service DODGE SPRINTER 2006 1.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: SPRINTER, Model: DODGE SPRINTER 2006 1.GPages: 330, PDF Size: 10.82 MB

Page 262 of 330

262 MAINTAINING YOUR VEHICLE

Failure to use MB 325.0 anticorrosion/antifreeze and/or

equivalent to DaimlerChrysler material standard MS-

9769 and/or adhere to the specified replacement interval

may result in a significantly shortened service life.

For coolant composition and water quality, contact

your authorized Sprinter Dealer.

Engine Coolant

The coolant is a mixture of water and a corrosion

inhibitor/antifreeze additive. Within the cooling

system, the corrosion inhibitor/antifreeze ensures

anti-corrosion protection

antifreeze protection

a higher boiling point.

The coolant added in the factory ensures adequate

antifreeze and anti-corrosion protection.

Refer to the "Recommended Fluids" chart for coolant

recommendations.

For reasons of anti-corrosion protection and to increase

the boiling point, the coolant added to the cooling

system is designed for all year round operation – even

in countries with high prevailing temperatures.Have the coolant renewed at least every 15 years or

after 160,000 miles.

When the coolant is renewed, the new coolant should

contain 50% antifreeze/corrosion inhibitor by volume.

This corresponds to antifreeze protection down to -

37 °C/-35°F.

Do not exceed a proportion of about 55 % by volume

(antifreeze protection down to about -45 °C/-49 °F) as

the heat dissipation properties then deteriorate.

In the event of coolant loss, do not add water only, but

sufficient antifreeze/corrosion inhibitor to maintain

the correct concentration.

The water in the coolant must satisfy certain

requirements. These are often met by tap supply

drinking water.

The water must be specially prepared if the water

quality does not come up to the required standards.

Have the corrosion inhibitor/antifreeze concentration

in the coolant checked at the outset of winter,

respectively once a year in countries with high

prevailing temperatures.

Page 263 of 330

MAINTAINING YOUR VEHICLE 263

7

A regular check is included in the maintenance service.

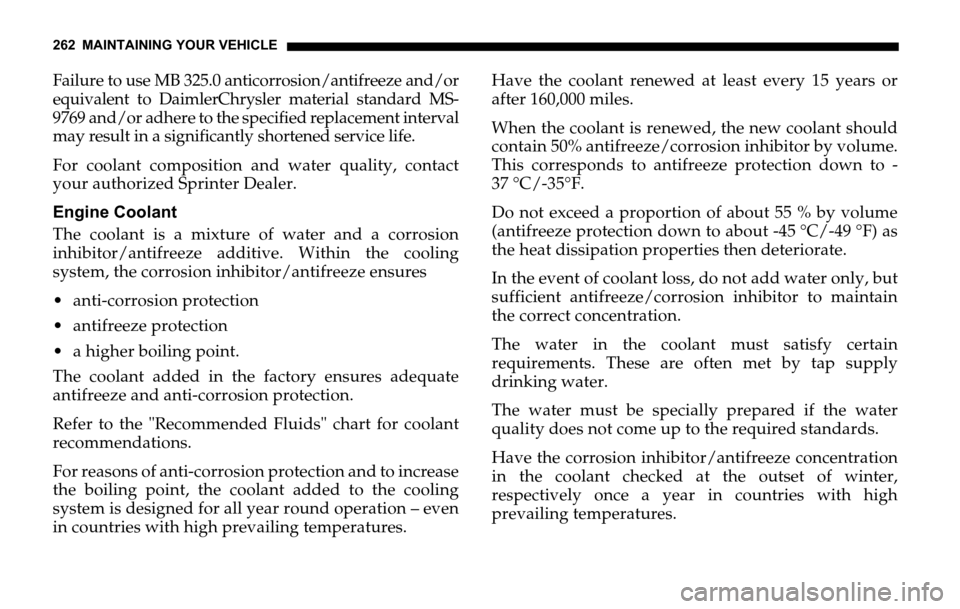

Checking Coolant Level

Pressure cap on coolant reservoir (1)

The cooling system is pressurized. Only check the

coolant level with the vehicle parking on a level surface

and with the engine switched off.

– Wait until the coolant temperature has dropped

below 194 °F (+90 °C).

WARNING!

In order to avoid any possibly serious burns:

If you see flames or smoke coming from the

engine compartment, or if the coolant

temperature gauge indicates that the engine is

overheated, do not open the hood. Move away

from the vehicle and do not open the hood until

the engine has cooled. If necessary, call the fire

department.

Do not remove pressure cap on coolant reservoir

if engine temperature is above 194 °F (+90 ×C).

Allow engine to cool down before removing cap.

The coolant reservoir contains hot fluid and is

under pressure.

Using a rag, slowly open cap approximately 1/2

turn to relieve excess pressure. If opened

immediately, scalding hot fluid and steam will

be blown out under pressure.

Page 266 of 330

266 MAINTAINING YOUR VEHICLE

The auxiliary battery is located underneath the front

passenger seat (optional equipment).

The battery will not achieve its maximum service life

unless it is kept adequately charged at all times. If the

vehicle is used primarily for short distances, or left

parked for lengthy periods, have the battery charge

checked more frequently.

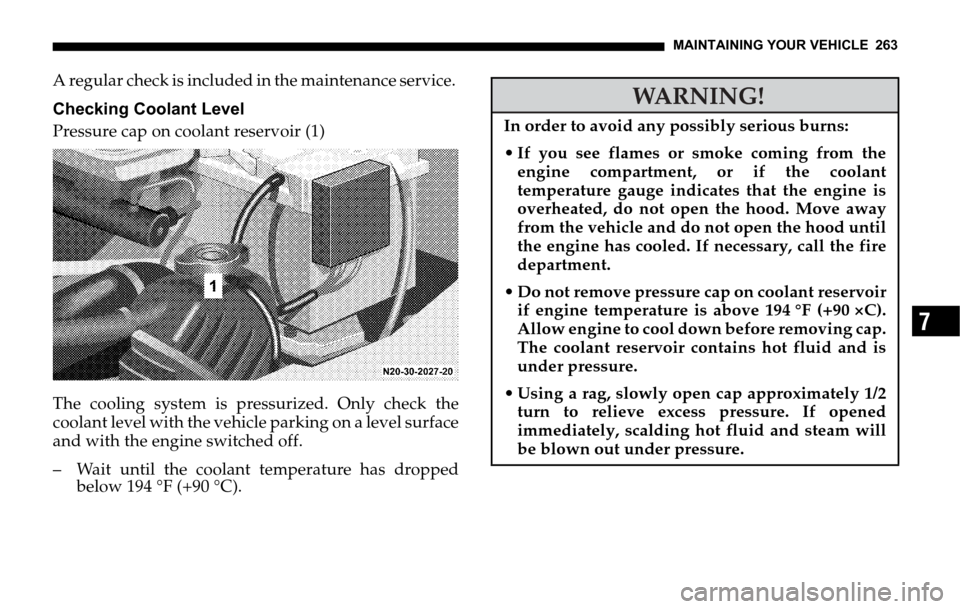

Disconnecting the BatteryReconnecting the Battery

Vent tube (1)

Fitting (2)

All electrical consumers must be switched off. First

connect and tighten the positive terminal clamp, then

the negative terminal. Make sure that the terminal

clamps are not switched.

NOTE: If batteries have to be replaced, only use

batteries with a central vent cap as this will prevent

corrosion damage.

Connect the battery vent tube (1) to the fitting (2).

CAUTION!

Do not loosen or remove the battery terminal

clamps while the engine is running or the key is in

the ignition lock as this could damage electrical or

electronic equipment beyond repair. All electrical

consumers must be switched off.

Do not place any metal objects on the battery.

Doing so may cause a short-circuit.

Loosen and remove the negative terminal clamp

first, then the positive terminal.

Afterwards disconnect vent tube from the fitting.

Page 268 of 330

268 MAINTAINING YOUR VEHICLE

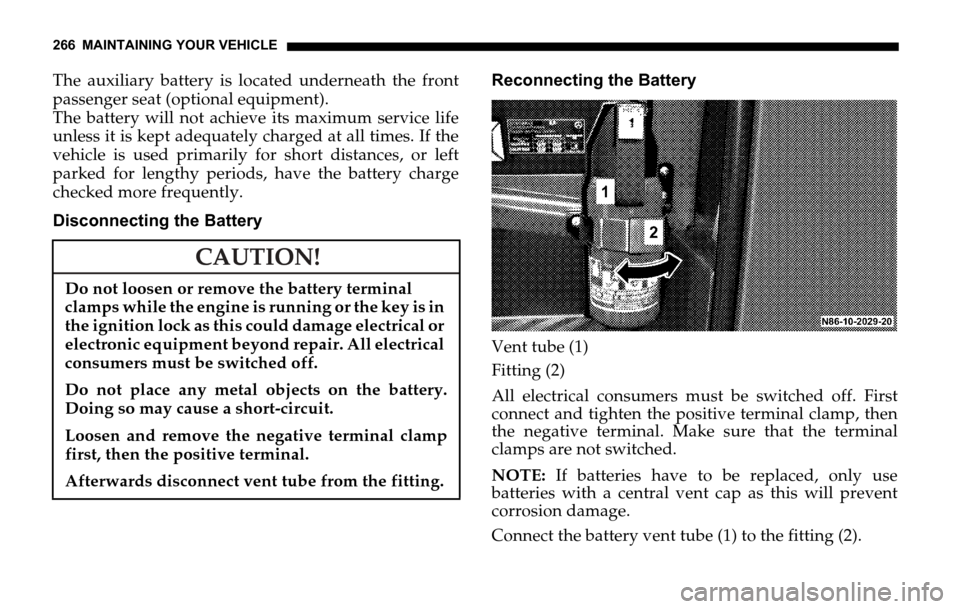

Refrigerant Recovery and Recycling

R-134a Air Conditioning Refrigerant is a

hydrofluorocarbon (HFC) that is endorsed by the

Environmental Protection Agency and is an ozone-

saving product. However, the manufacturer

recommends that air conditioning service be

performed by dealers or other service facilities using

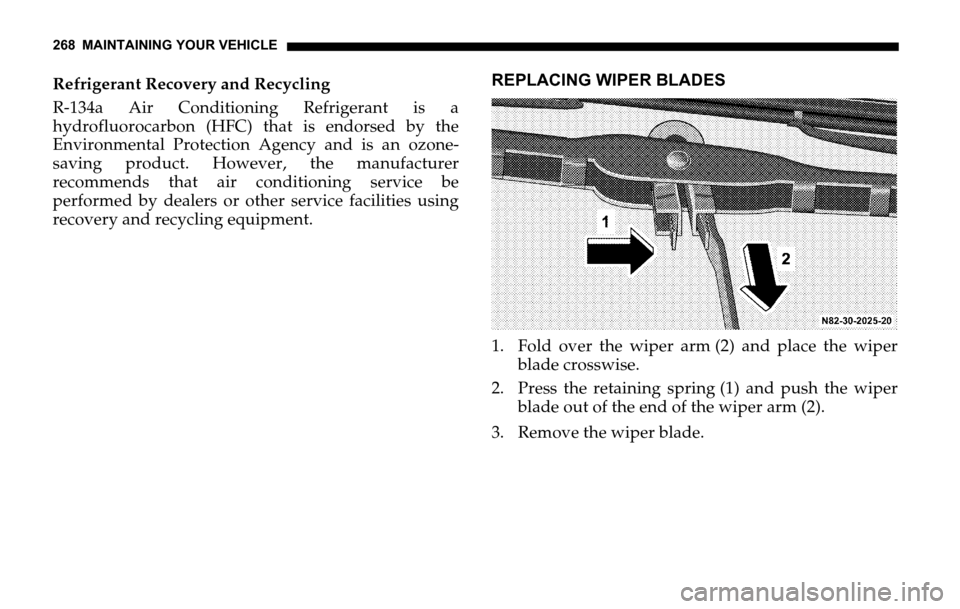

recovery and recycling equipment.REPLACING WIPER BLADES

1. Fold over the wiper arm (2) and place the wiper

blade crosswise.

2. Press the retaining spring (1) and push the wiper

blade out of the end of the wiper arm (2).

3. Remove the wiper blade.

Page 297 of 330

MAINTAINING YOUR VEHICLE 297

7

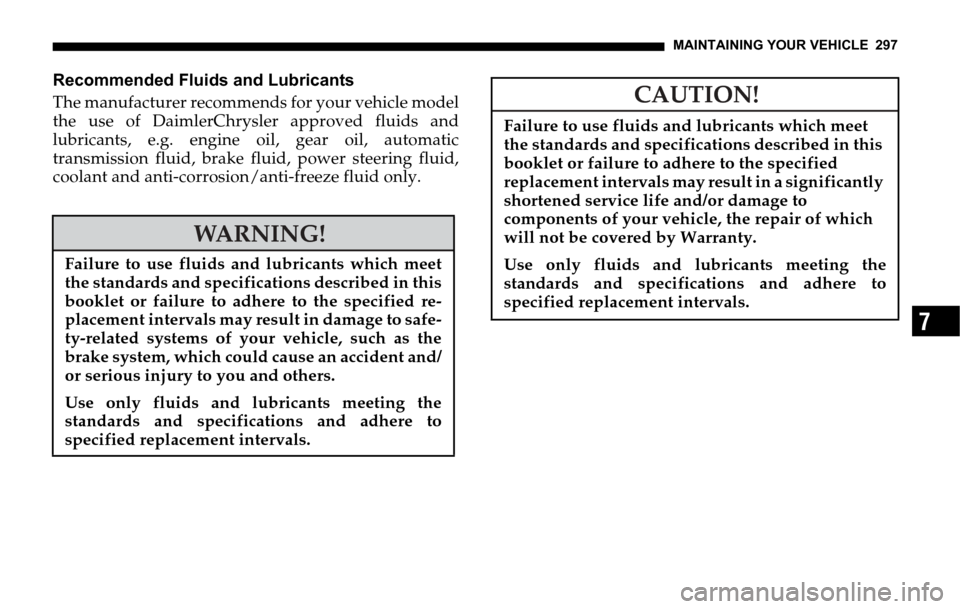

Recommended Fluids and Lubricants

The manufacturer recommends for your vehicle model

the use of DaimlerChrysler approved fluids and

lubricants, e.g. engine oil, gear oil, automatic

transmission fluid, brake fluid, power steering fluid,

coolant and anti-corrosion/anti-freeze fluid only.

WARNING!

Failure to use fluids and lubricants which meet

the standards and specifications described in this

booklet or failure to adhere to the specified re-

placement intervals may result in damage to safe-

ty-related systems of your vehicle, such as the

brake system, which could cause an accident and/

or serious injury to you and others.

Use only fluids and lubricants meeting the

standards and specifications and adhere to

specified replacement intervals.

CAUTION!

Failure to use fluids and lubricants which meet

the standards and specifications described in this

booklet or failure to adhere to the specified

replacement intervals may result in a significantly

shortened service life and/or damage to

components of your vehicle, the repair of which

will not be covered by Warranty.

Use only fluids and lubricants meeting the

standards and specifications and adhere to

specified replacement intervals.

Page 300 of 330

300 MAINTAINING YOUR VEHICLE

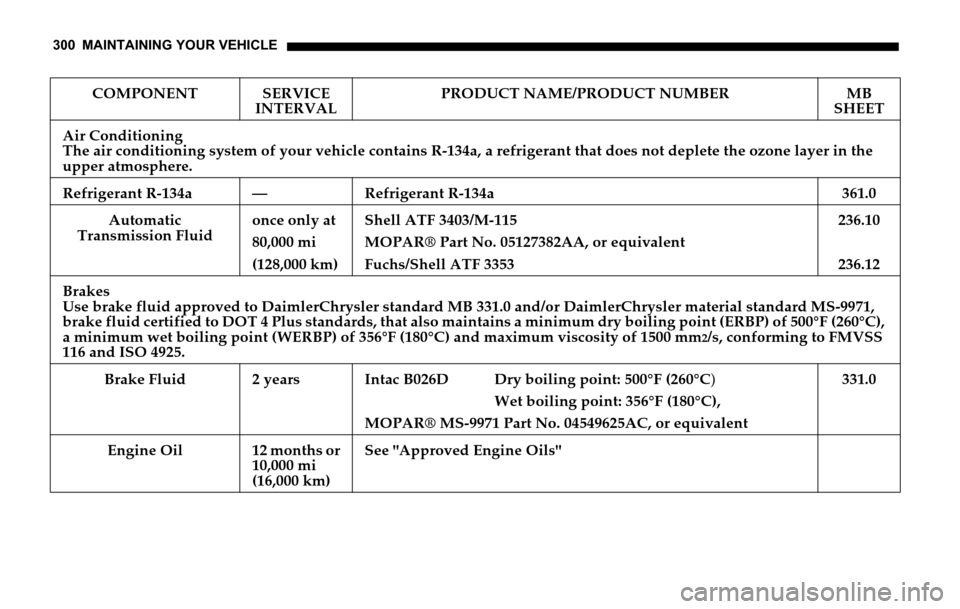

COMPONENT SERVICE

INTERVALPRODUCT NAME/PRODUCT NUMBER MB

SHEET

Air Conditioning

The air conditioning system of your vehicle contains R-134a, a refrigerant that does not deplete the ozone layer in the

upper atmosphere.

Refrigerant R-134a — Refrigerant R-134a 361.0

Automatic

Transmission Fluidonce only at

80,000 mi

(128,000 km)Shell ATF 3403/M-115

MOPAR® Part No. 05127382AA, or equivalent

Fuchs/Shell ATF 3353236.10

236.12

Brakes

Use brake fluid approved to DaimlerChrysler standard MB 331.0 and/or DaimlerChrysler material standard MS-9971,

brake fluid certified to DOT 4 Plus standards, that also maintains a minimum dry boiling point (ERBP) of 500°F (260°C),

a minimum wet boiling point (WERBP) of 356°F (180°C) and maximum viscosity of 1500 mm

2/s, conforming to FMVSS

116 and ISO 4925.

Brake Fluid 2 years Intac B026D Dry boiling point: 500°F (260°C)

Wet boiling point: 356°F (180°C),

MOPAR® MS-9971 Part No. 04549625AC, or equivalent331.0

Engine Oil 12 months or

10,000 mi

(16,000 km)See "Approved Engine Oils"

Page 301 of 330

MAINTAINING YOUR VEHICLE 301

7

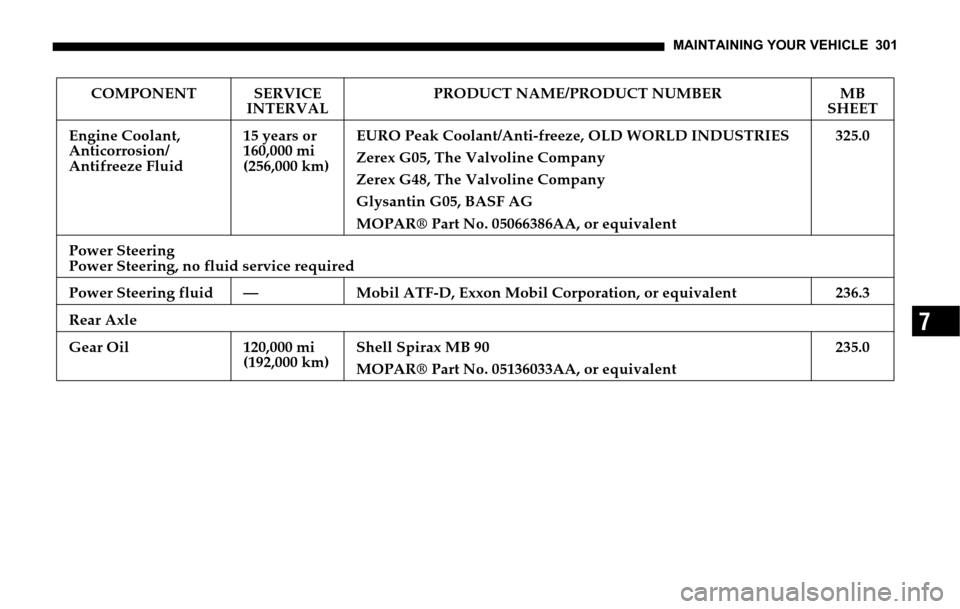

COMPONENT SERVICE

INTERVALPRODUCT NAME/PRODUCT NUMBER MB

SHEET

Engine Coolant,

Anticorrosion/

Antifreeze Fluid15 years or

160,000 mi

(256,000 km)EURO Peak Coolant/Anti-freeze, OLD WORLD INDUSTRIES

Zerex G05, The Valvoline Company

Zerex G48, The Valvoline Company

Glysantin G05, BASF AG

MOPAR® Part No. 05066386AA, or equivalent325.0

Power Steering

Power Steering, no fluid service required

Power Steering fluid — Mobil ATF-D, Exxon Mobil Corporation, or equivalent 236.3

Rear Axle

Gear Oil 120,000 mi

(192,000 km)Shell Spirax MB 90

MOPAR® Part No. 05136033AA, or equivalent235.0

Page 303 of 330

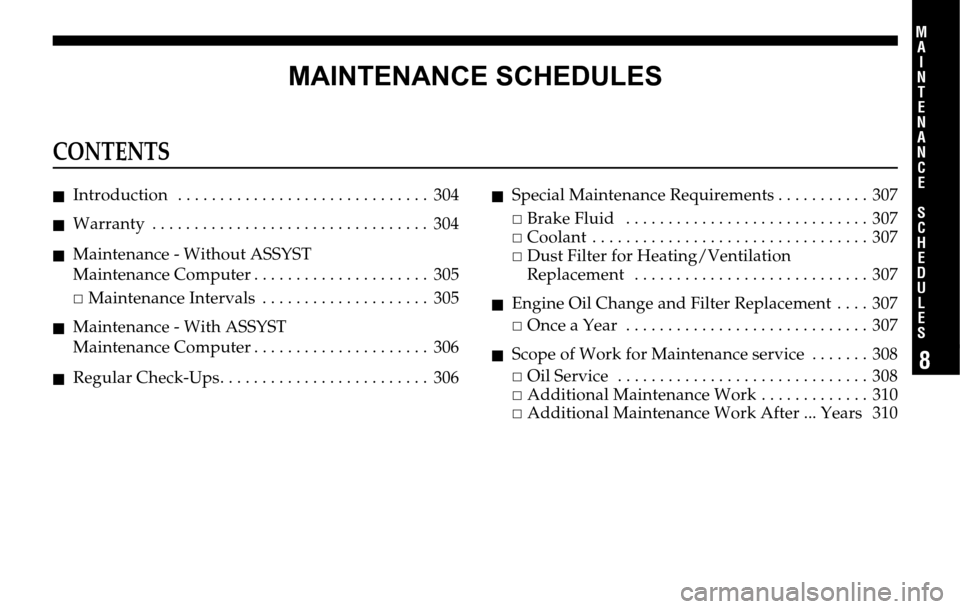

MAINTENANCE SCHEDULES

CONTENTS

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

�Q Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

�Q Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

�Q Maintenance - Without ASSYST

Maintenance Computer . . . . . . . . . . . . . . . . . . . . . 305

�…Maintenance Intervals . . . . . . . . . . . . . . . . . . . . 305

�Q Maintenance - With ASSYST

Maintenance Computer . . . . . . . . . . . . . . . . . . . . . 306

�Q Regular Check-Ups. . . . . . . . . . . . . . . . . . . . . . . . . 306

�Q Special Maintenance Requirements . . . . . . . . . . . 307

�…Brake Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

�…Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

�…Dust Filter for Heating/Ventilation

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

�Q Engine Oil Change and Filter Replacement . . . . 307

�…Once a Year . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

�Q Scope of Work for Maintenance service . . . . . . . 308

�…Oil Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

�…Additional Maintenance Work . . . . . . . . . . . . . 310

�…Additional Maintenance Work After ... Years 310

Page 304 of 330

304 MAINTENANCE SCHEDULESM

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

8

INTRODUCTION

This is intended as a guide to the service requirements

of your vehicle.

It contains all necessary instructions concerning

service intervals and operations which have to be

carried out.

Scope and frequency of maintenance work primarily

depend on the vehicle's operating conditions.

In the interest of maintaining the vehicle's operating

safety, the specified work should be performed

regularly and in good time.

Our vehicles are subject to ongoing development.

Technical progress may also affect the scope of service

work performed.

"Daily vehicle checks" before starting a journey are the

responsibility of the driver.WARRANTY

The Sprinter Dealer network is at your disposal for

maintenance work. Each of these workshops has the

equipment and tools, the specially trained, skilled and

experienced personnel and receives regular technical

instruction from DaimlerChrysler Corporation to

ensure that your vehicle is inspected and maintained

thoroughly and in accordance with the latest

procedures.

Please follow the instructions given in this Owner’s

Manual and ensure that they are observed, even if you

hand the vehicle over to a third party for use or care. By

not observing these instructions you may void your

warranty rights.

If the specified oil and maintenance services are not

carried out regularly or at the time intervals specified,

a decision as to the validity of a warranty claim can

only be made after DaimlerChrysler Corporation has

investigated your claim.

Page 305 of 330

MAINTENANCE SCHEDULES 305

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

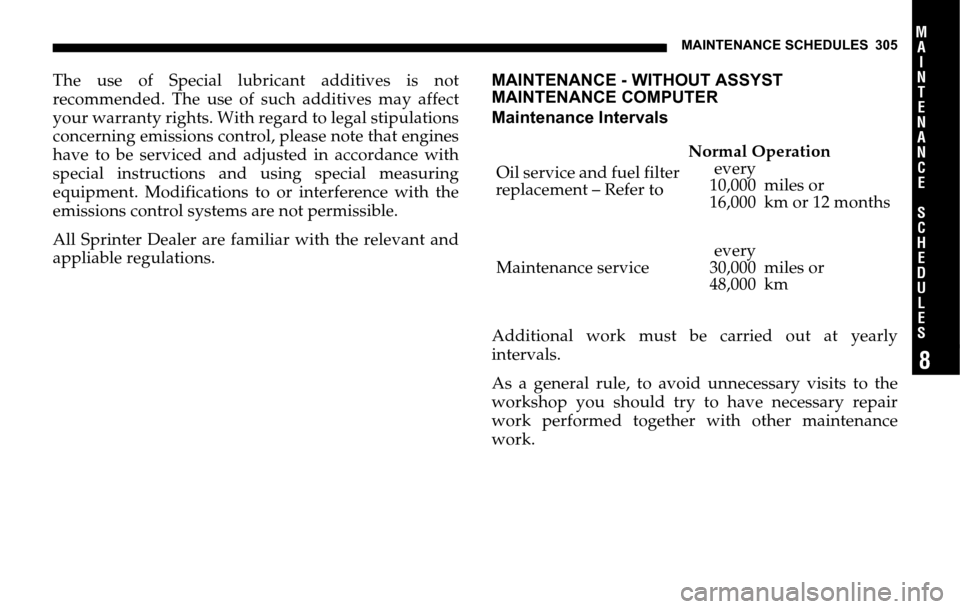

The use of Special lubricant additives is not

recommended. The use of such additives may affect

your warranty rights. With regard to legal stipulations

concerning emissions control, please note that engines

have to be serviced and adjusted in accordance with

special instructions and using special measuring

equipment. Modifications to or interference with the

emissions control systems are not permissible.

All Sprinter Dealer are familiar with the relevant and

appliable regulations.MAINTENANCE - WITHOUT ASSYST

MAINTENANCE COMPUTER

Maintenance Intervals

Additional work must be carried out at yearly

intervals.

As a general rule, to avoid unnecessary visits to the

workshop you should try to have necessary repair

work performed together with other maintenance

work.Oil service and fuel filter

replacement – Refer toNormal Operation

every

10,000 miles or

16,000 km or 12 months

Maintenance serviceevery

30,000 miles or

48,000 km