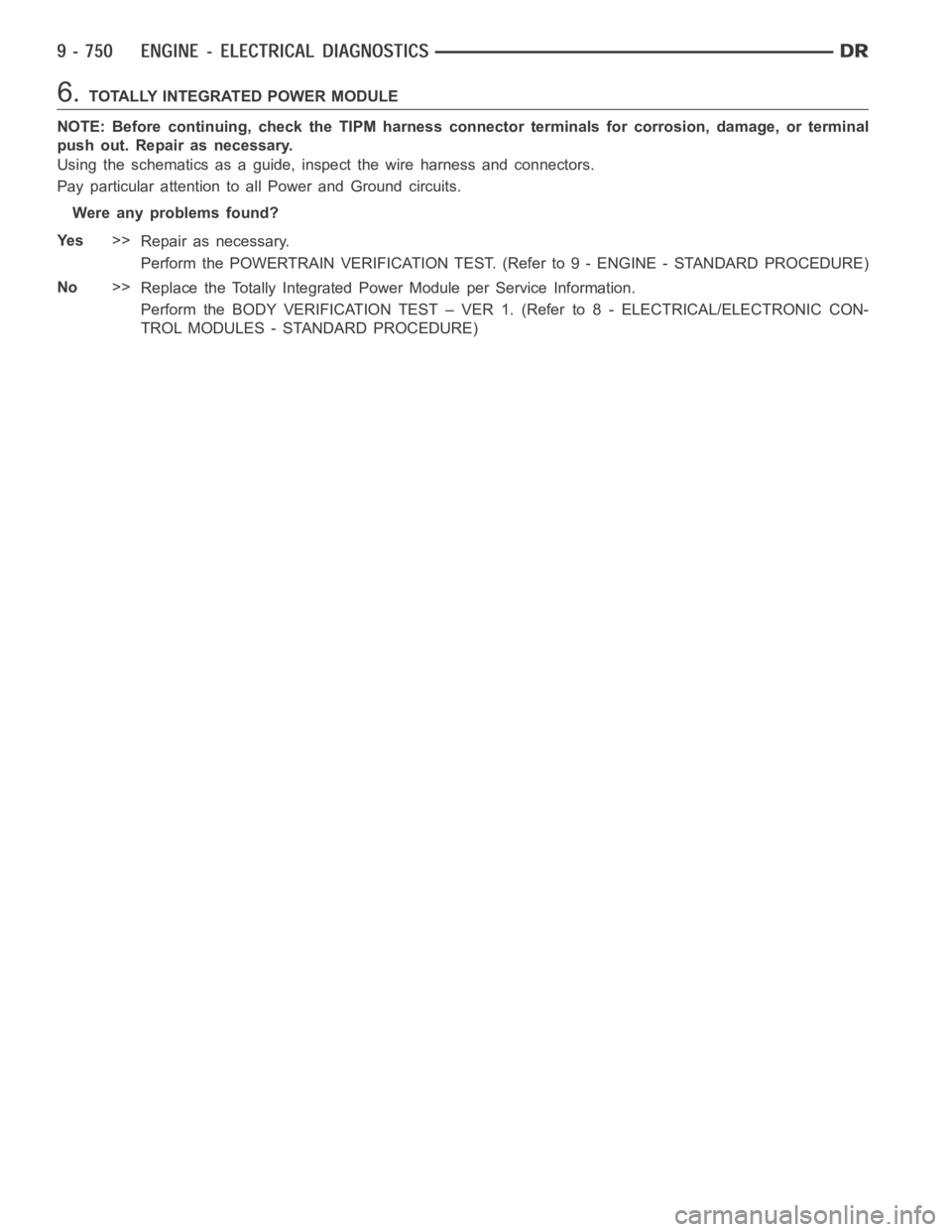

4.A/C CLUTCH GROUND CIRCUIT OPEN

Turn the ignition off.

Connect the C2 and C9 TIPM harness connectors.

Using a 12-volt test light connected to 12-volts, probe the (Z153) A/C

Clutch ground circuit at the A/C Compressor Clutch harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 5

No>>

Repair the excessive resistance in the (Z153) A/C Clutch

ground circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

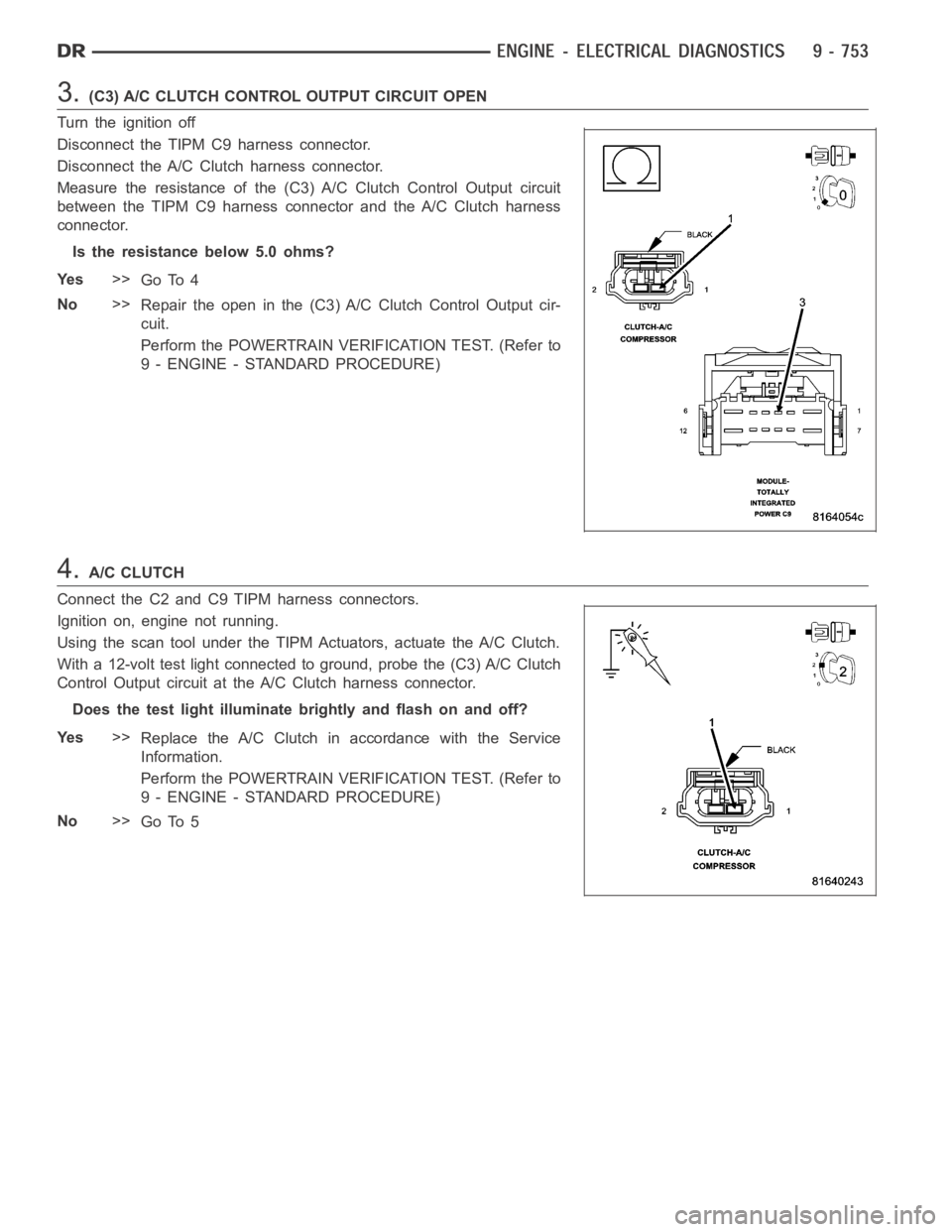

5.A/C COMPRESSOR CLUTCH

Ignition on, engine not running.

Using the scan tool under the TIPM Actuators, actuate the A/C Clutch.

With a 12-volt test light connected to ground, probe the (C3) A/C Clutch

Control Output circuit at the A/C Compressor Clutch harness connector.

Does the test light illuminate brightly and flash on and off?

Ye s>>

Replace the A/C Compressor Clutch per Service Informa-

tion.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

Page 59 of 5267

6.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to all Power and Ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform the BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES - STANDARD PROCEDURE)

Page 62 of 5267

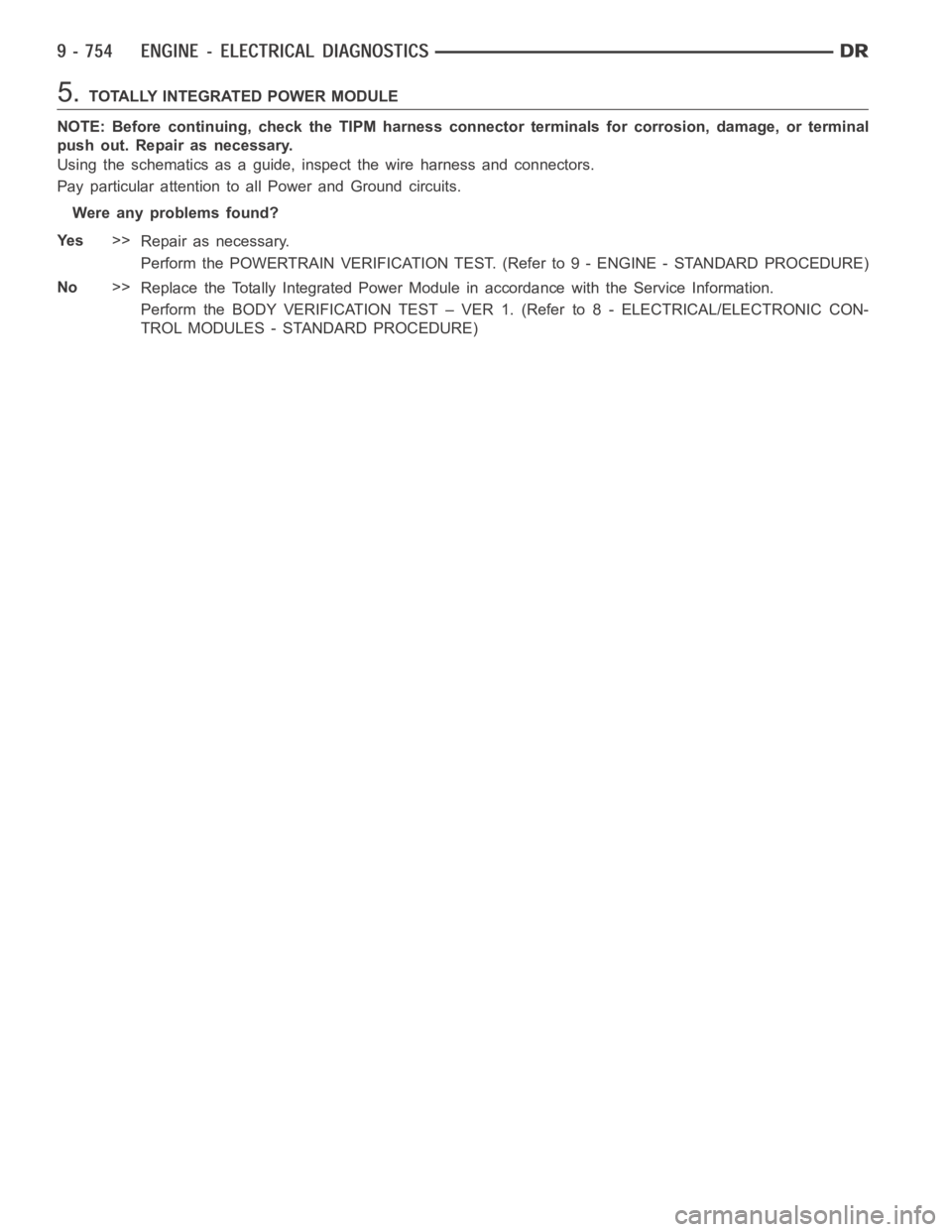

3.(C3) A/C CLUTCH CONTROL OUTPUT CIRCUIT OPEN

Turn the ignition off

Disconnect the TIPM C9 harness connector.

Disconnect the A/C Clutch harness connector.

Measure the resistance of the (C3) A/C Clutch Control Output circuit

between the TIPM C9 harness connector and the A/C Clutch harness

connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 4

No>>

Repair the open in the (C3) A/C Clutch Control Output cir-

cuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

4.A/C CLUTCH

Connect the C2 and C9 TIPM harness connectors.

Ignition on, engine not running.

Using the scan tool under the TIPM Actuators, actuate the A/C Clutch.

With a 12-volt test light connected to ground, probe the (C3) A/C Clutch

Control Output circuit at the A/C Clutch harness connector.

Does the test light illuminate brightly and flash on and off?

Ye s>>

Replace the A/C Clutch in accordance with the Service

Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

Page 63 of 5267

5.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to all Power and Ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module in accordance with the Service Information.

Perform the BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES - STANDARD PROCEDURE)

Page 66 of 5267

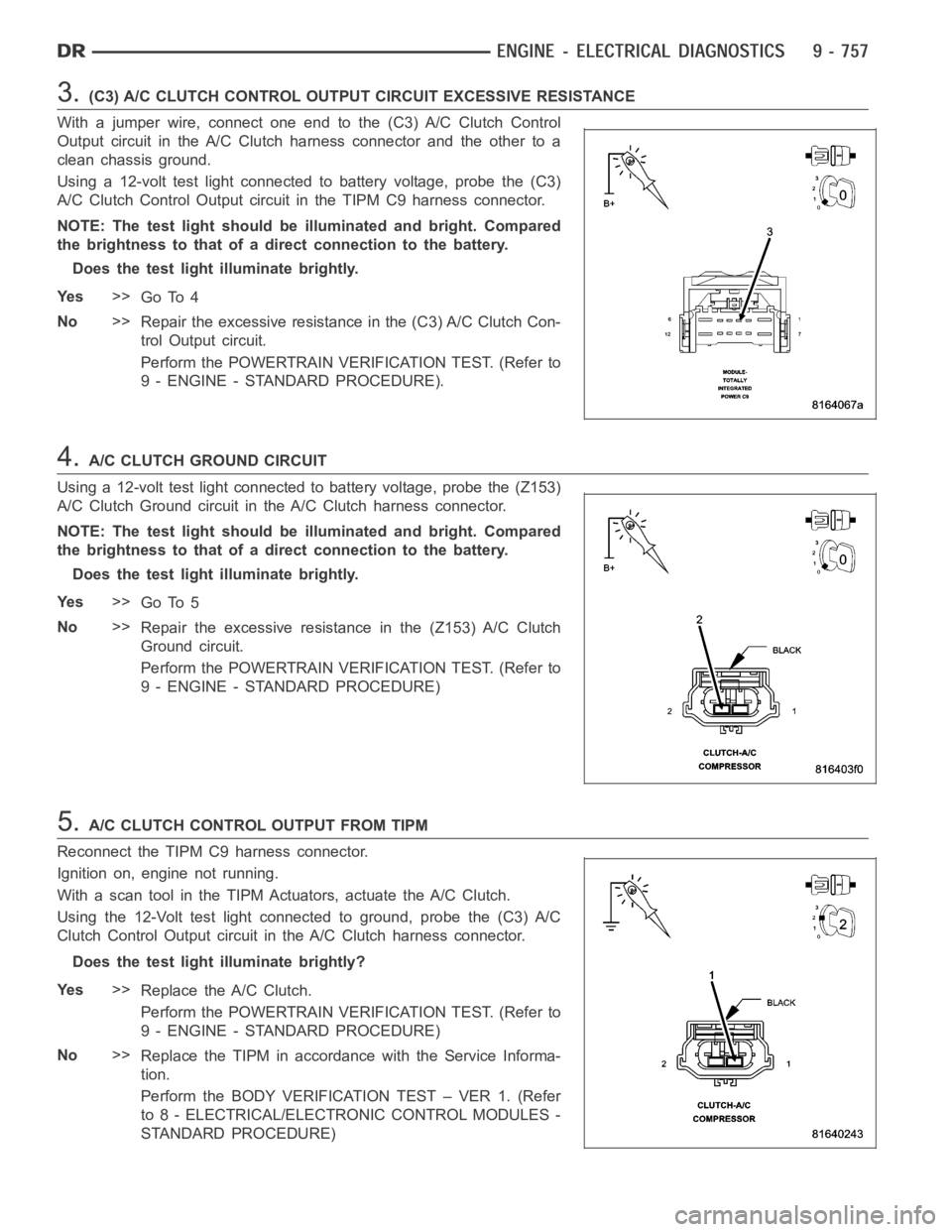

3.(C3) A/C CLUTCH CONTROL OUTPUT CIRCUIT EXCESSIVE RESISTANCE

With a jumper wire, connect one end to the (C3) A/C Clutch Control

Output circuit in the A/C Clutch harness connector and the other to a

clean chassis ground.

Using a 12-volt test light connected to battery voltage, probe the (C3)

A/C Clutch Control Output circuit in the TIPM C9 harness connector.

NOTE: The test light should be illuminated and bright. Compared

the brightness to that of a direct connection to the battery.

Does the test light illuminate brightly.

Ye s>>

Go To 4

No>>

Repair the excessive resistance in the (C3) A/C Clutch Con-

trol Output circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE).

4.A/C CLUTCH GROUND CIRCUIT

Using a 12-volt test light connected to battery voltage, probe the (Z153)

A/C Clutch Ground circuit in the A/C Clutch harness connector.

NOTE: The test light should be illuminated and bright. Compared

the brightness to that of a direct connection to the battery.

Does the test light illuminate brightly.

Ye s>>

Go To 5

No>>

Repair the excessive resistance in the (Z153) A/C Clutch

Ground circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

5.A/C CLUTCH CONTROL OUTPUT FROM TIPM

Reconnect the TIPM C9 harness connector.

Ignition on, engine not running.

With a scan tool in the TIPM Actuators, actuate the A/C Clutch.

Using the 12-Volt test light connected to ground, probe the (C3) A/C

Clutch Control Output circuit in the A/C Clutch harness connector.

Does the test light illuminate brightly?

Ye s>>

Replace the A/C Clutch.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the TIPM in accordance with the Service Informa-

tion.

Perform the BODY VERIFICATION TEST – VER 1. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE)

Page 69 of 5267

4.TIPM OPERATION

Reconnect the C9 TIPM harness connector.

Using a 12-volt test light connected ground, probe the (T40) Stater Relay Output circuit in the Starter Relay harness

connector.

Crank the engine.

Does the test light illuminate?

Ye s>>

Go To 5

No>>

Replace the TIPM is accordance with the Service information

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

5.STARTER RELAY

Turn the ignition off.

Install the Starter Relay.

NOTE: The Stater Solenoid harness connector must still be disconnected atthis time.

Crank the engine.

Using a 12-volt test light connected ground, probe the (T750) Stater RelayOutput circuit in the Starter Solenoid

harness connector.

Does the test light illuminate?

Ye s>>

Replace the Starter.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Starter Relay.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)