check engine DODGE RAM SRT-10 2006 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 210 of 5267

8.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 212 of 5267

When Monitored:

Ignition on and battery voltage greater than 10 volts.

Set Condition:

Just after key on, the throttle is opened and closed to test the system. If the TP Sensor does not return to

Limp Home Position at the end of this test, this DTC will set. One trip fault and the code will set within 5

seconds. ETC light is flashing.

Possible Causes

THROTTLE PLATE STUCK ABOVE LIMP HOME POSITION

TP SENSOR NO.1 AND TP SENSOR NO.2 BOTH READ 2.5 VOLTS

(K447) ETC POSITIVE CIRCUIT SHORTED TO BATTERY VOLTAGE

(K447) ETC POSITIVE CIRCUIT OPEN

(K448) ETC NEGATIVE CIRCUIT OPEN

(K447) ETC POSITIVE CIRCUIT SHORTED TO GROUND

(K448) ETC NEGATIVE CIRCUIT SHORTED TO GROUND

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Maximum engine speed could be reduced while this fault is active, it just depends where the throttle

gets stuck.

Ignition on, engine not running.

NOTE: The PCM tests the ETC Motor by opening and closing the Throttle Plate before starting the engine.

If during this test the Throttle plate does not return to the closed positionthisDTCsets.

With a scan tool read DTCs.

NOTE: Diagnose any TP Sensor or 5-Volt Supply DTCs before continuing.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.THROTTLE PLATE STUCK OPEN

Turn the ignition off.

NOTE: The PCM tests the ETC Motor by opening and closing the Throttle Plate before starting the engine.

If during this test the Throttle plate does not return to the closed positionthisDTCsets.

Remove the Air Cleaner Assembly from the Throttle Body.

Check for any signs of a foreign material causing the Throttle to remain open.

Using a scan tool actuate the ETC Motor.

Does the Throttle Plate move?

Ye s>>

Go To 3

No>>

Remove the debris if possible or replace the Throttle Body Assembly if signs of physical damage are

present. Disconnect the Battery when replacing the Throttle Body Assembly. After installation is com-

plete, use a scan tool and perform the ETC RELEARN function.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 213 of 5267

3.TP SENSOR NO.1 AND TP SENSOR NO.2 BOTH EQUAL 2.5 VOLTS

With a scan tool, perform the Throttle Follower test while reading both TP Sensor voltage readings.

Are both TP Sensor readings stuck at 2.5 volts?

Ye s>>

Check the TP Sensor Signal circuits for excessive resistance, being shorted to each other, or shorted to

the Sensor Return circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

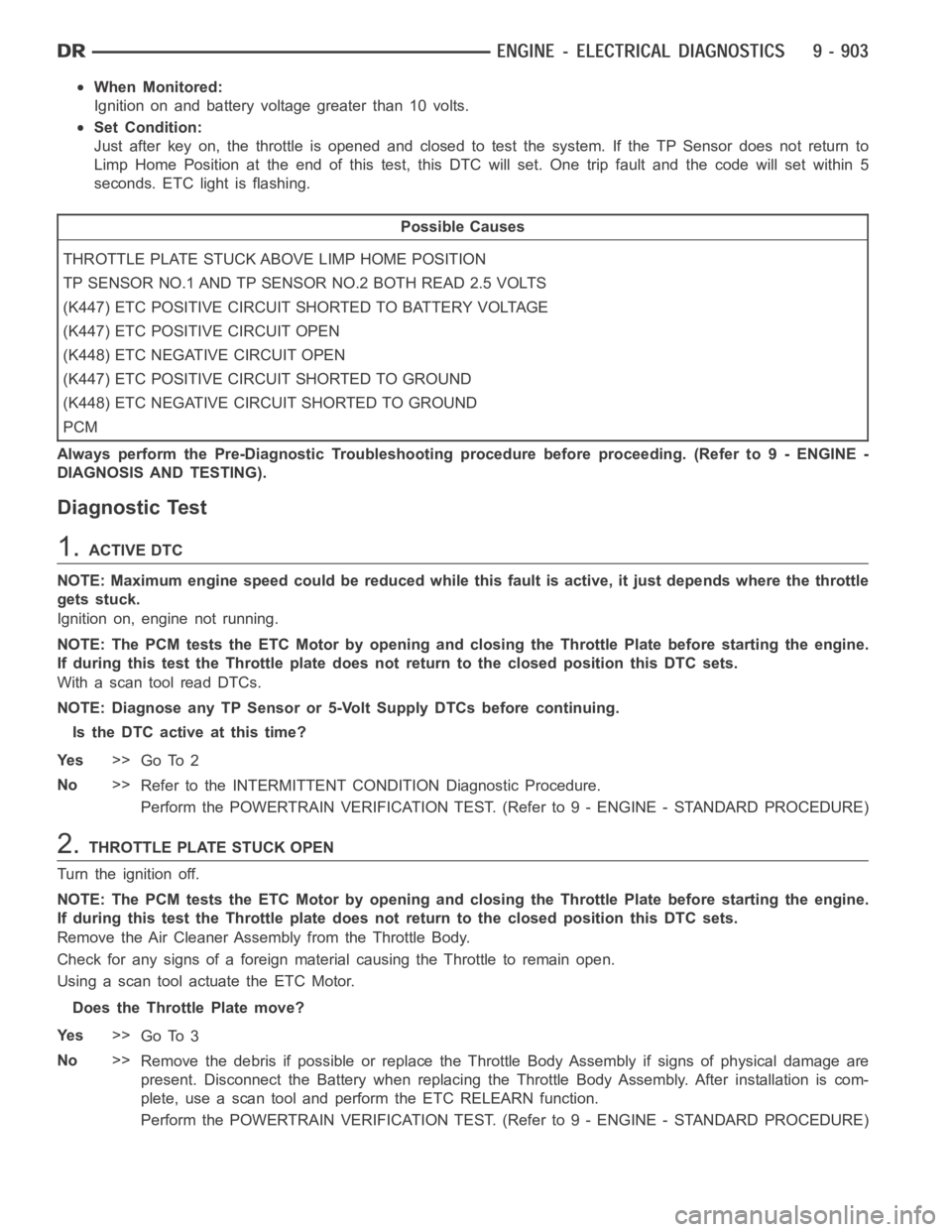

4.(K447) ETC POSITIVE CIRCUIT SHORTED TO BATTERY VOLTAGE

Turn the ignition off.

Disconnect the Throttle Body harness connector.

Disconnect the C2 PCM harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform the diagnostics.

Ignition on, engine not running.

With a 12-volt test light connected to ground, probe the (K447) ETC

Positive circuit at the appropriate terminal of special tool #8815.

Does the test light illuminate brightly?

Ye s>>

Repair the short to battery voltage on the (K447) ETC Pos-

itive circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

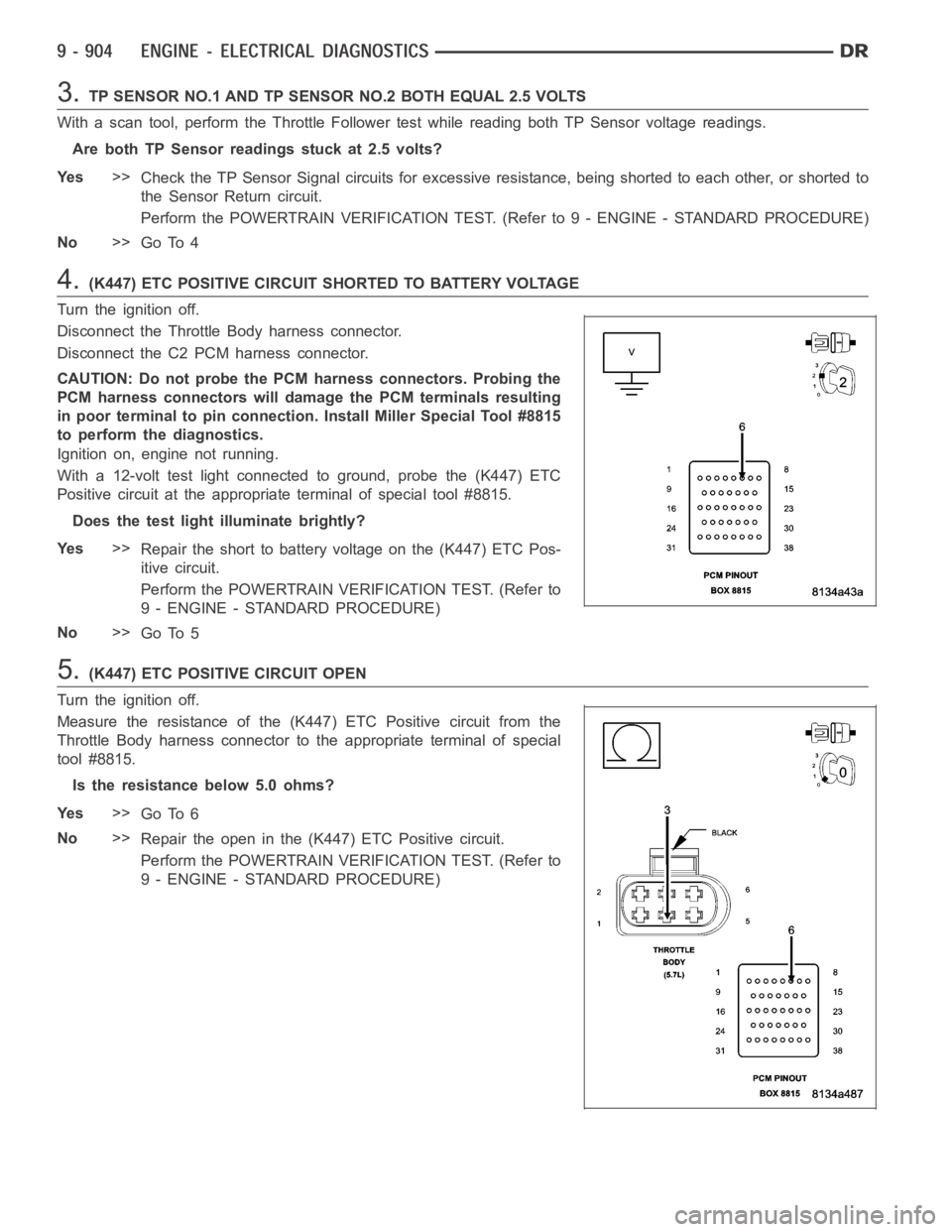

5.(K447) ETC POSITIVE CIRCUIT OPEN

Turn the ignition off.

Measure the resistance of the (K447) ETC Positive circuit from the

Throttle Body harness connector to the appropriate terminal of special

tool #8815.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 6

No>>

Repair the open in the (K447) ETC Positive circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 215 of 5267

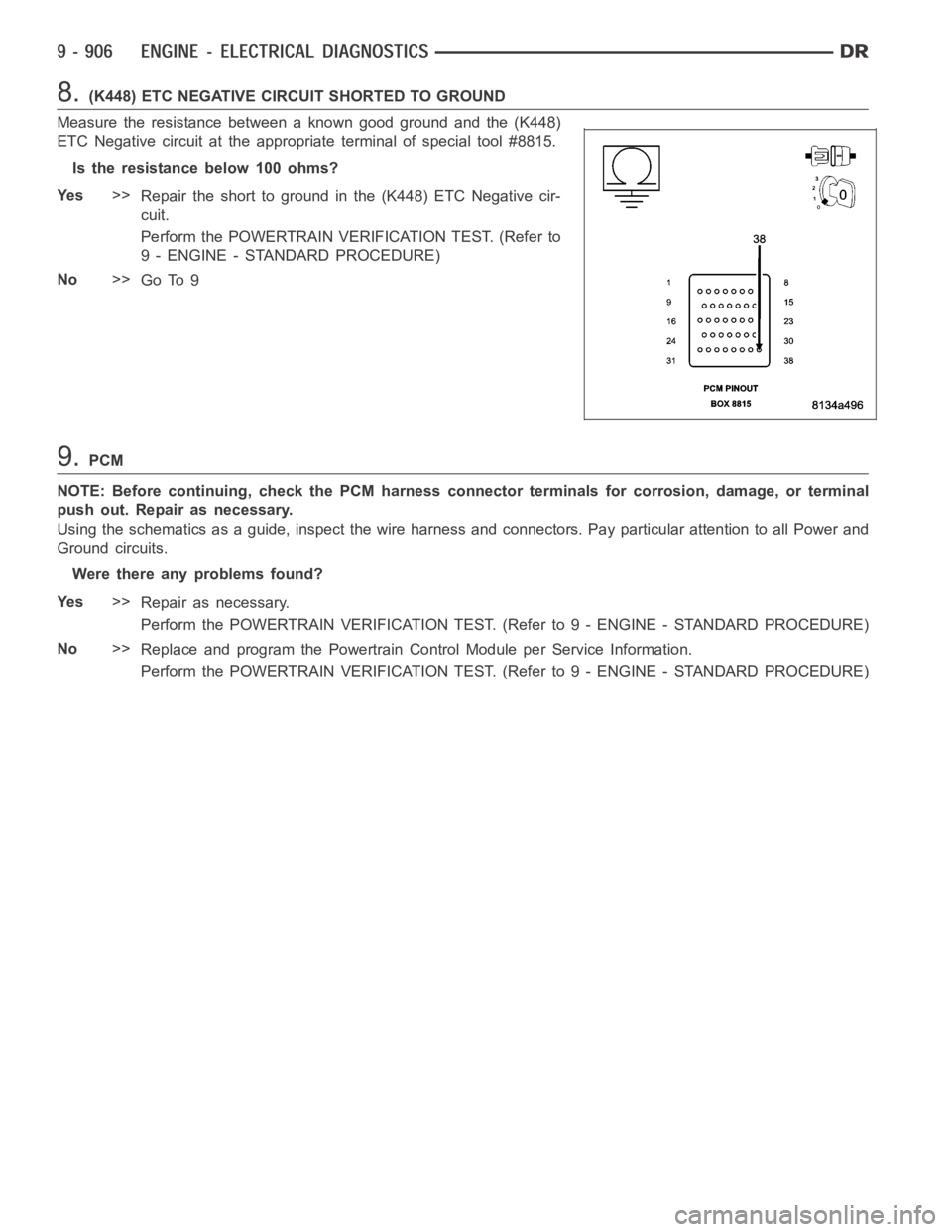

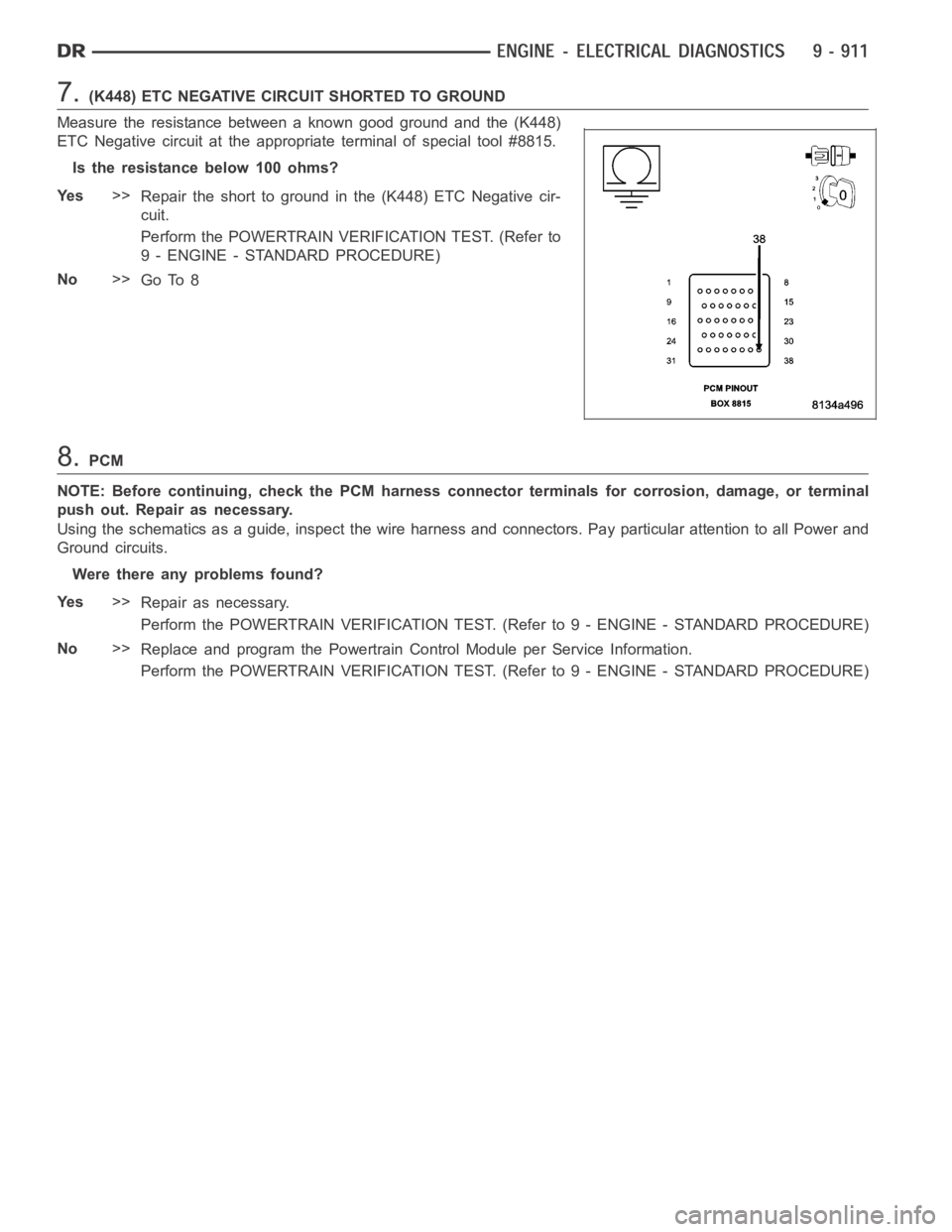

8.(K448) ETC NEGATIVE CIRCUIT SHORTED TO GROUND

Measure the resistance between a known good ground and the (K448)

ETC Negative circuit at the appropriate terminal of special tool #8815.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (K448) ETC Negative cir-

cuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 9

9.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 217 of 5267

When Monitored:

Ignition on and battery voltage greater than 10 volts.

Set Condition:

Just after key on, the throttle is opened and closed to test the system. If the TP Sensor does not return to

Limp Home Position at the end of this test, this DTC will set. One trip fault and the code will set within 5

seconds. ETC light is flashing.

Possible Causes

THROTTLE PLATE STUCK AT OR BELOW LIMP HOME POSITION

(K448) ETC NEGATIVE CIRCUIT SHORTED TO BATTERY VOLTAGE

(K447) ETC POSITIVE CIRCUIT OPEN

(K448) ETC NEGATIVE CIRCUIT OPEN

(K447) ETC POSITIVE CIRCUIT SHORTED TO GROUND

(K448) ETC NEGATIVE CIRCUIT SHORTED TO GROUND

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

NOTE: The PCM tests the ETC Motor by opening and closing the Throttle Plate before starting the engine.

If during this test the Throttle plate does not return to the closed positionthisDTCsets.

With a scan tool read DTCs.

NOTE: Diagnose any TP Sensor, Battery Voltage, and 5-Volt Supply DTCs before continuing.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.THROTTLE PLATE STUCK OPEN

Turn the ignition off.

NOTE: The PCM tests the ETC Motor by opening and closing the Throttle Plate before starting the engine.

If during this test the Throttle plate does not open this DTC sets.

Remove the Air Cleaner Assembly from the Throttle Body.

Check for any signs of a foreign material causing the Throttle to remain open.

Using a scan tool actuate the ETC Motor.

Does the Throttle Plate move?

Ye s>>

Go To 3

No>>

Remove the debris if possible or replace the Throttle Body Assembly. Disconnect the Battery when

replacing the Throttle Body Assembly. After installation is complete, use a scan tool and select the ETC

RELEARN function.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 220 of 5267

7.(K448) ETC NEGATIVE CIRCUIT SHORTED TO GROUND

Measure the resistance between a known good ground and the (K448)

ETC Negative circuit at the appropriate terminal of special tool #8815.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (K448) ETC Negative cir-

cuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 8

8.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 221 of 5267

P2115-ACCELERATOR PEDAL POSITION SENSOR 1 MINIMUM STOP

PERFORMANCE

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on. During in plant mode the APP Sensors need to be checked to make sure that idle and full pedal

travel can be reached on both sensors. The test for P2115 is only enabled once test for P2166 has passed.

Set Condition:

APPS No.1 has failed to achieve the required minimum value during In Plant testing. One trip fault and the

code will set within 5 seconds. Engine will only idle.

Possible Causes

IN PLANT TEST FAILURE

APPS RELEARN

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.IN PLANT TEST FAILURE

Ignition on, engine not running.

NOTE: This DTC is set when the APP Sensors are learned in plant but do not reach the Minimum or Max-

imum voltage range.

With a scan tool read DTCs.

With the scan tool, erase DTCs.

Start the engine.

With the scan tool, read DTCs.

NOTE: Diagnose any APPS out of Range and 5-Volt Supply DTCs before continuing.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.APPS RELEARN

With a scan tool select the ETC RELEARN function.

Next, erase DTCs.

Start the engine.

Does the DTC return?

Ye s>>

Replace the APPS Assembly per Service Information. After installation iscomplete, use a scan tool and

select the ETC RELEARN function.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 222 of 5267

P2116-ACCELERATOR PEDAL POSITION SENSOR 2 MINIMUM STOP

PERFORMANCE

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on. During in plant mode the APP Sensors need to be checked to make sure that idle and full pedal

travel can be reached on both sensors. The test for P2116 is only enabled once test for P2167 has passed.

Set Condition:

APPS No.2 has failed to achieve the required minimum value during In Plant testing. One trip fault and the

code will be stored within 5 seconds. Engine will only idle.

Possible Causes

IN PLANT TEST FAILURE

APPS RELEARN

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.IN PLANT TEST FAILURE

Ignition on, engine not running.

NOTE: This DTC is set when the APP Sensors are learned in plant but do not reach the Minimum or Max-

imum voltage range.

With a scan tool read DTCs and record the related Freeze Frame data.

With a scan tool, erase DTCs.

Start the engine.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.APPS RELEARN

With a scan tool select the ETC RELEARN function.

Next, erase DTCs.

Start the engine.

Does the DTC return?

Ye s>>

Replace the APPS Assembly per Service Information. After installation iscomplete, use a scan tool and

select the ETC RELEARN function.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 224 of 5267

When Monitored:

With the ignition on and the ETC Motor is not in Limp Home mode.

Set Condition:

When the PCM detects an internal error or a short between the ETC Motor - and ETC Motor + circuits in the

ETC Motor Driver. One trip fault. ETC light is flashing.

Possible Causes

THROTTLE PLATE / BORE INSPECTION

(K447) ETC POSITIVE CIRCUIT SHORTED TO BATTERY VOLTAGE

(K448) ETC NEGATIVE CIRCUIT SHORTED TO BATTERY VOLTAGE

(K447) ETC POSITIVE CIRCUIT SHORTED TO THE (K448) ETC NEGATIVE CIRCUIT

(K447) ETC POSITIVE CIRCUIT OPEN

(K447) ETC POSITIVE CIRCUIT SHORTED TO GROUND

(K448) ETC NEGATIVE CIRCUIT OPEN

(K448) ETC NEGATIVE CIRCUIT SHORTED TO GROUND

ETC MOTOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

NOTE: If the P2118 is intermittent, it is possible that the controller is overheating in extreme hot tempera-

tures, and this is considered a normal protection operation. No repair is necessary.

With a scan tool, read DTCs.

Look closely at the temperatures at which this DTC set.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.THROTTLE PLATE INSPECTION

Turn the ignition off.

Remove the Air Cleaner Assembly from the Throttle Body.

Check for any signs of a foreign material (ice or dirt) on the Throttle Plateor in the bore causing the Throttle Plate

to stick.

Were any signs of foreign material or scoring of the throttle plate or bore found?

Ye s>>

Remove the debris if possible or replace the Throttle Body Assembly. Disconnect the Battery when

replacing the Throttle Body Assembly. After installation is complete, use a scan tool and select the ETC

RELEARN function.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 228 of 5267

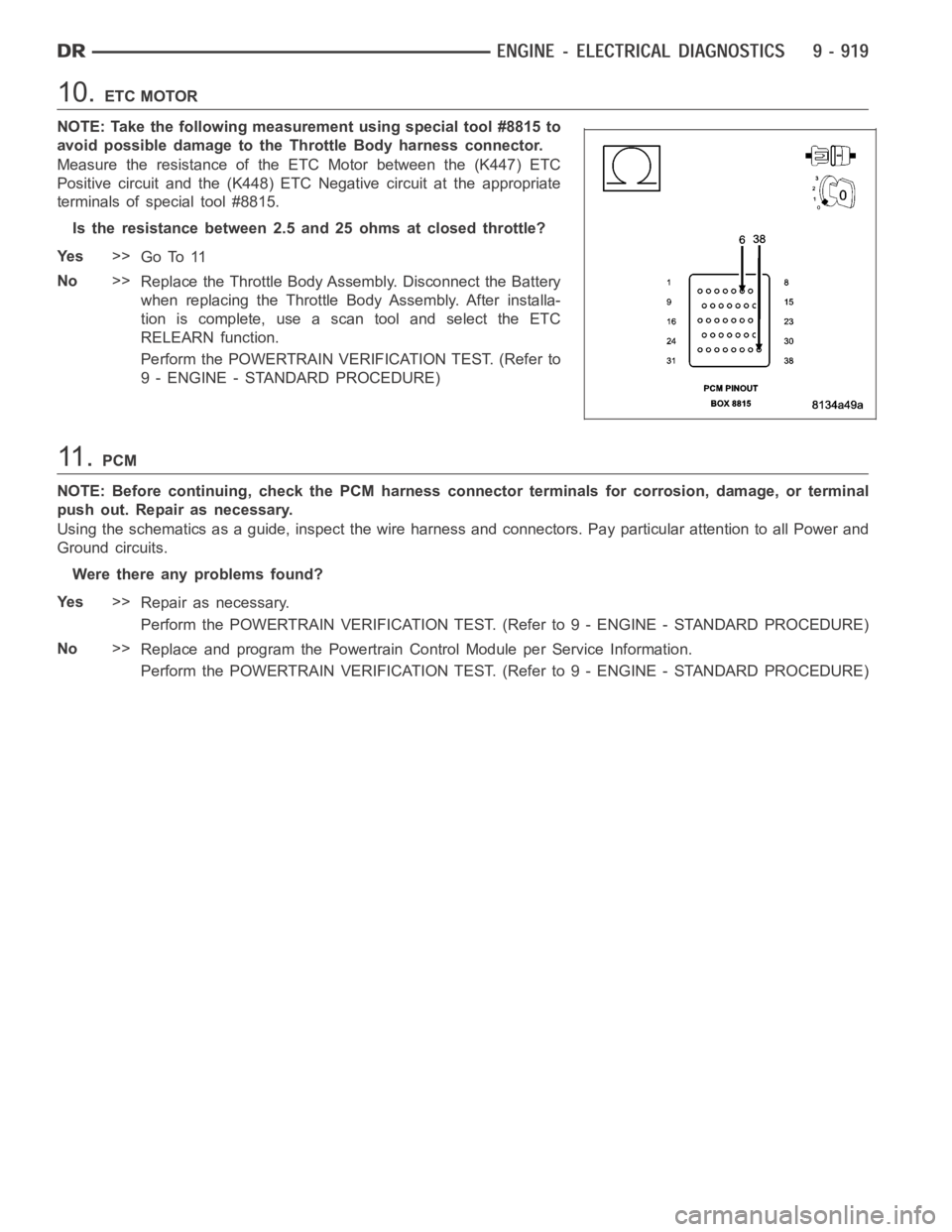

10.ETC MOTOR

NOTE: Take the following measurement using special tool #8815 to

avoid possible damage to the Throttle Body harness connector.

Measure the resistance of the ETC Motor between the (K447) ETC

Positive circuit and the (K448) ETC Negative circuit at the appropriate

terminals of special tool #8815.

Is the resistance between 2.5 and 25 ohms at closed throttle?

Ye s>>

Go To 11

No>>

Replace the Throttle Body Assembly. Disconnect the Battery

when replacing the Throttle Body Assembly. After installa-

tion is complete, use a scan tool and select the ETC

RELEARN function.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

11 .PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)