clock DODGE TOWN AND COUNTRY 2001 Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 1853 of 2321

GEARSHIFT CABLE -

CROSSOVER

REMOVAL

(1) Disconnect battery negative cable.

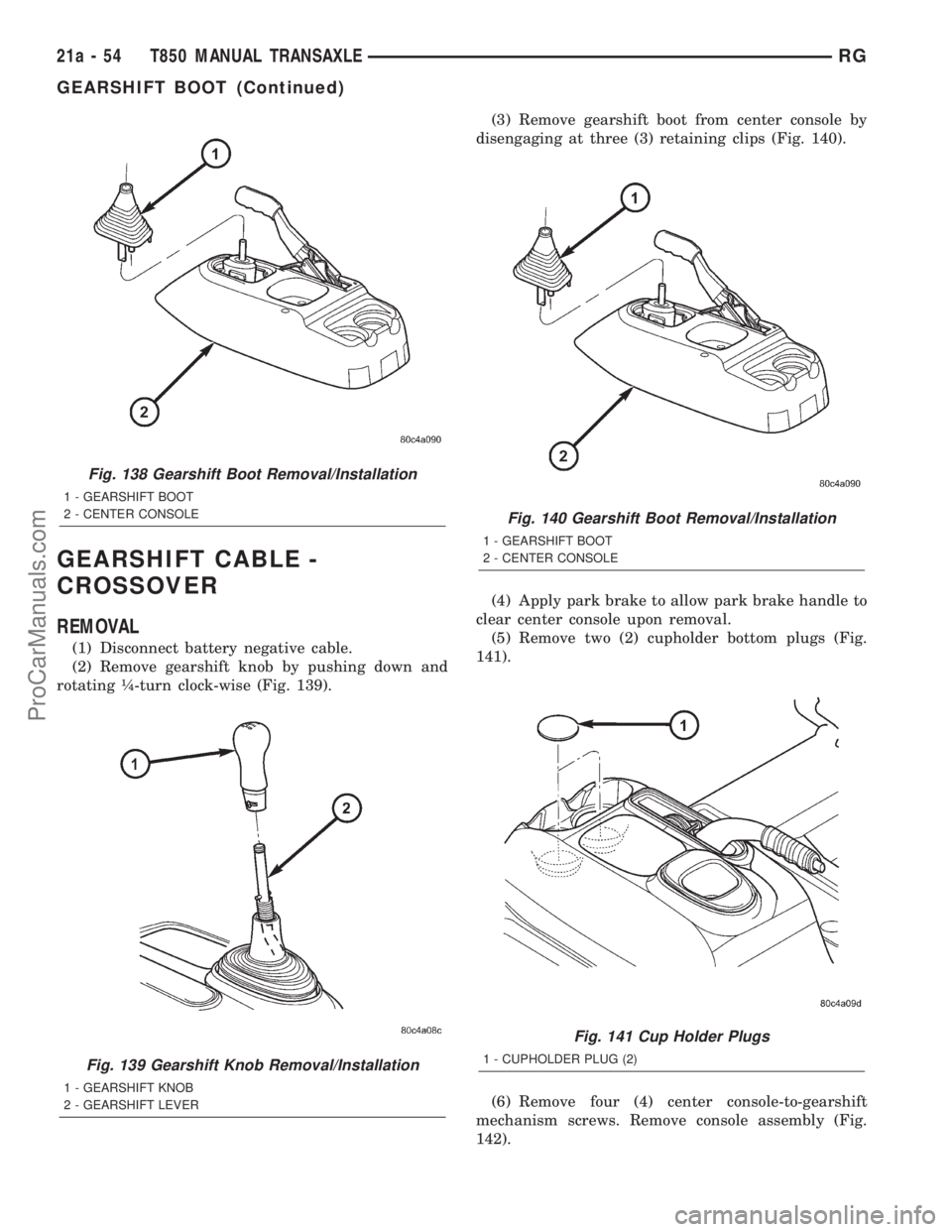

(2) Remove gearshift knob by pushing down and

rotating ò-turn clock-wise (Fig. 139).(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 140).

(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

141).

(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

142).

Fig. 138 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 139 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 140 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 141 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

21a - 54 T850 MANUAL TRANSAXLERG

GEARSHIFT BOOT (Continued)

ProCarManuals.com

Page 1858 of 2321

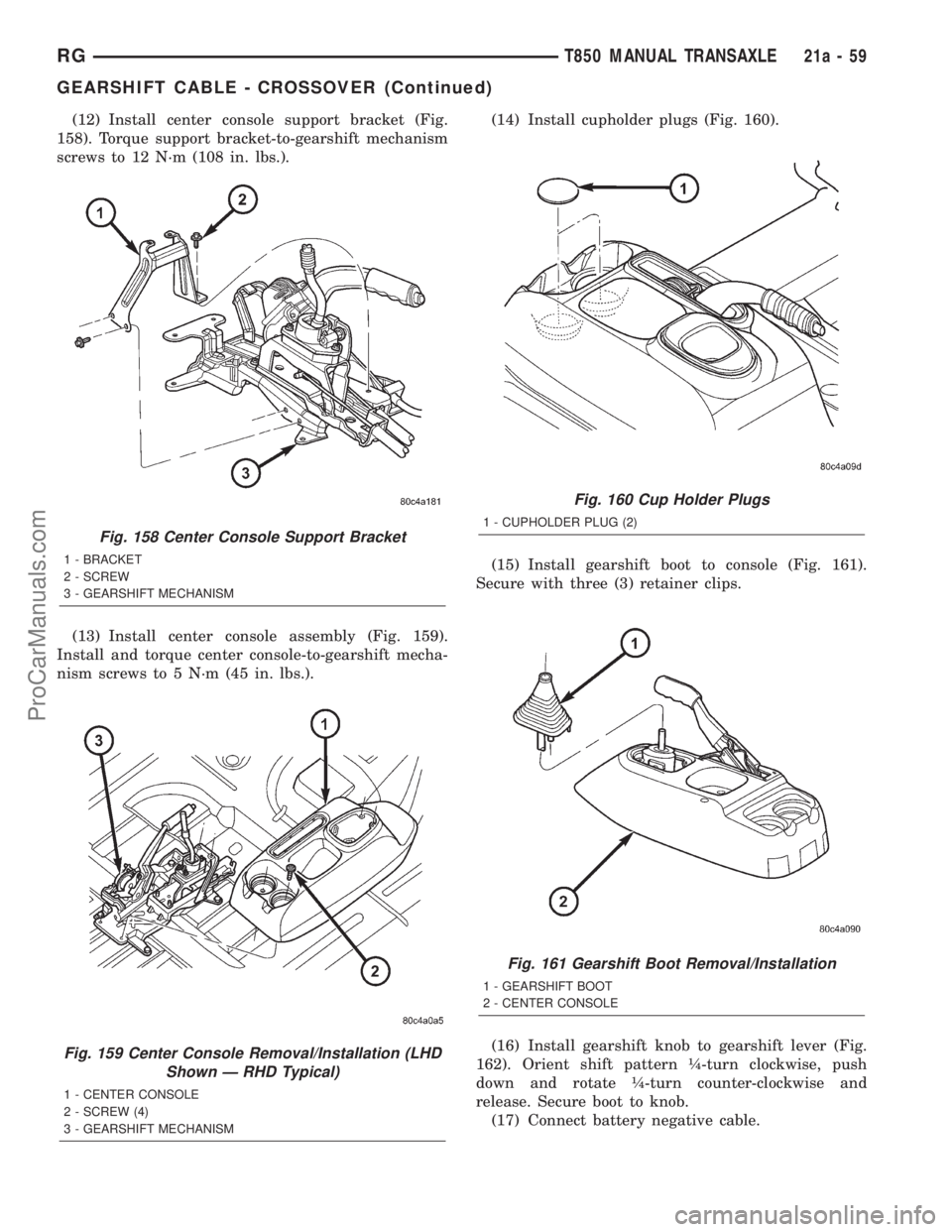

(12) Install center console support bracket (Fig.

158). Torque support bracket-to-gearshift mechanism

screws to 12 N´m (108 in. lbs.).

(13) Install center console assembly (Fig. 159).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).(14) Install cupholder plugs (Fig. 160).

(15) Install gearshift boot to console (Fig. 161).

Secure with three (3) retainer clips.

(16) Install gearshift knob to gearshift lever (Fig.

162). Orient shift pattern ò-turn clockwise, push

down and rotate ò-turn counter-clockwise and

release. Secure boot to knob.

(17) Connect battery negative cable.

Fig. 158 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 159 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 160 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 161 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

RGT850 MANUAL TRANSAXLE21a-59

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com

Page 1859 of 2321

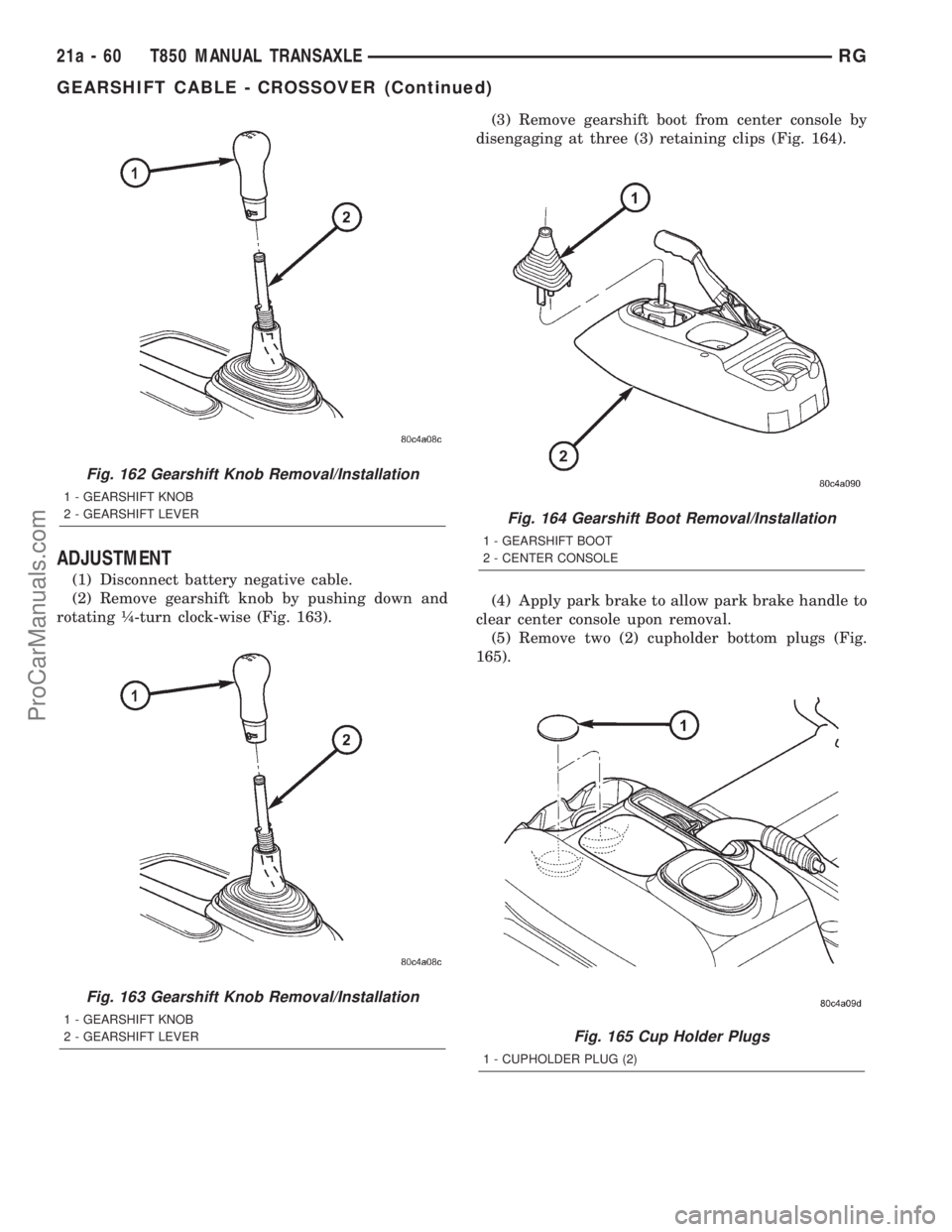

ADJUSTMENT

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating ò-turn clock-wise (Fig. 163).(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 164).

(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

165).

Fig. 162 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 163 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 164 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 165 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

21a - 60 T850 MANUAL TRANSAXLERG

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com

Page 1860 of 2321

(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

166).

(7) Loosen crossover cable adjustment screw (Fig.

167).

(8) Rock gearshift lever back and forth between

1±2 and 5±R planes. Release lever, allowing shifterspring to return lever to the neutral position in the

3±4 plane. Place gearshift lever in the 3rd gear posi-

tion.

(9) Torque crossover lever adjustment screw to 8

N´m (70 in. lbs.).No load should be applied to

the shifter lever in any direction (hands off)

while tightening screw.

(10) Verify gearshift lever travel through all gear

ranges with engine off (not running).

(11) Install center console assembly (Fig. 166).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

(12) Install cupholder plugs (Fig. 165).

(13) Install gearshift boot to console (Fig. 164).

Secure boot to console with three (3) retainer clips.

(14) Install gearshift knob to gearshift lever (Fig.

163). Orient shift pattern on knob ò-turn clockwise,

push down and rotate ò-turn counter-clockwise and

release. Secure boot to knob.

(15) Connect battery negative cable.

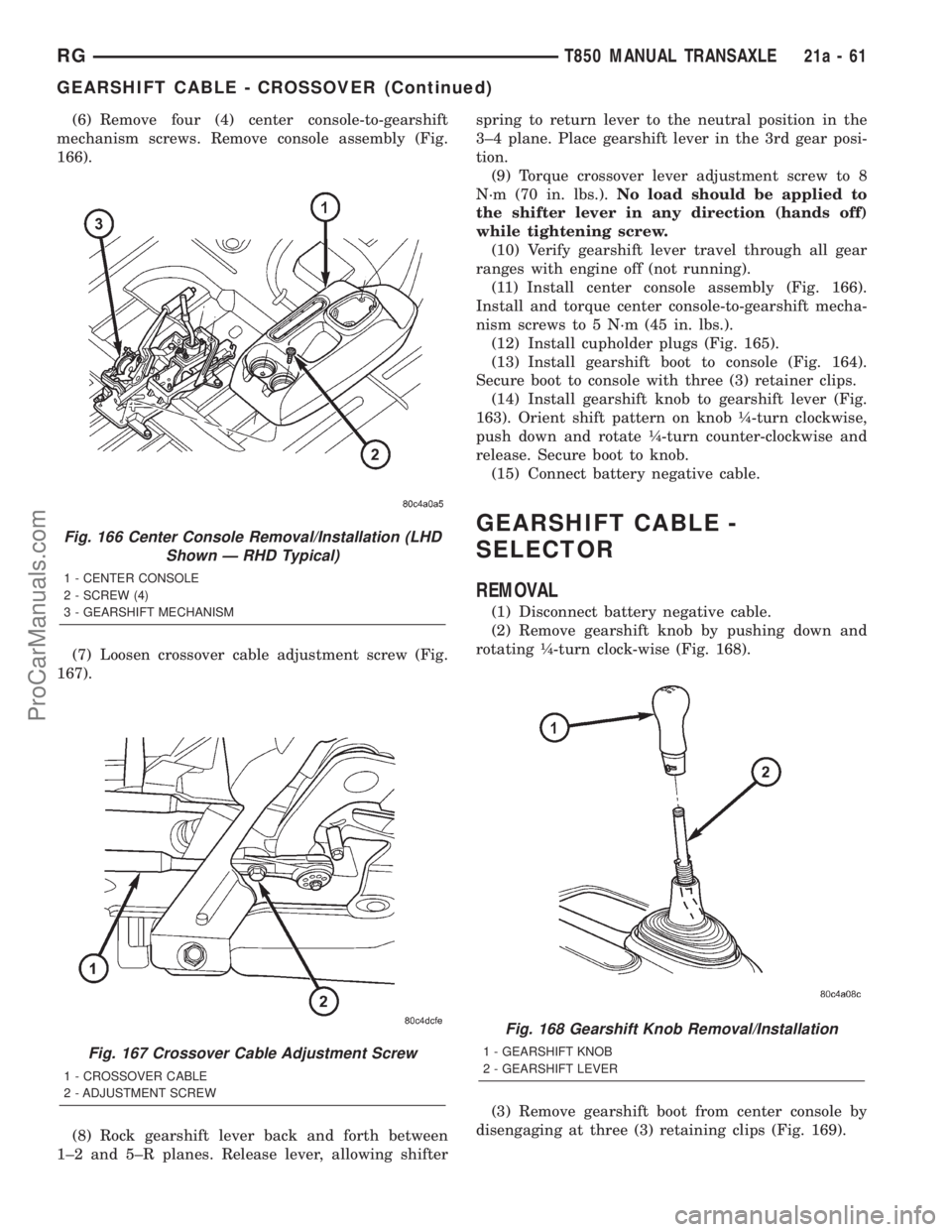

GEARSHIFT CABLE -

SELECTOR

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating ò-turn clock-wise (Fig. 168).

(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 169).

Fig. 166 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 167 Crossover Cable Adjustment Screw

1 - CROSSOVER CABLE

2 - ADJUSTMENT SCREW

Fig. 168 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

RGT850 MANUAL TRANSAXLE21a-61

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com

Page 1866 of 2321

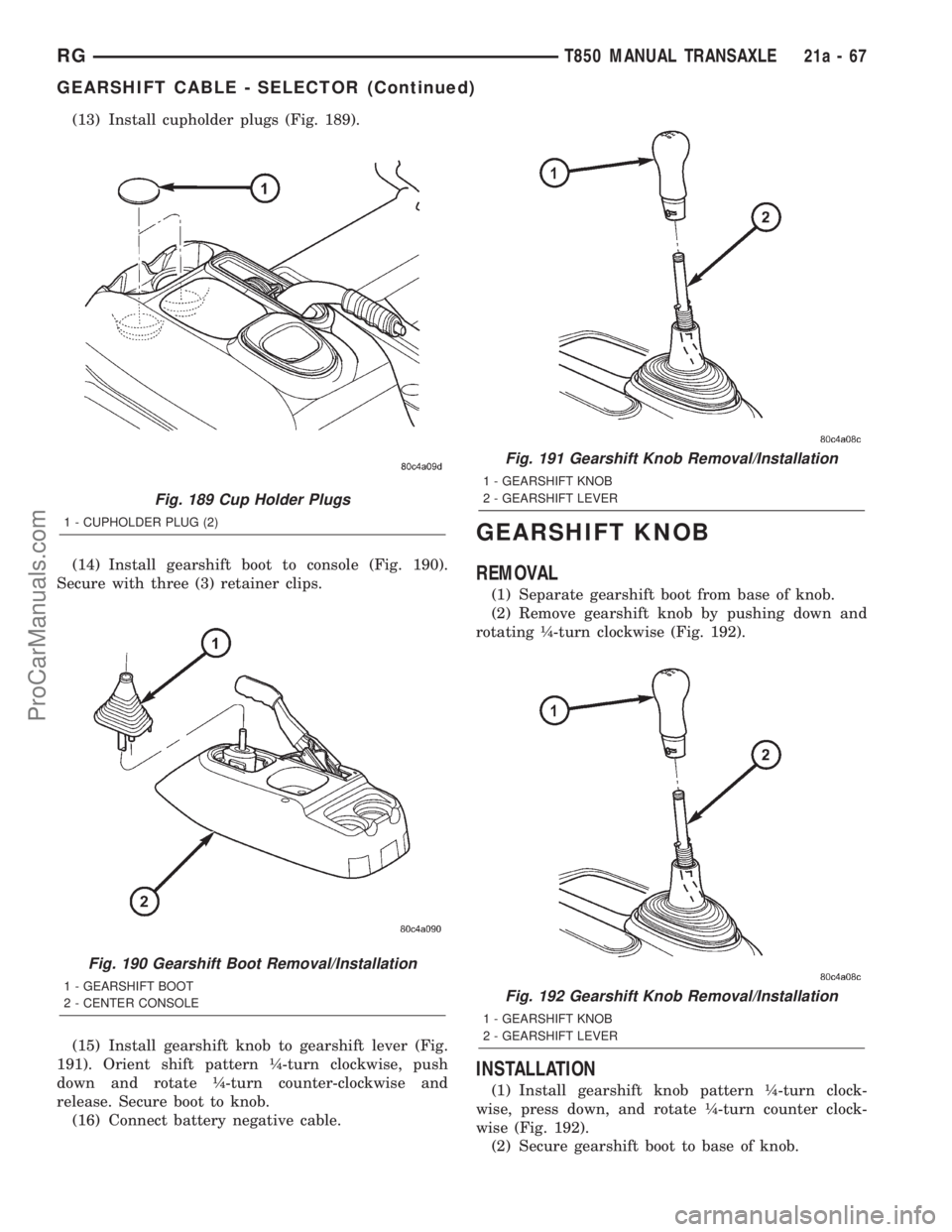

(13) Install cupholder plugs (Fig. 189).

(14) Install gearshift boot to console (Fig. 190).

Secure with three (3) retainer clips.

(15) Install gearshift knob to gearshift lever (Fig.

191). Orient shift pattern ò-turn clockwise, push

down and rotate ò-turn counter-clockwise and

release. Secure boot to knob.

(16) Connect battery negative cable.

GEARSHIFT KNOB

REMOVAL

(1) Separate gearshift boot from base of knob.

(2) Remove gearshift knob by pushing down and

rotating ò-turn clockwise (Fig. 192).

INSTALLATION

(1) Install gearshift knob pattern ò-turn clock-

wise, press down, and rotate ò-turn counter clock-

wise (Fig. 192).

(2) Secure gearshift boot to base of knob.

Fig. 189 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 190 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 191 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 192 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

RGT850 MANUAL TRANSAXLE21a-67

GEARSHIFT CABLE - SELECTOR (Continued)

ProCarManuals.com

Page 1867 of 2321

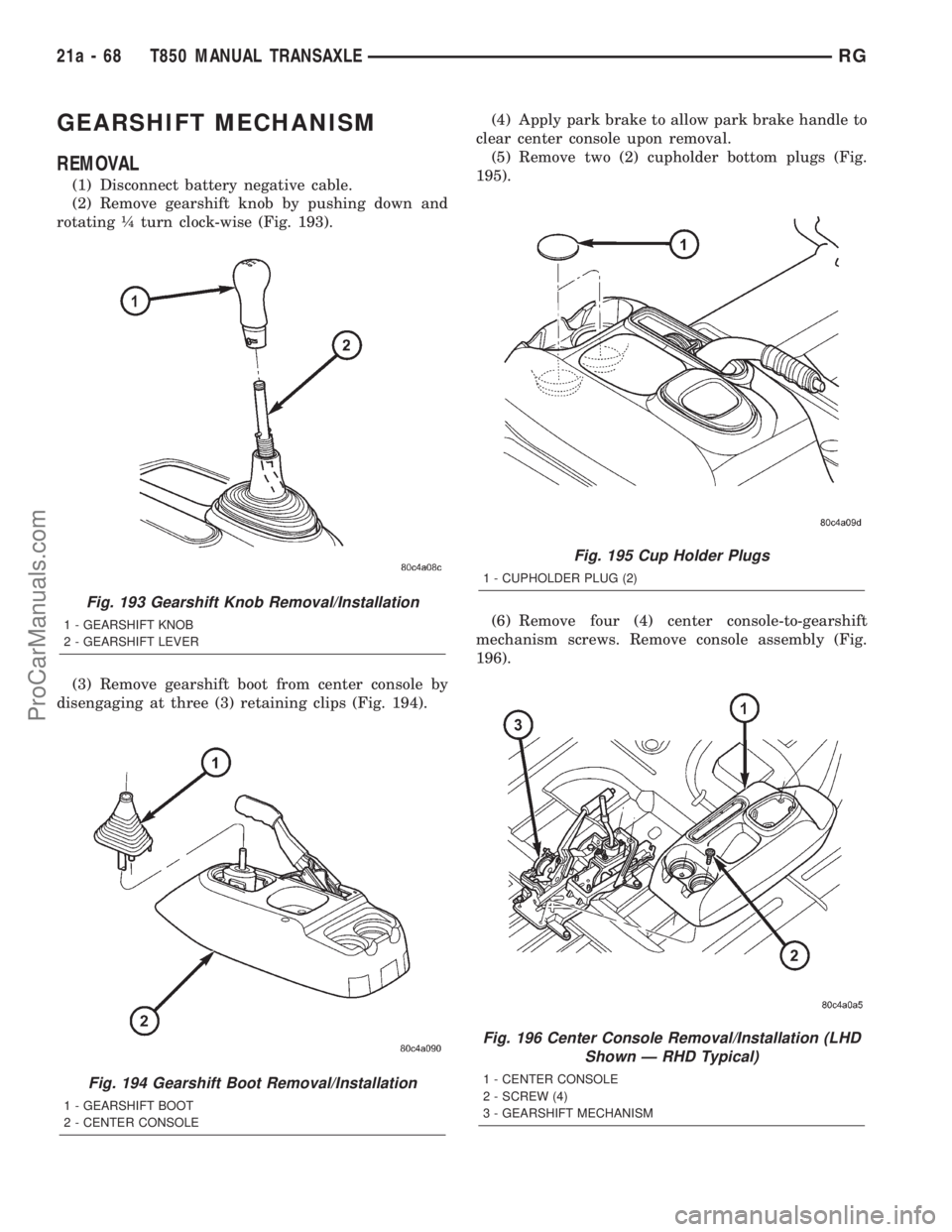

GEARSHIFT MECHANISM

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating ò turn clock-wise (Fig. 193).

(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 194).(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

195).

(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

196).

Fig. 193 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 194 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 195 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 196 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

21a - 68 T850 MANUAL TRANSAXLERG

ProCarManuals.com

Page 1871 of 2321

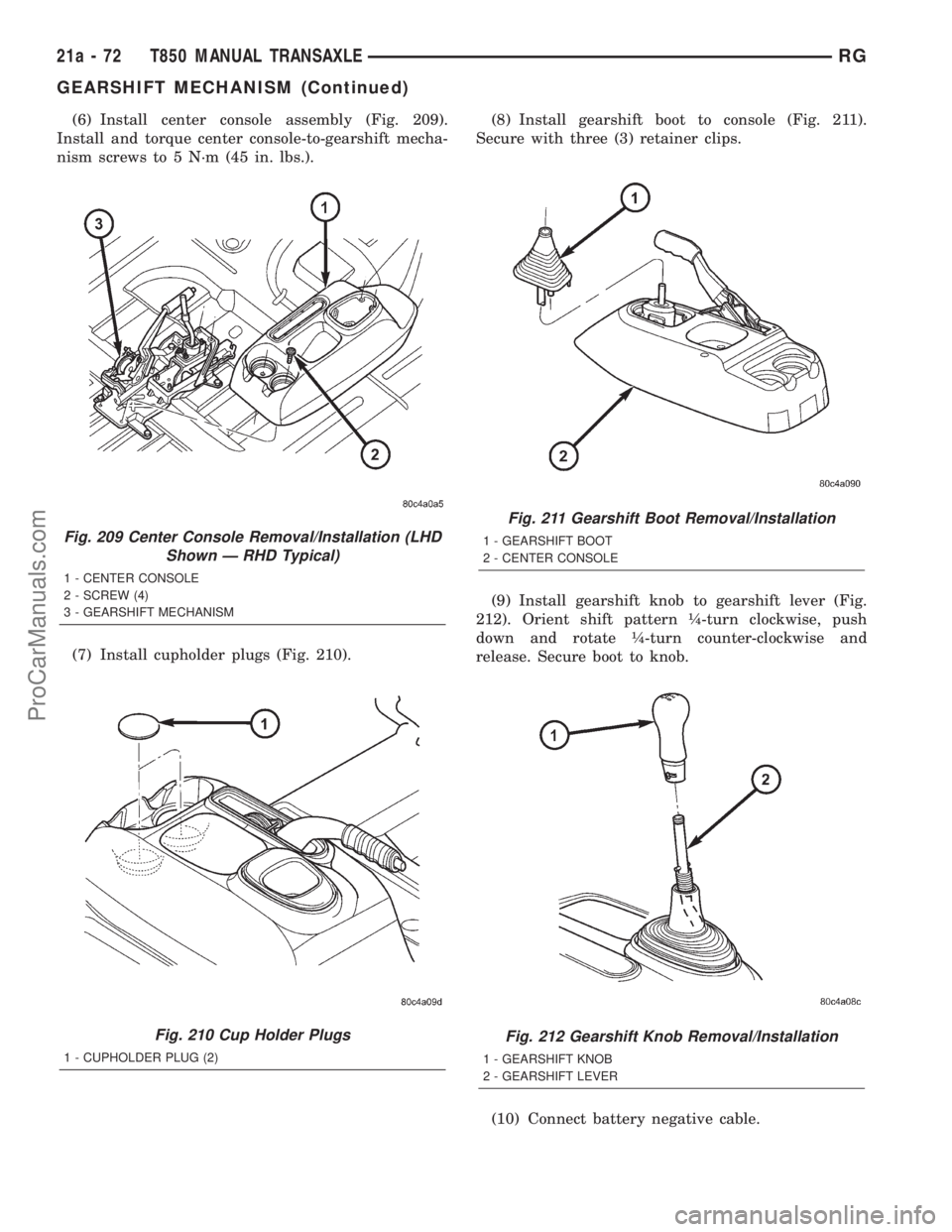

(6) Install center console assembly (Fig. 209).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

(7) Install cupholder plugs (Fig. 210).(8) Install gearshift boot to console (Fig. 211).

Secure with three (3) retainer clips.

(9) Install gearshift knob to gearshift lever (Fig.

212). Orient shift pattern ò-turn clockwise, push

down and rotate ò-turn counter-clockwise and

release. Secure boot to knob.

(10) Connect battery negative cable.

Fig. 209 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 210 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 211 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 212 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

21a - 72 T850 MANUAL TRANSAXLERG

GEARSHIFT MECHANISM (Continued)

ProCarManuals.com

Page 1896 of 2321

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING..................1

TIRE AND WHEEL VIBRATION..............1

STANDARD PROCEDURE...................4

TIRE AND WHEEL BALANCE...............4

TIRE AND WHEEL MATCH MOUNTING.......6

TIRE AND WHEEL ROTATION..............6

REMOVAL...............................7

INSTALLATION............................7

TIRES

DESCRIPTION............................8

DIAGNOSIS AND TESTING..................9

TIRE NOISE............................9

TIRE/VEHICLE LEAD.....................9

TIRE WEAR PATTERNS..................11

TREAD WEAR INDICATORS...............11

STANDARD PROCEDURE..................11

TIRE INFLATION PRESSURES.............11

TIRE PRESSURE FOR HIGH SPEED

OPERATION...........................12TIRE LEAK REPAIRING..................12

CLEANING..............................13

WHEELS

DESCRIPTION...........................13

DIAGNOSIS AND TESTING.................13

WHEEL INSPECTION....................13

CLEANING..............................14

SPECIFICATIONS........................14

WHEEL COVER

DESCRIPTION...........................14

REMOVAL..............................14

INSTALLATION...........................14

WHEEL MOUNTING STUDS - FRONT

REMOVAL..............................15

INSTALLATION...........................16

WHEEL MOUNTING STUDS - REAR

REMOVAL..............................16

INSTALLATION...........................17

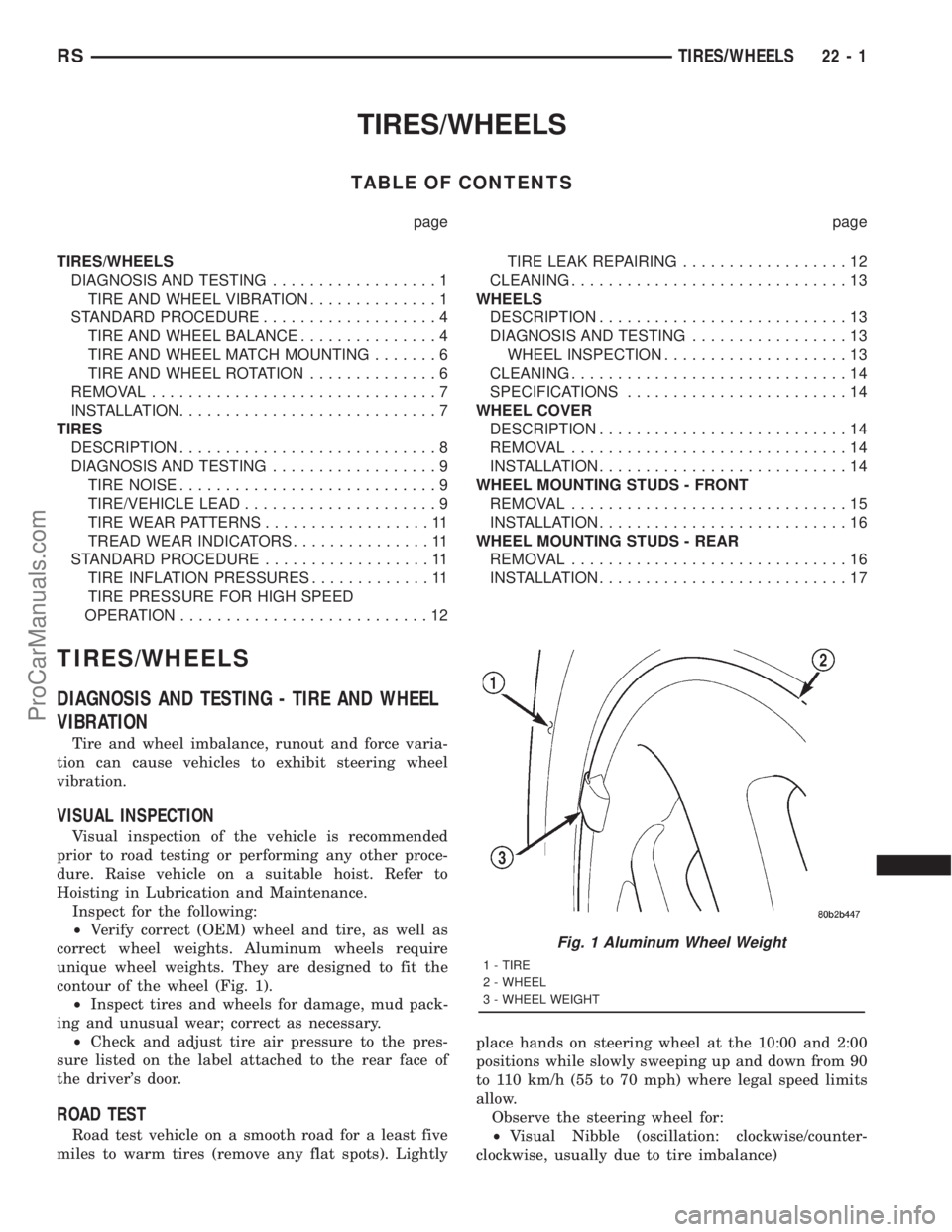

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND WHEEL

VIBRATION

Tire and wheel imbalance, runout and force varia-

tion can cause vehicles to exhibit steering wheel

vibration.

VISUAL INSPECTION

Visual inspection of the vehicle is recommended

prior to road testing or performing any other proce-

dure. Raise vehicle on a suitable hoist. Refer to

Hoisting in Lubrication and Maintenance.

Inspect for the following:

²Verify correct (OEM) wheel and tire, as well as

correct wheel weights. Aluminum wheels require

unique wheel weights. They are designed to fit the

contour of the wheel (Fig. 1).

²Inspect tires and wheels for damage, mud pack-

ing and unusual wear; correct as necessary.

²Check and adjust tire air pressure to the pres-

sure listed on the label attached to the rear face of

the driver's door.

ROAD TEST

Road test vehicle on a smooth road for a least five

miles to warm tires (remove any flat spots). Lightlyplace hands on steering wheel at the 10:00 and 2:00

positions while slowly sweeping up and down from 90

to 110 km/h (55 to 70 mph) where legal speed limits

allow.

Observe the steering wheel for:

²Visual Nibble (oscillation: clockwise/counter-

clockwise, usually due to tire imbalance)

Fig. 1 Aluminum Wheel Weight

1 - TIRE

2 - WHEEL

3 - WHEEL WEIGHT

RSTIRES/WHEELS22-1

ProCarManuals.com

Page 1902 of 2321

When wheels and tires are being installed, extra

care is needed to ensure that this direction of rota-

tion is maintained.

Refer to Owner's Manual for rotation schedule.

REMOVAL - TIRE AND WHEEL ASSEMBLY

(ALUMINUM WHEEL)

(1) Raise the vehicle so the tire and wheel assem-

bly clears ground level.

(2) Remove the 5 wheel mounting nuts from the

studs.

(3) Remove the tire and wheel from the hub.

REMOVAL - TIRE AND WHEEL ASSEMBLY

(STEEL WHEEL)

(1) Raise the vehicle so the tire and wheel assem-

bly clears ground level.

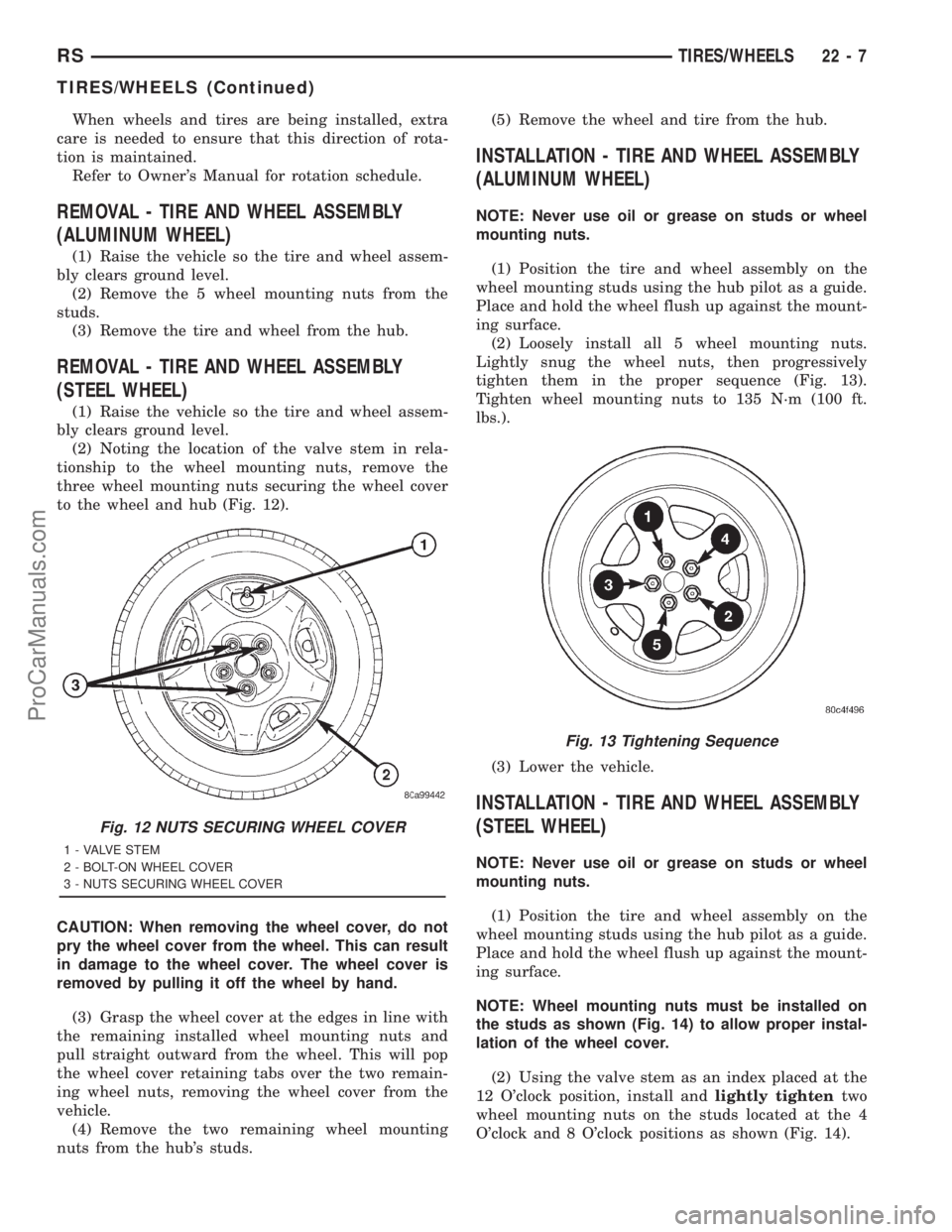

(2) Noting the location of the valve stem in rela-

tionship to the wheel mounting nuts, remove the

three wheel mounting nuts securing the wheel cover

to the wheel and hub (Fig. 12).

CAUTION: When removing the wheel cover, do not

pry the wheel cover from the wheel. This can result

in damage to the wheel cover. The wheel cover is

removed by pulling it off the wheel by hand.

(3) Grasp the wheel cover at the edges in line with

the remaining installed wheel mounting nuts and

pull straight outward from the wheel. This will pop

the wheel cover retaining tabs over the two remain-

ing wheel nuts, removing the wheel cover from the

vehicle.

(4) Remove the two remaining wheel mounting

nuts from the hub's studs.(5) Remove the wheel and tire from the hub.

INSTALLATION - TIRE AND WHEEL ASSEMBLY

(ALUMINUM WHEEL)

NOTE: Never use oil or grease on studs or wheel

mounting nuts.

(1) Position the tire and wheel assembly on the

wheel mounting studs using the hub pilot as a guide.

Place and hold the wheel flush up against the mount-

ing surface.

(2) Loosely install all 5 wheel mounting nuts.

Lightly snug the wheel nuts, then progressively

tighten them in the proper sequence (Fig. 13).

Tighten wheel mounting nuts to 135 N´m (100 ft.

lbs.).

(3) Lower the vehicle.

INSTALLATION - TIRE AND WHEEL ASSEMBLY

(STEEL WHEEL)

NOTE: Never use oil or grease on studs or wheel

mounting nuts.

(1) Position the tire and wheel assembly on the

wheel mounting studs using the hub pilot as a guide.

Place and hold the wheel flush up against the mount-

ing surface.

NOTE: Wheel mounting nuts must be installed on

the studs as shown (Fig. 14) to allow proper instal-

lation of the wheel cover.

(2) Using the valve stem as an index placed at the

12 O'clock position, install andlightly tightentwo

wheel mounting nuts on the studs located at the 4

O'clock and 8 O'clock positions as shown (Fig. 14).

Fig. 12 NUTS SECURING WHEEL COVER

1 - VALVE STEM

2 - BOLT-ON WHEEL COVER

3 - NUTS SECURING WHEEL COVER

Fig. 13 Tightening Sequence

RSTIRES/WHEELS22-7

TIRES/WHEELS (Continued)

ProCarManuals.com

Page 2084 of 2321

(8) Install center roller channel end cover (Fig. 16).

(9) Install center stop on sliding door. (Refer to 23

- BODY/DOORS - SLIDING/STOP BUMPER -

INSTALLATION)

(10) Place upper roller stop bumper in position on

upper roller arm.

(11) Install screw to hold upper roller arm stop

bumper to upper roller arm (Fig. 14).

(12) Remove masking tape from body surfaces.

(13) Verify door operation and fit. Adjust as neces-

sary. (Refer to 23 - BODY/DOORS - SLIDING/SLID-

ING DOOR - ADJUSTMENTS)

SLIDING DOOR ADJUSTMENTS

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

PRELIMINARY CHECKS

(1) Close the sliding door, visually checking C-post

striker alignment entry into latch. Striker at this

point must not affect alignment. Striker should go

straight into the latching mechanism.

(2) On vehicles with left sliding doors, check the

fuel door blocker striker entry into latch. Striker at

this point must not affect alignment.

(3) Check C-post and B-post for door to aperture

gaps and door to door gaps. All gaps should be 5 mm

1 mm.

(4) Check door for height using character lines as

a reference. Also check roof contour as a controlling

factor.

Using the procedures noted below, adjust the side

door in the order the individual steps are called out.

DOOR FLUSHNESS ADJUSTMENT

(1) Check sliding door flushness at the C-pillar

striker.

(2) Adjust the C-pillar striker in or out untill the

door is flush.

(3) Check upper B-pillar flushness to A-pillar

cover.

(4) Loosen one nut on upper hinge and adjust door

in or out untill the door is flush.

(5) Check flushness at upper C-pillar.

(6) If upper C-pillar flushness is out of specifica-

tion use a heavy rubber malet on the door assembly

until door is in spec.

DOOR GAP ADJUSTMENT - UP/DOWN

UP/DOWN ADJUSTMENT

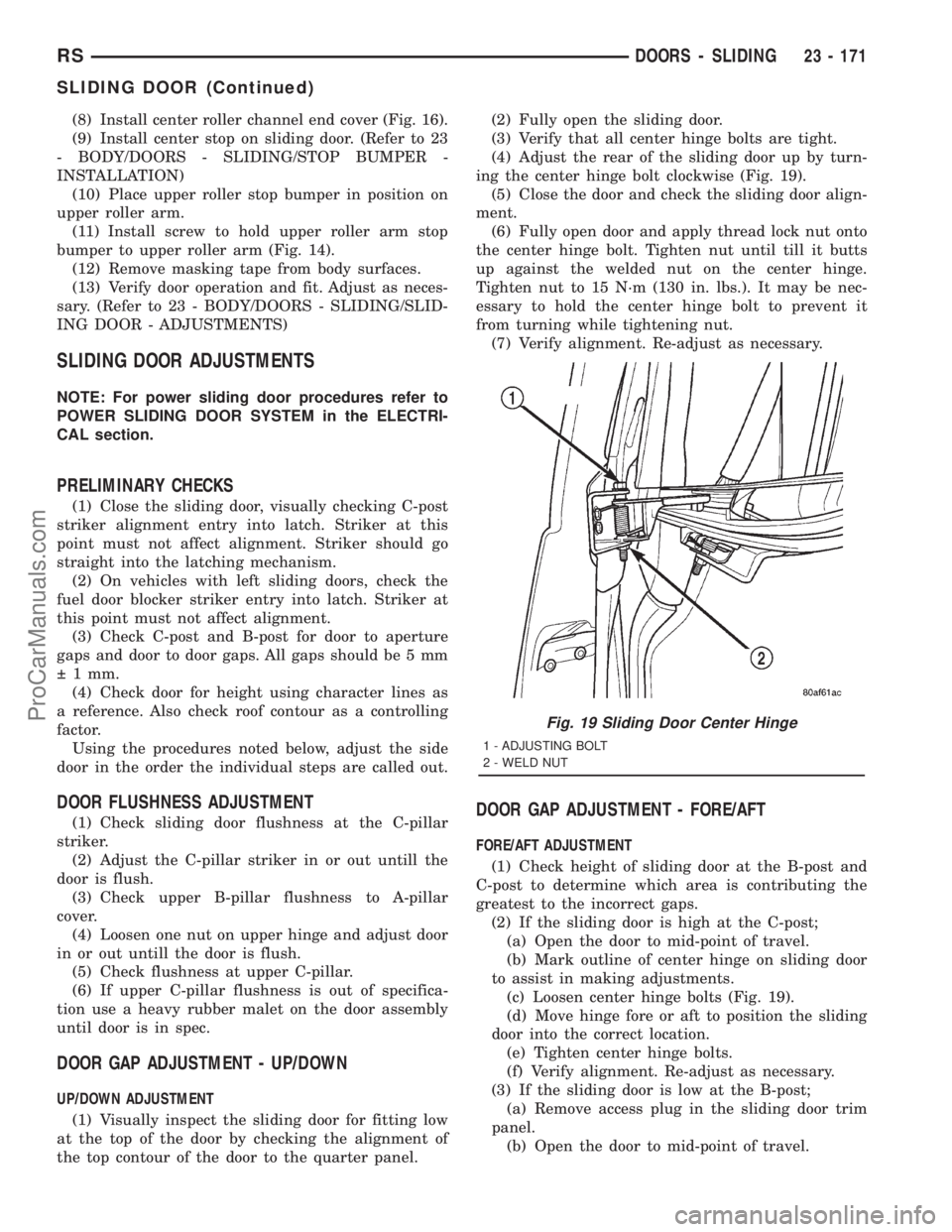

(1) Visually inspect the sliding door for fitting low

at the top of the door by checking the alignment of

the top contour of the door to the quarter panel.(2) Fully open the sliding door.

(3) Verify that all center hinge bolts are tight.

(4) Adjust the rear of the sliding door up by turn-

ing the center hinge bolt clockwise (Fig. 19).

(5) Close the door and check the sliding door align-

ment.

(6) Fully open door and apply thread lock nut onto

the center hinge bolt. Tighten nut until till it butts

up against the welded nut on the center hinge.

Tighten nut to 15 N´m (130 in. lbs.). It may be nec-

essary to hold the center hinge bolt to prevent it

from turning while tightening nut.

(7) Verify alignment. Re-adjust as necessary.

DOOR GAP ADJUSTMENT - FORE/AFT

FORE/AFT ADJUSTMENT

(1) Check height of sliding door at the B-post and

C-post to determine which area is contributing the

greatest to the incorrect gaps.

(2) If the sliding door is high at the C-post;

(a) Open the door to mid-point of travel.

(b) Mark outline of center hinge on sliding door

to assist in making adjustments.

(c) Loosen center hinge bolts (Fig. 19).

(d) Move hinge fore or aft to position the sliding

door into the correct location.

(e) Tighten center hinge bolts.

(f) Verify alignment. Re-adjust as necessary.

(3) If the sliding door is low at the B-post;

(a) Remove access plug in the sliding door trim

panel.

(b) Open the door to mid-point of travel.

Fig. 19 Sliding Door Center Hinge

1 - ADJUSTING BOLT

2 - WELD NUT

RSDOORS - SLIDING23 - 171

SLIDING DOOR (Continued)

ProCarManuals.com