trailer DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2174 of 5267

FRAME & BUMPERS

TABLE OF CONTENTS

page page

FRAMES & BUMPERS

SPECIFICATIONS

TORQUE .................................... 2

FRONT AIR DAM

REMOVAL ..................................... 3

INSTALLATION ................................ 3

FRONT BUMPER

REMOVAL ..................................... 4

INSTALLATION ................................ 4

FRONT FASCIA

REMOVAL ..................................... 5

INSTALLATION ................................ 6

REAR BUMPER

REMOVAL ..................................... 7

INSTALLATION ................................ 8

FASCIA-FRONT SRT-10

REMOVAL ..................................... 9

INSTALLATION ................................ 11

FASCIA-REAR SRT-10

REMOVAL .................................... 14

INSTALLATION ............................... 15

FRAME

WARNING

WARNINGS ................................ 17

STANDARD PROCEDURE

HYDROFORM FENDER RAIL REPAIR ........ 18REAR FRAME H-SECTION REPLACEMENT . . . 27

SPECIFICATIONS

WELD PROCESS ........................... 33

FRAME DIMENSIONS ....................... 34

TORQUE ................................... 45

FRONT CROSSMEMBER

REMOVAL .................................... 46

INSTALLATION ............................... 48

FRONT SKID PLATE

REMOVAL .................................... 50

INSTALLATION ............................... 51

FRONT TOW HOOK ASSEMBLY

REMOVAL .................................... 52

INSTALLATION ............................... 53

TRANSMISSION CROSSMEMBER

REMOVAL .................................... 54

INSTALLATION ............................... 56

TRAILER HITCH

REMOVAL .................................... 58

INSTALLATION ............................... 60

TRANSFER CASE SKID PLATE

REMOVAL .................................... 62

INSTALLATION ............................... 63

Page 2180 of 5267

REAR BUMPER

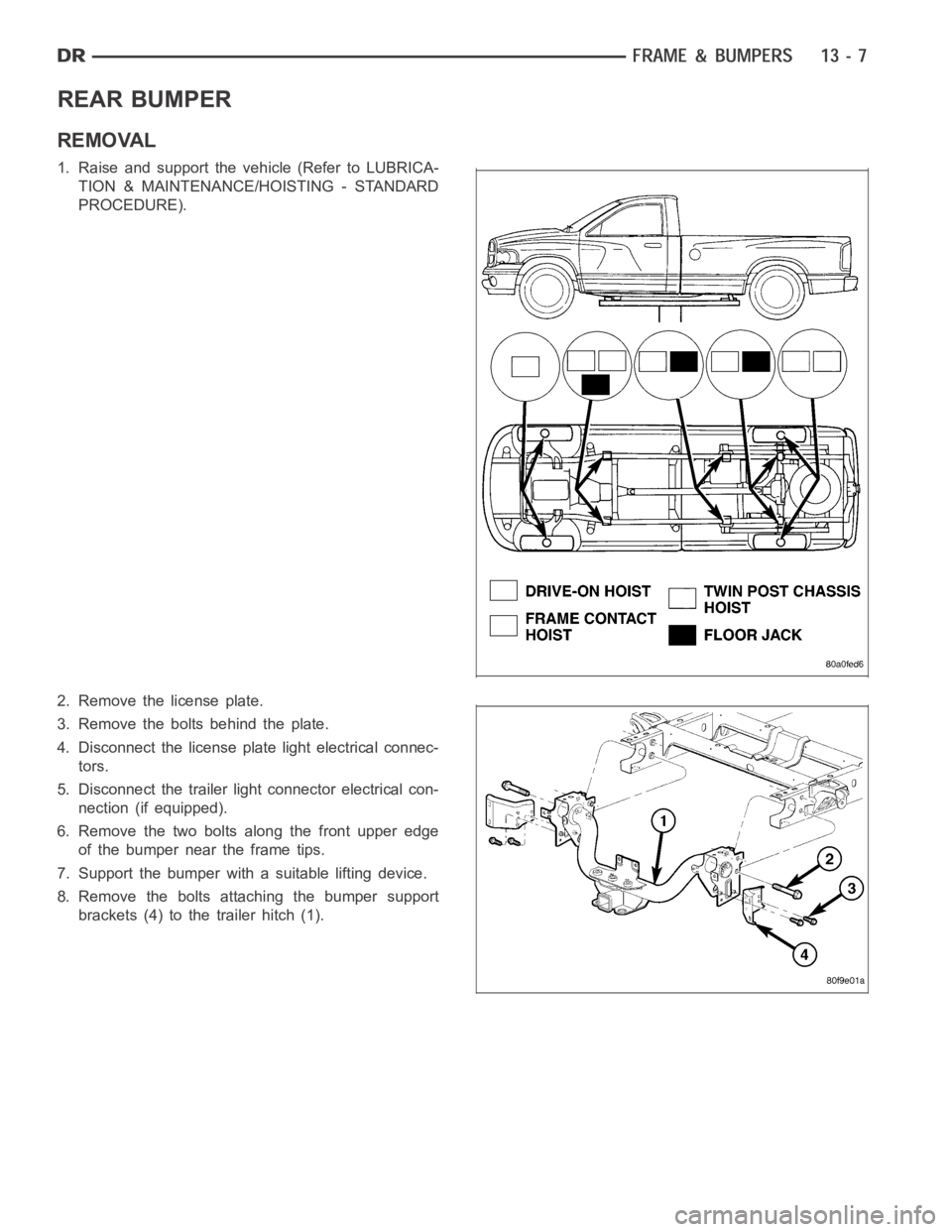

REMOVAL

1. Raise and support the vehicle (Refer to LUBRICA-

TION & MAINTENANCE/HOISTING - STANDARD

PROCEDURE).

2. Remove the license plate.

3. Remove the bolts behind the plate.

4. Disconnect the license plate light electrical connec-

tors.

5. Disconnect the trailer light connector electrical con-

nection (if equipped).

6. Remove the two bolts along the front upper edge

of the bumper near the frame tips.

7. Support the bumper with a suitable lifting device.

8. Remove the bolts attaching the bumper support

brackets (4) to the trailer hitch (1).

Page 2181 of 5267

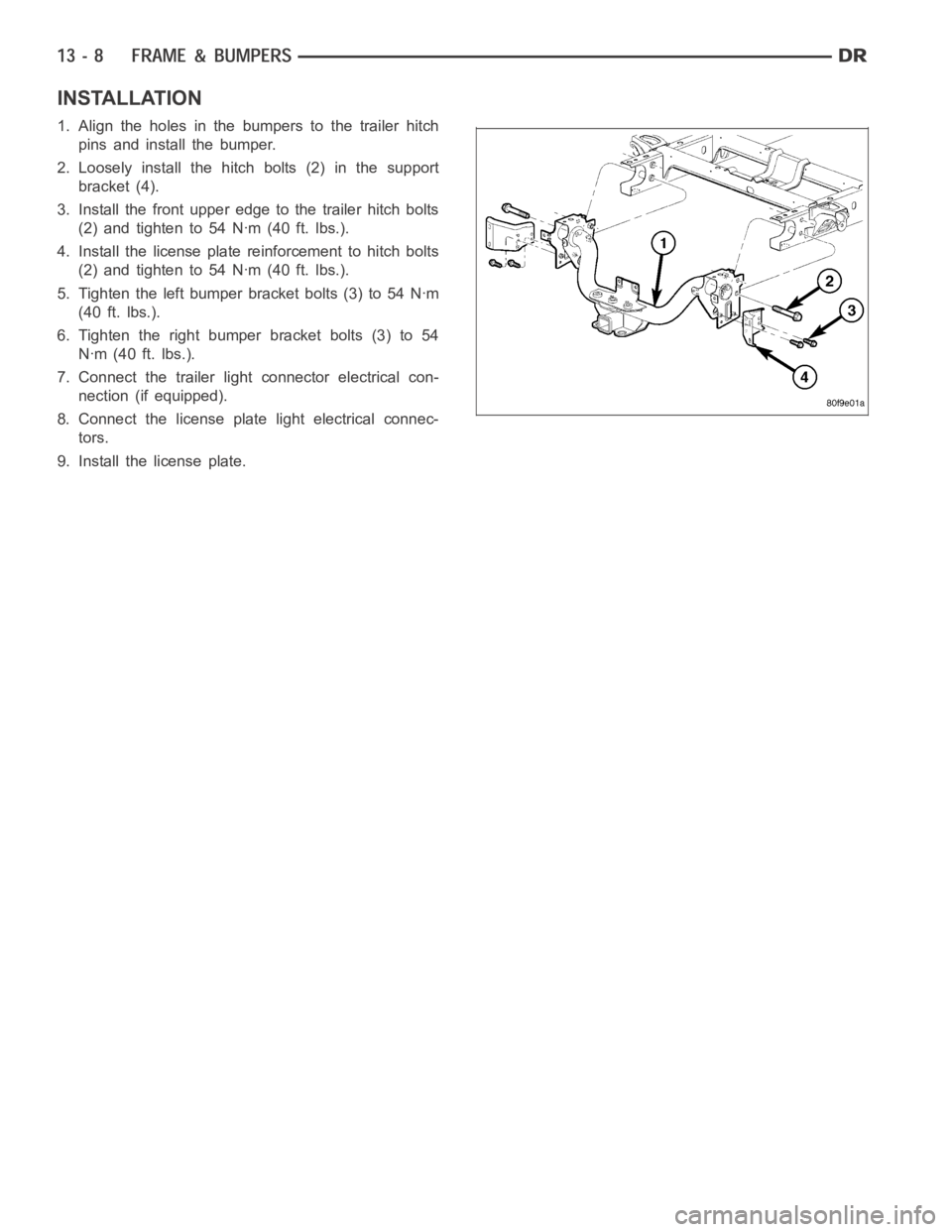

INSTALLATION

1. Align the holes in the bumpers to the trailer hitch

pins and install the bumper.

2. Loosely install the hitch bolts (2) in the support

bracket (4).

3. Install the front upper edge to the trailer hitch bolts

(2)andtightento54Nꞏm(40ft.lbs.).

4. Install the license plate reinforcement to hitch bolts

(2)andtightento54Nꞏm(40ft.lbs.).

5. Tighten the left bumper bracket bolts (3) to 54 Nꞏm

(40 ft. lbs.).

6. Tighten the right bumper bracket bolts (3) to 54

Nꞏm (40 ft. lbs.).

7. Connect the trailer light connector electrical con-

nection (if equipped).

8. Connect the license plate light electrical connec-

tors.

9. Install the license plate.

Page 2201 of 5267

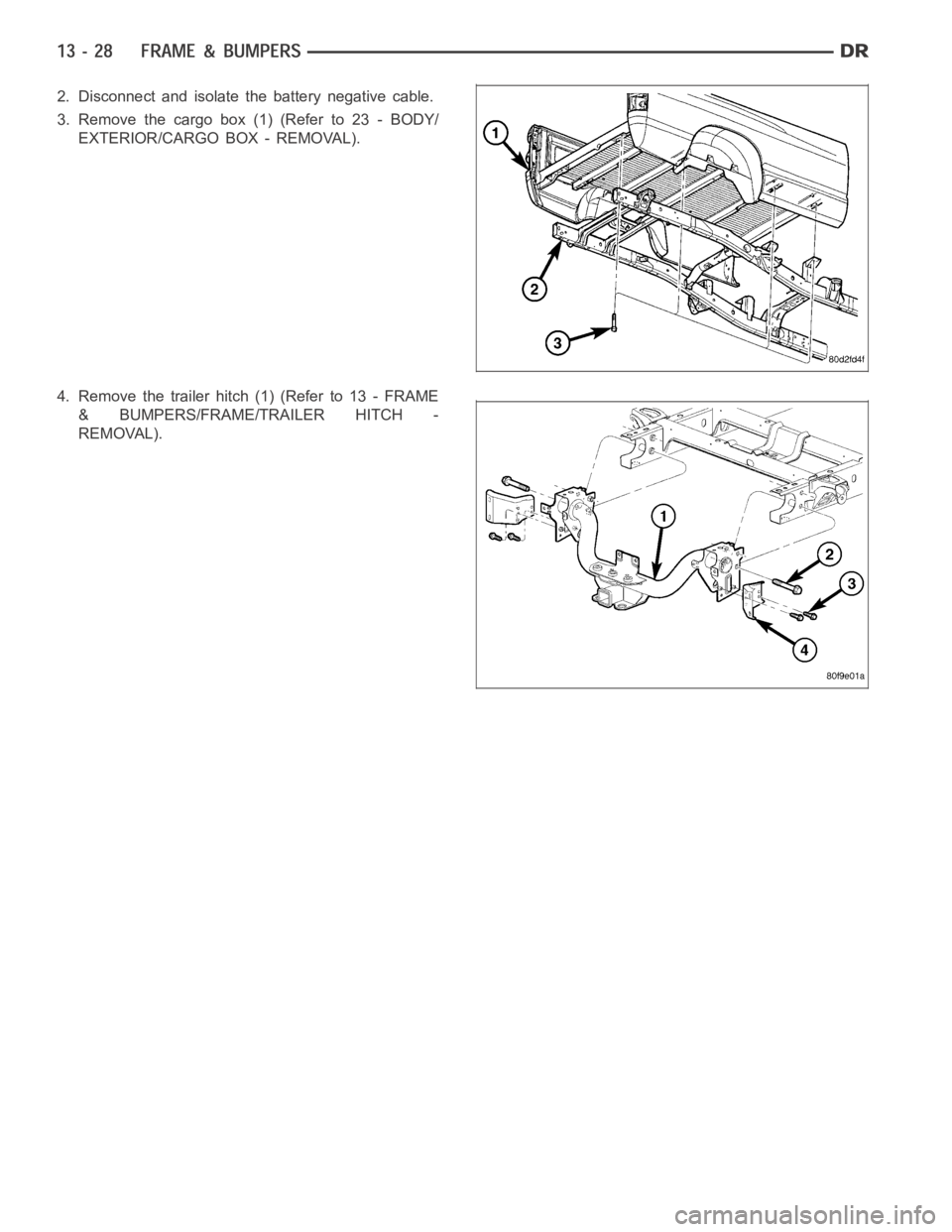

2. Disconnect and isolate the battery negative cable.

3. Remove the cargo box (1) (Refer to 23 - BODY/

EXTERIOR/CARGO BOX - REMOVAL).

4. Removethetrailerhitch(1)(Referto13-FRAME

& BUMPERS/FRAME/TRAILER HITCH -

REMOVAL).

Page 2205 of 5267

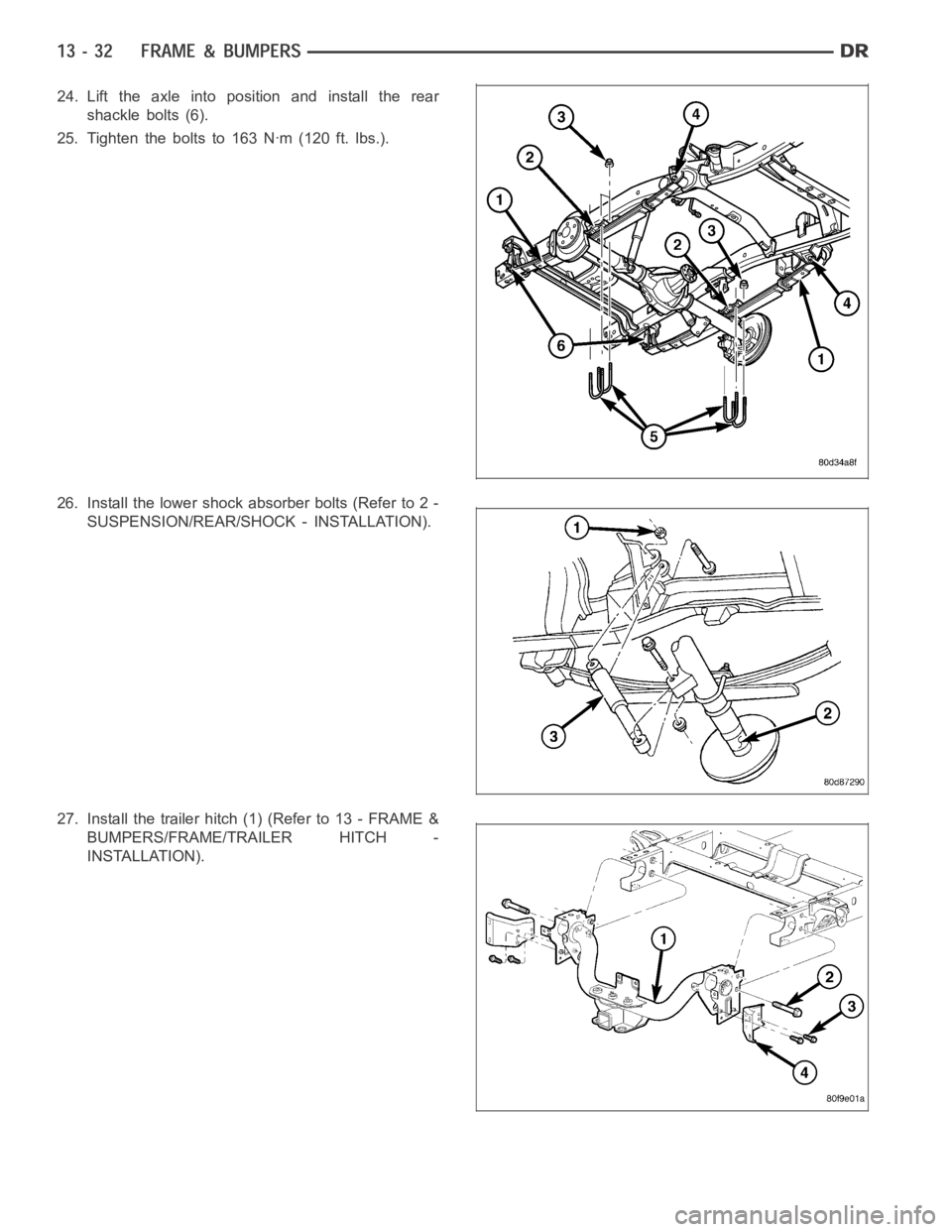

24. Lift the axle into position and install the rear

shackle bolts (6).

25. Tighten the bolts to 163 Nꞏm (120 ft. lbs.).

26. Install the lower shock absorber bolts (Refer to 2 -

SUSPENSION/REAR/SHOCK - INSTALLATION).

27. Install the trailer hitch (1) (Refer to 13 - FRAME &

BUMPERS/FRAME/TRAILER HITCH -

INSTALLATION).

Page 2218 of 5267

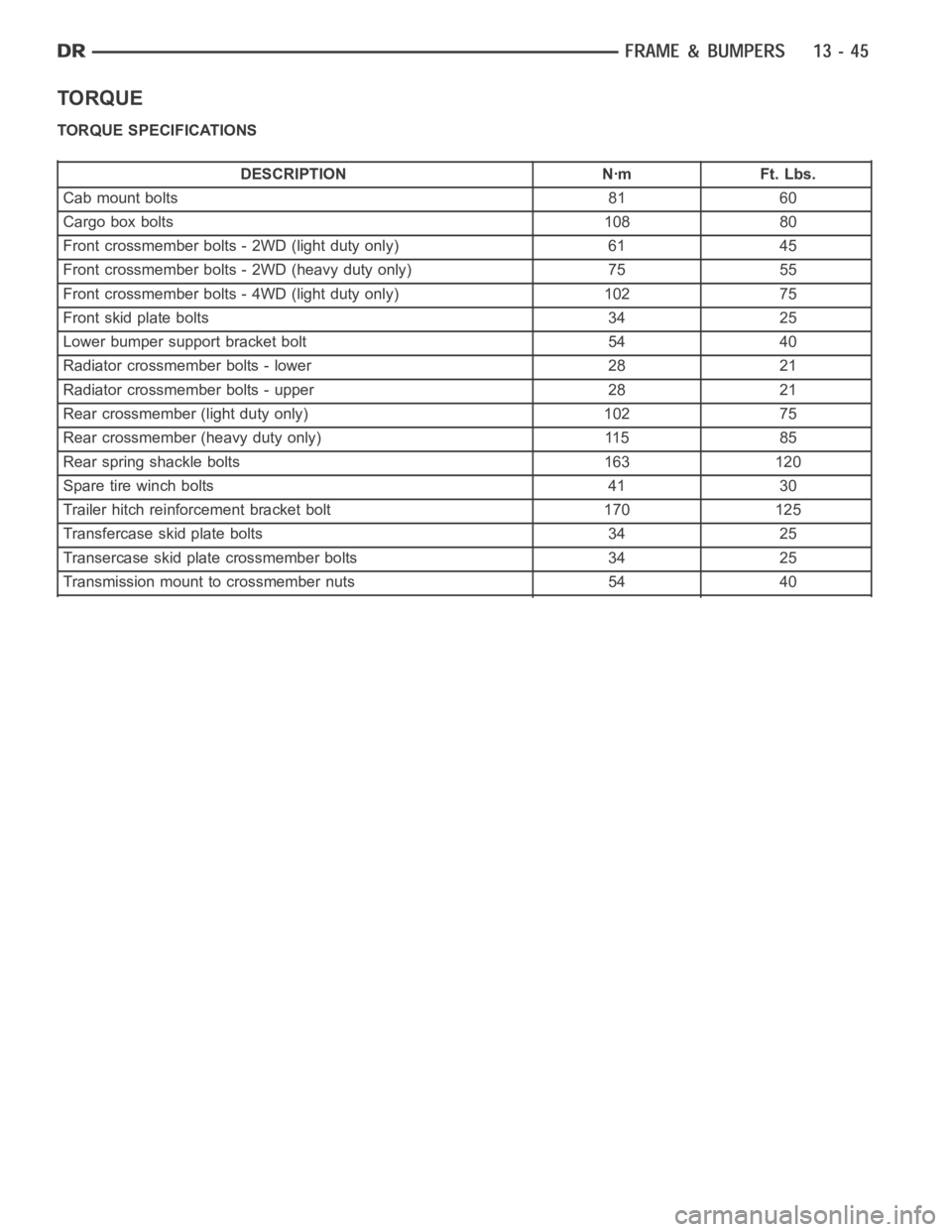

TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION Nꞏm Ft. Lbs.

Cab mount bolts 81 60

Cargo box bolts 108 80

Front crossmember bolts - 2WD (light duty only) 61 45

Front crossmember bolts - 2WD (heavy duty only) 75 55

Front crossmember bolts - 4WD (light duty only) 102 75

Front skid plate bolts 34 25

Lower bumper support bracket bolt 54 40

Radiator crossmember bolts - lower 28 21

Radiator crossmember bolts - upper 28 21

Rear crossmember (light duty only) 102 75

Rear crossmember (heavy duty only) 115 85

Rear spring shackle bolts 163 120

Sparetirewinchbolts 41 30

Trailer hitch reinforcement bracket bolt 170 125

Transfercase skid plate bolts 34 25

Transercase skid plate crossmember bolts 34 25

Transmission mount to crossmember nuts 54 40

Page 2231 of 5267

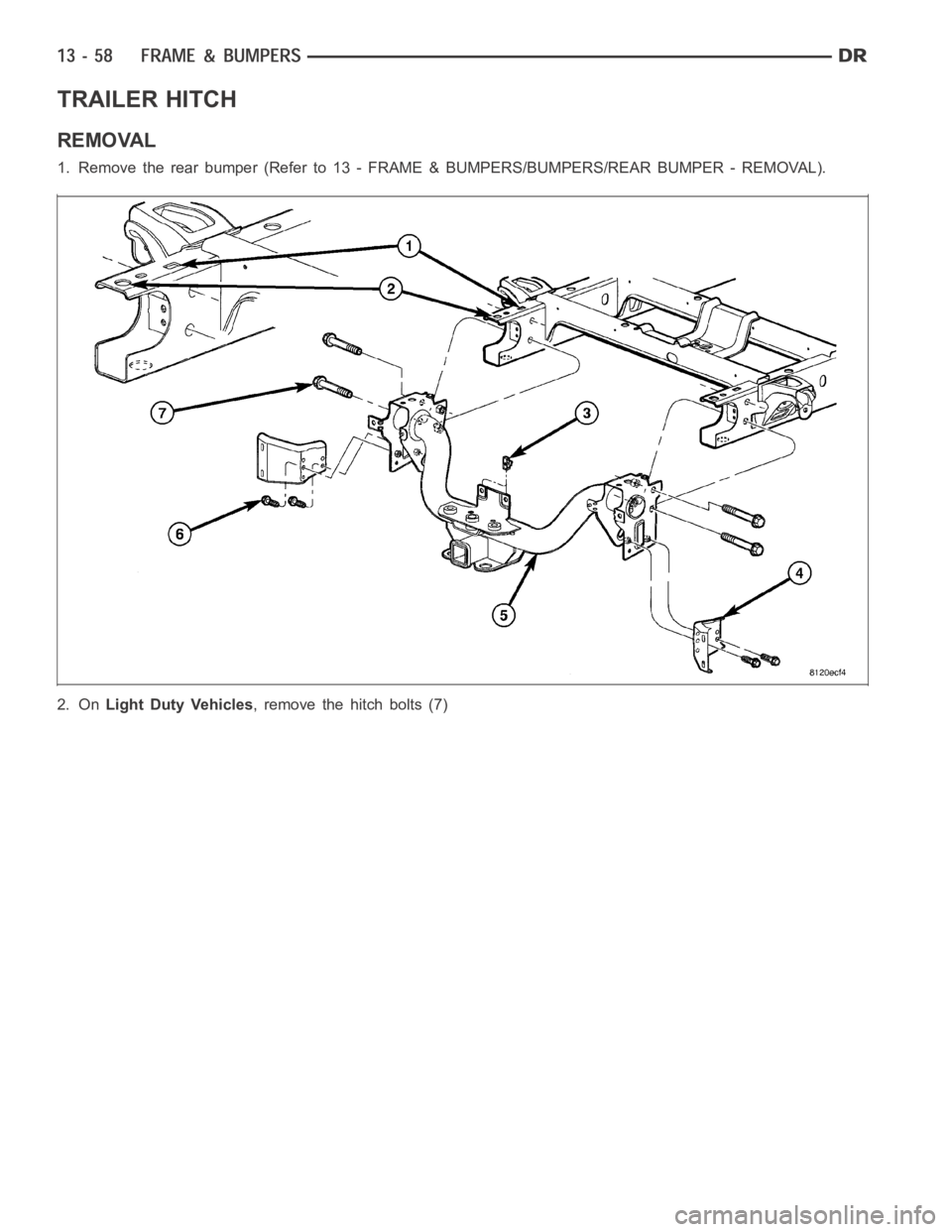

TRAILER HITCH

REMOVAL

1. Remove the rear bumper (Refer to 13 -FRAME & BUMPERS/BUMPERS/REAR BUMPER-REMOVAL).

2. OnLight Duty Vehicles, remove the hitch bolts (7)

Page 2732 of 5267

P0218-HIGH TEMPERATURE OPERATION ACTIVATED

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Whenever the engine is running.

Set Condition:

Immediately when a Overheat shift schedule is activated when the Transmission Oil Temperature reaches 155°

C or 240° F.

Possible Causes

ENGINE COOLING SYSTEM OPERATION

TRANSMISSION OIL COOLER PLUGGED

H I G H T E M P E R AT U R E O P E R AT I O N S A C T I VAT E D

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

If the transmission oil temperature rises above 115° C (240° F), the overheat shift schedule is activated refer to

Transmission Operation as a function of Transmission Oil Temperature andthe code is set. The DTC is an infor-

mational code only and is being set to aid the technician in determining root cause of a customer driveability issue.

The code is also intended to alert the technician to determine if a cooling system malfunction has occurred or if an

additional transmission air to oil cooler should be added to the vehicle ifthe customer regularly drives in a manner

that overheats the transmission. Extended operation above 115° C (240° F)will reduce the durability of the trans-

mission and should be avoided. Correcting the cooling system malfunctionor installing an additional transmission oil

cooler will improve transmission durability especially for customers who operate in city/construction stop and go traf-

fic, tow trailers regularly, drive aggressively in low gear or drive regularly in mountainous areas.

Diagnostic Test

1.CHECK ENGINE COOLING SYSTEM

Perform Engine Cooling System diagnostics per the Service Information.

Is the Engine Cooling System functioning properly?

Ye s>>

Go To 2

No>>

Repair the cause of the engine overheating. Refer to the Service Information for the related diagnostic

or repair procedures.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

2.TRANSMISSION OIL COOLER RESTRICTED

Check the Transmission Oil Cooler Flow in accordance with the Service Information.

Is the transmission oil cooler restricted or plugged?

Ye s>>

Go To 3

No>>

Repair the cause of the plugged Transmission Oil Cooler as necessary and repair or replace the Trans-

mission Oil Cooler per the Service Information.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Page 2899 of 5267

P1797-MANUAL SHIFT OVERHEAT

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Continuously with engine running.

Set Condition:

If the Engine Temperature exceeds 123° C (255° F) or the Transmission Temperature exceeds 135° C (275° F)

while in AutoStick

mode. Note: Aggressive driving or driving in low for extended periods of time will set this

DTC.

Possible Causes

MANUAL SHIFT OVERHEAT

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

The major cause of heat build up in the transmission is torque converter slip.WiththetransmissionintheAuto-

Stick

mode, the torque converter can slip during aggressive driving or heavy loading conditions such as trailer

towing or driving up steep grades. In the non AutoStick

mode, internal controller logic prevents the transmission

from overheating by managing the shift and EMCC schedule. In the AutoStick

mode, when the transmission or

engine temperature approaches an overheat condition, the manual shift overheat DTC sets and the AutoStick

mode is temporarily suspended until the temperature returns to normal.

Diagnostic Test

1.MANUAL SHIFT OVERHEAT

This is an informational DTC only.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Check the engine and transmission cooling system for proper operation.

Check the Radiator Cooling Fan operation.

Check the Transmission Cooling operation.

Check the Transmission Fluid Level per the Service Information to verify that it is not overfilled.

NOTE: Aggressive driving or driving in low for extended periods of time will set this DTC.

If there are no possible causes remaining, view repair.

Repair

If the Transmission Fluid is low, repair any Transmission Fluid leak as necessary and adjust the Trans-

mission Fluid Level per the Service Information. Refer to Service Information for the related symptoms

and repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Page 3014 of 5267

FLUID AND FILTER

DIAGNOSIS AND TESTING

CAUSES OF BURNT FLUID

Burnt, discolored fluid is a result of overheating which has two primary causes.

1. A result of restricted fluid flow through the main and/or auxiliary cooler. This condition is usually the result of a

faulty or improperly installed drainback valve, a damaged oil cooler, or severe restrictions in the coolers and lines

caused by debris or kinked lines.

2. Heavy duty operation with a vehicle not properly equipped for this type of operation. Trailer towing or similar high

load operation will overheat the transmission fluid if the vehicle is improperly equipped. Such vehicles should

have an auxiliary transmission fluid cooler, a heavy duty cooling system,and the engine/axle ratio combination

needed to handle heavy loads.

EFFECTS OF INCORRECT FLUID LEVEL

Alowfluidlevelallowsthepumptotakeinairalongwiththefluid.Airinthe fluid will cause fluid pressures to be

low and develop slower than normal. If the transmission is overfilled, thegears churn the fluid into foam. This aer-

ates the fluid and causing the same conditions occurring with a low level. In either case, air bubbles cause fluid

overheating, oxidation, and varnish buildup which interferes with valveand clutch operation. Foaming also causes

fluid expansion which can result in fluid overflow from the transmission vent or fill tube. Fluid overflow can easily be

mistaken for a leak if inspection is not careful.

FLUID CONTAMINATION

Transmission fluid contamination is generally a result of:

adding incorrect fluid

failure to clean dipstick and fill tube when checking level

engine coolant entering the fluid

internal failure that generates debris

overheat that generates sludge (fluid breakdown)

failure to replace contaminated converter after repair

The use of non-recommended fluids can result in transmission failure. Theusual results are erratic shifts, slippage,

abnormal wear and eventual failure due to fluid breakdown and sludge formation. Avoid this condition by using rec-

ommended fluids only.

The dipstick cap and fill tube should be wiped clean before checking fluid level. Dirt, grease and other foreign mate-

rial on the cap and tube could fall into the tube if not removed beforehand. Take the time to wipe the cap and tube

clean before withdrawing the dipstick.

Engine coolant in the transmission fluid is generally caused by a cooler malfunction. The only remedy is to replace

the radiator as the cooler in the radiator is not a serviceable part. If coolant has circulated through the transmission,

an overhaul is necessary.

The torque converter should also be replaced whenever a failure generatessludge and debris. This is necessary

because normal converter flushing procedures will not remove all contaminants.

STANDARD PROCEDURE

FLUID LEVEL CHECK

The transmission sump has a dipstick to check oil similar to most automatictransmissions. It is located on the left

side of the engine. Be sure to wipe all dirt from dipstick handle before removing.

The torque converter fills in both the PARK and NEUTRAL positions. Place the selector lever in PARK to be sure

that the fluid level check is accurate.The engine should be running at idle speed for at least one minute, with

the vehicle on level ground.At normal operating temperature (approximately 82° C or 180° F), the fluidlevel is

correct if it is in the HOT region (cross-hatched area) on the oil level indicator. The fluid level should be in COLD

region at 21° C (70° F) fluid temperature. Adjust fluid level as necessary.Use only Mopar

ATF+4, Automatic Trans-

mission Fluid.