transmission DODGE SPRINTER 2007 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2007, Model line: SPRINTER, Model: DODGE SPRINTER 2007 2.GPages: 393, PDF Size: 7.61 MB

Page 180 of 393

179 Operation

Driving tips

4

Always secure items in the trailer to pre-

vent load shifts while driving.

Take into consideration that when towing a

trailer, the handling characteristics are dif-

ferent and less stable from those when op-

erating the vehicle without a trailer. It is

important to avoid sudden maneuvers.

The vehicle and trailer combination is

heavier, and therefore is limited in acceler-

ation and climbing ability, and requires

longer stopping distances. It is more prone

to reacting to side wind gusts, and requires

more sensitive steering input.

In order to gain skill and an understanding

of the vehicle’s behavior, you should prac-

tice turning , st opping and backing up in a n

area which is free from traffic.

If possible, do not brake abruptly, but rath-

er engage the brake slightly at first to per-

mit the trailer to activate its brake. Then

increase the braking force.

Warning

G

Take into consideration that when towing a

trailer, the handling characteristics are dif-

ferent and less stable from those when op-

erating the vehicle without a trailer.

It is important to avoid sudden maneuvers.

Sudden maneuvers may lead to loss of con-

trol over the vehicle-trailer combination.

This could cause an accident resulting in

property damage or injury to you or others.!

CAUTION

If the transmission hunts between

gears on inclines, manually shift to a

lower gear (select

"4", "3", "2" or

"1").

A lower gear and reduction of speed re-

duces the chance of the engine over-

loading and / or overheating.

When going down a long hill, shift into

a lower gear and use the engine’s brak-

ing effect. Avoid riding the brakes, thus

overheating the vehicle and trailer

brakes.

If the engine coolant rises to an ex-

tremely high temperature (coolant tem-

perature needle approaching the red

zone) when the air conditioner is on,

turn off the air conditioner. Engine

coolant heat can be additionally vented

by opening the windows, switching the

climate control fan speed to high and

setting the temperature control to the

maximum hot position.

Extreme care must be exercised since

your vehicle with a trailer will require

additional passing distance ahead than

when driving without a trailer. Because

your vehicle and trailer is longer than

your vehicle alone, you will also need to

go much farther ahead of the passed

vehicle before you can return to your

lane.

Page 217 of 393

216 OperationTires and wheels

4

Reactivating the TPMS

The TPMS must be reactivated when you

have adjusted the tire inflation pressure to

a new level (e.g. because of different load

or driving conditions). The TPMS is then

recalibrated to the current tire inflation

pressures.\1Using the tire and loading information

placard on the driver’s door B-pillar

(\2page 206), make sure the tire infla-

tion pressure of all four tires is correct.

\1Switch on the ignition (\2page 67).

\1Press the 5menu button on the instru-

ment cluster until you see the

+CAL TPMS

message in the display.

TPMS malfunctions may occur for a variety

of reasons, including the installation of in-

compatible replacement or alternate tires or

wheels on the vehicle that prevent the TPMS

from functioning properly. Always check the

TPMS malfunction telltale after replacing

one or more tires or wheels on your vehicle

to ensure that the replacement or alternate

tires and wheels allow the TPMS to continue

to function properly.iIf a condition causing the TPMS to mal-

function develops, it may take up to 10

minutes for the system to signal a mal-

function using the TPMS telltale flash-

ing and illumination sequence.

The telltale extinguishes after driving a

few minutes if the malfunction has

been corrected.

iOperating radio transmission equip-

ment (e.g. wireless headsets, two-way

radios) in or near the vehicle could

cause the TPMS to malfunctionWarning

G

It is the driver’s responsibility to calibrate

the TPMS on the recommended cold infla-

tion pressure. Underinflated tires affect the

ability to steer or brake the vehicle. You

might lose control over the vehicle.

iReactivate the TPMS after adjusting

the tire inflation pressure to the infla-

tion pressure recommended for the ve-

hicle operating condition. Tire pressure

should only be adjusted on cold tires.

Observe the recommended tire infla-

tion pressure on the tire and loading in-

formation placard on the driver’s door

B-pillar (\2page 206).

Page 221 of 393

220 OperationTires and wheels

4

Reactivating Advanced TPMS

The TPMS must be reactivated when you

have adjusted the tire inflation pressure to

a new level (e.g. because of different load

or driving conditions). The TPMS is then

recalibrated to the current tire inflation

pressures.\1Using the tire and loading information

placard on the driver’s door B-pillar

(\2page 206), make sure the tire infla-

tion pressure of all four tires is correct.

\1Press buttonè orÿ on the mul-

tifunction steering wheel repeatedly

until the standard display menu ap-

pears in the multifunction display

(\2page 93).

TPMS malfunctions may occur for a variety

of reasons, including the installation of in-

compatible replacement or alternate tires or

wheels on the vehicle that prevent the TPMS

from functioning properly. Always check the

TPMS malfunction telltale after replacing

one or more tires or wheels on your vehicle

to ensure that the replacement or alternate

tires and wheels allow the TPMS to continue

to function properly.iIf a condition causing the TPMS to mal-

function develops, it may take up to 10

minutes for the system to signal a mal-

function using the TPMS telltale flash-

ing and illumination sequence.

The telltale extinguishes after driving a

few minutes if the malfunction has

been corrected.

iOperating radio transmission equip-

ment (e.g. wireless headsets, two-way

radios) in or near the vehicle could

cause the TPMS to malfunctionWarning!

G

It is the driver’s responsibility to calibrate

the TPMS on the recommended cold infla-

tion pressure. Underinflated tires affect the

ability to steer or brake the vehicle. You

might lose control over the vehicle.

iReactivate the TPMS after adjusting

the tire inflation pressure to the infla-

tion pressure recommended for the ve-

hicle operating condition. Tire pressure

should only be adjusted on cold tires.

Observe the recommended tire infla-

tion pressure on the tire and loading in-

formation placard on the driver’s door

B-pillar (\2page 206).

Page 229 of 393

228 OperationTires and wheels

4

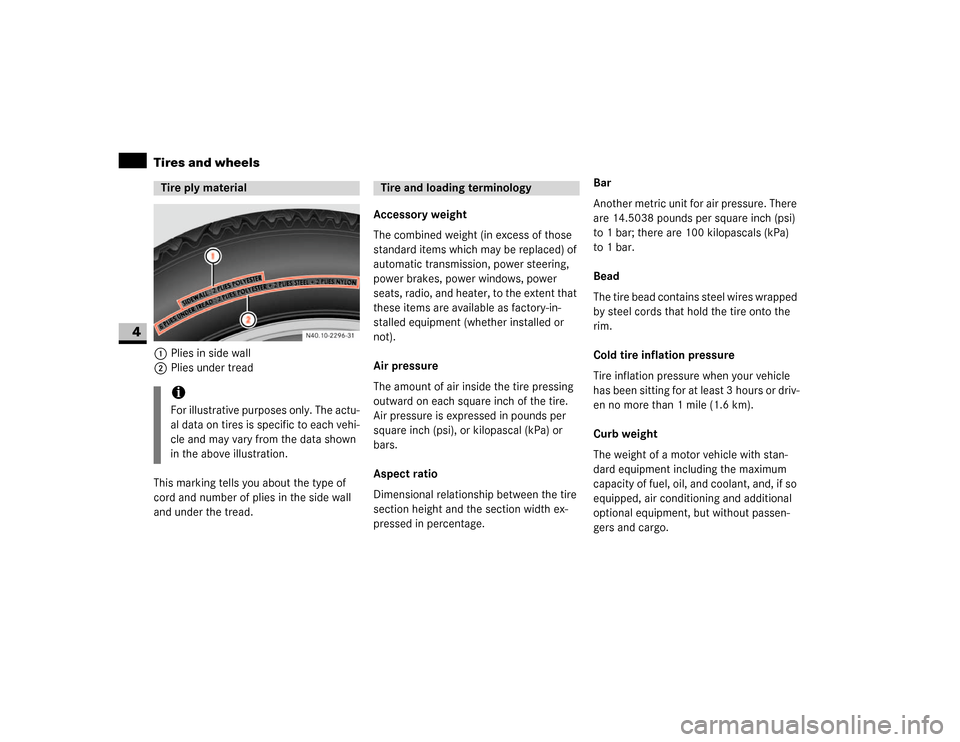

1Plies in side wall

2Plies under tread

This marking tells you about the type of

cord and number of plies in the side wall

and under the tread.Accessory weight

The combined weight (in excess of those

standard items which may be replaced) of

automatic transmission, power steering,

power brakes, power windows, power

seats, radio, and heater, to the extent that

these items are available as factory-in-

stalled equipment (whether installed or

not).

Air pressure

The amount of air inside the tire pressing

outward on each square inch of the tire.

Air pressure is expressed in pounds per

square inch (psi), or kilopascal (kPa) or

bars.

Aspect ratio

Dimensional relationship between the tire

section height and the section width ex-

pressed in percentage.Bar

Another metric unit for air pressure. There

are 14.5038 pounds per square inch (psi)

to 1 bar; there are 100 kilopascals (kPa)

to 1 bar.

Bead

The tire bead contains steel wires wrapped

by steel cords that hold the tire onto the

rim.

Cold tire inflation pressure

Tire inflation pressure when your vehicle

has been sitting for at least 3 hours or driv-

en no more than 1 mile (1.6 km).

Curb weight

The weight of a motor vehicle with stan-

dard equipment including the maximum

capacity of fuel, oil, and coolant, and, if so

equipped, air conditioning and additional

optional equipment, but without passen-

gers and cargo.Tire ply materialiFor illustrative purposes only. The actu-

al data on tires is specific to each vehi-

cle and may vary from the data shown

in the above illustration.

Tire and loading terminology

Page 257 of 393

256 Practical hintsWhat to do if ...

5

Automatic transmissionWarning

G

Always have maintenance work carried out

at an authorized Sprinter Dealer which has

the necessary specialist knowledge and

tools to carry out the work required.

The manufacturer recommends that you use

an authorized Sprinter Dealer for this pur-

pose.

In particular, work relevant to safety or on

safety-related systems must be carried out

at an authorized Sprinter Dealer. There is a

risk of an accident and injury if this work is

carried out incorrectly.

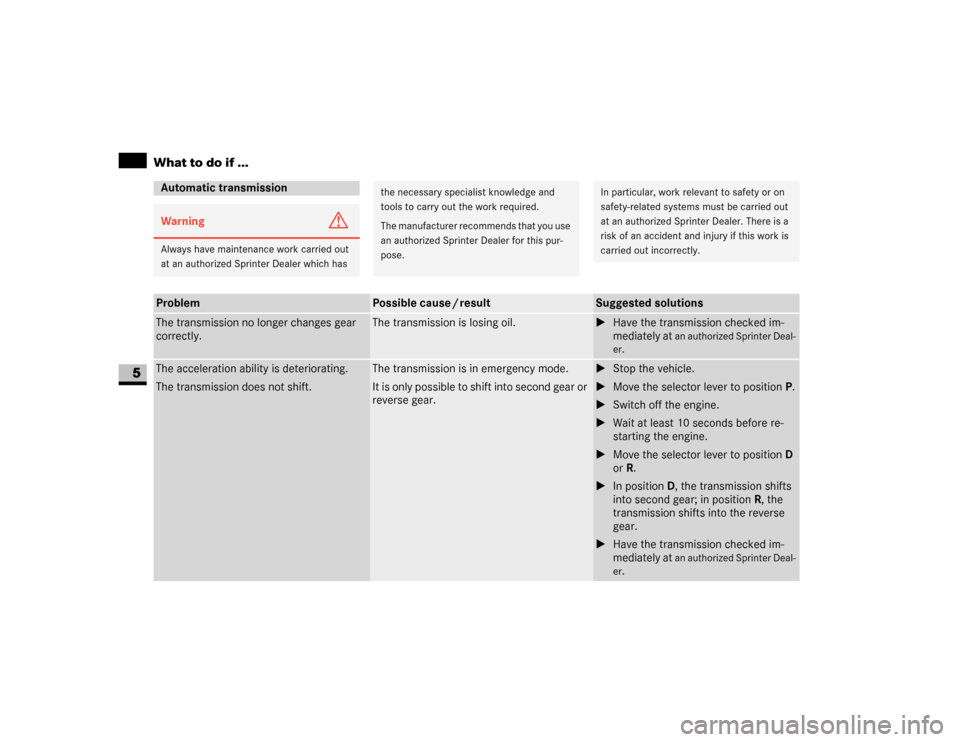

Problem

Possible cause / result

Suggested solutions

The transmission no longer changes gear

correctly.

The transmission is losing oil.

\1Have the transmission checked im-

mediately at

an authorized Sprinter Deal-

er

.

The acceleration ability is deteriorating.

The transmission does not shift.

The transmission is in emergency mode.

It is only possible to shift into second gear or

reverse gear.

\1Stop the vehicle.

\1Move the selector lever to positionP.

\1Switch off the engine.

\1Wait at least 10 seconds before re-

starting the engine.

\1Move the selector lever to positionD

or R.

\1In positionD, the transmission shifts

into second gear; in positionR, the

transmission shifts into the reverse

gear.

\1Have the transmission checked im-

mediately at

an authorized Sprinter Deal-

er

.

Page 342 of 393

341 Practical hints

Jump-starting

5

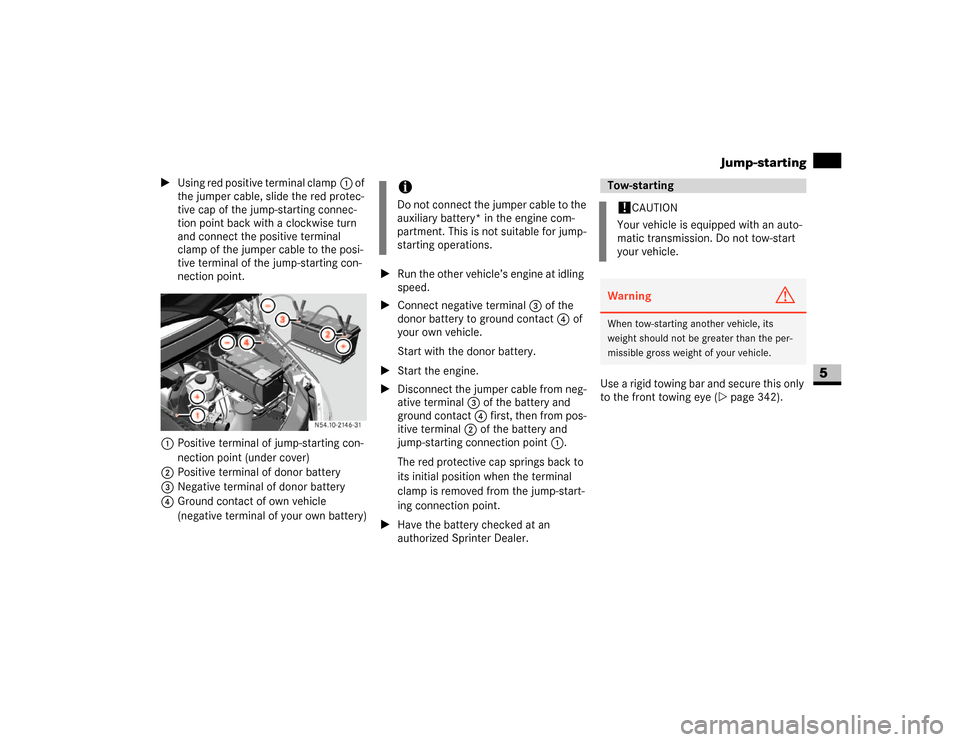

\1Using red positive terminal clamp1 of

the jumper cable, slide the red protec-

tive cap of the jump-starting connec-

tion point back with a clockwise turn

and connect the positive terminal

clamp of the jumper cable to the posi-

tive terminal of the jump-starting con-

nection point.

1Positive terminal of jump-starting con-

nection point (under cover)

2Positive terminal of donor battery

3Negative terminal of donor battery

4Ground contact of own vehicle

(negative terminal of your own battery)\1Run the other vehicle’s engine at idling

speed.

\1Connect negative terminal3 of the

donor battery to ground contact4 of

your own vehicle.

Start with the donor battery.

\1Start the engine.

\1Disconnect the jumper cable from neg-

ative terminal3 of the battery and

ground contact 4 first, then from pos-

itive terminal 2 of the battery and

jump-starting connection point 1.

The red protective cap springs back to

its initial position when the terminal

clamp is removed from the jump-start-

ing connection point.

\1Have the battery checked at an

authorized Sprinter Dealer.Use a rigid towing bar and secure this only

to the front towing eye (\2page 342).

iDo not connect the jumper cable to the

auxiliary battery* in the engine com-

partment. This is not suitable for jump-

starting operations.

Tow-starting!

CAUTION

Your vehicle is equipped with an auto-

matic transmission. Do not tow-start

your vehicle.

Warning

G

When tow-starting another vehicle, its

weight should not be greater than the per-

missible gross weight of your vehicle.

Page 344 of 393

343 Practical hints

Towing

5

\1Return the towing eye and the wheel

wrench to the vehicle tool kit.

\1Switch on the ignition (\2page 67).

\1For a distance of up to 30 miles

(50 km), move the selector lever to po-

sition N.

\1For a distance greater than 30 miles

(50 km), remove the propeller shafts to

the driven axles.Take great care when attempting to tow

the vehicle free if its drive wheels have be-

come embedded in loose earth or mud,

particularly if the vehicle is loaded.

Tow the vehicle smoothly and straight-

ahead. The chassis could otherwise be

damaged.

Do not attempt to tow out the vehicle if a

trailer is coupled up.

Where possible, tow the vehicle out back-

wards along the track made by the vehicle

previously.With transmission damage

\1Always remove the propeller shafts to

the driven axles.

With front axle damage

\1Turn the key to position 1 in the ignition

lock(\2page 67).

iDeactivate the automatic locking while

driving function when towing

(\2page 64). You could otherwise

become locked out when pushing or

towing the vehicle.!

CAUTION

Do not exceed a towing speed of

50 km / h, otherwise the transmission

could be damaged.

Towing out a vehicle that is stuck

Towing the vehicle in the event of

particular malfunctions!

CAUTION

Use new self-securing nuts when in-

stalling the propeller shafts.

!

CAUTION

The vehicle must not be towed with its

front wheels raised and with the key in

position2 in the ignition lock.

Active brake intervention by ESP

® or

ASR could otherwise lock the wheels

and damage the brake system.

Page 345 of 393

344 Practical hintsTowing

5

In the event of a malfunction in the

electrical system

If the battery is malfunctioning, the auto-

matic transmission will be locked in

positionP. To shift the automatic trans-

mission to positionN, you must provide

power to the vehicle’s electrical system in

the same way as jump-starting

(\2page 340).

Have the vehicle transported on a trans-

porter or trailer.The towing eye can be used to pull the ve-

hicle onto a special transporter or trailer

for transportation.

\1Shift the transmission to neutral or

move the selector lever to positionN.

Transporting the vehicle!

CAUTION

Only secure the vehicle at the wheels /

rims. Your vehicle could otherwise be

damaged.

Page 351 of 393

350 Practical hints

5

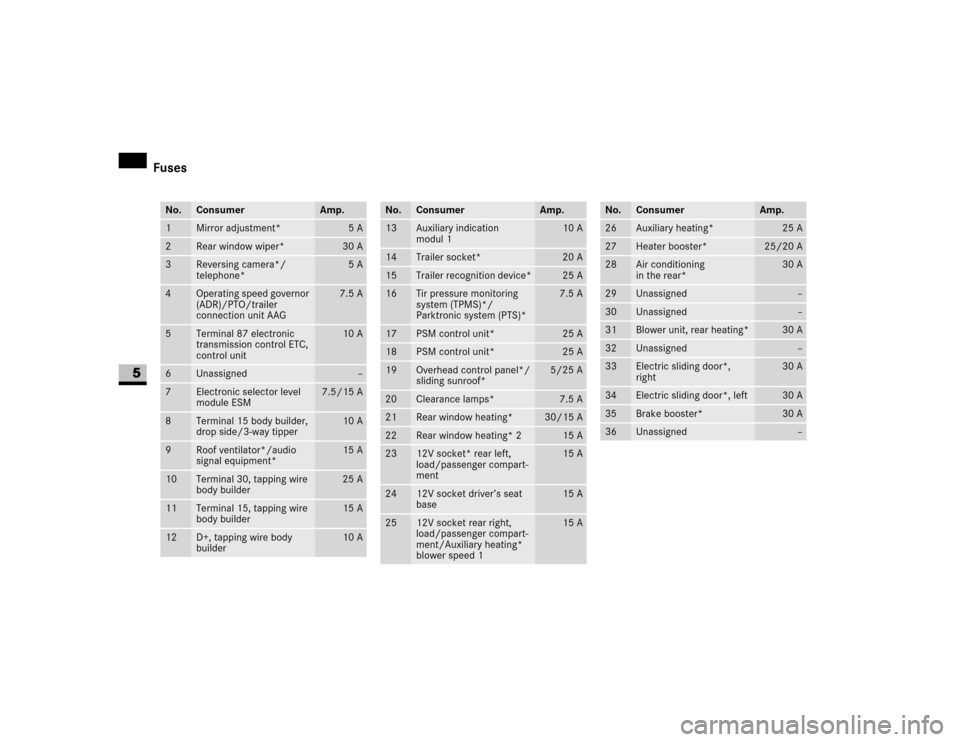

No.

Consumer

Amp.

1

Mirror adjustment*

5A

2

Rear window wiper*

30 A

3

Reversing camera*/

telephone*

5A

4

Operating speed governor

(ADR)/PTO/trailer

connection unit AAG

7.5 A

5

Terminal 87 electronic

transmission control ETC,

control unit

10 A

6

Unassigned

–

7

Electronic selector level

module ESM

7.5/15 A

8

Terminal 15 body builder,

drop side/3-way tipper

10 A

9

Roof ventilator*/audio

signal equipment*

15 A

10

Terminal 30, tapping wire

body builder

25 A

11

Terminal 15, tapping wire

body builder

15 A

12

D+, tapping wire body

builder

10 A

No.

Consumer

Amp.

13

Auxiliary indication

modul 1

10 A

14

Trailer socket*

20 A

15

Trailer recognition device*

25 A

16

Tir pressure monitoring

system (TPMS)*/

Parktronic system (PTS)*

7.5 A

17

PSM control unit*

25 A

18

PSM control unit*

25 A

19

Overhead control panel*/

sliding sunroof*

5/25 A

20

Clearance lamps*

7.5 A

21

Rear window heating*

30/15 A

22

Rear window heating* 2

15 A

23

12V socket* rear left,

load/passenger compart-

ment

15 A

24

12V socket driver’s seat

base

15 A

25

12V socket rear right,

load/passenger compart-

ment/Auxiliary heating*

blower speed 1

15 A

No.

Consumer

Amp.

26

Auxiliary heating*

25 A

27

Heater booster*

25/20 A

28

Air conditioning

in the rear*

30 A

29

Unassigned

–

30

Unassigned

–

31

Blower unit, rear heating*

30 A

32

Unassigned

–

33

Electric sliding door*,

right

30 A

34

Electric sliding door*, left

30 A

35

Brake booster*

30 A

36

Unassigned

–

Fuses

Page 363 of 393

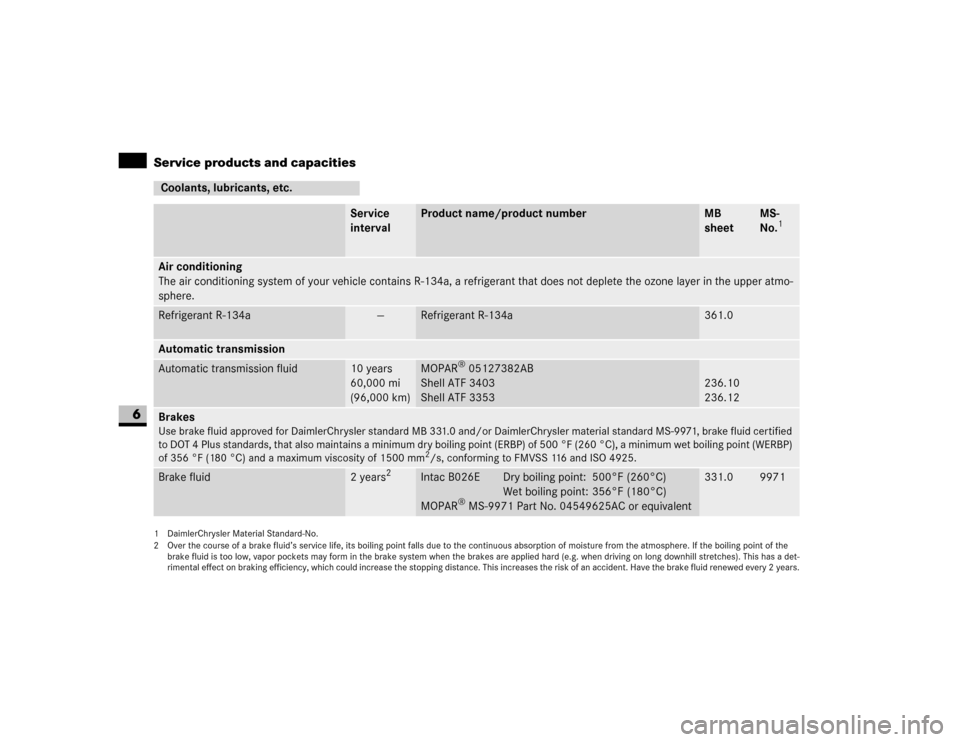

362 *Technical dataService products and capacities

6

Coolants, lubricants, etc.

Service

interval

Product name/product number

MB

sheet

MS-

No.

1

Air conditioning

The air conditioning system of your vehicle contains R-134a, a refrigerant that does not deplete the ozone layer in the upper atmo-

sphere.Refrigerant R-134a

—

Refrigerant R-134a

361.0

Automatic transmissionAutomatic transmission fluid

10 years

60,000 mi

(96,000 km)

MOPAR

® 05127382AB

Shell ATF 3403

Shell ATF 3353

236.10

236.12

BrakesUse brake fluid approved for DaimlerChrysler standard MB 331.0 and/or DaimlerChrysler material standard MS-9971, brake fluid certified

to DOT 4 Plus standards, that also maintains a minimum dry boiling point (ERBP) of 500 °F (260°C), a minimum wet boiling point (WERBP)

of 356 °F (180 °C) and a maximum viscosity of 1500 mm

2/s, conforming to FMVSS 116 and ISO 4925.

Brake fluid

2 years

2

Intac B026E Dry boiling point: 500°F (260°C)

Wet boiling point: 356°F (180°C)

MOPAR

® MS-9971 Part No. 04549625AC or equivalent

331.0

9971

1 DaimlerChrysler Material Standard-No.

2 Over the course of a brake fluid’s service life, its boiling point falls due to the continuous absorption of moisture from the atmosphere. If the boiling point of the

brake fluid is too low, vapor pockets may form in the brake system when the brakes are applied hard (e.g. when driving on long downhill stretches). This has a det-

rimental effect on braking efficiency, which could increase the stopping distance. This increases the risk of an accident. Have the brake fluid renewed every 2 years.