wheel DODGE SPRINTER 2006 1.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: SPRINTER, Model: DODGE SPRINTER 2006 1.GPages: 330, PDF Size: 10.82 MB

Page 238 of 330

238 WHAT TO DO IN EMERGENCIES

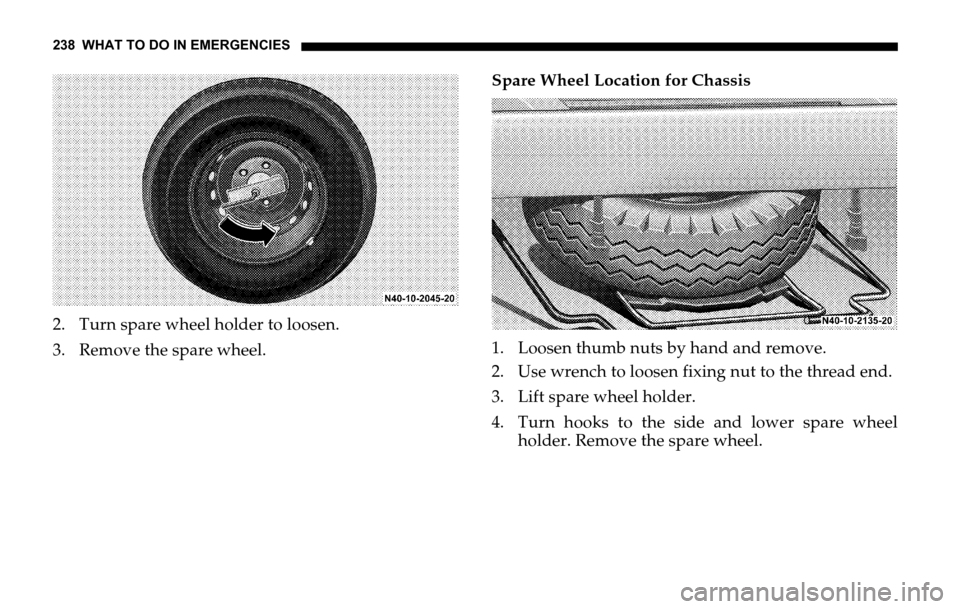

2. Turn spare wheel holder to loosen.

3. Remove the spare wheel.Spare Wheel Location for Chassis

1. Loosen thumb nuts by hand and remove.

2. Use wrench to loosen fixing nut to the thread end.

3. Lift spare wheel holder.

4. Turn hooks to the side and lower spare wheel

holder. Remove the spare wheel.

Page 239 of 330

WHAT TO DO IN EMERGENCIES 239

6

JACK Using the Jack

The jack is located together with the vehicle tool kit

under the hatch in the front passenger footwell, refer to

"Vehicle Tool Kit".

1. Loosen the wheel bolts before raising the vehicle.

2. Close the release valve on the jack.

3. Assemble the pump lever provided and insert it

into the socket on the jack.

4. Secure the lever by turning it clockwise in the

socket.

Position the jack under the appropriate jack point and

raise the vehicle by pumping the lever.

WARNING!

To avoid the risk of serious or fatal injuries or vehicle

damage, please bear the following points in mind:

The jack is intended only for raising the vehicle

briefly, for instance, when changing a wheel. If it is

not designed to enable work to be carried out

underneath the vehicle.

Do not crawl under the jacked-up vehicle. For work

under the vehicle, stands must be used.

The jack must be placed on a firm, flat surface only.

Do not change wheels on uphill or downhill

gradients under any circumstances.

Make sure that no persons are present in the vehicle

when jacking up the vehicle.

Do not start the engine while the vehicle is raised.

Make sure that the distance between the underside

of the tires and the ground does not exceed 1.2 in (30

mm). Otherwise the vehicle may tip over.

Page 242 of 330

242 WHAT TO DO IN EMERGENCIES

REMOVING A WHEEL

1. Loosen the wheel bolts/nuts.

2. Jack up the vehicle until the wheel is clear of the

ground.

3. Unscrew the wheel bolts and remove the wheel

(keep the wheel bolts clean).

NOTE: If the vehicle moves forwards or backwards

while it is being jacked-up, lower it again and

reposition the jack. When the vehicle is jacked-up, the

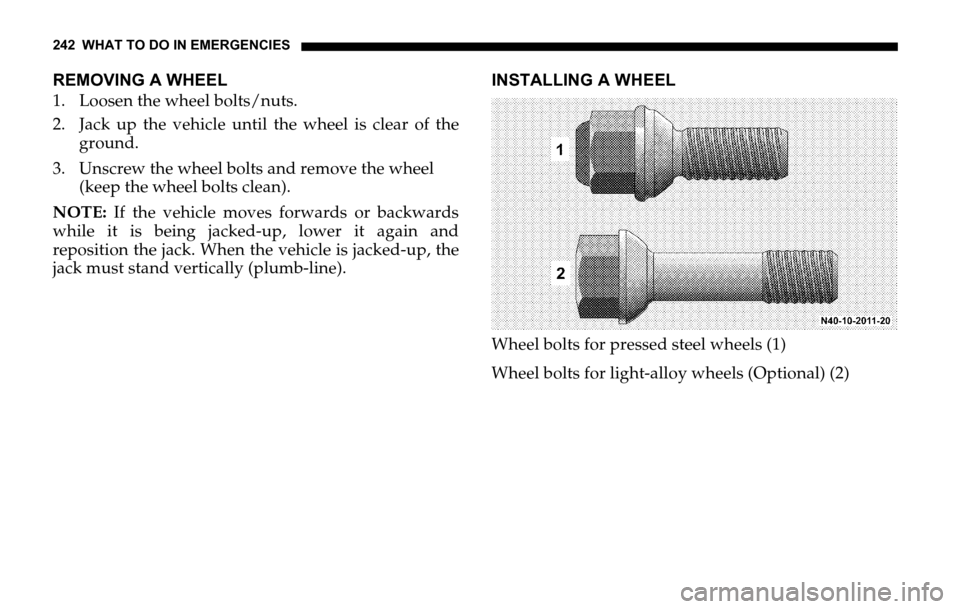

jack must stand vertically (plumb-line).INSTALLING A WHEEL

Wheel bolts for pressed steel wheels (1)

Wheel bolts for light-alloy wheels (Optional) (2)

Page 243 of 330

WHAT TO DO IN EMERGENCIES 243

6NOTE: The optional light alloy wheels are supplied

with 5 short wheel lug bolts enclosed for the steel spare

wheel in the vehicle tool kit.

Before fitting the spare wheel, clean rust and dirt off

the contact surfaces of the wheel and the wheel hub,

and from the wheel bolts.

Note the specified wheel and tire size, tire load

capacity and speed code.

Do not change the tire’s direction of rotation.

Do not damage, grease or oil wheel bolts or their

threads.

WARNING!

Different wheel bolts are required for pressed

steel and light-alloy wheels.

Incorrect wheel lug bolts for the wheels could

work loose, thereby causing you to lose control of

the vehicle. This could cause an accident resulting

in severe personal injuries and and property

damage.

WARNING!

Incorrect mounting bolts or improperly tightened

mounting bolts can cause the wheel to come off.

To avoid the risk of serious or fatal injuries or ve-

hicle damage, please bear the following points in

mind:

Always replace wheel bolts that are damaged or

rusted.

Never apply oil or grease to wheel bolts

If a wheel hub thread is damaged, you must not

drive the vehicle. Consult a qualified specialist

workshop.

Only use genuine DaimlerChrysler wheel bolts

specified for your vehicle’s rims.

Page 244 of 330

244 WHAT TO DO IN EMERGENCIES

Centering wheels with wheel bolts/nuts

If dual assemblies are used, before placement the

inner wheel should be inspected to ensure that all

ball bearing rings are in proper position.

Install the wheel and snug the wheel bolts/nuts.

Slightly tighten wheel bolts/nuts.

Slowly open jack release valve to lower vehicle until

tire is resting on ground.

WARNING!

Do not tighten the wheel bolts and wheel nuts

completely while the vehicle is still jacked up.

The vehicle could tip.

Page 245 of 330

WHAT TO DO IN EMERGENCIES 245

6

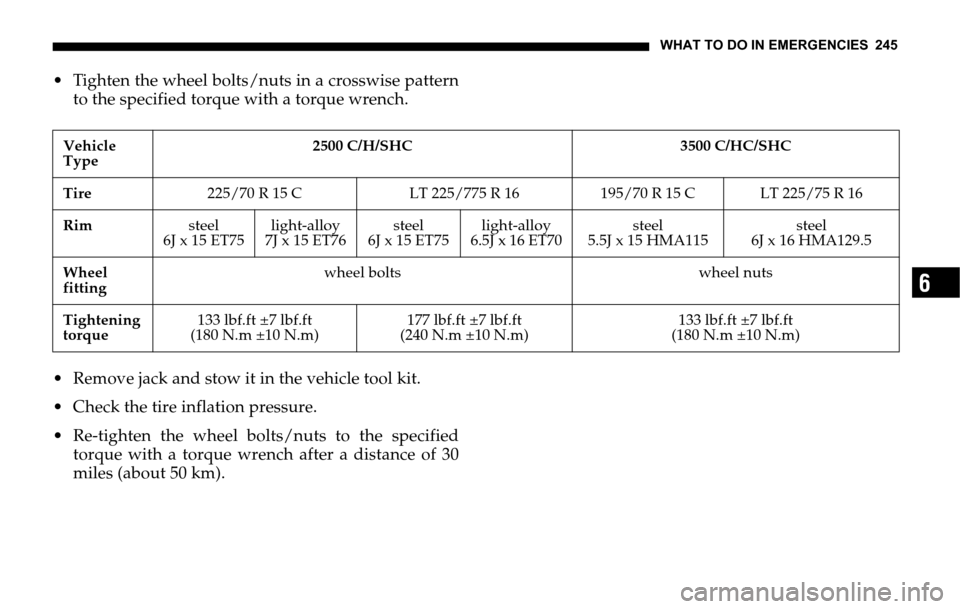

Tighten the wheel bolts/nuts in a crosswise pattern

to the specified torque with a torque wrench.

Remove jack and stow it in the vehicle tool kit.

Check the tire inflation pressure.

Re-tighten the wheel bolts/nuts to the specified

torque with a torque wrench after a distance of 30

miles (about 50 km).

Vehicle

Type2500 C/H/SHC 3500 C/HC/SHC

Tire225/70 R 15 C LT 225/775 R 16 195/70 R 15 C LT 225/75 R 16

Rimsteel

6J x 15 ET75light-alloy

7J x 15 ET76steel

6J x 15 ET75light-alloy

6.5J x 16 ET70steel

5.5J x 15 HMA115steel

6J x 16 HMA129.5

Wheel

fittingwheel bolts wheel nuts

Tightening

torque133 lbf.ft ±7 lbf.ft

(180 N.m ±10 N.m)177 lbf.ft ±7 lbf.ft

(240 N.m ±10 N.m)133 lbf.ft ±7 lbf.ft

(180 N.m ±10 N.m)

Page 246 of 330

246 WHAT TO DO IN EMERGENCIES

JUMP STARTING

If the battery is dead, the engine can be started with

jumper cables from another vehicle’s battery.

WARNING!

After changing a wheel, you must, for safety reasons,

have the specified tightening torque checked. The

wheels could otherwise work loose.

check the tire inflation pressure and correct it if

necessary.

retighten the wheel bolts and wheel nuts to the

specified tightening torque once the vehicle has

been driven for 30 miles (50 km). If new or

repainted wheels are fitted, the wheel bolts or nuts

must be retightened again after about 600 to 3,000

miles (about 1,000 to 5,000 km).

have a reversed direction of tire rotation corrected

as soon as possible at a qualified specialist

workshop. The vehicle handling characteristics

could otherwise be affected.WARNING!

A battery will produce hydrogen gas, which is

flammable and very explosive. Avoid open flames

and the formation of sparks in the vicinity of the

batteries. Refrain from smoking or cell phone use.

Avoid improper connection of jumper cables.

Observe safety precautions when handling

batteries.

Exercise care near moving engine components and

electrical cables.

Failure to follow these directions will cause

damage to the electronic components and can lead

to a battery explosion and severe injury or death.

Page 249 of 330

WHAT TO DO IN EMERGENCIES 249

6

*Vehicle Type 2500 onlyIf the Engine is Damaged

For towing distances up to 30 miles (about 50 km)

Shift gear selector lever to "N" position.

Do not exceed a towing speed of 30 mph (50 km / h).

For towing distances greater than 30 miles (about

50 km)

Remove the propeller shafts leading to the drive

axles.

The vehicle can be towed without restriction.

If the Transmission is Damaged

Remove the propeller shafts leading to the drive

axles.

If the Front Axle is Damaged

Raise the front axle.

Observe the same towing restrictions as for engine

damage.

If the Rear Axle is Damaged

Raise the rear axle.

NOTE: Comply with local legal regulations regarding

towing vehicles.

WARNING!

Do not tow the vehicle if the key cannot be turned

in the ignition lock.

If the key cannot be turned, the ignition lock re-

mains locked and the vehicle cannot be steered.

With the engine not running there is no power

assistance for the braking and steering systems.

In this case, it is important to keep in mind that a

considerably higher degree of effort is necessary

to brake and steer the vehicle.

The vehicle must not be towed with the front axle

raised and the key in position 2 in the ignition

lock as the drive wheels could then lock due to the

acceleration skid control (ASR) or the optional

Electronic Stability Program (ESP

®)*.

Page 252 of 330

252 MAINTAINING YOUR VEHICLE

�…Headlamps, Taillamps, Identification Lamps,

Turn Signal Lenses . . . . . . . . . . . . . . . . . . . . . . . 273

�…Reversing Aid Sensors . . . . . . . . . . . . . . . . . . . . 273

�…Window Cleaning . . . . . . . . . . . . . . . . . . . . . . . 274

�…Wiper Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

�…Light Alloy Wheels . . . . . . . . . . . . . . . . . . . . . . 275

�…Instrument Cluster . . . . . . . . . . . . . . . . . . . . . . . 275

�…Steering Wheel and Gear Selector Lever . . . . 275

�…Cup Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

�…Seat Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

�…Headliner and Shelf Below Rear Window . . . 275

�…Upholstery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

�…Hard Plastic Trim Items . . . . . . . . . . . . . . . . . . 276

�…Plastic and Rubber Parts . . . . . . . . . . . . . . . . . . 276

�Q Electrical Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

�…Standard Fuse and Relay Equipment . . . . . . . 277

�…Relay Assignment, Standard Equipment . . . . 281

�…Fuse and Relay Optional Equipment . . . . . . . 281

�Q Bulb Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 284

�…Front Lamp Unit . . . . . . . . . . . . . . . . . . . . . . . . . 284

�…Taillamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

�…License Plate Lamps

(Cargo/Passenger Vans Only) . . . . . . . . . . . . . 291

�…Additional Brake Lamp

(Cargo/Passenger Vans Only) . . . . . . . . . . . . . 291

�…Side-Mounted Turn Signals . . . . . . . . . . . . . . . 292

�…Side-Marker Lamps,

Standing Lamps (Optional) . . . . . . . . . . . . . . . . 292

�…Identification Lamps

(Cargo/passenger vans only) . . . . . . . . . . . . . . 293

�…Interior Lighting in Passenger

Compartment and Load Compartment . . . . . 293

�…Interior Lighting with Reading Lamp . . . . . . . 294

�…Interior Lighting with Interior Sensor

Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

�…Exit Lamps (Optional) . . . . . . . . . . . . . . . . . . . . 295

�Q Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

�…Recommended Fluids and Lubricants . . . . . . 297

Page 257 of 330

MAINTAINING YOUR VEHICLE 257

7

The following checks should be performed at regular

intervals (for example once a week or each time the

vehicle is refueled):

Windshield washer system/headlamp cleaning

system (optional) – washer system fluid reservoir.

Air strainer, in vehicles with an air strainer element

maintenance indicator (optional equipment).

Engine oil level.

Checking ribbed V-belt.

Hydraulic brake system, clutch mechanism fluid

level.

Coolant level.

Tire and spare wheel condition and pressures of the

same. For more information, refer to "Wheels and

Tires".

Spare wheel location.

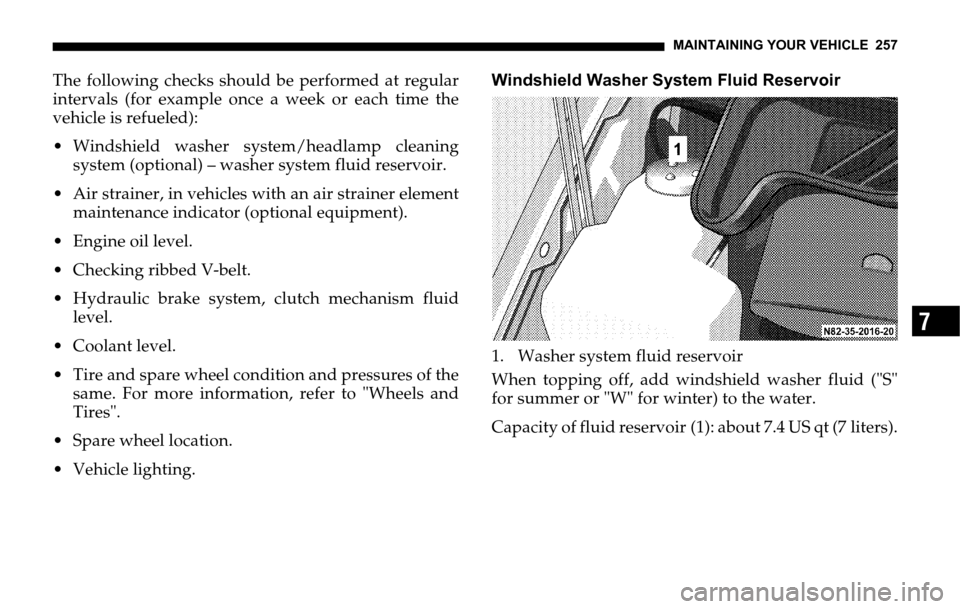

Vehicle lighting.Windshield Washer System Fluid Reservoir

1. Washer system fluid reservoir

When topping off, add windshield washer fluid ("S"

for summer or "W" for winter) to the water.

Capacity of fluid reservoir (1): about 7.4 US qt (7 liters).