tire size DODGE SPRINTER 2006 1.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: SPRINTER, Model: DODGE SPRINTER 2006 1.GPages: 330, PDF Size: 10.82 MB

Page 195 of 330

STARTING AND OPERATING 195

5

Tire Speed Rating

The tire speed rating (7) indicates the approved

maximum speed for the tire.

The commercial vehicle tires based on European

standards may have an additional index in the

parentheses (as illustrated). In such case, the index

preceding the parentheses is valid for European

countries and the parenthesized for the USA and

Canada.

NOTE: Always observe the speed rating of the winter

tires installed on your Sprinter vehicle. If the

maximum speed for which your tires are rated is belowthe speed rating of your Sprinter vehicle, youmust

place a notice to this effect where it will be seen by the

driver.

Such notices are available at your tire dealer or any

authorized Sprinter Dealer.

NOTE: Tire load rating (6) and tire speed rating (7) are

also referred to as "service description".

WARNING!

Even when permitted by law, never operate a vehicle at

speeds greater than the maximum speed rating

of the

tires.

Exceeding the maximum speed for which tires are

rated can lead to sudden tire failure, causing loss

of vehicle control and possibly resulting in an

accident and/or personal injury and possible

death, for you and for others.

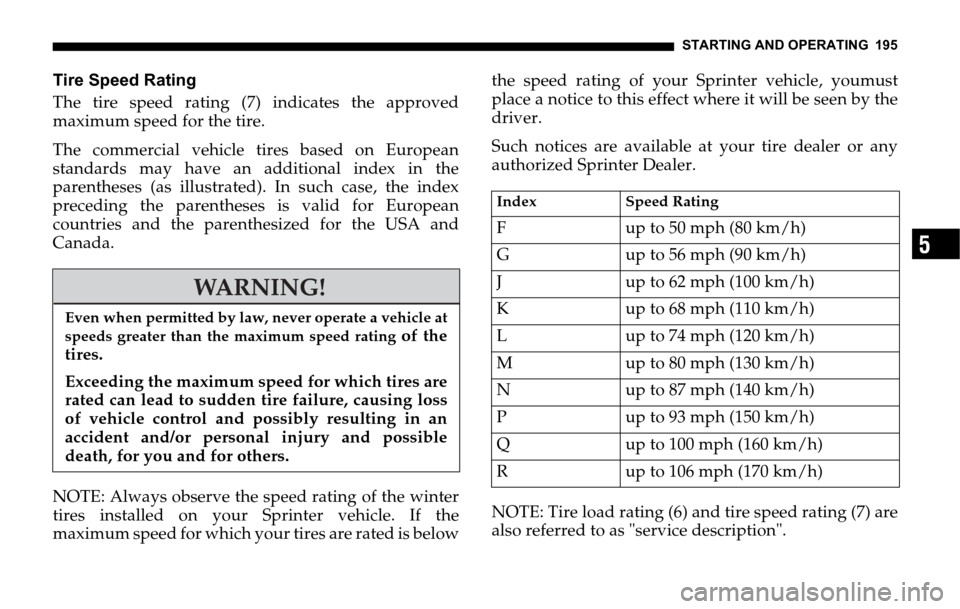

Index Speed Rating

F up to 50 mph (80 km/h)

G up to 56 mph (90 km/h)

J up to 62 mph (100 km/h)

K up to 68 mph (110 km/h)

L up to 74 mph (120 km/h)

M up to 80 mph (130 km/h)

N up to 87 mph (140 km/h)

P up to 93 mph (150 km/h)

Q up to 100 mph (160 km/h)

R up to 106 mph (170 km/h)

Page 196 of 330

196 STARTING AND OPERATING

DOT, Tire Identification Number (TIN)

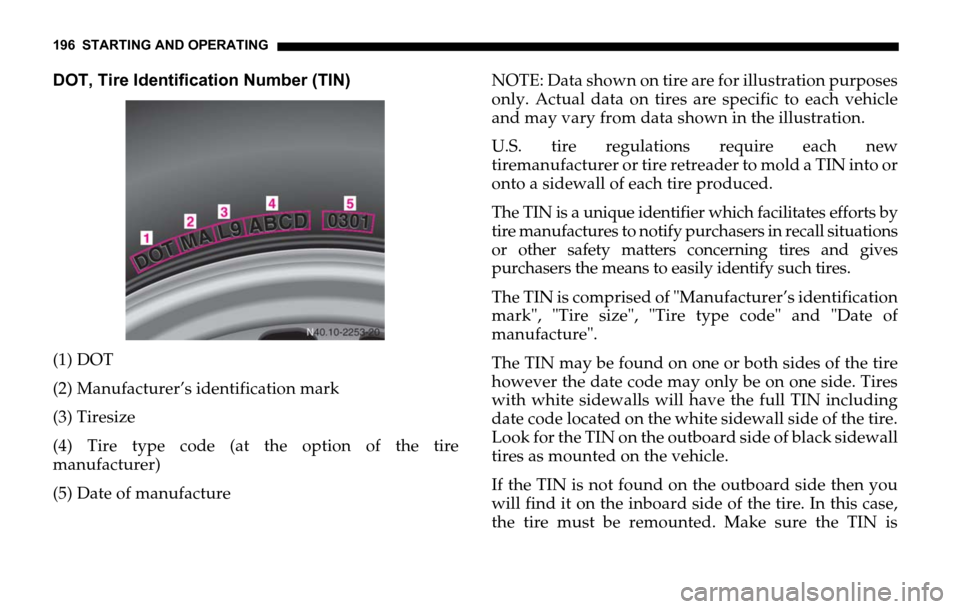

(1) DOT

(2) Manufacturer’s identification mark

(3) Tiresize

(4) Tire type code (at the option of the tire

manufacturer)

(5) Date of manufacture NOTE: Data shown on tire are for illustration purposes

only. Actual data on tires are specific to each vehicle

and may vary from data shown in the illustration.

U.S. tire regulations require each new

tiremanufacturer or tire retreader to mold a TIN into or

onto a sidewall of each tire produced.

The TIN is a unique identifier which facilitates efforts by

tire manufactures to notify purchasers in recall situations

or other safety matters concerning tires and gives

purchasers the means to easily identify such tires.

The TIN is comprised of "Manufacturer’s identification

mark", "Tire size", "Tire type code" and "Date of

manufacture".

The TIN may be found on one or both sides of the tire

however the date code may only be on one side. Tires

with white sidewalls will have the full TIN including

date code located on the white sidewall side of the tire.

Look for the TIN on the outboard side of black sidewall

tires as mounted on the vehicle.

If the TIN is not found on the outboard side then you

will find it on the inboard side of the tire. In this case,

the tire must be remounted. Make sure the TIN is

Page 197 of 330

STARTING AND OPERATING 197

5

visible on the outboard side of the tire and if applicable

that the direction of rotation is correct when

remounting the tire.

Rotation (spinning) direction, refer to "Direction of

Rotation".

DOT (Department Of Transportation)

A tire branding symbol (1) which denotes the tire

meets requirements of the U.S. Department of

Transportation.

Manufacturer’s Identification Mark

Themanufacturer’s identificationmark (2) denotes the

tire manufacturer.

New tires have a mark with two symbols.

Retreaded tires have a mark with four symbols. For

more information on retreaded tires, refer to "Tires and

Wheels".

Tire Size

The code (3) indicates the tire size.Tire Type Code

The code (4) may, at the option of the manufacturer, be

used as a descriptive code for identifying significant

characteristics of the tire.

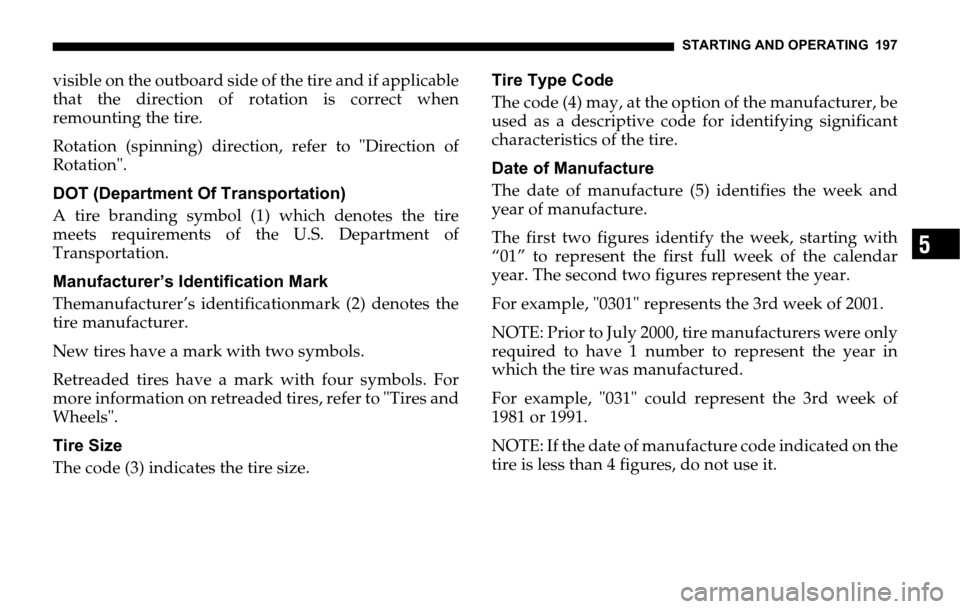

Date of Manufacture

The date of manufacture (5) identifies the week and

year of manufacture.

The first two figures identify the week, starting with

“01” to represent the first full week of the calendar

year. The second two figures represent the year.

For example, "0301" represents the 3rd week of 2001.

NOTE: Prior to July 2000, tire manufacturers were only

required to have 1 number to represent the year in

which the tire was manufactured.

For example, "031" could represent the 3rd week of

1981 or 1991.

NOTE: If the date of manufacture code indicated on the

tire is less than 4 figures, do not use it.

Page 198 of 330

198 STARTING AND OPERATING

Maximum Tire Load

(1) Maximum tire load rating

NOTE: Data shown on tire are for illustration purposes

only. Actual data on tires are specific to each vehicle

and may vary from data shown in the illustration.The maximum tire load is the maximum weight the

tires are designed to support.

For more information on tire load rating, refer to "Tire

Size Designation, Load and Speed Rating".

For information on calculating total and cargo load

capacities, refer to "Tire and Loading Information".

WARNING!

Tires and spare tire should be replaced after 6

years, regardless of the remaining tread.

WARNING!

Do not overload the tires by exceeding the specified

load limit as indicated on the Tire and Loading

Information placard on the driver’s door B-pillar.

Overloading the tires can overheat them, possibly

causing a blowout.

Overloading the tires can also result in handling or

steering problems, or brake failure.

Page 203 of 330

STARTING AND OPERATING 203

5

TIN (Tire Identification Number)

Unique identifier which facilitates efforts by tire

manufacturers to notify purchasers in recall situations

or other safety matters concerning tires and gives

purchases the means to easily identify such tires. The

TIN is comprised of "Manufacturer’s identification

mark", "Tire size", "Tire type code" and "Date of

manufacture".

Tire Load Rating

Numerical code associated with the maximum load a

tire can support.

Tire Ply Composition and Material used

This indicates the number of plies or the number of

layers of rubber-coated fabric in the tire tread and

sidewall. Tire manufacturers also must indicate the ply

materials in the tire and sidewall, which include steel,

nylon, polyester, and others.

Tire Speed Rating

Part of tire designation; indicates the speed range for

which a tire is approved.Traction

Force exerted by the vehicle on the road via the tires.

The amount of grip provided.

Tread

The portion of a tire that comes into contact with the

road.

Treadwear Indicators

Narrow bands, sometimes called "wear bars" that

show across the tread of a tire when only 1/16 in (1.6

mm) of tread remains.

TWR (Tongue Weight Rating)

Maximum permissible weight on trailer tongue.

Uniform Tire Quality Grading Standards

A tire information system that provides consumers

with ratings for a tire’s traction, temperature and

treadwear.

Ratings are determined by tire manufacturers using

government testing procedures. The ratings are

molded into the sidewall of the tire.

Page 205 of 330

STARTING AND OPERATING 205

5

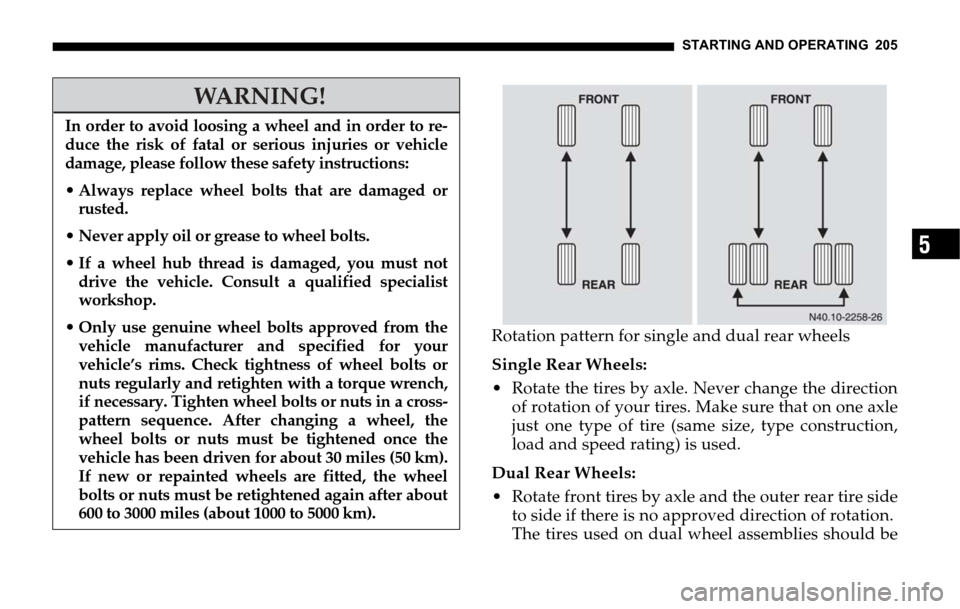

Rotation pattern for single and dual rear wheels

Single Rear Wheels:

Rotate the tires by axle. Never change the direction

of rotation of your tires. Make sure that on one axle

just one type of tire (same size, type construction,

load and speed rating) is used.

Dual Rear Wheels:

Rotate front tires by axle and the outer rear tire side

to side if there is no approved direction of rotation.

The tires used on dual wheel assemblies should be

WARNING!

In order to avoid loosing a wheel and in order to re-

duce the risk of fatal or serious injuries or vehicle

damage, please follow these safety instructions:

Always replace wheel bolts that are damaged or

rusted.

Never apply oil or grease to wheel bolts.

If a wheel hub thread is damaged, you must not

drive the vehicle. Consult a qualified specialist

workshop.

Only use genuine wheel bolts approved from the

vehicle manufacturer and specified for your

vehicle’s rims. Check tightness of wheel bolts or

nuts regularly and retighten with a torque wrench,

if necessary. Tighten wheel bolts or nuts in a cross-

pattern sequence. After changing a wheel, the

wheel bolts or nuts must be tightened once the

vehicle has been driven for about 30 miles (50 km).

If new or repainted wheels are fitted, the wheel

bolts or nuts must be retightened again after about

600 to 3000 miles (about 1000 to 5000 km).

Page 206 of 330

206 STARTING AND OPERATING

matched for wear to prevent overloading one tire in

a set.

To check if tires are even, lay a straight edge across

all four tires.

The straight edge should touch all the tires.Alignment and Balance

Poor suspension alignment may result in:

Fast tire wear

Uneven tire wear, such as feathering and one-sided

wear

Vehicle pull to right or left

Tires may also cause the vehicle to pull to the left or

right.

Alignment will not correct this condition. See an

authorized Sprinter Dealer for proper diagnosis.

Improper alignment will not cause vehicle vibration.

Vibration may be a result of tire and wheel out-of-

balance.

Proper balancing will reduce vibration and avoid tire

cupping and spotty wear.

Winter tires

Always use winter tires at temperatures below 45°F

(7°C) and whenever wintry road conditions prevail.

Winter tires should be of the same size and type

construction as the summer tires. Winter tires should

also be operated as printed at the Tire and Loading

WARNING!

3500 Dual Rear Tires have only one approved di-

rection of rotation. This is to accomodate the asy-

metrical design (tread pattern) of the ON/OFF

road tire and the use of Outline White Letter

(OWL) tires.

When replacing a flat tire, the spare tire may have

to be remounted on the rim or installed at a

different location tomaintain the correct

placement of the tire on the wheel relative to the

tire/wheel position on the vehicle. For example, if

the spare is used to replace an outer rear tire it will

have to remounted on the rim so that the wheel is

dished inward. That way the tread design of

asymmetrical tires and the white writing of the

OWL tires will maintain proper position.

Page 208 of 330

208 STARTING AND OPERATING

NOTE: Chains must be the proper size for the vehicle,

as recommended by the chain manufacturer.

Snow chains should only be driven on snow-covered

roads at speeds not to exceed 30 mph (50 km/h).

Remove chains as soon as possible when driving on

roads without snow.

NOTE: When driving with snow chains, you may wish

to deactivate the ASR before setting the vehicle in

motion. This will improve the vehicle’s traction.Please observe the following guidelines when using

snow chains:

Snow chains should only be used on rear wheels. In

vehicles with dual rear wheels, they should be

mounted on the exterior wheels. Follow the

manufacturer’s mounting instructions.

Only use snow chains that are approved by the

vehicle manufacturer. For approved snow chains,

please contact your authorized Sprinter Dealer.

Use of snow chains may be prohibited depending

on location. Always check local and state laws

before installing snow chains.

WARNING!

Use snow chains on rear wheels only.

Some tire sizes do not leave adequate clearance for

snowchains. To help avoid serious damage to

your vehicle or tires, use of snow chains is not

permissible with the spare wheel.

Page 216 of 330

216 STARTING AND OPERATING

Bleeding the Diesel Fuel System

The diesel fuel system must be bled before starting the

engine.

Turn the key in the ignition lock position 2 for at

least 30 seconds.

Return the key to position 0.

Start the engine three to four times. The engine

control unit indicator lamp± must go out.

NOTE: Too many attempts to start the engine could

drain the battery. If the engine does not start after

several attempts, consult an authorized Sprinter

Dealer.PERMISSIBLE ROOF LOAD

The maximum permissible roof load is:

Vehicles with low roof 660 lbs (300 kg)

Vehicles with high roof 330 lbs (150 kg)

The weight of any load carried on the roof,

including the roof rack, must not exceed the

maximum permissible roof load.

LOADING THE VEHICLE

Two labels on the vehicle show how much weight it

may properly carry.

The Tire and Loading Information placard can be

found on the driver’s door B-pillar. This placard

tells you important information about the number

of people that can be in the vehicle and the total

weight that can be carried in the vehicle. It also

contains information on the proper size and

recommended tire inflation pressures for the

original equipment tires on the vehicle.

The Certification Label can be found below the

driver’s seat on an outward facing position of the

mounting pillar. It tells you about the gross weight

Page 217 of 330

STARTING AND OPERATING 217

5

capacity of your vehicle, called the Gross Vehicle

Weight Rating (GVWR). The GVWR includes the

weight of the vehicle, all occupants, fuel and cargo.

The Certification Label also tells you about the front

and rear axle weight capacity, called the Gross Axle

Weight Rating (GAWR). The GAWR is the total

allowable weight that can be carried by a single axle

(front or rear). Never exceed the GVWR or GAWR

for either the front axle or rear axle.

Following is a discussion on how to work with the

information contained on the two placards with

regards to loading your Sprinter vehicle.Tire and Loading Information

WARNING!

Do not overload the tires by exceeding the speci-

fied load limit as indicated on the Tire and Load-

ing Information placard on the driver’s door B-

pillar. Overloading the tires can overheat them,

possibly causing a blowout. Overloading the tires

can also result in handling or steering problems,

or brake failure.

Overloading of tires is dangerous. Overloading

can cause tire failure, affect vehicle handling, and

increase the stopping distance. Use tires of the

recommended load capacity for the vehicle. Never

overload them.

The vehicle maximum load on the tire must not

exceed the load carrying capacity of the tire on

your vehicle. You will not exceed the tire’s load

carrying capacity if you adhere to the loading

conditions, tire size and cold tire inflation

pressures specified on the Tire and Loading

Information placard and this section.