wheel DODGE SPRINTER 2008 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: SPRINTER, Model: DODGE SPRINTER 2008 2.GPages: 666, PDF Size: 14.11 MB

Page 557 of 666

555 Practical hints

Flat tire

5

Vehicles with wheel caps:

Make sure that the opening in the

wheel cap is positioned over the tire

vent.

Vehicles with center caps:

Make sure that the retaining lugs of

the hub cap are positioned over the

bolts.

\1

Compress the piston of the hydraulic

jack and close the pressure release

screw.

\1

Store the jack and the remaining ve-

hicle tools.

\1

Place the defective wheel in the

spare wheel bracket after changing

the wheel (

\2

page 517).

\1

Check the tire pressure

(\2

page 361).

\1

Retighten the wheel bolts and wheel

nuts to the specified tightening

torque once the vehicle has been

driven for 30 miles (50 km).

iGive the middle of the center cap a

knock to engage it on the wheel.

Warning

G

For safety reasons, you must observe the

following after changing a wheel:Have the tightening torque checked:for wheel bolts 177 lb-ft (240 Nm) (steel

wheel)/133 lb-ft (180 Nm) (light-alloy

wheel) orfor wheel nuts133 lb-ft (180 Nm).The wheels could otherwise come loose.

Continued

nf_BA.book Page 555 Friday, January 25, 2008 3:53 PM

Page 558 of 666

556 Practical hintsFlat tire

5

Warning (Continued)

G

Check the tire pressure and correct it if

necessaryHave the wheel bolts or wheel nuts re-

tightened after 30 miles (50 km) to a

torque of:177 lb-ft (240 Nm) (steel wheel)/ 133 lb-

ft (180 Nm) (light-alloy wheel) for wheel

bolts or133 lb-ft (180 Nm) for wheel nuts.

Continued

Warning (Continued)

G

Have the direction of tire rotation correct-

ed, if reversed, as soon as possible at an

authorized Sprinter Dealer. The vehicle

handling characteristics could otherwise

be affected.

Warning

G

Loose wheel nuts or bolts could cause the

vehicle to lose a wheel while it is in mo-

tion. This would jeopardize the operating

and road safety of the vehicle. You could

lose control of the vehicle as a result,

cause an accident and injure yourself or

others.

If new or repainted wheels are mounted,

the wheel bolts or wheel nuts must be re-

tightened again after approximately 600

to 3000 miles (about 1000 to 5000 km).

nf_BA.book Page 556 Friday, January 25, 2008 3:53 PM

Page 562 of 666

560 Practical hintsFlat tire

5

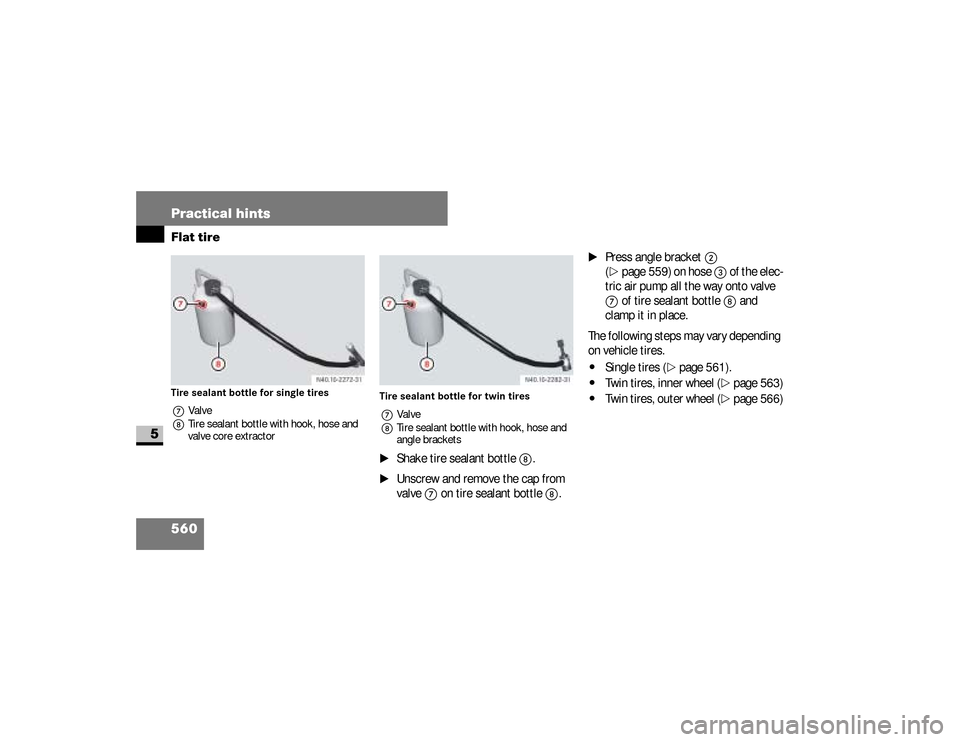

Tire sealant bottle for single tires

7Valve

8Tire sealant bottle with hook, hose and

valve core extractorTire sealant bottle for twin tires

7Valve

8Tire sealant bottle with hook, hose and

angle brackets

\1

Shake tire sealant bottle

8

.

\1

Unscrew and remove the cap from

valve

7

on tire sealant bottle

8

.

\1

Press angle bracket

2

(

\2

page 559) on hose

3

of the elec-

tric air pump all the way onto valve

7

of tire sealant bottle

8

and

clamp it in place.

The following steps may vary depending

on vehicle tires.

\4

Single tires (

\2

page 561).

\4

Twin tires, inner wheel (

\2

page 563)

\4

Twin tires, outer wheel (

\2

page 566)

nf_BA.book Page 560 Friday, January 25, 2008 3:53 PM

Page 563 of 666

561 Practical hints

Flat tire

5

Single tire

9

Hook

a

Knob

b

Lever

c

Valve core extractor

d

Tire valve

\1

Pull knob

a

out of valve core extrac-

tor

c

as far as the stop.

\1

Unscrew and remove the valve cap

from tire valve

d

on the flat tire.

\1

Hook the tire sealant bottle into the

upper vent hole in the wheel using

hook

9

.

\1

Keep lever

b

pressed, connect

valve core extractor

c

firmly to tire

valve

d

and release lever

b

.

\1

Press knob

a

into the valve core of

tire valve

d

, turning it gently as you

do so, until the shaft of valve core

extractor

c

engages.

\1

Turn knob

a

counterclockwise until

the valve core is unscrewed.

\1

Pull knob

a

out of valve core extrac-

tor

c

as far as the stop.

\1

This pulls the valve core into the

valve core extractor and seals it

against the valve core extractor stop.

\1

Make sure that the pressure release

screw on pressure gauge

5

is

closed.

\1

Connect connector

6

to the 12 V

socket (12 V, 25 A, 300 watts) on

the center console (

\2

page 297).

nf_BA.book Page 561 Friday, January 25, 2008 3:53 PM

Page 565 of 666

563 Practical hints

Flat tire

5

\1

Press lever

b

and remove valve

core extractorc

from tire valve

d

.

\1

Screw the valve cap onto tire

valve

d

.

After filling with tire sealant

(

\2

page 570).

Twin tires, inner wheel

9

Valve extension

a

Valve core extractor

\1

Unscrew and remove the valve cap

from valve extension

9

on the flat

tire.

\1

Screw valve core extractor

a

clock-

wise all the way onto valve

extension

9

.

\1

Continue to screw valve core

extractor

a

about half a rotation to

loosen the valve extension.

\1

Unscrew and remove the valve ex-

tension and valve core extractor

counterclockwise from tire valve.

\1

Unscrew and remove the valve ex-

tension from the valve core extrac-

tor.

nf_BA.book Page 563 Friday, January 25, 2008 3:53 PM

Page 566 of 666

564 Practical hintsFlat tire

5

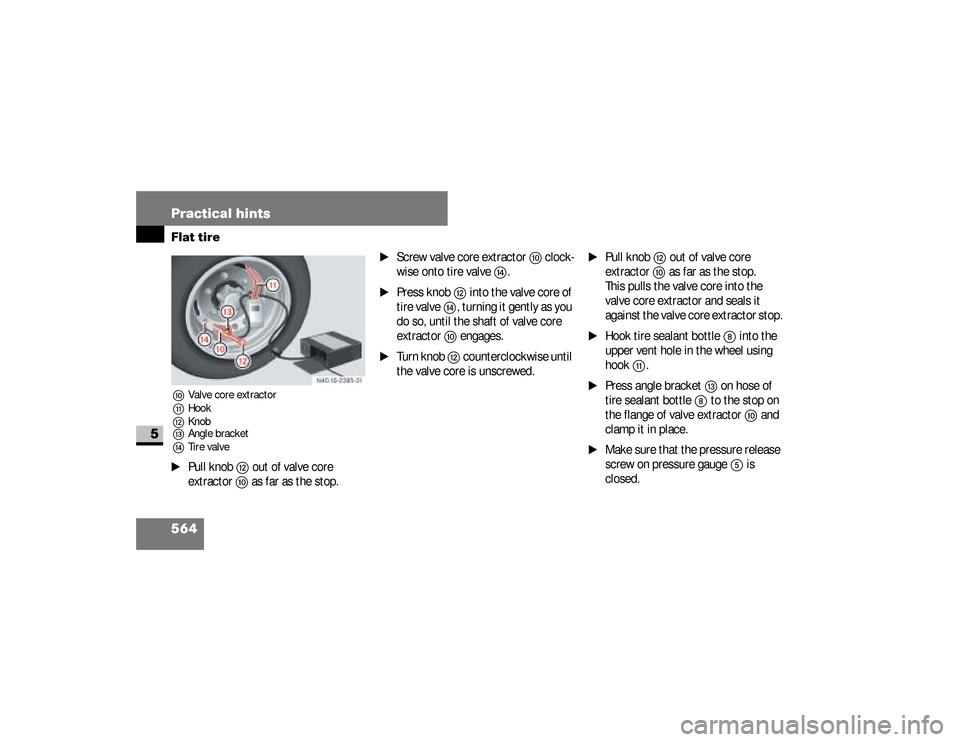

aValve core extractor

bHook

cKnob

dAngle bracket

eTire valve\1

Pull knob

c

out of valve core

extractor

a

as far as the stop.

\1

Screw valve core extractor

a

clock-

wise onto tire valve

e

.

\1

Press knob

c

into the valve core of

tire valve

e

, turning it gently as you

do so, until the shaft of valve core

extractor

a

engages.

\1

Turn knob

c

counterclockwise until

the valve core is unscrewed.

\1

Pull knob

c

out of valve core

extractor

a

as far as the stop.

This pulls the valve core into the

valve core extractor and seals it

against the valve core extractor stop.

\1

Hook tire sealant bottle

8

into the

upper vent hole in the wheel using

hook

b

.

\1

Press angle bracket

d

on hose of

tire sealant bottle

8

to the stop on

the flange of valve extractor

a

and

clamp it in place.

\1

Make sure that the pressure release

screw on pressure gauge

5

is

closed.

nf_BA.book Page 564 Friday, January 25, 2008 3:53 PM

Page 568 of 666

566 Practical hintsFlat tire

5

\1

Turn knob

c

clockwise until the

valve core is firmly screwed into tire

valve

e

.

\1

Pull knob

c

out of valve core

extractor

a

as far as the stop.

\1

Unscrew valve core extractor

a

counterclockwise and remove it

from tire valve

e

.

\1

Screw valve extension

9

onto tire

valve

e

and tighten.

\1

Screw the valve cap onto valve

extension

9

.

After filling with tire sealant

(

\2

page 570).

Twin tires, outer wheelThe tire valve is on the inside of the out-

er wheel and should be horizontal on the

left-hand side of the vehicle for the re-

pair procedure.Valve tool with handle and turning work-

piece

iDo not unscrew the valve core ex-

tractor from the tire valve while the

valve core is unscrewed from the tire

valve. Tire sealant could otherwise

escape onto your hands.

The tire sealant is water soluble. If

tire sealant escapes, you can wash it

away with water.

nf_BA.book Page 566 Friday, January 25, 2008 3:53 PM

Page 569 of 666

567 Practical hints

Flat tire

5

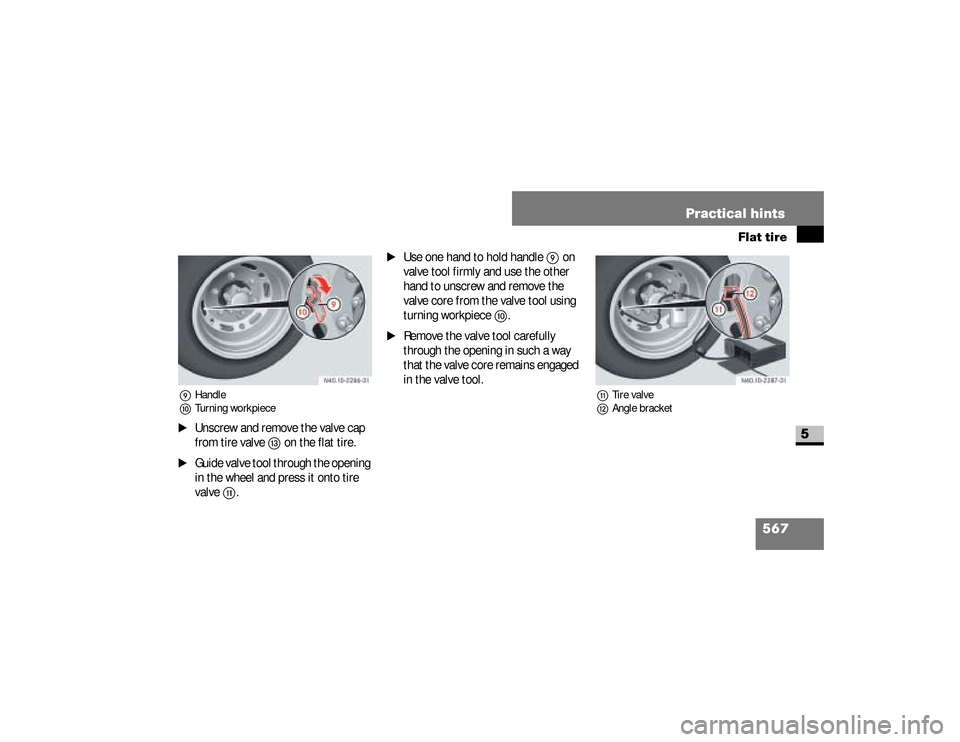

9Handle

aTurning workpiece\1

Unscrew and remove the valve cap

from tire valve

d

on the flat tire.

\1

Guide valve tool through the opening

in the wheel and press it onto tire

valve

b

.

\1

Use one hand to hold handle

9

on

valve tool firmly and use the other

hand to unscrew and remove the

valve core from the valve tool using

turning workpiece

a

.

\1

Remove the valve tool carefully

through the opening in such a way

that the valve core remains engaged

in the valve tool.

bTire valve

cAngle bracket

nf_BA.book Page 567 Friday, January 25, 2008 3:53 PM

Page 570 of 666

568 Practical hintsFlat tire

5

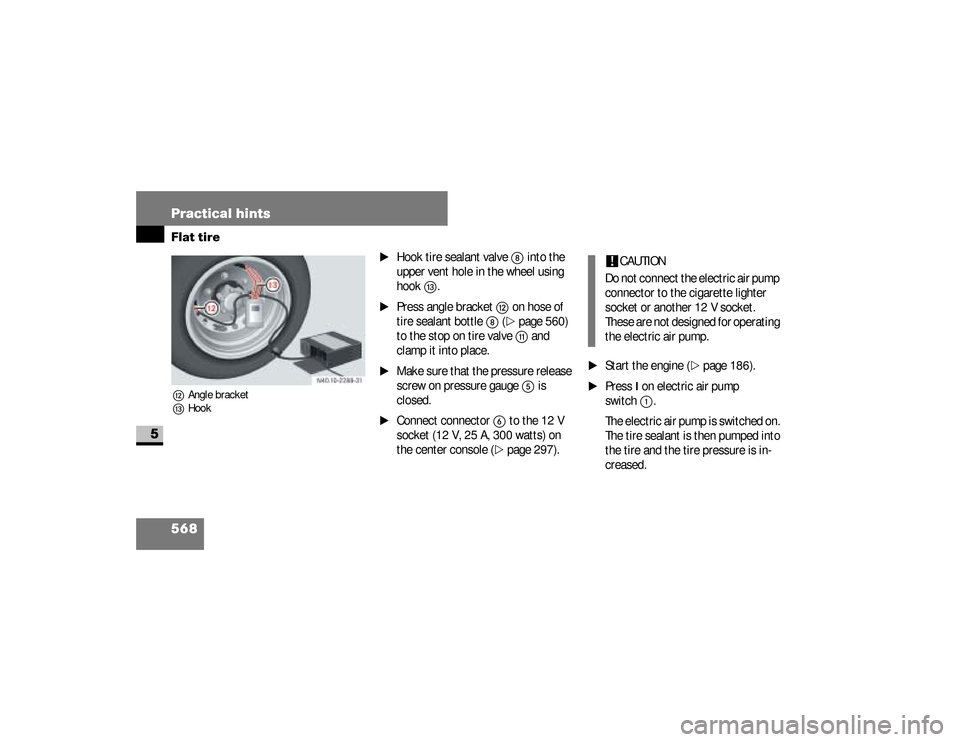

cAngle bracket

dHook

\1

Hook tire sealant valve

8

into the

upper vent hole in the wheel using

hook

d

.

\1

Press angle bracket

c

on hose of

tire sealant bottle

8

(\2

page 560)

to the stop on tire valveb

and

clamp it into place.

\1

Make sure that the pressure release

screw on pressure gauge

5

is

closed.

\1

Connect connector

6

to the 12 V

socket (12 V, 25 A, 300 watts) on

the center console (

\2

page 297).

\1

Start the engine (

\2

page 186).

\1

Press

I on electric air pump

switch1

.

The electric air pump is switched on.

The tire sealant is then pumped into

the tire and the tire pressure is in-

creased.

!

CAUTION

Do not connect the electric air pump

connector to the cigarette lighter

socket or another 12 V socket.

These are not designed for operating

the electric air pump.

nf_BA.book Page 568 Friday, January 25, 2008 3:53 PM

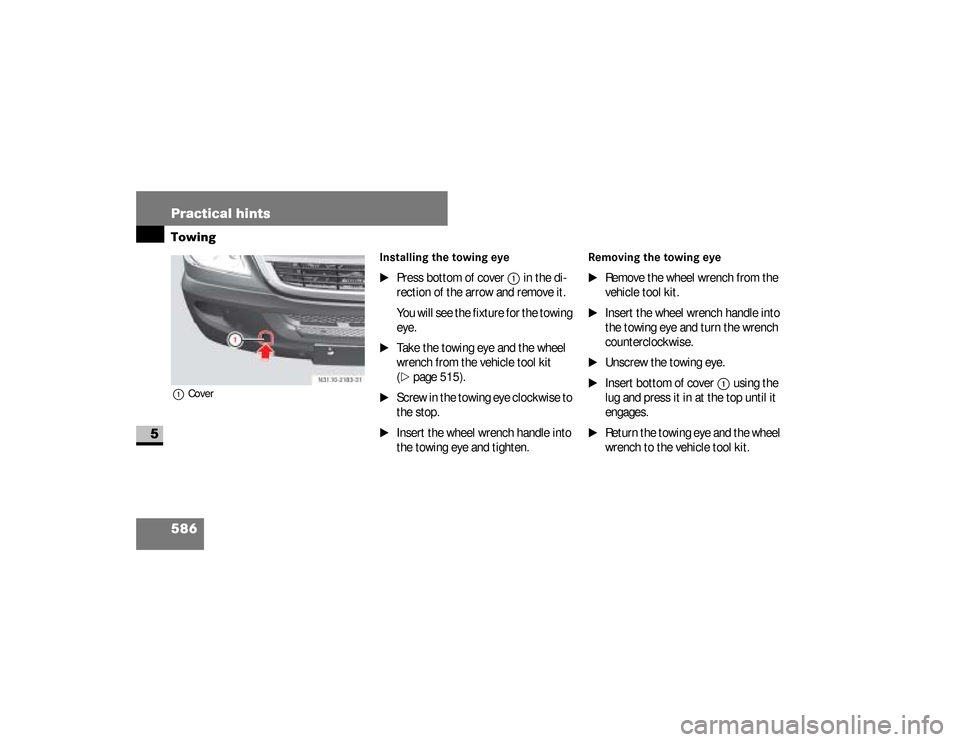

Page 588 of 666

586 Practical hintsTowing

5

1Cover

Installing the towing eye

\1

Press bottom of cover

1

in the di-

rection of the arrow and remove it.

You will see the fixture for the towing

eye.

\1

Take the towing eye and the wheel

wrench from the vehicle tool kit

(\2

page 515).

\1

Screw in the towing eye clockwise to

the stop.

\1

Insert the wheel wrench handle into

the towing eye and tighten.

Removing the towing eye

\1

Remove the wheel wrench from the

vehicle tool kit.

\1

Insert the wheel wrench handle into

the towing eye and turn the wrench

counterclockwise.

\1

Unscrew the towing eye.

\1

Insert bottom of cover

1

using the

lug and press it in at the top until it

engages.

\1

Return the towing eye and the wheel

wrench to the vehicle tool kit.

nf_BA.book Page 586 Friday, January 25, 2008 3:53 PM