fuel cap DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 466 of 5267

INTERMITTENT CONDITION

For a complete wiring diagramRefer to Section 8W.

POSSIBLE CAUSES

INTERMITTENT CONDITION

Diagnostic Test

1.INTERMITTENT CONDITION

NOTE: The conditions that set the DTC are not present at this time. The following list may help in identi-

fying the intermittent condition.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Refer to any Technical Service Bulletins (TSBs) that may apply.

Review the scan tool Freeze Frame information. If possible, try to duplicate the conditions under which the DTC set.

With the engine running at normal operating temperature, monitor the scantool parameters relatedtotheDTCwhile

wiggling the wire harness. Look for parameter values to change and/or a DTCto set.

Turn the ignition off.

Visually inspect the related wire harness. Disconnect all the related harness connectors. Look for any chafed,

pierced, pinched, partially broken wires and broken, bent, pushed out, orcorroded terminals.

Perform a voltage drop test on the related circuits between the suspected faulty component and the ECM.

Inspect and clean all ECM, engine, and chassis grounds that are related to the most current DTC.

If numerous trouble codes were set, use a wire schematic and look for any common ground or supply circuits.

For any Relay DTCs, actuate the Relay with the scan tool and wiggle the related wire harness to try to interrupt the

actuation.

For intermittent Evaporative Emission trouble codes perform a visual andphysical inspection of the related parts

including hoses and the Fuel Filler cap.

For intermittent Misfire DTC’s check for restrictions in the Intake and Exhaust system, proper installation of Sensors,

vacuum leaks, and binding components that are run by the accessory drive belt.

Use the scan tool to perform a System Test if one applies to failing component.

A co-pilot, data recorder, and/or lab scope should be used to help diagnoseintermittent conditions.

Were any problems found during the above inspections?

Ye s>>

Perform the necessary repairs.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL).

No>>

Te s t C o m p l e t e .

Page 896 of 5267

*INJECTOR RETURN FLOW TEST

Diagnostic Test

1.* INJECTOR RETURN FLOW TEST

1. Operate the engine until the engine is at operating temperature.

2. Remove the banjo connector from the fuel drain tube at the rear of the fuelfilter housing.

3. Install fuel system test fitting (9012) in place of the banjo connector.

4. Remove the vehicle fuel return line from the engine fuel drain tube. Route this hose into a container to catch bled

fuel.

5. Install a piece of fuel line onto the test fitting and into a fuel container or into the fuel tank.

6. Install one end of a test hose onto the fuel drain tube. Place the other endof the test hose into a graduated

cylinder.

7. Start the engine and let it idle for one minute.

8. Measure the amount of fuel in the graduated cylinder.

9. If the flow is less than 180-ml/minute, the test has successfully passed.

10. If the flow is greater than 180 ml/minute, shut off the engine and removeall of the fuel injector supply lines. Re

torque all of the high-pressure connector nuts. Install all of the fuel injector supply lines.

11. Start the engine and idle for one minute. Measure the amount of fuel in the graduated cylinder.

12. If the flow is less than 180ml/minute, the condition has been fixed.

13. If the flow is greater than 180 ml/minute after step 12, shut off the engine and remove the #1 fuel injector supply

line. Re torque the high-pressure connector nut. Cap the #1 fuel port usingtool #9011 on the fuel rail and the #1

high pressure connector.

14. Start the engine. Measure the amount of fuel in the graduated cylinder.

15. If the amount of fuel is less than 180 ml/minute, shut off the engine and remove the #1 high pressure connector

and the #1 fuel injector. Inspect for damage, repair/replace as necessary.

16. If the amount of fuel is not less than 180-ml/minute, repeat steps 14-16for cylinders 2-6.

17. Install all high-pressure connectors, fuel injectors, and fuel injector supply lines. Repeat steps 1-8 to confirm

repair.

SPECIFICATION:Less than 180 ml/minute total fuel return flow

Repair

Te s t C o m p l e t e .

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 916 of 5267

INTERMITTENT CONDITION

For a complete wiring diagramRefer to Section 8W.

POSSIBLE CAUSES

INTERMITTENT CONDITION

Diagnostic Test

1.INTERMITTENT CONDITION

NOTE: The conditions that set the DTC are not present at this time. The following list may help in identi-

fying the intermittent condition.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Refer to any Technical Service Bulletins (TSBs) that may apply.

Review the scan tool Freeze Frame information. If possible, try to duplicate the conditions under which the DTC set.

With the engine running at normal operating temperature, monitor the scantool parameters relatedtotheDTCwhile

wiggling the wire harness. Look for parameter values to change and/or a DTCto set.

Turn the ignition off.

Visually inspect the related wire harness. Disconnect all the related harness connectors. Look for any chafed,

pierced, pinched, partially broken wires and broken, bent, pushed out, orcorroded terminals.

Perform a voltage drop test on the related circuits between the suspected faulty component and the PCM.

Inspect and clean all PCM, engine, and chassis grounds that are related to the most current DTC.

If numerous trouble codes were set, use a wire schematic and look for any common ground or supply circuits.

For any Relay DTCs, actuate the Relay with the scan tool and wiggle the related wire harness to try to interrupt the

actuation.

For intermittent Evaporative Emission trouble codes perform a visual andphysical inspection of the related parts

including hoses and the Fuel Filler cap.

For intermittent Misfire DTC’s check for restrictions in the Intake and Exhaust system, proper installation of Sensors,

vacuum leaks, and binding components that are run by the accessory drive belt.

Use the scan tool to perform a System Test if one applies to failing component.

A co-pilot, data recorder, and/or lab scope should be used to help diagnoseintermittent conditions.

Were any problems found during the above inspections?

Ye s>>

Perform the necessary repairs.

Perform POWERTRAIN VERIFICATION TEST VER - 1.

No>>

Te s t C o m p l e t e .

Page 1273 of 5267

3.VISUAL AND PHYSICAL INSPECTION

Perform a visual and physical inspection of the entire Evaporative Emission system.

Check for the follow conditions:

- Holes or cracks

- Loose seal points

- Evidence of damaged components

- Incorrect routing of hoses and tubes

- Fuel Cap gasket seal

Were any of the above conditions found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.VERIFY EVAPORATIVE EMISSION LEAK

To continue testing you will need Miller Tool #8404A Evaporative EmissionLeak Detector (EELD).

WARNING: Keep lit cigarettes, sparks, flames, and other ignition sourcesaway from the test area to prevent

the ignition of explosive gases. Keep the test area well ventilated.

NOTE: The fuel tank should have between 20% and 80% of fuel tank capacity to properly test the Evap

system.

Connect the red power lead of the EELD to the battery positive terminal and the black ground lead to battery neg-

ative terminal.

Block the vent hose of the canister if using the service port.

Connect shop air to the EELD.

Set the smoke/air control switch to AIR.

Insert the tester’s AIR supply tip (clear hose) into the appropriate calibration orifice on the tester’s control panel

(based on DTC leak size).

Press the remote smoke/air start button.

Position the red flag on the air flow meter so it is aligned with the indicatorball.

When the calibration is complete, release the remote button. The EELD flowmeter is now calibrated in liters per

minute to the size leak indicated by the DTC set in the PCM.

Install the service port adapter #8404-14 on the vehicle’s service port and block the vent hose of the EVAP Canister

(if equipped) or install the #8404-ADP service adaptor into the filter line.

Connect the Air supply hose from the EELD to the service port (if equipped) or to the #8404-ADP adapter.

Press the remote button to activate AIR flow.

NOTE: Larger volume fuel tanks, lower fuel levels or if the vehicle is equipped with a Flow Management

Valve may indicate high flow and will require 4 to 5 minutes to fill.

Compare the flow meter indicator ball reading to the red flag.

ABOVE the red flag indicates a leak present.

BELOW the red flag indicates a sealed system.

Is the indicator ball above the red flag?

Ye s>>

Go To 5

No>>

Refer to the Freeze Frame data recorded in Step 1. If the data indicates thatthe vehicle was in motion

when the DTC was set, verify that all hoses are properly connected. Test Complete.

Page 1274 of 5267

5.EVAPORATIVE EMISSION LEAK DETECTION

NOTE: A thorough visual inspection of the Evap system hoses, tubes, and connections may save time in

your diagnosis. Look for any physical damage or signs of wetness at connections. The strong smell of fuel

vapors may also aid diagnosis.

To continue testing, you will need Miller Tool #8404A Evaporative Emissions Leak Detector (EELD).

Remove the Air supply hose from the service port (if equipped) or from the #8404-ADP adapter.

Connect the SMOKE supply tip (black hose) to the service port (if equipped)or to the #8404-ADP adapter.

Set the smoke/air control switch to SMOKE.

NOTE: The flow meter indicator ball will not move in the smoke mode.

Press the remote smoke/air start button.

NOTE: Make sure that smoke has filled the EVAP system by continuing to presstheremotesmoke/airstart

button, remove the vehicle fuel cap, and wait for the smoke to exit. Once smoke is indicated reinstall the

fuel cap.

NOTE: For optimal performance, introduce smoke into the system for an additional 60 seconds; continue

introducing smoke at 15 second intervals, as necessary.

While still holding the remote smoke/air start button, use the white light(#8404-CLL) to follow the EVAP system

path, and look for the source of the leak indicated by exiting smoke.

If a leak is concealed from view (i.e., top of fuel tank), release the remotesmoke/air start button, and use the ultra-

violet (UV) black light #8404-UVL and the yellow goggles 8404-20 to look for residual traces of dye that is left

behind by the smoke.

The exiting smoke deposits a residual fluid that is either bright green or bright yellow in color when viewed with a

UV light.

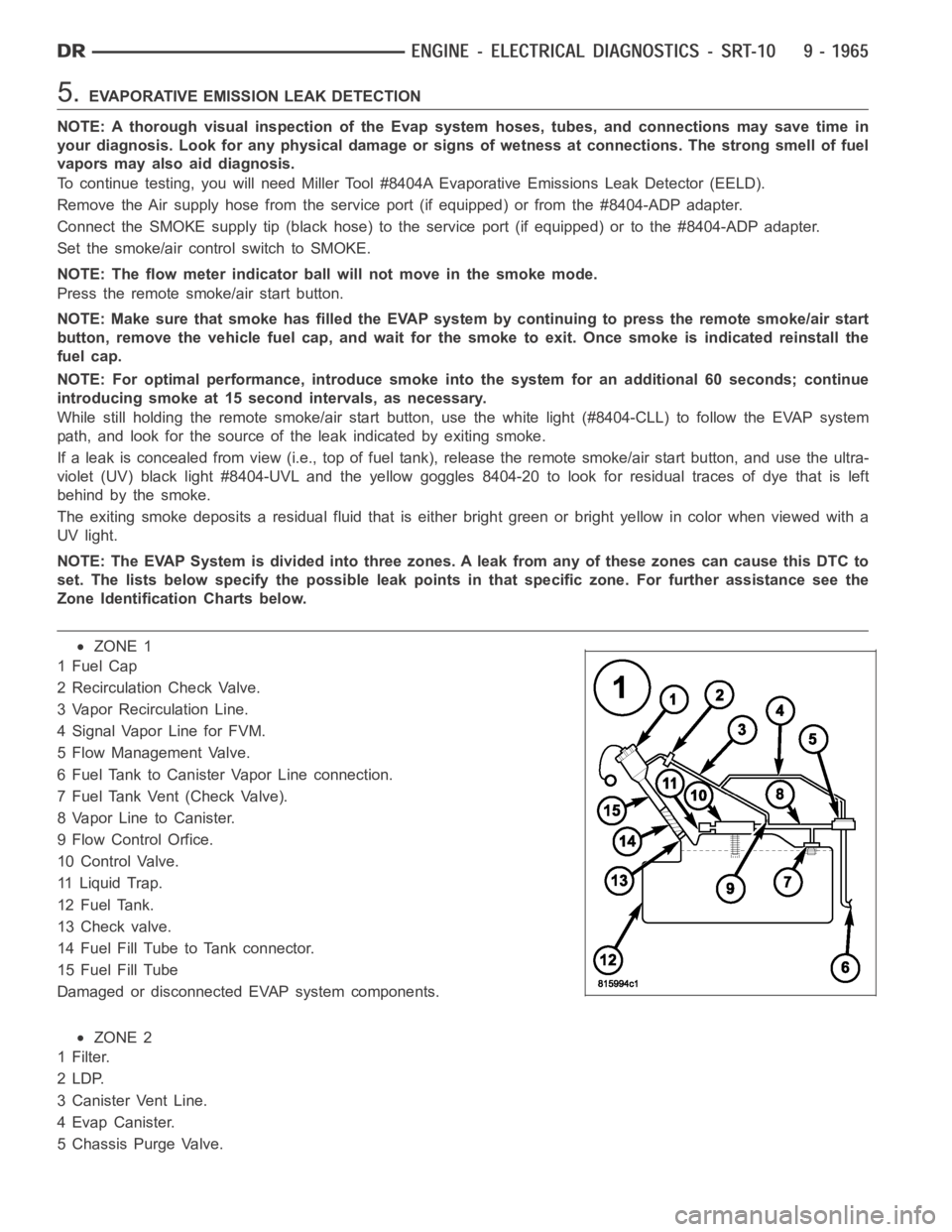

NOTE: The EVAP System is divided into three zones. A leak from any of these zonescancausethisDTCto

set. The lists below specify the possible leak points in that specific zone. For further assistance see the

Zone Identification Charts below.

ZONE 1

1FuelCap

2 Recirculation Check Valve.

3 Vapor Recirculation Line.

4 Signal Vapor Line for FVM.

5 Flow Management Valve.

6 Fuel Tank to Canister Vapor Line connection.

7 Fuel Tank Vent (Check Valve).

8 Vapor Line to Canister.

9 Flow Control Orfice.

10 Control Valve.

11 Liquid Trap.

12 Fuel Tank.

13 Check valve.

14 Fuel Fill Tube to Tank connector.

15 Fuel Fill Tube

Damaged or disconnected EVAP system components.

ZONE 2

1Filter.

2LDP.

3 Canister Vent Line.

4EvapCanister.

5 Chassis Purge Valve.

Page 1276 of 5267

6.LEAK AT GAS CAP

Remove the SMOKE supply tip (black hose) from the service port (if equipped) or to the #8404–ADP adapter.

Install gas cap adapter, Miller Tool #8382 (1/4 turn cap) or #6922 (screw cap) and #8399* (secondary seal depres-

sor) and repeat test 5.

Was a leak found at the gas cap adapter?

Ye s>>

Replace the Fuel Filler tube assembly.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the gas cap.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

7.LEAK DETECTION PUMP

Apply an external vacuum to the LDP.

Using a scan tool, close the LDP seal to atmosphere.

Inject smoke into the Evap system using the EELD.

Examine the LDP filter port for smoke.

Is smoke visible from the LDP?

Ye s>>

Replace the Leak Detection Pump.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 8

8.EVAP PURGE SOLENOID OPERATION

To continue testing you will need Miller Tool #8404 Evaporative Emission Leak Detector (EELD).

Connect the red power lead of the EELD to the battery positive terminal and the black ground lead to the battery

negative ternal.

Disconnect the vacuum hoses at the Evap Purge Solenoid.

Connect the SMOKE supply tip (black hose) to the service port (if equipped)or to the #8404-ADP adapter.

Set the smoke/air control switch to SMOKE.

Press the remote smoke/air start button.

NOTE: Below is an optional method of checking the purge valve for leaks if the EELD is unavailable.

Turn the ignition off.

Disconnect the vacuum hoses at the Evap Purge Solenoid.

Using a hand vacuum pump, apply 10 in Hg to the

CANof the EVAP Purge Solenoid.

With the scan tool, actuate the Evap Purge Solenoid.

NOTE: If the Evap Purge Solenoid does not hold a vacuum, it will need to be repalced..

Is smoke visible from the Evap Purge Solenoid?

Ye s>>

Replace the Evap Purge Solenoid.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 1283 of 5267

3.VISUAL AND PHYSICAL INSPECTION

Perform a visual and physical inspection of the entire Evaporative Emission system.

Check for the follow conditions:

- Holes or cracks

- Loose seal points

- Evidence of damaged components

- Incorrect routing of hoses and tubes

- Fuel Cap gasket seal

Were any of the above conditions found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.VERIFY EVAPORATIVE EMISSION LEAK

To continue testing you will need Miller Tool #8404A Evaporative EmissionLeak Detector (EELD).

WARNING: Keep lit cigarettes, sparks, flames, and other ignition sourcesaway from the test area to prevent

the ignition of explosive gases. Keep the test area well ventilated.

NOTE: The fuel tank should have between 20% and 80% of fuel tank capacity to properly test the Evap

system.

Connect the red power lead of the EELD to the battery positive terminal and the black ground lead to battery neg-

ative terminal.

Block the vent hose of the canister if using the service port.

Connect shop air to the EELD.

Set the smoke/air control switch to AIR.

Insert the tester’s AIR supply tip (clear hose) into the appropriate calibration orifice on the tester’s control panel

(based on DTC leak size).

Press the remote smoke/air start button.

Position the red flag on the air flow meter so it is aligned with the indicatorball.

When the calibration is complete, release the remote button. The EELD flowmeter is now calibrated in liters per

minute to the size leak indicated by the DTC set in the PCM.

Install the service port adapter #8404-14 on the vehicle’s service port and block the vent hose of the EVAP Canister

(if equipped) or install the #8404-ADP service adaptor into the filter line.

Connect the Air supply hose from the EELD to the service port (if equipped) or to the #8404-ADP adapter.

Press the remote button to activate AIR flow.

NOTE: Larger volume fuel tanks, lower fuel levels or if the vehicle is equipped with a Flow Management

Valve may indicate high flow and will require 4 to 5 minutes to fill.

Compare the flow meter indicator ball reading to the red flag.

ABOVE the red flag indicates a leak present.

BELOW the red flag indicates a sealed system.

Is the indicator ball above the red flag?

Ye s>>

Go To 5

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1284 of 5267

5.EVAPORATIVE EMISSION LEAK DETECTION

NOTE: A thorough visual inspection of the Evap system hoses, tubes, and connections may save time in

your diagnosis. Look for any physical damage or signs of wetness at connections. The strong smell of fuel

vapors may also aid diagnosis.

To continue testing, you will need Miller Tool #8404A Evaporative Emissions Leak Detector (EELD).

Remove the Air supply hose from the service port (if equipped) or from the #8404-ADP adapter.

Connect the SMOKE supply tip (black hose) to the service port (if equipped)or to the #8404-ADP adapter.

Set the smoke/air control switch to SMOKE.

NOTE: The flow meter indicator ball will not move in the smoke mode.

Press the remote smoke/air start button.

NOTE: Make sure that smoke has filled the EVAP system by continuing to presstheremotesmoke/airstart

button, remove the vehicle fuel cap, and wait for the smoke to exit. Once smoke is indicated reinstall the

fuel cap.

NOTE: For optimal performance, introduce smoke into the system for an additional 60 seconds; continue

introducing smoke at 15 second intervals, as necessary.

While still holding the remote smoke/air start button, use the white light(#8404-CLL) to follow the EVAP system

path, and look for the source of the leak indicated by exiting smoke.

If a leak is concealed from view (i.e., top of fuel tank), release the remotesmoke/air start button, and use the ultra-

violet (UV) black light #8404-UVL and the yellow goggles 8404-20 to look for residual traces of dye that is left

behind by the smoke.

The exiting smoke deposits a residual fluid that is either bright green or bright yellow in color when viewed with a

UV light.

NOTE: Carefully inspect the vent side of the EVAP Canister. Due to the filtering system in the canister the

smoke may not be as thick. Introducing smoke into the filtered side of the canister may assist in locating

the leak.

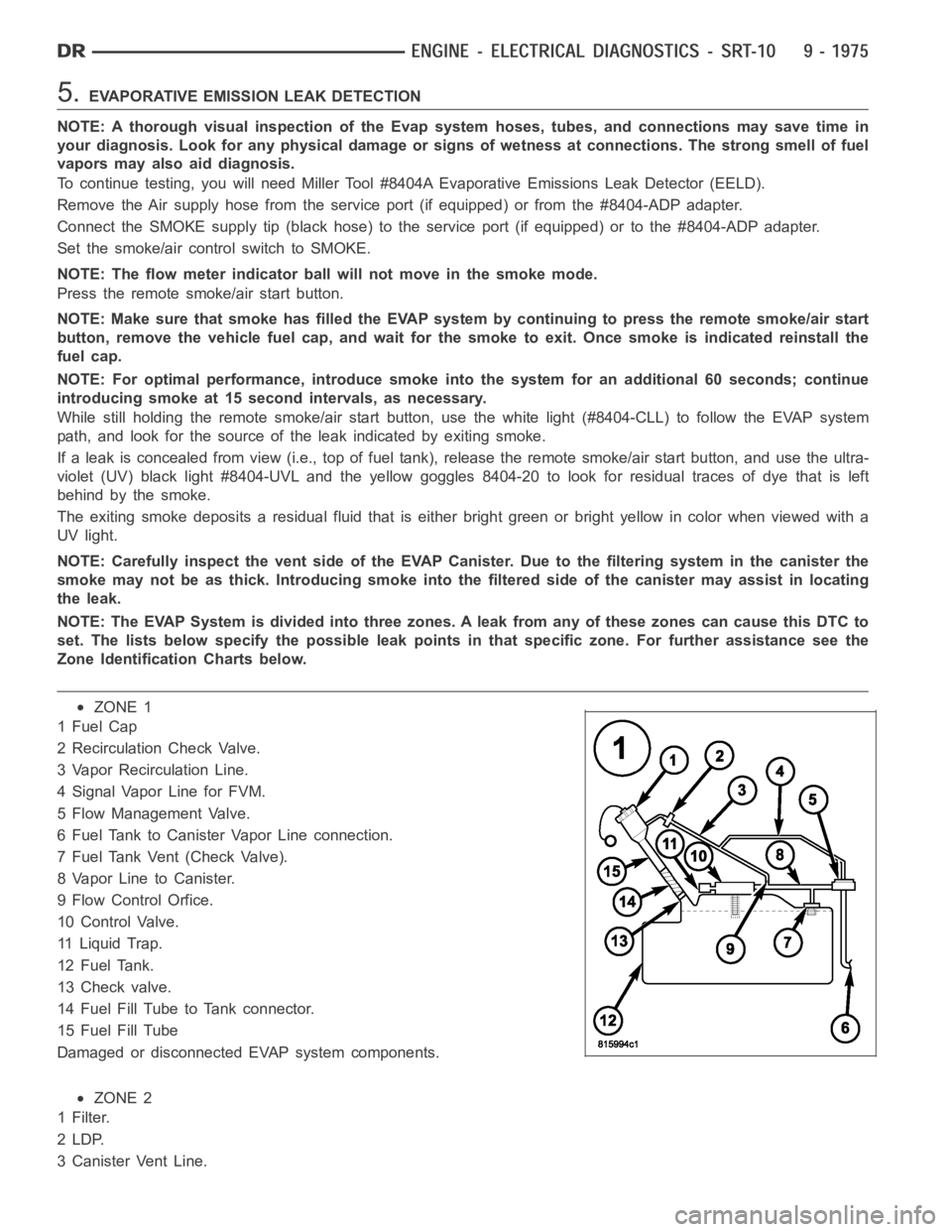

NOTE: The EVAP System is divided into three zones. A leak from any of these zonescancausethisDTCto

set. The lists below specify the possible leak points in that specific zone. For further assistance see the

Zone Identification Charts below.

ZONE 1

1FuelCap

2 Recirculation Check Valve.

3 Vapor Recirculation Line.

4 Signal Vapor Line for FVM.

5 Flow Management Valve.

6 Fuel Tank to Canister Vapor Line connection.

7 Fuel Tank Vent (Check Valve).

8 Vapor Line to Canister.

9 Flow Control Orfice.

10 Control Valve.

11 Liquid Trap.

12 Fuel Tank.

13 Check valve.

14 Fuel Fill Tube to Tank connector.

15 Fuel Fill Tube

Damaged or disconnected EVAP system components.

ZONE 2

1Filter.

2LDP.

3 Canister Vent Line.

Page 1286 of 5267

6.LEAK AT GAS CAP

Remove the SMOKE supply tip (black hose) from the service port (if equipped) or to the #8404–ADP adapter.

Install gas cap adapter, Miller Tool #8382 (1/4 turn cap) or #6922 (screw cap) and #8399* (secondary seal depres-

sor) and repeat test 5.

Was a leak found at the gas cap adapter?

Ye s>>

Replace the Fuel Filler tube assembly.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the gas cap.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

7.LEAK DETECTION PUMP

Apply an external vacuum to the LDP.

Using a scan tool, close the LDP seal to atmosphere.

Inject smoke into the Evap system using the EELD.

Examine the LDP filter port for smoke.

Is smoke visible from the LDP?

Ye s>>

Replace the Leak Detection Pump.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 8

8.EVAP PURGE SOLENOID OPERATION

To continue testing you will need Miller Tool #8404 Evaporative Emission Leak Detector (EELD).

Connect the red power lead of the EELD to the battery positive terminal and the black ground lead to the battery

negative ternal.

Disconnect the vacuum hoses at the Evap Purge Solenoid.

Connect the SMOKE supply tip (black hose) to the service port (if equipped)or to the #8404-ADP adapter.

Set the smoke/air control switch to SMOKE.

Press the remote smoke/air start button.

NOTE: Below is an optional method of checking the purge valve for leaks if the EELD is unavailable.

Turn the ignition off.

Disconnect the vacuum hoses at the Evap Purge Solenoid.

Using a hand vacuum pump, apply 10 in Hg to the

CANof the EVAP Purge Solenoid.

With the scan tool, actuate the Evap Purge Solenoid.

NOTE: If the Evap Purge Solenoid does not hold a vacuum, it will need to be repalced..

Is smoke visible from the Evap Purge Solenoid?

Ye s>>

Replace the Evap Purge Solenoid.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 1287 of 5267

P0460-FUEL LEVEL SENDING UNIT NO CHANGE OVER MILES

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Engine running and fuel level either below 15% or above 85% of capacity.

Set Condition:

The PCM sees low fuel, less than 15%, for more than 120 miles or fuel level does not change by at least 4%

for more than 250 miles.

Possible Causes

PHYSICALLY DAMAGED/DEFORMED/OBSTRUCTED FUEL TANK

FUEL LEVEL SENSOR

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.CHECKING FOR A DAMAGED/DEFORMED/OBSTRUCTED FUEL TANK

Turn the ignition off.

WARNING: WARNING: The fuel system is under a constant pressure, even with the engine off. Before test-

ing or servicing any fuel system hose, fitting or line, the fuel system pressure must be released.

Inspect the outside of the fuel tank for defects.

Remove the fuel tank.

Remove the fuel pump module from the fuel tank.

Inspect the inside of the fuel tank for any obstructions or deformities.

Is the fuel tank free from defects?

Ye s>>

Go To 2

No>>

Repair or replace the fuel tank as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.FUEL LEVEL SENSOR

If there are no possible causes remaining, view repair.

Repair

Replace the Fuel Level Sensor.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)