brake light DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 23 of 5267

When Monitored:

Ignition on.

Set Condition:

When the PCM recognizes Brake Switch No.2 voltage is not equal to the applied value at the PCM when

Brake Switch No.1 is applied. This could be a normal condition. If this condition is seen repeatedly by the PCM

the fault is set. Cruise will not work for the rest of the key cycle.

Possible Causes

(V30)FUSEDIGNITIONSWITCHOUTPUTCIRCUIT

(V32) BRAKE SWITCH NO.2 SIGNAL CIRCUIT OPEN

(V32) BRAKE SWITCH NO.2 SIGNAL CIRCUIT SHORTED TO BATTERY VOLTAGE

(V32) BRAKE SWITCH NO.2 SIGNAL CIRCUIT SHORTED TO GROUND

(B29) BRAKE SWITCH NO.1 SIGNAL CIRCUIT OPEN

STOP LAMP SWITCH

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Make sure the Stop Lamp Switch is adjusted properly before continuing.

NOTE: Make sure the Stop Lamp Switch is properly wired, such as (B29) Brake Switch No.1 and (L50) Brake

Lamp Switch Output are not switched at the harness connector.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

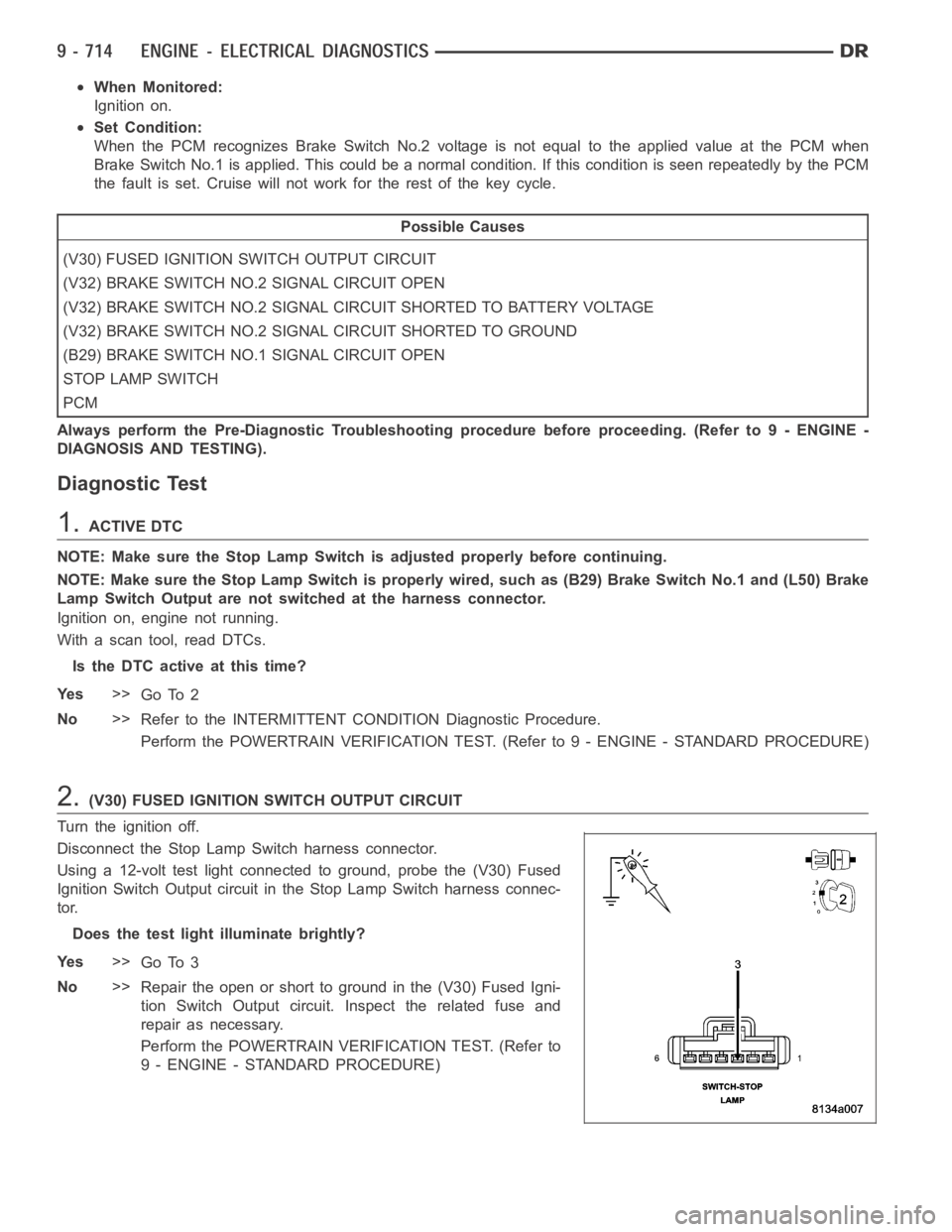

2.(V30) FUSED IGNITION SWITCH OUTPUT CIRCUIT

Turn the ignition off.

Disconnect the Stop Lamp Switch harness connector.

Using a 12-volt test light connected to ground, probe the (V30) Fused

Ignition Switch Output circuit in the Stop Lamp Switch harness connec-

tor.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Repair the open or short to ground in the (V30) Fused Igni-

tion Switch Output circuit. Inspect the related fuse and

repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 230 of 5267

When Monitored:

With the ignition on and no other APPS No.1 DTCs present.

Set Condition:

When the APP Sensor No.1 voltage is toolow. Engine will additionally idle if the brake pedal is pressed or has

failed. Acceleration rate and Engine output are limited. One trip fault and the code will set within 5 seconds.

ETC light is flashing.

Possible Causes

(F855) 5-VOLT SUPPLY CIRCUIT OPEN

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

(K23) APP SENSOR NO.1 SIGNAL CIRCUIT OPEN

(K23) APP SENSOR NO.1 SIGNAL CIRCUIT SHORTED TO GROUND

(K23) APP SENSOR NO.1 SIGNAL CIRCUIT SHORTED TO THE (K167) APP SENSOR NO.1 RETURN CIRCUIT

(K23) APP SENSOR NO.1 SIGNAL CIRCUIT SHORTED TO THE (K400) APP SENSOR NO.2 RETURN CIRCUIT

APP SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.APP SENSOR BELOW 0.25 OF A VOLT

Ignition on, engine not running.

With a scan tool, read the APP Sensor No.1 voltage.

Is the voltage below 0.25 of a volt?

Ye s>>

Go To 2

No>>

Go To 11

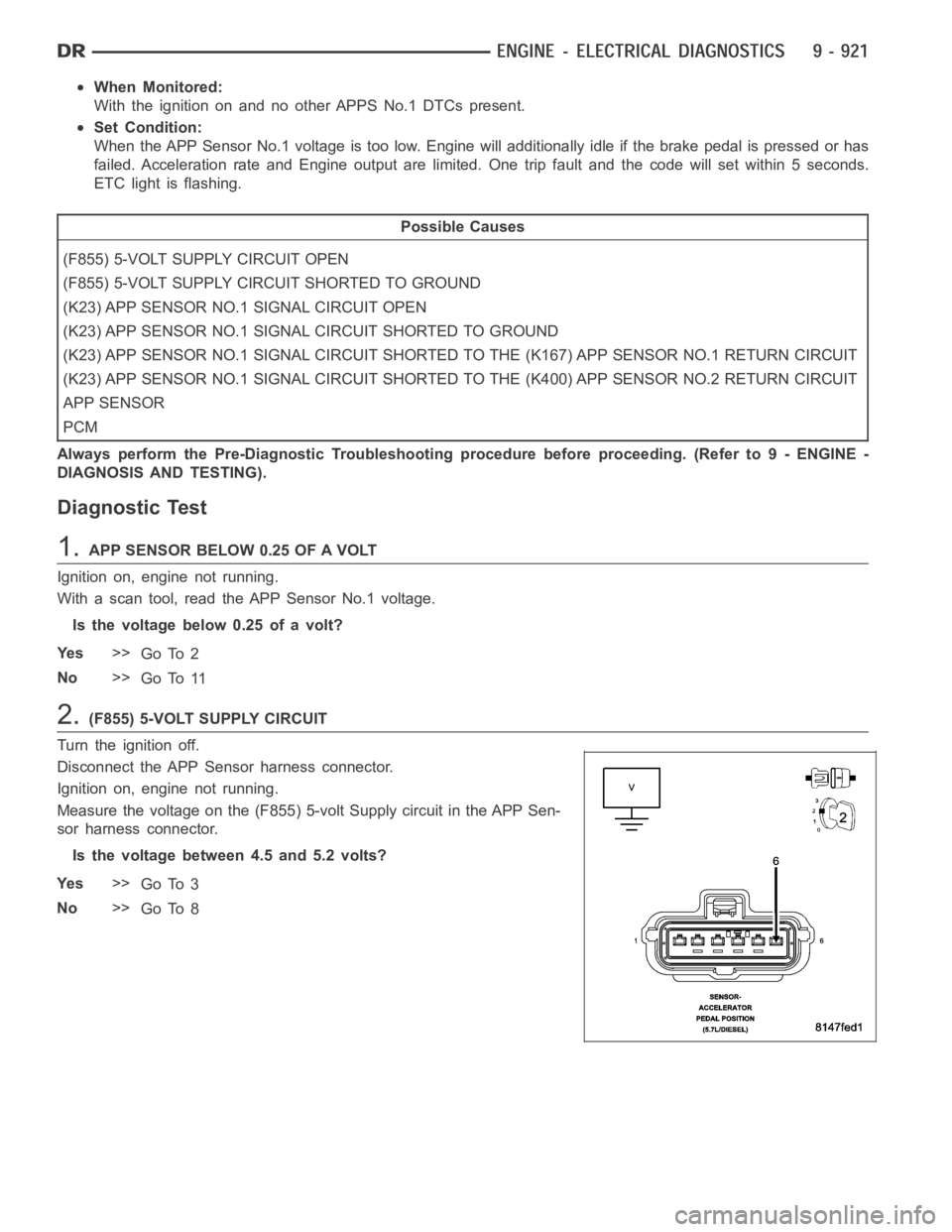

2.(F855) 5-VOLT SUPPLY CIRCUIT

Turn the ignition off.

Disconnect the APP Sensor harness connector.

Ignition on, engine not running.

Measure the voltage on the (F855) 5-volt Supply circuit in the APP Sen-

sor harness connector.

Is the voltage between 4.5 and 5.2 volts?

Ye s>>

Go To 3

No>>

Go To 8

Page 236 of 5267

When Monitored:

With the ignition on and no other APPS No.1 DTCs present.

Set Condition:

When APP Sensor No.1 voltage is too high. Engine will additionally idle if the brake pedal is pressed or has

failed. Acceleration rate and Engine output are limited. One trip fault and the code will set within 5 seconds.

ETC light is flashing.

Possible Causes

(K23) APP SENSOR NO.1 SIGNAL CIRCUIT SHORTED TO BATTERY VOLTAGE

(K23) APP SENSOR NO.1 SIGNAL SHORTED TO THE (F855) 5-VOLT SUPPLY CIRCUIT

(K23) APP SENSOR NO.1 SIGNAL SHORTED TO THE (F856) 5-VOLT SUPPLY CIRCUIT

(K167) APP SENSOR NO.1 RETURN CIRCUIT OPEN

APP SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.APPS NO.1 VOLTAGE ABOVE 4.8 VOLTS

Ignition on, engine not running.

With a scan tool, read the APP Sensor No.1 voltage.

Is the voltage above 4.8 volts?

Ye s>>

Go To 2

No>>

Go To 8

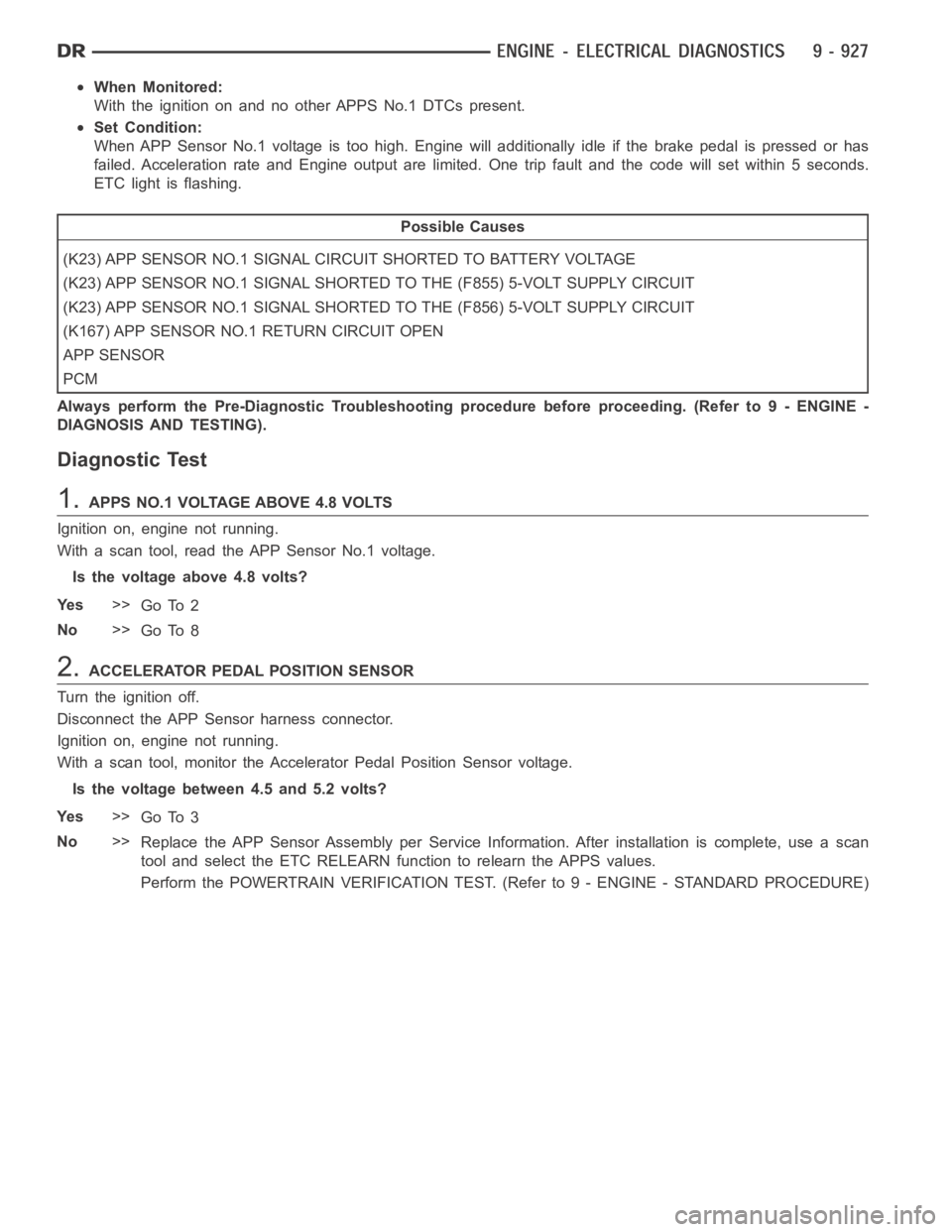

2.ACCELERATOR PEDAL POSITION SENSOR

Turn the ignition off.

Disconnect the APP Sensor harness connector.

Ignition on, engine not running.

With a scan tool, monitor the Accelerator Pedal Position Sensor voltage.

Is the voltage between 4.5 and 5.2 volts?

Ye s>>

Go To 3

No>>

Replace the APP Sensor Assembly per Service Information. After installation is complete, use a scan

tool and select the ETC RELEARN function to relearn the APPS values.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 240 of 5267

When Monitored:

With the ignition on and no other APPS No.2 DTCs present.

Set Condition:

When the APP Sensor No.2 voltage is too low. Engine will only idle if the Brake pedal is Pressed or has failed.

Acceleration rate and Engine output are limited. One trip fault and the code will set within 5 seconds. ETC light

is flashing.

Possible Causes

(F856) 5-VOLT SUPPLY CIRCUIT OPEN

(F856) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

(K29) APP SENSOR NO.2 SIGNAL CIRCUIT OPEN

(K29) APP SENSOR NO.2 SIGNAL CIRCUIT SHORTED TO GROUND

(K29) APP SENSOR NO.2 SIGNAL CIRCUIT SHORTED TO THE (K167) APP SENSOR NO.1 RETURN CIRCUIT

(K29) APP SENSOR NO.2 SIGNAL CIRCUIT SHORTED TO THE (K400) APP SENSOR NO.2 RETURN CIRCUIT

APP SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.APP SENSOR BELOW 0.25 OF A VOLT

Ignition on, engine not running.

With a scan tool, read the APP Sensor No.1 voltage.

NOTE: Sensor No. 2 is pulled low by the PCM as part of its system testing. Thistest happens a couple of

times a second. So you can expect to see voltages close to zero occasionallywith a normal sensor.

Is the voltage consistently below 0.25 of a volt?

Ye s>>

Go To 2

No>>

Go To 11

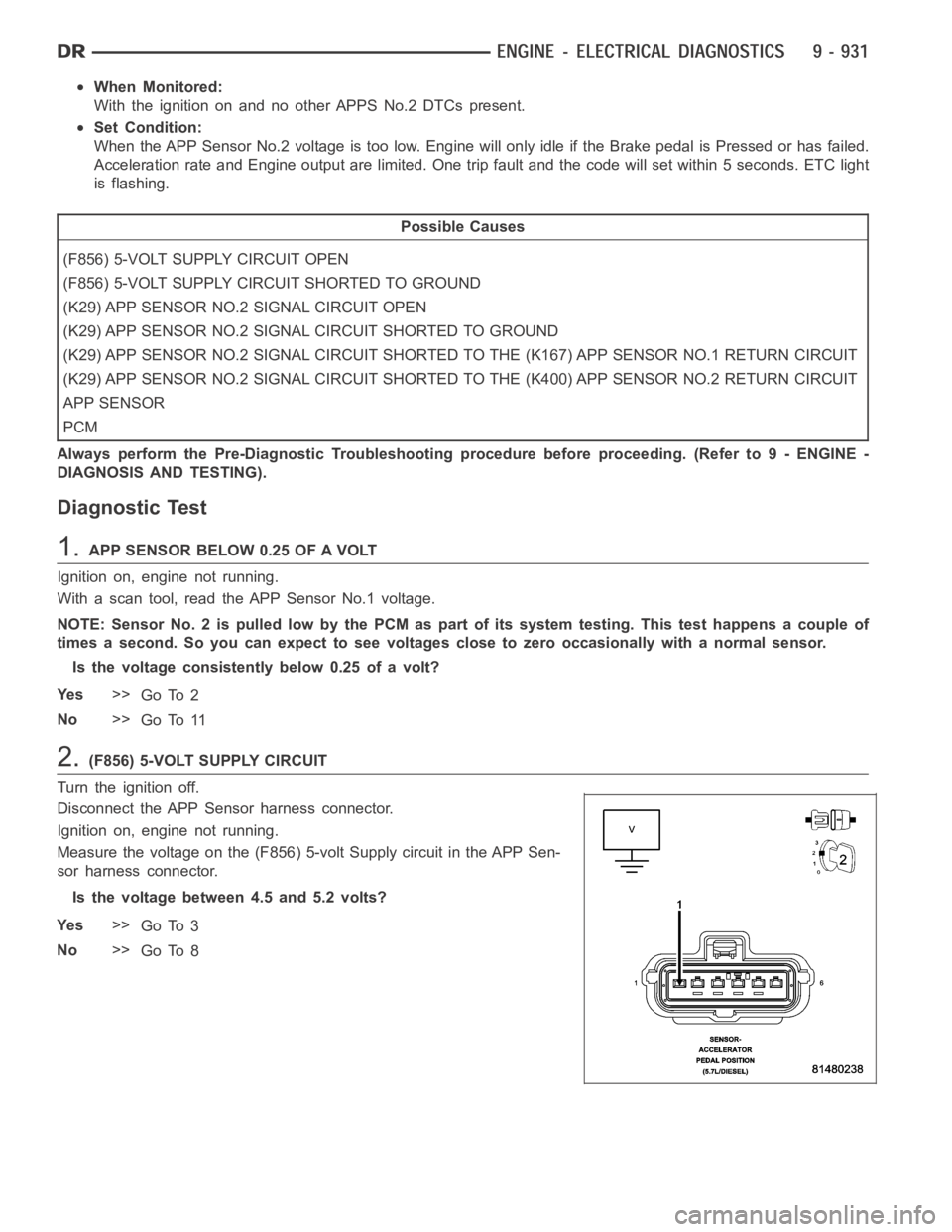

2.(F856) 5-VOLT SUPPLY CIRCUIT

Turn the ignition off.

Disconnect the APP Sensor harness connector.

Ignition on, engine not running.

Measure the voltage on the (F856) 5-volt Supply circuit in the APP Sen-

sor harness connector.

Is the voltage between 4.5 and 5.2 volts?

Ye s>>

Go To 3

No>>

Go To 8

Page 246 of 5267

When Monitored:

With the ignition on and no other APPS No.2 DTCs present.

Set Condition:

When APP Sensor No.2 voltage is too high. Idle is additionally forced any time the brake is applied or failed.

Acceleration rate and Engine output are limited. One trip fault and the code will set within 5 seconds. ETC light

is flashing.

Possible Causes

(K29) APP SENSOR NO.2 SIGNAL CIRCUIT SHORTED TO BATTERY VOLTAGE

(K29) APP SENSOR NO.2 SIGNAL SHORTED TO THE (F856) 5-VOLT SUPPLY CIRCUIT

(K29) APP SENSOR NO.2 SIGNAL SHORTED TO THE (F855) 5-VOLT SUPPLY CIRCUIT

(K400) APP SENSOR NO.2 RETURN CIRCUIT OPEN

APP SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.APPS NO.2 VOLTAGE ABOVE 3.0 VOLTS

Ignition on, engine not running.

With a scan tool, read the APP Sensor No.2 voltage.

NOTE: Diagnose any 5-Volt Supply DTCs before continuing.

Is the voltage above 3.0 volts?

Ye s>>

Go To 2

No>>

Go To 8

2.ACCELERATOR PEDAL POSITION SENSOR

Turn the ignition off.

Disconnect the APPS harness connector.

Ignition on, engine not running.

With a scan tool, monitor the Accelerator Pedal Position Sensor voltage.

Is the voltage above 3.0 volts?

Ye s>>

Go To 3

No>>

Replace the APP Sensor Assembly per Service Information. After installation is complete, use a scan

tool and select the ETC RELEARN function to relearn the APPS values.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 258 of 5267

When Monitored:

With the ignition on and no APPS No.1 and APPS No.2 DTC present.

Set Condition:

APPS values No.1 and No.2 are not coherent. Idle is additionally forced when the brake pedal is pressed or

failed. Acceleration rate and Engine output are limited. One trip fault and the code will set within 5 seconds.

ETC light is flashing.

Possible Causes

EXCESSIVE RESISTANCE IN THE (F855) 5-VOLT SUPPLY CIRCUIT

EXCESSIVE RESISTANCE IN THE (F856) 5-VOLT SUPPLY CIRCUIT

EXCESSIVE RESISTANCE IN THE (K167) SENSOR NO.1 RETURN CIRCUIT

EXCESSIVE RESISTANCE IN THE (K400) SENSOR NO.2 RETURN CIRCUIT

EXCESSIVE RESISTANCE IN THE (K23) APP SENSOR NO.1 SIGNAL CIRCUIT

EXCESSIVE RESISTANCE IN THE (K29) APP SENSOR NO.2 SIGNAL CIRCUIT

APP SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With a scan tool, read DTCs.

NOTE: Repair any other 5-Volt Supply or APPS High and Low DTCs before diagnosing P2138.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 264 of 5267

When Monitored:

Ignition on.

Set Condition:

PCM recognizes Vehicle speed input No.2 erratic or high. VSS No.2 is based on the average of the Front

Wheel Speeds. One trip fault and the code will set within 5 seconds. No MIL and No ETC light. Cruise is

disabled.

Possible Causes

(B222) VEHICLE SPEED NO.2 SIGNAL CIRCUIT SHORTED TO VOLTAGE

(B222) VEHICLE SPEED NO.2 SIGNAL CIRCUIT OPEN

(B222) VEHICLE SPEED NO.2 SIGNAL CIRCUIT SHORTED TO GROUND

TIRE CIRCUMFERENCE

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

NOTE: Check for any Bus Communication DTCs. If no Bus or Communication DTCsare set, check for active

DTCs stored in the Anti-Lock Brake Module. Any bus or communication DTCs orVSS DTCs in the Anti-Lock

Brake Module must be properly diagnosed before continuing.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.VISUAL INSPECTION

NOTE: This code can set due to tire circumference differences and from the front or rear wheels being on

a slippery surface while the opposite tires are not.

This code may also set on a hard acceleration on loose gravel or during otheroff road driving conditions.

Check tire pressure of all the tires.

Checktirewearonallthetires.

Ask the customer what the road and driving conditions were like when the fault set.

Were any problems found?

Ye s>>

Repair as necessary. If the code set during a front OR rear wheel spin condition, no repair is necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 316 of 5267

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on. No Break or APPS faults present.

Set Condition:

The PCM recognizes a brake application following the APPS showing a fixed pedal opening. Temporary or

permanent. Internally the PCM will reduce throttle opening below driver demand. One trip fault and the code

will be set within 5 seconds. ETC light will illuminate, the light will onlystay illuminated while DTC is active.

Possible Causes

CUSTOMER PRESSING ACCLERATOR PEDAL, THEN PRESSING BRAKE PEDAL, AND CONTINUES

HOLDING THEM DOWN SIMULTANEOUSLY

STOP LAMP SWITCH

APP SENSOR

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.DTC INFORMATION

NOTE: If a pedal assembly becomes mechanically stuck the voltage output will stay fixed, if this is also

Followed by a long application of the brakes this code will set.

NOTE: When this code sets the pedal position in the PCM software will ramp toidle. If the Pedal voltage

changes OR the brake pedal is released, the pedal position in the PCM software will ramp up to the pedal

position and the ETC light will go out.

With a scan tool, read DTCs and record the related Freeze Frame data.

Diagnose all other Stop Lamp Switch and APP Sensor codes before continuing.

This code can be set by a driver who uses both feet while driving, one for the Accelerator Pedal and the other for

the Brake Pedal.

NOTE: The most likely cause of this DTC is caused by the customer Brake Torquing the engine by pressing

the Accelerator pedal and the pressing the Brake Pedal.

Ask the driver of the vehicle if these conditions apply to their driving habits.

Are the listed conditions part of the customers driving habits?

Ye s>>

Advise the customer of what caused the DTC. This is normal operation of a ETCequipped vehicle

because of safety issues.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

2.STOP LAMP SWITCH OPERATION

With a scan tool, read both Stop Lamp Switch statuses while pressing and releasing the Brake Pedal.

Does the scan tool display the Pressed and Released while pressing and releasing the Pedal?

Ye s>>

Go To 3

No>>

Check the Stop Lamp Switch for proper installation and check the related circuits for opens and shorts

using the appropriate wiring diagram. If OK, replace the Stop Lamp Switch assembly.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 439 of 5267

3.EXCESSIVE RESISTANCE IN THE BATTERY CIRCUIT

Turn the ignition off.

Check the Battery Cables for excessive resistance using the service information procedure.

Did either Battery Cable have a voltage drop greater than 0.2 of a volt?

Ye s>>

Repair the excessive resistance in the Battery circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.STARTER RELAY

Turn ignition off.

Remove the Starter Relay from IPM.

CAUTION: The Parking Brake must be on and the Transmission must be in park for a vehicle equipped with

an automatic transmission.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Briefly connect a jumper wire from the Internal Fused B+ circuit to the (T750) Starter Relay Output circuit.

Did the Starter Motor crank the engine?

Ye s>>

Go To 5

No>>

Go To 7

5.(T751) FUSED IGNITION SWITCH OUTPUT CIRCUIT

Ignition on, engine not running.

Using a 12-volt test light, probe the (T751) Fused Ignition Switch Output circuit in the Starter Relay connector.

While observing 12-volt test light, hold ignition key in the start position.

Does the test light illuminate brightly?

Ye s>>

Go To 6

No>>

Repair the excessive resistance in the(T751)FusedIgnitionSwitchOutput circuit. Inspect related fuses

and repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 451 of 5267

POWERTRAIN VERIFICATION TEST

For a complete wiring diagramRefer to Section 8W.

Diagnostic Test

1.SELECTING THE PROPER VERIFICATION TEST

The following verification test are for different repairs. Select the appropriate Verification test for the

repair that has been completed.

Speed Control repair

Go To 2

Charging System repair

Go To 3

NVLD System repair

Go To 4

All other repairs

Go To 5

2.POWERTRAIN VERIFICATION TEST 1

NOTE: 1. If this vehicle is equipped with an Electronic Throttle Control system, and the APP Sensors, PCM,

or Throttle Body Assembly have been replaced, use the scan tool to perform the ETC RELEARN function.

NOTE: 2. After completing the Powertrain Verification Test the Transmission Verification Test must be per-

formed.

NOTE: 3. If the PCM has been replaced and the correct VIN and mileage have notbeen programmed, a DTC

will set in the ABS Module, Airbag Module and the SKIM/SKREEM.

NOTE: 4. If the vehicle is equipped with a Sentry Key Remote Entry, Secret Key data must be updated. Refer

to the Service Information for the PCM, SKIM/SKREEM and the Transponder (ignition key) for programming

information. Using the scan tool, program the Secret Key information intothe PCM using the PCM replaced

function under the WCM menu.

5. Inspect the vehicle to make sure that all engine components are properlyinstalled and connected.

6. Connect the scan tool to the data link connector and erase all codes.

7. Turn the speed control ON (if equipped, cruise light will be on).

8. Depress and release the SET Switch when the vehicle speed is greater than35 MPH. The speed control should

engage and hold the selected speed.

9. Press and hold the RESUME/ACCEL Switch. The vehicle speed should increase by at least 2 MPH.

10. Press and hold the COAST switch. The vehicle speed should decrease.

11. Using caution, press and release the brake pedal. The speed control should disengage.

12. Bring the vehicle speed back up to 35 MPH.

13. Press the RESUME/ACCEL switch. The speed control should resume the previously set speed.

14. Hold down the SET switch. The vehicle should decelerate.

15. Make sure vehicle speed is greater than 35 mph and release the SET Switch. The vehicle should adjust and set

a new vehicle speed.

16. Press and release the CANCEL switch. The speed control should disengage.

17. Bring the vehicle speed back up above 35 mph and engage speed control.

18. Turn the Speed Control Off. (Cruise light will be off). The speed control should disengage.

NOTE: OVERSHOOT/UNDERSHOOT FOLLOWING SPEED CONTROL SET.

19. If the vehicle operator repeatedly presses and releases the SET buttonwith their foot off of the accelerator

(referred to as

lift foot set), the vehicle may accelerate and exceed the desired set speed by up to 5 mph (8km/h).

20. It may also decelerate to less than the desired set speed, before finally achieving the desired set speed.

21. The Speed Control System has an adaptive strategy that compensates forvehicle-to-vehicle variations in speed

control cable lengths.

22. When the speed control is set with the vehicles operators foot off of theaccelerator pedal, the speed control

thinks there is excessive speed control cable slack and adapts accordingly.