ignition DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 707 of 5267

4.SIGNAL CIRCUIT OPEN FROM RELAY TO ECM

Disconnect the ECM harness connectors.

Check connectors - Clean/repair as necessary.

Measure the resistance of the intake air heater relay signal circuit between the ECM connector and the intake air

heater relay connector.

Is the resistance less than 10 Ohms?

Ye s>>

Go To 5

No>>

Repair the open signal circuit from PDC to ECM harness connector.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

5.SIGNAL CIRCUIT SHORTED TO BATTERY NEGATIVE

Measure the voltage between the signal circuit of the intake air heater relay and battery negative.

Is the voltage greater than 1 volts?

Ye s>>

Repair the signal circuit shorted to Battery negative.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 6

6.ECM

Reconnect the ECM harness connectors.

Disconnect the intake air heater relay signal wire and use a jumper to connect it to battery negative.

Turn the ignition on.

With the scan tool, read DTCs.

Did DTC P0542 set?

Ye s>>

Refer to the INTERMITTENT CONDITION Symptom (Diagnostic Procedure). (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

No>>

Replace the ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 709 of 5267

When Monitored:

When the ignition is on.

Set Condition:

When the signal from the #1 Intake Air Heater output does not match the signal from the #1 Intake Air Heater

feedback.

Possible Causes

LOOSE CONNECTION

INTAKEAIRHEATERRELAY

SIGNAL CIRCUIT SHORTED TO BATTERY NEGATIVE

ECM

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.RELAY CLICKING

Ignition on, engine not running.

With the scan tool, actuate the Intake Air Heater relay.

Can you hear the Relay clicking?

Ye s>>

Go To 2

No>>

Go To 3

2.LOOSE CONNECTION

While the relay is clicking , wiggle the wiring harness and connectors.

Does this interrupt the clicking?

Ye s>>

Repair the poor connection.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 3

3.INTAKE AIR HEATER RELAY

Turn the ignition off.

Remove the Intake Air Heater Relay.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance between the signal and return posts of the intake air heater relay.

Is the resistance between 15 and 25 Ohms?

Ye s>>

Go To 4

No>>

Replace the Intake Air Heater relay.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 710 of 5267

4.SIGNAL CIRCUIT SHORTED TO BATTERY NEGATIVE

Disconnect the ECM harness connector(s).

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance between the signal circuit of the intake air heaterrelay and battery negative.

Is the resistance greater than 100 K ohms?

Ye s>>

Go To 5

No>>

Repair signal circuit shorted to battery negative.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

5.SIGNAL CIRCUIT SHORTED TO OTHER CIRCUITS

Measure the resistance between the signal circuit of the intake air heaterrelay and all other circuits in the ECM

harness connector.

Is the resistance greater than 100 K ohms?

Ye s>>

Go To 6

No>>

Repair signal circuit shorted to other circuits.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

6.ECM

Reconnect the ECM harness connectors.

Turn the ignition on.

Disconnect the intake air heater relay signal wire.

Did DTC P0542 or 2608 set?

Ye s>>

Refer to the INTERMITTENT CONDITION Symptom (Diagnostic Procedure). (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

No>>

Replace the ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 713 of 5267

4.BATTERY TERMINAL CONNECTIONS

Visually inspect the positive and negative connections at the batteries and inspect the battery negative connections

at the engine block.

Are the connections free of corrosion and are they tight?

Ye s>>

Go To 5

No>>

Repair the poor connections.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

5.ACCESSORY WIRING

Check for add-on or accessory wiring at positive (+) terminal of the battery

Are there any damaged wires at the battery?

Ye s>>

Repair accessory wiring.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 6

6.BATTERY(S)

Perform battery load test using the Midtronics Micro 420 battery system tester.

Did the battery(s) pass the test?

Ye s>>

Go To 7

No>>

Replace the weak battery or batteries.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

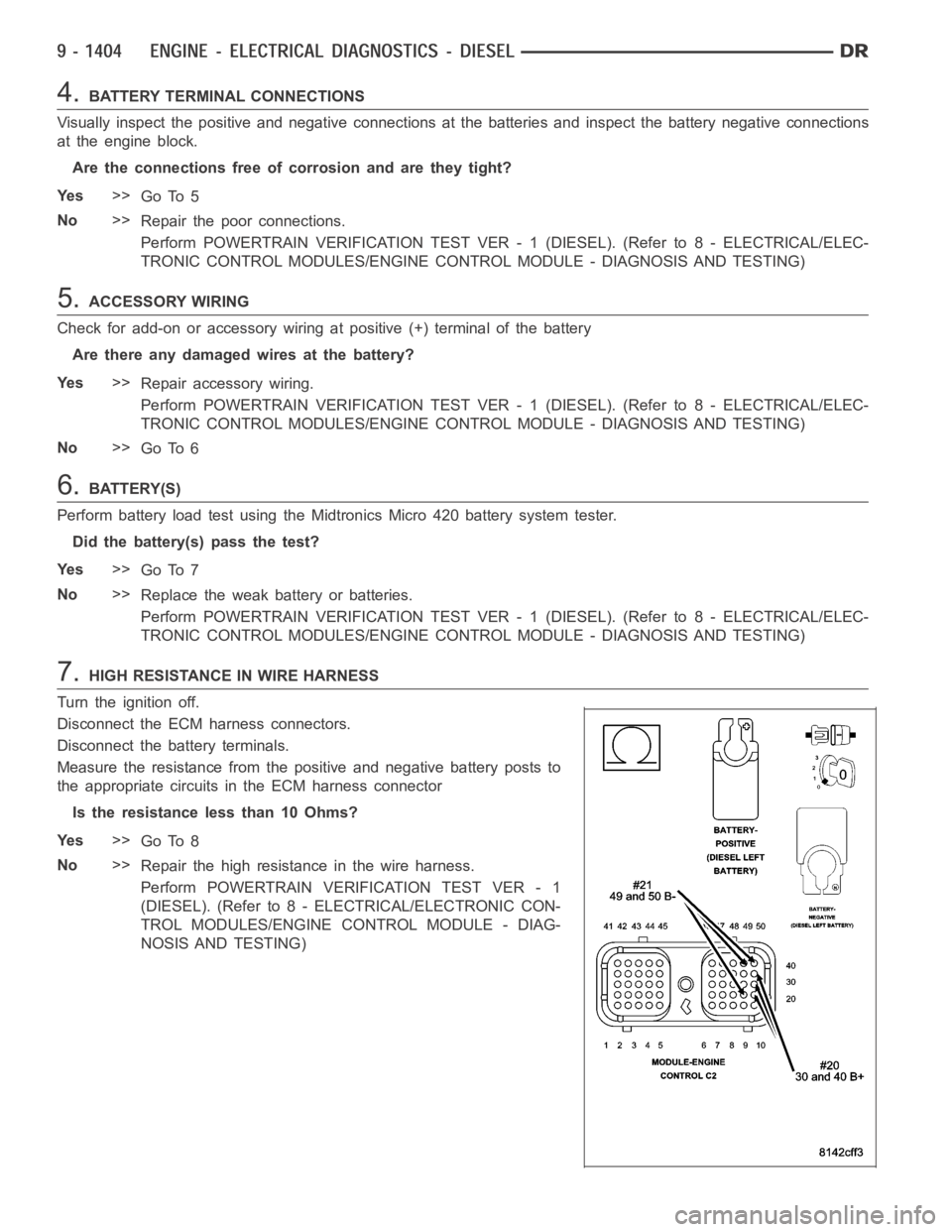

7.HIGH RESISTANCE IN WIRE HARNESS

Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the battery terminals.

Measure the resistance from the positive and negative battery posts to

the appropriate circuits in the ECM harness connector

Is the resistance less than 10 Ohms?

Ye s>>

Go To 8

No>>

Repair the high resistance in the wire harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 719 of 5267

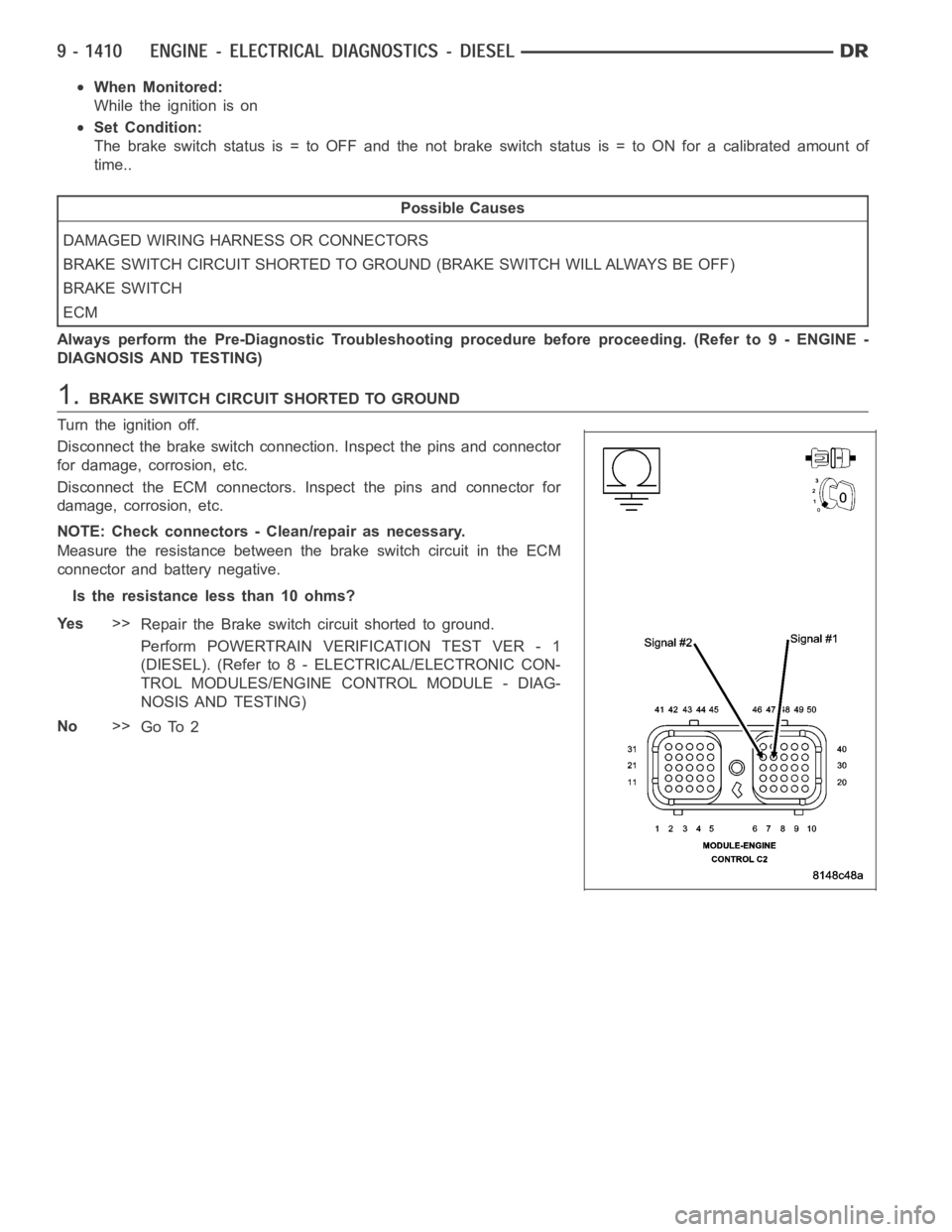

When Monitored:

While the ignition is on

Set Condition:

The brake switch status is = to OFF and the not brake switch status is = to ON for a calibrated amount of

time..

Possible Causes

DAMAGED WIRING HARNESS OR CONNECTORS

BRAKE SWITCH CIRCUIT SHORTED TO GROUND (BRAKE SWITCH WILL ALWAYS BE OFF)

BRAKE SWITCH

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.BRAKE SWITCH CIRCUIT SHORTED TO GROUND

Turn the ignition off.

Disconnect the brake switch connection. Inspect the pins and connector

for damage, corrosion, etc.

Disconnect the ECM connectors. Inspect the pins and connector for

damage, corrosion, etc.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance between the brake switch circuit in the ECM

connector and battery negative.

Is the resistance less than 10 ohms?

Ye s>>

Repair the Brake switch circuit shorted to ground.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Go To 2

Page 721 of 5267

4.

Reconnect the brake switch connector.

Using the scan tool, clear the DTC’s.

Turn the ignition on.

Cycle the brake pedal several times.

Using the scan tool, read the DTC’s.

Has the brake switch low DTC returned?

Ye s>>

Replace the brake switch.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Perform Intermittent condition test. (Refer to 9 - ENGINE - DIAGNOSIS AND TESTING)

Page 723 of 5267

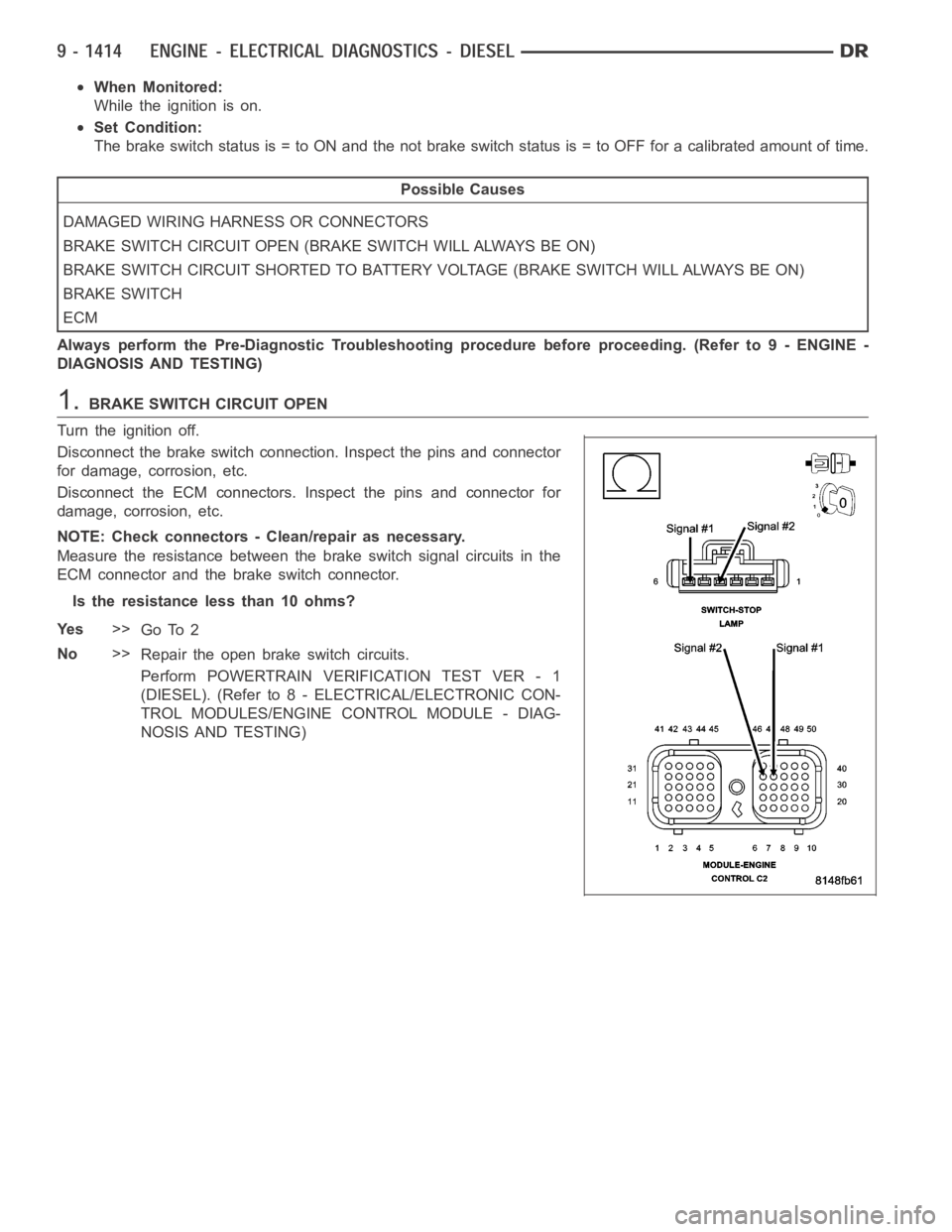

When Monitored:

While the ignition is on.

Set Condition:

The brake switch status is = to ON and the not brake switch status is = to OFF for a calibrated amount of time.

Possible Causes

DAMAGED WIRING HARNESS OR CONNECTORS

BRAKE SWITCH CIRCUIT OPEN (BRAKE SWITCH WILL ALWAYS BE ON)

BRAKE SWITCH CIRCUIT SHORTED TO BATTERY VOLTAGE (BRAKE SWITCH WILL ALWAYSBE ON)

BRAKE SWITCH

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.BRAKE SWITCH CIRCUIT OPEN

Turn the ignition off.

Disconnect the brake switch connection. Inspect the pins and connector

for damage, corrosion, etc.

Disconnect the ECM connectors. Inspect the pins and connector for

damage, corrosion, etc.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance between the brake switch signal circuits in the

ECM connector and the brake switch connector.

Is the resistance less than 10 ohms?

Ye s>>

Go To 2

No>>

Repair the open brake switch circuits.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 724 of 5267

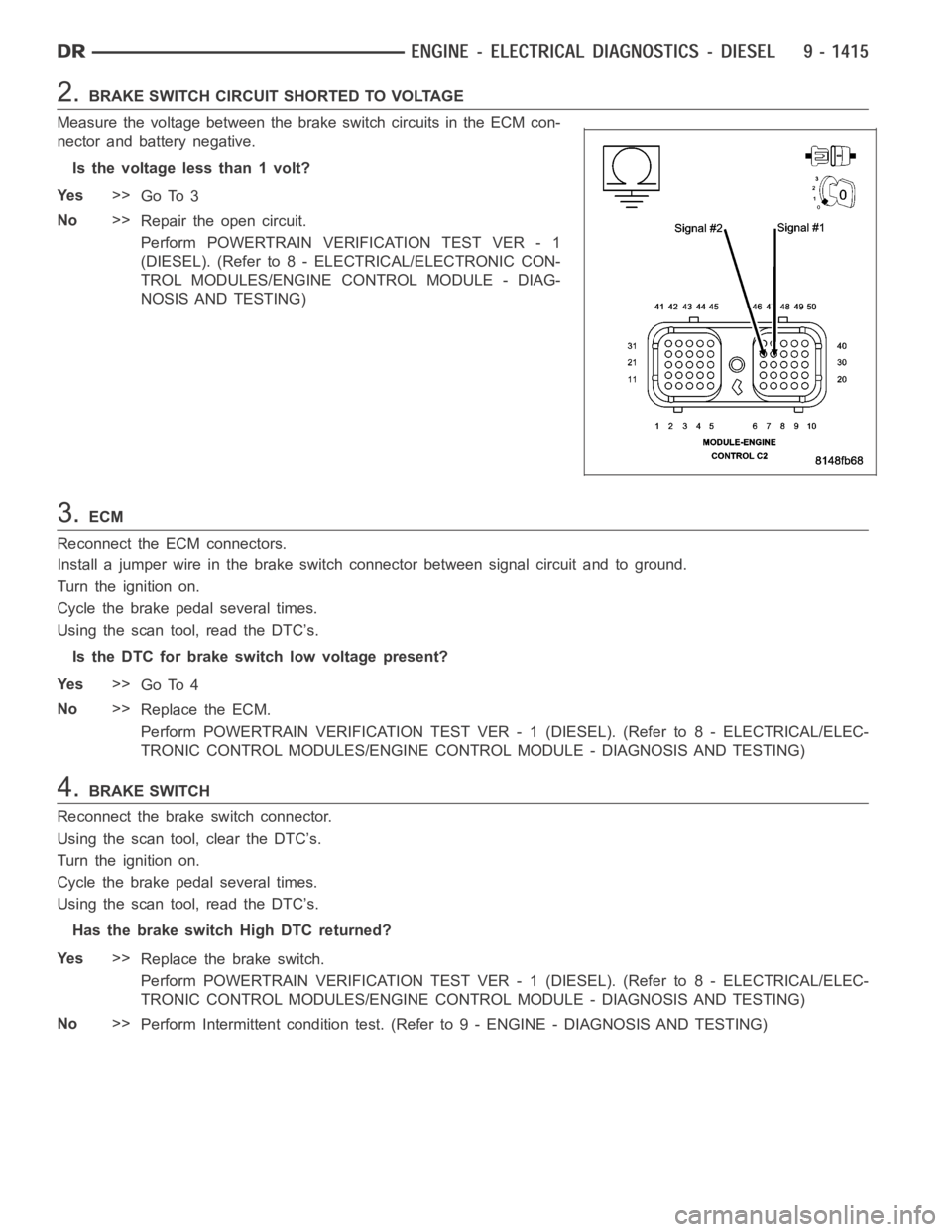

2.BRAKE SWITCH CIRCUIT SHORTED TO VOLTAGE

Measure the voltage between the brake switch circuits in the ECM con-

nector and battery negative.

Is the voltage less than 1 volt?

Ye s>>

Go To 3

No>>

Repair the open circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

3.ECM

Reconnect the ECM connectors.

Install a jumper wire in the brake switch connector between signal circuitand to ground.

Turn the ignition on.

Cycle the brake pedal several times.

Using the scan tool, read the DTC’s.

Is the DTC for brake switch low voltage present?

Ye s>>

Go To 4

No>>

Replace the ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

4.BRAKE SWITCH

Reconnect the brake switch connector.

Using the scan tool, clear the DTC’s.

Turn the ignition on.

Cycle the brake pedal several times.

Using the scan tool, read the DTC’s.

Has the brake switch High DTC returned?

Ye s>>

Replace the brake switch.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Perform Intermittent condition test. (Refer to 9 - ENGINE - DIAGNOSIS AND TESTING)

Page 726 of 5267

When Monitored:

While the ignition is on

Set Condition:

Speed control MUX switch below 1.0 volts for 5 seconds.

Possible Causes

S/C WIRING HARNESS OBSERVABLE PROBLEM

S/C SWITCH (ON/OFF)

CLOCKSPRING SHORTED TO GROUND

S/C SWITCH (RESUME/ACCEL)

S/C SWITCH SIGNAL CIRCUIT SHORTED TO GROUND

S/C SIGNAL CIRCUIT SHORTED TO SENSOR GROUND

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.S/C SWITCH VOLTAGE BELOW 1.0 VOLT

Turn the ignition on.

With the scan tool, read the S/C Switch volts status in the ECM.

Is the S/C Switch voltage below 1.0 volt?

Ye s>>

Go To 3

No>>

Go To 2

2.S/C WIRING HARNESS OBSERVABLE PROBLEM

Turn the ignition off.

Using the Schematics as a guide, inspect the Wiring and Connectors.

Were any problems found?

Ye s>>

Repair as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 3

3.S/C SWITCH (ON/OFF)

Turn the ignition off.

Disconnect the S/C ON/OFF Switch harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Turn the ignition on.

With the scan tool in Sensors, read the S/C Switch volts in the ECM.

Did the S/C Switch volts change to 5.0 volts?

Ye s>>

Replace the S/C ON/OFF Switch.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 4

Page 727 of 5267

4.S/C SWITCH (RESUME/ACCEL)

Turn the ignition off.

Disconnect the S/C RESUME/ACCEL Switch harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

With the scan tool in Sensors, read the S/C Switch volts in the ECM.

Did the S/C Switch volts go above 4.0 volts?

Ye s>>

Replace the Resume/Accel Switch.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 5

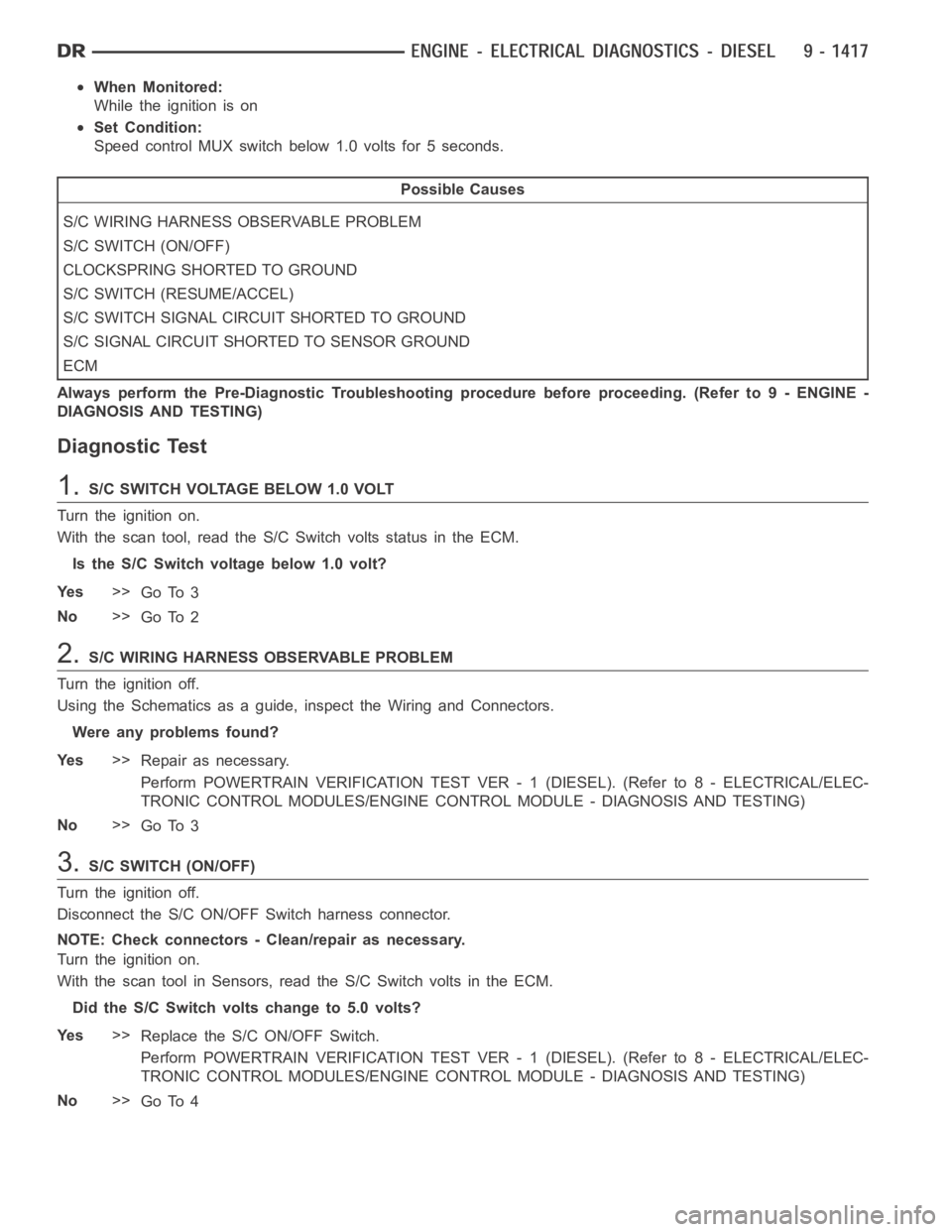

5.CLOCKSPRING SHORTED TO GROUND

Turn the ignition off.

Disconnect the clockspring6-way harness connector (instrument panel

wiring side).

Turn the ignition on.

With the scan tool in Sensors, read the S/C Switch volts in the ECM.

Did the S/C Switch volts change to 5.0 volts?

Ye s>>

Replace the Clockspring.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Go To 6

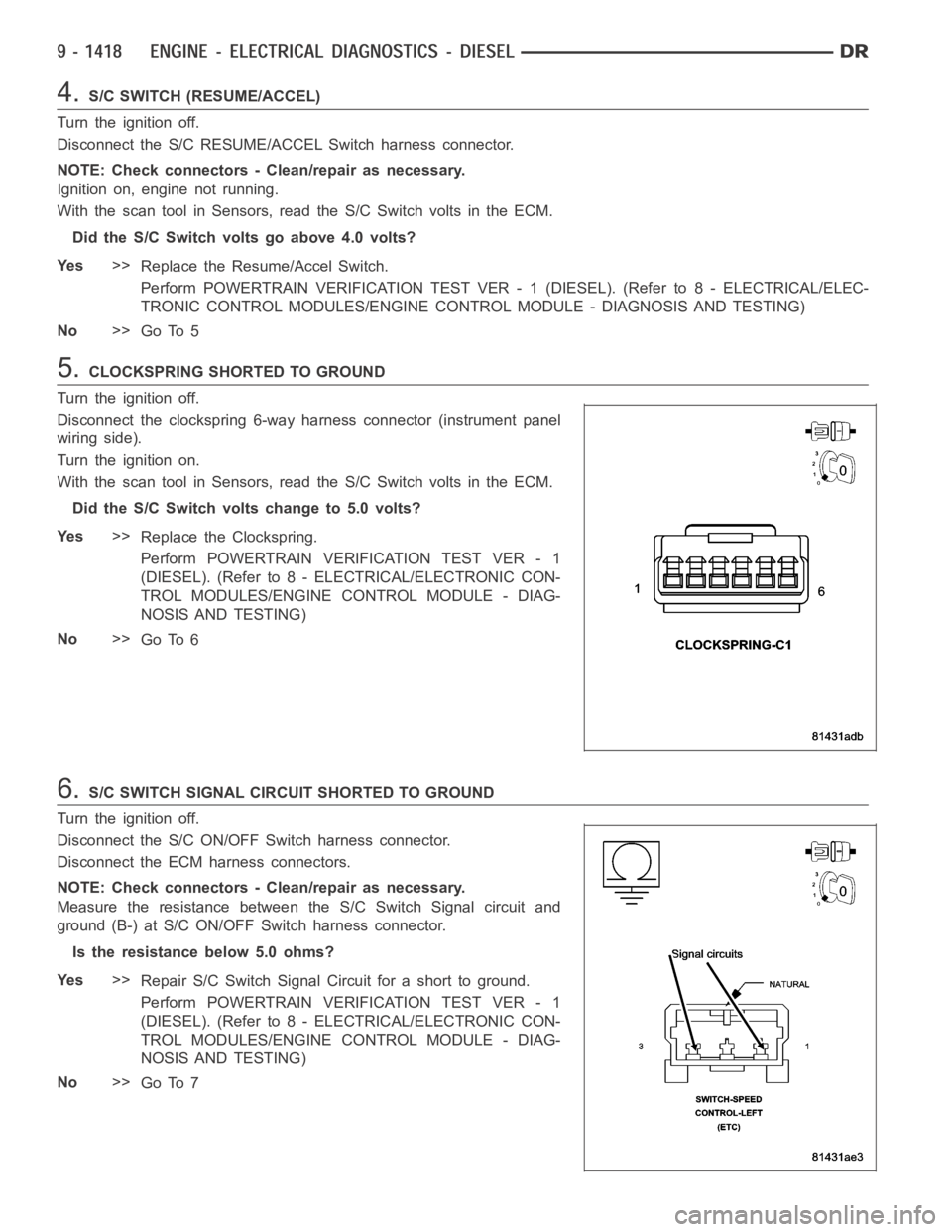

6.S/C SWITCH SIGNAL CIRCUIT SHORTED TO GROUND

Turn the ignition off.

Disconnect the S/C ON/OFF Switch harness connector.

Disconnect the ECM harness connectors.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance between the S/C Switch Signal circuit and

ground (B-) at S/C ON/OFF Switch harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Repair S/C Switch Signal Circuit for a short to ground.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Go To 7