differential DODGE RAM SRT-10 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4230 of 5267

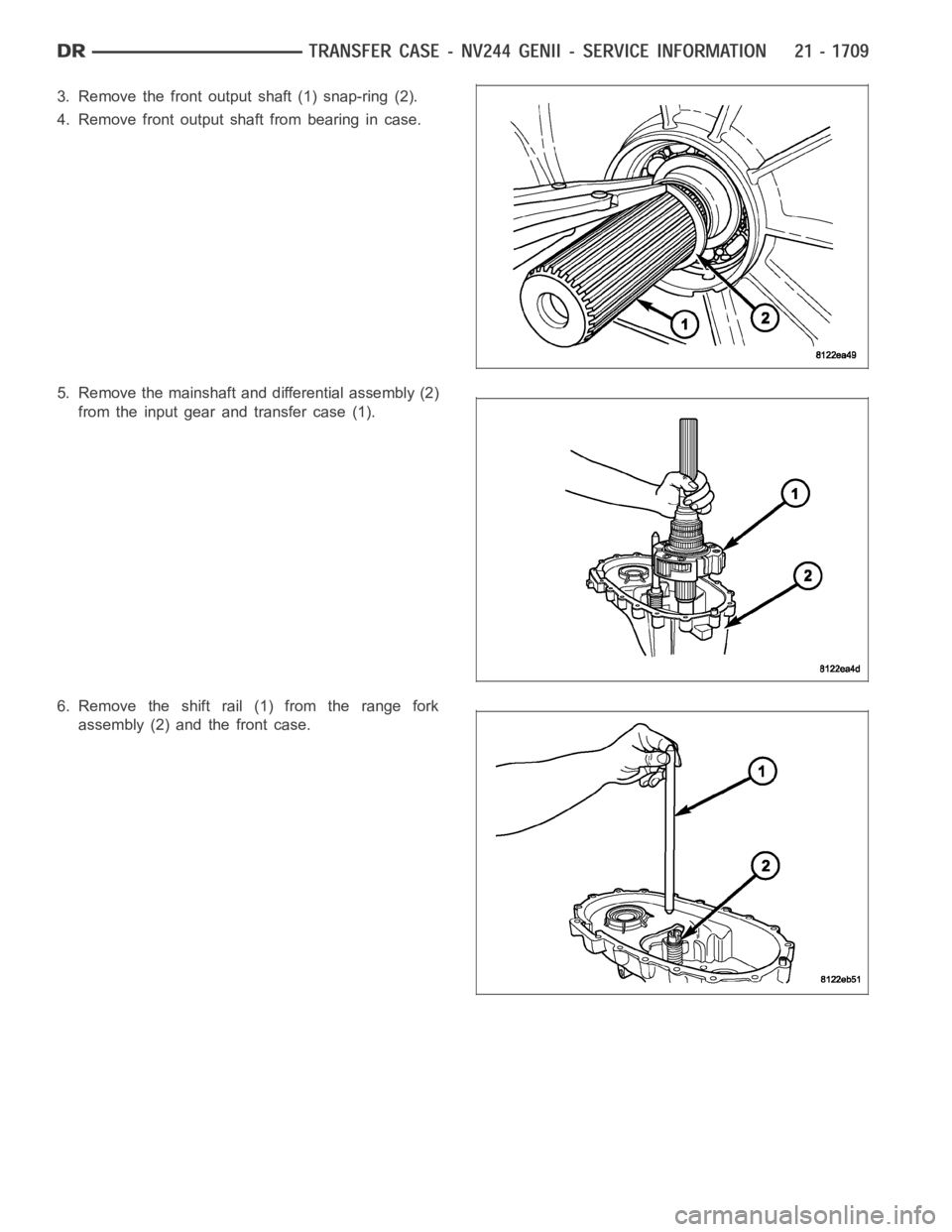

3. Remove the front output shaft (1) snap-ring (2).

4. Remove front output shaft from bearing in case.

5. Remove the mainshaft and differential assembly (2)

from the input gear and transfer case (1).

6. Remove the shift rail (1) from the range fork

assembly (2) and the front case.

Page 4233 of 5267

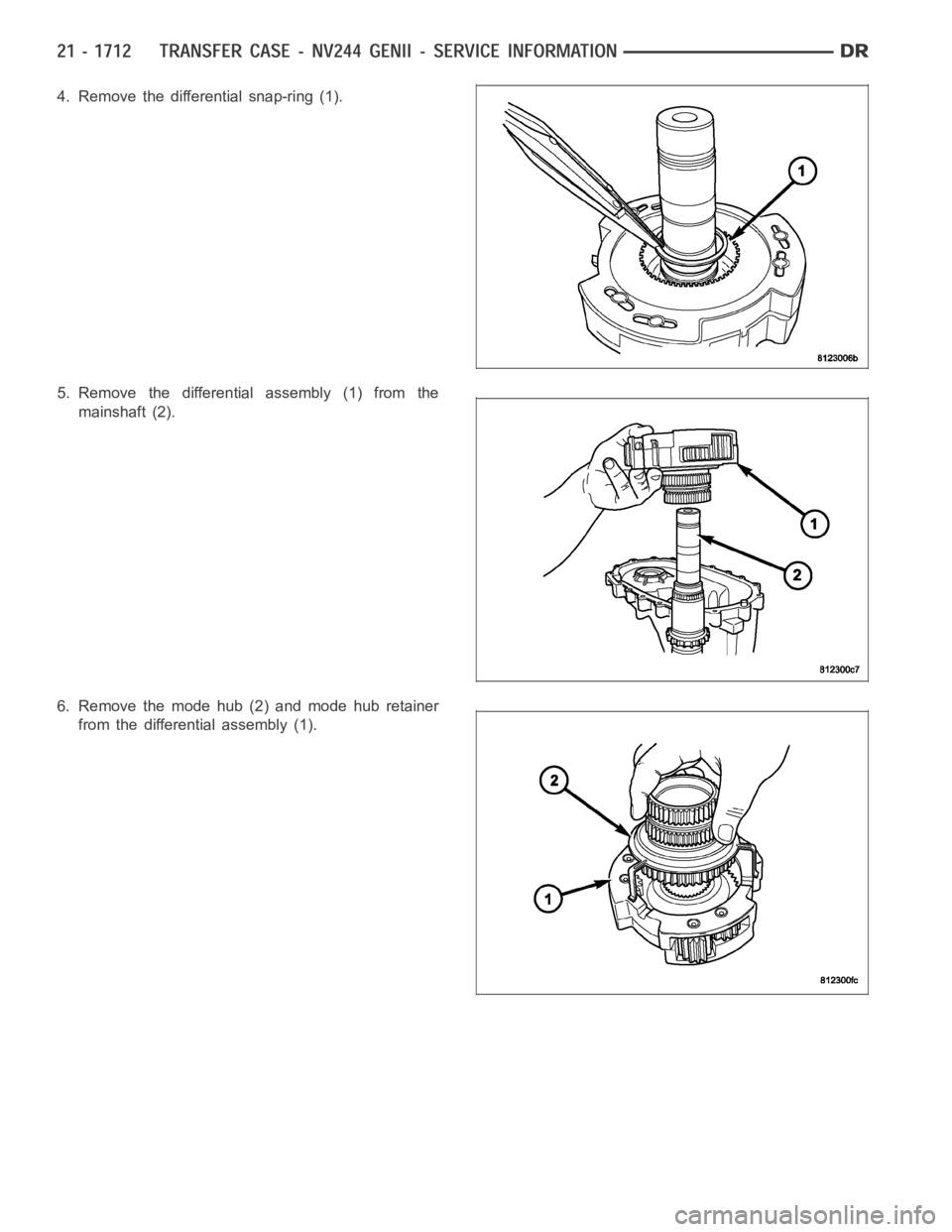

4. Remove the differential snap-ring (1).

5. Remove the differential assembly (1) from the

mainshaft (2).

6. Remove the mode hub (2) and mode hub retainer

from the differential assembly (1).

Page 4242 of 5267

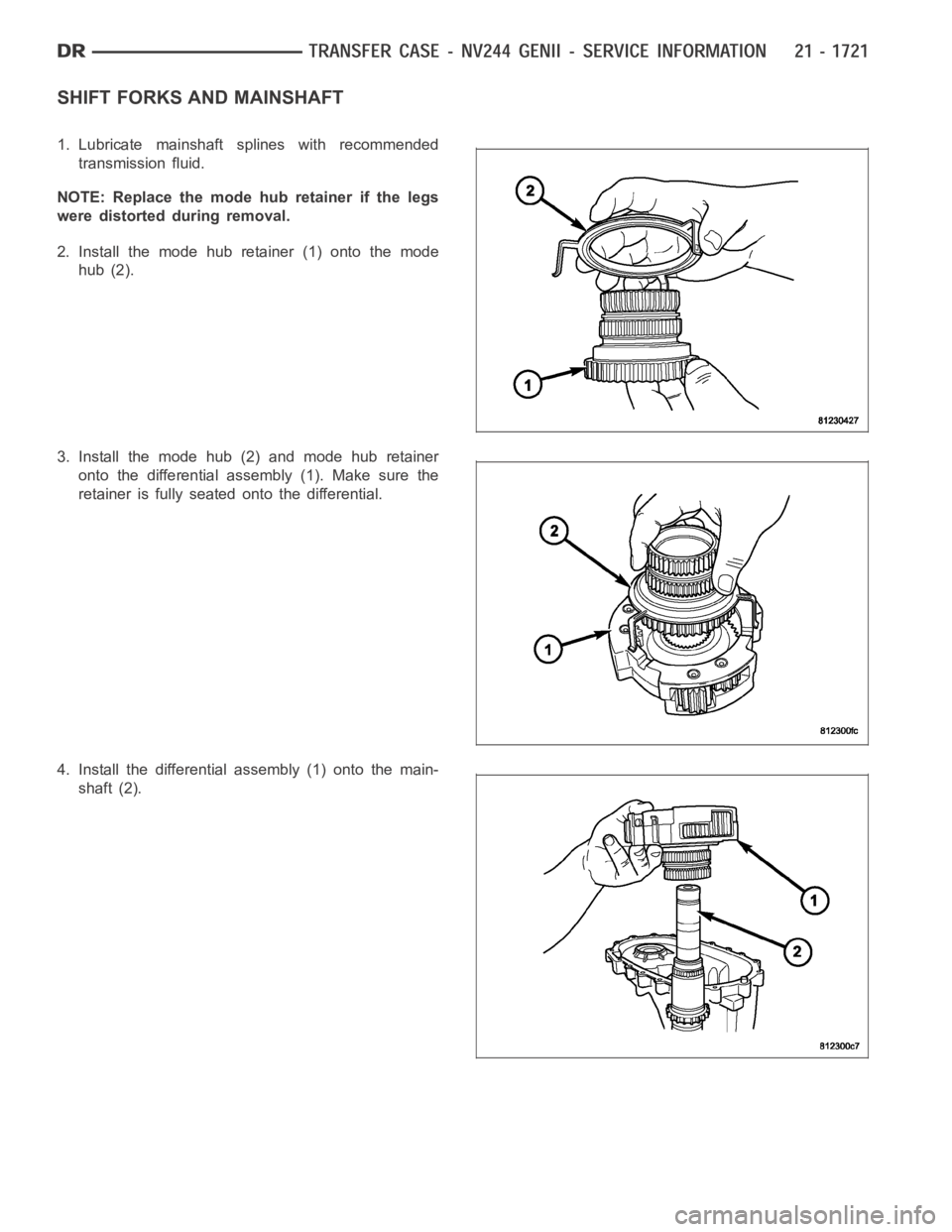

SHIFT FORKS AND MAINSHAFT

1. Lubricate mainshaft splines with recommended

transmission fluid.

NOTE: Replace the mode hub retainer if the legs

were distorted during removal.

2. Install the mode hub retainer (1) onto the mode

hub (2).

3. Install the mode hub (2) and mode hub retainer

onto the differential assembly (1). Make sure the

retainer is fully seated onto the differential.

4. Install the differential assembly (1) onto the main-

shaft (2).

Page 4243 of 5267

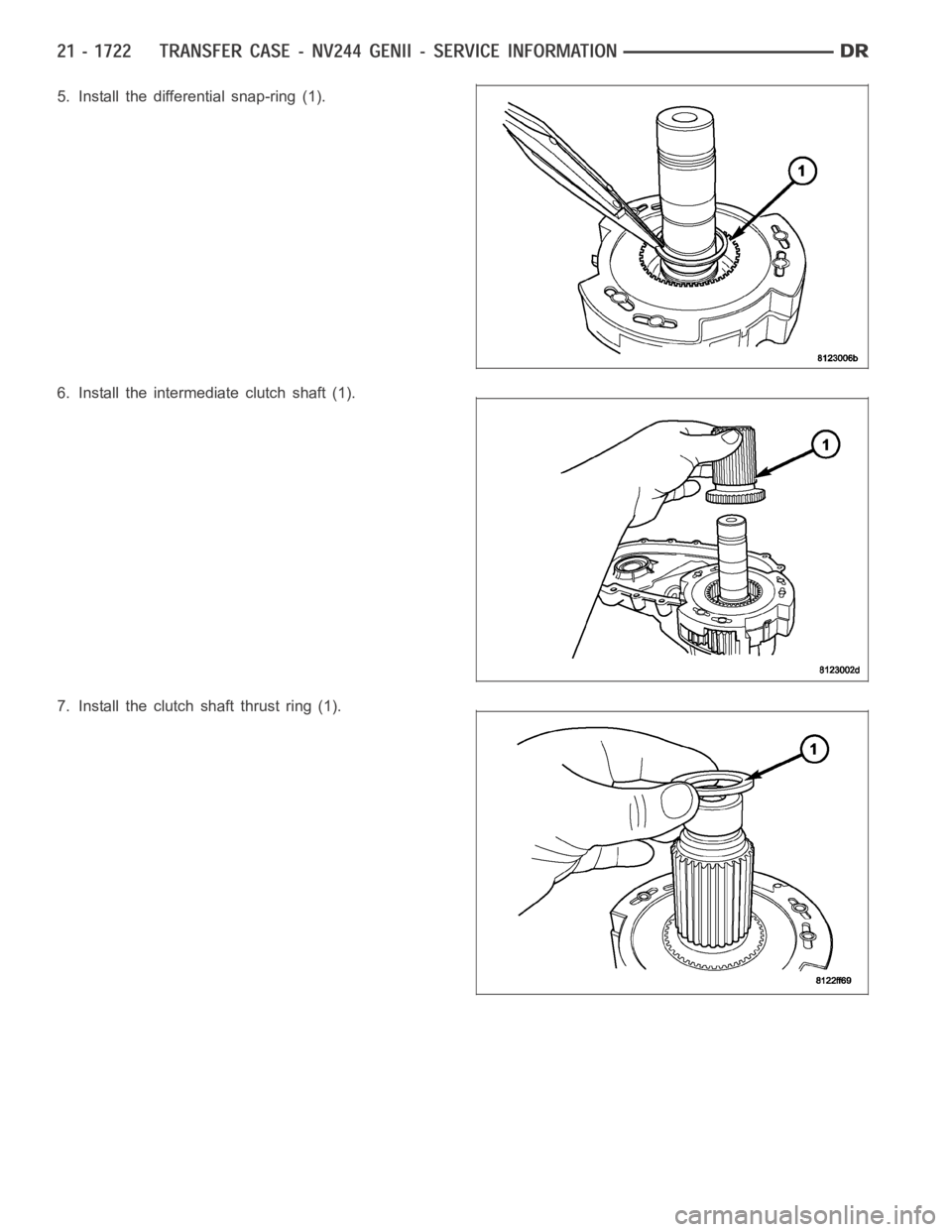

5. Install the differential snap-ring (1).

6. Install the intermediate clutch shaft (1).

7. Install the clutch shaft thrust ring (1).

Page 4245 of 5267

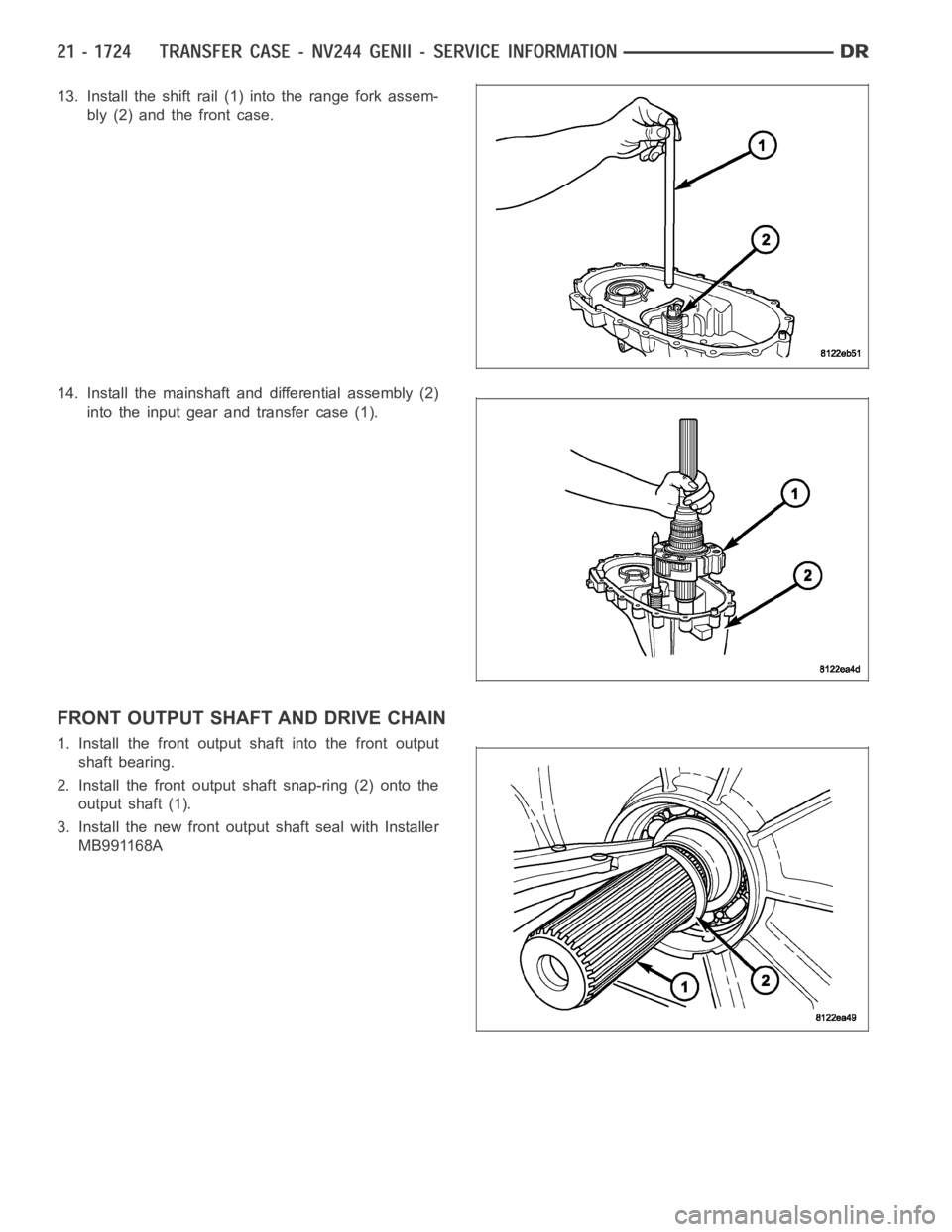

13. Install the shift rail (1) into the range fork assem-

bly (2) and the front case.

14. Install the mainshaft and differential assembly (2)

into the input gear and transfer case (1).

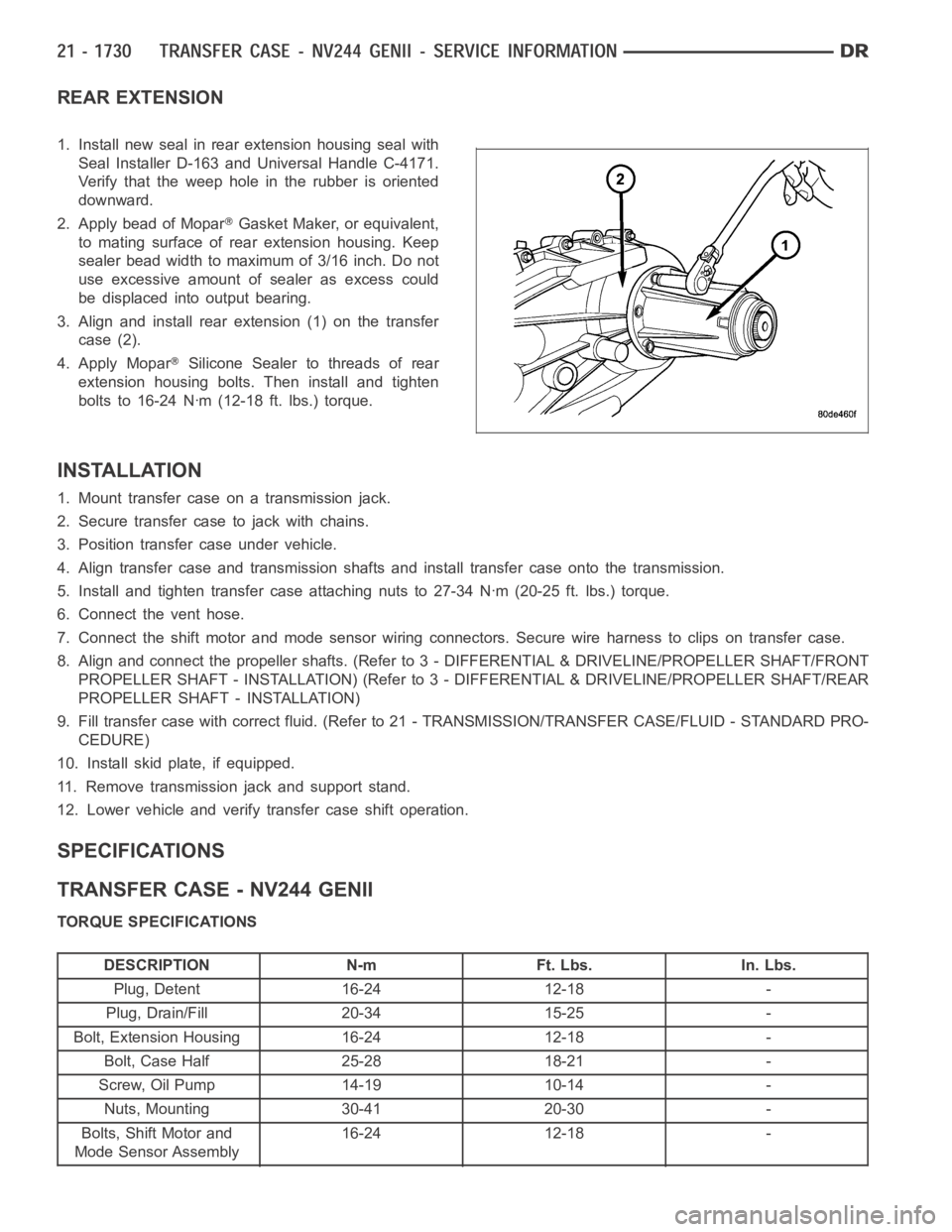

FRONT OUTPUT SHAFT AND DRIVE CHAIN

1. Install the front output shaft into the front output

shaft bearing.

2. Install the front output shaft snap-ring (2) onto the

output shaft (1).

3. Install the new front output shaft seal with Installer

MB991168A

Page 4251 of 5267

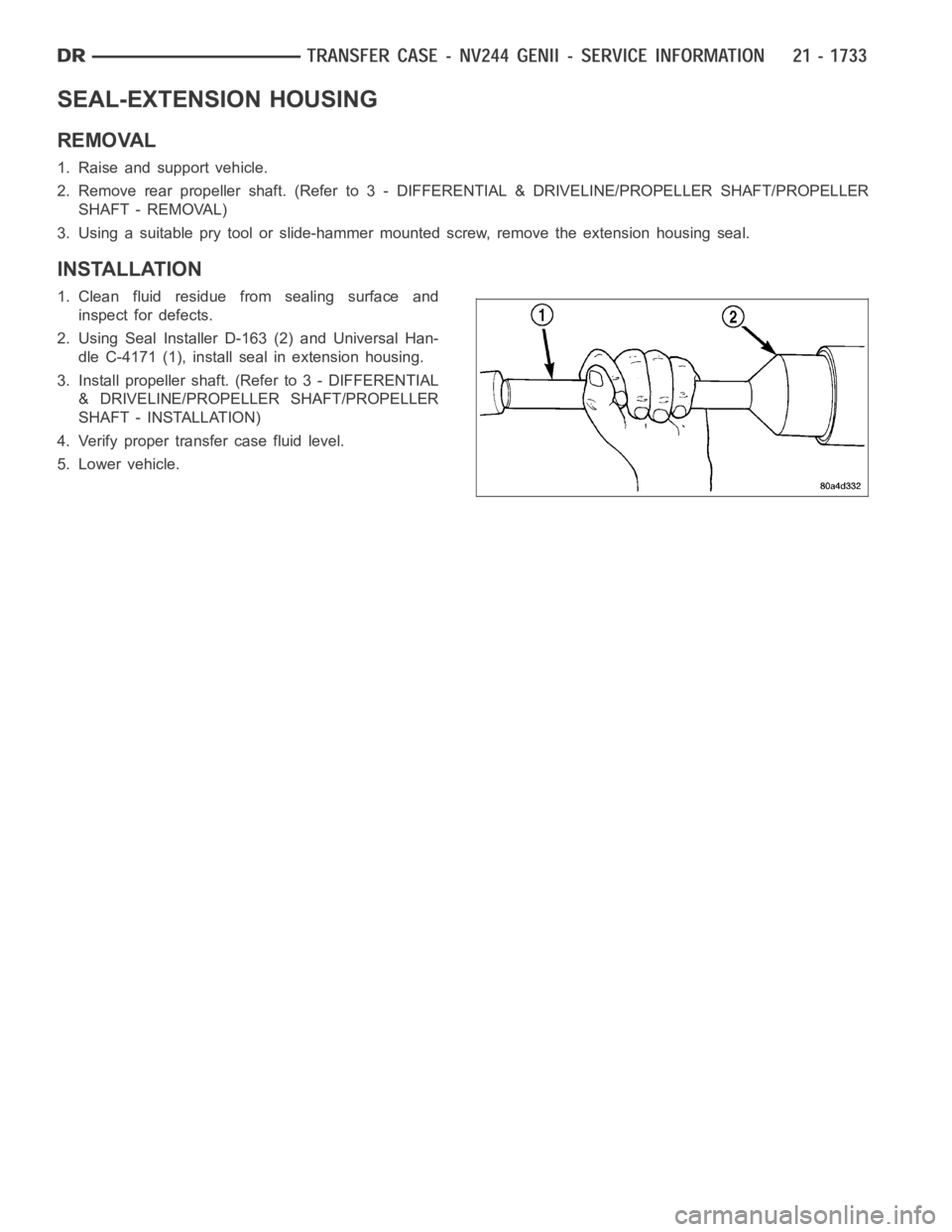

REAR EXTENSION

1. Install new seal in rear extension housing seal with

Seal Installer D-163 and Universal Handle C-4171.

Verify that the weep hole in the rubber is oriented

downward.

2. Apply bead of Mopar

Gasket Maker, or equivalent,

to mating surface of rear extension housing. Keep

sealer bead width to maximum of 3/16 inch. Do not

use excessive amount of sealer as excess could

be displaced into output bearing.

3. Align and install rear extension (1) on the transfer

case (2).

4. Apply Mopar

Silicone Sealer to threads of rear

extension housing bolts. Then install and tighten

bolts to 16-24 Nꞏm (12-18 ft. lbs.) torque.

INSTALLATION

1. Mount transfer case on a transmission jack.

2. Secure transfer case to jack with chains.

3. Position transfer case under vehicle.

4. Align transfer case and transmission shafts and install transfer case onto the transmission.

5. Install and tighten transfer case attaching nuts to 27-34 Nꞏm (20-25 ft.lbs.) torque.

6. Connect the vent hose.

7. Connect the shift motor and mode sensor wiring connectors. Secure wire harness to clips on transfer case.

8. Align and connect the propeller shafts. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/FRONT

PROPELLER SHAFT - INSTALLATION) (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/REAR

PROPELLER SHAFT - INSTALLATION)

9. Fill transfer case with correct fluid. (Refer to 21 - TRANSMISSION/TRANSFER CASE/FLUID - STANDARD PRO-

CEDURE)

10. Install skid plate, if equipped.

11. Remove transmission jack and support stand.

12. Lower vehicle and verify transfer case shift operation.

SPECIFICATIONS

TRANSFER CASE - NV244 GENII

TORQUE SPECIFICATIONS

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Plug, Detent 16-24 12-18 -

Plug, Drain/Fill 20-34 15-25 -

Bolt, Extension Housing 16-24 12-18 -

Bolt, Case Half 25-28 18-21 -

Screw, Oil Pump 14-19 10-14 -

Nuts, Mounting 30-41 20-30 -

Bolts, Shift Motor and

Mode Sensor Assembly16-24 12-18 -

Page 4254 of 5267

SEAL-EXTENSION HOUSING

REMOVAL

1. Raise and support vehicle.

2. Remove rear propeller shaft. (Referto 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/PROPELLER

SHAFT - REMOVAL)

3. Using a suitable pry tool or slide-hammer mounted screw, remove the extension housing seal.

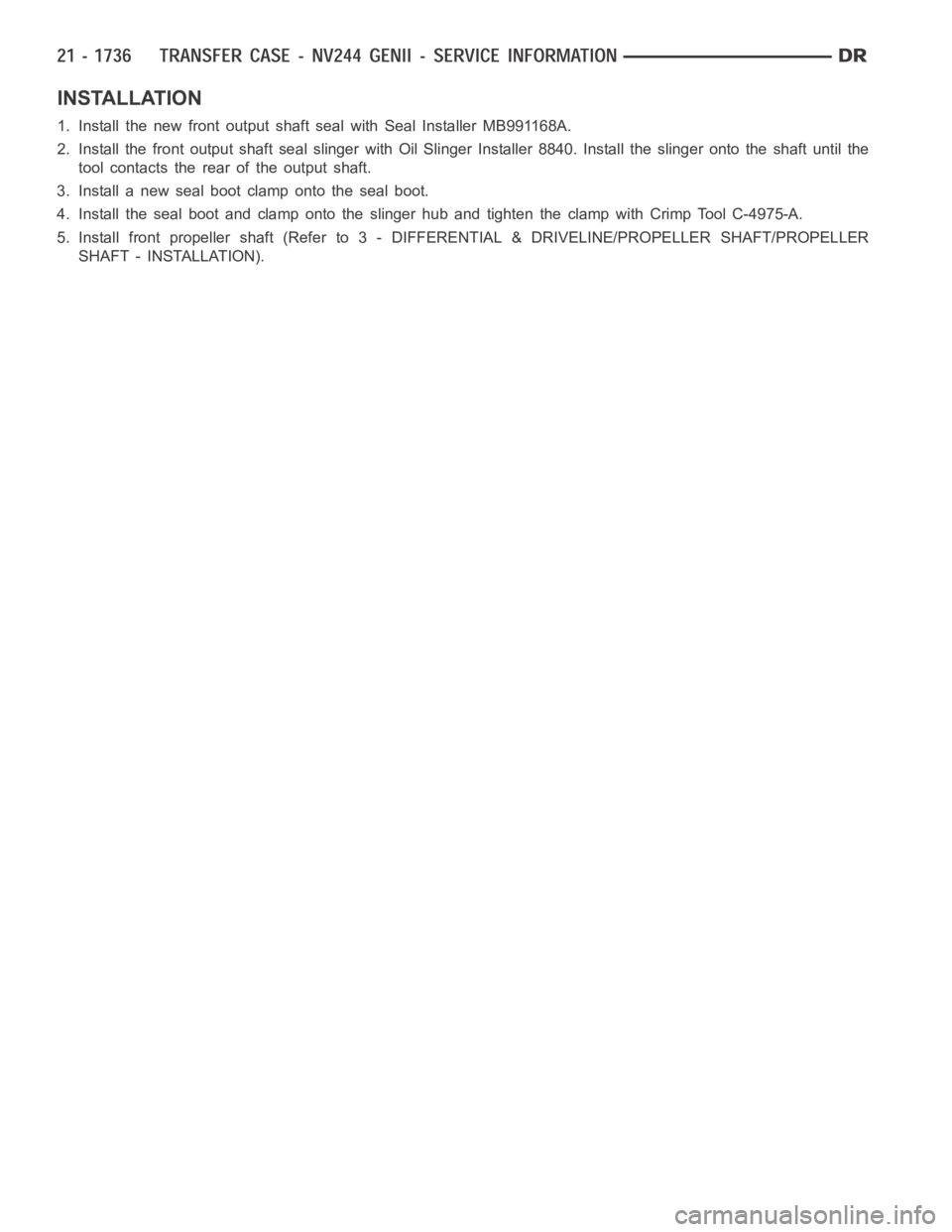

INSTALLATION

1. Clean fluid residue from sealing surface and

inspect for defects.

2. Using Seal Installer D-163 (2) and Universal Han-

dle C-4171 (1), install seal in extension housing.

3. Install propeller shaft. (Refer to 3 - DIFFERENTIAL

& DRIVELINE/PROPELLER SHAFT/PROPELLER

SHAFT - INSTALLATION)

4. Verify proper transfer case fluid level.

5. Lower vehicle.

Page 4257 of 5267

INSTALLATION

1. Install the new front output shaft seal with Seal Installer MB991168A.

2. Install the front output shaft seal slinger with Oil Slinger Installer 8840. Install the slinger onto the shaft until the

tool contacts the rear of the output shaft.

3. Install a new seal boot clamp onto the seal boot.

4. Install the seal boot and clamp onto the slinger hub and tighten the clampwith Crimp Tool C-4975-A.

5. Install front propeller shaft (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/PROPELLER

SHAFT - INSTALLATION).

Page 4301 of 5267

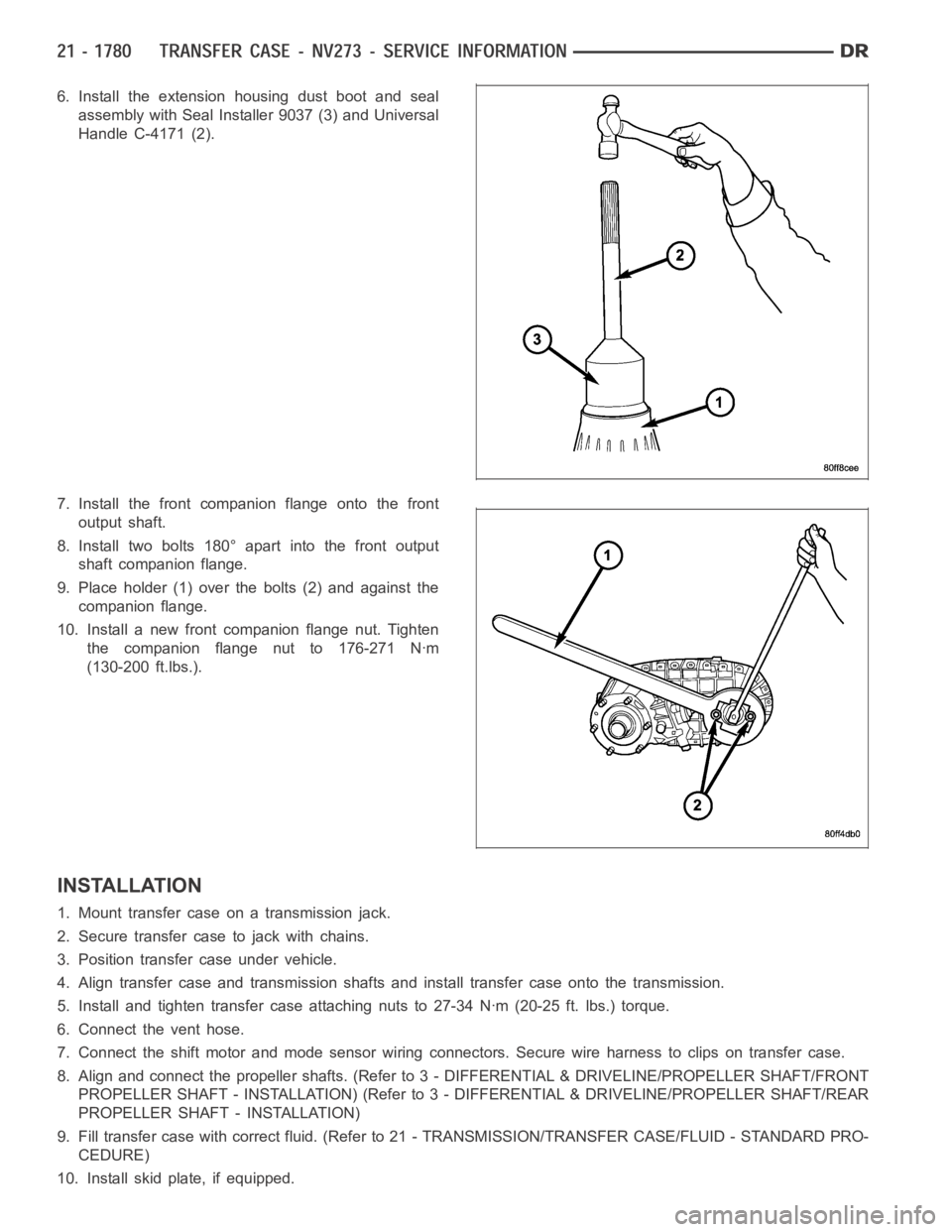

6. Install the extension housing dust boot and seal

assembly with Seal Installer 9037 (3) and Universal

Handle C-4171 (2).

7. Install the front companion flange onto the front

output shaft.

8. Install two bolts 180° apart into the front output

shaft companion flange.

9. Place holder (1) over the bolts (2) and against the

companion flange.

10. Install a new front companion flange nut. Tighten

the companion flange nut to 176-271 Nꞏm

(130-200 ft.lbs.).

INSTALLATION

1. Mount transfer case on a transmission jack.

2. Secure transfer case to jack with chains.

3. Position transfer case under vehicle.

4. Align transfer case and transmission shafts and install transfer case onto the transmission.

5. Install and tighten transfer case attaching nuts to 27-34 Nꞏm (20-25 ft.lbs.) torque.

6. Connect the vent hose.

7. Connect the shift motor and mode sensor wiring connectors. Secure wire harness to clips on transfer case.

8. Align and connect the propeller shafts. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/FRONT

PROPELLER SHAFT - INSTALLATION) (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/REAR

PROPELLER SHAFT - INSTALLATION)

9. Fill transfer case with correct fluid. (Refer to 21 - TRANSMISSION/TRANSFER CASE/FLUID - STANDARD PRO-

CEDURE)

10. Install skid plate, if equipped.

Page 4305 of 5267

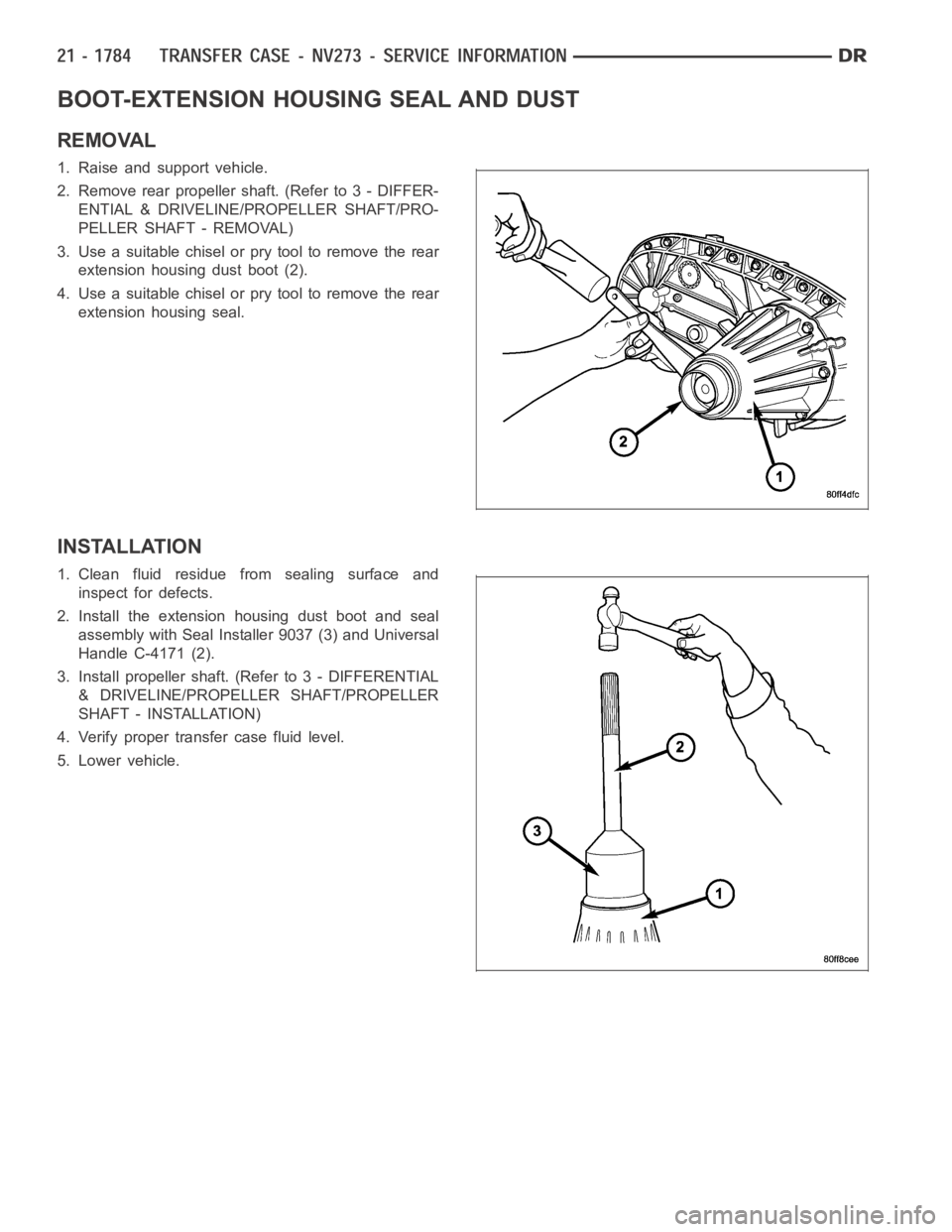

BOOT-EXTENSION HOUSING SEAL AND DUST

REMOVAL

1. Raise and support vehicle.

2. Remove rear propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - REMOVAL)

3. Use a suitable chisel or pry tool to remove the rear

extension housing dust boot (2).

4. Use a suitable chisel or pry tool to remove the rear

extension housing seal.

INSTALLATION

1. Clean fluid residue from sealing surface and

inspect for defects.

2. Install the extension housing dust boot and seal

assembly with Seal Installer 9037 (3) and Universal

Handle C-4171 (2).

3. Install propeller shaft. (Refer to 3 - DIFFERENTIAL

& DRIVELINE/PROPELLER SHAFT/PROPELLER

SHAFT - INSTALLATION)

4. Verify proper transfer case fluid level.

5. Lower vehicle.