steering DODGE RAM SRT-10 2006 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2410 of 5267

FLOW AND PRESSURE TEST

1. Check the power steering belt to ensure it is in good condition and adjusted properly.

2. Connect pressure gauge hose from the Power Steering Analyzer to adapter6826.

3. Connect tube 6825A to Power Steering Analyzer test valve end.

4. Disconnect the high pressure hose from the power steering pump.

5. Connect the tube 6825A to the pump fitting.

6. Connect the power steering hose from the steering gear to the adapter 6826.

NOTE: If fluid leaked from the steering system, it should be filled to correct lervel prior to starting the

engine.

7. Open the test valve completely.

8. Start engine and let idle long enough to circulate power steering fluid through flow/pressure test gauge and to get

air out of the fluid. Then shut off engine.

9. Check fluid level, add fluid as necessary. Start engine again and let idle.

10. Gauge should read below 862 kPa (125 psi), if above, inspect the hoses for restrictions and repair as neces-

sary. The initial pressure reading should be in the range of 345-552 kPa (50-80 psi).

11. Increase the engine speed to 1500 RPM and read the flow meter. If the flowrate (GPM) is below specification,

(refer to pump specification chart for GPM) the pump should be replaced.

CAUTION: The following test procedure involves testing maximum pump pressure output and flow control

valve operation. Do not leave valve closed for more than three seconds as the pump could be damaged.

12. Close valve fully three times and record highest pressure indicated each time.All three readings must be

above specifications and within 345 kPa (50 psi) of each other.

Pressures above specifications but not within 345 kPa (50 psi) of each other, replace pump.

Pressures within 345 kPa (50 psi) of each other but below specifications, replace pump.

13. Open the test valve and turn the steering wheel to the extreme left and right positions three times against the

stops. Record the highest pressure reading at each position. Compare readings to the pump specifications

chart. If pressures readings are not within 50 psi of each other, the gear isleaking internally and must be

replaced.

CAUTION: Do not force the pump to operate against the stops for more than 2 to3 seconds at a time

because, pump damage will result.

PUMP SPECIFICATION

ENGINE RELIEF PRESSURE ± 65 FLOW RATE (GPM) AT 1500 RPM

1500 series 11032 kPa (1615 ± 65 psi) 3.1 - 3.5

2500 & 3500

series12400 kPa (1800 ± 50 psi) 3.5 - 4.0

Page 2411 of 5267

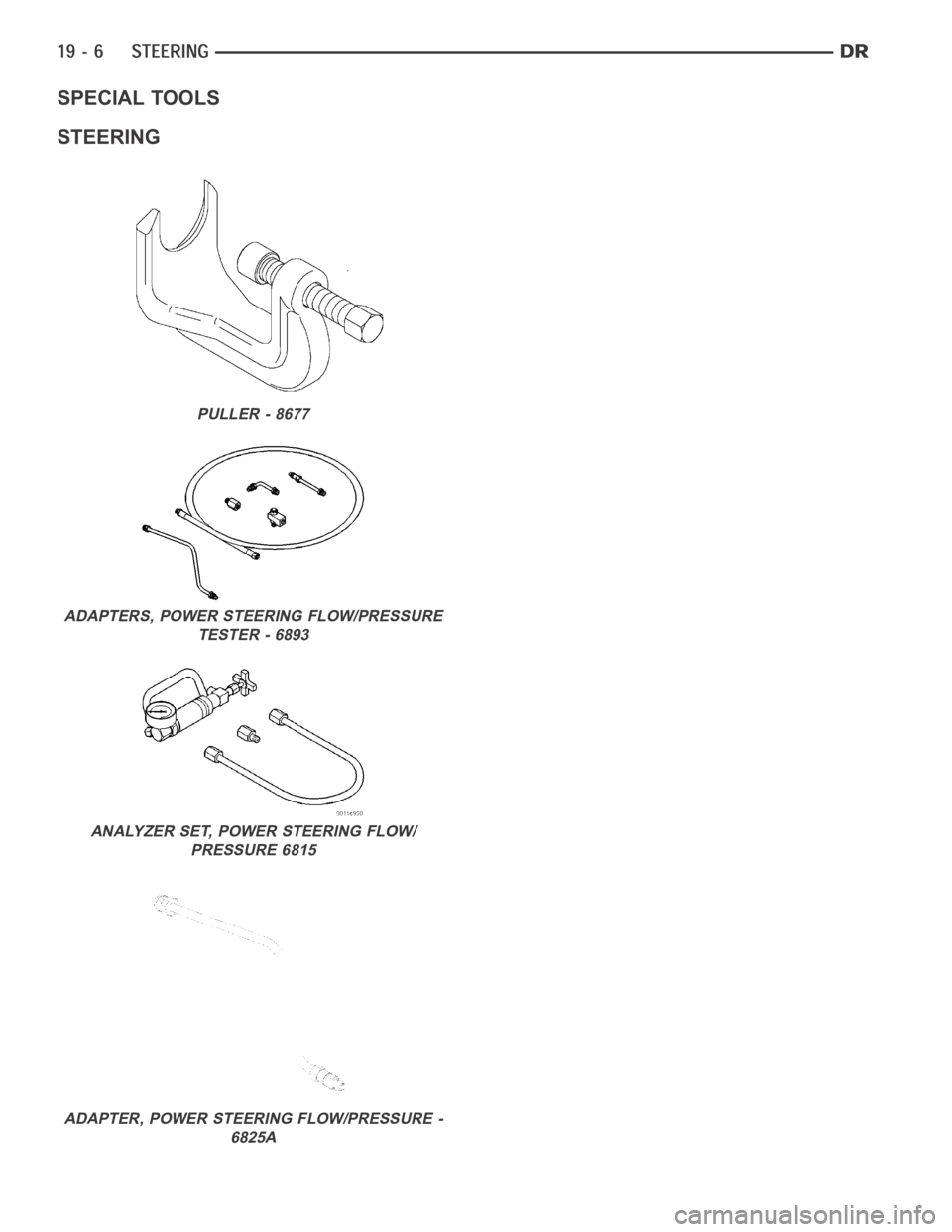

SPECIAL TOOLS

STEERING

PULLER - 8677

ADAPTERS, POWER STEERING FLOW/PRESSURE

TESTER - 6893

ANALYZER SET, POWER STEERING FLOW/

PRESSURE 6815

ADAPTER, POWER STEERING FLOW/PRESSURE -

6825A

Page 2412 of 5267

page page

COLUMN

DESCRIPTION

DESCRIPTION ............................... 8

DESCRIPTION - SRT10 ....................... 9

DIAGNOSIS AND TESTING

STEERING COLUMN ......................... 9

REMOVAL ..................................... 9

INSTALLATION ............................... 12

SPECIFICATIONS

TORQUE ................................... 14

IGNITION SWITCH

DESCRIPTION ................................ 15

OPERATION .................................. 15

DIAGNOSIS AND TESTING

IGNITION SWITCH .......................... 15

REMOVAL .................................... 16

INSTALLATION ............................... 17

IGNITION SWITCH - SRT10

REMOVAL - SRT10 ............................ 19

INSTALLATION - SRT10 ....................... 21

KEY-IN IGNITION SWITCH

DESCRIPTION ................................ 22

DIAGNOSIS AND TESTING

IGNITION SWITCH AND KEY LOCK

CYLINDER................................. 22KEY CYLINDER

REMOVAL .................................... 23

INSTALLATION ............................... 23

STEERING WHEEL

REMOVAL .................................... 24

INSTALLATION ............................... 24

TILT LEVER KNOB RELEASE

REMOVAL .................................... 25

INSTALLATION ............................... 26

GEAR SHIFT LEVER

REMOVAL .................................... 28

INSTALLATION ............................... 29

UPPER STEERING COUPLING

REMOVAL .................................... 32

INSTALLATION ............................... 33

LOWER STEERING COUPLING

REMOVAL

ALL LD & HD EXCEPT 4X4 HD ............... 34

4X4 HD .................................... 34

INSTALLATION

ALL LD & HD EXCEPT 4X4 HD ............... 36

4X4 HD .................................... 36

Page 2413 of 5267

COLUMN

DESCRIPTION

DESCRIPTION

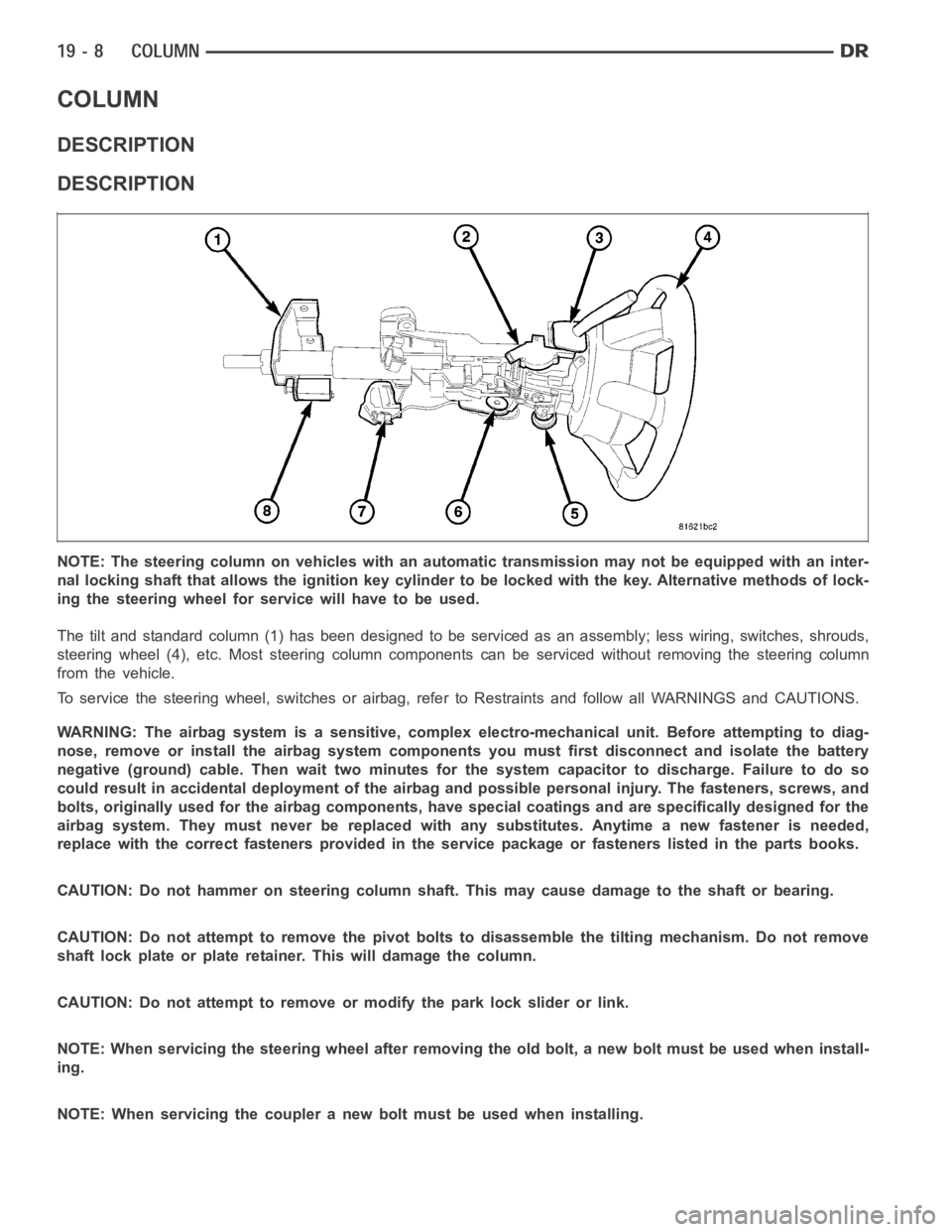

NOTE: The steering column on vehicles with an automatic transmission may not be equipped with an inter-

nal locking shaft that allows the ignition key cylinder to be locked with the key. Alternative methods of lock-

ing the steering wheel for service will have to be used.

The tilt and standard column (1) has been designed to be serviced as an assembly; less wiring, switches, shrouds,

steering wheel (4), etc. Most steering column components can be serviced without removing the steering column

from the vehicle.

To service the steering wheel, switches or airbag, refer to Restraints andfollow all WARNINGS and CAUTIONS.

WARNING: The airbag system is a sensitive, complex electro-mechanical unit. Before attempting to diag-

nose, remove or install the airbag system components you must first disconnect and isolate the battery

negative (ground) cable. Then wait two minutes for the system capacitor todischarge. Failure to do so

could result in accidental deployment of the airbag and possible personalinjury. The fasteners, screws, and

bolts, originally used for the airbag components, have special coatings and are specifically designed for the

airbag system. They must never be replaced with any substitutes. Anytime anew fastener is needed,

replace with the correct fasteners provided in the service package or fasteners listed in the parts books.

CAUTION: Do not hammer on steering column shaft. This may cause damage to the shaft or bearing.

CAUTION: Do not attempt to remove the pivot bolts to disassemble the tilting mechanism. Do not remove

shaft lock plate or plate retainer. This will damage the column.

CAUTION: Do not attempt to remove or modify the park lock slider or link.

NOTE: When servicing the steering wheel after removing the old bolt, a new bolt must be used when install-

ing.

NOTE: When servicing the coupler a new bolt must be used when installing.

Page 2414 of 5267

DESCRIPTION - SRT10

The SRT-10 column has noSTARTposition on the key cylinder. The push starter button switch is mounted on the

Instrument panel center stack. All SRT-10 columns are Tilt columns, Standard cab trucks come with manual trans-

missions, Quad cab trucks come equipped with automatic transmissions.

DIAGNOSIS AND TESTING

STEERING COLUMN

If the vehicle is involved in a front end collision/the air bag has deployedthe column must be inspected. This

inspection will determine if the Column has collapsed. Inspect the columnmounting capsules visually and manually

push and pull them to check for separation or fractures. If capsules are fractured or have moved the column MUST

be replaced.

REMOVAL

WARNING: Before servicing the steering column the airbag system must be disarmed. Refer to electrical

restraint system for service procedures. Failure to do so may result in accidental deployment of the airbag

and possible personal injury.

CAUTION: All fasteners must be torqued to specification to ensure proper operation of the steering column.

1. Position the front wheelsstraight ahead.

2. Disconnect the negative (ground) cable from the battery.

3. Remove the airbag, (Refer to 8 - ELECTRICAL/RE-

STRAINTS/DRIVER AIRBAG - REMOVAL).

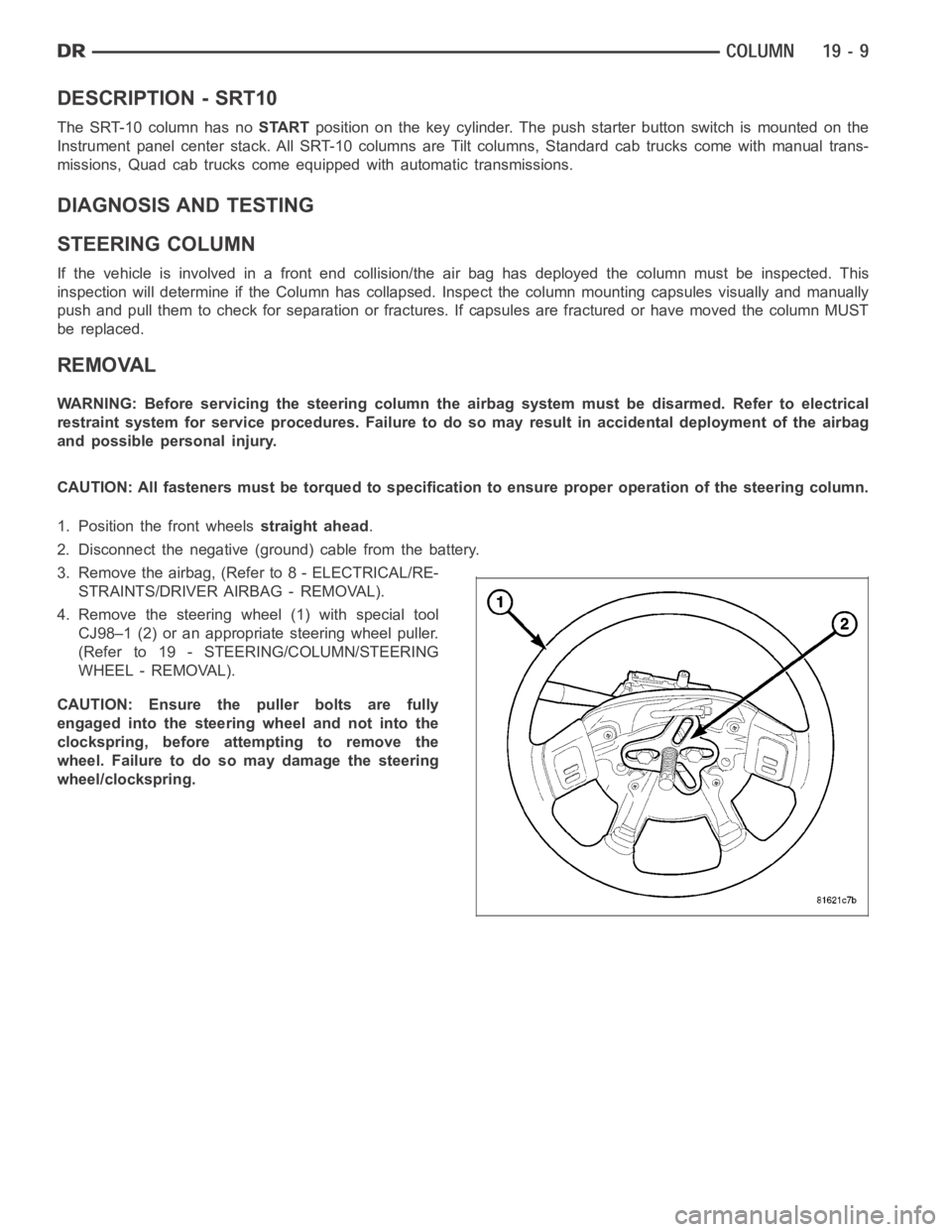

4. Remove the steering wheel (1) with special tool

CJ98–1 (2) or an appropriate steering wheel puller.

(Refer to 19 - STEERING/COLUMN/STEERING

WHEEL - REMOVAL).

CAUTION: Ensure the puller bolts are fully

engaged into the steering wheel and not into the

clockspring, before attempting to remove the

wheel. Failure to do so may damage the steering

wheel/clockspring.

Page 2415 of 5267

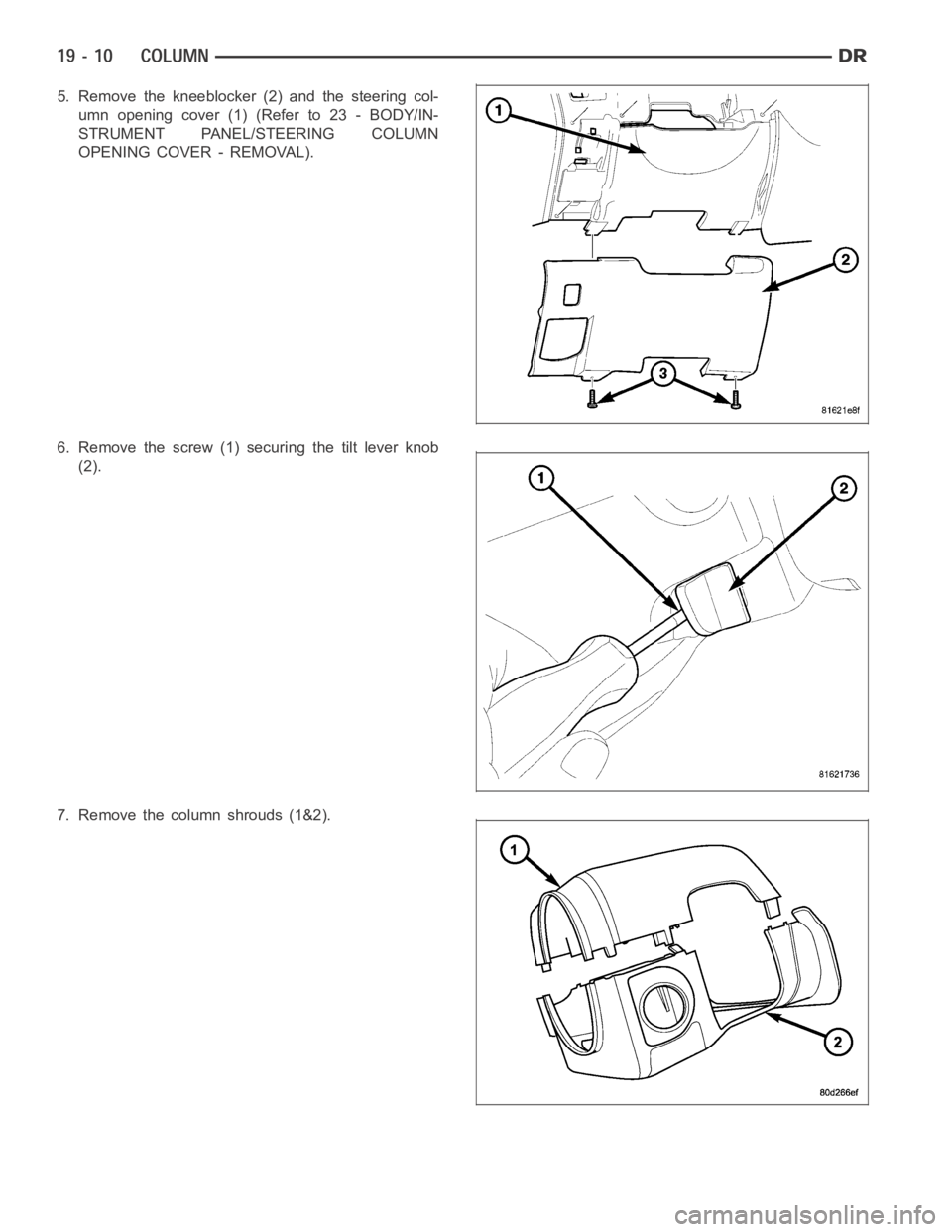

5. Remove the kneeblocker (2) and the steering col-

umn opening cover (1) (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

6. Remove the screw (1) securing the tilt lever knob

(2).

7. Remove the column shrouds (1&2).

Page 2416 of 5267

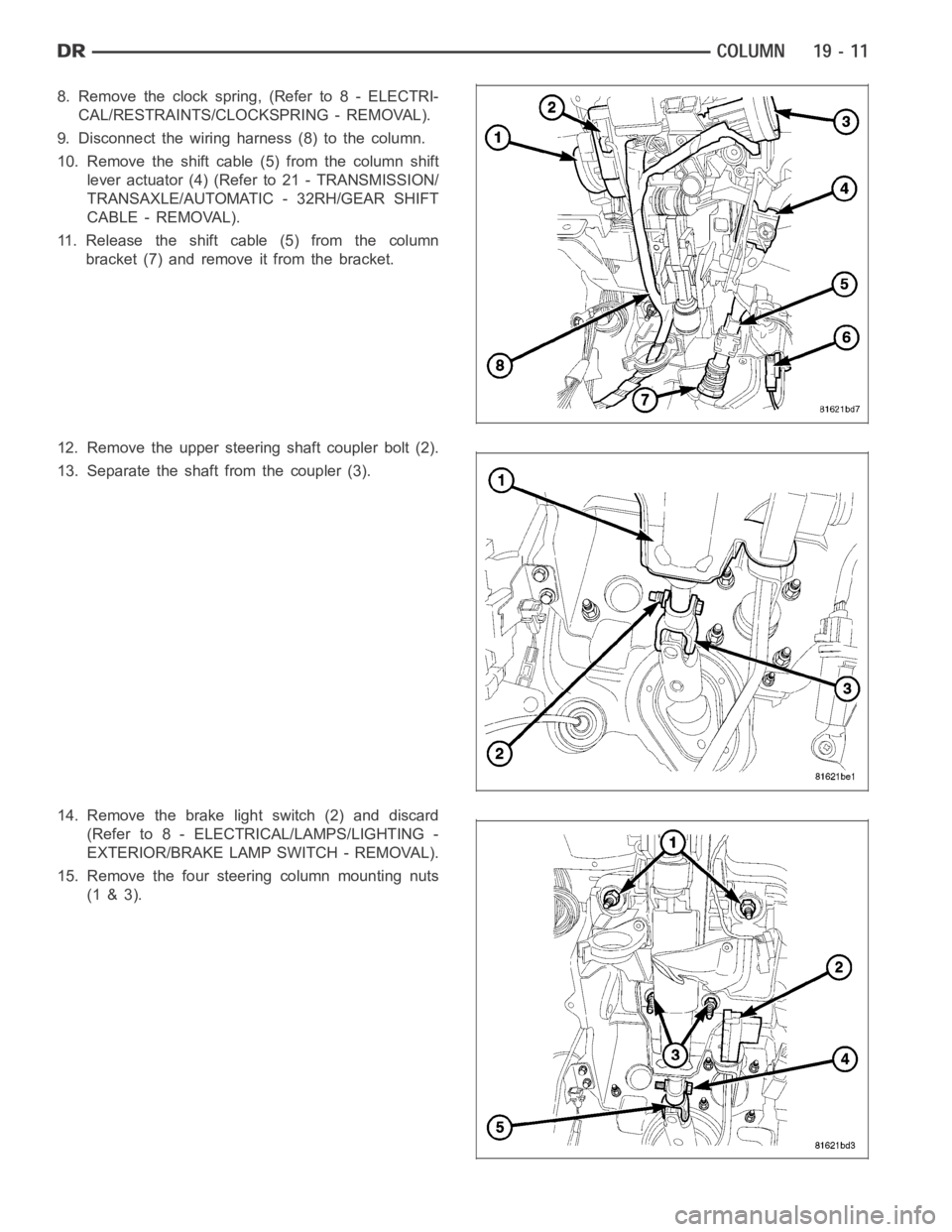

8. Remove the clock spring, (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/CLOCKSPRING - REMOVAL).

9. Disconnect the wiring harness (8) to the column.

10. Remove the shift cable (5) from the column shift

lever actuator (4) (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 32RH/GEAR SHIFT

CABLE - REMOVAL).

11. Release the shift cable (5) from the column

bracket (7) and remove it from the bracket.

12. Remove the upper steering shaft coupler bolt (2).

13. Separate the shaft from the coupler (3).

14. Remove the brake light switch (2) and discard

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/BRAKE LAMP SWITCH - REMOVAL).

15. Remove the four steering column mounting nuts

(1 & 3).

Page 2417 of 5267

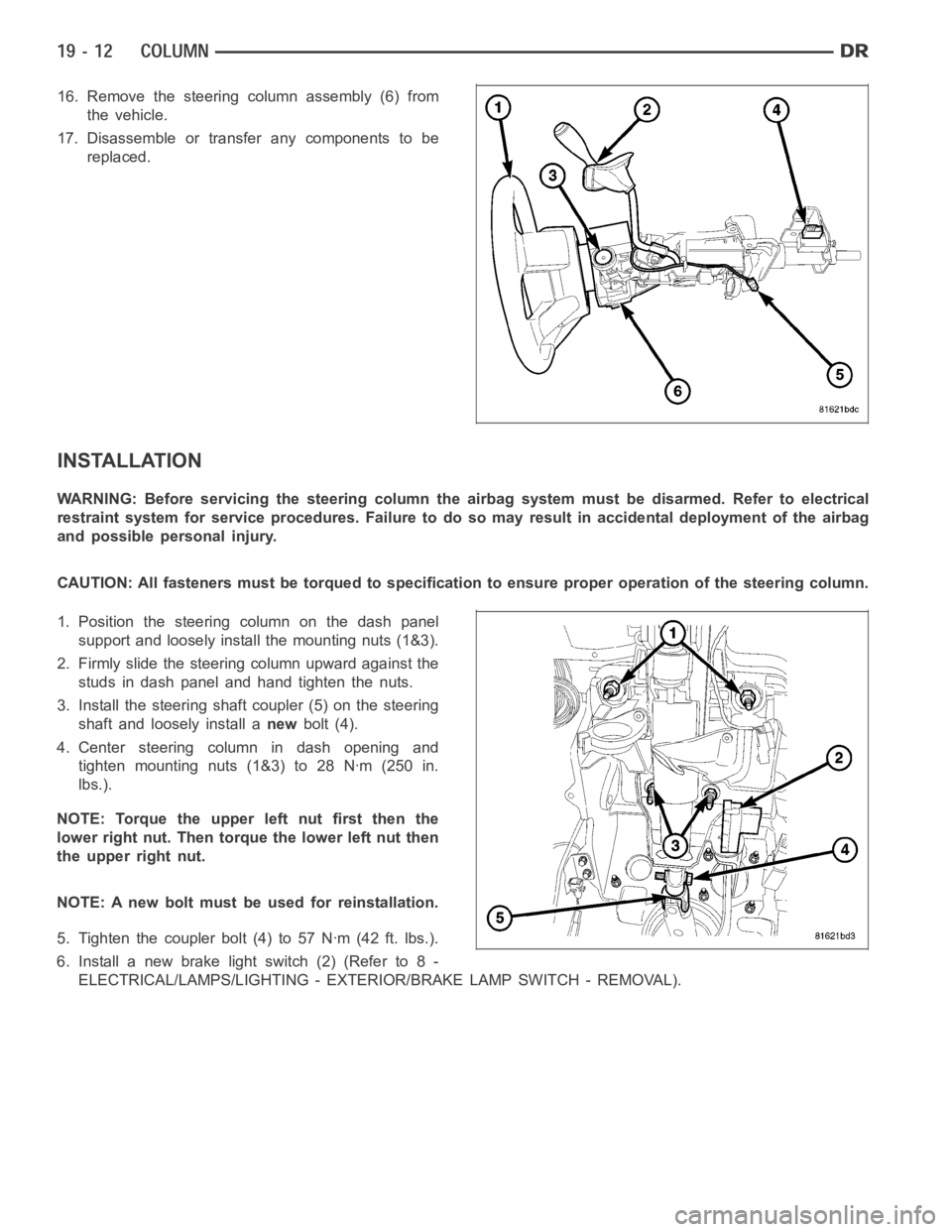

16. Remove the steering column assembly (6) from

the vehicle.

17. Disassemble or transfer any components to be

replaced.

INSTALLATION

WARNING: Before servicing the steering column the airbag system must be disarmed. Refer to electrical

restraint system for service procedures. Failure to do so may result in accidental deployment of the airbag

and possible personal injury.

CAUTION: All fasteners must be torqued to specification to ensure proper operation of the steering column.

1. Position the steering column on the dash panel

support and loosely install the mounting nuts (1&3).

2. Firmly slide the steering column upward against the

studs in dash panel and hand tighten the nuts.

3. Install the steering shaft coupler (5) on the steering

shaft and loosely install anewbolt (4).

4. Center steering column in dash opening and

tighten mounting nuts (1&3) to 28 Nꞏm (250 in.

lbs.).

NOTE: Torque the upper left nut first then the

lower right nut. Then torque the lower left nut then

the upper right nut.

NOTE: A new bolt must be used for reinstallation.

5. Tighten the coupler bolt (4) to 57 Nꞏm (42 ft. lbs.).

6. Install a new brake light switch (2) (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP SWITCH - REMOVAL).

Page 2418 of 5267

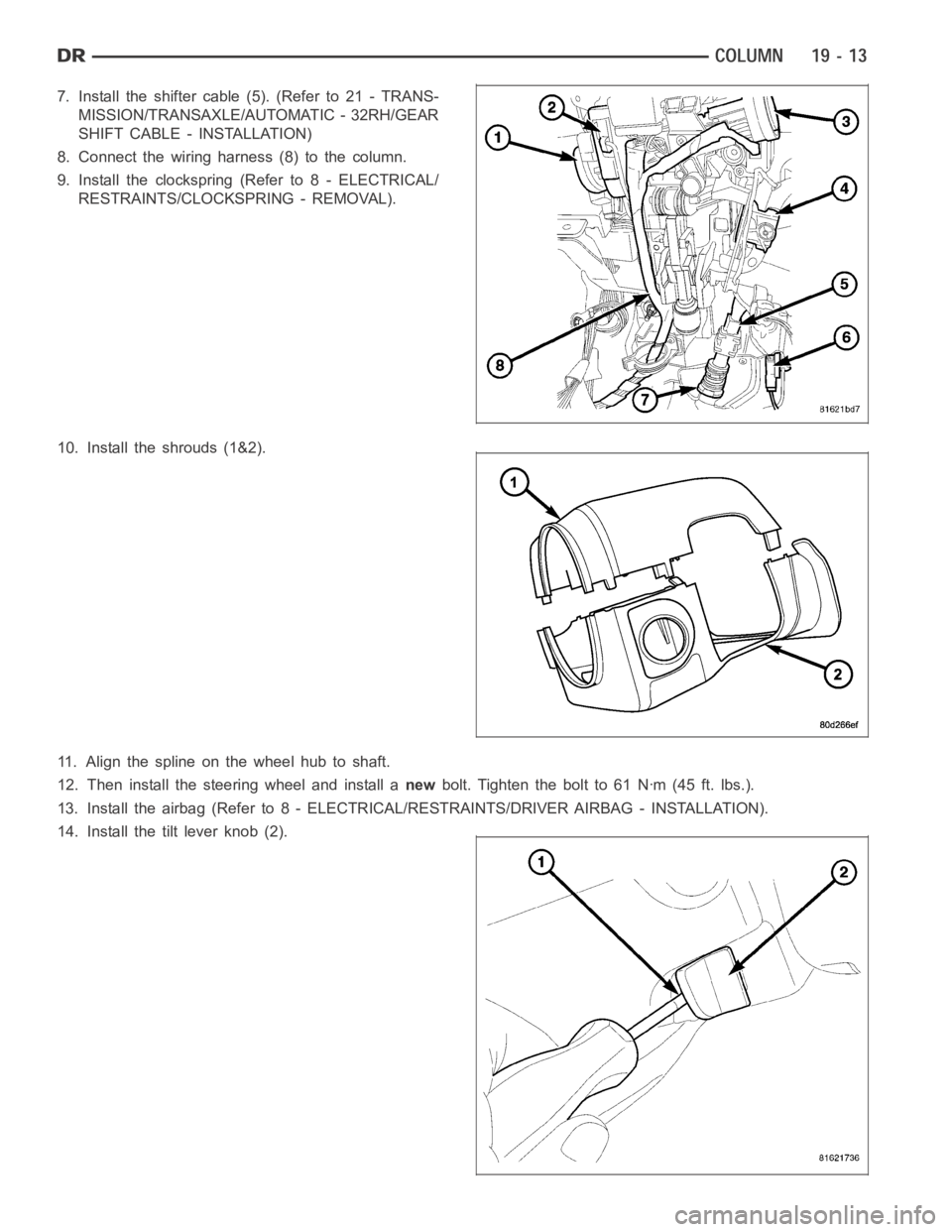

7. Install the shifter cable (5). (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 32RH/GEAR

SHIFT CABLE - INSTALLATION)

8. Connect the wiring harness (8) to the column.

9. Install the clockspring (Refer to 8 - ELECTRICAL/

RESTRAINTS/CLOCKSPRING - REMOVAL).

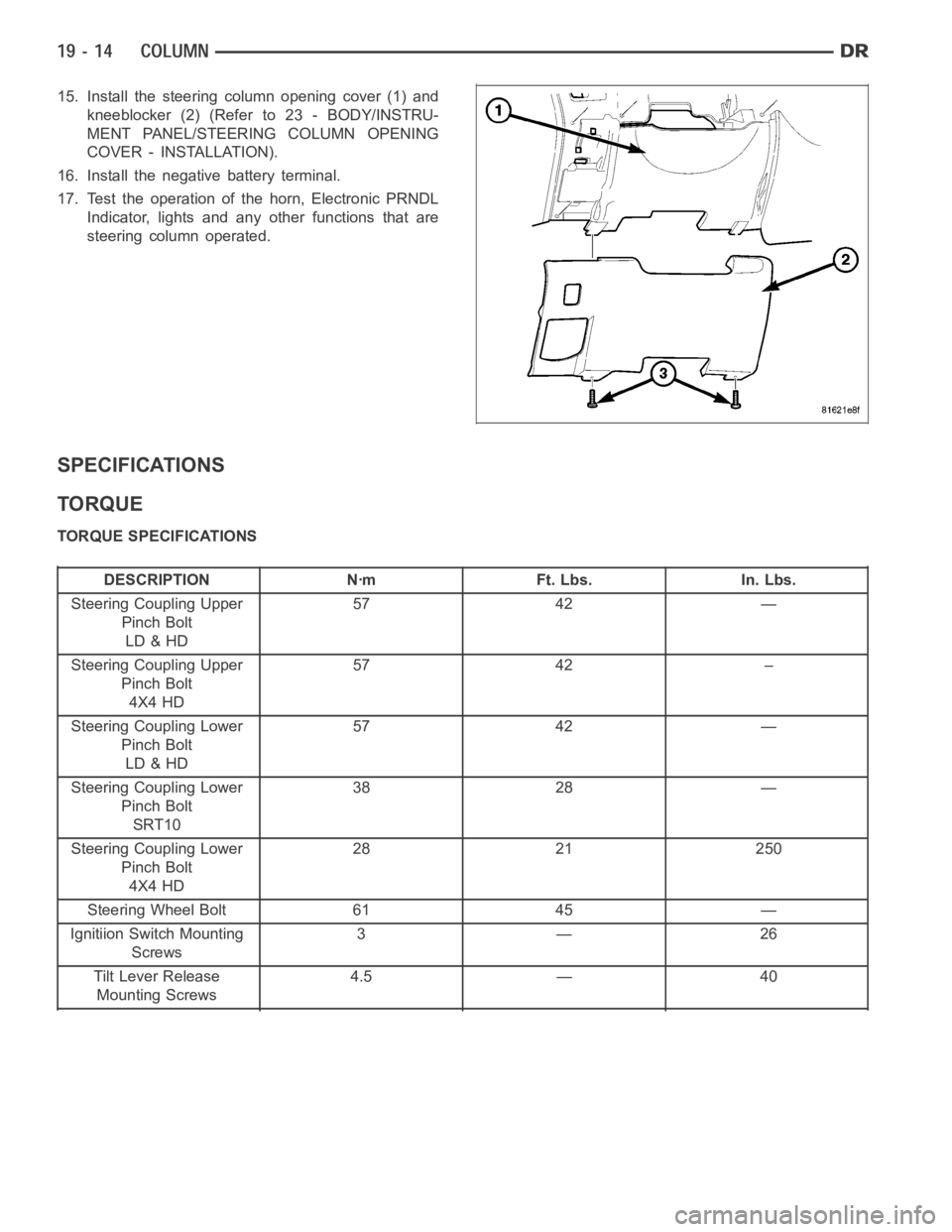

10. Install the shrouds (1&2).

11. Align the spline on the wheel hub to shaft.

12. Then install the steering wheel and install anewbolt. Tighten the bolt to 61 Nꞏm (45 ft. lbs.).

13. Install the airbag (Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER AIRBAG- INSTALLATION).

14. Install the tilt lever knob (2).

Page 2419 of 5267

15. Install the steering column opening cover (1) and

kneeblocker (2) (Refer to 23 - BODY/INSTRU-

MENT PANEL/STEERING COLUMN OPENING

COVER - INSTALLATION).

16. Install the negative battery terminal.

17. Test the operation of the horn, Electronic PRNDL

Indicator, lights and any other functions that are

steering column operated.

SPECIFICATIONS

TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Steering Coupling Upper

Pinch Bolt

LD & HD57 42 —

Steering Coupling Upper

Pinch Bolt

4X4 HD57 42 –

Steering Coupling Lower

Pinch Bolt

LD & HD57 42 —

Steering Coupling Lower

Pinch Bolt

SRT1038 28 —

Steering Coupling Lower

Pinch Bolt

4X4 HD28 21 250

Steering Wheel Bolt 61 45 —

Ignitiion Switch Mounting

Screws3—26

Tilt Lever Release

Mounting Screws4.5 — 40