brakes DODGE SPRINTER 2006 1.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: SPRINTER, Model: DODGE SPRINTER 2006 1.GPages: 330, PDF Size: 10.82 MB

Page 202 of 330

202 STARTING AND OPERATING

Kilopascal (kPa)

Themetric unit for air pressure. There are 6.9 kPa to 1

psi; another metric unit for air pressure is bars. There

are 100 kilopascals (kPa) to 1 bar.

Maximum Load Rating

The maximum load in kilograms and pounds that can

be carried by the tire.

Maximum Loaded Vehicle Weight

The sum of curb weight, accessory weight, vehicle

capacity weight and production options weight.

Maximum Tire Inflation Pressure

This number is the greatest amount of air pressure that

should ever be put in the tire under normal driving

conditions.

Normal Occupant Weight

The number of occupants the vehicle is designed to

seat, multiplied by 68 kilograms (150 lbs).

Occupant Distribution

The distribution of occupants in a vehicle at their

designated seating positions.Production Options Weight

The combined weight of those installed regular

production options weighing over 5 lbs (2.3 kilograms)

in excess of those standard items which they replace,

not previously considered in curb weight or accessory

weight, including heavy duty brakes, ride levelers,

roof rack, heavy duty battery, and special trim.

PSI (Pounds per Square Inch)

A standard unit of measure for air pressure. Another

metric unit for air pressure is bars or kilopascal (kPa).

Recommended Tire Inflation Pressure

Recommended tire inflation pressure listed on Tire

and Loading Information placard on the driver’s door

B-pillar for normal driving conditions. Provides best

handling, tread life and riding comfort.

Rim

A metal support for a tire or a tire and tube assembly

upon which the tire beads are seated.

Sidewall

The portion of a tire between the tread and the bead.

Page 224 of 330

224 STARTING AND OPERATING

Checking Weights of Vehicle and Trailer

To assure that the tow vehicle and trailer are in

compliance with the maximum permissible weight

limits, and to know the actual weights, have the loaded

vehicle-trailer combination (tow vehicle including

driver, passengers and cargo, trailer fully loaded)

weighed on a commercial scale.

Check the vehicle’s front and rear Gross Axle Weight

(GAW), the GTW and TW. The values as measured

must not be exceeded, according to the weight listed

under “Vehicle and trailer weight and ratings”.

Attaching a Trailer

Please observe maximum permitted trailer dimensions

(width and length).

Most states and all Canadian provinces require safety

chains between your tow vehicle and the trailer. The

chains should be crisscrossed under the trailer tongue.

They must be attached to the hitch receiver, and not to

the vehicle’s bumper or axle. Be sure to leave enough

slack in the chains to permit turning corners.

Most states and all Canadian provinces require a

separate brake system at various trailer weights.

WARNING!

Do not connect a trailer brake system (if trailer is

so equipped) directly to the vehicle’s hydraulic

brake system as your vehicle is equipped with an-

tilock brakes. If you do, neither the vehicle’s

brakes nor the trailer’s brakes will function prop-

erly. This could cause an accident resulting in

property damage, injury or death to you or others.

The provided vehicle electrical wiring harness for

trailer towing has a brake signal wire for hook-up

to a brake controller.

Most states and all Canadian provinces require a

break-away switch on trailers with a separate

brake system. The switch activates the trailer

brakes in the possible event that the trailer might

separate from the tow vehicle.

You should consider using a trailer sway control

system. For further information see your

authorized Sprinter Dealer.

Page 225 of 330

STARTING AND OPERATING 225

5

Towing a Trailer

There are many different laws, including speed limit

restrictions, having to do with trailer towing. Make

sure that your vehicle-trailer combination will be legal,

not only for where you reside, but also for where you

will be driving. A good source for this information can

be the police or local authorities.

Before you start driving with the trailer, check the

trailer hitch, break-away switch, safety chains,

electrical connections, lighting and tires. Also adjust

the mirrors to permit unobstructed view beyond rear

of trailer.

If the trailer has electric brakes, start your vehicle and

trailer moving slowly, and then apply only the trailer

brake controller by hand to be sure the brakes are

working properly.

When towing a trailer, check occasionally to be sure

that the load is secure, and that lighting and trailer

brakes (if so equipped) are functioning properly.

Always secure items in the trailer to prevent load shifts

while driving.Take into consideration that when towing a trailer, the

handling characteristics are different and less stable

from those when operating the vehicle without a

trailer. It is important to avoid sudden maneuvers. The

vehicle and trailer combination is heavier, and

therefore is limited in acceleration and climbing ability,

and requires longer stopping distances. It is more

prone to reacting to side wind gusts, and requires more

sensitive steering input.

In order to gain skill and an understanding of the

vehicle’s behavior, you should practice turning, stopping

and backing up in an area which is free from traffic.

If possible, do not brake abruptly, but rather engage

the brake slightly at first to permit the trailer to activate

its brake. Then increase the braking force.

Page 226 of 330

226 STARTING AND OPERATING

WARNING!

Take into consideration that when towing a trail-

er, the handling characteristics are different and

less stable from those when operating the vehicle

without a trailer.

It is important to avoid sudden maneuvers.

Sudden maneuvers may lead to loss of control

over the vehicle-trailer combination. This could

cause an accident resulting in property damage or

injury to you or others.

CAUTION!

If the transmission hunts between gears on

inclines, manually shift to a lower gear (select

"4",

"3", "2" or"1"). A lower gear and reduction of

speed reduces the chance of engine overloading

and / or overheating.

When going down a long hill, shift into a lower

gear and use the engine’s braking effect. Avoid

riding the brakes, thus overheating the vehicle

and trailer brakes.

If the engine coolant rises to an extremely high

temperature (coolant temperature needle

approaching the red zone) when the air

conditioner is on, turn off the air conditioner.

Engine coolant heat can be additionally vented by

opening the windows, switching the climate

control fan speed to high and setting the

temperature control to the maximum hot position.

Page 261 of 330

MAINTAINING YOUR VEHICLE 261

7

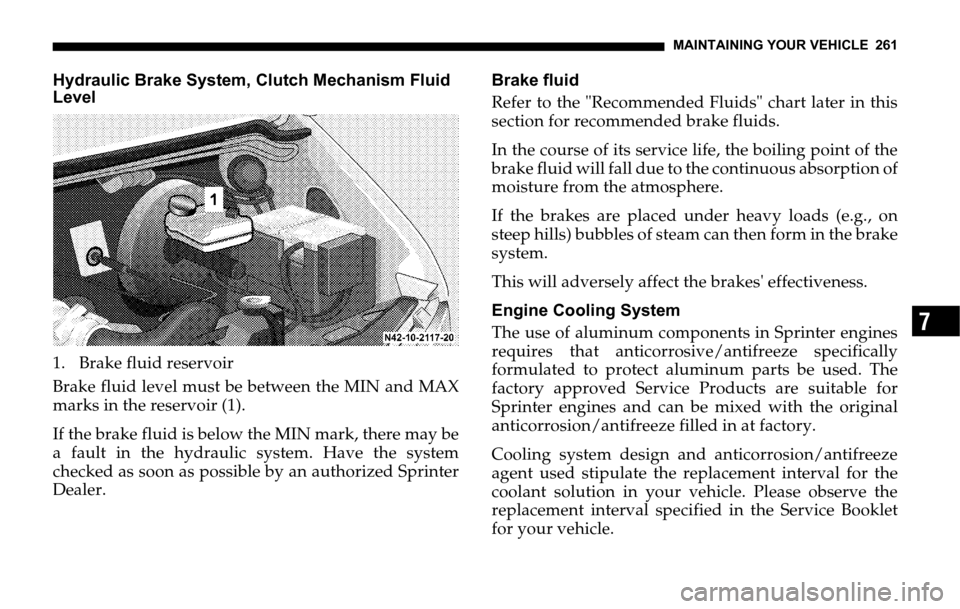

Hydraulic Brake System, Clutch Mechanism Fluid

Level

1. Brake fluid reservoir

Brake fluid level must be between the MIN and MAX

marks in the reservoir (1).

If the brake fluid is below the MIN mark, there may be

a fault in the hydraulic system. Have the system

checked as soon as possible by an authorized Sprinter

Dealer.Brake fluid

Refer to the "Recommended Fluids" chart later in this

section for recommended brake fluids.

In the course of its service life, the boiling point of the

brake fluid will fall due to the continuous absorption of

moisture from the atmosphere.

If the brakes are placed under heavy loads (e.g., on

steep hills) bubbles of steam can then form in the brake

system.

This will adversely affect the brakes' effectiveness.

Engine Cooling System

The use of aluminum components in Sprinter engines

requires that anticorrosive/antifreeze specifically

formulated to protect aluminum parts be used. The

factory approved Service Products are suitable for

Sprinter engines and can be mixed with the original

anticorrosion/antifreeze filled in at factory.

Cooling system design and anticorrosion/antifreeze

agent used stipulate the replacement interval for the

coolant solution in your vehicle. Please observe the

replacement interval specified in the Service Booklet

for your vehicle.

Page 300 of 330

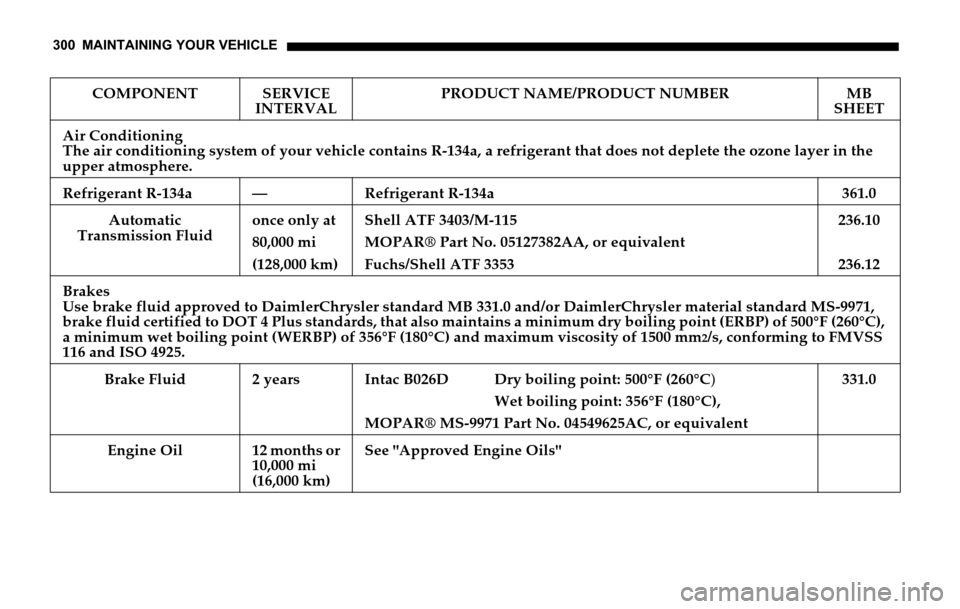

300 MAINTAINING YOUR VEHICLE

COMPONENT SERVICE

INTERVALPRODUCT NAME/PRODUCT NUMBER MB

SHEET

Air Conditioning

The air conditioning system of your vehicle contains R-134a, a refrigerant that does not deplete the ozone layer in the

upper atmosphere.

Refrigerant R-134a — Refrigerant R-134a 361.0

Automatic

Transmission Fluidonce only at

80,000 mi

(128,000 km)Shell ATF 3403/M-115

MOPAR® Part No. 05127382AA, or equivalent

Fuchs/Shell ATF 3353236.10

236.12

Brakes

Use brake fluid approved to DaimlerChrysler standard MB 331.0 and/or DaimlerChrysler material standard MS-9971,

brake fluid certified to DOT 4 Plus standards, that also maintains a minimum dry boiling point (ERBP) of 500°F (260°C),

a minimum wet boiling point (WERBP) of 356°F (180°C) and maximum viscosity of 1500 mm

2/s, conforming to FMVSS

116 and ISO 4925.

Brake Fluid 2 years Intac B026D Dry boiling point: 500°F (260°C)

Wet boiling point: 356°F (180°C),

MOPAR® MS-9971 Part No. 04549625AC, or equivalent331.0

Engine Oil 12 months or

10,000 mi

(16,000 km)See "Approved Engine Oils"

Page 318 of 330

318 INDEX

ASSYST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

ASSYST Maintenance Computer . . . . . . . . . . . . . . . 112

Automatic Lock Feature . . . . . . . . . . . . . . . . . . . . . . . . 19

Automatic Transmission . . . . . . . . . . . . . . . . . . . . . . 148

Accelerator Position . . . . . . . . . . . . . . . . . . . . . . . . 149

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Gear Selector Lever Position . . . . . . . . . . . . . . . . . 150

Maneuvering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Selector Lever Manually Unlocking. . . . . . . . . . . 153

Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Auxiliary Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Auxiliary Heat Exchanger . . . . . . . . . . . . . . . . . . . . . 139

Auxiliary Heater

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Timer Auxiliary Heater (Water and Air Heater) 134

Tips for Coping with Problems . . . . . . . . . . . . . . 140

BBatteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Charging the Battery . . . . . . . . . . . . . . . . . . . . . . . 267

Disconnecting the Battery . . . . . . . . . . . . . . . . . . . 266

Reconnecting the Battery . . . . . . . . . . . . . . . . . . . . 266

Replacing Batteries in Remote Keyless Entry . . . . 22Battery Charge Indicator Lamp . . . . . . . . . . . . . . . . . 106

Belt Tensioners

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Belt Tensioners and Airbag . . . . . . . . . . . . . . . . . . . . . 49

Bleeding the Diesel Fuel System . . . . . . . . . . . . . . . . 216

Body Builder Guideline . . . . . . . . . . . . . . . . . . . . . . . 229

Brake Assist System (BAS) . . . . . . . . . . . . . . . . . . . . . 172

Brake fluid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Brake Fluid Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . 261

Brake Indicator Lamp . . . . . . . . . . . . . . . . . . . . . . . . . 160

Brake Pad Wear Indicator. . . . . . . . . . . . . . . . . . . . . . 159

Brake System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Fluid Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Brake System, Anti-Lock . . . . . . . . . . . . . . . . . . . . . . 165

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Brake Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Service Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Bulbs

Bulb Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Front Lamp Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

CCapacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296