DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4891 of 5267

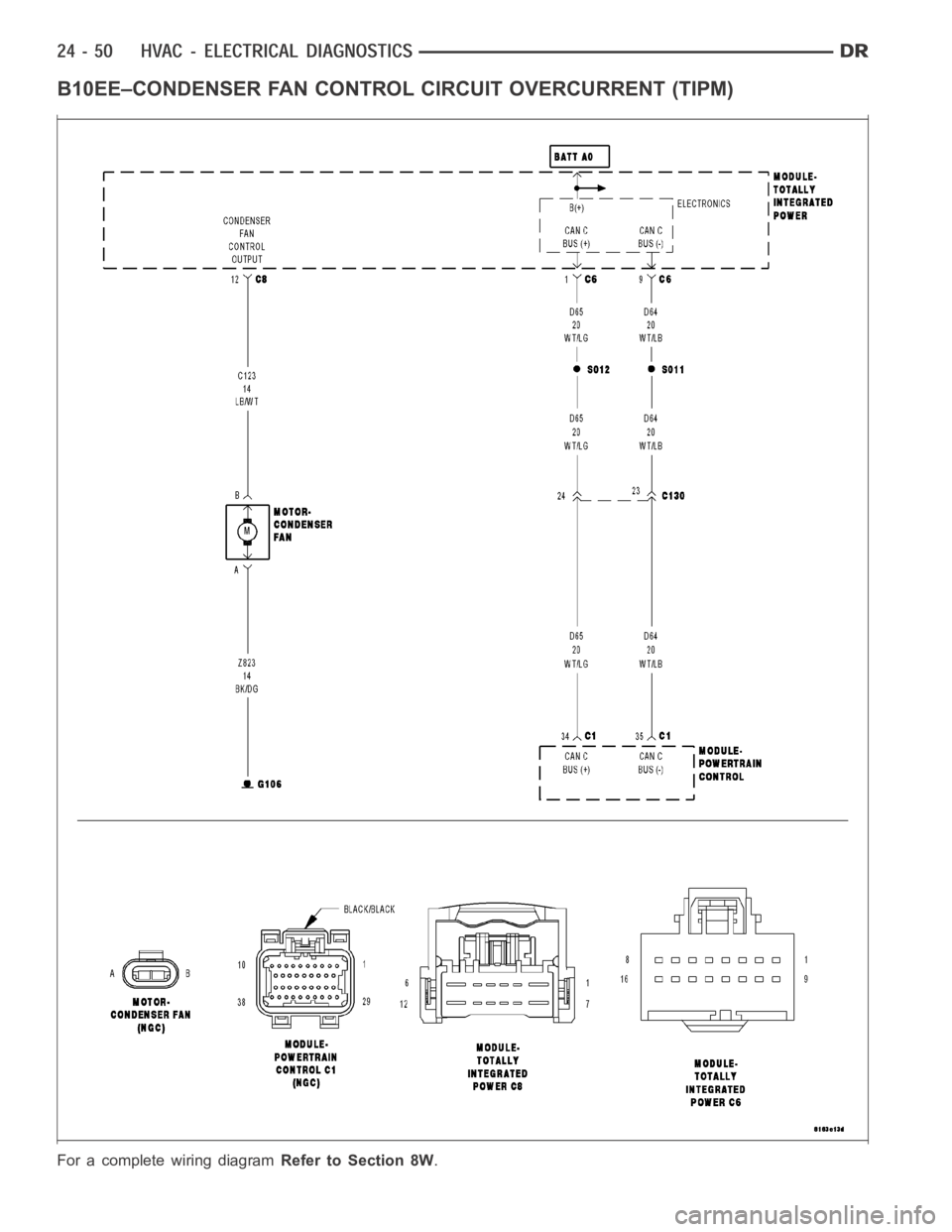

B10EE–CONDENSER FAN CONTROLCIRCUIT OVERCURRENT (TIPM)

For a complete wiring diagramRefer to Section 8W.

Page 4892 of 5267

When Monitored:

With the ignition on. Battery voltage greater than 10.4 volts. PCM requesting Condenser Fan operation.

Set Condition:

If the Totally Integrated Power Module (TIPM) detects an overcurrent condition on the (C123) Condenser Fan

Control Output circuit.

Possible Causes

TERMINAL DAMAGE OR CORROSION

(Z823) GROUND CIRCUIT HIGH RESISTANCE

(C123) CONDENSER FAN CONTROL OUTPUT CIRCUIT HIGH RESISTANCE

CONDENSER FAN MOTOR

TIPM

Diagnostic Test

1.VERIFY DTC IS ACTIVE

Turn the ignition on.

With the scan tool, erase TIPM DTCs.

Turn the ignition off, wait 10 seconds, and turn the ignition on.

With the scan tool, actuate the Condenser Fan.

With the scan tool, read TIPM DTCs.

Does this DTC reset?

Ye s>>

With the scan tool, de-actuate the Condenser Fan. Then, Go To 2

No>>

With the scan tool, de-actuate the Condenser Fan. Then, check for an intermittent condition by inspect-

ing the related wiring harness for chafed, pierced, pinched, and partially broken wires. Also, inspect the

related connectors for broken, bent, corroded, and contaminated terminals.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

2.INSPECT RELATED WIRING HARNESS & CONNECTORS

Turn the ignition off.

Disconnect the TIPM C8 harness connector.

Disconnect the Condenser Fan Motor harness connector.

Inspect the terminal and connector condition. Check for signs of corrosion build up and damage that would com-

promise the terminal to controller pin connection.

NOTE: Make sure that all in-line connectors are inspected for corrosion and damage.

Visually inspect the wiring harness. Look for any chafed, pierced, pinched or partially broken wires hidden in the

wire insulation.

Were any of the above conditions found?

Ye s>>

Repair or replace as necessary.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

No>>

Go To 3

Page 4893 of 5267

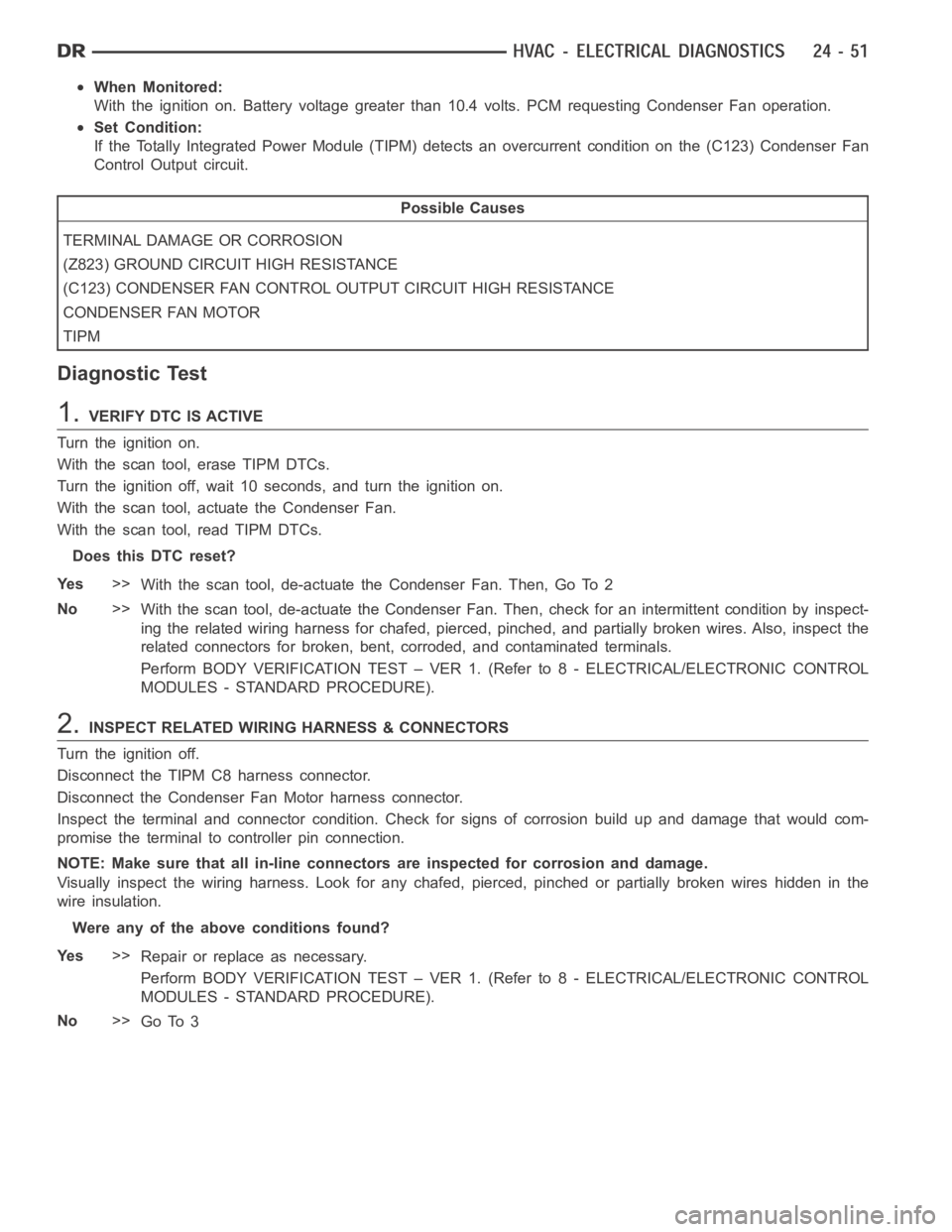

3.CHECK (C123) CONDENSER FAN CONTROL OUTPUT CIRCUIT FOR HIGH RESISTANCE

Connect one end of a jumper wire to the (C123) Condenser Fan Control

Output circuit in the Condenser Fan Motor harness connector and con-

nect the other end to a clean chassis ground.

Using a 12-volt test light connected to 12 volts, probe the (C123) Con-

denser Fan Control Output circuit in the TIPM C8 harness connector.

NOTE: The test light should illuminate brightly. Compare the

brightness to that of a direct connection to the battery.

Does the test light illuminate brightly.

Ye s>>

Go To 4

No>>

Repair the excessive resistance in the (C123) Condenser

Fan Control Output circuit.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

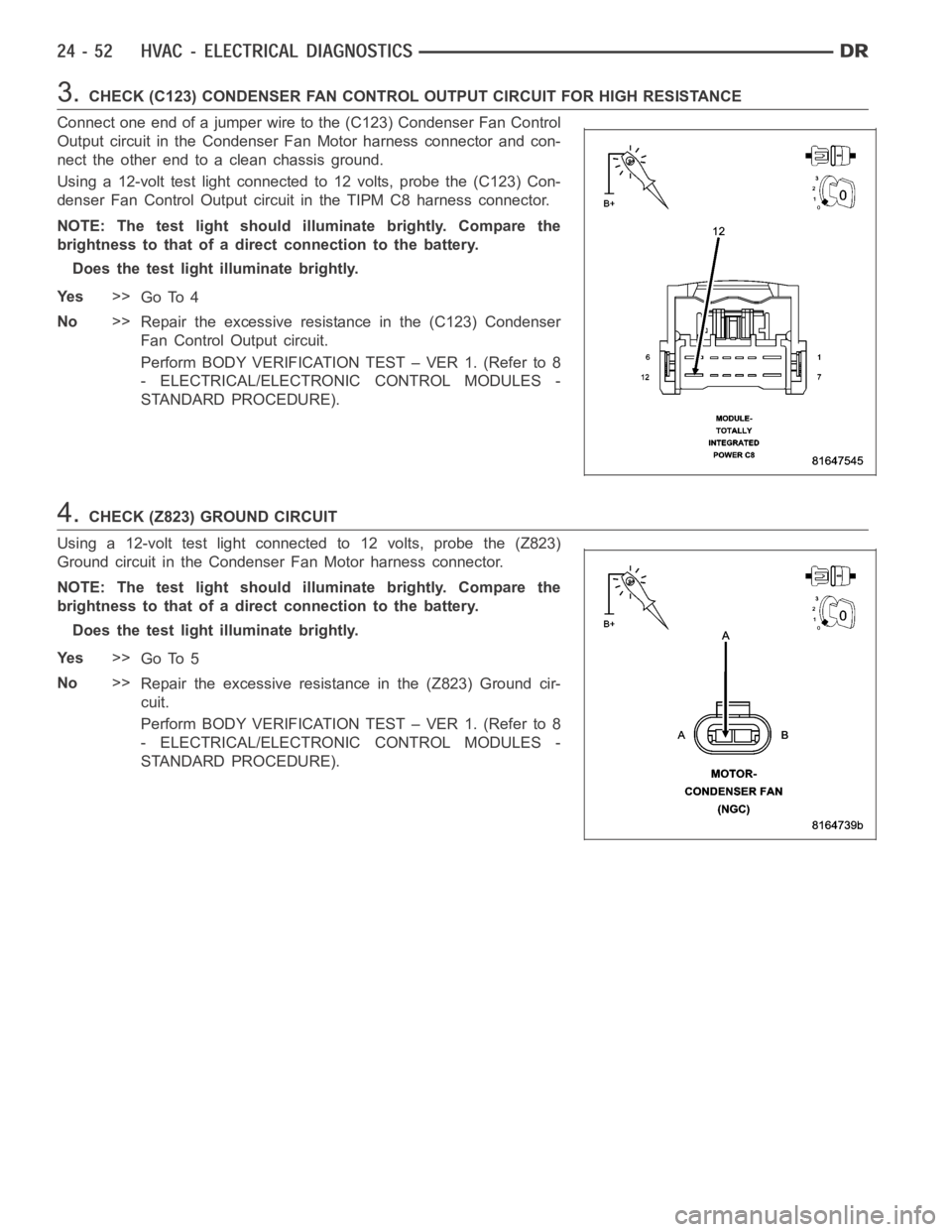

4.CHECK (Z823) GROUND CIRCUIT

Using a 12-volt test light connected to 12 volts, probe the (Z823)

Ground circuit in the Condenser Fan Motor harness connector.

NOTE: The test light should illuminate brightly. Compare the

brightness to that of a direct connection to the battery.

Does the test light illuminate brightly.

Ye s>>

Go To 5

No>>

Repair the excessive resistance in the (Z823) Ground cir-

cuit.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

Page 4894 of 5267

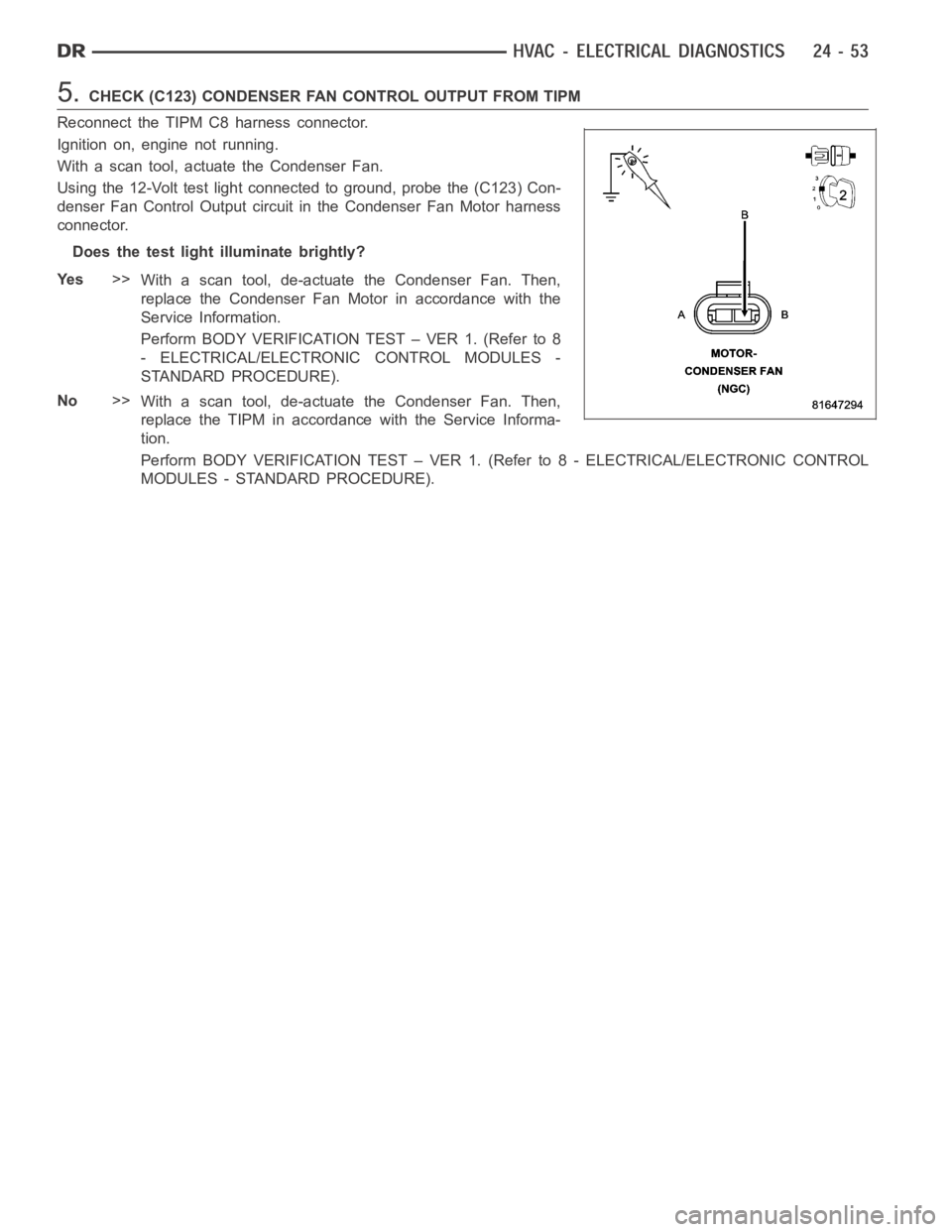

5.CHECK (C123) CONDENSER FAN CONTROL OUTPUT FROM TIPM

Reconnect the TIPM C8 harness connector.

Ignition on, engine not running.

With a scan tool, actuate the Condenser Fan.

Using the 12-Volt test light connected to ground, probe the (C123) Con-

denser Fan Control Output circuit in the Condenser Fan Motor harness

connector.

Does the test light illuminate brightly?

Ye s>>

With a scan tool, de-actuate the Condenser Fan. Then,

replace the Condenser Fan Motor in accordance with the

Service Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

No>>

With a scan tool, de-actuate the Condenser Fan. Then,

replace the TIPM in accordance with the Service Informa-

tion.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Page 4895 of 5267

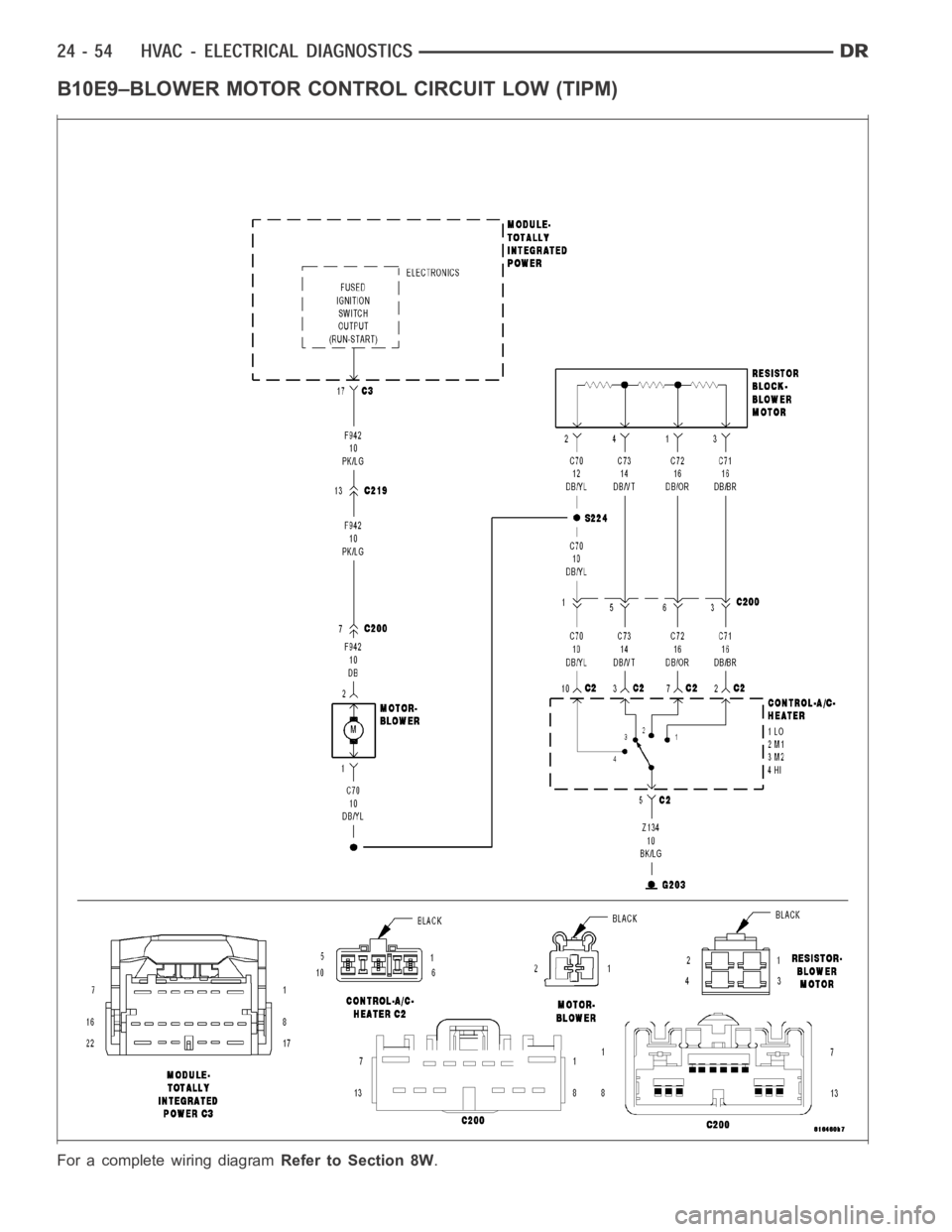

B10E9–BLOWER MOTOR CONTROL CIRCUIT LOW (TIPM)

For a complete wiring diagramRefer to Section 8W.

Page 4896 of 5267

When Monitored:

With the ignition on.

Set Condition:

If the Totally Integrated Power Module (TIPM) detects an excessive current draw on the (F942) Fused Ignition

Switch Output (Run-Start) circuit for 20 micro seconds when blower motor operation is requested.

Possible Causes

(F942) FUSED IGNITION SWITCH OUTPUT (RUN-START) CIRCUIT SHORTED TO GROUND

BLOWER MOTOR

TIPM

Diagnostic Test

1.VERIFY DTC IS ACTIVE

Turn the blower control switch to off.

Turn the ignition off, wait 10 seconds, and turn the ignition on.

With the scan tool, erase TIPM DTCs.

Turn the ignition off, wait 10 seconds, and turn the ignition on.

Turn the blower control switch to on.

With the scan tool, read TIPM DTCs.

Does this DTC reset?

Ye s>>

Go To 2

No>>

Check for an intermittent condition by inspecting the related wiring harness for chafed, pierced, pinched,

and partially broken wires. Also, inspect the related connectors for broken, bent, corroded, and contam-

inated terminals.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

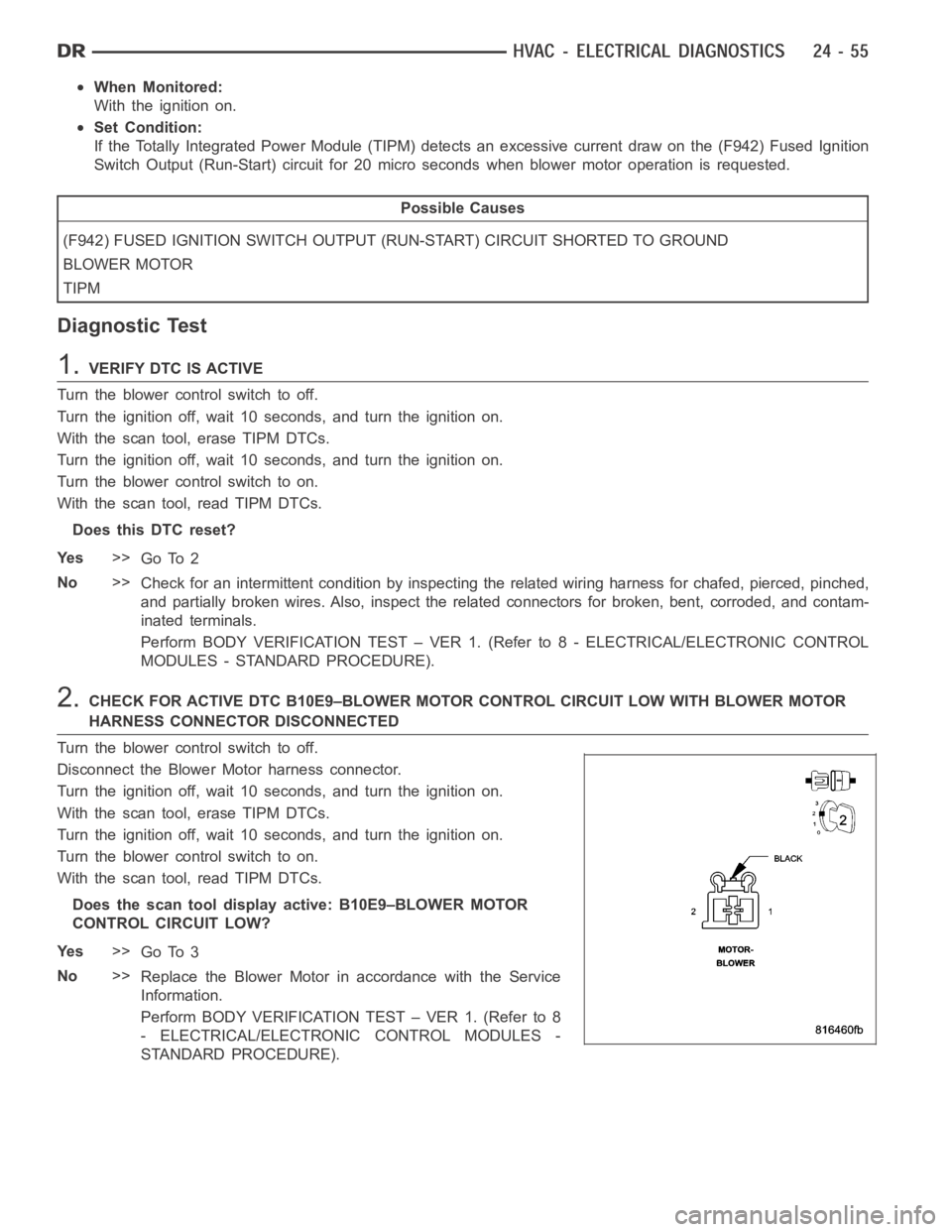

2.CHECK FOR ACTIVE DTC B10E9–BLOWER MOTOR CONTROL CIRCUIT LOW WITH BLOWER MOTOR

HARNESS CONNECTOR DISCONNECTED

Turn the blower control switch to off.

Disconnect the Blower Motor harness connector.

Turn the ignition off, wait 10 seconds, and turn the ignition on.

With the scan tool, erase TIPM DTCs.

Turn the ignition off, wait 10 seconds, and turn the ignition on.

Turn the blower control switch to on.

With the scan tool, read TIPM DTCs.

Does the scan tool display active: B10E9–BLOWER MOTOR

CONTROL CIRCUIT LOW?

Ye s>>

Go To 3

No>>

Replace the Blower Motor in accordance with the Service

Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

Page 4897 of 5267

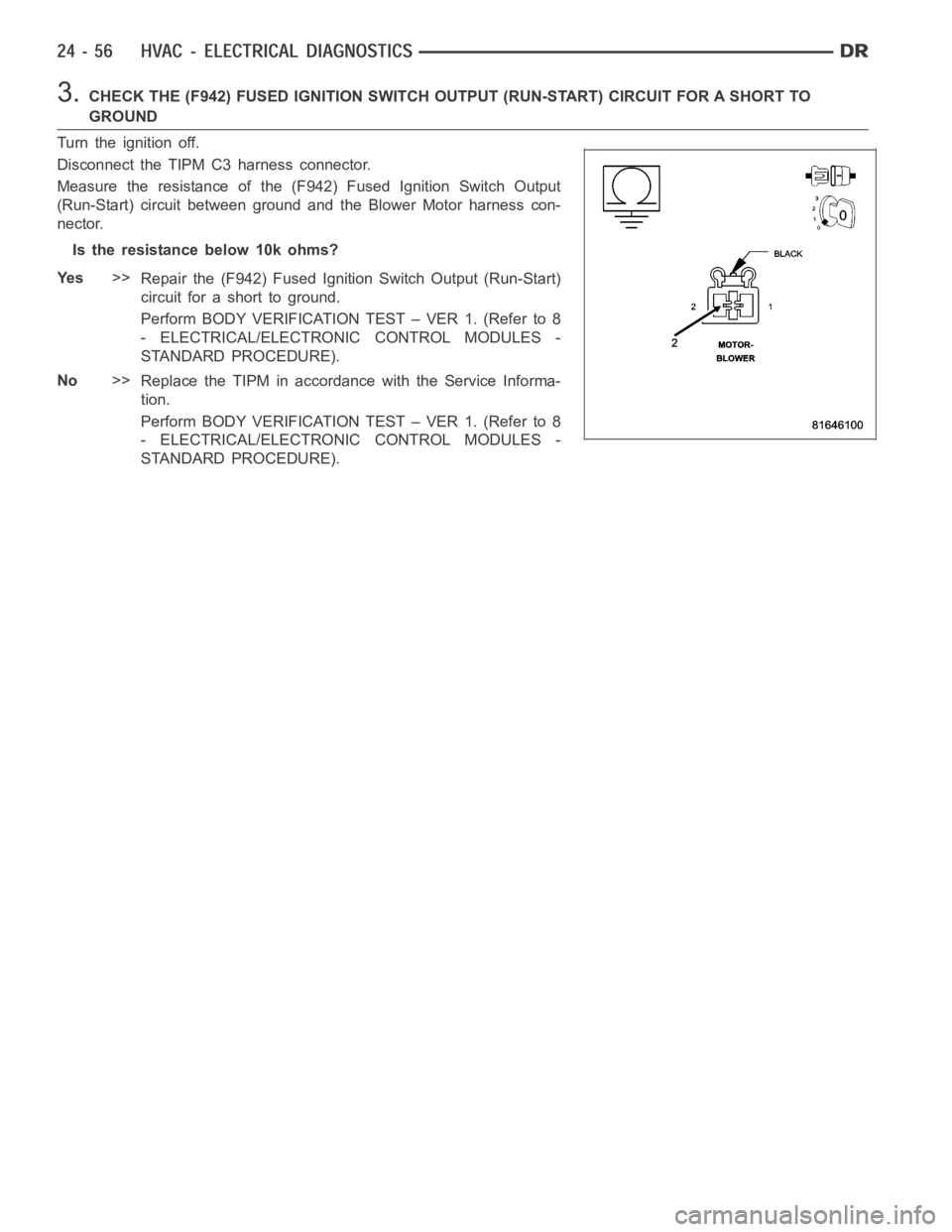

3.CHECK THE (F942) FUSED IGNITION SWITCH OUTPUT (RUN-START) CIRCUIT FOR A SHORT TO

GROUND

Turn the ignition off.

Disconnect the TIPM C3 harness connector.

Measure the resistance of the (F942) Fused Ignition Switch Output

(Run-Start) circuit between ground and the Blower Motor harness con-

nector.

Istheresistancebelow10kohms?

Ye s>>

Repair the (F942) Fused Ignition Switch Output (Run-Start)

circuit for a short to ground.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

No>>

Replace the TIPM in accordance with the Service Informa-

tion.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

Page 4898 of 5267

B104A–FLOOR/DEFROST MODEDOOR TRAVEL RANGE TOO SMALL

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

The A/C Heater Control calibrates each actuator individually. Automaticcalibration occurs upon power up after

installing a new A/C Heater Control. Manual calibration occurs by sendinga command with the scan tool. The pur-

pose of actuator calibration is to determine the total span of door travel between physical stops. To calibrate the

actuator, the A/C Heater Control first moves the door to an end stop, and then counts the number of pulses it takes

to move the door to its other stop. An expected range of span is stored in the control’s memory. If the measured

calibration value is less than the expected range for this actuator, this DTC will set. Note thatthe control clears all

stored calibration faults at the beginning of the calibration procedure.

When Monitored:

During actuator calibration.

Set Condition:

If the total span of the Mode 2 (Defrost to Floor) Door is less than the low range limit.

Possible Causes

DOOR DRIVER ELECTRICAL CIRCUIT(S)

MODE 2 (DEFROST TO FLOOR) DOOR SEIZED, BINDING, OBSTRUCTED

MODE DOOR 2 (DEFROST TO FLOOR) ACTUATOR

A/C HEATER CONTROL

Diagnostic Test

1.CHECK FOR ACTIVE CONTROL CIRCUIT/PERFORMANCE DTCs

Turn the ignition on.

With the scan tool, read active HVAC DTCs.

Does the scan tool display any active: XXXX CONTROL CIRCUIT/PERFORMANCE DTCs?

Ye s>>

Diagnose and repair the DTC(s). Refer to the Table of Contents in this Section for a complete list of

HVAC related symptoms.

No>>

Go To 2

2.CHECK FOR ACTIVE CONTROL CIRCUIT OPEN DTCs

With the scan tool, read active HVAC DTCs.

Does the scan tool display any active: XXXX CONTROL CIRCUIT OPEN DTCs?

Ye s>>

Diagnose and repair the DTC(s). Refer to the Table of Contents in this Section for a complete list of

HVAC related symptoms.

No>>

Go To 3

3.RUN THE ACTUATOR DTC DETECTION TEST

With the scan tool in HVAC, select System Tests and then select Actuator DTCDetection. When the test is com-

plete, select View DTCs.

Does the scan tool display any DTCs?

Yes, Dual-Zone System

Diagnose and repair the DTC(s). If multiple DTCs are present, beginning with the passenger blend door,

diagnose and repair all short high DTCs and then all short low DTCs. Refer tothe Table of Contents in

this Section for a complete list of HVAC related symptoms.

Yes, Single-Zone System

Page 4899 of 5267

>>

Diagnose and repair the DTC(s). If multiple DTCs are present, beginning with the common circuit, diag-

nose and repair all short high DTCs first and then all short low DTCs. Refer to the Table of Contents in

this Section for a complete list of HVAC related symptoms.

No>>

Go To 4

4.INSPECT ACTUATOR & HOUSING ASSEMBLY FOR A CONDITION CAUSING THE DOOR TO SEIZE OR

BIND

Turn the ignition off.

Inspect the actuator, linkage, and housing assembly for a condition causing the door to seize or bind.

Are there any physical or mechanical problems with the door, housing, linkage, or actuator?

Ye s>>

Repair as necessary in accordance with the Service Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

No>>

Go To 5

5.CHECK MODE 2 (DEFROST TO FLOOR) DOOR TRAVEL

Remove the Mode Door 2 (Defrost to Floor) Actuator from the A/C Heater Housing Assembly.

By hand, attempt to rotate the door in both directions. The door should operate smoothly in both directions over

approximately 103 degrees of travel.

Does the door operate smoothly in both directions over approximately 103 degrees of travel?

Ye s>>

Replace the Mode Door 2 (Defrost to Floor) Actuator in accordance with the Service Information. Then,

Go To 6.

No>>

Repair as necessary in accordance with the Service Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

6.RUN ACTUATOR CALIBRATION TEST

Turn the ignition on.

With the scan tool, select System Tests and then select Actuator Calibration Test. When the test is complete, select

View DTCs.

Does the scan tool display: B104A–FLOOR/DEFROST MODE DOOR TRAVEL RANGE TOOSMALL?

Ye s>>

Replace the A/C Heater Control in accordance with the Service Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

No>>

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Page 4900 of 5267

B104B–FLOOR/DEFROST MODEDOOR TRAVEL RANGE TOO LARGE

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

The A/C Heater Control calibrates each actuator individually. Automaticcalibration occurs upon power up after

installing a new A/C Heater Control. Manual calibration occurs by sendinga command with the scan tool. The pur-

pose of actuator calibration is to determine the total span of door travel between physical stops. To calibrate the

actuator, the A/C Heater Control first moves the door to an end stop, and then counts the number of pulses it takes

to move the door to its other stop. An expected range of span is stored in the control’s memory. If the measured

calibration value exceeds the expected range for this actuator, this DTC will set. Note that the control clears all

stored calibration faults at the beginning of the calibration procedure.

When Monitored:

During actuator calibration.

Set Condition:

If the total span of the Mode 2 (Defrost to Floor) Door exceeds the high rangelimit.

Possible Causes

DOOR DRIVER ELECTRICAL CIRCUIT(S)

MODE 2 (DEFROST TO FLOOR) DOOR OR A/C HEATER HOUSING COMPONENTS WARPED, WORN,

DAMAGED, MISSING, BROKEN

MODE DOOR 2 (DEFROST TO FLOOR) ACTUATOR

A/C HEATER CONTROL

Diagnostic Test

1.CHECK FOR ACTIVE CONTROL CIRCUIT/PERFORMANCE DTCs

Turn the ignition on.

With the scan tool, read active HVAC DTCs.

Does the scan tool display any active: XXXX CONTROL CIRCUIT/PERFORMANCE DTCs?

Ye s>>

Diagnose and repair the DTC(s). Refer to the Table of Contents in this Section for a complete list of

HVAC related symptoms.

No>>

Go To 2

2.CHECK FOR ACTIVE CONTROL CIRCUIT OPEN DTCs

With the scan tool, read active HVAC DTCs.

Does the scan tool display any active: XXXX CONTROL CIRCUIT OPEN DTCs?

Ye s>>

Diagnose and repair the DTC(s). Refer to the Table of Contents in this Section for a complete list of

HVAC related symptoms.

No>>

Go To 3