ECU DODGE STRATUS COUPE 2004 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: STRATUS COUPE, Model: DODGE STRATUS COUPE 2004 2.GPages: 388, PDF Size: 2.28 MB

Page 158 of 388

Transaxle Reset Mode

The transaxle is monitored for abnormal conditions. If a

condition is detected that could cause damage, the trans-

axle automatically shifts into second gear. The transaxle

remains in second gear despite the forward gear selected.

Park (P), Reverse (R), and Neutral (N) will continue to

operate. This Reset feature allows the vehicle to be driven

to a dealer for service without damaging the transaxle.

If the problem has been momentary, the transaxle can be

reset to regain all forward gears.

²Stop the vehicle and shift into PARK (P).

²Turn the key to OFF then start the engine.

²Shift into ªDº and resume driving.

NOTE:Even if the transaxle can be reset, we recom-

mend that you visit a dealer at your earliest possible

convenience. Your dealer has diagnostic equipment to

determine if the problem could recur.

If the transaxle cannot be reset, dealer service is required.

AUTOMATIC TRANSAXLE AUTOSTICK

(IF SO EQUIPPED)

Designed for optimum control and equipped with adap-

tive control capabilities, the electronically controlled

transaxle optimally matches gear shifts to almost all

driving and road conditions.

DRIVING UPHILL

The transaxle may not upshift to a higher gear if the

computer determines the current speed cannot be main-

tained once a higher gear is engaged.

For smoother vehicle performance, if you release the

throttle while climbing a steep grade, the transaxle may

not upshift. This is normal, as the computer is controlling

the shifting. After reaching the top of the hill, normal gear

shift function will resume.

DRIVING DOWNHILL

When traveling down steep grades and depressing the

brake pedal, the computer may automatically select a

lower gear. This function assists engine braking efforts,

reducing the need to use the brakes.

158 STARTING AND DRIVING

Page 164 of 388

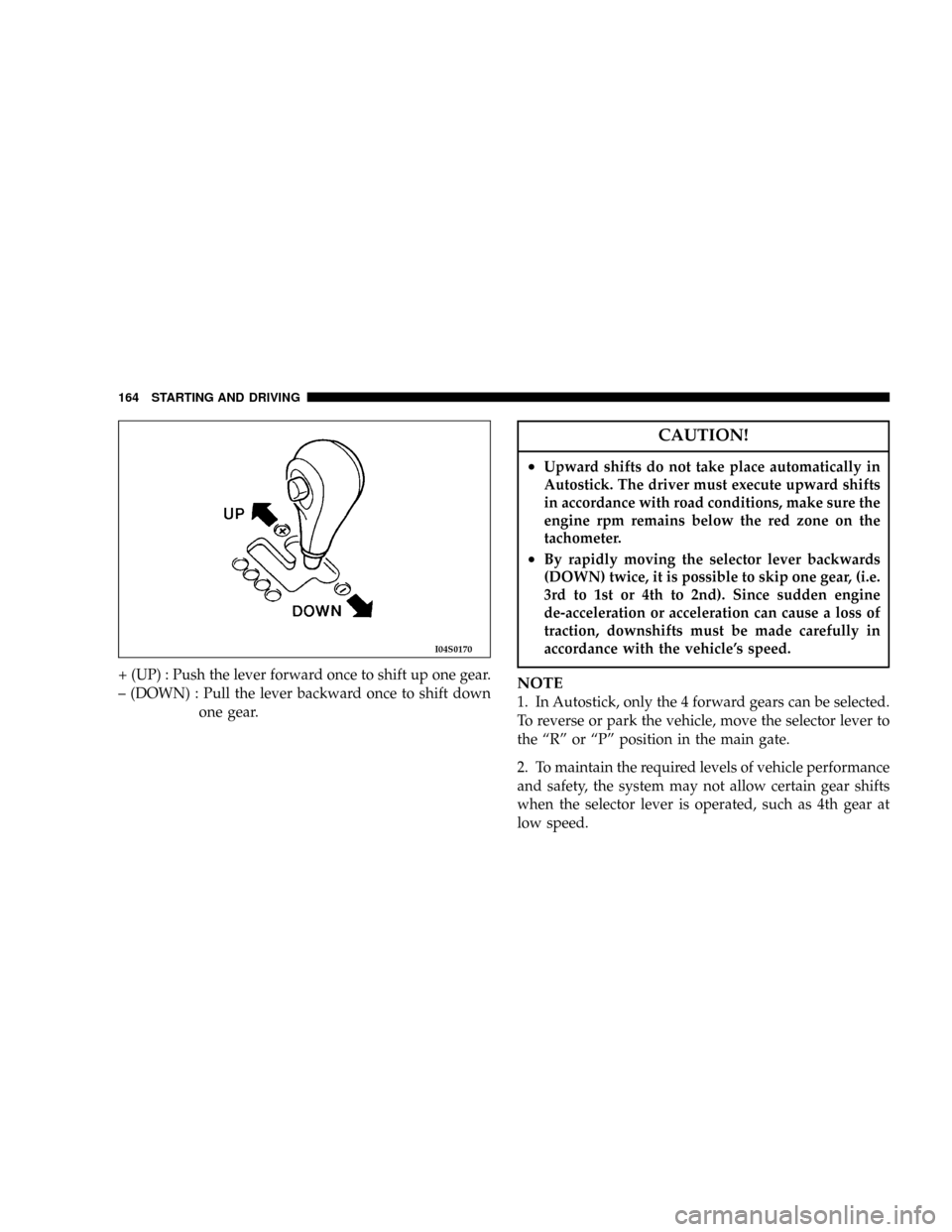

+ (UP) : Push the lever forward once to shift up one gear.

± (DOWN) : Pull the lever backward once to shift down

one gear.

CAUTION!

²Upward shifts do not take place automatically in

Autostick. The driver must execute upward shifts

in accordance with road conditions, make sure the

engine rpm remains below the red zone on the

tachometer.

²By rapidly moving the selector lever backwards

(DOWN) twice, it is possible to skip one gear, (i.e.

3rd to 1st or 4th to 2nd). Since sudden engine

de-acceleration or acceleration can cause a loss of

traction, downshifts must be made carefully in

accordance with the vehicle's speed.

NOTE

1. In Autostick, only the 4 forward gears can be selected.

To reverse or park the vehicle, move the selector lever to

the ªRº or ªPº position in the main gate.

2. To maintain the required levels of vehicle performance

and safety, the system may not allow certain gear shifts

when the selector lever is operated, such as 4th gear at

low speed.

I04S0170

164 STARTING AND DRIVING

Page 166 of 388

Transaxle Reset Mode

The transaxle is monitored for abnormal conditions. If a

condition is detected that could cause damage, the trans-

axle automatically shifts into second gear. The transaxle

remains in second gear despite the forward gear selected.

Park (P), Reverse (R), and Neutral (N) will continue to

operate. This Reset feature allows the vehicle to be driven

to a dealer for service without damaging the transaxle.

If the problem has been momentary, the transaxle can be

reset to regain all forward gears.

²Stop the vehicle and shift into PARK (P).

²Turn the key to OFF then start the engine.

²Shift into ªDº and resume driving.

NOTE:Even if the transaxle can be reset, we recom-

mend that you visit a dealer at your earliest possible

convenience. Your dealer has diagnostic equipment to

determine if the problem could recur.

If the transaxle cannot be reset, dealer service is required.

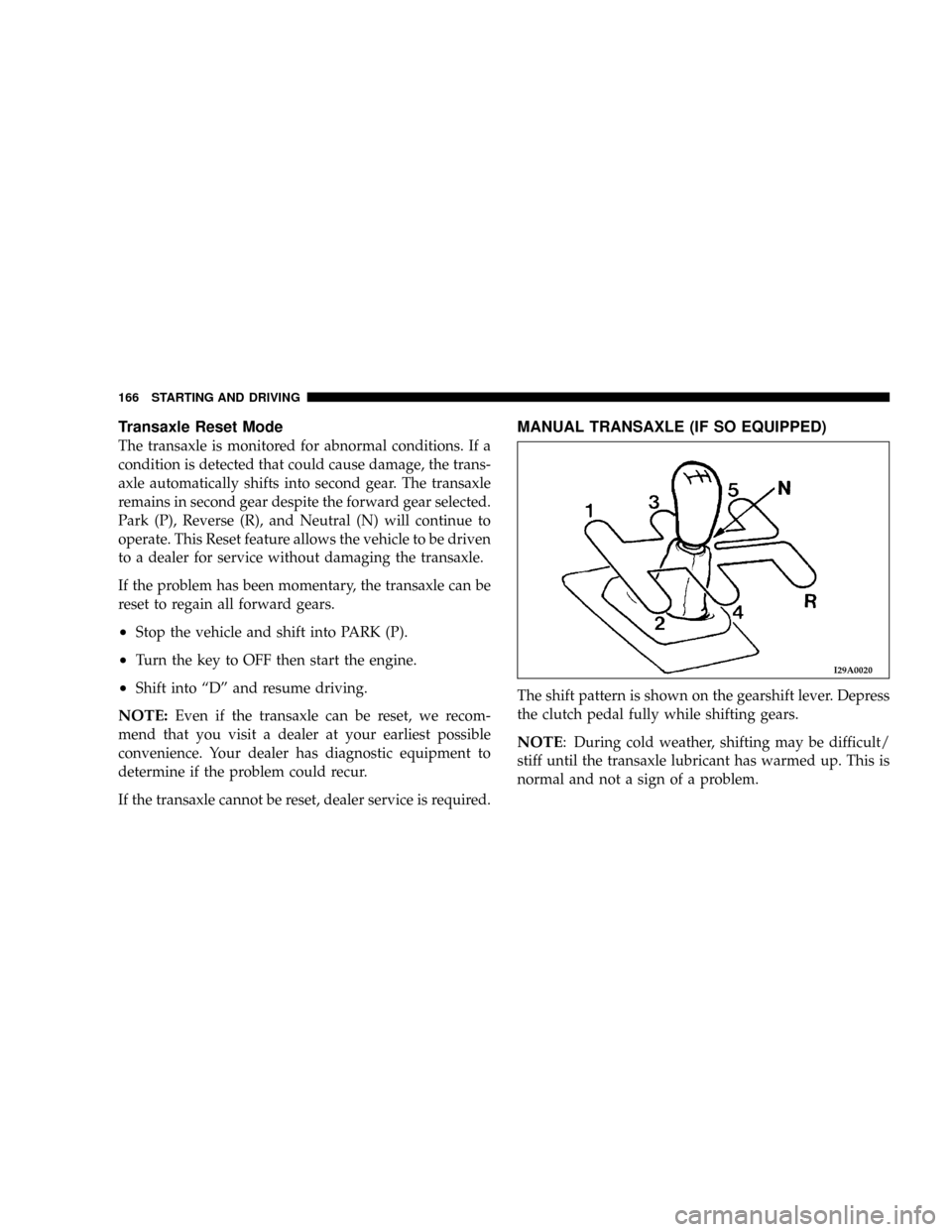

MANUAL TRANSAXLE (IF SO EQUIPPED)

The shift pattern is shown on the gearshift lever. Depress

the clutch pedal fully while shifting gears.

NOTE: During cold weather, shifting may be difficult/

stiff until the transaxle lubricant has warmed up. This is

normal and not a sign of a problem.

I29A0020

166 STARTING AND DRIVING

Page 175 of 388

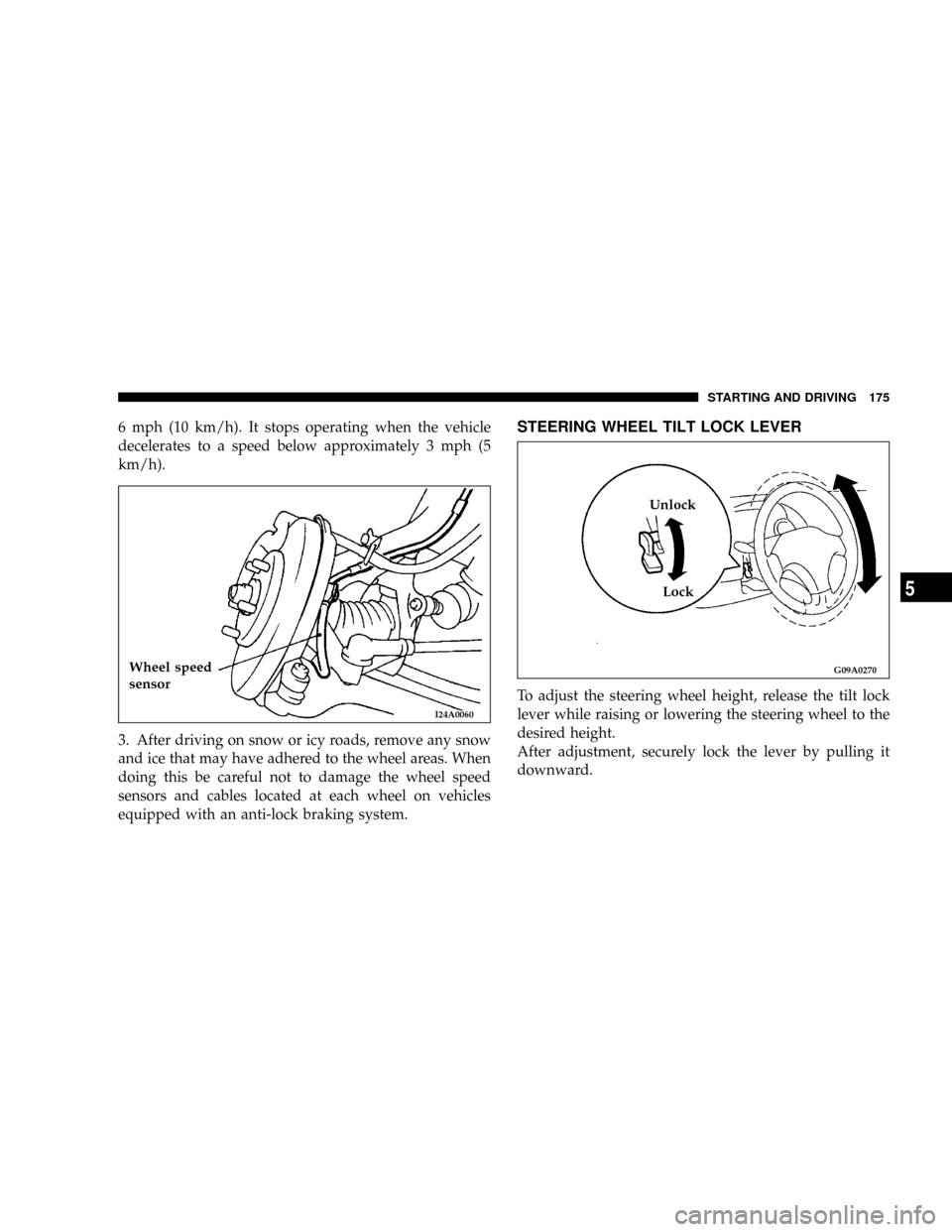

6 mph (10 km/h). It stops operating when the vehicle

decelerates to a speed below approximately 3 mph (5

km/h).

3. After driving on snow or icy roads, remove any snow

and ice that may have adhered to the wheel areas. When

doing this be careful not to damage the wheel speed

sensors and cables located at each wheel on vehicles

equipped with an anti-lock braking system.STEERING WHEEL TILT LOCK LEVER

To adjust the steering wheel height, release the tilt lock

lever while raising or lowering the steering wheel to the

desired height.

After adjustment, securely lock the lever by pulling it

downward.

I24A0060

Wheel speed

sensorG09A0270

Unlock

Lock

STARTING AND DRIVING 175

5

Page 267 of 388

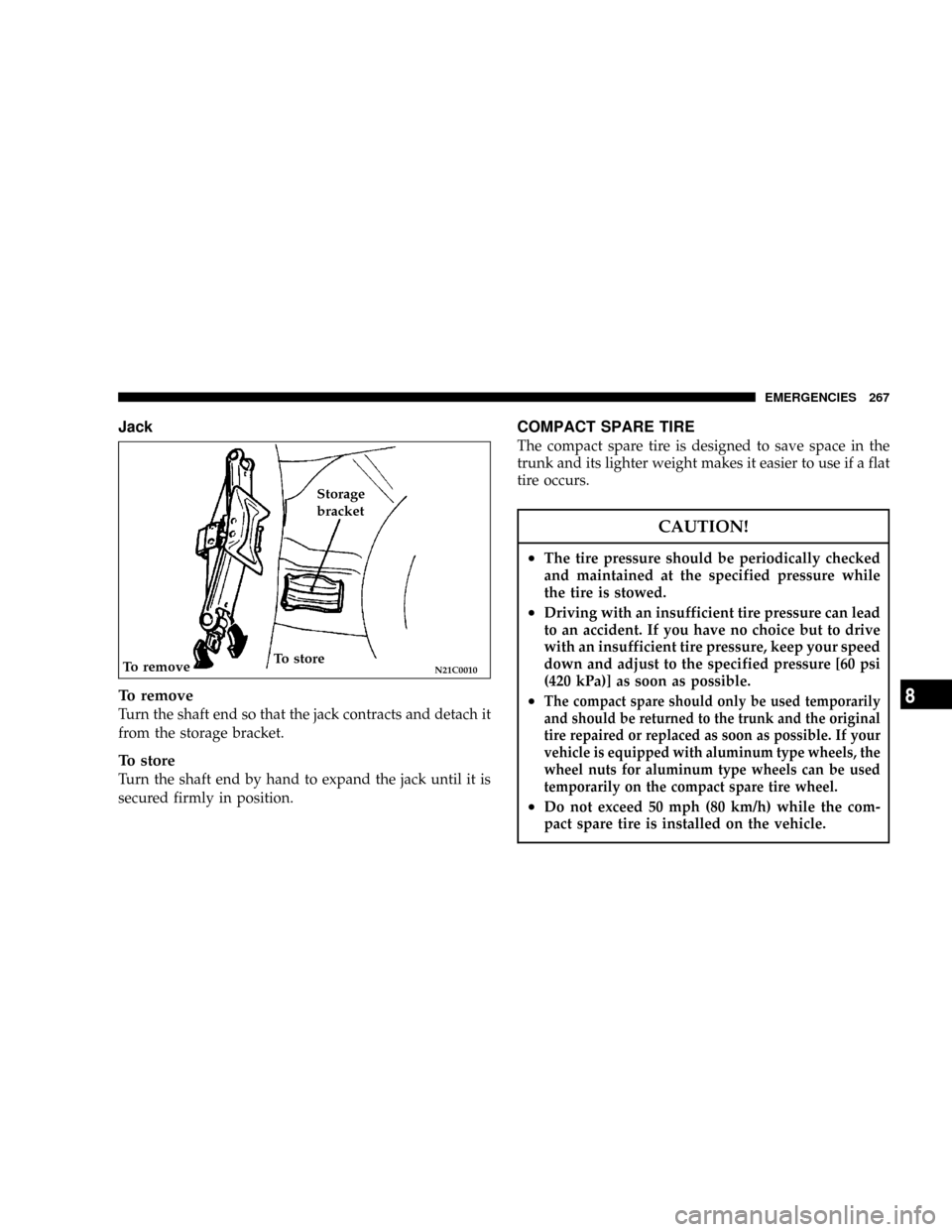

Jack

To remove

Turn the shaft end so that the jack contracts and detach it

from the storage bracket.

To store

Turn the shaft end by hand to expand the jack until it is

secured firmly in position.

COMPACT SPARE TIRE

The compact spare tire is designed to save space in the

trunk and its lighter weight makes it easier to use if a flat

tire occurs.

CAUTION!

²The tire pressure should be periodically checked

and maintained at the specified pressure while

the tire is stowed.

²Driving with an insufficient tire pressure can lead

to an accident. If you have no choice but to drive

with an insufficient tire pressure, keep your speed

down and adjust to the specified pressure [60 psi

(420 kPa)] as soon as possible.

²The compact spare should only be used temporarily

and should be returned to the trunk and the

original

tire repaired or replaced as soon as possible. If your

vehicle is equipped with aluminum type wheels, the

wheel nuts for aluminum type wheels can be used

temporarily on the compact spare tire wheel.

²Do not exceed 50 mph (80 km/h) while the com-

pact spare tire is installed on the vehicle.

N21C0010To removeTo storeStorage

bracket

EMERGENCIES 267

8

Page 269 of 388

NOTE: The wheel cover is made of plastic; use caution

when prying it off.

NOTE: Some styles of wheels will have bolt-on type

wheel covers. To remove this style, remove the bolts that

hold the cover to the wheel.

CAUTION!

Trying to simply remove the wheel cover with your

bare hands may severely injure your fingers.

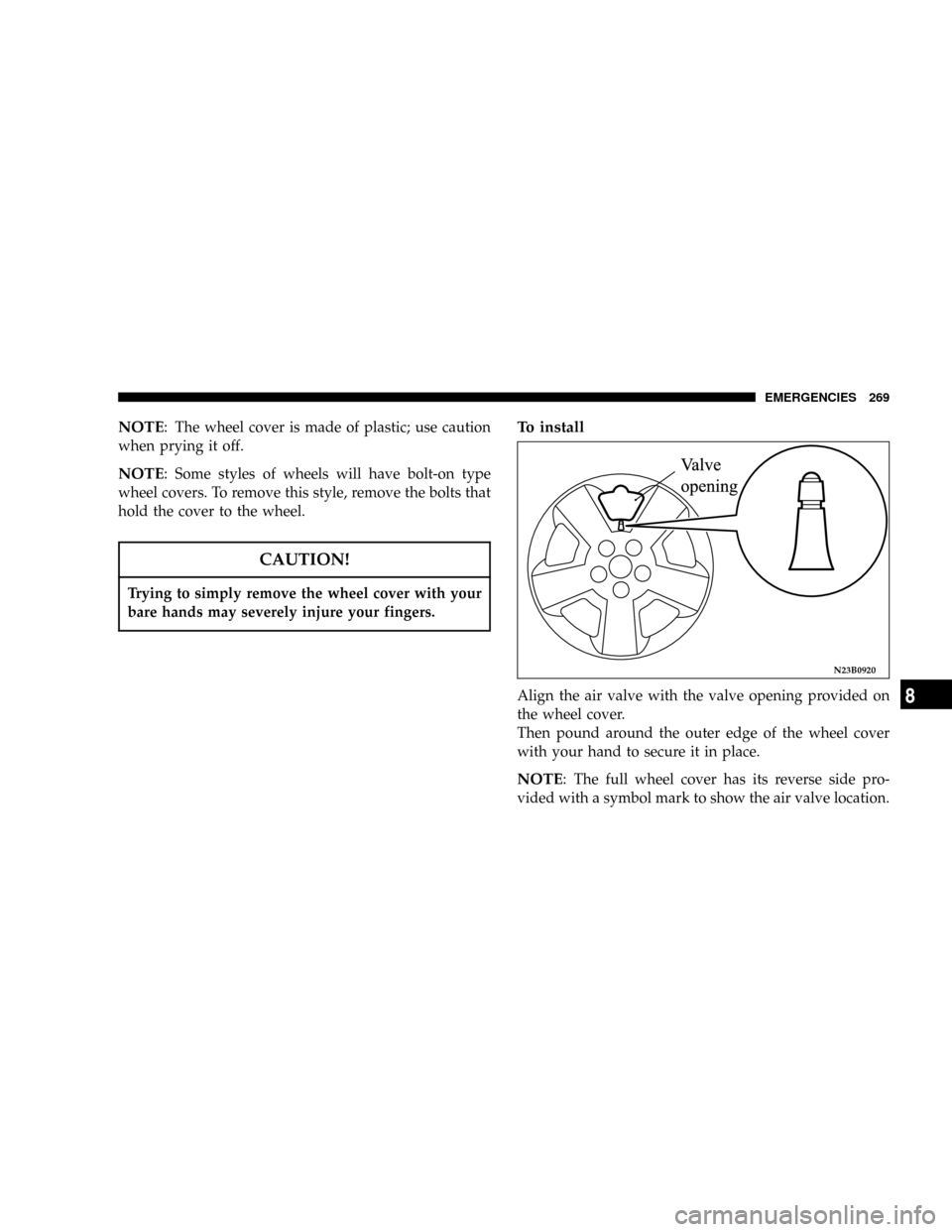

To install

Align the air valve with the valve opening provided on

the wheel cover.

Then pound around the outer edge of the wheel cover

with your hand to secure it in place.

NOTE: The full wheel cover has its reverse side pro-

vided with a symbol mark to show the air valve location.

N23B0920

EMERGENCIES 269

8

Page 285 of 388

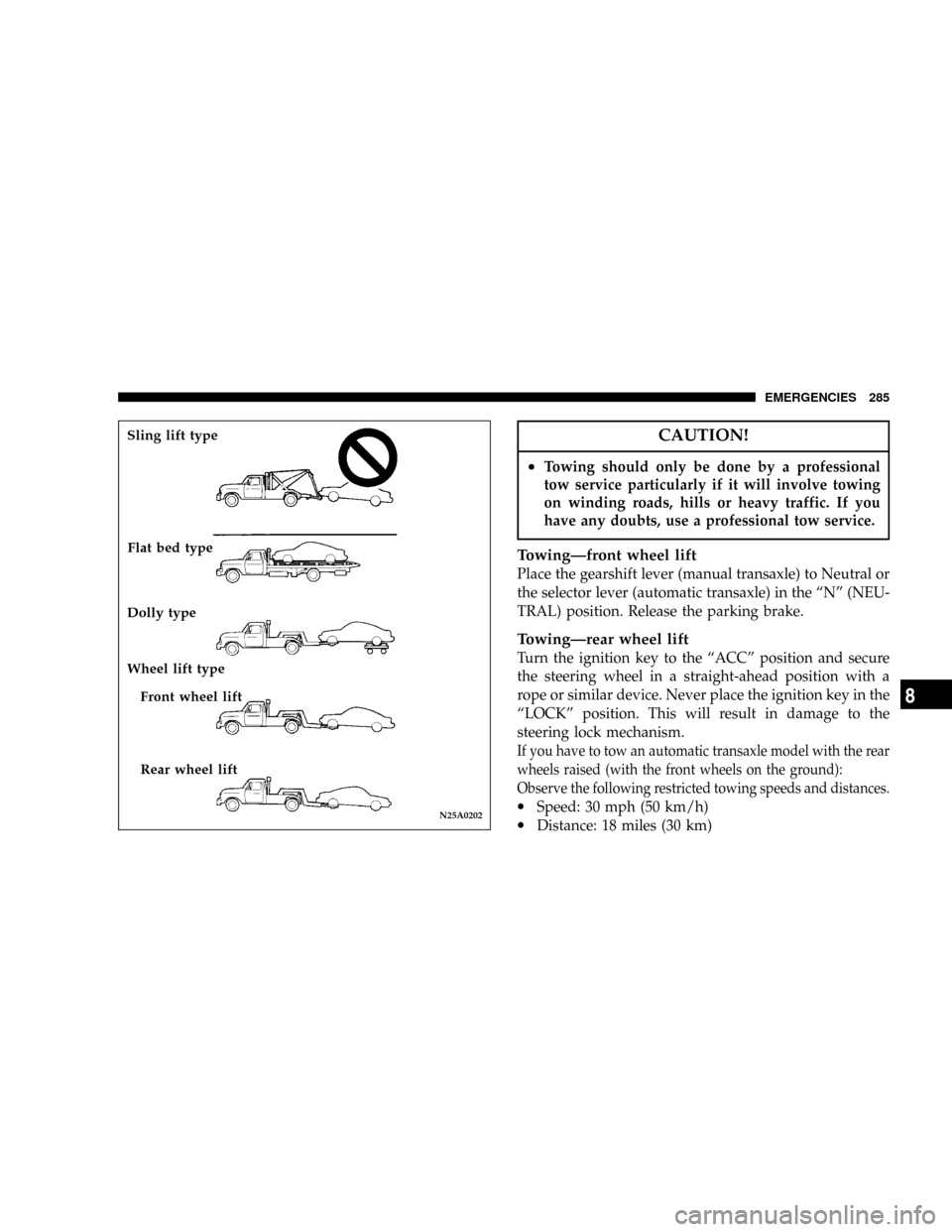

CAUTION!

²Towing should only be done by a professional

tow service particularly if it will involve towing

on winding roads, hills or heavy traffic. If you

have any doubts, use a professional tow service.

TowingÐfront wheel lift

Place the gearshift lever (manual transaxle) to Neutral or

the selector lever (automatic transaxle) in the ªNº (NEU-

TRAL) position. Release the parking brake.

TowingÐrear wheel lift

Turn the ignition key to the ªACCº position and secure

the steering wheel in a straight-ahead position with a

rope or similar device. Never place the ignition key in the

ªLOCKº position. This will result in damage to the

steering lock mechanism.

If you have to tow an automatic transaxle model with the rear

wheels raised (with the front wheels on the ground):

Observe the following restricted towing speeds and distances.

·Speed: 30 mph (50 km/h)

·Distance: 18 miles (30 km)N25A0202

Sling lift type

Flat bed type

Dolly type

Wheel lift type

Front wheel lift

Rear wheel lift

EMERGENCIES 285

8

Page 292 of 388

5. Insert a new fuse of the same capacity securely into the

fuse block location.

CAUTION!

²Never use a fuse with a capacity larger than that

specified or any substitute, such as wire, foil, etc.

Doing so will cause the circuit wiring to heat up

and could cause a fire.

²If the newly inserted fuse blows again after a

short time, have the electrical system checked by

an authorized dealer to find and correct the cause.

REPLACEMENT OF LIGHT BULBS

Before replacing a bulb, be sure the light is off. Do not

touch the glass part of the new bulb with your bare

fingers; the skin oil left on the glass will evaporate when

the bulb gets hot and the vapor will condense on the

reflector and dim the surface.

Bulb capacity

A bulb should only be replaced with a new bulb of the

same rating and type. The designation can be found on

the base of the bulb.

N29C0010

292 EMERGENCIES

Page 315 of 388

If the light is flashing, severe catalytic converter damage

and power loss will soon occur. Immediate service is

required.

If the gas cap is not tightened properly, the light may

come on. Be sure the gas cap is tightened every time you

add fuel. Tighten the cap until you hear it ªclick.º

REPLACEMENT PARTS

Use of genuine Mopar parts for normal/scheduled main-

tenance and repairs is highly recommended to insure the

designed performance. Damage or failures caused by the

use of non-Mopar parts for maintenance and repairs will

not be covered by the manufacturers warranty.

Fuel system (tank, filler tube, connections, and

fuel tank filler cap)

Check periodically for damage or leakage in the fuel lines

and connections, and check for damage and looseness of

the fuel tank filler tube cap. Particular attention should be

paid to examining those fuel lines nearest to high heat

sources such as the exhaust manifold.

WARNING!

If you see a fuel leak or if you smell fuel, do not

operate the vehicle. Any spark (including from the

ignition ), flame or smoking material could cause an

explosion or fire. Call an authorized dealer for

assistance.

Fuel hoses

Inspect the surfaces of hoses for evidence of heat and

mechanical damage, hard and brittle rubber, cracking,

tears, cuts and abrasions. Particular attention should be

paid to examining those hose surfaces nearest to high

heat sources such as the exhaust manifold. Inspect all

hose connections, such as clamps and couplings, to make

sure they are secure and that no leaks exist. If there is any

evidence of deterioration or damage, hoses should be

replaced immediately.

MAINTENANCE 315

9

Page 327 of 388

NOTE

1. Check each battery terminal for corrosion. If necessary,

neutralize corrosion by washing with a solution of bak-

ing soda and water. Apply grease to posts and clamps

after cleaning or tightening.

2. Before cleaning the battery, tighten all filler port caps

to prevent foreign matter from entering the battery.

3. Check to see if the battery is securely installed and

cannot be moved. Also check each terminal for tightness.

4. When the vehicle is to be left unused for a long period

of time, remove the battery and store it in a place where

the battery fluid will not freeze. The battery should be

stored only in a fully charged condition.

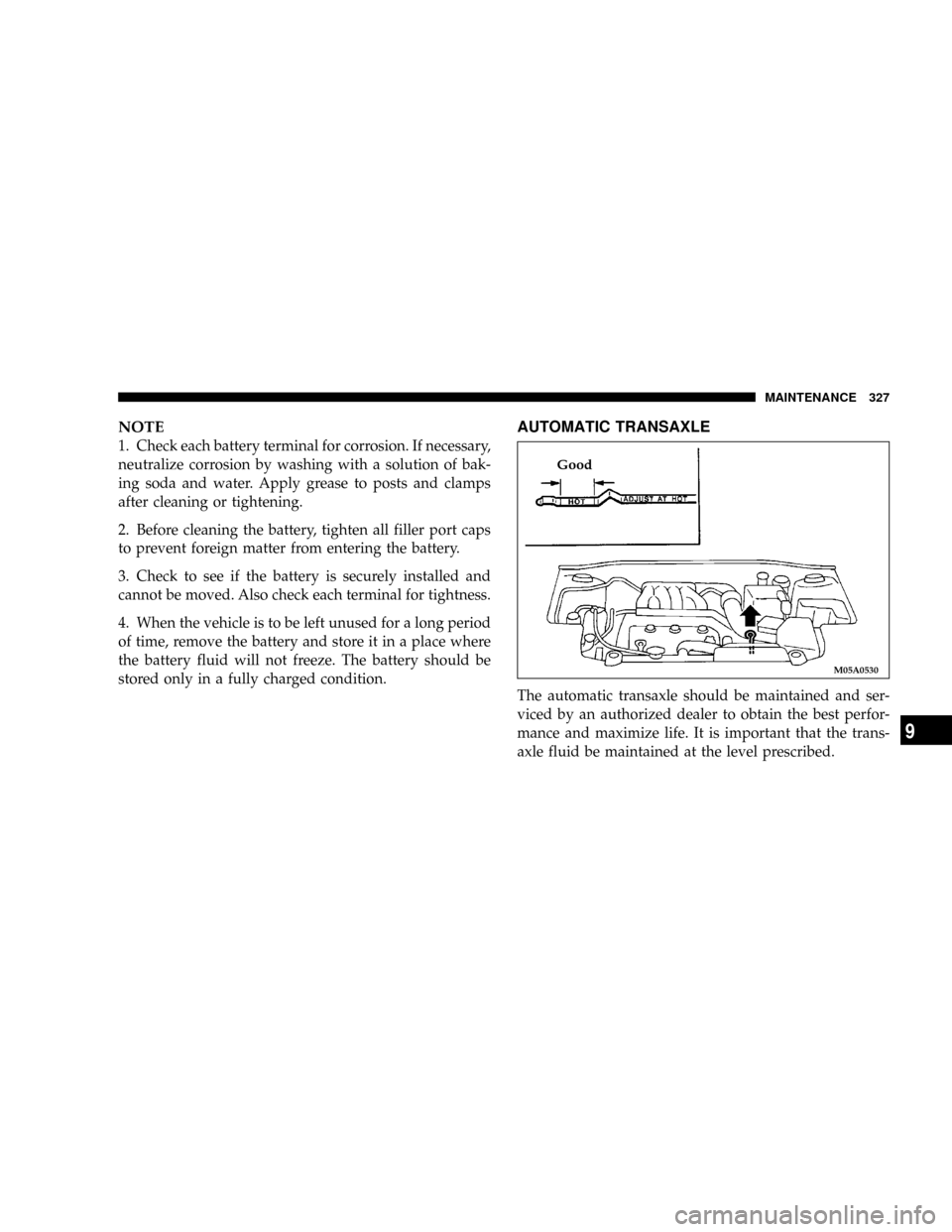

AUTOMATIC TRANSAXLE

The automatic transaxle should be maintained and ser-

viced by an authorized dealer to obtain the best perfor-

mance and maximize life. It is important that the trans-

axle fluid be maintained at the level prescribed.

M05A0530

Good

MAINTENANCE 327

9