transmission oil DODGE TOWN AND COUNTRY 2001 User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 136 of 2321

adjustment, maintenance or fluid checks required

during the life of the unit.

The overrunning clutch allows the rear wheels to

overrun the front wheels during a rapid front wheel

lock braking maneuver. The overrunning action pre-

vents any feed-back of front wheel braking torque to

the rear wheels. It also allows the braking system to

control the braking behavior as a two wheel drive

(2WD) vehicle.

The overrunning clutch housing has a separate oil

sump and is filled independently from the differen-

tial. The fill plug is located on the side of the over-

running clutch case. When filling the overrunning

clutch with lubricant use MopartATF+4 (Automatic

Transmission FluidÐType 9602) or equivalent.

The differential assembly contains a conventional

open differential with hypoid ring gear and pinion

gear set. The hypoid gears are lubricated by SAE

80W-90 gear lubricant.DIAGNOSIS AND TESTING - REAR DRIVELINE

MODULE NOISE

Different sources can be the cause of noise that the

rear driveline module assembly is suspected of mak-

ing. Refer to the following causes for noise diagnosis.

DRIVELINE MODULE ASSEMBLY NOISE

The most important part of driveline module ser-

vice is properly identifying the cause of failures and

noise complaints. The cause of most driveline module

failures is relatively easy to identify. The cause of

driveline module noise is more difficult to identify.

If vehicle noise becomes intolerable, an effort

should be made to isolate the noise. Many noises that

are reported as coming from the driveline module

may actually originate at other sources. For example:

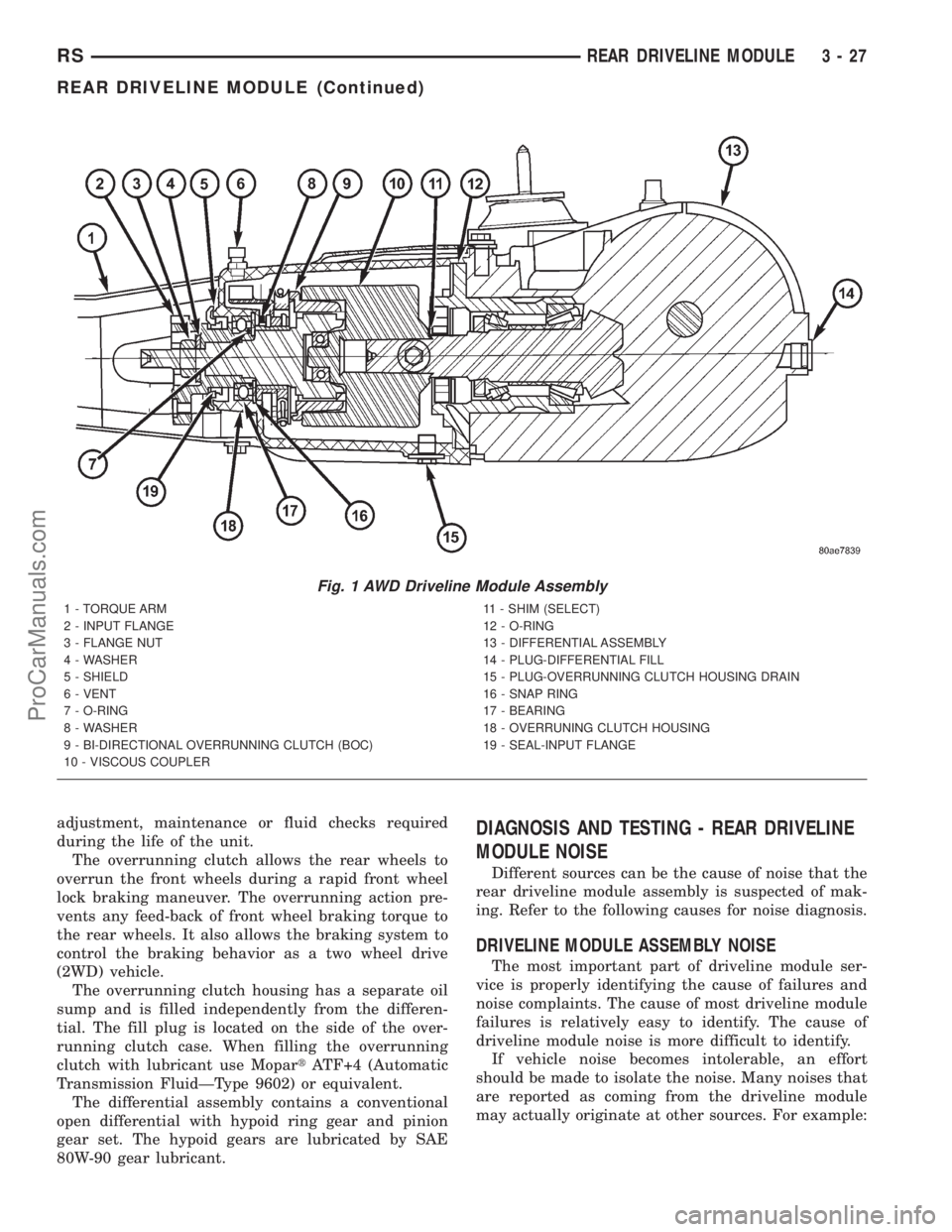

Fig. 1 AWD Driveline Module Assembly

1 - TORQUE ARM

2 - INPUT FLANGE

3 - FLANGE NUT

4 - WASHER

5 - SHIELD

6 - VENT

7 - O-RING

8 - WASHER

9 - BI-DIRECTIONAL OVERRUNNING CLUTCH (BOC)

10 - VISCOUS COUPLER11 - SHIM (SELECT)

12 - O-RING

13 - DIFFERENTIAL ASSEMBLY

14 - PLUG-DIFFERENTIAL FILL

15 - PLUG-OVERRUNNING CLUTCH HOUSING DRAIN

16 - SNAP RING

17 - BEARING

18 - OVERRUNING CLUTCH HOUSING

19 - SEAL-INPUT FLANGE

RSREAR DRIVELINE MODULE3-27

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 183 of 2321

CLEANING - CALIPER

WARNING: DUST AND DIRT ACCUMULATING ON

BRAKE PARTS DURING NORMAL USE MAY CON-

TAIN ASBESTOS FIBERS FROM PRODUCTION OR

AFTERMARKET BRAKE LININGS. BREATHING

EXCESSIVE CONCENTRATIONS OF ASBESTOS

FIBERS CAN CAUSE SERIOUS BODILY HARM.

EXERCISE CARE WHEN SERVICING BRAKE

PARTS. DO NOT SAND OR GRIND BRAKE LINING

UNLESS EQUIPMENT USED IS DESIGNED TO CON-

TAIN THE DUST RESIDUE. DO NOT CLEAN BRAKE

PARTS WITH COMPRESSED AIR OR BY DRY

BRUSHING. CLEANING SHOULD BE DONE BY

DAMPENING THE BRAKE COMPONENTS WITH A

FINE MIST OF WATER, THEN WIPING THE BRAKE

COMPONENTS CLEAN WITH A DAMPENED CLOTH.

DISPOSE OF CLOTH AND ALL RESIDUE CONTAIN-

ING ASBESTOS FIBERS IN AN IMPERMEABLE

CONTAINER WITH THE APPROPRIATE LABEL. FOL-

LOW PRACTICES PRESCRIBED BY THE OCCUPA-

TIONAL SAFETY AND HEALTH ADMINISTRATION

(OSHA) AND THE ENVIRONMENTAL PROTECTION

AGENCY (EPA) FOR THE HANDLING, PROCESSING,

AND DISPOSING OF DUST OR DEBRIS THAT MAY

CONTAIN ASBESTOS FIBERS.

To clean or flush the internal passages of the brake

caliper, use fresh brake fluid or MopartNon-Chlori-

nated Brake Parts Cleaner. Never use gasoline, ker-

osene, alcohol, oil, transmission fluid or any fluid

containing mineral oil to clean the caliper. These flu-

ids will damage rubber cups and seals.

INSPECTION - CALIPER

Inspect the disc brake caliper for the following:

²Brake fluid leaks in and around boot area and

inboard lining

²Ruptures, brittleness or damage to the piston

dust boot

²Damaged, dry or brittle guide pin dust boots

If caliper fails inspection, disassemble and recondi-

tion caliper, replacing the seals and dust boots.

ASSEMBLY - CALIPER GUIDE PIN BUSHINGS

(DISC/DISC BRAKES)

(1) Fold the guide pin bushing in half lengthwise.

NOTE: To avoid damage to the bushing, do not use

a sharp object to install the guide pin bushing.

(2) Insert the folded bushing into the caliper

mounting boss using your fingers from the rear of

the caliper.

(3) Unfold the bushing using your fingers or a

wooden dowel until the bushing is fully seated intothe caliper housing. The bushing flanges should be

seated evenly on both sides of the bushing hole.

(4) Lubricate inside surfaces of bushing using

MopartDielectric Grease or equivalent.

(5) Repeat the procedure for remaining bushing.

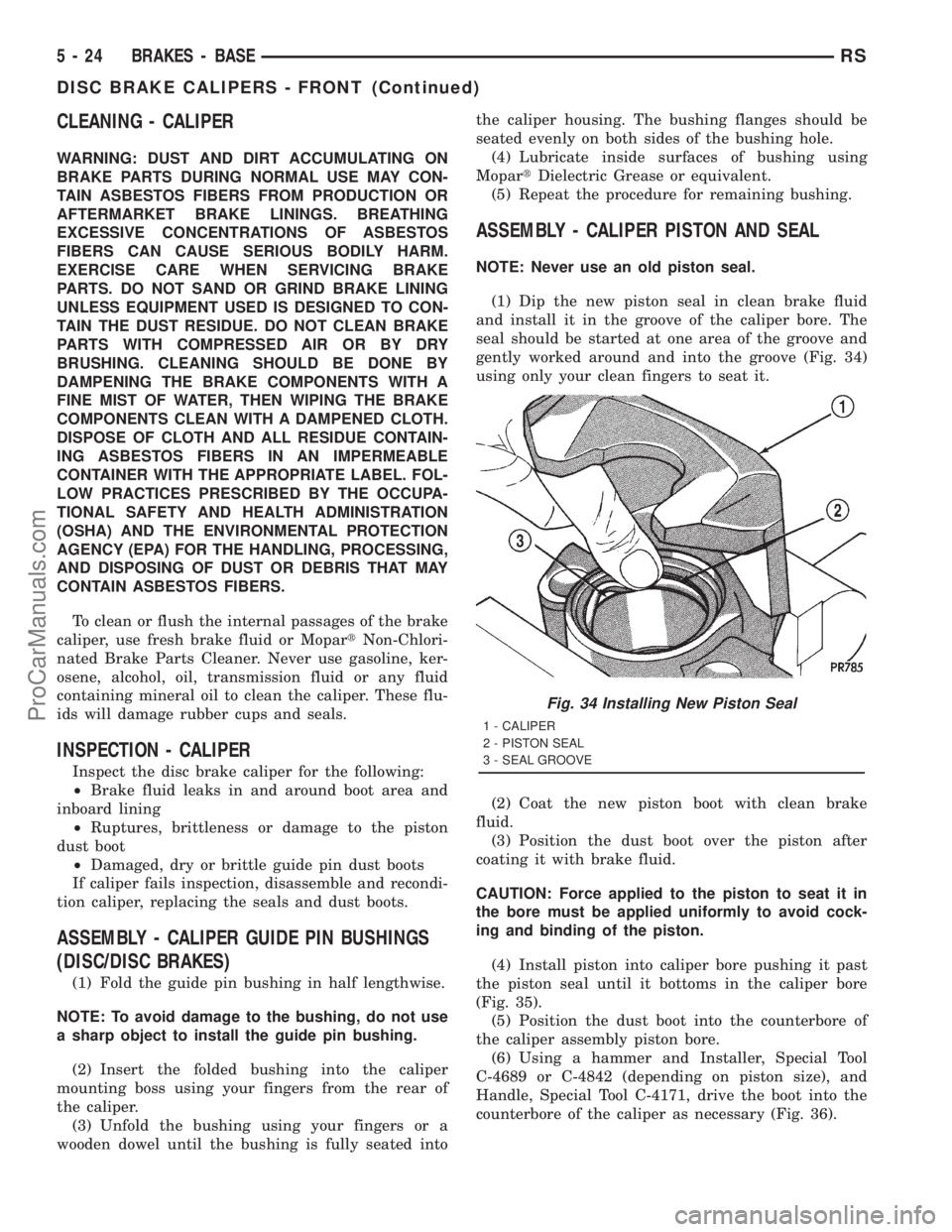

ASSEMBLY - CALIPER PISTON AND SEAL

NOTE: Never use an old piston seal.

(1) Dip the new piston seal in clean brake fluid

and install it in the groove of the caliper bore. The

seal should be started at one area of the groove and

gently worked around and into the groove (Fig. 34)

using only your clean fingers to seat it.

(2) Coat the new piston boot with clean brake

fluid.

(3) Position the dust boot over the piston after

coating it with brake fluid.

CAUTION: Force applied to the piston to seat it in

the bore must be applied uniformly to avoid cock-

ing and binding of the piston.

(4) Install piston into caliper bore pushing it past

the piston seal until it bottoms in the caliper bore

(Fig. 35).

(5) Position the dust boot into the counterbore of

the caliper assembly piston bore.

(6) Using a hammer and Installer, Special Tool

C-4689 or C-4842 (depending on piston size), and

Handle, Special Tool C-4171, drive the boot into the

counterbore of the caliper as necessary (Fig. 36).

Fig. 34 Installing New Piston Seal

1 - CALIPER

2 - PISTON SEAL

3 - SEAL GROOVE

5 - 24 BRAKES - BASERS

DISC BRAKE CALIPERS - FRONT (Continued)

ProCarManuals.com

Page 187 of 2321

CLEANING - CALIPER

WARNING: DUST AND DIRT ACCUMULATING ON

BRAKE PARTS DURING NORMAL USE MAY CON-

TAIN ASBESTOS FIBERS FROM PRODUCTION OR

AFTERMARKET BRAKE LININGS. BREATHING

EXCESSIVE CONCENTRATIONS OF ASBESTOS

FIBERS CAN CAUSE SERIOUS BODILY HARM.

EXERCISE CARE WHEN SERVICING BRAKE

PARTS. DO NOT SAND OR GRIND BRAKE LINING

UNLESS EQUIPMENT USED IS DESIGNED TO CON-

TAIN THE DUST RESIDUE. DO NOT CLEAN BRAKE

PARTS WITH COMPRESSED AIR OR BY DRY

BRUSHING. CLEANING SHOULD BE DONE BY

DAMPENING THE BRAKE COMPONENTS WITH A

FINE MIST OF WATER, THEN WIPING THE BRAKE

COMPONENTS CLEAN WITH A DAMPENED CLOTH.

DISPOSE OF CLOTH AND ALL RESIDUE CONTAIN-

ING ASBESTOS FIBERS IN AN IMPERMEABLE

CONTAINER WITH THE APPROPRIATE LABEL. FOL-

LOW PRACTICES PRESCRIBED BY THE OCCUPA-

TIONAL SAFETY AND HEALTH ADMINISTRATION

(OSHA) AND THE ENVIRONMENTAL PROTECTION

AGENCY (EPA) FOR THE HANDLING, PROCESSING,

AND DISPOSING OF DUST OR DEBRIS THAT MAY

CONTAIN ASBESTOS FIBERS.

To clean or flush the internal passages of the brake

caliper, use fresh brake fluid or MopartNon-Chlori-

nated Brake Parts Cleaner. Never use gasoline, ker-

osene, alcohol, oil, transmission fluid or any fluid

containing mineral oil to clean the caliper. These flu-

ids will damage rubber cups and seals.

INSPECTION - CALIPER

Inspect the disc brake caliper for the following:

²Brake fluid leaks in and around boot area and

inboard lining

²Ruptures, brittleness or damage to the piston

dust boot

²Damaged, dry or brittle guide pin dust boots

If caliper fails inspection, disassemble and recondi-

tion caliper, replacing the seals and dust boots.

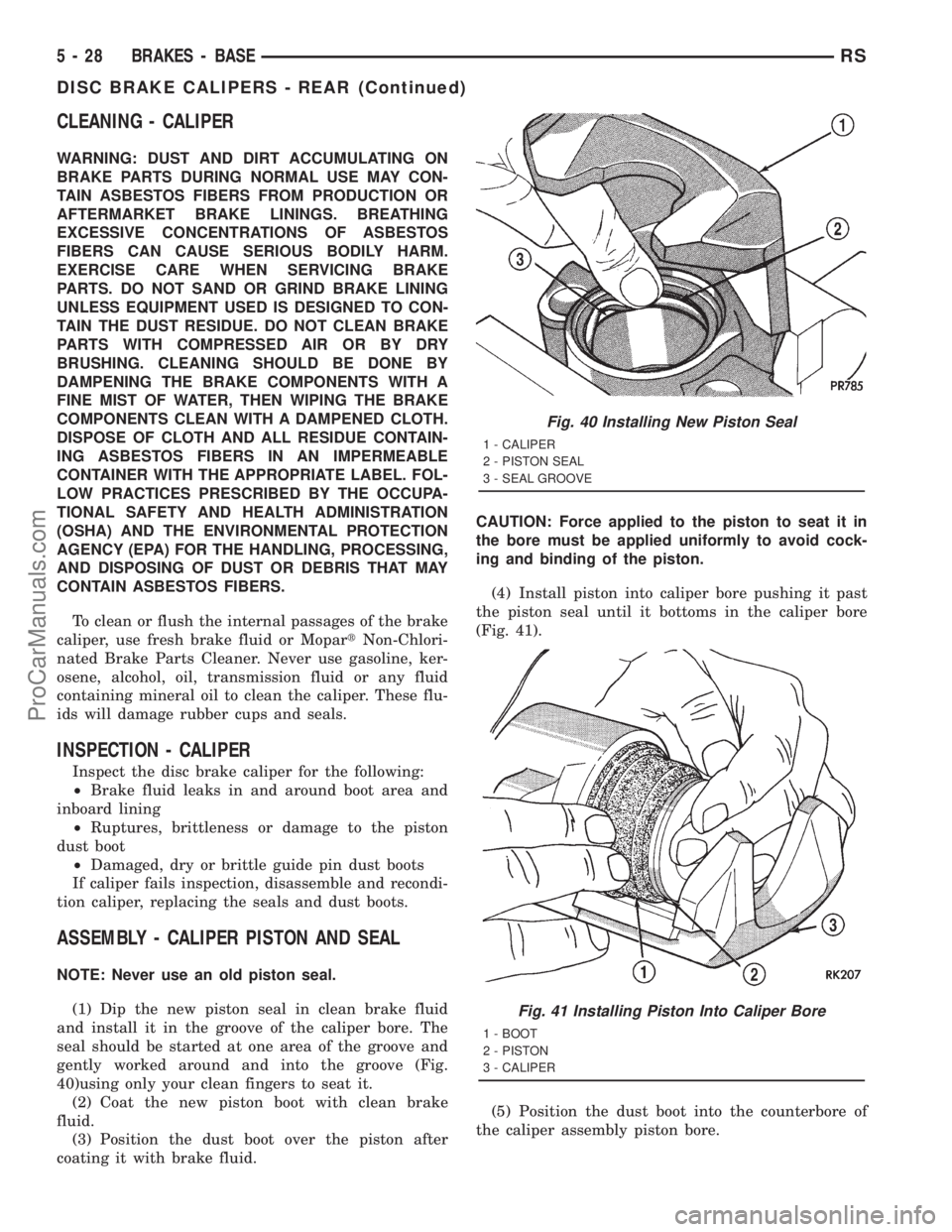

ASSEMBLY - CALIPER PISTON AND SEAL

NOTE: Never use an old piston seal.

(1) Dip the new piston seal in clean brake fluid

and install it in the groove of the caliper bore. The

seal should be started at one area of the groove and

gently worked around and into the groove (Fig.

40)using only your clean fingers to seat it.

(2) Coat the new piston boot with clean brake

fluid.

(3) Position the dust boot over the piston after

coating it with brake fluid.CAUTION: Force applied to the piston to seat it in

the bore must be applied uniformly to avoid cock-

ing and binding of the piston.

(4) Install piston into caliper bore pushing it past

the piston seal until it bottoms in the caliper bore

(Fig. 41).

(5) Position the dust boot into the counterbore of

the caliper assembly piston bore.

Fig. 40 Installing New Piston Seal

1 - CALIPER

2 - PISTON SEAL

3 - SEAL GROOVE

Fig. 41 Installing Piston Into Caliper Bore

1 - BOOT

2 - PISTON

3 - CALIPER

5 - 28 BRAKES - BASERS

DISC BRAKE CALIPERS - REAR (Continued)

ProCarManuals.com

Page 191 of 2321

STANDARD PROCEDURE - BRAKE FLUID

LEVEL CHECKING

Check master cylinder reservoir fluid level a mini-

mum of twice annually.

Fluid reservoirs are marked with the words FULL

and ADD to indicate proper brake fluid fill level of

the master cylinder.

If necessary, add brake fluid to bring the level to

the bottom of the FULL mark on the side of the mas-

ter cylinder fluid reservoir.

Use only Mopartbrake fluid or equivalent from a

sealed container. Brake fluid must conform to DOT 3

specifications (DOT 4 or DOT 4+ are acceptable).

DO NOTuse brake fluid with a lower boiling

point, as brake failure could result during prolonged

hard braking.

Use only brake fluid that was stored in a tightly-

sealed container.

DO NOTuse petroleum-based fluid because seal

damage will result. Petroleum based fluids would be

items such as engine oil, transmission fluid, power

steering fluid etc.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications (DOT 4 and DOT 4+ are

acceptable) and SAE J1703 standards. No other type

of brake fluid is recommended or approved for usage

in the vehicle brake system. Use only MopartBrake

Fluid or equivalent from a tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

JUNCTION BLOCK

DESCRIPTION - NON-ABS JUNCTION BLOCK

A junction block is used on vehicles that are not

equipped with antilock brakes (ABS). The junction

block mounts in the same location as the integrated

control unit (ICU) does on vehicles equipped withABS. This allows for use of the same brake tube con-

figuration on all vehicles. The junction block is

located on the driver's side of the front suspension

cradle/crossmember below the master cylinder (Fig.

46).

It has six threaded ports to which the brake tubes

connect. Two are for the primary and secondary

brake tubes coming from the master cylinder. The

remaining four are for the chassis brake tubes going

to each brake assembly.

OPERATION - NON-ABS JUNCTION BLOCK

The junction block distributes the brake fluid com-

ing from the master cylinder primary and secondary

ports to the four chassis brake tubes leading to the

brakes at each wheel. Since the junction block

mounts in the same location as the ABS integrated

control unit (ICU), it allows for the common use of

brake tubes going to the brakes whether the vehicle

is equipped with or without ABS.

NOTE: Although the brake tubes coming from the

master cylinder to the junction block or ABS ICU

may appear to be the same, they are not. They are

unique to each brake system application.

REMOVAL - NON-ABS JUNCTION BLOCK

(1) Using a brake pedal depressor, move and lock

the brake pedal to a position past its first 1 inch of

travel. This will prevent brake fluid from draining

out of the master cylinder when the brake tubes are

removed from the junction block.

(2) Disconnect the battery negative cable.

(3) If the vehicle is equipped with speed control,

perform the following:

(a) Disconnect the battery positive cable.

(b) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(c) Disconnect the vacuum hose connector at the

tank built into the battery tray.

(d) Remove the screw securing the coolant filler

neck to the battery tray.

(e) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(f) Remove the fasteners and move the speed

control servo off to the side, out of the way.

CAUTION: Before removing the brake tubes from

the junction block, the junction block and the brake

tubes must be thoroughly cleaned. This is required

to prevent contamination from entering the brake

hydraulic system.

5 - 32 BRAKES - BASERS

FLUID (Continued)

ProCarManuals.com

Page 239 of 2321

Use only brake fluid that was stored in a tightly-

sealed container.

DO NOTuse petroleum-based fluid because seal

damage will result. Petroleum based fluids would be

items such as engine oil, transmission fluid, power

steering fluid etc.

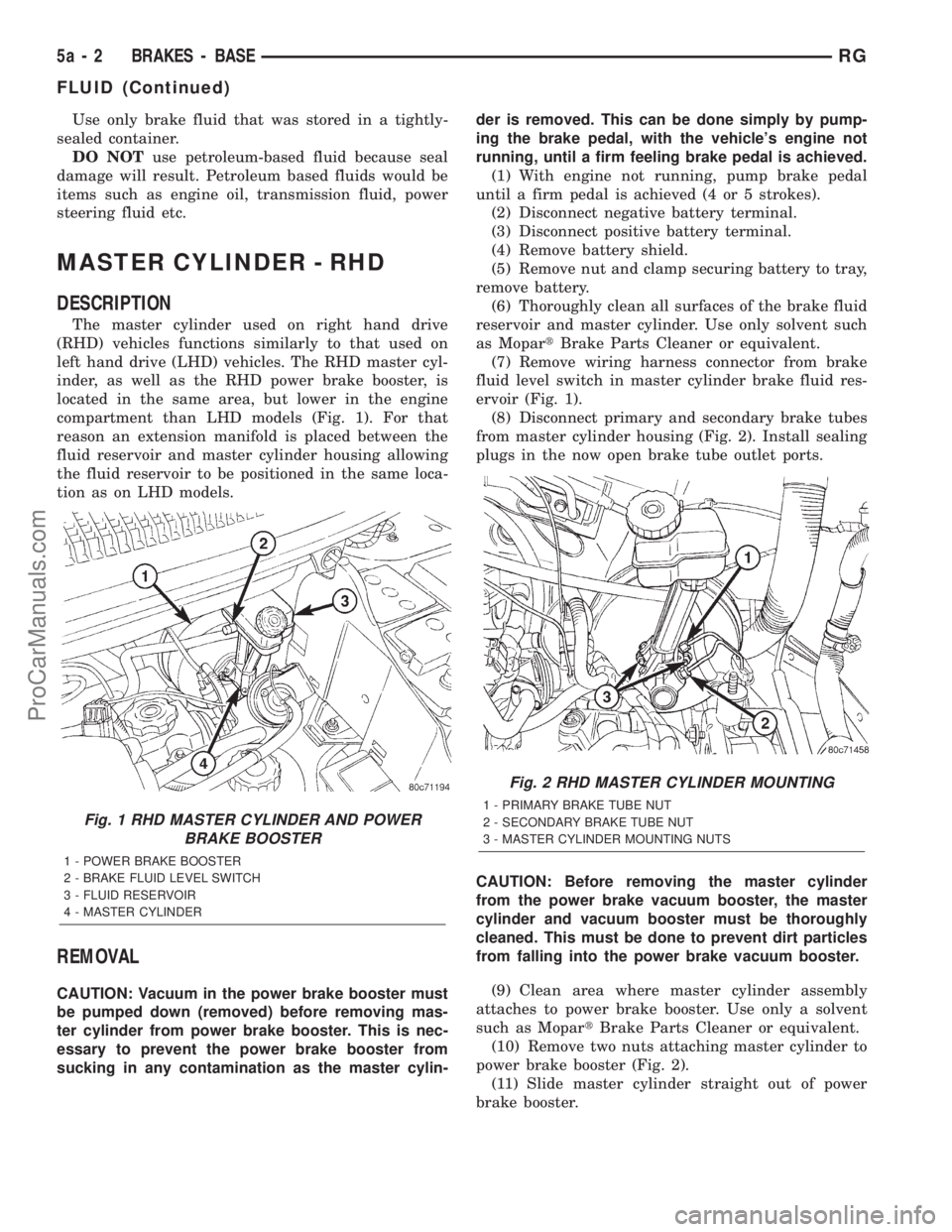

MASTER CYLINDER - RHD

DESCRIPTION

The master cylinder used on right hand drive

(RHD) vehicles functions similarly to that used on

left hand drive (LHD) vehicles. The RHD master cyl-

inder, as well as the RHD power brake booster, is

located in the same area, but lower in the engine

compartment than LHD models (Fig. 1). For that

reason an extension manifold is placed between the

fluid reservoir and master cylinder housing allowing

the fluid reservoir to be positioned in the same loca-

tion as on LHD models.

REMOVAL

CAUTION: Vacuum in the power brake booster must

be pumped down (removed) before removing mas-

ter cylinder from power brake booster. This is nec-

essary to prevent the power brake booster from

sucking in any contamination as the master cylin-der is removed. This can be done simply by pump-

ing the brake pedal, with the vehicle's engine not

running, until a firm feeling brake pedal is achieved.

(1) With engine not running, pump brake pedal

until a firm pedal is achieved (4 or 5 strokes).

(2) Disconnect negative battery terminal.

(3) Disconnect positive battery terminal.

(4) Remove battery shield.

(5) Remove nut and clamp securing battery to tray,

remove battery.

(6) Thoroughly clean all surfaces of the brake fluid

reservoir and master cylinder. Use only solvent such

as MopartBrake Parts Cleaner or equivalent.

(7) Remove wiring harness connector from brake

fluid level switch in master cylinder brake fluid res-

ervoir (Fig. 1).

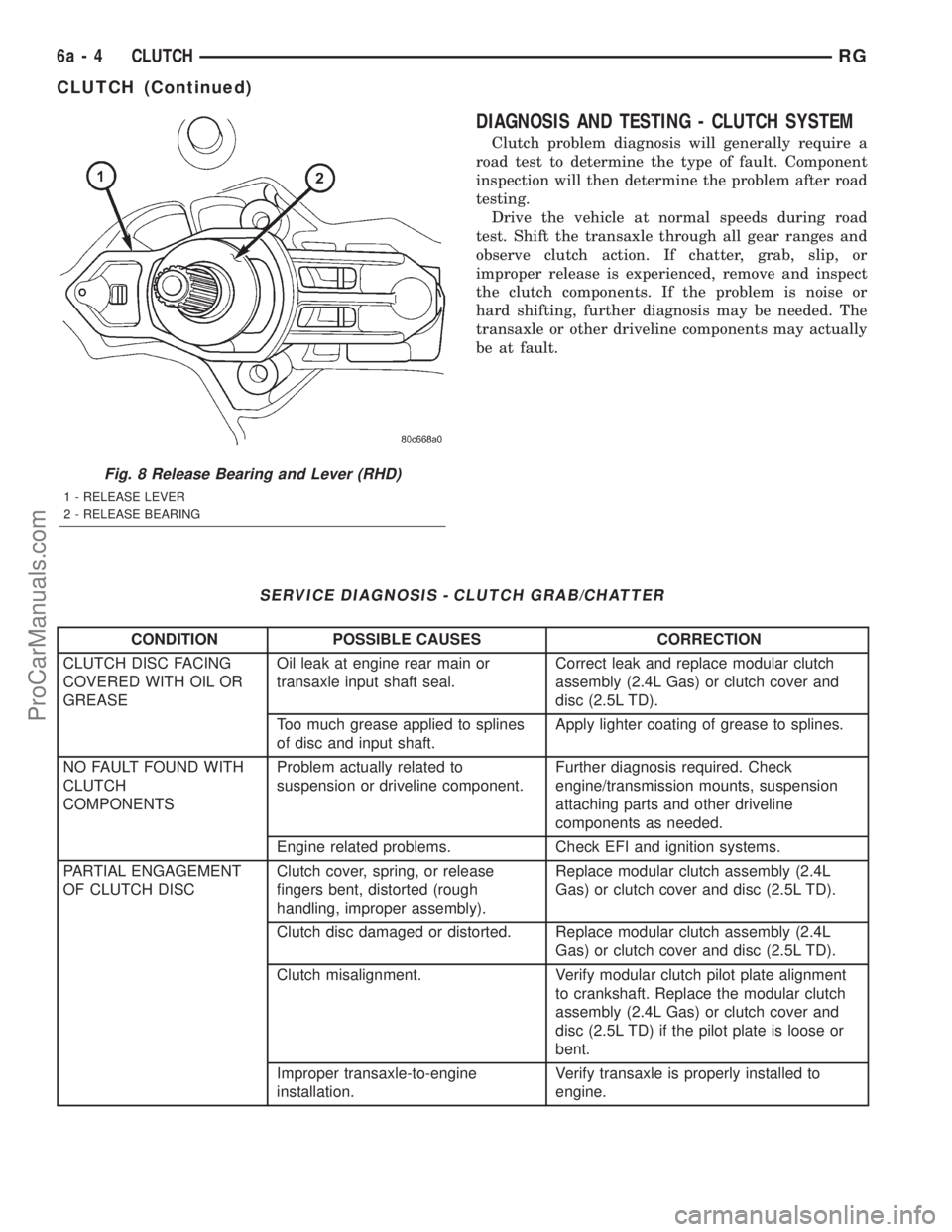

(8) Disconnect primary and secondary brake tubes

from master cylinder housing (Fig. 2). Install sealing

plugs in the now open brake tube outlet ports.

CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughly

cleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(9) Clean area where master cylinder assembly

attaches to power brake booster. Use only a solvent

such as MopartBrake Parts Cleaner or equivalent.

(10) Remove two nuts attaching master cylinder to

power brake booster (Fig. 2).

(11) Slide master cylinder straight out of power

brake booster.

Fig. 1 RHD MASTER CYLINDER AND POWER

BRAKE BOOSTER

1 - POWER BRAKE BOOSTER

2 - BRAKE FLUID LEVEL SWITCH

3 - FLUID RESERVOIR

4 - MASTER CYLINDER

Fig. 2 RHD MASTER CYLINDER MOUNTING

1 - PRIMARY BRAKE TUBE NUT

2 - SECONDARY BRAKE TUBE NUT

3 - MASTER CYLINDER MOUNTING NUTS

5a - 2 BRAKES - BASERG

FLUID (Continued)

ProCarManuals.com

Page 255 of 2321

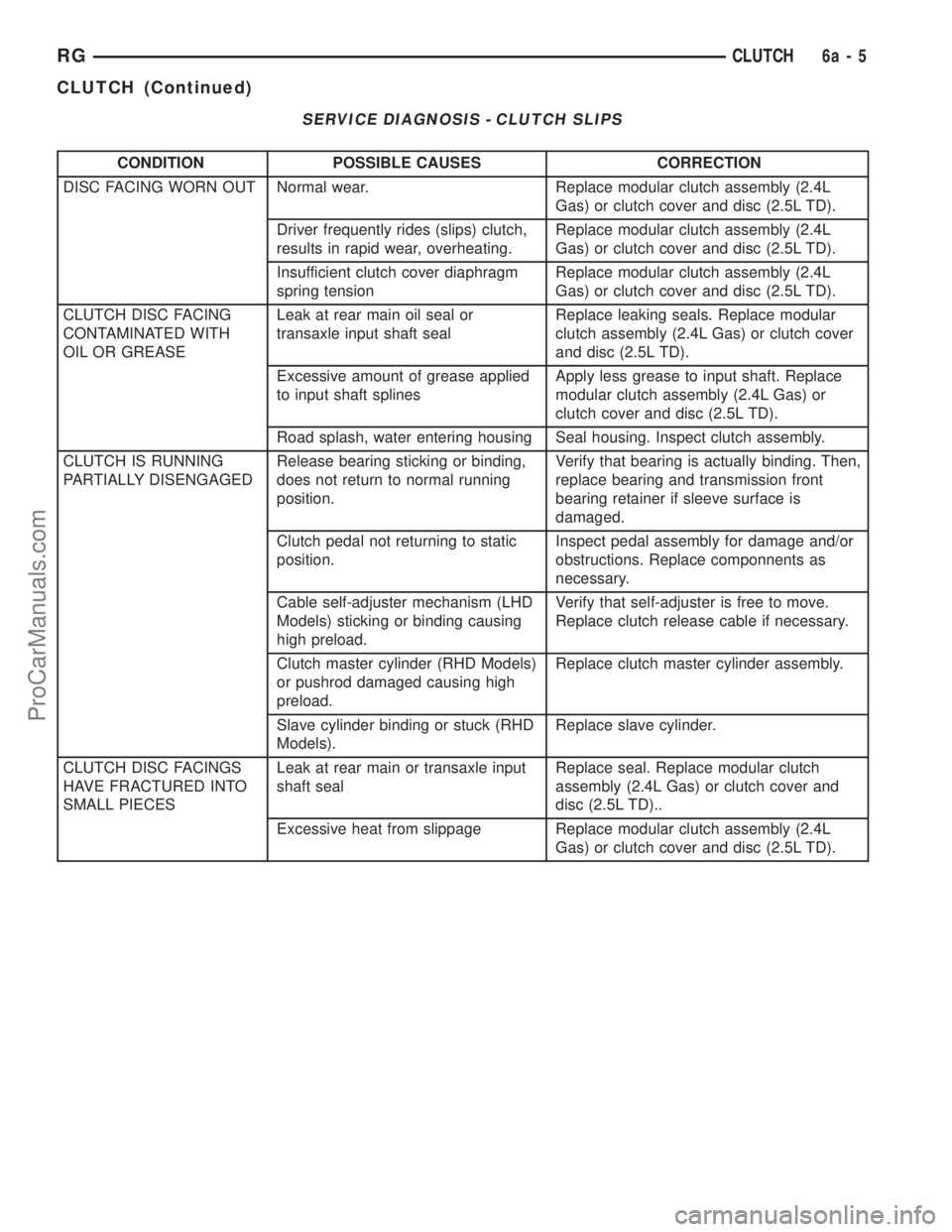

DIAGNOSIS AND TESTING - CLUTCH SYSTEM

Clutch problem diagnosis will generally require a

road test to determine the type of fault. Component

inspection will then determine the problem after road

testing.

Drive the vehicle at normal speeds during road

test. Shift the transaxle through all gear ranges and

observe clutch action. If chatter, grab, slip, or

improper release is experienced, remove and inspect

the clutch components. If the problem is noise or

hard shifting, further diagnosis may be needed. The

transaxle or other driveline components may actually

be at fault.

SERVICE DIAGNOSIS - CLUTCH GRAB/CHATTER

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH DISC FACING

COVERED WITH OIL OR

GREASEOil leak at engine rear main or

transaxle input shaft seal.Correct leak and replace modular clutch

assembly (2.4L Gas) or clutch cover and

disc (2.5L TD).

Too much grease applied to splines

of disc and input shaft.Apply lighter coating of grease to splines.

NO FAULT FOUND WITH

CLUTCH

COMPONENTSProblem actually related to

suspension or driveline component.Further diagnosis required. Check

engine/transmission mounts, suspension

attaching parts and other driveline

components as needed.

Engine related problems. Check EFI and ignition systems.

PARTIAL ENGAGEMENT

OF CLUTCH DISCClutch cover, spring, or release

fingers bent, distorted (rough

handling, improper assembly).Replace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

Clutch disc damaged or distorted. Replace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

Clutch misalignment. Verify modular clutch pilot plate alignment

to crankshaft. Replace the modular clutch

assembly (2.4L Gas) or clutch cover and

disc (2.5L TD) if the pilot plate is loose or

bent.

Improper transaxle-to-engine

installation.Verify transaxle is properly installed to

engine.

Fig. 8 Release Bearing and Lever (RHD)

1 - RELEASE LEVER

2 - RELEASE BEARING

6a - 4 CLUTCHRG

CLUTCH (Continued)

ProCarManuals.com

Page 256 of 2321

SERVICE DIAGNOSIS - CLUTCH SLIPS

CONDITION POSSIBLE CAUSES CORRECTION

DISC FACING WORN OUT Normal wear. Replace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

Driver frequently rides (slips) clutch,

results in rapid wear, overheating.Replace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

Insufficient clutch cover diaphragm

spring tensionReplace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

CLUTCH DISC FACING

CONTAMINATED WITH

OIL OR GREASELeak at rear main oil seal or

transaxle input shaft sealReplace leaking seals. Replace modular

clutch assembly (2.4L Gas) or clutch cover

and disc (2.5L TD).

Excessive amount of grease applied

to input shaft splinesApply less grease to input shaft. Replace

modular clutch assembly (2.4L Gas) or

clutch cover and disc (2.5L TD).

Road splash, water entering housing Seal housing. Inspect clutch assembly.

CLUTCH IS RUNNING

PARTIALLY DISENGAGEDRelease bearing sticking or binding,

does not return to normal running

position.Verify that bearing is actually binding. Then,

replace bearing and transmission front

bearing retainer if sleeve surface is

damaged.

Clutch pedal not returning to static

position.Inspect pedal assembly for damage and/or

obstructions. Replace componnents as

necessary.

Cable self-adjuster mechanism (LHD

Models) sticking or binding causing

high preload.Verify that self-adjuster is free to move.

Replace clutch release cable if necessary.

Clutch master cylinder (RHD Models)

or pushrod damaged causing high

preload.Replace clutch master cylinder assembly.

Slave cylinder binding or stuck (RHD

Models).Replace slave cylinder.

CLUTCH DISC FACINGS

HAVE FRACTURED INTO

SMALL PIECESLeak at rear main or transaxle input

shaft sealReplace seal. Replace modular clutch

assembly (2.4L Gas) or clutch cover and

disc (2.5L TD)..

Excessive heat from slippage Replace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

RGCLUTCH6a-5

CLUTCH (Continued)

ProCarManuals.com

Page 258 of 2321

DIAGNOSIS AND TESTING - DRIVE PLATE

MISALIGNMENT

Common causes of misalignment are:

²Heat warping

²Mounting drive plate on a dirty crankshaft

flange

²Incorrect bolt tightening

²Improper seating on the crankshaft shoulder

²Loose crankshaft bolts

Clean the crankshaft flange before mounting the

drive plate. Dirt and grease on the flange surface

may misalign the flywheel, causing excessive runout.

Use new bolts when mounting drive plate to crank-

shaft. Tighten drive plate bolts to specified torque

only. Over-tightening can distort the drive plate hub

causing excessive runout.

DIAGNOSIS AND TESTING - CLUTCH COVER

AND DISC RUNOUT

Check condition of the clutch cover before installa-

tion. A warped cover or diaphragm spring will cause

grab and/or incomplete release or engagement. Use

care when handling the clutch assembly. Impact can

distort the cover, diaphragm spring, and release fin-

gers.

DIAGNOSIS AND TESTING - CLUTCH CHATTER

COMPLAINTS

For all clutch chatter complaints, perform the fol-

lowing:

(1) Check for loose, misaligned, or broken engine

and transmission mounts. If present, they should be

corrected at this time. Test vehicle for chatter. If

chatter is gone, there is no need to go any further.

(2) If chatter persists, check hydraulic clutch

release system is functioning properly.

(3) Check for loose connections in drivetrain. Cor-

rect any problems and determine if clutch chatter

complaints have been satisfied. If not:

(a) Remove transaxle.

(b) Check to see if the release bearing is sticky

or binding. Replace bearing, if needed.

(c) Check linkage for excessive wear on the pivot

stud and fork fingers. Replace all worn parts.

(d) Check clutch assembly for contamination

(dirt, oil). Replace clutch assembly, if required.

(e) Check to see if the clutch disc hub splines

are damaged. Replace with new clutch assembly, if

necessary.

(f) Check input shaft splines for damage.

Replace, if necessary.

(g) Check for uneven wear on clutch fingers.

(h) Check for broken clutch cover diaphragm

spring fingers. Replace with new clutch assembly,

if necessary.

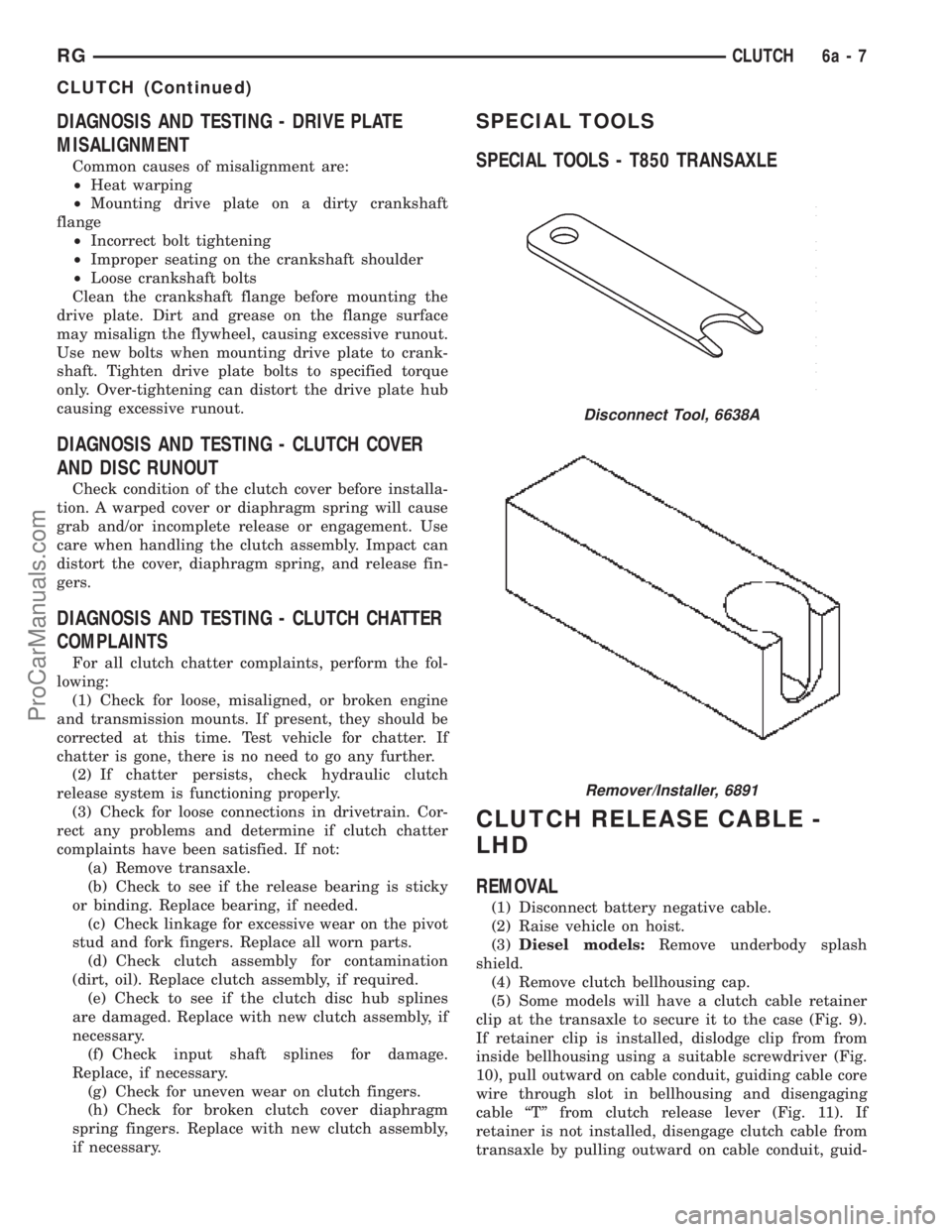

SPECIAL TOOLS

SPECIAL TOOLS - T850 TRANSAXLE

CLUTCH RELEASE CABLE -

LHD

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise vehicle on hoist.

(3)Diesel models:Remove underbody splash

shield.

(4) Remove clutch bellhousing cap.

(5) Some models will have a clutch cable retainer

clip at the transaxle to secure it to the case (Fig. 9).

If retainer clip is installed, dislodge clip from from

inside bellhousing using a suitable screwdriver (Fig.

10), pull outward on cable conduit, guiding cable core

wire through slot in bellhousing and disengaging

cable ªTº from clutch release lever (Fig. 11). If

retainer is not installed, disengage clutch cable from

transaxle by pulling outward on cable conduit, guid-

Disconnect Tool, 6638A

Remover/Installer, 6891

RGCLUTCH6a-7

CLUTCH (Continued)

ProCarManuals.com

Page 268 of 2321

COOLING

TABLE OF CONTENTS

page page

COOLING

DESCRIPTION............................1

OPERATION.............................1

DIAGNOSIS AND TESTING..................3

COOLING SYSTEM LEAK TEST.............3

COOLING SYSTEM FLOW CHECK..........3

COOLING SYSTEM AERATION.............3

COOLING SYSTEM DEAERATION...........3

STANDARD PROCEDURE...................4COOLING SYSTEM - DRAINING............4

COOLING SYSTEM - REFILLING............4

COOLANT - ADDING ADDITIONAL...........4

COOLANT LEVEL CHECK - ROUTINE........5

SPECIFICATIONS.........................6

SPECIAL TOOLS..........................6

ACCESSORY DRIVE.......................7

ENGINE................................13

TRANSMISSION.........................36

COOLING

DESCRIPTION - COOLING SYSTEM

The cooling system components consist of a radia-

tor, electric fan motors, shroud, pressure cap, thermo-

stat, transmission oil cooler, water pump, hoses,

clamps, coolant, and a coolant reserve system to com-

plete the circuit.

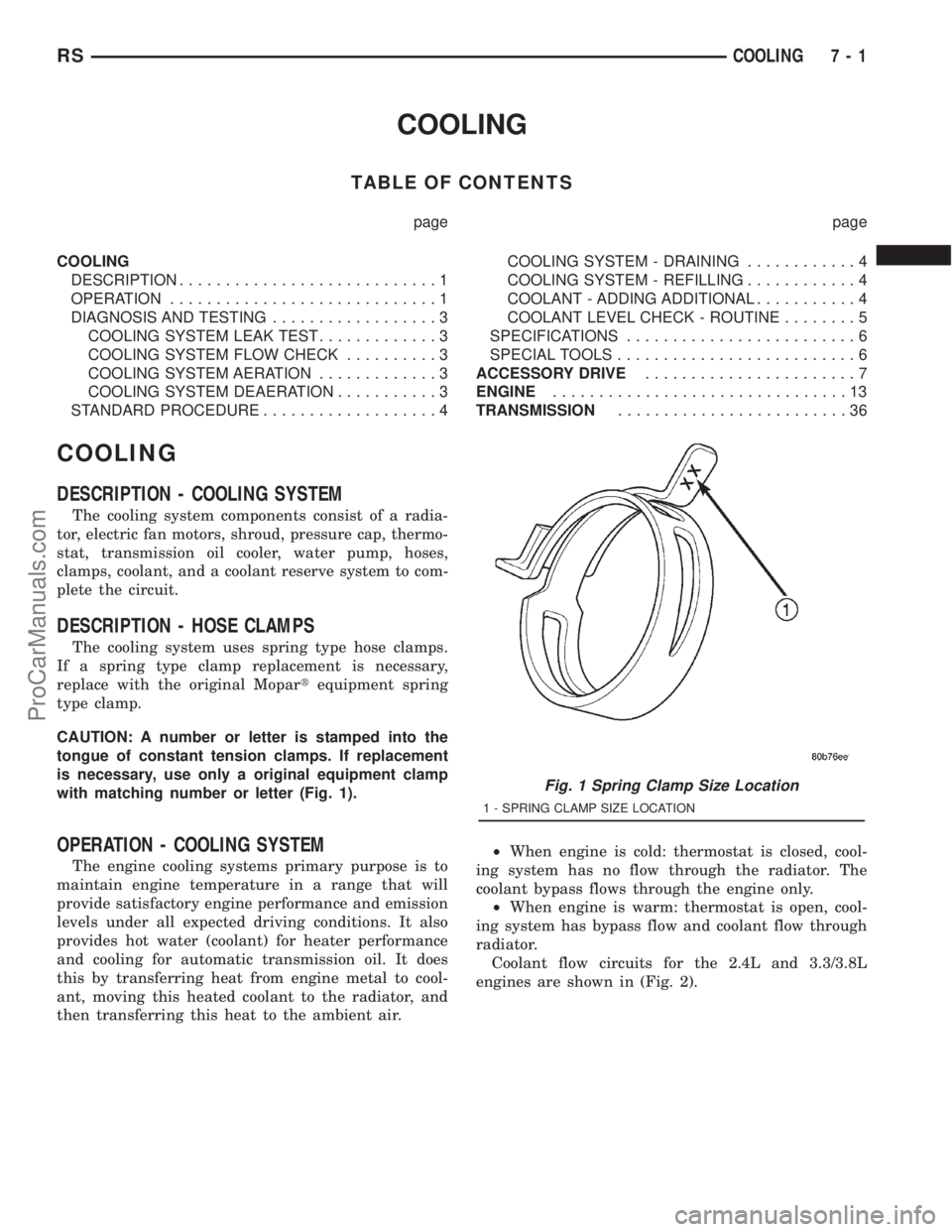

DESCRIPTION - HOSE CLAMPS

The cooling system uses spring type hose clamps.

If a spring type clamp replacement is necessary,

replace with the original Mopartequipment spring

type clamp.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 1).

OPERATION - COOLING SYSTEM

The engine cooling systems primary purpose is to

maintain engine temperature in a range that will

provide satisfactory engine performance and emission

levels under all expected driving conditions. It also

provides hot water (coolant) for heater performance

and cooling for automatic transmission oil. It does

this by transferring heat from engine metal to cool-

ant, moving this heated coolant to the radiator, and

then transferring this heat to the ambient air.²When engine is cold: thermostat is closed, cool-

ing system has no flow through the radiator. The

coolant bypass flows through the engine only.

²When engine is warm: thermostat is open, cool-

ing system has bypass flow and coolant flow through

radiator.

Coolant flow circuits for the 2.4L and 3.3/3.8L

engines are shown in (Fig. 2).

Fig. 1 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

RSCOOLING7-1

ProCarManuals.com

Page 296 of 2321

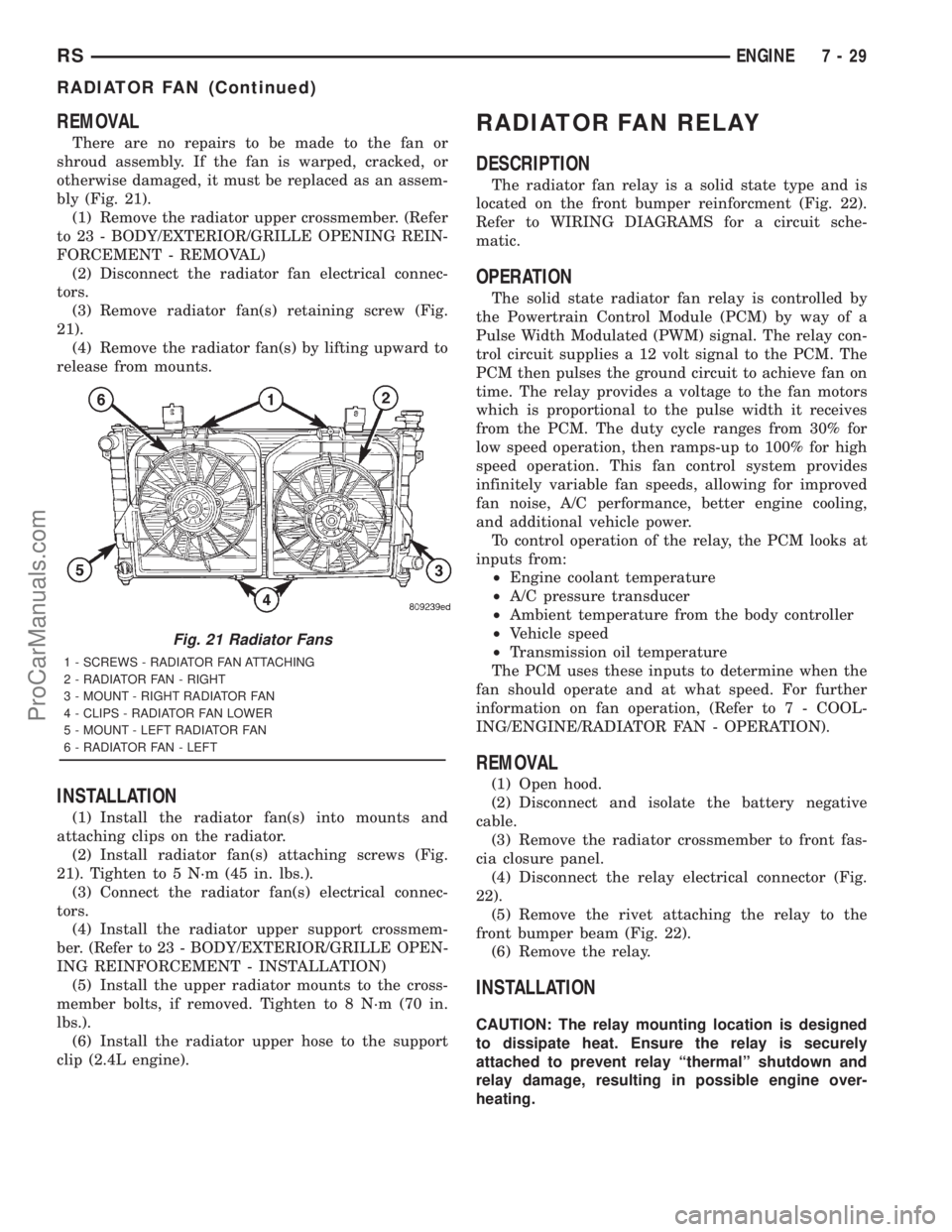

REMOVAL

There are no repairs to be made to the fan or

shroud assembly. If the fan is warped, cracked, or

otherwise damaged, it must be replaced as an assem-

bly (Fig. 21).

(1) Remove the radiator upper crossmember. (Refer

to 23 - BODY/EXTERIOR/GRILLE OPENING REIN-

FORCEMENT - REMOVAL)

(2) Disconnect the radiator fan electrical connec-

tors.

(3) Remove radiator fan(s) retaining screw (Fig.

21).

(4) Remove the radiator fan(s) by lifting upward to

release from mounts.

INSTALLATION

(1) Install the radiator fan(s) into mounts and

attaching clips on the radiator.

(2) Install radiator fan(s) attaching screws (Fig.

21). Tighten to 5 N´m (45 in. lbs.).

(3) Connect the radiator fan(s) electrical connec-

tors.

(4) Install the radiator upper support crossmem-

ber. (Refer to 23 - BODY/EXTERIOR/GRILLE OPEN-

ING REINFORCEMENT - INSTALLATION)

(5) Install the upper radiator mounts to the cross-

member bolts, if removed. Tighten to 8 N´m (70 in.

lbs.).

(6) Install the radiator upper hose to the support

clip (2.4L engine).

RADIATOR FAN RELAY

DESCRIPTION

The radiator fan relay is a solid state type and is

located on the front bumper reinforcment (Fig. 22).

Refer to WIRING DIAGRAMS for a circuit sche-

matic.

OPERATION

The solid state radiator fan relay is controlled by

the Powertrain Control Module (PCM) by way of a

Pulse Width Modulated (PWM) signal. The relay con-

trol circuit supplies a 12 volt signal to the PCM. The

PCM then pulses the ground circuit to achieve fan on

time. The relay provides a voltage to the fan motors

which is proportional to the pulse width it receives

from the PCM. The duty cycle ranges from 30% for

low speed operation, then ramps-up to 100% for high

speed operation. This fan control system provides

infinitely variable fan speeds, allowing for improved

fan noise, A/C performance, better engine cooling,

and additional vehicle power.

To control operation of the relay, the PCM looks at

inputs from:

²Engine coolant temperature

²A/C pressure transducer

²Ambient temperature from the body controller

²Vehicle speed

²Transmission oil temperature

The PCM uses these inputs to determine when the

fan should operate and at what speed. For further

information on fan operation, (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - OPERATION).

REMOVAL

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the radiator crossmember to front fas-

cia closure panel.

(4) Disconnect the relay electrical connector (Fig.

22).

(5) Remove the rivet attaching the relay to the

front bumper beam (Fig. 22).

(6) Remove the relay.

INSTALLATION

CAUTION: The relay mounting location is designed

to dissipate heat. Ensure the relay is securely

attached to prevent relay ªthermalº shutdown and

relay damage, resulting in possible engine over-

heating.

Fig. 21 Radiator Fans

1 - SCREWS - RADIATOR FAN ATTACHING

2 - RADIATOR FAN - RIGHT

3 - MOUNT - RIGHT RADIATOR FAN

4 - CLIPS - RADIATOR FAN LOWER

5 - MOUNT - LEFT RADIATOR FAN

6 - RADIATOR FAN - LEFT

RSENGINE7-29

RADIATOR FAN (Continued)

ProCarManuals.com