DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Trending: height, engine, spark plugs, fuel pump, lumbar support, air suspension, Crankshaft

Page 3001 of 5267

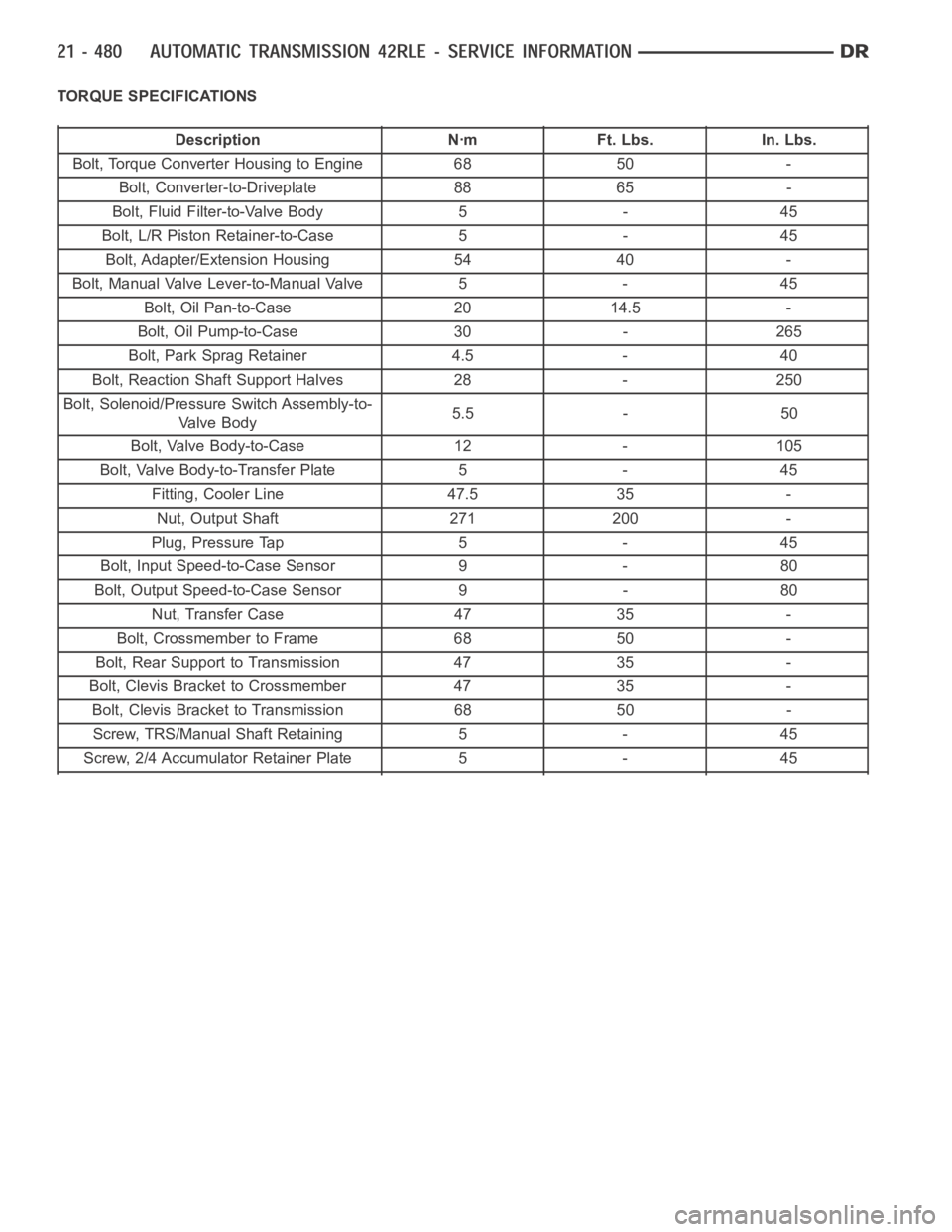

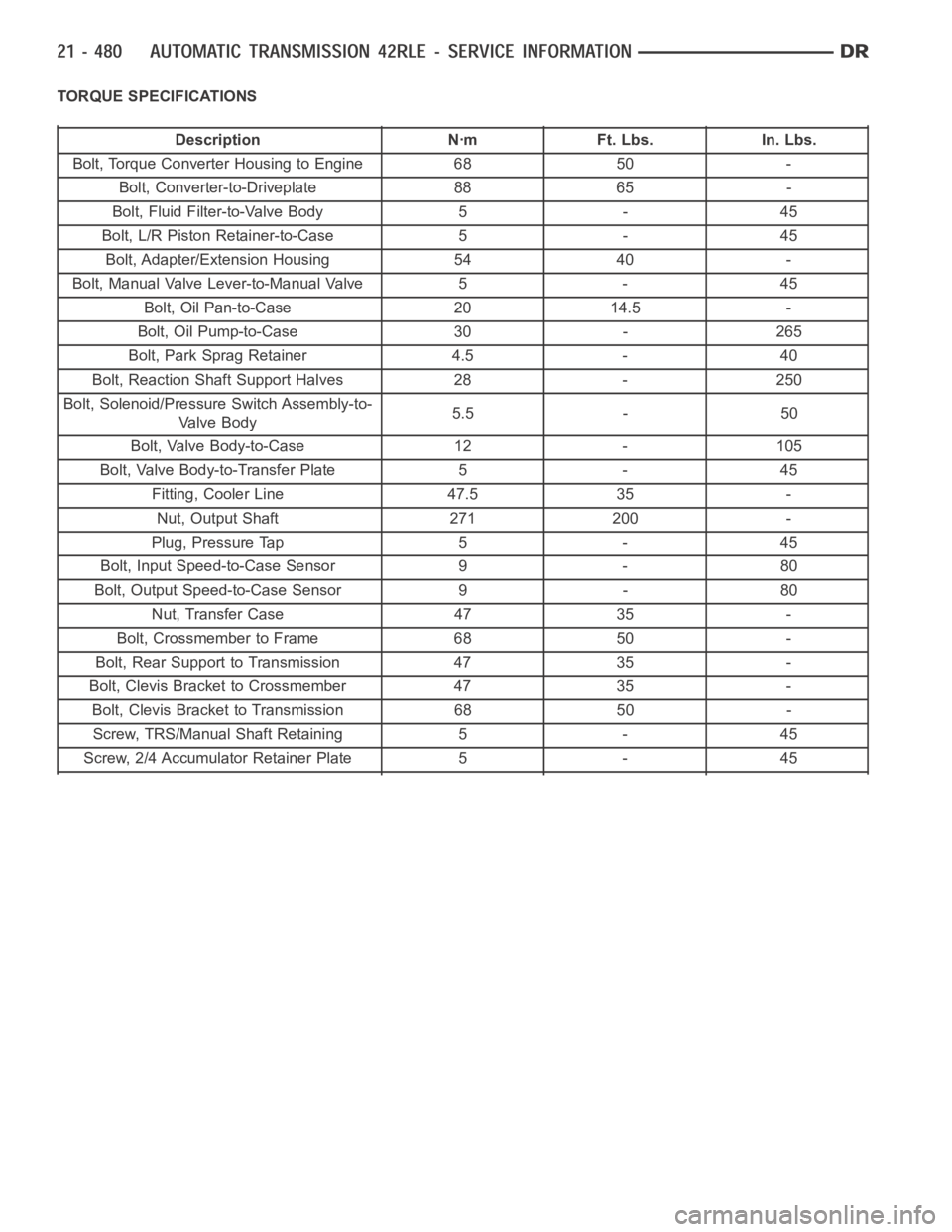

TORQUE SPECIFICATIONS

Description Nꞏm Ft. Lbs. In. Lbs.

Bolt, Torque Converter Housing to Engine 68 50 -

Bolt, Converter-to-Driveplate 88 65 -

Bolt, Fluid Filter-to-Valve Body 5 - 45

Bolt, L/R Piston Retainer-to-Case 5 - 45

Bolt, Adapter/Extension Housing 54 40 -

Bolt, Manual Valve Lever-to-Manual Valve 5 - 45

Bolt, Oil Pan-to-Case 20 14.5 -

Bolt, Oil Pump-to-Case 30 - 265

Bolt, Park Sprag Retainer 4.5 - 40

Bolt, Reaction Shaft Support Halves 28 - 250

Bolt, Solenoid/Pressure Switch Assembly-to-

Valve Body5.5 - 50

Bolt, Valve Body-to-Case 12 - 105

Bolt, Valve Body-to-Transfer Plate 5 - 45

Fitting, Cooler Line 47.5 35 -

Nut, Output Shaft 271 200 -

Plug, Pressure Tap 5 - 45

Bolt, Input Speed-to-Case Sensor 9 - 80

Bolt, Output Speed-to-Case Sensor 9 - 80

Nut, Transfer Case 47 35 -

Bolt, Crossmember to Frame 68 50 -

Bolt, Rear Support to Transmission 47 35 -

Bolt, Clevis Bracket to Crossmember 47 35 -

Bolt, Clevis Bracket to Transmission 68 50 -

Screw, TRS/Manual Shaft Retaining 5 - 45

Screw, 2/4 Accumulator Retainer Plate 5 - 45

Page 3002 of 5267

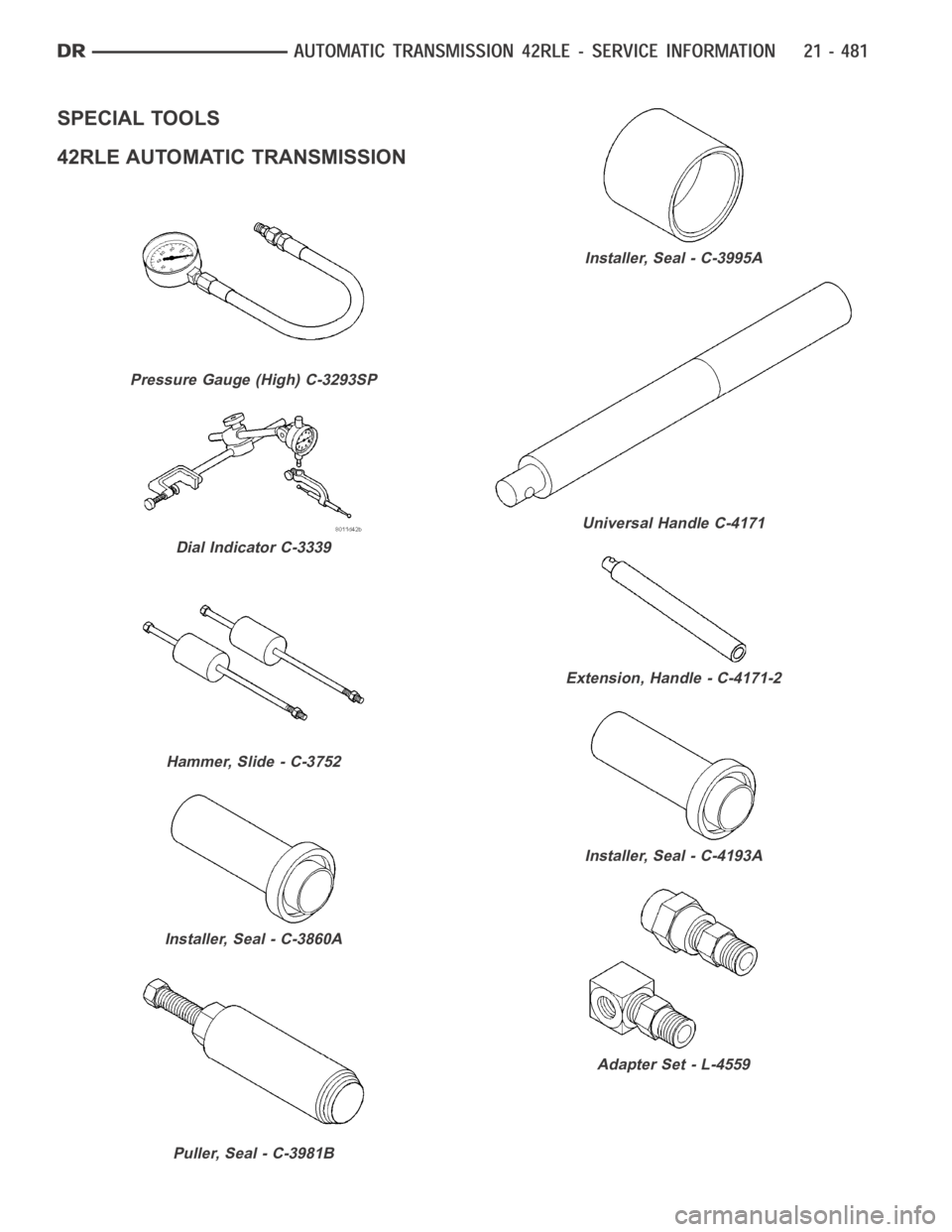

SPECIAL TOOLS

42RLE AUTOMATIC TRANSMISSION

Pressure Gauge (High) C-3293SP

Dial Indicator C-3339

Hammer, Slide - C-3752

Installer, Seal - C-3860A

Puller, Seal - C-3981B

Installer, Seal - C-3995A

Universal Handle C-4171

Extension, Handle - C-4171-2

Installer, Seal - C-4193A

Adapter Set - L-4559

Page 3003 of 5267

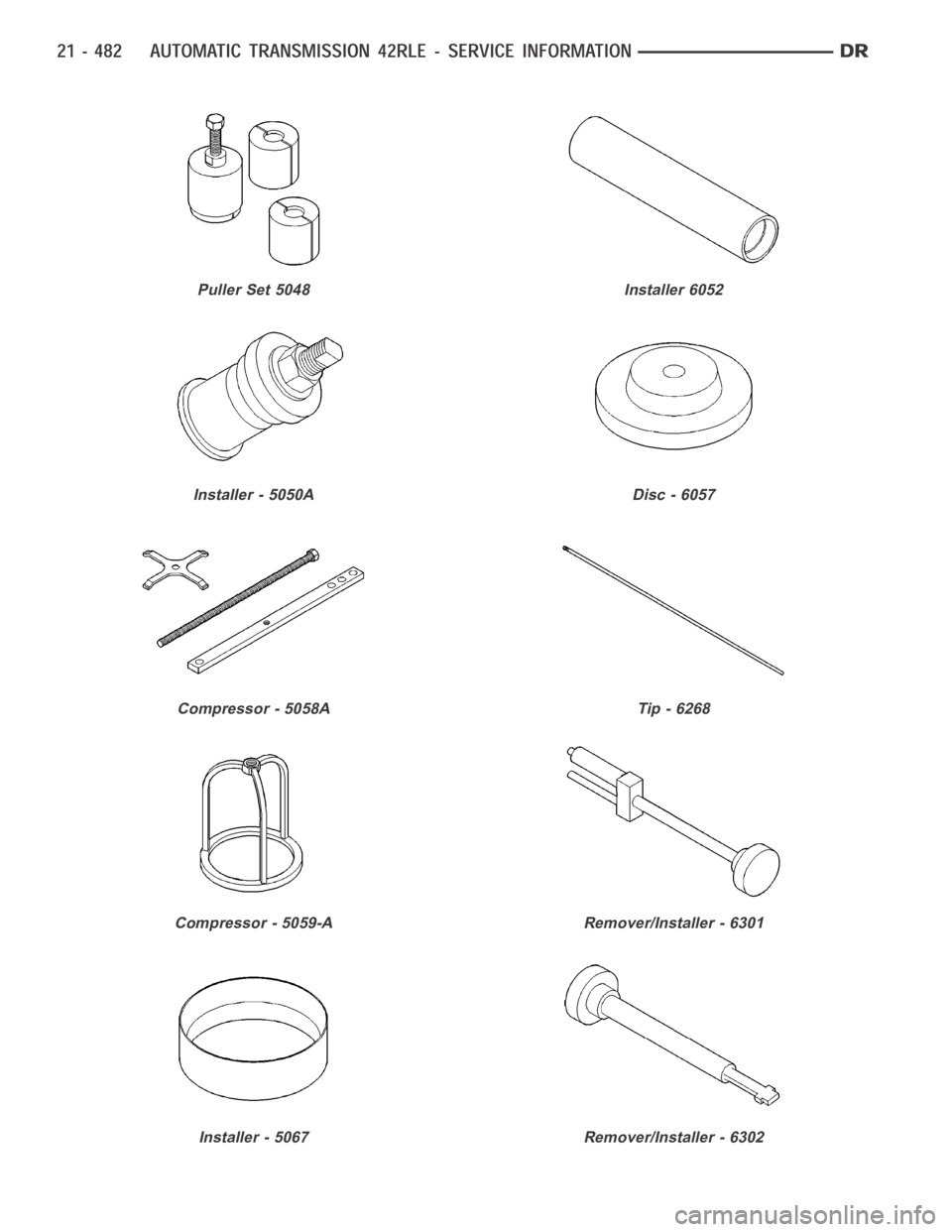

Puller Set 5048

Installer - 5050A

Compressor - 5058A

Compressor - 5059-A

Installer - 5067

Installer 6052

Disc - 6057

Tip - 6268

Remover/Installer - 6301

Remover/Installer - 6302

Page 3004 of 5267

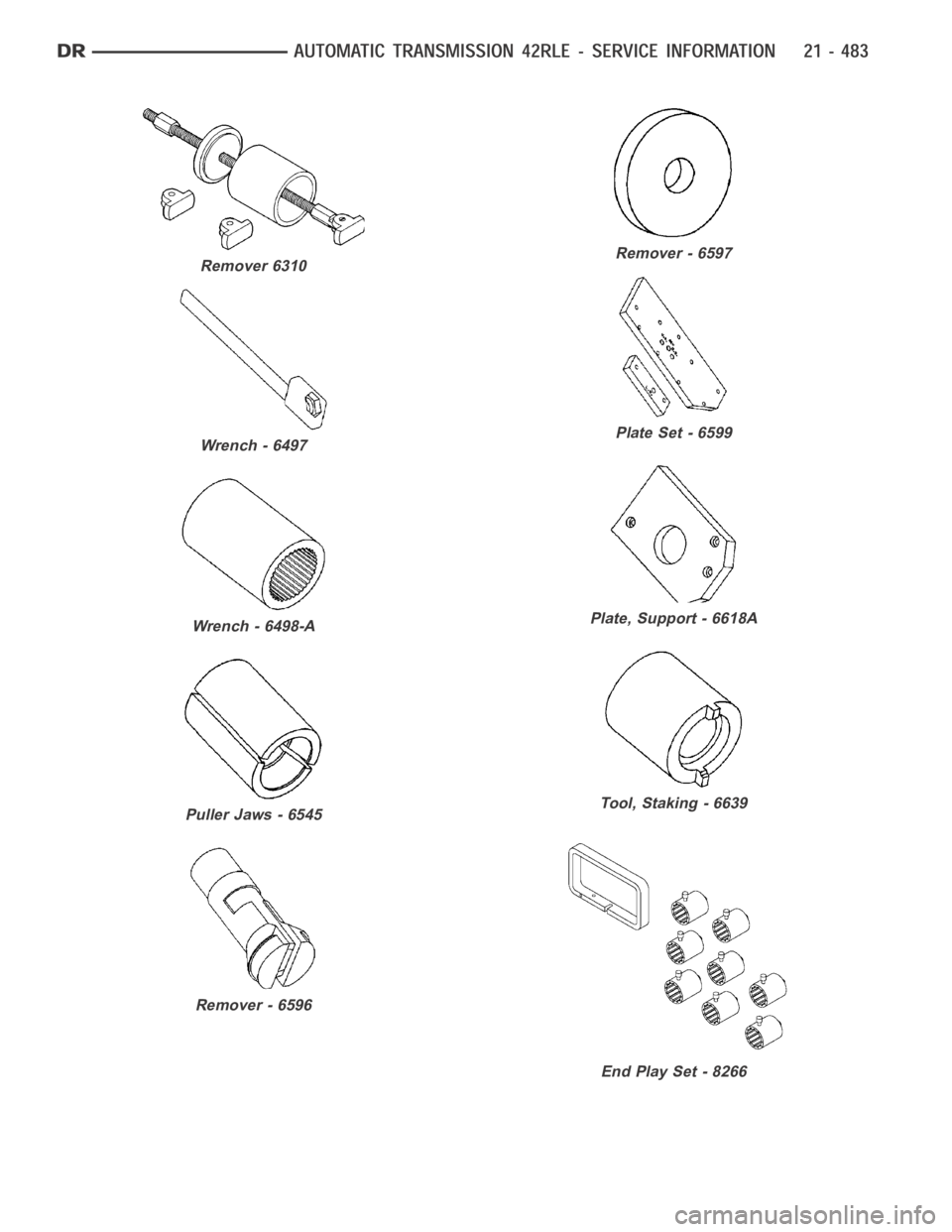

Remover 6310

Wrench - 6497

Wrench - 6498-A

Puller Jaws - 6545

Remover - 6596

Remover - 6597

Plate Set - 6599

Plate, Support - 6618A

Tool, Staking - 6639

End Play Set - 8266

Page 3005 of 5267

Page 3006 of 5267

ACCUMULATOR

DESCRIPTION

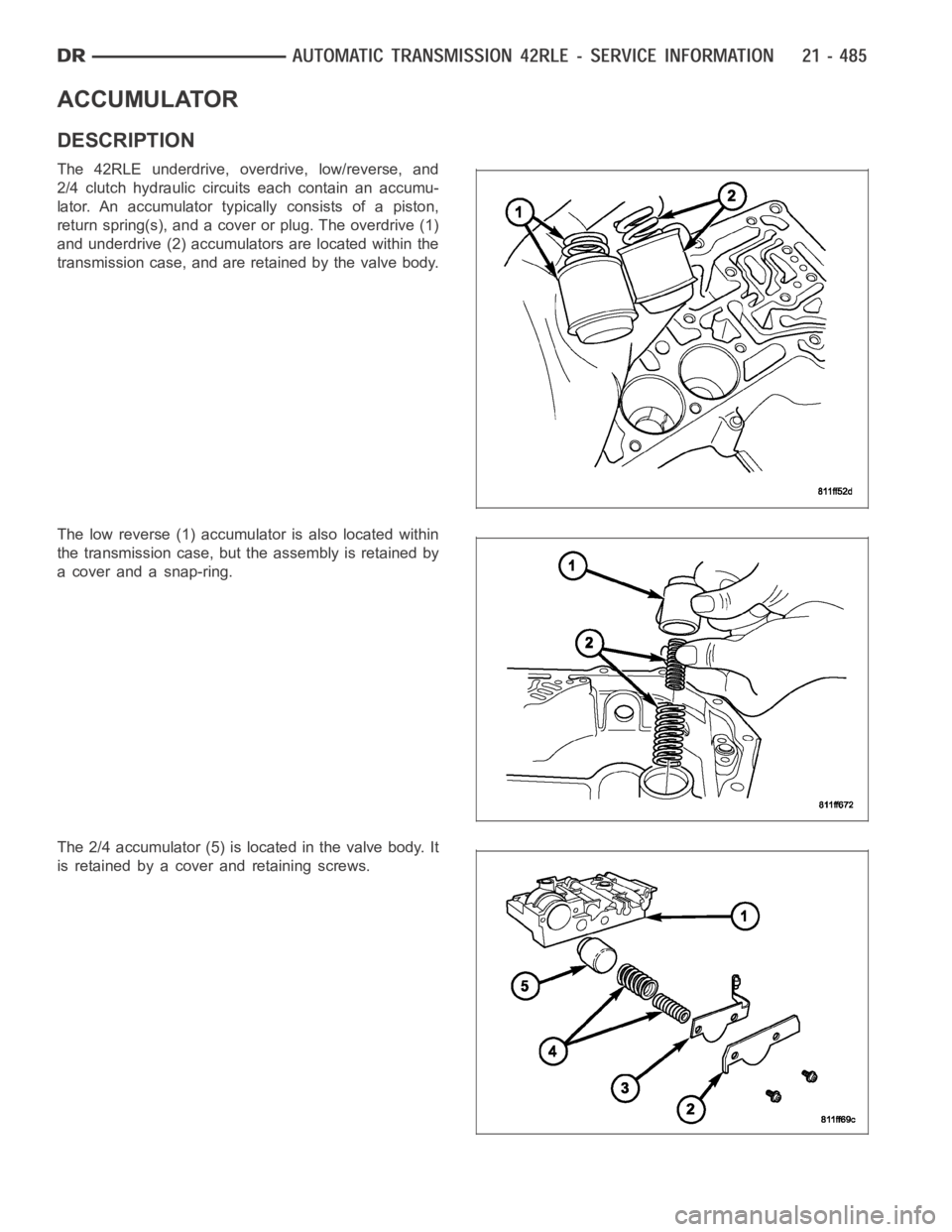

The 42RLE underdrive, overdrive, low/reverse, and

2/4 clutch hydraulic circuits each contain an accumu-

lator. An accumulator typically consists of a piston,

return spring(s), and a cover or plug. The overdrive (1)

and underdrive (2) accumulators are located within the

transmission case, and are retained by the valve body.

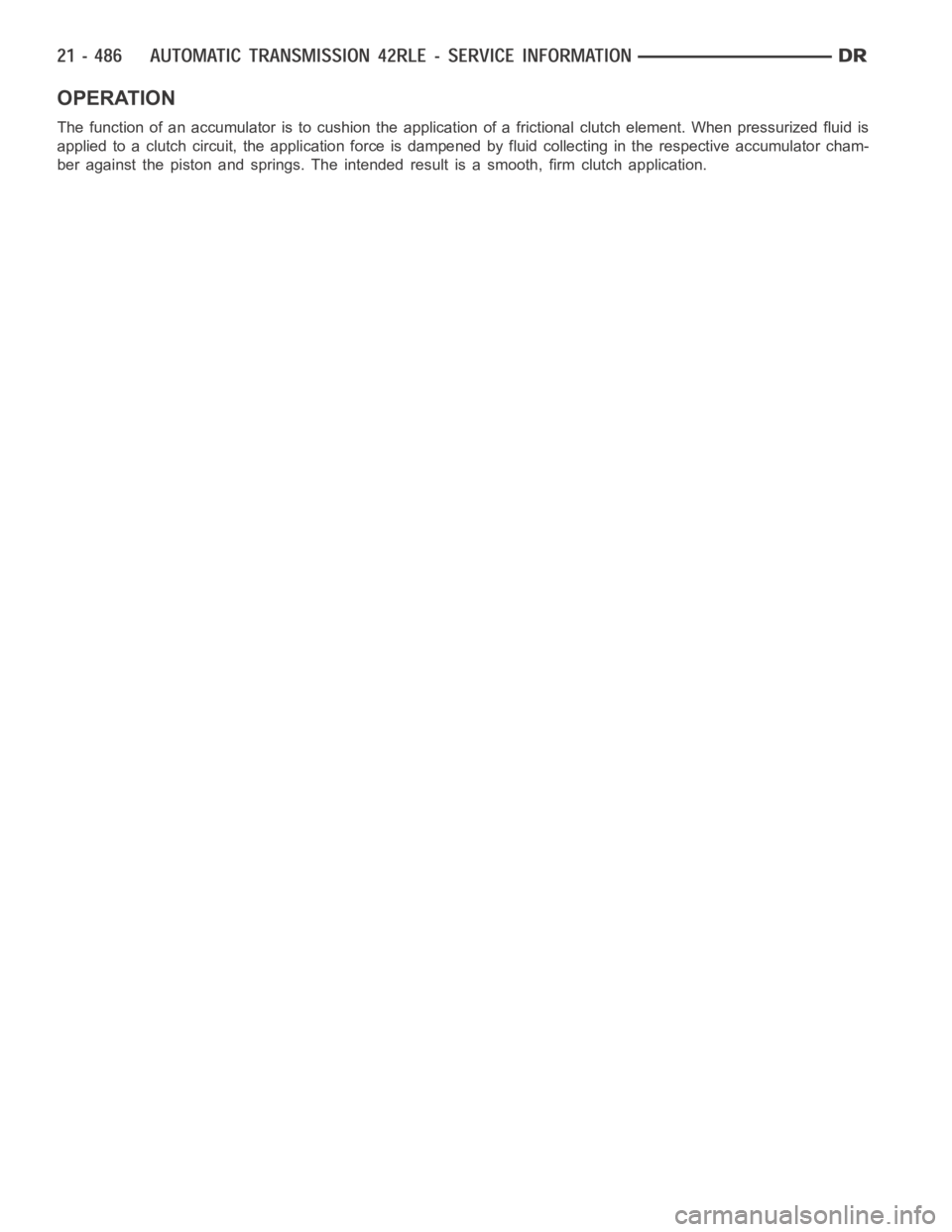

The low reverse (1) accumulator is also located within

the transmission case, but the assembly is retained by

a cover and a snap-ring.

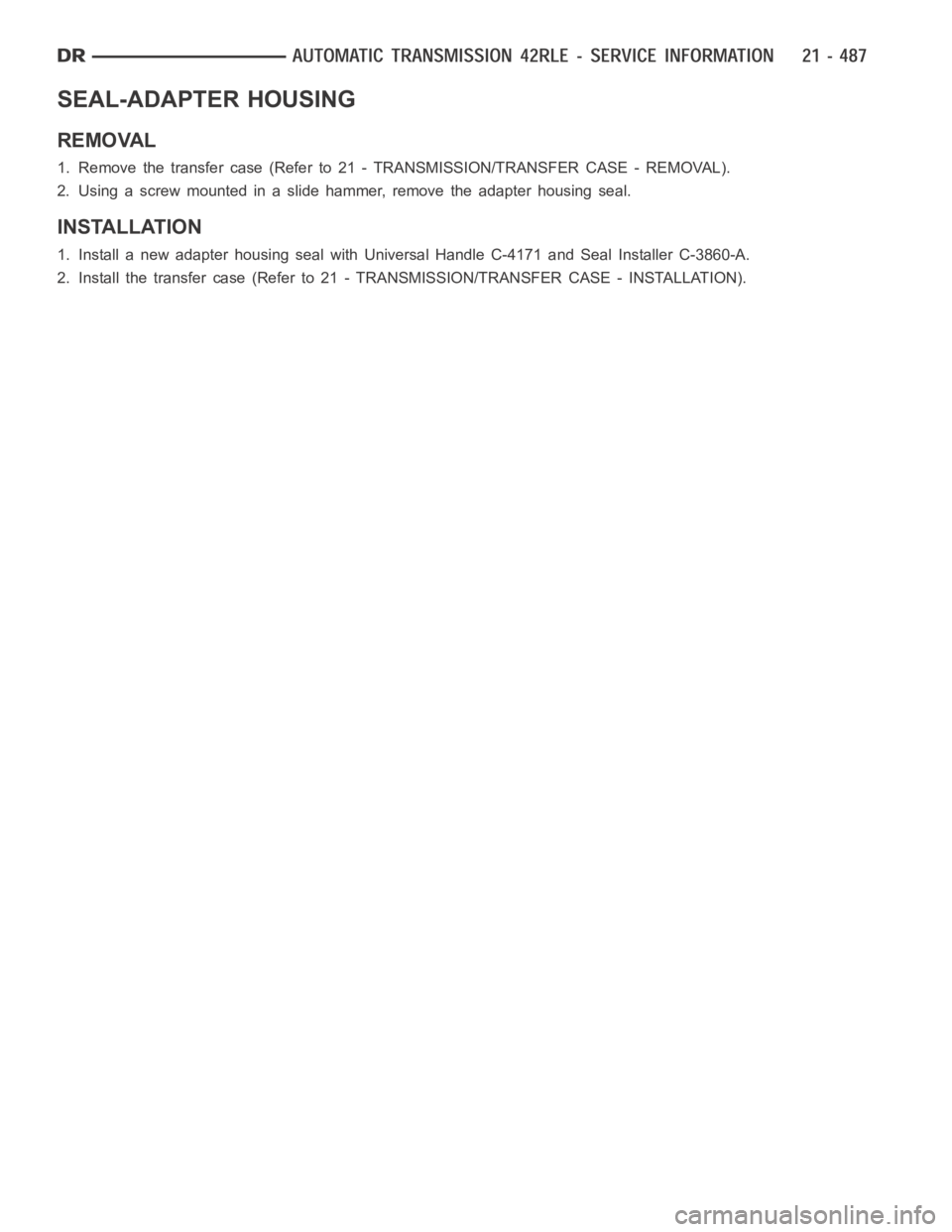

The 2/4 accumulator (5) is located in the valve body. It

is retained by a cover and retaining screws.

Page 3007 of 5267

OPERATION

The function of an accumulator is to cushion the application of a frictional clutch element. When pressurized fluid is

applied to a clutch circuit, the application force is dampened by fluid collecting in the respective accumulator cham-

ber against the piston and springs. The intended result is a smooth, firm clutch application.

Page 3008 of 5267

SEAL-ADAPTER HOUSING

REMOVAL

1. Remove the transfer case (Refer to 21 - TRANSMISSION/TRANSFER CASE - REMOVAL).

2. Using a screw mounted in a slide hammer, remove the adapter housing seal.

INSTALLATION

1. Install a new adapter housing seal with Universal Handle C-4171 and SealInstaller C-3860-A.

2. Install the transfer case (Refer to 21 - TRANSMISSION/TRANSFER CASE - INSTALLATION).

Page 3009 of 5267

BEARINGS

ADJUSTMENTS

BEARING ADJUSTMENT PROCEDURES

Take extreme care when removing andinstalling bearing cups and cones.Use only an arbor press for installa-

tion,as a hammer may not properly align the bearing cup or cone. Burrs or nicks on the bearing seat will give a

false end play reading, while gauging for proper shims. Improperly seatedbearing cup and cones are subject to

low-mileage failure.

Bearing cups and cones should be replaced if they show signs of pitting or heat distress.

If distress is seen on either the cup or bearing rollers, both cup and cone must be replaced.

NOTE: Bearing drag torque specifications must be maintained to avoid premature bearing failures.

Used (original) bearing may lose up to 50 percent of the original drag torque after break-in.

NOTE: All bearing adjustments must be made with no other component interference or gear inter-mesh.

Oil all bearings before checking turning torque.

Page 3010 of 5267

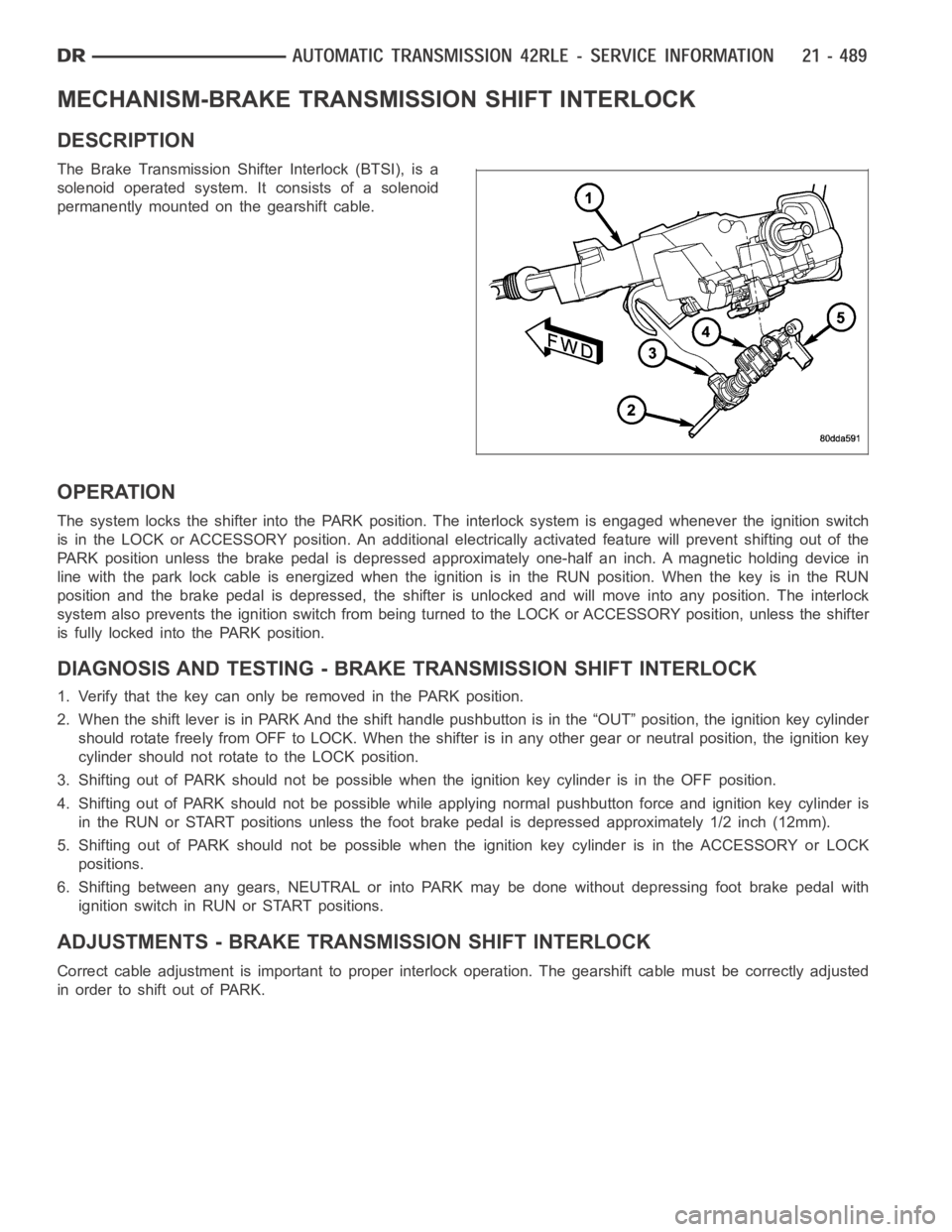

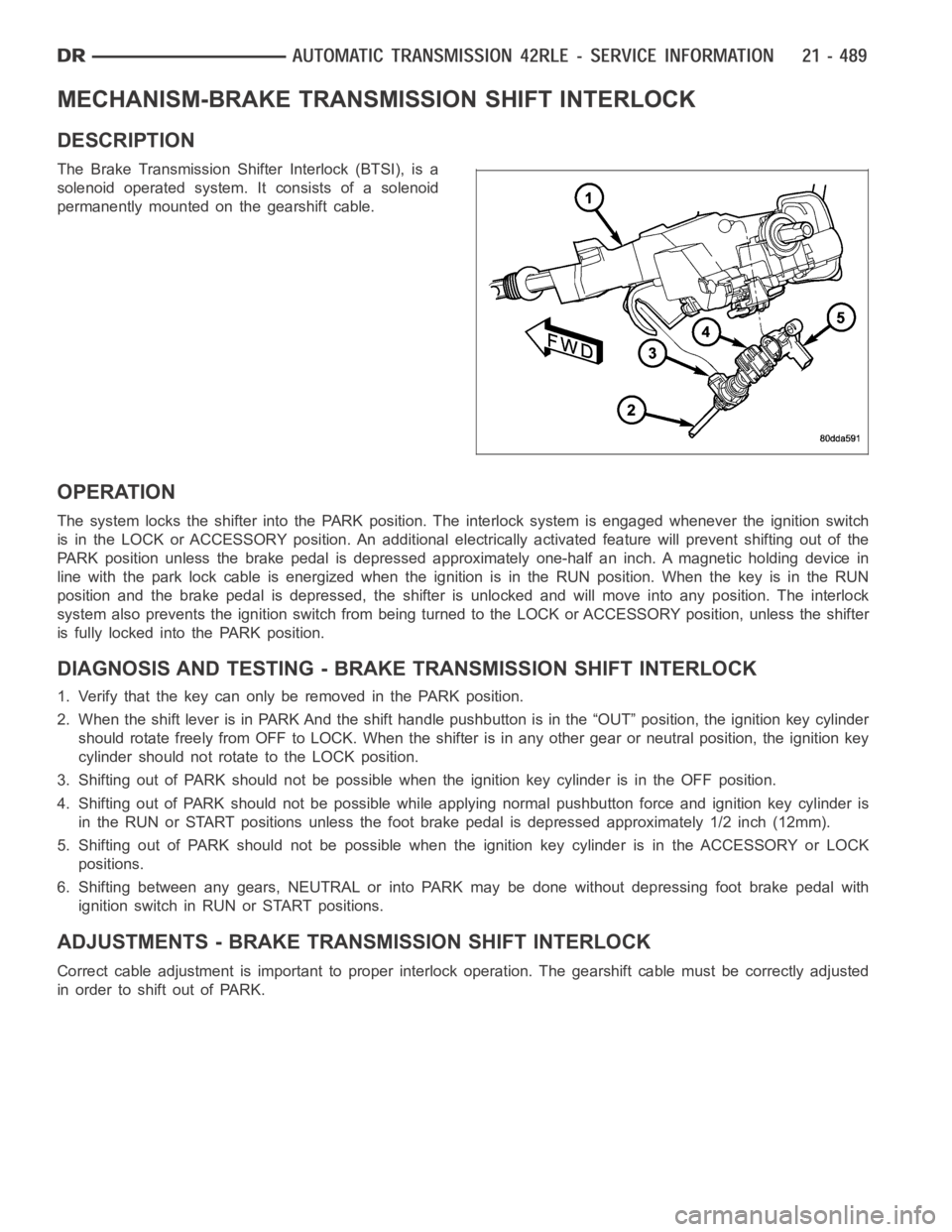

MECHANISM-BRAKE TRANSMISSION SHIFT INTERLOCK

DESCRIPTION

The Brake Transmission Shifter Interlock (BTSI), is a

solenoid operated system. It consists of a solenoid

permanently mounted on the gearshift cable.

OPERATION

The system locks the shifter into the PARK position. The interlock system is engaged whenever the ignition switch

is in the LOCK or ACCESSORY position. An additional electrically activated feature will prevent shifting out of the

PARK position unless the brake pedal is depressed approximately one-halfan inch. A magnetic holding device in

line with the park lock cable is energized when the ignition is in the RUN position. When the key is in the RUN

position and the brake pedal is depressed, the shifter is unlocked and willmove into any position. The interlock

system also prevents the ignition switch from being turned to the LOCK or ACCESSORY position, unless the shifter

is fully locked into the PARK position.

DIAGNOSIS AND TESTING - BRAKE TRANSMISSION SHIFT INTERLOCK

1. Verify that the key can only be removed in the PARK position.

2. When the shift lever is in PARK And the shift handle pushbutton is in the “OUT” position, the ignition key cylinder

should rotate freely from OFF to LOCK. When the shifter is in any other gear or neutral position, the ignition key

cylinder should not rotate to the LOCK position.

3. Shifting out of PARK should not be possible when the ignition key cylinder is in the OFF position.

4. Shifting out of PARK should not be possible while applying normal pushbutton force and ignition key cylinder is

in the RUN or START positions unless the foot brake pedal is depressed approximately 1/2 inch (12mm).

5. Shifting out of PARK should not be possible when the ignition key cylinderisintheACCESSORYorLOCK

positions.

6. Shifting between any gears, NEUTRAL or into PARK may be done without depressing foot brake pedal with

ignition switch in RUN or START positions.

ADJUSTMENTS - BRAKE TRANSMISSION SHIFT INTERLOCK

Correct cable adjustment is important to proper interlock operation. Thegearshift cable must be correctly adjusted

in order to shift out of PARK.

Trending: odometer, coolant capacity, brake sensor, brake, run flat, remote start, wheelbase