weight DODGE SPRINTER 2007 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2007, Model line: SPRINTER, Model: DODGE SPRINTER 2007 2.GPages: 393, PDF Size: 7.61 MB

Page 231 of 393

230 OperationTires and wheels

4

Production options weight

The combined weight of those installed

regular production options weighing over

5 lbs (2.3 kilograms) in excess of those

standard items which they replace, not

previously considered in curb weight or ac-

cessory weight, including heavy duty

brakes, ride levelers, roof rack, heavy duty

battery, and special trim.

PSI (P

ounds per S

quare I

nch)

A standard unit of measure for air pres-

sure. Another metric unit for air pressure is

bar or kilopascal (kPa).

Recommended tire inflation pressure

Recommended tire inflation pressure list-

ed on the placard located on driver’s door

B-pillar for normal driving conditions. Pro-

vides best handling, tread life and riding

comfort.Rim

A metal support for a tire or a tire and tube

assembly upon which the tire beads are

seated.

Side wall

The portion of a tire between the tread and

the bead.

TIN (T

ire I

dentification N

umber)

Unique identifier which facilitates efforts

by tire manufacturers to notify purchasers

in recall situations or other safety matters

concerning tires and gives purchases the

means to easily identify such tires. The TIN

is comprised of the “manufacturer’s identi-

fication mark”, “tire size”, “tire type code”

and “date of manufacture”.

Tire load rating

Numerical code associated with the maxi-

mum load a tire can support.Tire ply composition and material used

This indicates the number of plies or the

number of layers of rubber-coated fabric in

the tire tread and side wall. Tire manufac-

turers also must indicate the ply materials

in the tire and side wall, which include

steel, nylon, polyester, and others.

Tire speed rating

Part of tire designation; indicates the

speed range for which a tire is approved.

Traction

Force exerted by the vehicle on the road

via the tires. The amount of grip provided.

Tread

The portion of a tire that comes into con-

tact with the road.

Treadwear Indicators

Narrow bands, sometimes called

“wear bars” that show across the tread of

a tire when only

1/16

in (1.6 mm) of tread

remains.

Page 232 of 393

231 Operation

Tires and wheels

4

TWR (T

ongue W

eight R

ating)

Maximum permissible weight on the trailer

tongue.

Uniform tire quality grading standards

A tire information system that provides

consumers with ratings for a tire’s traction,

temperature and treadwear. Ratings are

determined by tire manufacturers using

government testing procedures. The rat-

ings are molded into the side wall of the

tire.

Vehicle capacity weight

Rated cargo and luggage load plus

68 kilograms (150 lbs) times the vehicle’s

designated seating capacity.

Vehicle maximum load on the tire

Load on an individual tire that is deter-

mined by distributing to each axle its share

of the maximum loaded vehicle weight and

dividing it by two.

Tires on the front and rear axles of vehicles

operate at different loads and perform dif-

ferent steering, driving and braking func-

tions. For these reasons, they wear at unequal rates, and develop irregular wear

patterns. These effects can be reduced by

timely rotation of tires.

The benefits of rotation are especially

worthwhile with aggressive tread designs

such as those on On/Off Road type tires.

Rotation will increase tread life, help to

maintain mud, snow, and wet traction lev-

els, and contribute to a smooth ride.

If applicable to your vehicle’s tire configu-

ration, tires can be rotated according to

the tire manufacturer’s recommended in-

tervals in the tire manufacturer’s warranty

pamphlet located in your vehicle literature

portfolio. If none is available, tires should

be rotated every 10,000 miles

(16,000 km), or sooner if necessary, ac-

cording to the degree of tire wear.

The same rotation (spinning) direction

must be maintained when mounted, see

"Direction of rotation" (\2page 204).

Rotate tires before the characteristic tire

wear pattern becomes visible (shoulder

wear on front tires and tread center wear

on rear tires).

Rotating tiresWarning

G

Rotate front and rear wheels only if they are

of the same dimension.

Changing the tire dimension for an axle

\4could cause the tire to come into con-

tact with the vehicle body or axle parts.

Damage to the tire or the vehicle may be

the result.

\4could result in changes to steering, han-

dling, and braking of your Sprinter vehi-

cle. This can cause unpredictable

handling and stress to steering and sus-

pension components. You could lose

control and have an accident resulting in

serious injury or death.

\4could result in tire overloading and fail-

ure, if the tires' load index are not iden-

tical. You could lose control and have an

accident.

Page 244 of 393

243 Operation

Cleaning and care of the vehicle

4

Steps

Engine cleaningLight-alloy wheels*

Clean light-alloy wheels on a regular basis.

Outside of windshield and wiper blades

\1Turn key to position1 in ignition lock

(\2page 67).

\1Switch on windshield wipers

(\2page 126).

\1When the wiper arms are vertical, turn

key to position0 in the ignition lock or

remove the key.

\1Fold the wiper arms away from the

windshield until you feel them engage

in place.\1You can now clean the windshield and

the wiper blades.

\1Fold the windshield wipers back again

before you switch on the ignition.Warning

G

Dirty or iced-up steps and entrances create

a risk of slipping or falling.

Keep steps, entrances and footwear free

from dirt (e.g. mud, clay, snow and ice).!

CAUTION

Do not allow water to enter the intake

and ventilation openings.

When cleaning with high-pressure wa-

ter or steam cleaners, the spray must

not be aimed directly at electrical com-

ponents or at the end of electrical

lines.

Treat the engine with preservative

agents after cleaning. Protect the belt

drive system from the preservative

when you do so.

!

CAUTION

Do not use any acidic or alkaline clean-

ing agents. They can cause corrosion of

the wheel bolts (wheel nuts) or the bal-

ancing weight retainers.

!

CAUTION

Do not fold the windshield wipers away

from the windshield unless the hood is

closed. You will otherwise damage the

hood.

Warning

G

Switch off the ignition before cleaning the

windshield or the wiper blades. The wind-

shield wipers could otherwise move and in-

jure you.

Page 342 of 393

341 Practical hints

Jump-starting

5

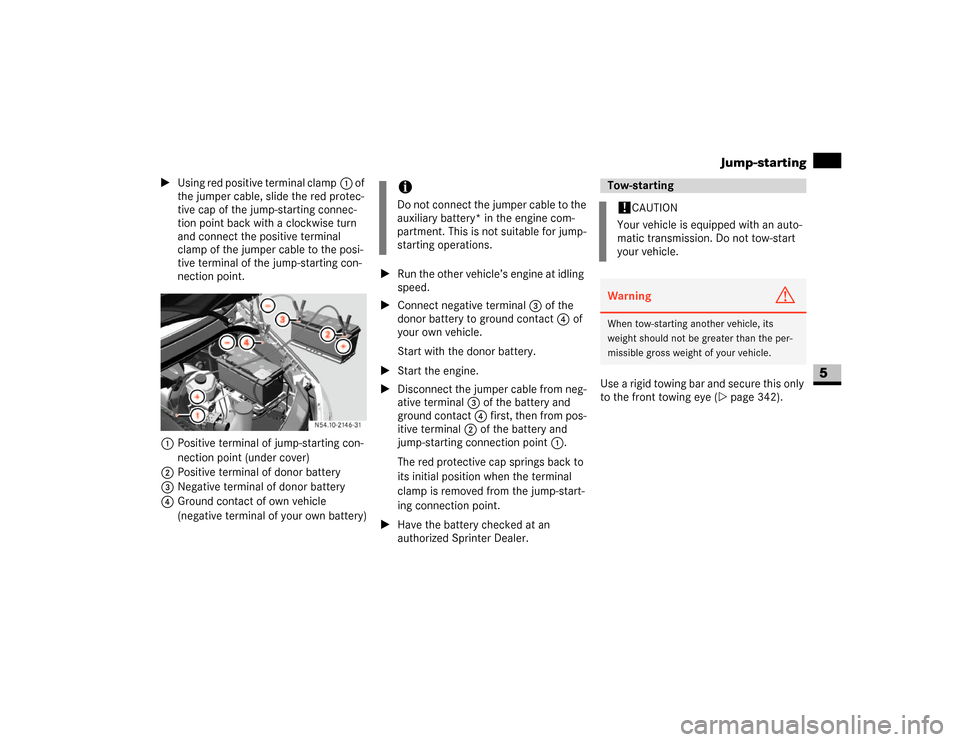

\1Using red positive terminal clamp1 of

the jumper cable, slide the red protec-

tive cap of the jump-starting connec-

tion point back with a clockwise turn

and connect the positive terminal

clamp of the jumper cable to the posi-

tive terminal of the jump-starting con-

nection point.

1Positive terminal of jump-starting con-

nection point (under cover)

2Positive terminal of donor battery

3Negative terminal of donor battery

4Ground contact of own vehicle

(negative terminal of your own battery)\1Run the other vehicle’s engine at idling

speed.

\1Connect negative terminal3 of the

donor battery to ground contact4 of

your own vehicle.

Start with the donor battery.

\1Start the engine.

\1Disconnect the jumper cable from neg-

ative terminal3 of the battery and

ground contact 4 first, then from pos-

itive terminal 2 of the battery and

jump-starting connection point 1.

The red protective cap springs back to

its initial position when the terminal

clamp is removed from the jump-start-

ing connection point.

\1Have the battery checked at an

authorized Sprinter Dealer.Use a rigid towing bar and secure this only

to the front towing eye (\2page 342).

iDo not connect the jumper cable to the

auxiliary battery* in the engine com-

partment. This is not suitable for jump-

starting operations.

Tow-starting!

CAUTION

Your vehicle is equipped with an auto-

matic transmission. Do not tow-start

your vehicle.

Warning

G

When tow-starting another vehicle, its

weight should not be greater than the per-

missible gross weight of your vehicle.

Page 343 of 393

342 Practical hintsTowing

5

\3 TowingComply with legal regulations when tow-

ing.

Having the vehicle carried away on a trans-

porter or trailer is preferable to towing it

away. We recommend the use of a rigid

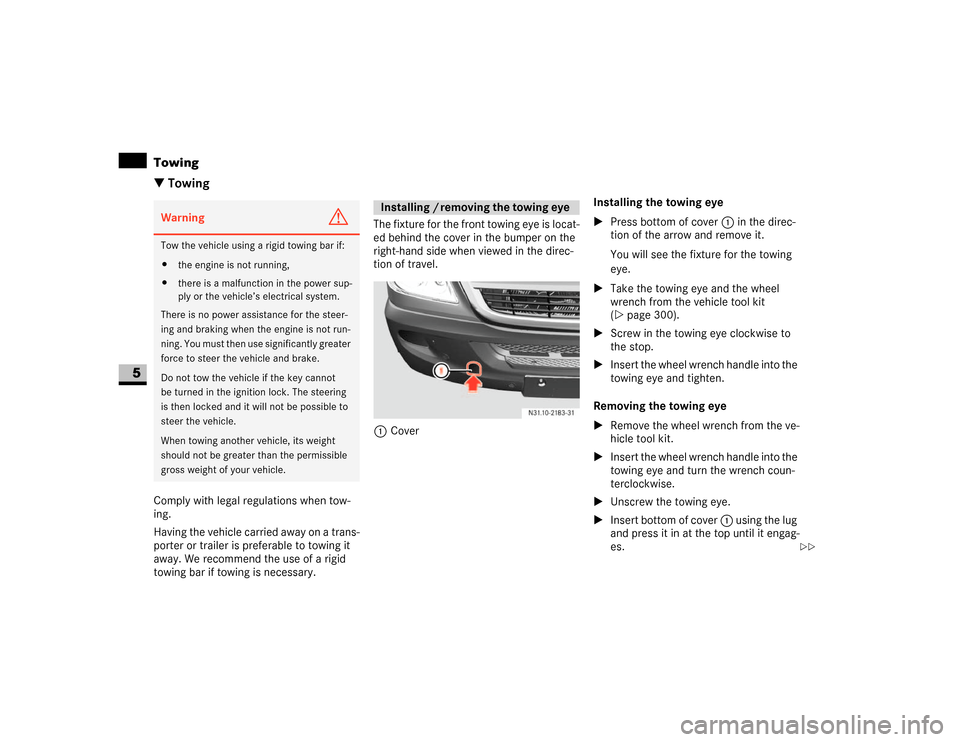

towing bar if towing is necessary.The fixture for the front towing eye is locat-

ed behind the cover in the bumper on the

right-hand side when viewed in the direc-

tion of travel.

1CoverInstalling the towing eye

\1Press bottom of cover1 in the direc-

tion of the arrow and remove it.

You will see the fixture for the towing

eye.

\1Take the towing eye and the wheel

wrench from the vehicle tool kit

(\2page 300).

\1Screw in the towing eye clockwise to

the stop.

\1Insert the wheel wrench handle into the

towing eye and tighten.

Removing the towing eye

\1Remove the wheel wrench from the ve-

hicle tool kit.

\1Insert the wheel wrench handle into the

towing eye and turn the wrench coun-

terclockwise.

\1Unscrew the towing eye.

\1Insert bottom of cover 1 using the lug

and press it in at the top until it engag-

es.Warning

G

Tow the vehicle using a rigid towing bar if:

\4the engine is not running,

\4there is a malfunction in the power sup-

ply or the vehicle’s electrical system.

There is no power assistance for the steer-

ing and braking when the engine is not run-

ning. You must then use significantly greater

force to steer the vehicle and brake.

Do not tow the vehicle if the key cannot

be turned in the ignition lock. The steering

is then locked and it will not be possible to

steer the vehicle.

When towing another vehicle, its weight

should not be greater than the permissible

gross weight of your vehicle.

Installing / removing the towing eye

\2\2

Page 353 of 393

352 *Technical dataGenuine Sprinter parts

6

\3 Genuine Sprinter parts The “Technical data” section contains im-

portant technical data regarding your vehi-

cle.

You will find other vehicle-specific and

equipment-dependent technical data, such

as:

\4engine power output data

\4speeds

\4vehicle dimensions

\4vehicle weights

in your vehicle documents.Make sure that spare parts are suitable for

your vehicle. Parts that constitute a modi-

fication to the vehicle by:

\4changing the type of vehicle approved

in the general operating permit,

\4creating a risk to road users or

\4having an adverse effect on the vehi-

cle’s emissions and noise levels,

will in many countries invalidate the gen-

eral operating permit. The use of non-

approved parts could have a detrimental

effect on road safety.Every authorized Sprinter Dealer maintains

a stock of genuine sprinter parts for main-

tenance and repair work.

Over 6000 retailers around the world guar-

antee that you can be supplied with genu-

ine sprinter parts wherever you are. Over

300,000 different parts and assemblies,

including parts for older vehicle models,

are distributed from a central parts ware-

house using an optimally tuned logistics

concept.

Page 368 of 393

367 *Technical data

Rims and tires

6

\3 Rims and tires

!

CAUTION

Only use tires which have been tested

and approved for your Sprinter vehicle

by the vehicle manufacturer. Tires ap-

proved by the vehicle manufacturer are

developed to provide the best possible

performance in conjunction with the

driving safety systems on your Sprinter

vehicle such as ABS, BAS, ASR or ESP

®.

Using tires other than those approved

by the vehicle manufacturer may result

in damage that is not covered by the

Sprinter warranty.

Using tires other than those approved

by the vehicle manufacturer can have

detrimental effects, such as

\4poor handling characteristics

\4increased noise

\4increased fuel consumption

Moreover, tires and rims not approved

by the vehicle manufacturer may, un-

der load, exhibit dimensional variations

and different tire deformation charac-

teristics that could cause them to come

into contact with the vehicle body or

axle parts. Damage to the tires or the

vehicle may be the result.

Warning

G

Loose wheel nuts or bolts could cause the

vehicle to lose a wheel while it is in motion.

This would jeopardize the operating and

road safety of the vehicle. You could lose

control of the vehicle as a result, cause an

accident an injure yourself or others.

If a wheel was replaced or new wheel nuts

are used, the wheel bolts or wheel nuts must

be retightened to the specified tightening

torque after 30 miles (50 km).

If new or repainted wheels are mounted, the

wheel bolts or wheel nuts must be retight-

ened again to the specified tightening

torque after approximately 600 to 3000

miles (about 1000 to 5000 km).

iFurther information on tires and rims is

available at any authorized Sprinter

Dealer. A placard with the recommend-

ed tire inflation pressures is located on

\4the driver’s door B-pillar for vehi-

cles with a gross weight capacity

less than 10,000 lbs (4500 kg)

(\2page 375)

\4on a label below the driver’s seat on

an outward facing position of the

mounting pillar for vehicles with a

gross weight capacity above

10,000 lbs (4500 kg) (\2page 375)

The tire inflation pressure should be

checked regularly and should only be

adjusted on cold tires.

Page 370 of 393

369 *Technical data

Tire inflation pressure

6

\3 Tire inflation pressureFor vehicles with a gross weight capacity

above 10,000 lbs (4500 kg) only.

For vehicles with a gross weight capacity

less than 10,000 lbs (4500 kg) observe the

recommended cold tire inflation pressures

listed on the tire and loading information

placard on the driver’s door B-pillar

(\2page 210).

Observe the information on recommended

tyre inflation pressure in the “Operation”

section (\2page 210).

The following table lists the recommended

cold tire inflation pressures for all load

conditions up to the maximum permissible

weight limits (GAWR). The tire inflation

pressures listed apply to the tires installed

as original equipment.

Set the correct tyre pressure before load-

ing the vehicle. If the vehicle has been

loaded, check the tyre pressures and cor-

rect them if necessary.The tires can be considered cold if the ve-

hicle has been parked for at least 3 hours

or driven less than 1 mile (1.6 km) at an

ambient temperature of approximately

68 °F (20 °C).

Keeping the tires properly inflated pro-

vides the best handling, tread life and

riding comfort.

Tire temperature and tire inflation pressure

are also increased while driving, depending

on the driving speed and the tire load.

Tire inflation pressure changes by approxi-

mately 1.5 psi (0.1 bar) per 18 °F (10 °C)

of air temperature change. Keep this in

mind when checking tire inflation pressure

where the temperature is different from

the outside temperature.

iIn addition to the following table the

recommended cold tire inflation pres-

sures are listed on a label below the

driver’s seat on an outward facing posi-

tion of the mounting pillar.

Warning

G

Follow recommended tire inflation pres-

sures.

Do not underinflate tires. Underinflated tires

wear excessively and/or unevenly, adverse-

ly affect handling and fuel economy, and are

more likely to fail from being overheated.

Do not overinflate tires. Overinflated tires

can adversely affect handling and ride com-

fort, wear unevenly, increase stopping dis-

tance, and result in sudden deflation

(blowout) because they are more likely to

become punctured or damaged by road de-

bris, potholes etc.

Page 372 of 393

371 *Technical data

Lashing points and carrier systems

6

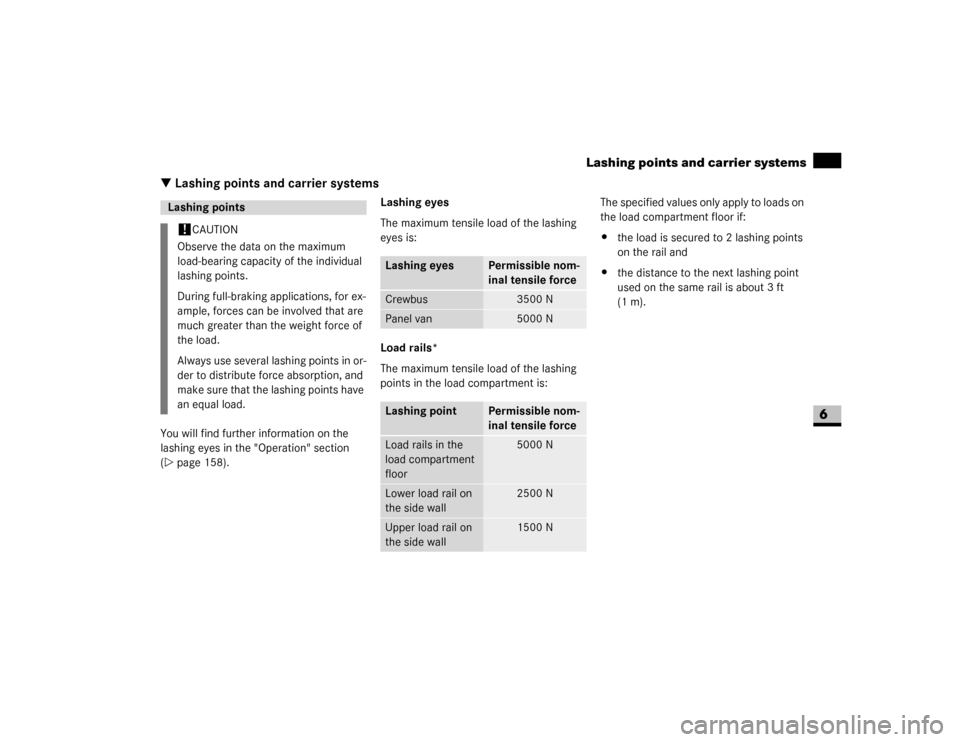

\3 Lashing points and carrier systemsYou will find further information on the

lashing eyes in the "Operation" section

(\2page 158).Lashing eyes

The maximum tensile load of the lashing

eyes is:

Load rails*

The maximum tensile load of the lashing

points in the load compartment is:The specified values only apply to loads on

the load compartment floor if:

\4the load is secured to 2 lashing points

on the rail and

\4the distance to the next lashing point

used on the same rail is about 3 ft

(1 m).Lashing points!

CAUTION

Observe the data on the maximum

load-bearing capacity of the individual

lashing points.

During full-braking applications, for ex-

ample, forces can be involved that are

much greater than the weight force of

the load.

Always use several lashing points in or-

der to distribute force absorption, and

make sure that the lashing points have

an equal load.

Lashing eyes

Permissible nom-

inal tensile force

Crewbus

3500 N

Panel van

5000 N

Lashing point

Permissible nom-

inal tensile force

Load rails in the

load compartment

floor

5000 N

Lower load rail on

the side wall

2500 N

Upper load rail on

the side wall

1500 N

Page 373 of 393

372 *Technical dataLashing points and carrier systems

6

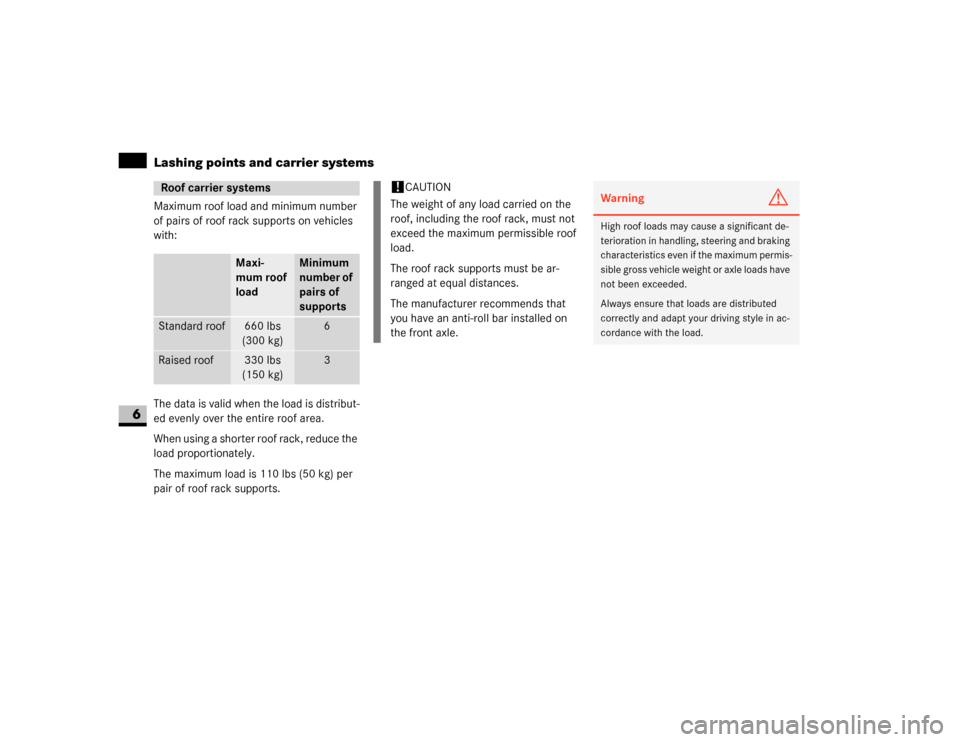

Maximum roof load and minimum number

of pairs of roof rack supports on vehicles

with:

The data is valid when the load is distribut-

ed evenly over the entire roof area.

When using a shorter roof rack, reduce the

load proportionately.

The maximum load is 110 lbs (50 kg) per

pair of roof rack supports.Roof carrier systems

Maxi-

mum roof

load

Minimum

number of

pairs of

supports

Standard roof

660 lbs

(300 kg)

6

Raised roof

330 lbs

(150 kg)

3

!

CAUTION

The weight of any load carried on the

roof, including the roof rack, must not

exceed the maximum permissible roof

load.

The roof rack supports must be ar-

ranged at equal distances.

The manufacturer recommends that

you have an anti-roll bar installed on

the front axle.

Warning

G

High roof loads may cause a significant de-

terioration in handling, steering and braking

characteristics even if the maximum permis-

sible gross vehicle weight or axle loads have

not been exceeded.

Always ensure that loads are distributed

correctly and adapt your driving style in ac-

cordance with the load.