DODGE TOWN AND COUNTRY 2001 Service Manual

Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 1811 of 2321

(14) Disconnect back-up lamp switch connector.

(15) Remove structural collar.

(16) Remove modular clutch assembly-to-drive

plate bolts.

(17) Position screw jack and wood block to engine

oil pan.

(18) Remove transmission upper mount through-

bolt from left frame rail.

(19) Lower engine/transaxle assembly on screw

jack.

(20) Remove four (4) upper mount-to-transaxle

bolts and remove mount (Fig. 15).

(21) Obtain helper and transmission jack. Secure

transaxle to transmission jack and remove transaxle-

to-engine bolts.

(22) Remove transaxle from engine.

(23) Inspect modular clutch assembly, clutch

release components, and engine drive plate.

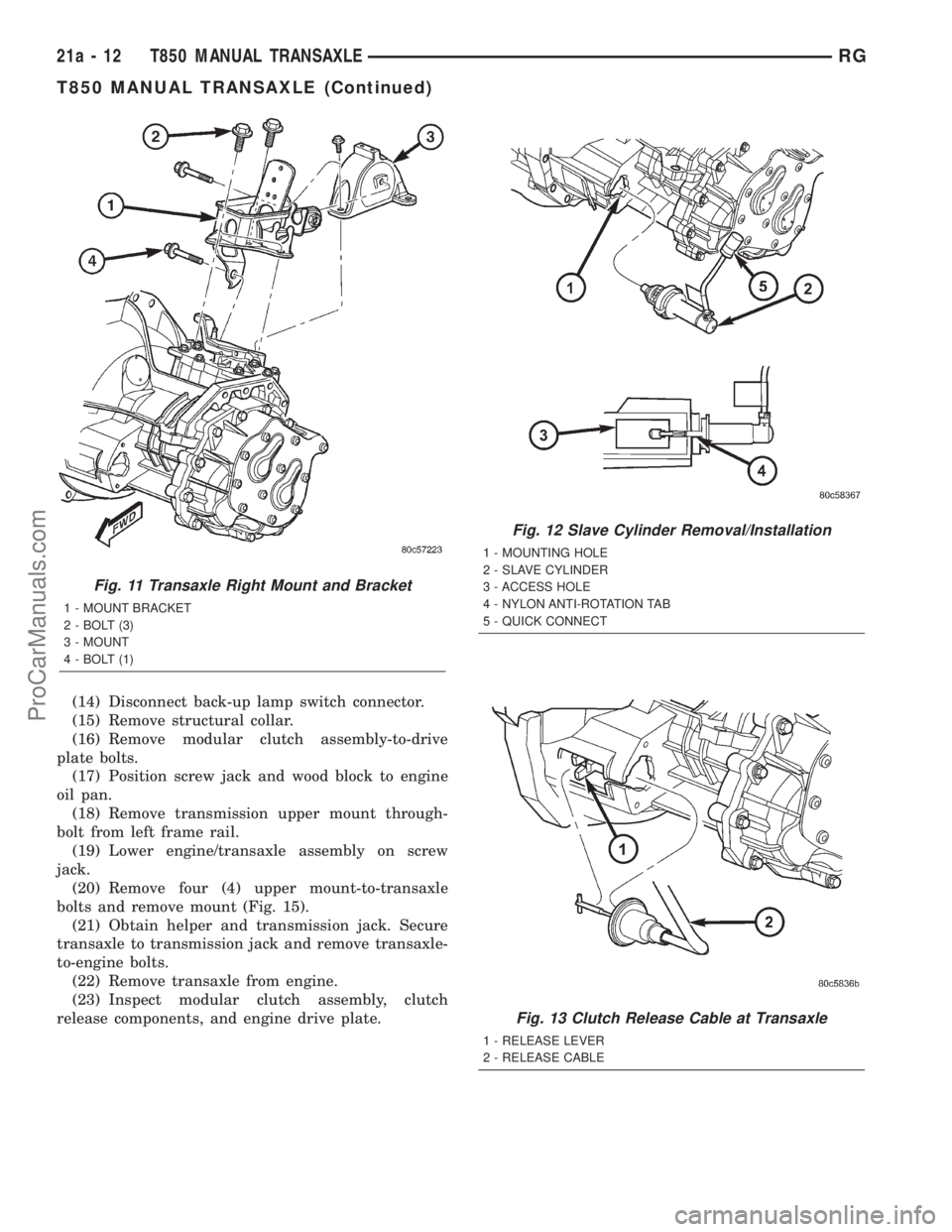

Fig. 11 Transaxle Right Mount and Bracket

1 - MOUNT BRACKET

2 - BOLT (3)

3 - MOUNT

4 - BOLT (1)

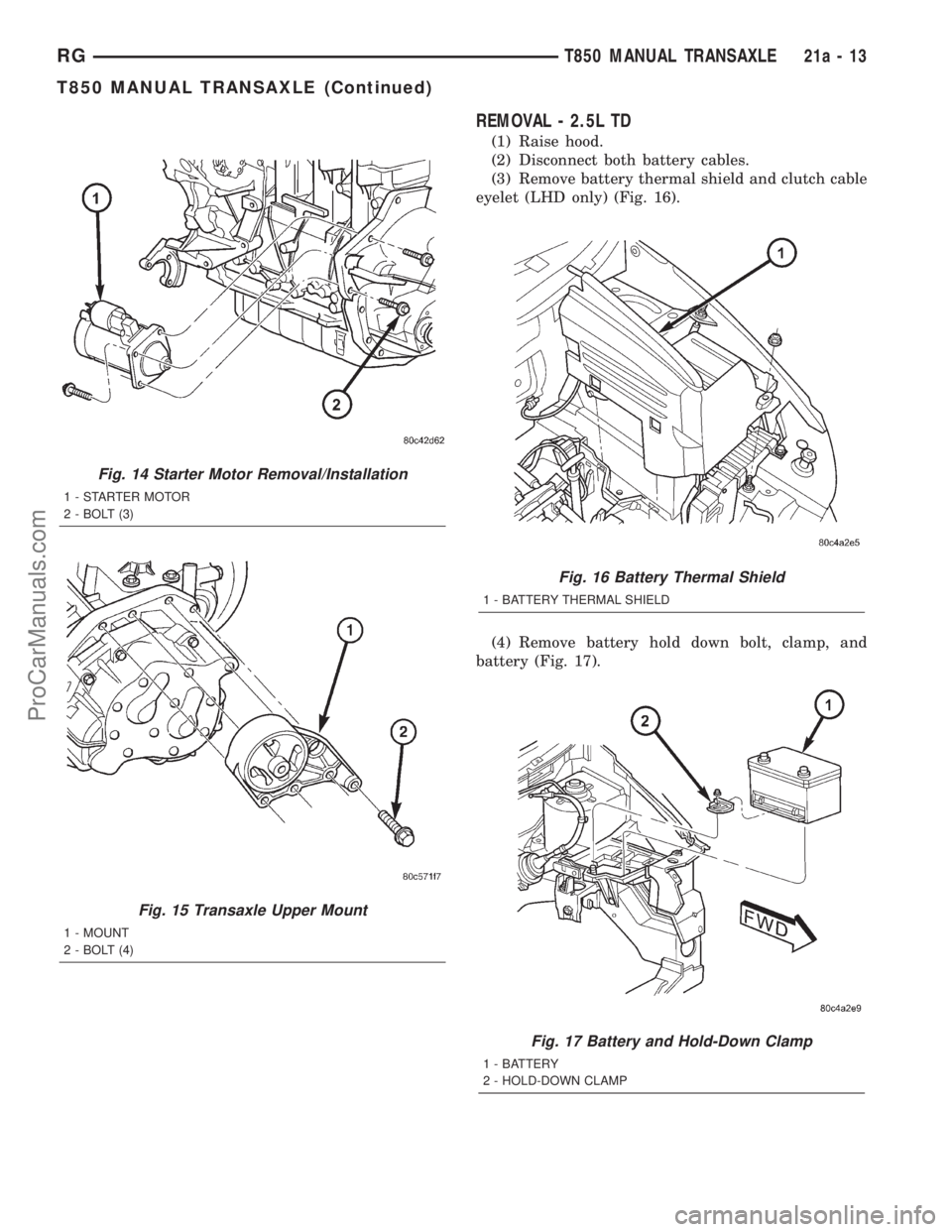

Fig. 12 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 13 Clutch Release Cable at Transaxle

1 - RELEASE LEVER

2 - RELEASE CABLE

21a - 12 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1812 of 2321

REMOVAL - 2.5L TD

(1) Raise hood.

(2) Disconnect both battery cables.

(3) Remove battery thermal shield and clutch cable

eyelet (LHD only) (Fig. 16).

(4) Remove battery hold down bolt, clamp, and

battery (Fig. 17).

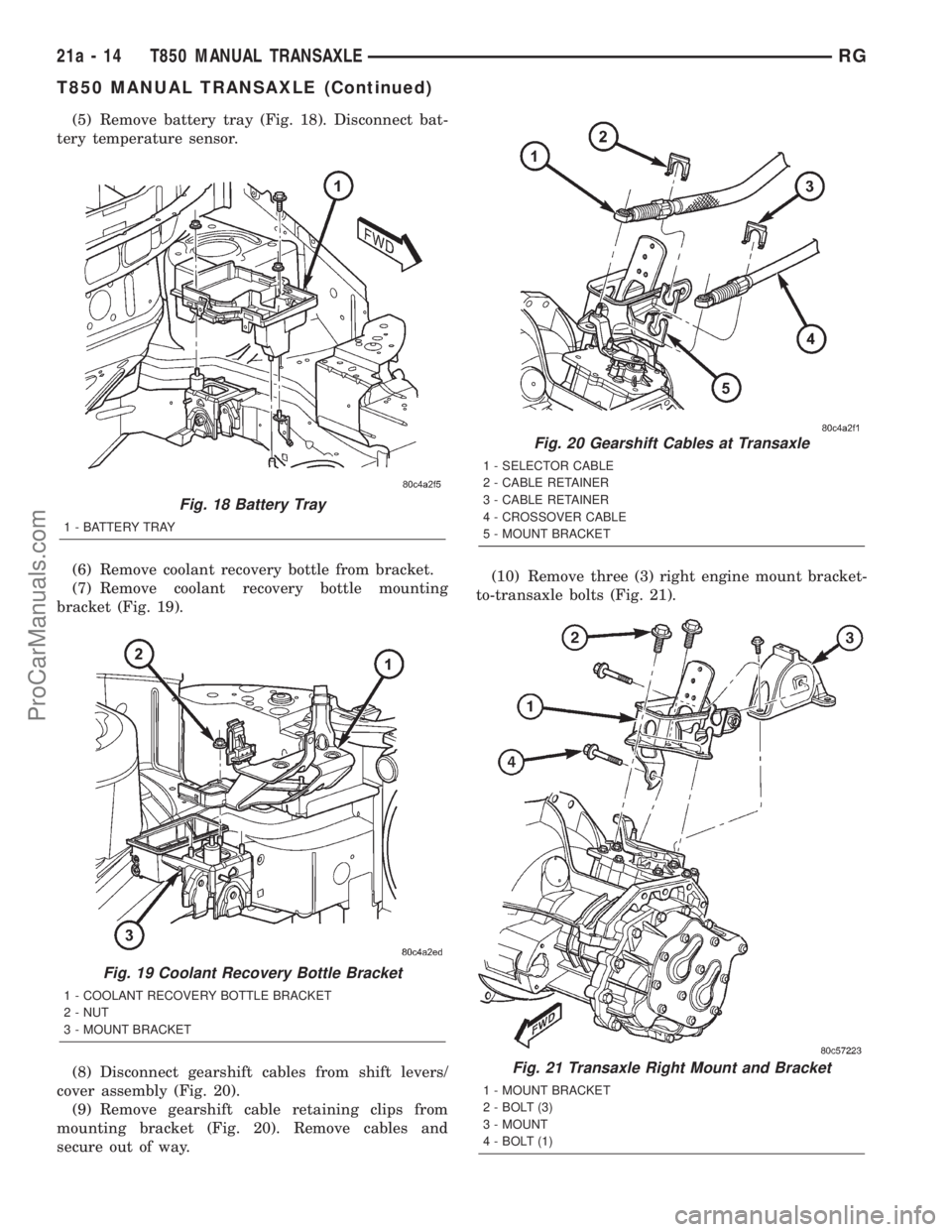

Fig. 14 Starter Motor Removal/Installation

1 - STARTER MOTOR

2 - BOLT (3)

Fig. 15 Transaxle Upper Mount

1 - MOUNT

2 - BOLT (4)

Fig. 16 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

Fig. 17 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

RGT850 MANUAL TRANSAXLE21a-13

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1813 of 2321

(5) Remove battery tray (Fig. 18). Disconnect bat-

tery temperature sensor.

(6) Remove coolant recovery bottle from bracket.

(7) Remove coolant recovery bottle mounting

bracket (Fig. 19).

(8) Disconnect gearshift cables from shift levers/

cover assembly (Fig. 20).

(9) Remove gearshift cable retaining clips from

mounting bracket (Fig. 20). Remove cables and

secure out of way.(10) Remove three (3) right engine mount bracket-

to-transaxle bolts (Fig. 21).

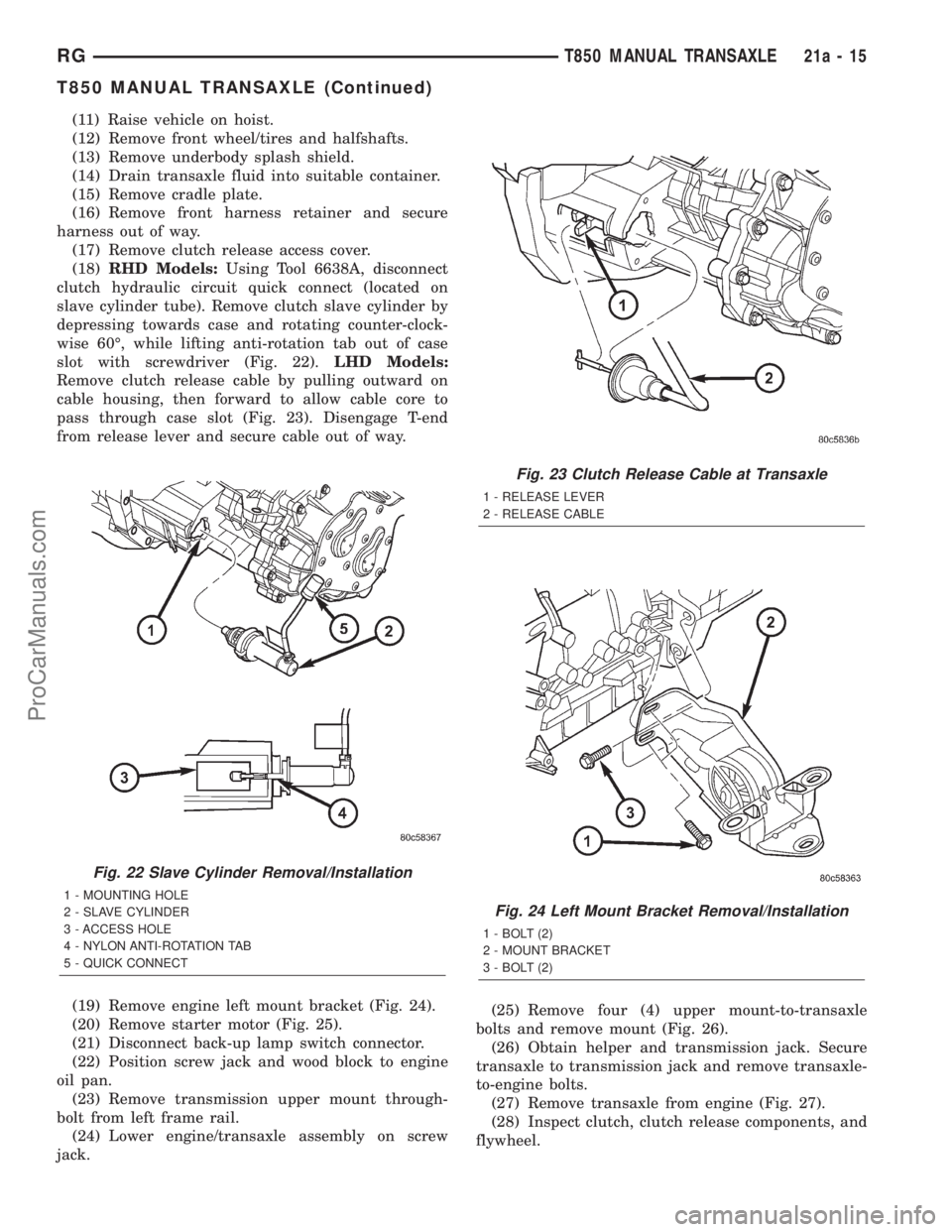

Fig. 18 Battery Tray

1 - BATTERY TRAY

Fig. 19 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

Fig. 20 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 21 Transaxle Right Mount and Bracket

1 - MOUNT BRACKET

2 - BOLT (3)

3 - MOUNT

4 - BOLT (1)

21a - 14 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1814 of 2321

(11) Raise vehicle on hoist.

(12) Remove front wheel/tires and halfshafts.

(13) Remove underbody splash shield.

(14) Drain transaxle fluid into suitable container.

(15) Remove cradle plate.

(16) Remove front harness retainer and secure

harness out of way.

(17) Remove clutch release access cover.

(18)RHD Models:Using Tool 6638A, disconnect

clutch hydraulic circuit quick connect (located on

slave cylinder tube). Remove clutch slave cylinder by

depressing towards case and rotating counter-clock-

wise 60É, while lifting anti-rotation tab out of case

slot with screwdriver (Fig. 22).LHD Models:

Remove clutch release cable by pulling outward on

cable housing, then forward to allow cable core to

pass through case slot (Fig. 23). Disengage T-end

from release lever and secure cable out of way.

(19) Remove engine left mount bracket (Fig. 24).

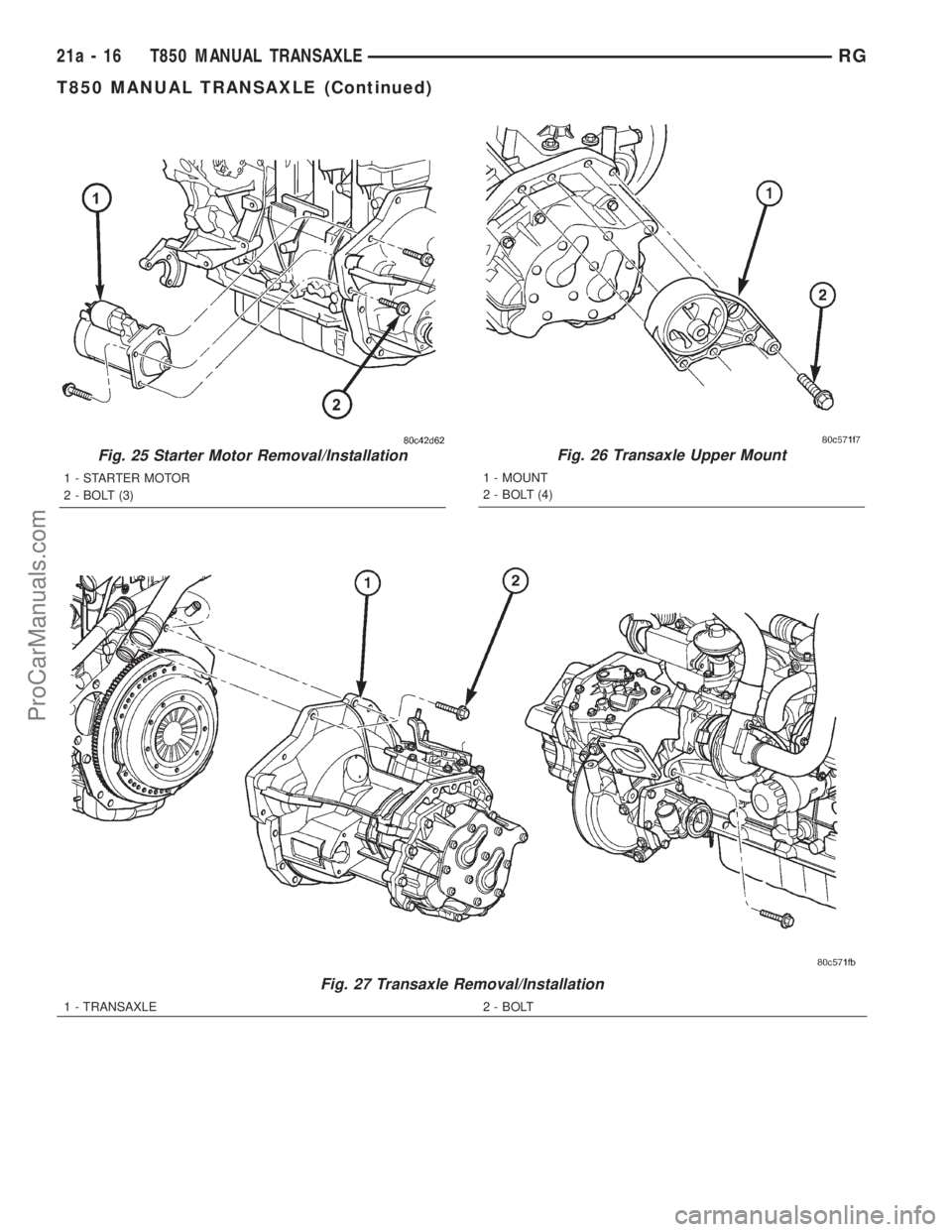

(20) Remove starter motor (Fig. 25).

(21) Disconnect back-up lamp switch connector.

(22) Position screw jack and wood block to engine

oil pan.

(23) Remove transmission upper mount through-

bolt from left frame rail.

(24) Lower engine/transaxle assembly on screw

jack.(25) Remove four (4) upper mount-to-transaxle

bolts and remove mount (Fig. 26).

(26) Obtain helper and transmission jack. Secure

transaxle to transmission jack and remove transaxle-

to-engine bolts.

(27) Remove transaxle from engine (Fig. 27).

(28) Inspect clutch, clutch release components, and

flywheel.

Fig. 22 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 23 Clutch Release Cable at Transaxle

1 - RELEASE LEVER

2 - RELEASE CABLE

Fig. 24 Left Mount Bracket Removal/Installation

1 - BOLT (2)

2 - MOUNT BRACKET

3 - BOLT (2)

RGT850 MANUAL TRANSAXLE21a-15

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1815 of 2321

Fig. 25 Starter Motor Removal/Installation

1 - STARTER MOTOR

2 - BOLT (3)

Fig. 26 Transaxle Upper Mount

1 - MOUNT

2 - BOLT (4)

Fig. 27 Transaxle Removal/Installation

1 - TRANSAXLE 2 - BOLT

21a - 16 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1816 of 2321

DISASSEMBLY

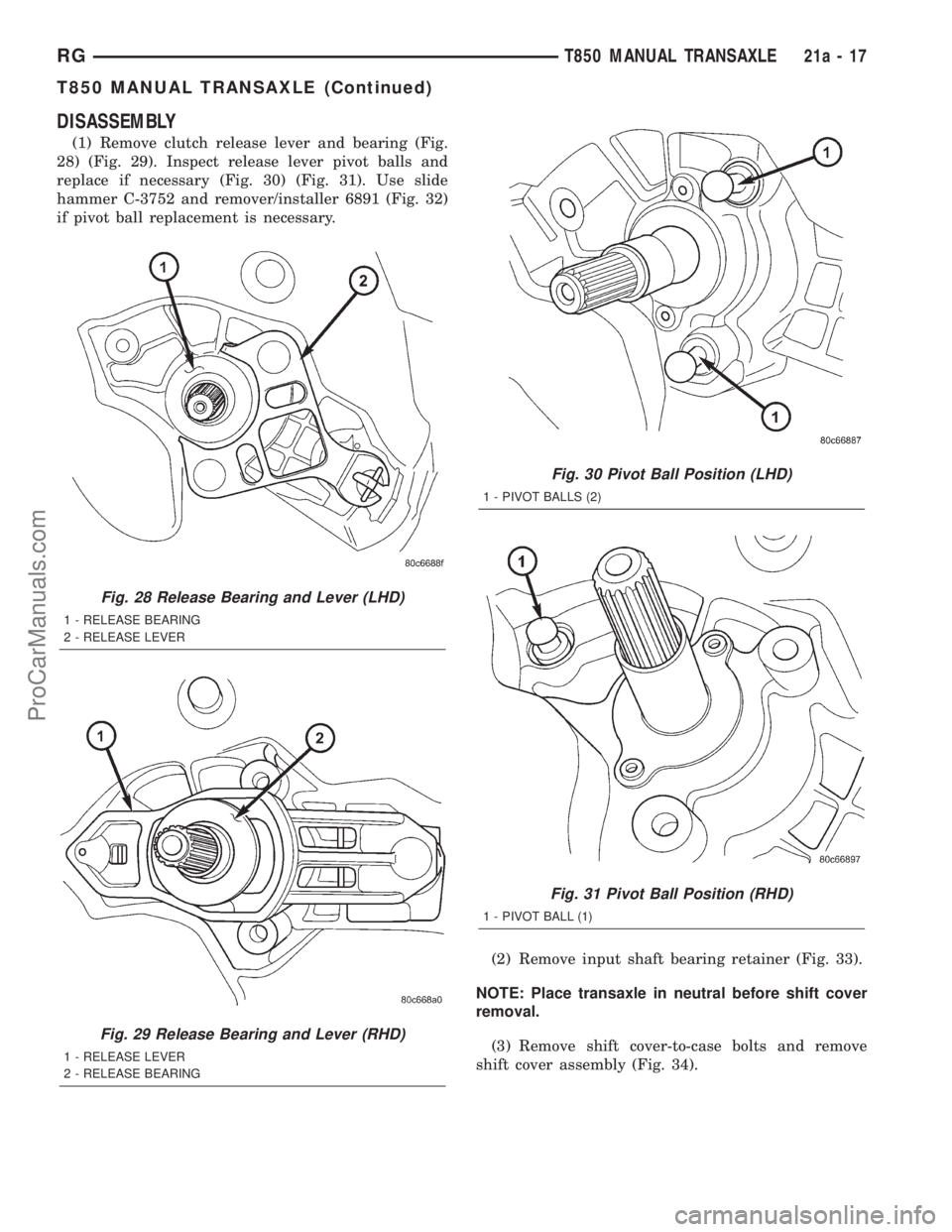

(1) Remove clutch release lever and bearing (Fig.

28) (Fig. 29). Inspect release lever pivot balls and

replace if necessary (Fig. 30) (Fig. 31). Use slide

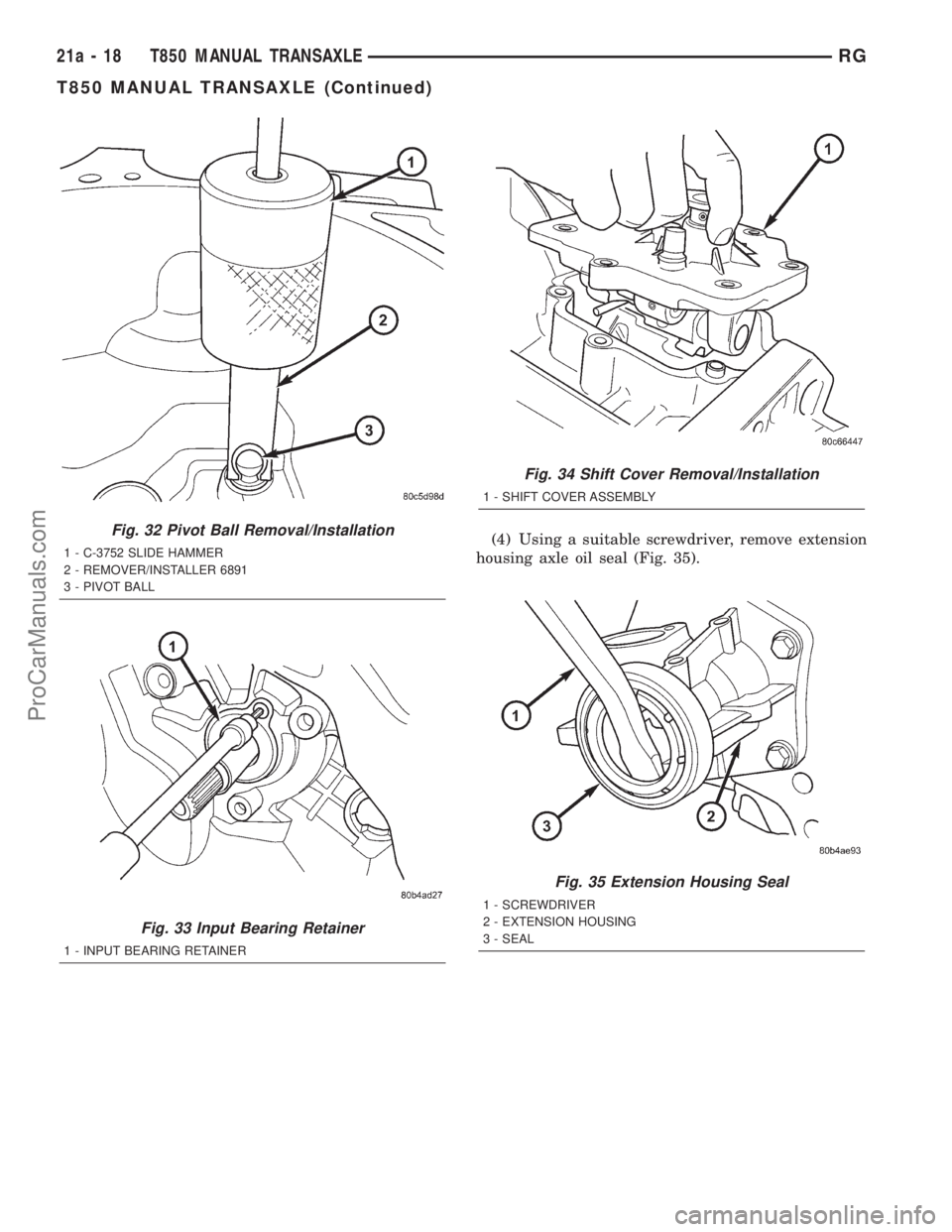

hammer C-3752 and remover/installer 6891 (Fig. 32)

if pivot ball replacement is necessary.

(2) Remove input shaft bearing retainer (Fig. 33).

NOTE: Place transaxle in neutral before shift cover

removal.

(3) Remove shift cover-to-case bolts and remove

shift cover assembly (Fig. 34).

Fig. 28 Release Bearing and Lever (LHD)

1 - RELEASE BEARING

2 - RELEASE LEVER

Fig. 29 Release Bearing and Lever (RHD)

1 - RELEASE LEVER

2 - RELEASE BEARING

Fig. 30 Pivot Ball Position (LHD)

1 - PIVOT BALLS (2)

Fig. 31 Pivot Ball Position (RHD)

1 - PIVOT BALL (1)

RGT850 MANUAL TRANSAXLE21a-17

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1817 of 2321

(4) Using a suitable screwdriver, remove extension

housing axle oil seal (Fig. 35).Fig. 32 Pivot Ball Removal/Installation

1 - C-3752 SLIDE HAMMER

2 - REMOVER/INSTALLER 6891

3 - PIVOT BALL

Fig. 33 Input Bearing Retainer

1 - INPUT BEARING RETAINER

Fig. 34 Shift Cover Removal/Installation

1 - SHIFT COVER ASSEMBLY

Fig. 35 Extension Housing Seal

1 - SCREWDRIVER

2 - EXTENSION HOUSING

3 - SEAL

21a - 18 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1818 of 2321

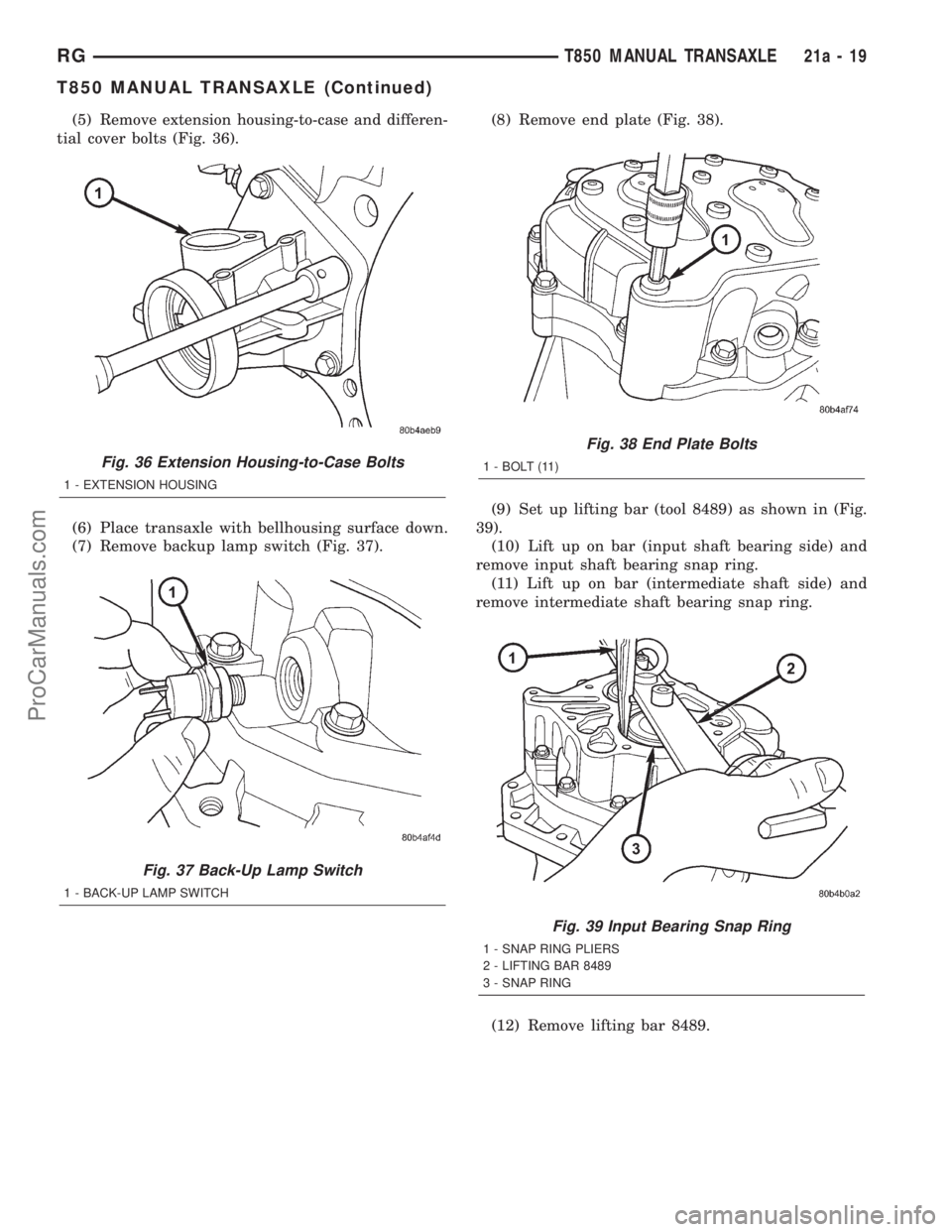

(5) Remove extension housing-to-case and differen-

tial cover bolts (Fig. 36).

(6) Place transaxle with bellhousing surface down.

(7) Remove backup lamp switch (Fig. 37).(8) Remove end plate (Fig. 38).

(9) Set up lifting bar (tool 8489) as shown in (Fig.

39).

(10) Lift up on bar (input shaft bearing side) and

remove input shaft bearing snap ring.

(11) Lift up on bar (intermediate shaft side) and

remove intermediate shaft bearing snap ring.

(12) Remove lifting bar 8489.

Fig. 36 Extension Housing-to-Case Bolts

1 - EXTENSION HOUSING

Fig. 37 Back-Up Lamp Switch

1 - BACK-UP LAMP SWITCH

Fig. 38 End Plate Bolts

1 - BOLT (11)

Fig. 39 Input Bearing Snap Ring

1 - SNAP RING PLIERS

2 - LIFTING BAR 8489

3 - SNAP RING

RGT850 MANUAL TRANSAXLE21a-19

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1819 of 2321

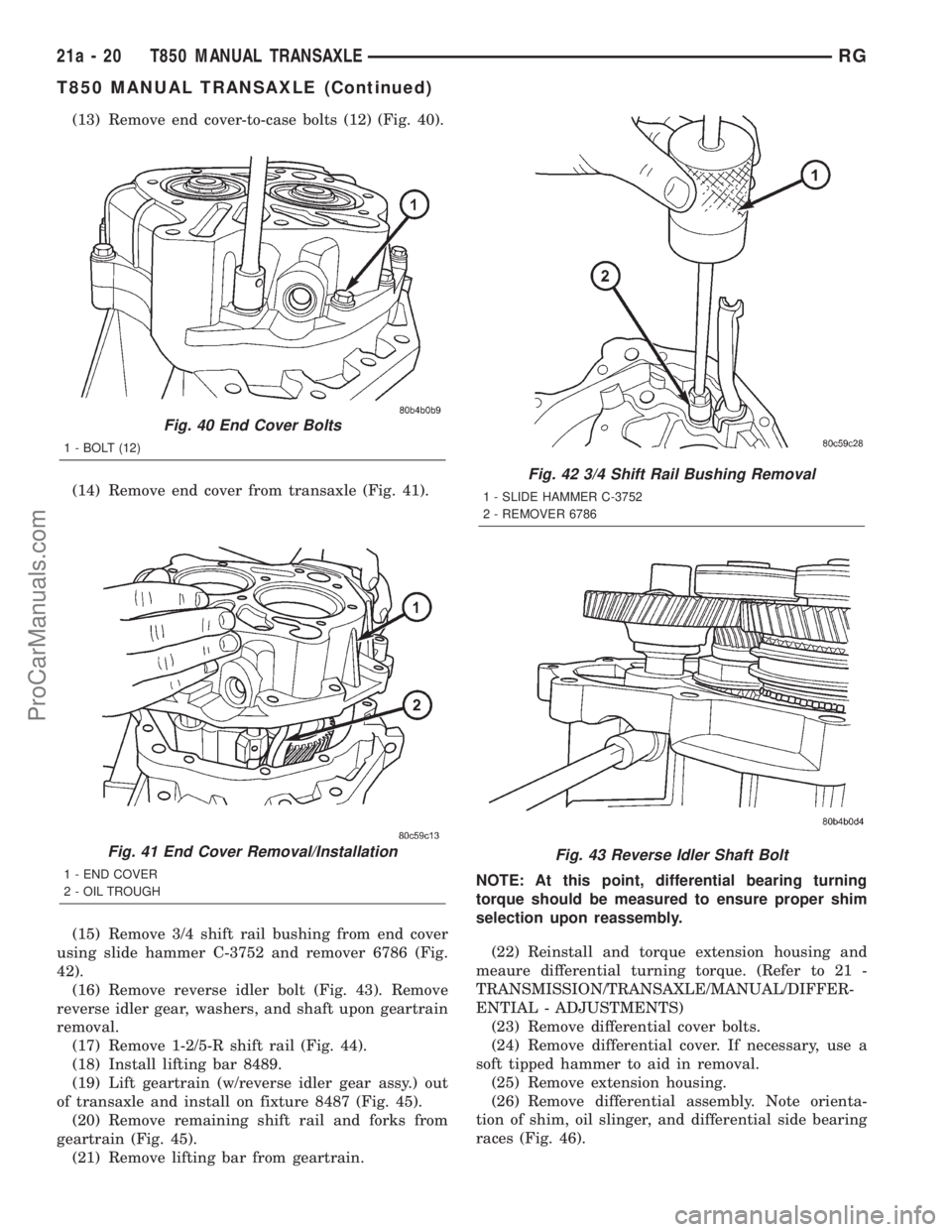

(13) Remove end cover-to-case bolts (12) (Fig. 40).

(14) Remove end cover from transaxle (Fig. 41).

(15) Remove 3/4 shift rail bushing from end cover

using slide hammer C-3752 and remover 6786 (Fig.

42).

(16) Remove reverse idler bolt (Fig. 43). Remove

reverse idler gear, washers, and shaft upon geartrain

removal.

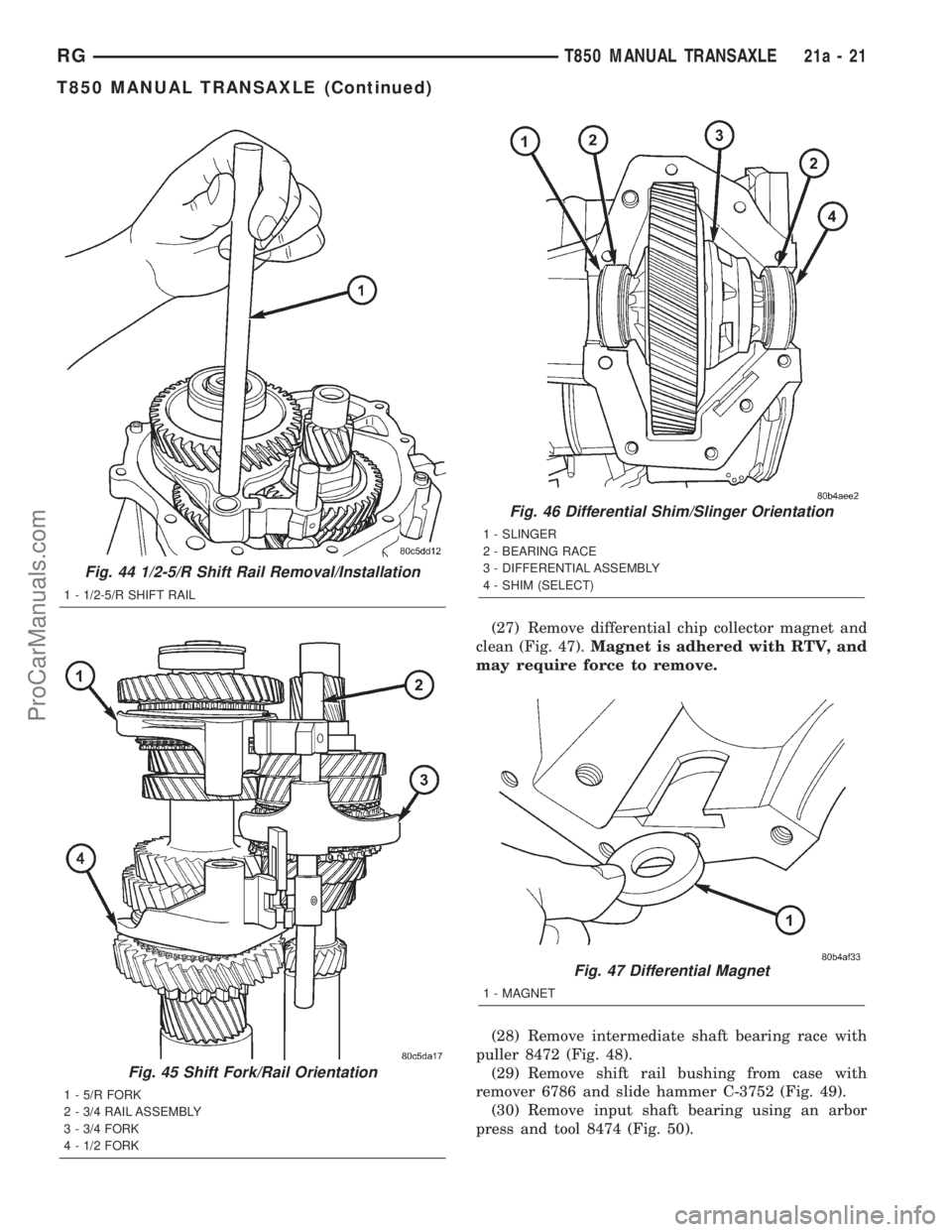

(17) Remove 1-2/5-R shift rail (Fig. 44).

(18) Install lifting bar 8489.

(19) Lift geartrain (w/reverse idler gear assy.) out

of transaxle and install on fixture 8487 (Fig. 45).

(20) Remove remaining shift rail and forks from

geartrain (Fig. 45).

(21) Remove lifting bar from geartrain.NOTE: At this point, differential bearing turning

torque should be measured to ensure proper shim

selection upon reassembly.

(22) Reinstall and torque extension housing and

meaure differential turning torque. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL/DIFFER-

ENTIAL - ADJUSTMENTS)

(23) Remove differential cover bolts.

(24) Remove differential cover. If necessary, use a

soft tipped hammer to aid in removal.

(25) Remove extension housing.

(26) Remove differential assembly. Note orienta-

tion of shim, oil slinger, and differential side bearing

races (Fig. 46).

Fig. 40 End Cover Bolts

1 - BOLT (12)

Fig. 41 End Cover Removal/Installation

1 - END COVER

2 - OIL TROUGH

Fig. 42 3/4 Shift Rail Bushing Removal

1 - SLIDE HAMMER C-3752

2 - REMOVER 6786

Fig. 43 Reverse Idler Shaft Bolt

21a - 20 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1820 of 2321

(27) Remove differential chip collector magnet and

clean (Fig. 47).Magnet is adhered with RTV, and

may require force to remove.

(28) Remove intermediate shaft bearing race with

puller 8472 (Fig. 48).

(29) Remove shift rail bushing from case with

remover 6786 and slide hammer C-3752 (Fig. 49).

(30) Remove input shaft bearing using an arbor

press and tool 8474 (Fig. 50).

Fig. 44 1/2-5/R Shift Rail Removal/Installation

1 - 1/2-5/R SHIFT RAIL

Fig. 45 Shift Fork/Rail Orientation

1 - 5/R FORK

2 - 3/4 RAIL ASSEMBLY

3 - 3/4 FORK

4 - 1/2 FORK

Fig. 46 Differential Shim/Slinger Orientation

1 - SLINGER

2 - BEARING RACE

3 - DIFFERENTIAL ASSEMBLY

4 - SHIM (SELECT)

Fig. 47 Differential Magnet

1 - MAGNET

RGT850 MANUAL TRANSAXLE21a-21

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com