wheel DODGE SPRINTER 2004 1.G Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: SPRINTER, Model: DODGE SPRINTER 2004 1.GPages: 272, PDF Size: 22.71 MB

Page 188 of 272

188 WHAT TO DO IN EMERGENCIES

Procedure:

1. Park the vehicle on a firm, level, non-slippery

surface.

2. Switch on the hazard warning flasher switch, apply

the parking brake, and place the transmission

selector in "P".

WARNING!

The jack is designed exclusively for jacking up the

vehicle at the jack take-up brackets built into ei-

ther side of the vehicle. To help avoid personal in-

jury, use the jack only to lift the vehicle during a

wheel change. Never get beneath the vehicle

while it is supported by the jack only.

Keep hands and feet away from the area under the

lifted vehicle. Always firmly set parking brake

and block wheels before raising vehicle with jack.

Do not disengage parking brake while the vehicle

is raised.

Always use the jack on a level surface.

Do not change wheels on either steep uphill or

downhill grades. Be sure that the jack arm end is

fully seated in the jack take-up bracket. The

vehicle may begin to move and fall from the jack

which could cause serious or fatal personal injury

and property damage.

Always lower the vehicle onto sufficient capacity

jack stands before working under the vehicle.

Precautions when changing a wheel:

For the torque, refer to "Installing a wheel";

Do not damage, grease or oil wheel bolts or their

threads.

Do not jack the vehicle up more than 1.2 in (30

mm) between the tire and the surface. Otherwise,

the vehicle may tip over and may cause serious

injury or death to you or others.

Precautions when changing a wheel:

For the torque, refer to "Installing a wheel";

Do not damage, grease or oil wheel bolts or their

threads.

Freightliner-all.book Pag e 188 Monday, December 1, 2003 2:54 PM

Page 189 of 272

WHAT TO DO IN EMERGENCIES 189

6

3. Everyone must leave the vehicle before you jack it

up.

4. Everyone must leave the danger zone, before

jacking the vehicle.

5. The vehicle must be safeguarded in accordance

with legal regulations (such as using a warning

triangle).

6. Prevent vehicle from rolling away by blocking

wheels with wheel chocks (not supplied with

vehicle) or sizable wood block or stone.

On a level road, place one chock in front of and one

behind the wheel that is diagonally opposite to the

wheel being changed.

When changing a wheel on mild uphill or downhill

grades, place chocks on the downhill side blocking

both wheels of the other axle.

Spare Wheel Location

WARNING!

Do not change wheels on either steep uphill or

downhill grades. The vehicle may begin to move

and fall from the jack which could cause personal

injury and property damage.

WARNING!

If the rear cargo doors are opened to 90° (detent

position), the rear lights will be concealed. The ve-

hicle is then not sufficiently safeguarded at the

rear and may only be seen by other road users

when they are close to the vehicle. This could lead

to an accident.

The vehicle must then be clearly marked in

accordance with state and local laws, e.g., with a

warning triangle.

Freightliner-all.book Pag e 189 Monday, December 1, 2003 2:54 PM

Page 190 of 272

190 WHAT TO DO IN EMERGENCIESNOTE: Lug wrench and jack, refer to "Vehicle Tool

Kit". For reasons of safety, check at regular intervals

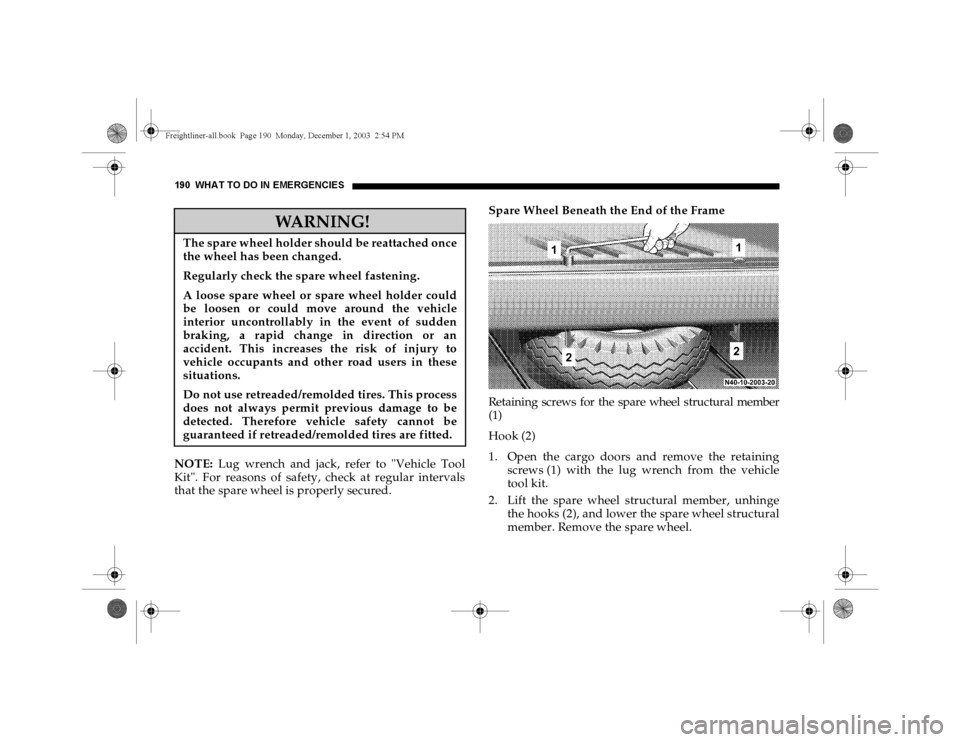

that the spare wheel is properly secured.Spare Wheel Beneath the End of the Frame

Retaining screws for the spare wheel structural member

(1)Hook (2)

1. Open the cargo doors and remove the retaining

screws (1) with the lug wrench from the vehicle

tool kit.

2. Lift the spare wheel structural member, unhinge

the hooks (2), and lower the spare wheel structural

member. Remove the spare wheel.

WARNING!

The spare wheel holder should be reattached once

the wheel has been changed.

Regularly check the spare wheel fastening.

A loose spare wheel or spare wheel holder could

be loosen or could move around the vehicle

interior uncontrollably in the event of sudden

braking, a rapid change in direction or an

accident. This increases the risk of injury to

vehicle occupants and other road users in these

situations.

Do not use retreaded/remolded tires. This process

does not always permit previous damage to be

detected. Therefore vehicle safety cannot be

guaranteed if retreaded/remolded tires are fitted.

Freightliner-all.book Pag e 190 Monday, December 1, 2003 2:54 PM

Page 191 of 272

WHAT TO DO IN EMERGENCIES 191

6

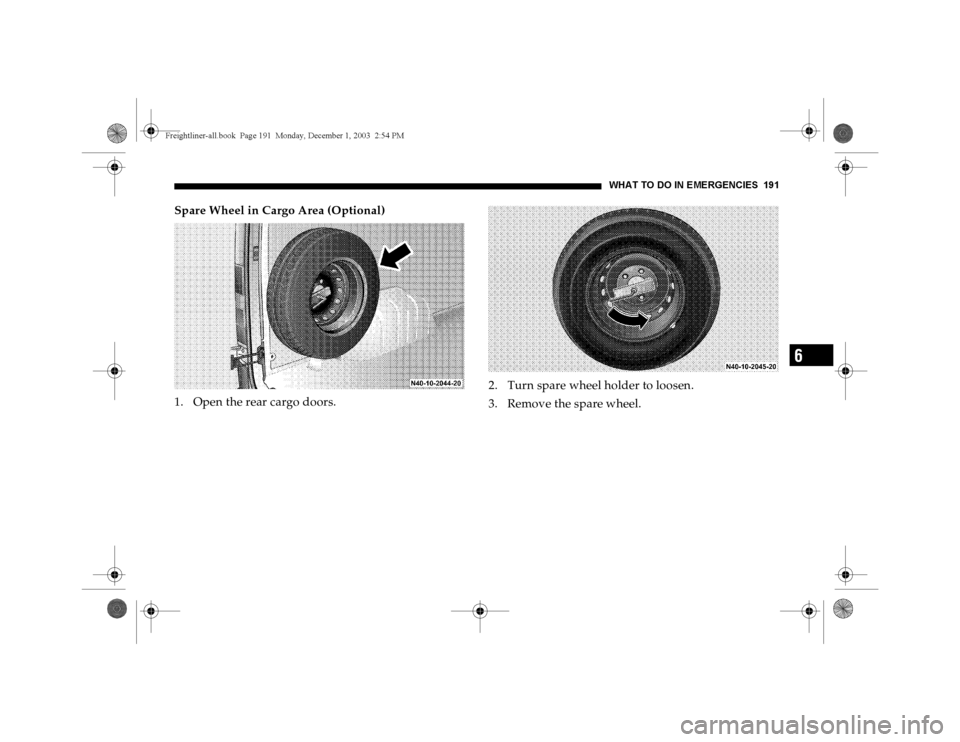

Spare Wheel in Cargo Area (Optional)

1. Open the rear cargo doors.2. Turn spare wheel holder to loosen.

3. Remove the spare wheel.Freightliner-all.book Pag e 191 Monday, December 1, 2003 2:54 PM

Page 192 of 272

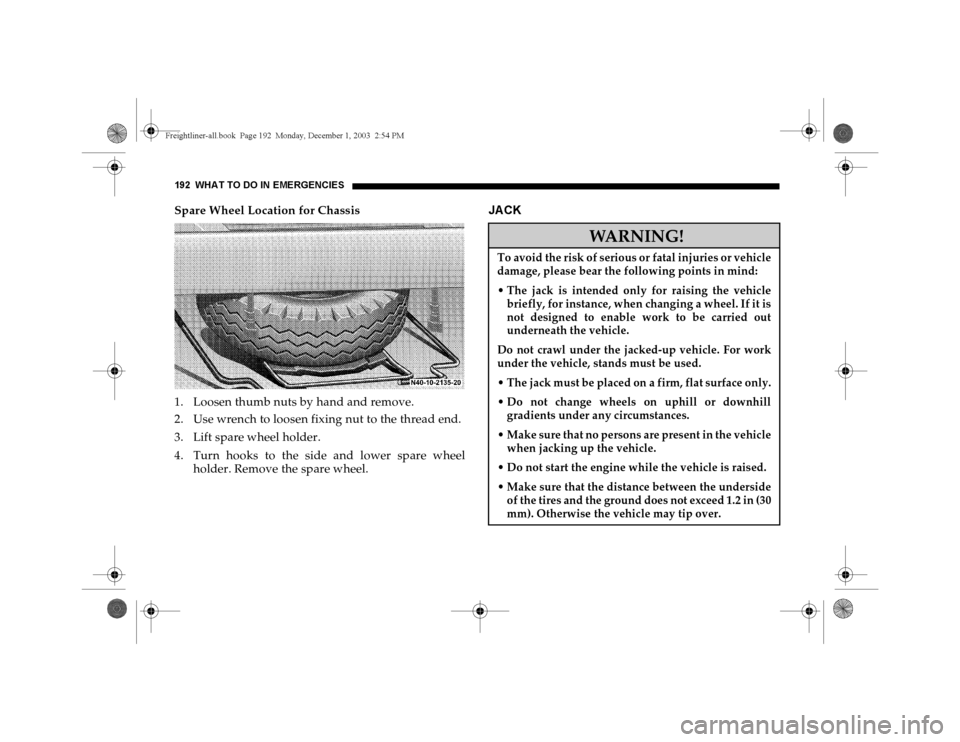

192 WHAT TO DO IN EMERGENCIESSpare Wheel Location for Chassis

1. Loosen thumb nuts by hand and remove.

2. Use wrench to loosen fixing nut to the thread end.

3. Lift spare wheel holder.

4. Turn hooks to the side and lower spare wheel

holder. Remove the spare wheel.

JA CK

WARNING!

To avoid the risk of serious or fatal injuries or vehicle

damage, please bear the following points in mind:

The jack is intended only for raising the vehicle

briefly, for instance, when changing a wheel. If it is

not designed to enable work to be carried out

underneath the vehicle.

Do not crawl under the jacked-up vehicle. For work

under the vehicle, stands must be used.

The jack must be placed on a firm, flat surface only.

Do not change wheels on uphill or downhill

gradients under any circumstances.

Make sure that no persons are present in the vehicle

when jacking up the vehicle.

Do not start the engine while the vehicle is raised.

Make sure that the distance between the underside

of the tires and the ground does not exceed 1.2 in (30

mm). Otherwise the vehicle may tip over.

Freightliner-all.book Pag e 192 Monday, December 1, 2003 2:54 PM

Page 193 of 272

WHAT TO DO IN EMERGENCIES 193

6

Using the JackThe jack is located together with the vehicle tool kit

under the hatch in the front passenger footwell, refer to

"Vehicle Tool Kit".

1. Loosen the wheel bolts before raising the vehicle.

2. Close the release valve on the jack.

3. Assemble the pump lever provided and insert it

into the socket on the jack.

4. Secure the lever by turning it clockwise in the

socket.

Position the jack under the appropriate jack point and

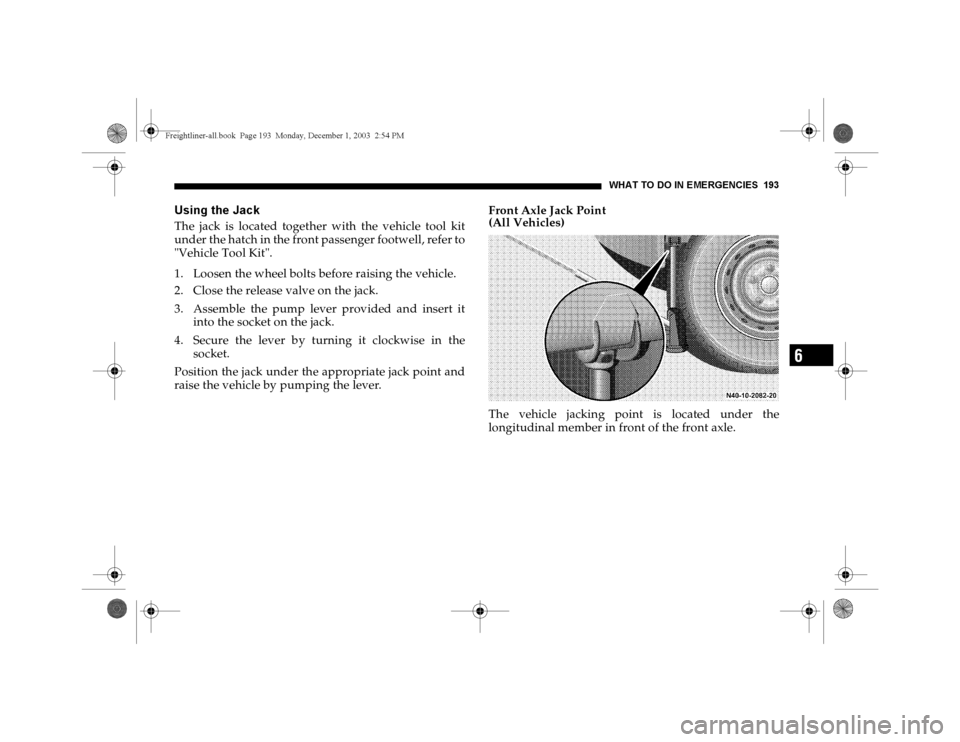

raise the vehicle by pumping the lever.Front Axle Jack Point

(All Vehicles)

The vehicle jacking point is located under the

longitudinal member in front of the front axle.Freightliner-all.book Pag e 193 Monday, December 1, 2003 2:54 PM

Page 195 of 272

WHAT TO DO IN EMERGENCIES 195

6

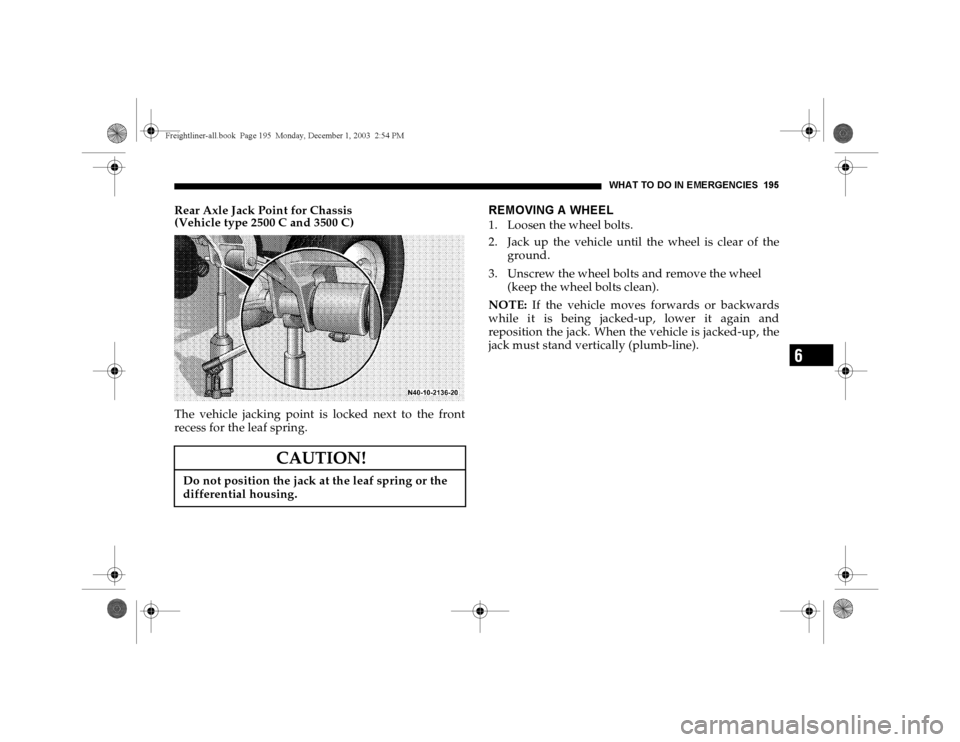

Rear Axle Jack Point for Chassis

(Vehicle type 2500 C and 3500 C)

The vehicle jacking point is locked next to the front

recess for the leaf spring.

REMOVING A WHEEL1. Loosen the wheel bolts.

2. Jack up the vehicle until the wheel is clear of the

ground.

3. Unscrew the wheel bolts and remove the wheel

(keep the wheel bolts clean).

NOTE: If the vehicle moves forwards or backwards

while it is being jacked-up, lower it again and

reposition the jack. When the vehicle is jacked-up, the

jack must stand vertically (plumb-line).

CAUTION!

Do not position the jack at the leaf spring or the

differential housing.

Freightliner-all.book Pag e 195 Monday, December 1, 2003 2:54 PM

Page 196 of 272

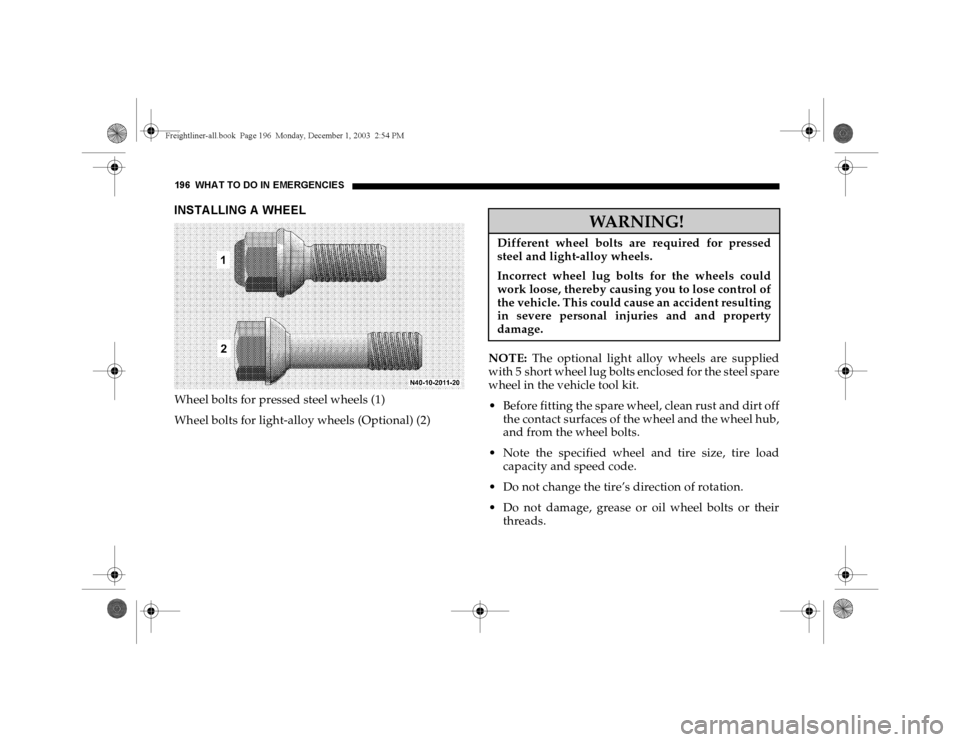

196 WHAT TO DO IN EMERGENCIESINSTALLING A WHEELWheel bolts for pressed steel wheels (1)

Wheel bolts for light-alloy wheels (Optional) (2)NOTE: The optional light alloy wheels are supplied

with 5 short wheel lug bolts enclosed for the steel spare

wheel in the vehicle tool kit.

Before fitting the spare wheel, clean rust and dirt off

the contact surfaces of the wheel and the wheel hub,

and from the wheel bolts.

Note the specified wheel and tire size, tire load

capacity and speed code.

Do not change the tire’s direction of rotation.

Do not damage, grease or oil wheel bolts or their

threads.

WARNING!

Different wheel bolts are required for pressed

steel and light-alloy wheels.

Incorrect wheel lug bolts for the wheels could

work loose, thereby causing you to lose control of

the vehicle. This could cause an accident resulting

in severe personal injuries and and property

damage.

Freightliner-all.book Pag e 196 Monday, December 1, 2003 2:54 PM

Page 197 of 272

WHAT TO DO IN EMERGENCIES 197

6

Centering wheels with wheel bolts

If dual assemblies are used, before placement the

inner wheel should be inspected to ensure that all

ball bearing rings are in proper position.

Install the wheel and snug the wheel bolts.

Slightly tighten wheel bolts.

Slowly open jack release valve to lower vehicle until

tire is resting on ground.

Tighten the wheel bolts in a crosswise pattern to the

specified torque with a torque wrench.

Tightening torque for 8,550 lbs (3,880 kgs)

(vehicle type 2500 C/HC/SHC):

Steel wheel – 177 lbf.ft ±7 lbf.ft (240 N.m ±10 N.m)

Light alloy wheel – 138 lbf.ft ±14 lbf.ft

(190 N.m ±20 N.m)

WARNING!

Incorrect mounting bolts or improperly tightened

mounting bolts can cause the wheel to come off.

To avoid the risk of serious or fatal injuries or ve-

hicle damage, please bear the following points in

mind:• Always replace wheel bolts that are damaged or

rusted.• Never apply oil or grease to wheel bolts• If a wheel hub thread is damaged, you must not

drive the vehicle. Consult a qualified specialist

workshop.

WARNING!

Do not tighten the wheel bolts and wheel nuts

completely while the vehicle is still jacked up.

The vehicle could tip.

Freightliner-all.book Pag e 197 Monday, December 1, 2003 2:54 PM

Page 198 of 272

198 WHAT TO DO IN EMERGENCIES

Tightening torque for 9,990 lbs (4,530 kgs)

(vehicle type 3500 C/HC/SHC):

Steel wheel – 138 lbf.ft ±14 lbf.ft (190 N.m ±20 N.m)

Remove jack and stow it in the vehicle tool kit.

Check the tire pressure.

Re-tighten the wheel bolts to the specified torque

with a torque wrench after a distance of 30 miles

(about 50 km).

JUMP STA RTINGIf the battery is dead, the engine can be started with

jumper cables from another vehicle’s battery.

WARNING!

After changing a wheel, you must, for safety reasons,

have the specified tightening torque checked. The

wheels could otherwise work loose.

check the tire pressure and correct it if necessary.

retighten the wheel bolts and wheel nuts to the

specified tightening torque once the vehicle has

been driven for 30 miles (50 km).

have a reversed direction of tire rotation corrected

as soon as possible at a qualified specialist

workshop. The vehicle handling characteristics

could otherwise be affected.

WARNING!

A battery will also produce hydrogen gas, which

is flammable and very explosive. Avoid open

flames and the formation of sparks in the vicinity

of the batteries. Refrain from smoking or cell

phone use. Avoid improper connection of jumper

cables.

Observe safety precautions when handling

batteries.

Exercise care near moving engine components and

electrical cables.

Failure to follow these directions will cause

damage to the electronic components and can lead

to a battery explosion and severe injury or death.

Freightliner-all.book Pag e 198 Monday, December 1, 2003 2:54 PM