clock DODGE SPRINTER 2005 1.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2005, Model line: SPRINTER, Model: DODGE SPRINTER 2005 1.GPages: 288, PDF Size: 27.89 MB

Page 185 of 288

STARTING AND OPERATING 185

5

Open immediately the water drain screw (3) about 1 turn (counterclockwise) until fluid emerges. Ensure

that the fluid is collected in the receptacle.

Close the water drain screw (3) as soon as about 0.25 US qt (0.2 liters) are emerged.

After draining, return the key in the ignition lock to position 0.

Dispose of the collected fluid in an environmentally responsible manner.

If the filter is still saturated, drain the filter once more.

After draining, the engine may run briefly but stall for

lack of fuel. If this occurs, bleed the system.

NOTE: Should the water in the fuel indicator lamp

still not go out after the fuel filter has been drained

twice, the cause should be examined by an authorized

Sprinter Dealer.

Bleeding the Diesel Fuel SystemThe diesel fuel system must be bled before starting the

engine.

Turn the key in the ignition lock position 2 for at

least 30 seconds.

Return the key to position 0.

Start the engine three to four times. The engine control unit indicator lamp ± must go out.

NOTE: Too many attempts to start the engine could

drain the battery. If the engine does not start after

several attempts, consult an authorized Sprinter

Dealer.

Page 203 of 288

WHAT TO DO IN EMERGENCIES 203

6

JACK Using the Jack

The jack is located together with the vehicle tool kit

under the hatch in the front passenger footwell, refer to

"Vehicle Tool Kit".

1. Loosen the wheel bolts before raising the vehicle.

2. Close the release valve on the jack.

3. Assemble the pump leve r provided and insert it

into the socket on the jack.

4. Secure the lever by turning it clockwise in the socket.

Position the jack under the appropriate jack point and

raise the vehicle by pumping the lever.

WARNING!

To avoid the risk of serious or fatal injuries or vehicle

damage, please bear the fo llowing points in mind:

The jack is intended only for raising the vehicle briefly, for instance, when changing a wheel. If it is

not designed to enable work to be carried out

underneath the vehicle.

Do not crawl under the jacked-up vehicle. For work

under the vehicle, stands must be used.

The jack must be placed on a firm, flat surface only.

Do not change wheels on uphill or downhill gradients under any circumstances.

Make sure that no persons are present in the vehicle when jacking up the vehicle.

Do not start the engine while the vehicle is raised.

Make sure that the distance between the underside of the tires and the ground does not exceed 1.2 in (30

mm). Otherwise the vehicle may tip over.

Page 241 of 288

MAINTAINING YOUR VEHICLE 241

7

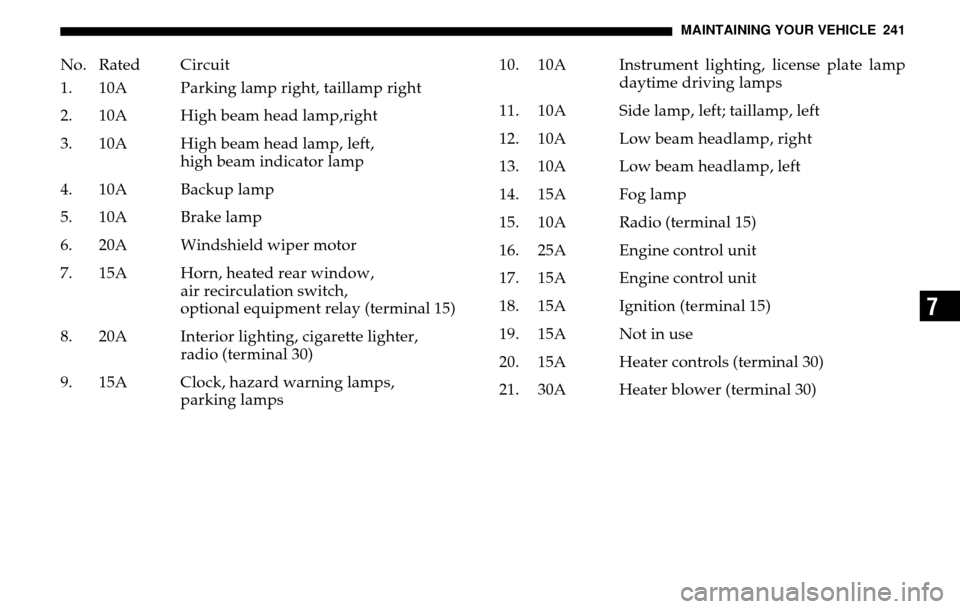

No. Rated Circuit

1. 10A Parking lamp right, taillamp right

2. 10A High beam head lamp,right

3. 10A High beam head lamp, left, high beam indicator lamp

4. 10A Backup lamp

5. 10A Brake lamp

6. 20A Windshield wiper motor

7. 15A Horn, heated rear window, air recirculation switch,

optional equipment relay (terminal 15)

8. 20A Interior lighting, cigarette lighter, radio (terminal 30)

9. 15A Clock, hazard warning lamps, parking lamps 10. 10A Instrument lighting, license plate lamp

daytime driving lamps

11. 10A Side lamp, left; taillamp, left

12. 10A Low beam headlamp, right

13. 10A Low beam headlamp, left

14. 15A Fog lamp

15. 10A Radio (terminal 15)

16. 25A Engine control unit

17. 15A Engine control unit

18. 15A Ignition (terminal 15)

19. 15A Not in use

20. 15A Heater controls (terminal 30)

21. 30A Heater blower (terminal 30)

Page 246 of 288

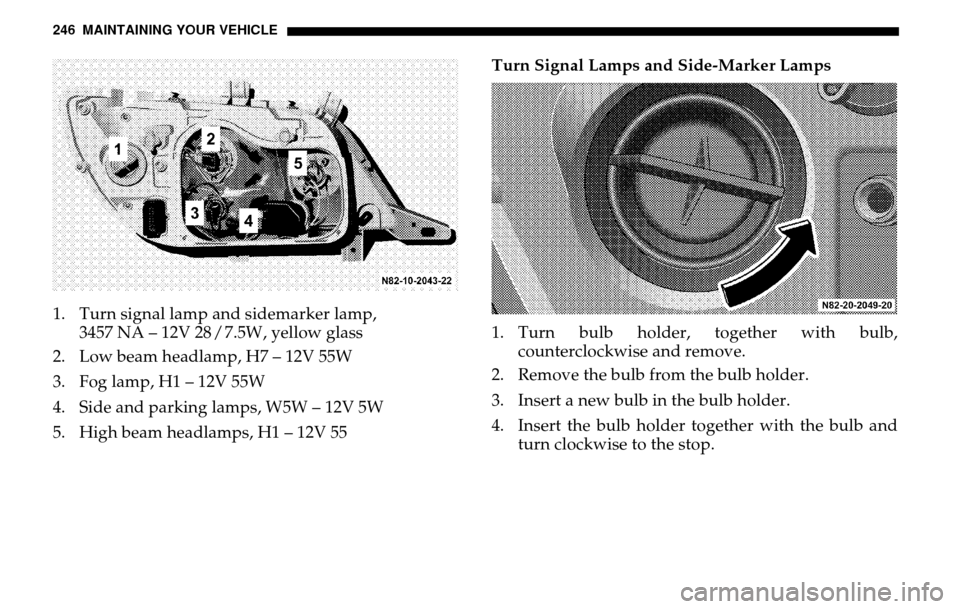

246 MAINTAINING YOUR VEHICLE1. Turn signal lamp and sidemarker lamp, 3457 NA – 12V 28 / 7.5W, yellow glass

2. Low beam headlamp, H7 – 12V 55W

3. Fog lamp, H1 – 12V 55W

4. Side and parking lamps, W5W – 12V 5W

5. High beam headlamps, H1 – 12V 55 Turn Signal Lamps and Side-Marker Lamps

1. Turn bulb holder, together with bulb,

counterclockwise and remove.

2. Remove the bulb from the bulb holder.

3. Insert a new bulb in the bulb holder.

4. Insert the bulb holder together with the bulb and turn clockwise to the stop.

Page 250 of 288

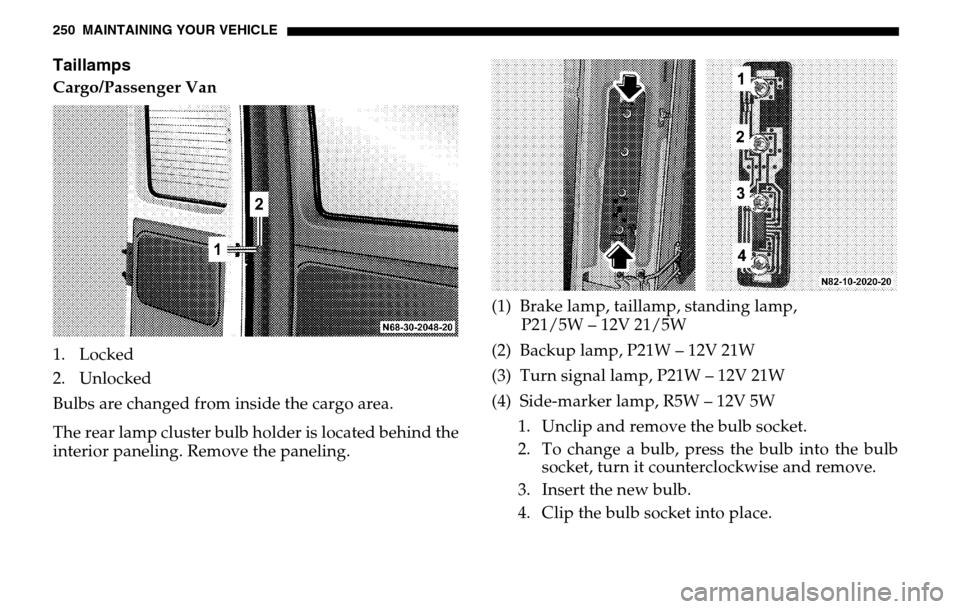

250 MAINTAINING YOUR VEHICLETaillampsCargo/Passenger Van

1. Locked

2. Unlocked

Bulbs are changed from inside the cargo area.

The rear lamp cluster bulb holder is located behind the

interior paneling. Remove the paneling. (1) Brake lamp, taillamp, standing lamp,

P21/5W – 12V 21/5W

(2) Backup lamp, P21W – 12V 21W

(3) Turn signal lamp, P21W – 12V 21W

(4) Side-marker lamp, R5W – 12V 5W 1. Unclip and remove the bulb socket.

2. To change a bulb, press the bulb into the bulb socket, turn it counterclockwise and remove.

3. Insert the new bulb.

4. Clip the bulb socket into place.

Page 251 of 288

MAINTAINING YOUR VEHICLE 251

7

Chassis

(1) Retaining screws

(2) Clearance lamp, R5W - 12V 5W

(3) Turn signal lamp, P21W - 12V 21W

(4) Stop lamp, P21W - 12V 21W

(5) Taillamp, R5W - 12V 5W

(6) Backup lamp, P21W - 12V 21W

(7) License plate lamp (driver‘s side only), R5W - 12V 5W 1. Loosen retaining screw a and remove lamp

housing.

2. To change a bulb, press the bulb into the bulb socket, turn it counterclockwise and remove.

3. Insert the new bulb.

4. Install lamp housing.

Page 252 of 288

252 MAINTAINING YOUR VEHICLELicense Plate Lamps

(Cargo/Passenger Vans Only)1. Press the bulb socket to the left, against the force of the spring, and remove.

2. Replace the bulb, C5W – 12V 5W.

3. Install the cover.

4. Re-install the bulb socket.

Additional Brake Lamp

(Cargo/Passenger Vans Only)(1) Retaining screws

1. Take out the retaining screws (1) and remove the lamp housing.

2. To change a bulb, P21W – 12V 21W Press the bulb into the bulb socket, turn it

counterclockwise and remove.

3. Insert the new bulb.

4. Install the lamp housing.

Page 253 of 288

MAINTAINING YOUR VEHICLE 253

7

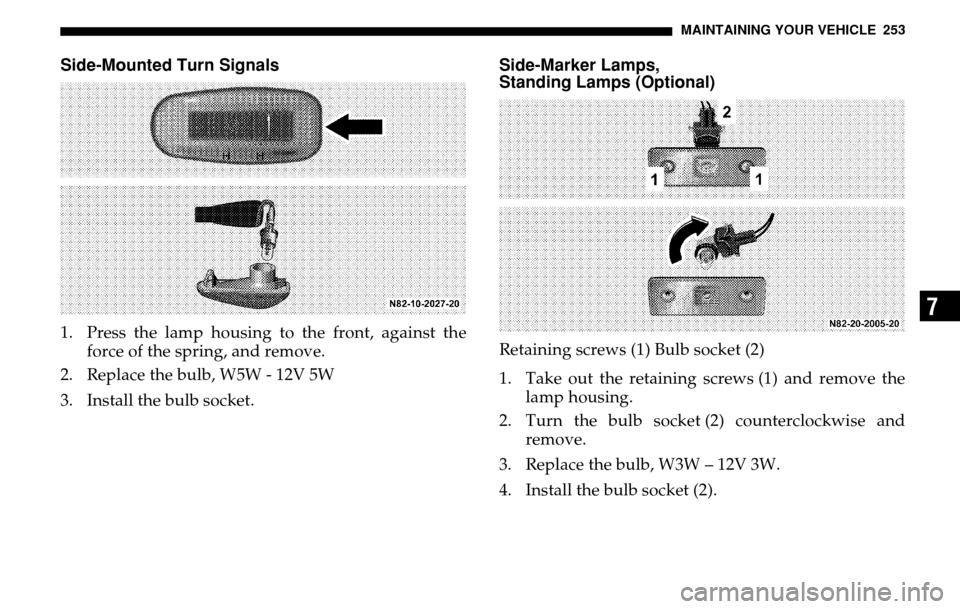

Side-Mounted Turn Signals1. Press the lamp housing to the front, against the force of the spring, and remove.

2. Replace the bulb, W5W - 12V 5W

3. Install the bulb socket.

Side-Marker Lamps,

Standing Lamps (Optional)Retaining screws (1) Bulb socket (2)

1. Take out the retaining screws (1) and remove the lamp housing.

2. Turn the bulb socket (2) counterclockwise and remove.

3. Replace the bulb, W3W – 12V 3W.

4. Install the bulb socket (2).

Page 254 of 288

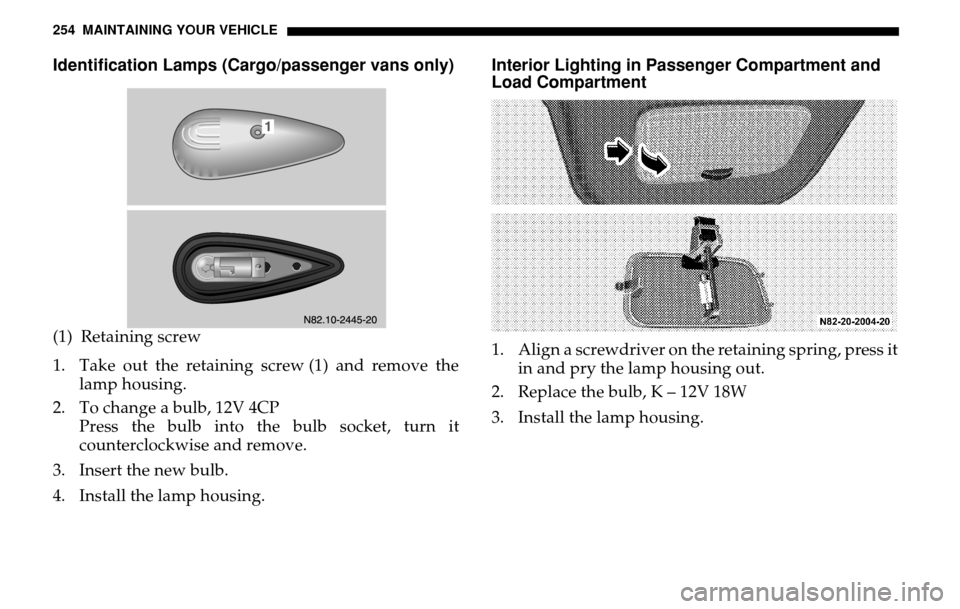

254 MAINTAINING YOUR VEHICLEIdentification Lamps (Cargo/passenger vans only)(1) Retaining screw

1. Take out the retaining screw (1) and remove the lamp housing.

2. To change a bulb, 12V 4CP Press the bulb into the bulb socket, turn it

counterclockwise and remove.

3. Insert the new bulb.

4. Install the lamp housing.

Interior Lighting in Passenger Compartment and

Load Compartment1. Align a screwdriver on the retaining spring, press it in and pry the lamp housing out.

2. Replace the bulb, K – 12V 18W

3. Install the lamp housing.

Page 280 of 288

280 INDEXClock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Comfort Tire Pressures . . . . . . . . . . . . . . . . . . . . . . . . 178

Compartments in Front Doors. . . . . . . . . . . . . . . . . . . 86

Constant RPMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Consumer Assistance Be Reasonable with Request . . . . . . . . . . . . . . . . . 272

If You Need Assistance . . . . . . . . . . . . . . . . . . . . . 272

Prepare a List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Prepare for the Appointment . . . . . . . . . . . . . . . . 272

Coolant Level Indicator Lamp . . . . . . . . . . . . . . . . . . 106

Coolant Temperature Gauge . . . . . . . . . . . . . . . . . . . 101

Coolant, Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Cooling System, Engine . . . . . . . . . . . . . . . . . . . . . . . 223

Corrosion Protection . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Cup Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85DDe-Fogging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Dehumidification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

De-Icing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Diesel Fuels for Use at Very Low Temperatures . . 180

Displaying Engine Oil Level . . . . . . . . . . . . . . . . . . . 113

Doors Front Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Rear Cargo Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Sliding Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Draining Fuel Filter with Water Separator . . . . . . . 184

Driver’s Airbag. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Driving Safety Systems . . . . . . . . . . . . . . . . . . . . . . . . 160

EElectric Sun Roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Electrical Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238 Fuse and Relay Optional Equipment . . . . . . . . . . 242

Fuse, Relay, and Diode Assignments - Optional

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Relay Assignment, Standard Equipment . . . . . . 242

Standard Fuse and Relay Equipment. . . . . . . . . . 239

Electrical Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Electronic Brake Force Distribution . . . . . . . . . . . . . 164

Electronic Brake Force Distribution Lamp . . . . . . . . 157

Electronic Stability Program . . . . . . . . . . . . . . . . . . . 166

Emission Label, Vehicle/Engine . . . . . . . . . . . . . . . . . . 7

Emission Related Component . . . . . . . . . . . . . . . . . . 218

Emissions Control System . . . . . . . . . . . . . . . . . . . . . 192

Engine Break-in Recommendations . . . . . . . . . . . . . . 52