DODGE TOWN AND COUNTRY 2001 Service Manual

Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 1791 of 2321

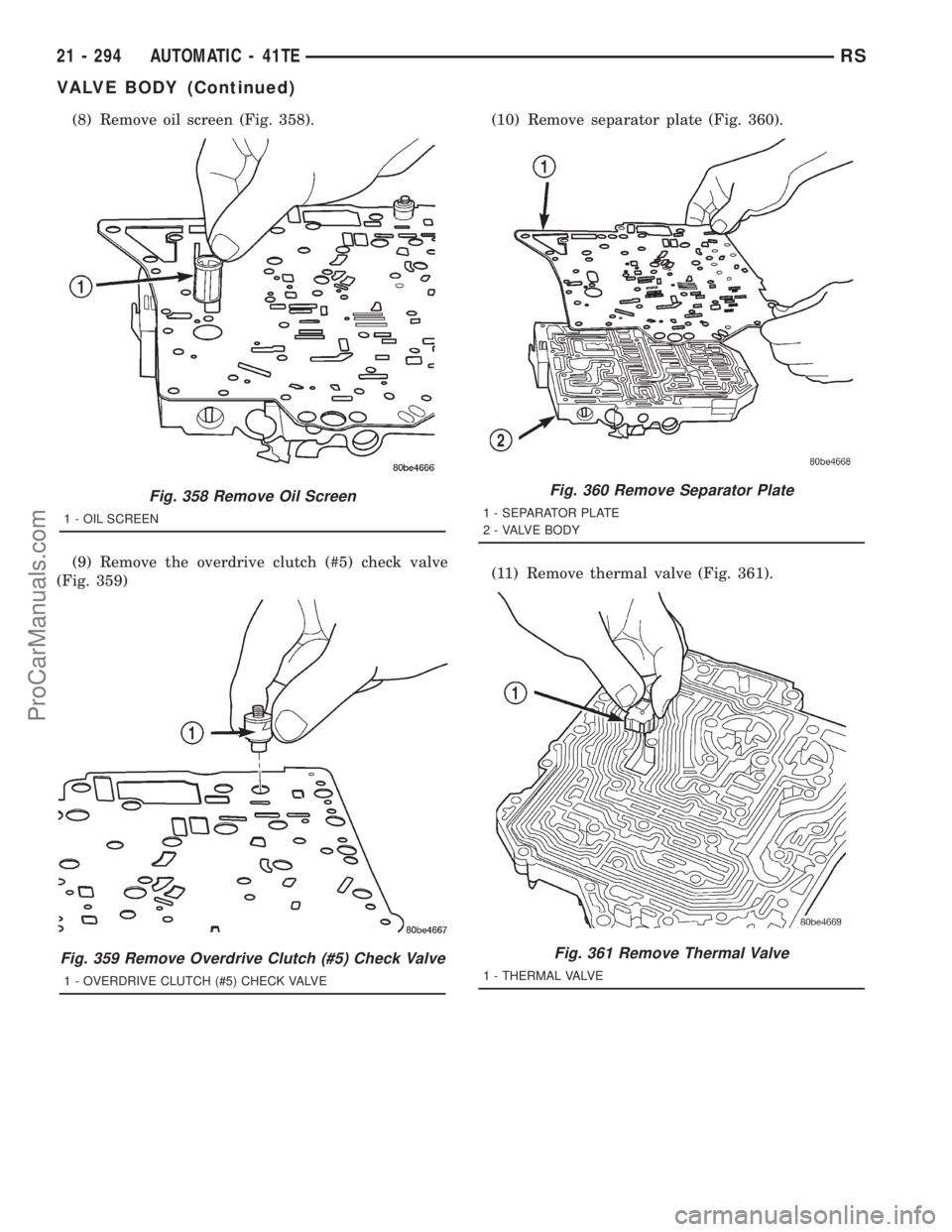

(8) Remove oil screen (Fig. 358).

(9) Remove the overdrive clutch (#5) check valve

(Fig. 359)(10) Remove separator plate (Fig. 360).

(11) Remove thermal valve (Fig. 361).

Fig. 358 Remove Oil Screen

1 - OIL SCREEN

Fig. 359 Remove Overdrive Clutch (#5) Check Valve

1 - OVERDRIVE CLUTCH (#5) CHECK VALVE

Fig. 360 Remove Separator Plate

1 - SEPARATOR PLATE

2 - VALVE BODY

Fig. 361 Remove Thermal Valve

1 - THERMAL VALVE

21 - 294 AUTOMATIC - 41TERS

VALVE BODY (Continued)

ProCarManuals.com

Page 1792 of 2321

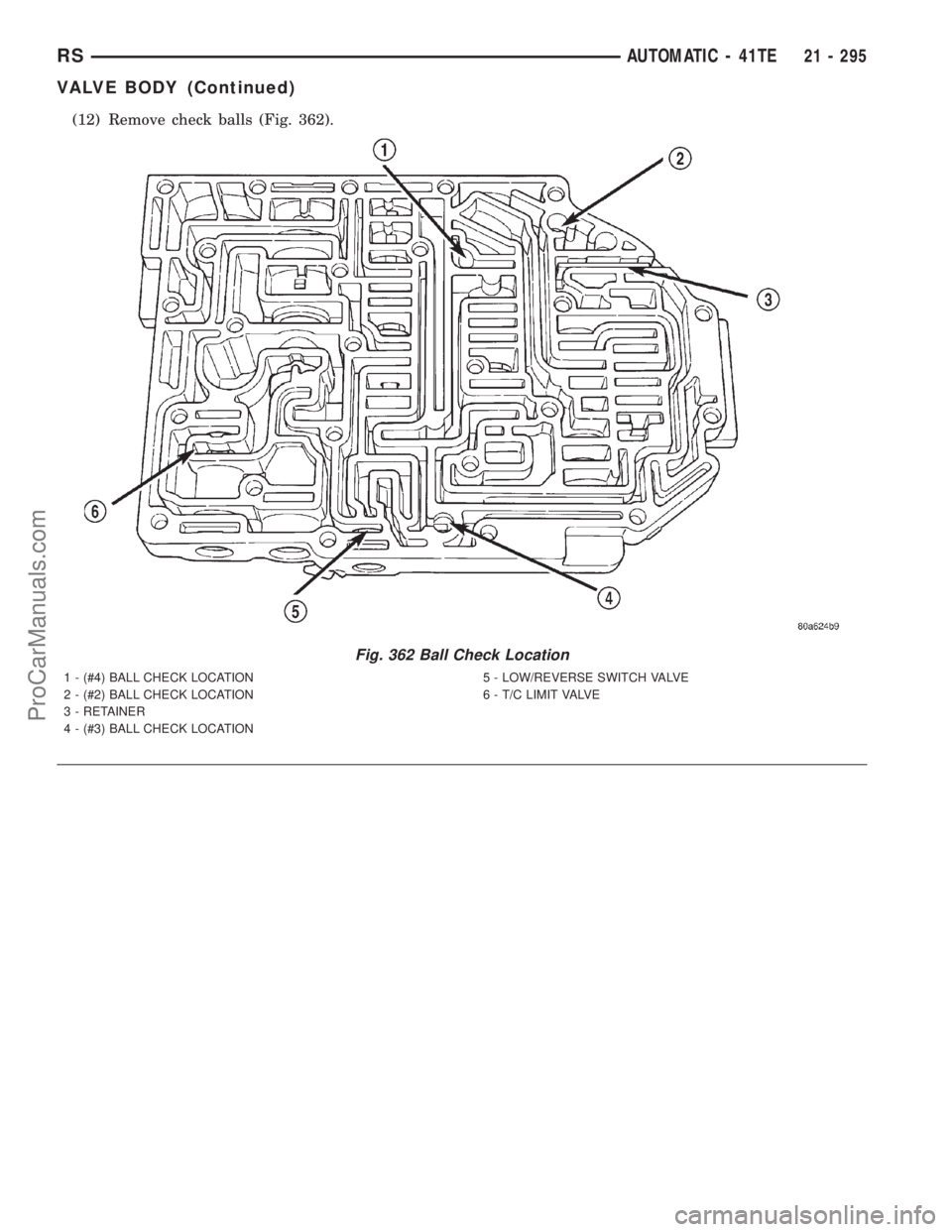

(12) Remove check balls (Fig. 362).

Fig. 362 Ball Check Location

1 - (#4) BALL CHECK LOCATION

2 - (#2) BALL CHECK LOCATION

3 - RETAINER

4 - (#3) BALL CHECK LOCATION5 - LOW/REVERSE SWITCH VALVE

6 - T/C LIMIT VALVE

RSAUTOMATIC - 41TE21 - 295

VALVE BODY (Continued)

ProCarManuals.com

Page 1793 of 2321

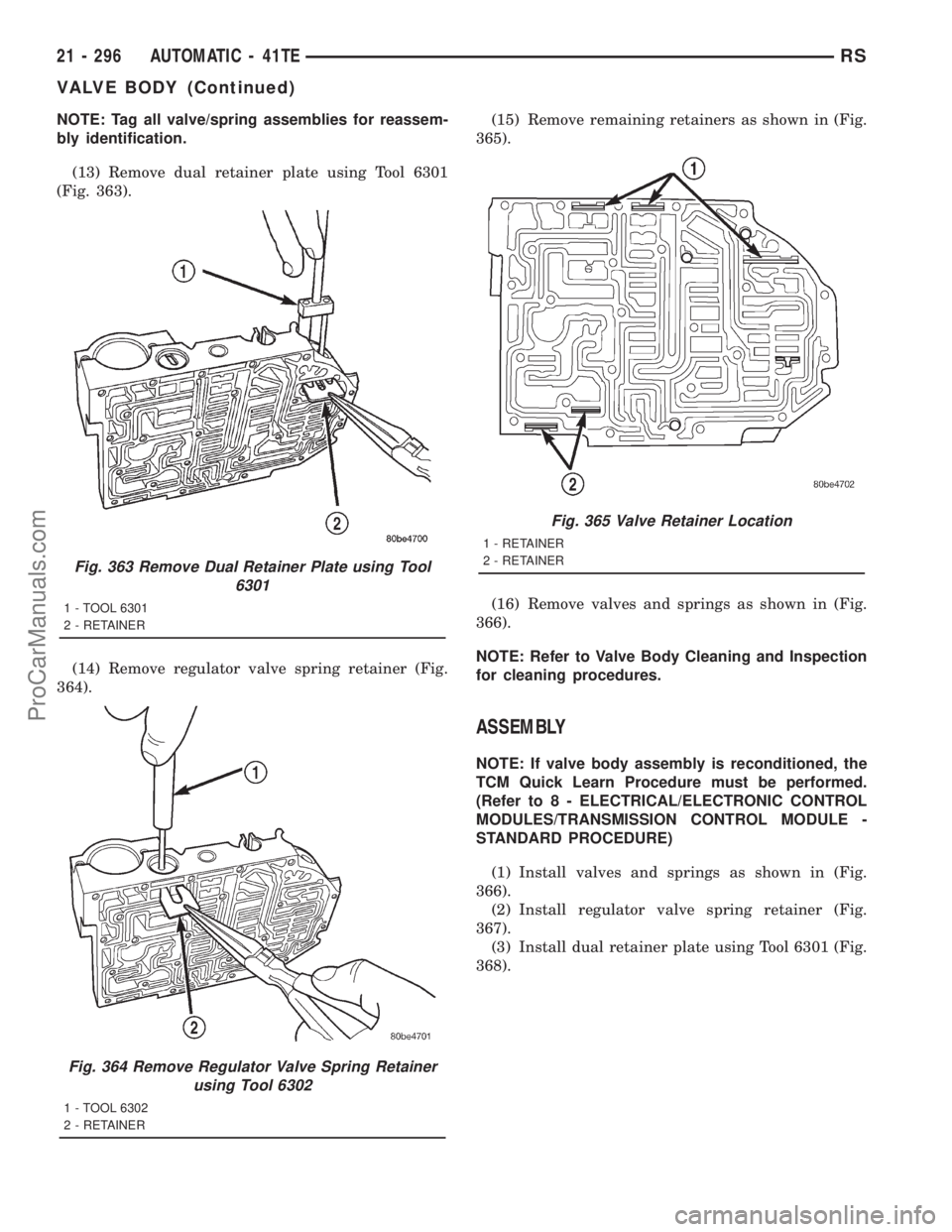

NOTE: Tag all valve/spring assemblies for reassem-

bly identification.

(13) Remove dual retainer plate using Tool 6301

(Fig. 363).

(14) Remove regulator valve spring retainer (Fig.

364).(15) Remove remaining retainers as shown in (Fig.

365).

(16) Remove valves and springs as shown in (Fig.

366).

NOTE: Refer to Valve Body Cleaning and Inspection

for cleaning procedures.

ASSEMBLY

NOTE: If valve body assembly is reconditioned, the

TCM Quick Learn Procedure must be performed.

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/TRANSMISSION CONTROL MODULE -

STANDARD PROCEDURE)

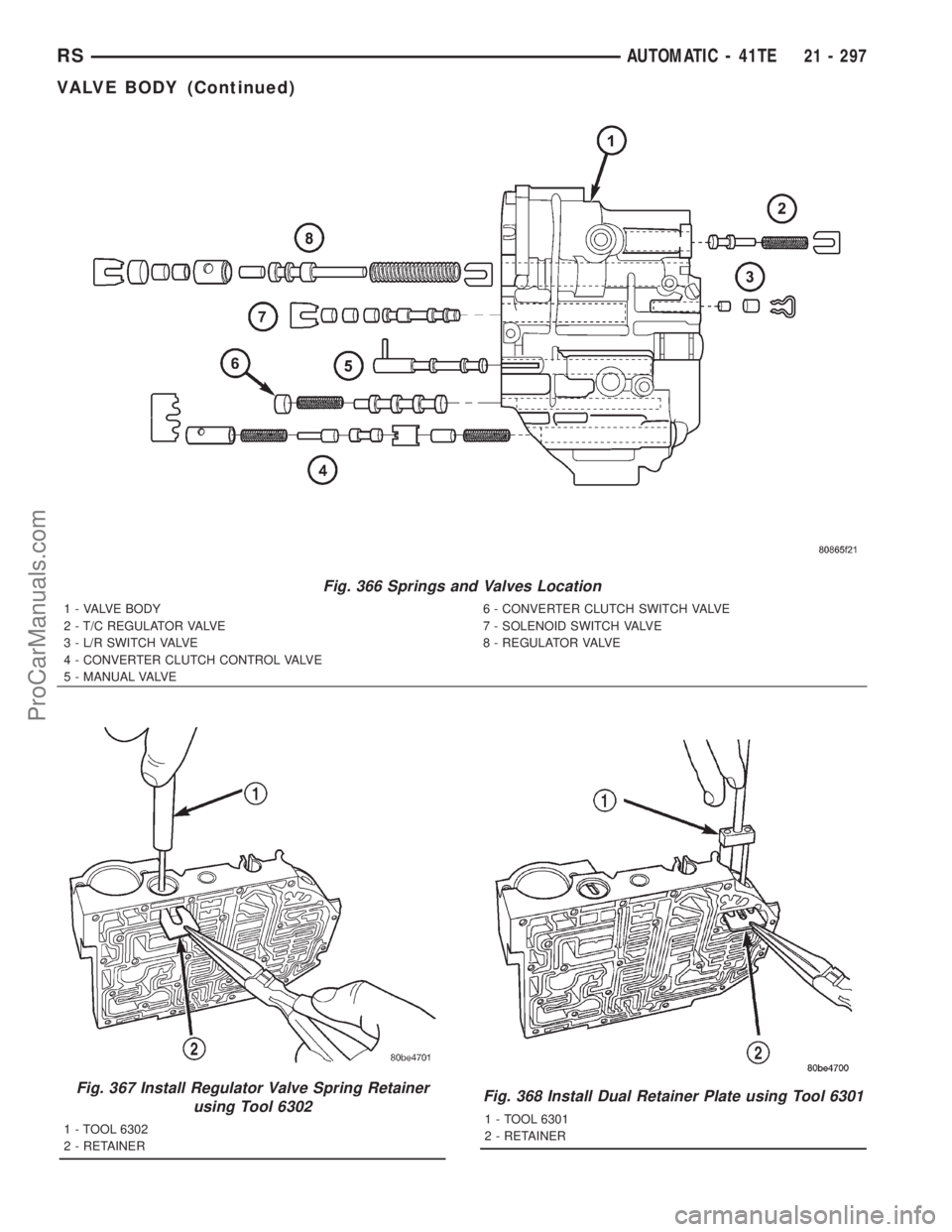

(1) Install valves and springs as shown in (Fig.

366).

(2) Install regulator valve spring retainer (Fig.

367).

(3) Install dual retainer plate using Tool 6301 (Fig.

368).

Fig. 363 Remove Dual Retainer Plate using Tool

6301

1 - TOOL 6301

2 - RETAINER

Fig. 364 Remove Regulator Valve Spring Retainer

using Tool 6302

1 - TOOL 6302

2 - RETAINER

Fig. 365 Valve Retainer Location

1 - RETAINER

2 - RETAINER

21 - 296 AUTOMATIC - 41TERS

VALVE BODY (Continued)

ProCarManuals.com

Page 1794 of 2321

Fig. 366 Springs and Valves Location

1 - VALVE BODY

2 - T/C REGULATOR VALVE

3 - L/R SWITCH VALVE

4 - CONVERTER CLUTCH CONTROL VALVE

5 - MANUAL VALVE6 - CONVERTER CLUTCH SWITCH VALVE

7 - SOLENOID SWITCH VALVE

8 - REGULATOR VALVE

Fig. 367 Install Regulator Valve Spring Retainer

using Tool 6302

1 - TOOL 6302

2 - RETAINER

Fig. 368 Install Dual Retainer Plate using Tool 6301

1 - TOOL 6301

2 - RETAINER

RSAUTOMATIC - 41TE21 - 297

VALVE BODY (Continued)

ProCarManuals.com

Page 1795 of 2321

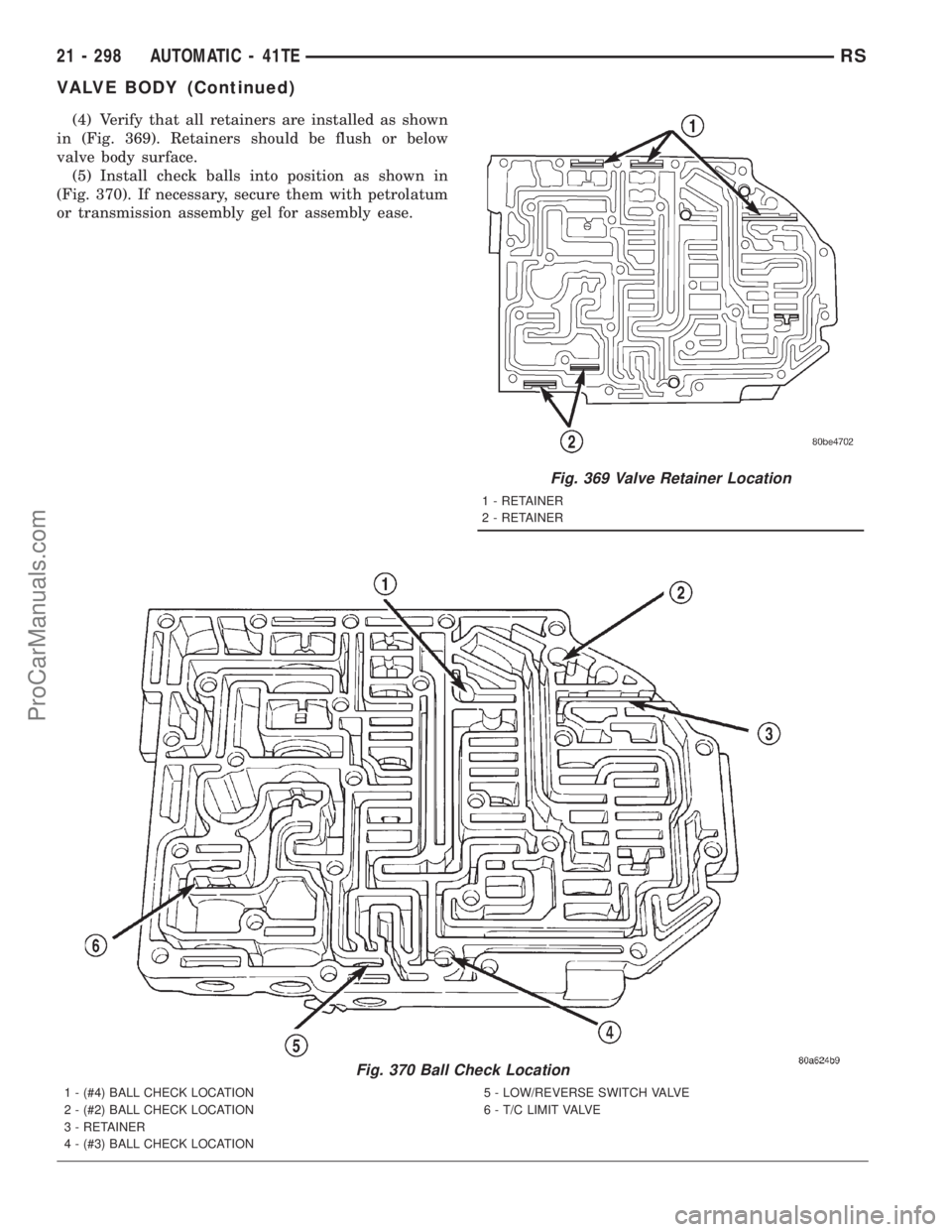

(4) Verify that all retainers are installed as shown

in (Fig. 369). Retainers should be flush or below

valve body surface.

(5) Install check balls into position as shown in

(Fig. 370). If necessary, secure them with petrolatum

or transmission assembly gel for assembly ease.

Fig. 369 Valve Retainer Location

1 - RETAINER

2 - RETAINER

Fig. 370 Ball Check Location

1 - (#4) BALL CHECK LOCATION

2 - (#2) BALL CHECK LOCATION

3 - RETAINER

4 - (#3) BALL CHECK LOCATION5 - LOW/REVERSE SWITCH VALVE

6 - T/C LIMIT VALVE

21 - 298 AUTOMATIC - 41TERS

VALVE BODY (Continued)

ProCarManuals.com

Page 1796 of 2321

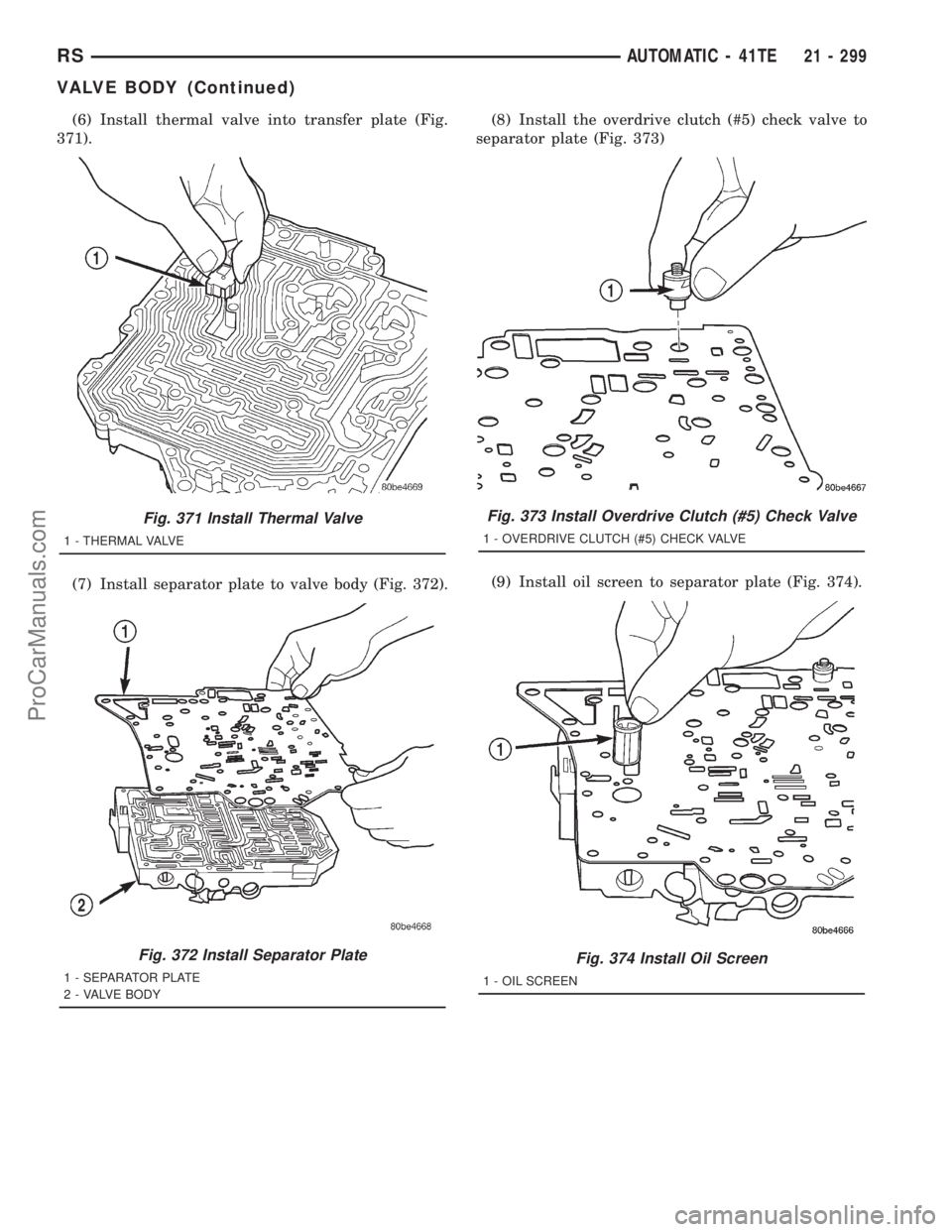

(6) Install thermal valve into transfer plate (Fig.

371).

(7) Install separator plate to valve body (Fig. 372).(8) Install the overdrive clutch (#5) check valve to

separator plate (Fig. 373)

(9) Install oil screen to separator plate (Fig. 374).

Fig. 371 Install Thermal Valve

1 - THERMAL VALVE

Fig. 372 Install Separator Plate

1 - SEPARATOR PLATE

2 - VALVE BODY

Fig. 373 Install Overdrive Clutch (#5) Check Valve

1 - OVERDRIVE CLUTCH (#5) CHECK VALVE

Fig. 374 Install Oil Screen

1 - OIL SCREEN

RSAUTOMATIC - 41TE21 - 299

VALVE BODY (Continued)

ProCarManuals.com

Page 1797 of 2321

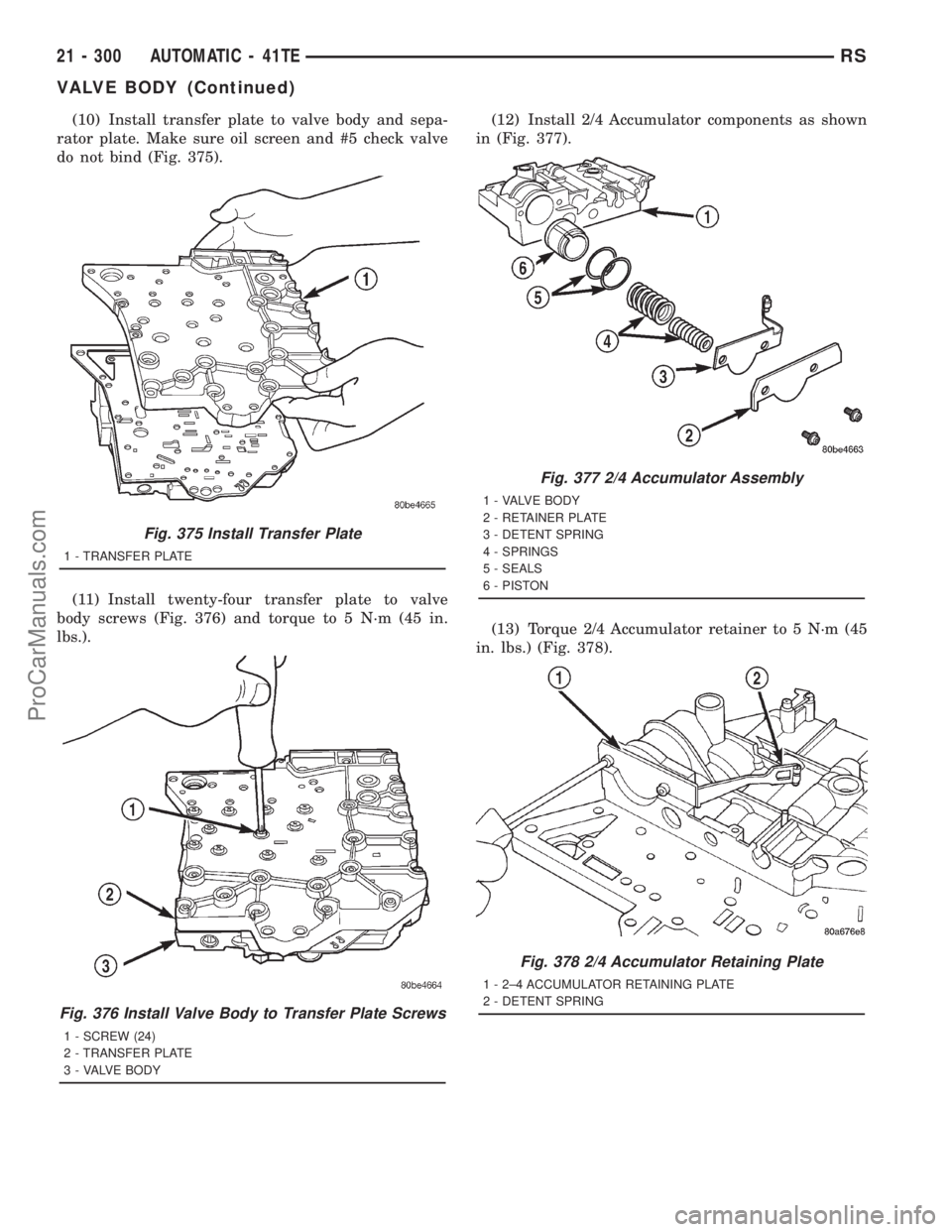

(10) Install transfer plate to valve body and sepa-

rator plate. Make sure oil screen and #5 check valve

do not bind (Fig. 375).

(11) Install twenty-four transfer plate to valve

body screws (Fig. 376) and torque to 5 N´m (45 in.

lbs.).(12) Install 2/4 Accumulator components as shown

in (Fig. 377).

(13) Torque 2/4 Accumulator retainer to 5 N´m (45

in. lbs.) (Fig. 378).

Fig. 375 Install Transfer Plate

1 - TRANSFER PLATE

Fig. 376 Install Valve Body to Transfer Plate Screws

1 - SCREW (24)

2 - TRANSFER PLATE

3 - VALVE BODY

Fig. 377 2/4 Accumulator Assembly

1 - VALVE BODY

2 - RETAINER PLATE

3 - DETENT SPRING

4 - SPRINGS

5 - SEALS

6 - PISTON

Fig. 378 2/4 Accumulator Retaining Plate

1 - 2±4 ACCUMULATOR RETAINING PLATE

2 - DETENT SPRING

21 - 300 AUTOMATIC - 41TERS

VALVE BODY (Continued)

ProCarManuals.com

Page 1798 of 2321

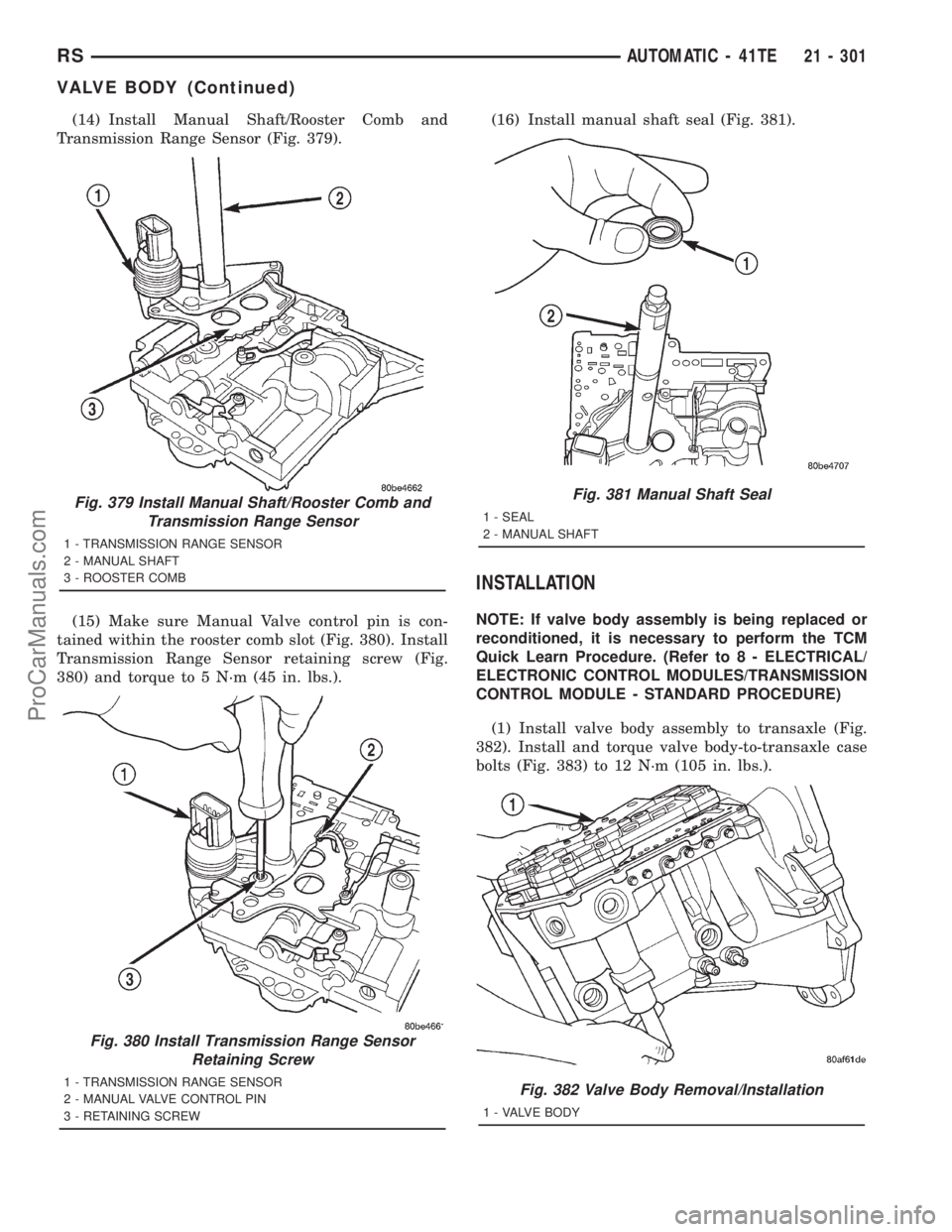

(14) Install Manual Shaft/Rooster Comb and

Transmission Range Sensor (Fig. 379).

(15) Make sure Manual Valve control pin is con-

tained within the rooster comb slot (Fig. 380). Install

Transmission Range Sensor retaining screw (Fig.

380) and torque to 5 N´m (45 in. lbs.).(16) Install manual shaft seal (Fig. 381).

INSTALLATION

NOTE: If valve body assembly is being replaced or

reconditioned, it is necessary to perform the TCM

Quick Learn Procedure. (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/TRANSMISSION

CONTROL MODULE - STANDARD PROCEDURE)

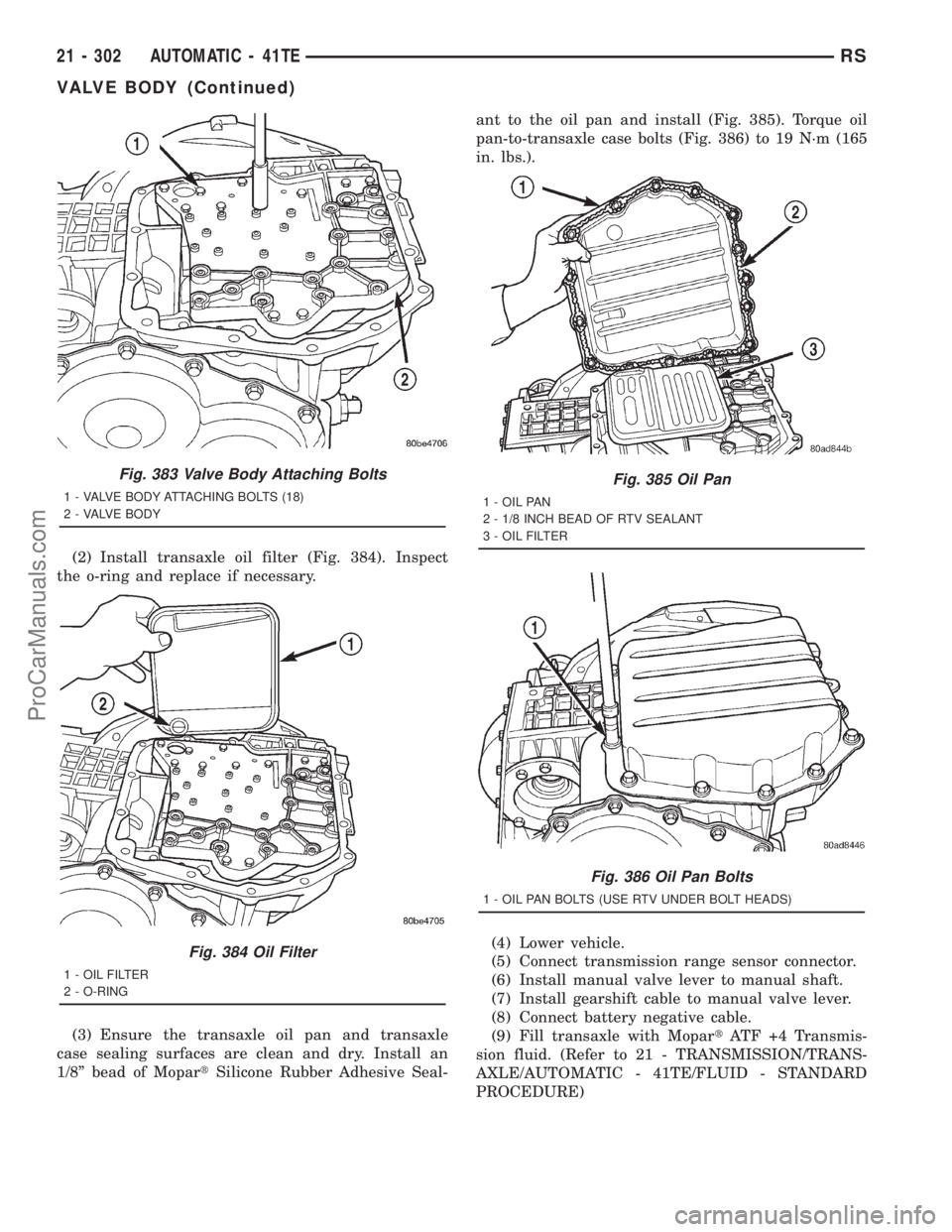

(1) Install valve body assembly to transaxle (Fig.

382). Install and torque valve body-to-transaxle case

bolts (Fig. 383) to 12 N´m (105 in. lbs.).

Fig. 379 Install Manual Shaft/Rooster Comb and

Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL SHAFT

3 - ROOSTER COMB

Fig. 380 Install Transmission Range Sensor

Retaining Screw

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL VALVE CONTROL PIN

3 - RETAINING SCREW

Fig. 381 Manual Shaft Seal

1 - SEAL

2 - MANUAL SHAFT

Fig. 382 Valve Body Removal/Installation

1 - VALVE BODY

RSAUTOMATIC - 41TE21 - 301

VALVE BODY (Continued)

ProCarManuals.com

Page 1799 of 2321

(2) Install transaxle oil filter (Fig. 384). Inspect

the o-ring and replace if necessary.

(3) Ensure the transaxle oil pan and transaxle

case sealing surfaces are clean and dry. Install an

1/8º bead of MopartSilicone Rubber Adhesive Seal-ant to the oil pan and install (Fig. 385). Torque oil

pan-to-transaxle case bolts (Fig. 386) to 19 N´m (165

in. lbs.).

(4) Lower vehicle.

(5) Connect transmission range sensor connector.

(6) Install manual valve lever to manual shaft.

(7) Install gearshift cable to manual valve lever.

(8) Connect battery negative cable.

(9) Fill transaxle with MopartATF +4 Transmis-

sion fluid. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 41TE/FLUID - STANDARD

PROCEDURE)

Fig. 383 Valve Body Attaching Bolts

1 - VALVE BODY ATTACHING BOLTS (18)

2 - VALVE BODY

Fig. 384 Oil Filter

1 - OIL FILTER

2 - O-RING

Fig. 385 Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF RTV SEALANT

3 - OIL FILTER

Fig. 386 Oil Pan Bolts

1 - OIL PAN BOLTS (USE RTV UNDER BOLT HEADS)

21 - 302 AUTOMATIC - 41TERS

VALVE BODY (Continued)

ProCarManuals.com

Page 1800 of 2321

T850 MANUAL TRANSAXLE

TABLE OF CONTENTS

page

T850 MANUAL TRANSAXLE.................1

T850 MANUAL TRANSAXLE

TABLE OF CONTENTS

page page

T850 MANUAL TRANSAXLE

DESCRIPTION............................2

OPERATION.............................4

DIAGNOSIS AND TESTING.................11

DIAGNOSIS AND TESTING - COMMON

PROBLEM CAUSES.....................11

REMOVAL..............................11

DISASSEMBLY...........................17

ASSEMBLY.............................22

INSTALLATION...........................31

SPECIFICATIONS........................37

SPECIAL TOOLS.........................39

AXLE SEALS

REMOVAL..............................42

INSTALLATION...........................42

BACK-UP LAMP SWITCH

REMOVAL..............................43

INSTALLATION...........................43

DIFFERENTIAL

DESCRIPTION...........................43

OPERATION.............................43

DISASSEMBLY...........................44

ASSEMBLY.............................47

ADJUSTMENTS..........................50

FLUID

STANDARD PROCEDURE..................52

STANDARD PROCEDURE - FLUID LEVEL

CHECK...............................52

STANDARD PROCEDURE - FLUID DRAIN

AND FILL.............................53

GEARSHIFT BOOT

REMOVAL..............................53

INSTALLATION...........................53

GEARSHIFT CABLE - CROSSOVER

REMOVAL..............................54INSTALLATION...........................56

ADJUSTMENTS..........................60

GEARSHIFT CABLE - SELECTOR

REMOVAL..............................61

INSTALLATION...........................64

GEARSHIFT KNOB

REMOVAL..............................67

INSTALLATION...........................67

GEARSHIFT MECHANISM

REMOVAL..............................68

INSTALLATION...........................70

INPUT SHAFT

DESCRIPTION...........................73

DISASSEMBLY...........................74

ASSEMBLY.............................77

INTERMEDIATE SHAFT

DESCRIPTION...........................81

DISASSEMBLY...........................81

ASSEMBLY.............................88

SHIFT COVER

DESCRIPTION...........................94

SHIFT FORK AND SHAFT

DESCRIPTION...........................95

SYNCHRONIZER

DESCRIPTION...........................95

DISASSEMBLY...........................95

CLEANING..............................95

INSPECTION............................95

ASSEMBLY.............................95

VEHICLE SPEED SENSOR

REMOVAL..............................96

INSTALLATION...........................96

RGT850 MANUAL TRANSAXLE21a-1

ProCarManuals.com