transmission oil DODGE TOWN AND COUNTRY 2001 Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 303 of 2321

TRANSMISSION

TABLE OF CONTENTS

page page

TRANSMISSION

DIAGNOSIS AND TESTING.................36

TRANS OIL COOLER FLOW TESTING.......36

STANDARD PROCEDURE..................37

FLUSHING COOLERS AND TUBES.........37

TRANS COOLER

DESCRIPTION...........................38REMOVAL..............................38

CLEANING..............................38

INSPECTION............................38

INSTALLATION...........................38

TRANS COOLER LINES

REMOVAL..............................38

INSTALLATION...........................39

TRANSMISSION

DIAGNOSIS AND TESTING - TRANSMISSION

OIL COOLER FLOW

To determine proper transmission oil flow through

the oil cooler perform the following procedure:

(1) Disconnect the hose from the ªcooler returnº

fitting on the transmission. (Refer to 7 - COOLING/

TRANSMISSION/TRANS COOLER LINES -

REMOVAL)

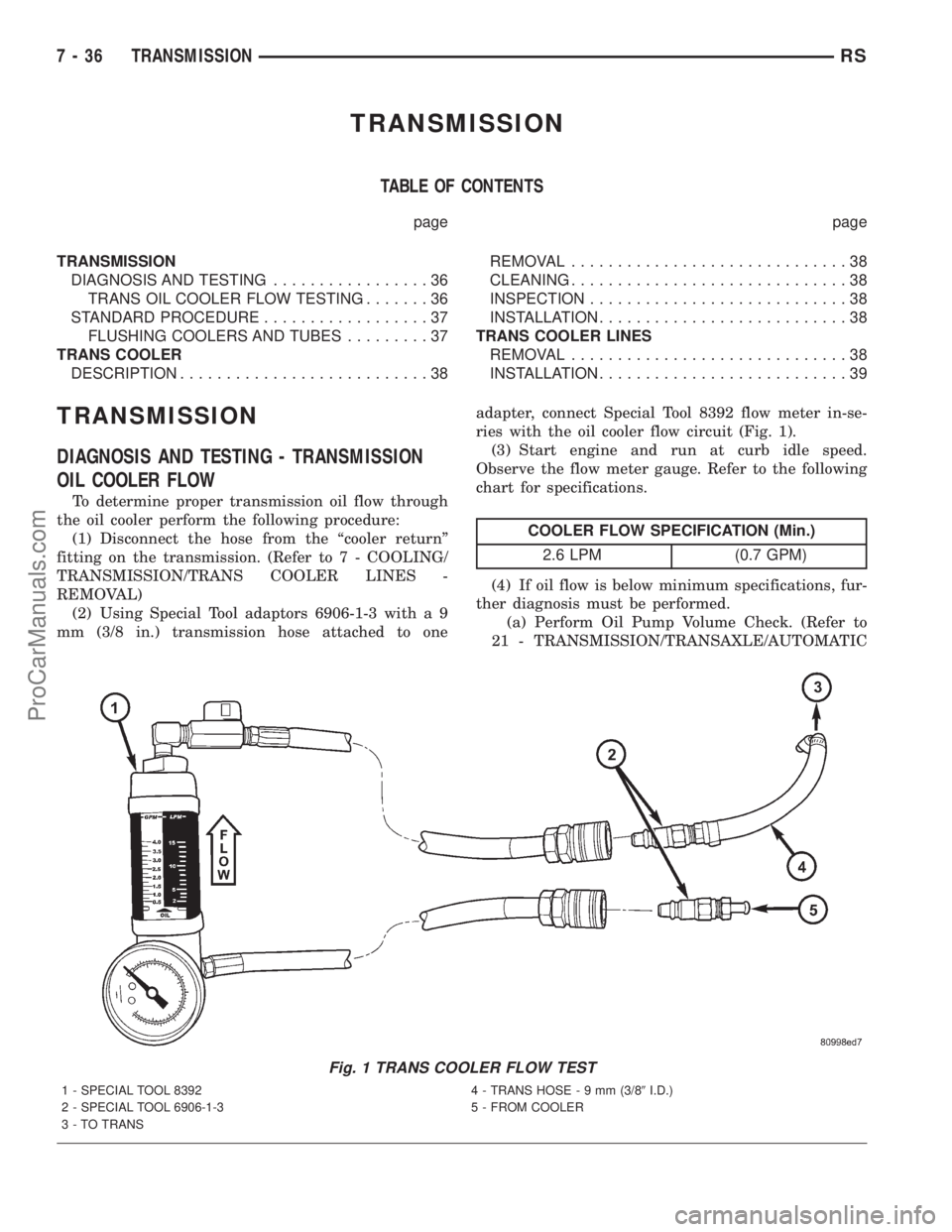

(2) Using Special Tool adaptors 6906-1-3 with a 9

mm (3/8 in.) transmission hose attached to oneadapter, connect Special Tool 8392 flow meter in-se-

ries with the oil cooler flow circuit (Fig. 1).

(3) Start engine and run at curb idle speed.

Observe the flow meter gauge. Refer to the following

chart for specifications.

COOLER FLOW SPECIFICATION (Min.)

2.6 LPM (0.7 GPM)

(4) If oil flow is below minimum specifications, fur-

ther diagnosis must be performed.

(a) Perform Oil Pump Volume Check. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

Fig. 1 TRANS COOLER FLOW TEST

1 - SPECIAL TOOL 8392 4 - TRANS HOSE-9mm(3/89I.D.)

2 - SPECIAL TOOL 6906-1-3 5 - FROM COOLER

3 - TO TRANS

7 - 36 TRANSMISSIONRS

ProCarManuals.com

Page 304 of 2321

- 31TH/OIL PUMP - STANDARD PROCEDURE)

(Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 41TE/OIL PUMP - STANDARD PRO-

CEDURE)

(b) If oil pump volume is within specification, a

possible restriction in the cooler lines or cooler has

occurred.

(c) If oil pump volume is not within specification,

possible internal transmission restrictions, compo-

nent wear or damage has occurred. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH - DIAGNOSIS AND TESTING) (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

41TE - DIAGNOSIS AND TESTING)

(d) If an oil cooler restriction is suspected, per-

form further inspections and flow meter testing by

isolating components (i.e. lines, coolers).

(e) After a restriction is isolated, perform cooler

flush procedure. (Refer to 7 - COOLING/TRANS-

MISSION - STANDARD PROCEDURE)

(f) Re-test cooler flow. If cooler flow does not

exceed minimum specification, replace compo-

nent(s) as necessary.

STANDARD PROCEDURE - FLUSHING

COOLERS AND TUBES

The recommended procedure for cooler flushing is

to use Tool 6906 Cooler Flusher.

WARNING:

WEAR PROTECTIVE EYEWEAR THAT MEETS THE

REQUIREMENTS OF OSHA AND ANSI Z87.1±1968.

WEAR STANDARD INDUSTRIAL RUBBER GLOVES.

KEEP LIGHTED CIGARETTES, SPARKS, FLAMES,

AND OTHER IGNITION SOURCES AWAY FROM THE

AREA TO PREVENT THE IGNITION OF COMBUSTI-

BLE LIQUIDS AND GASES. KEEP A CLASS (B) FIRE

EXTINGUISHER IN THE AREA WHERE THE

FLUSHER WILL BE USED.

KEEP THE AREA WELL VENTILATED.

DO NOT LET FLUSHING SOLVENT COME IN CON-

TACT WITH YOUR EYES OR SKIN: IF EYE CONTAM-

INATION OCCURS, FLUSH EYES WITH WATER FOR15 TO 20 SECONDS. REMOVE CONTAMINATED

CLOTHING AND WASH AFFECTED SKIN WITH

SOAP AND WATER. SEEK MEDICAL ATTENTION.

(1) Remove cover plate filler plug on Tool 6906.

Fill reservoir 1/2 to 3/4 full of fresh flushing solution.

Use MopartTransmission Cooler Flush (MS-552) or

equivalent solution conforming to MS-552. Flushing

solvents are petroleum based solutions generally

used to clean automatic transmission components.

DO NOTuse solvents containing acids, water, gaso-

line, or any other corrosive liquids.

(2) Reinstall filler plug on Tool 6906.

(3) Verify pump power switch is turned OFF. Con-

nect red alligator clip to positive (+) battery post.

Connect black (-) alligator clip to a good ground.

NOTE: When flushing transmission cooler and

lines, ALWAYS reverse flush.

(4) Connect the BLUE pressure line to the OUT-

LET (From) cooler line.

(5) Connect the CLEAR return line to the INLET

(To) cooler line

(6) Turn pump ON for two to three minutes to

flush cooler and lines.

(7) Turn pump OFF.

(8) Disconnect CLEAR suction line from reservoir

at cover plate. Disconnect CLEAR return line at

cover plate, and place it in a drain pan.

(9) Turn pump ON for 30 seconds to purge flush-

ing solution from cooler and lines. Turn pump OFF.

(10) Place CLEAR suction line into a one quart

container of MopartATF+4 (Automatic Transmission

FluidÐType 9602).

(11) Turn pump ON until all transmission fluid is

removed from the one quart container and lines. This

purges any residual cleaning solvent from the trans-

mission cooler and lines. Turn pump OFF.

(12) Disconnect alligator clips from battery. Recon-

nect flusher lines to cover plate, and remove flushing

adapters from cooler lines.

RSTRANSMISSION7-37

TRANSMISSION (Continued)

ProCarManuals.com

Page 305 of 2321

TRANS COOLER

DESCRIPTION

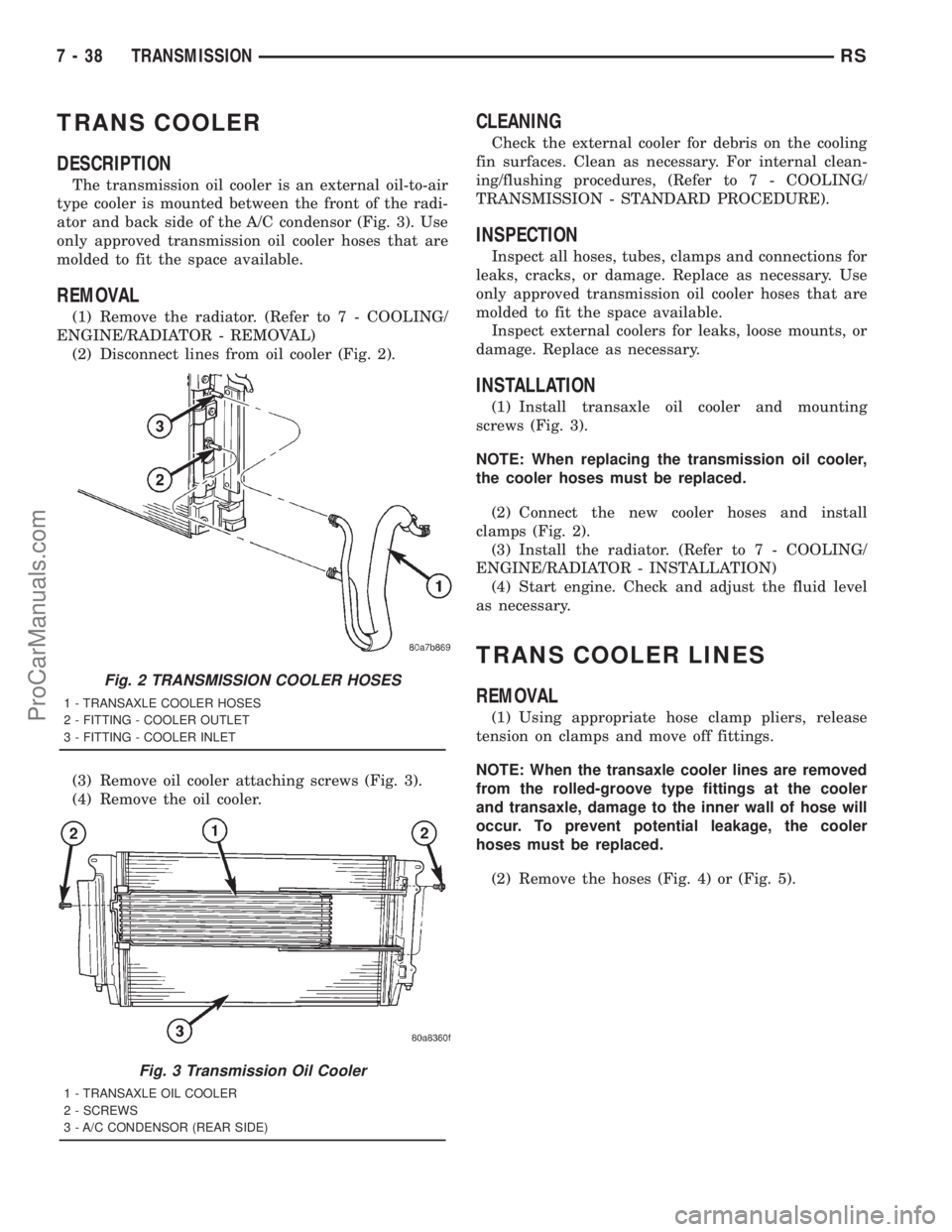

The transmission oil cooler is an external oil-to-air

type cooler is mounted between the front of the radi-

ator and back side of the A/C condensor (Fig. 3). Use

only approved transmission oil cooler hoses that are

molded to fit the space available.

REMOVAL

(1) Remove the radiator. (Refer to 7 - COOLING/

ENGINE/RADIATOR - REMOVAL)

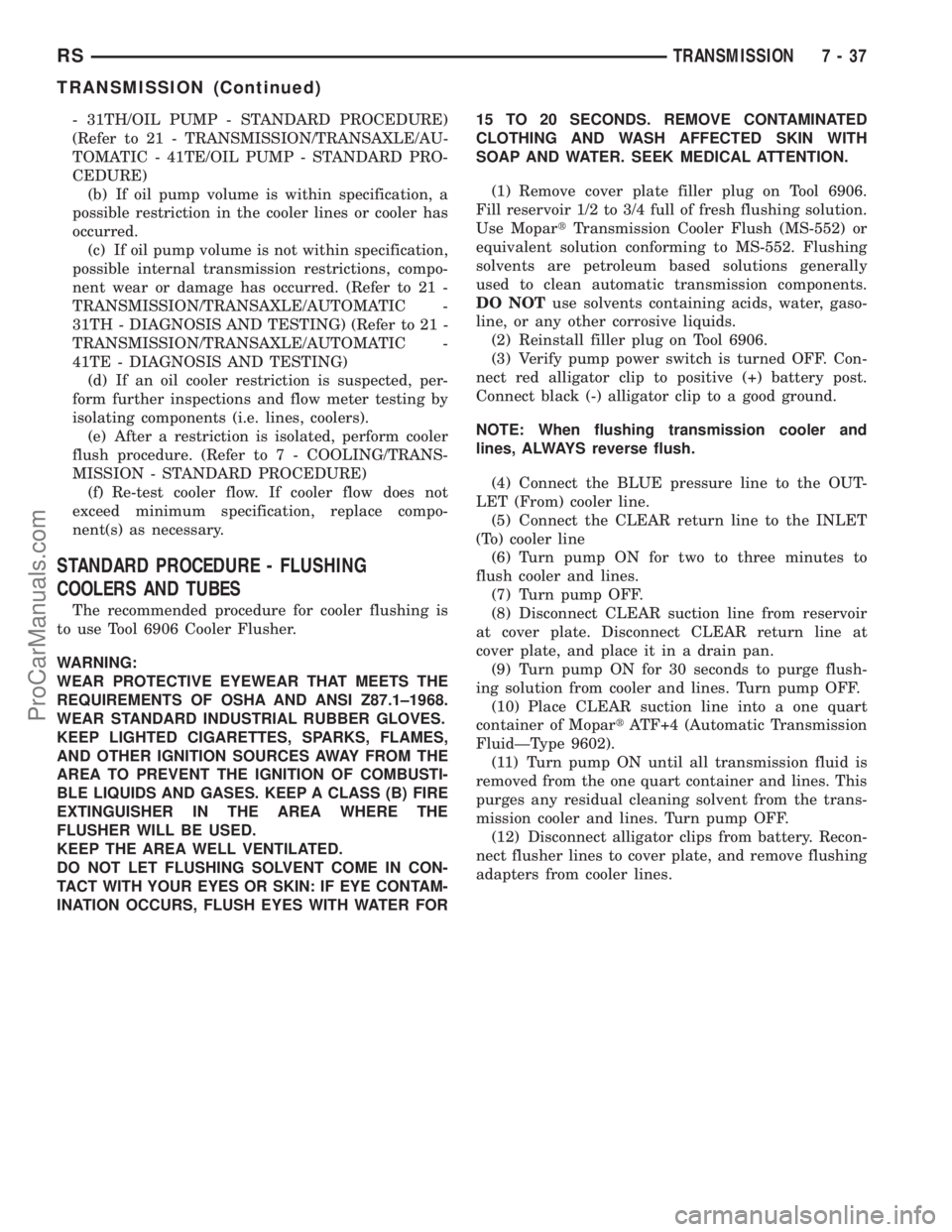

(2) Disconnect lines from oil cooler (Fig. 2).

(3) Remove oil cooler attaching screws (Fig. 3).

(4) Remove the oil cooler.

CLEANING

Check the external cooler for debris on the cooling

fin surfaces. Clean as necessary. For internal clean-

ing/flushing procedures, (Refer to 7 - COOLING/

TRANSMISSION - STANDARD PROCEDURE).

INSPECTION

Inspect all hoses, tubes, clamps and connections for

leaks, cracks, or damage. Replace as necessary. Use

only approved transmission oil cooler hoses that are

molded to fit the space available.

Inspect external coolers for leaks, loose mounts, or

damage. Replace as necessary.

INSTALLATION

(1) Install transaxle oil cooler and mounting

screws (Fig. 3).

NOTE: When replacing the transmission oil cooler,

the cooler hoses must be replaced.

(2) Connect the new cooler hoses and install

clamps (Fig. 2).

(3) Install the radiator. (Refer to 7 - COOLING/

ENGINE/RADIATOR - INSTALLATION)

(4) Start engine. Check and adjust the fluid level

as necessary.

TRANS COOLER LINES

REMOVAL

(1) Using appropriate hose clamp pliers, release

tension on clamps and move off fittings.

NOTE: When the transaxle cooler lines are removed

from the rolled-groove type fittings at the cooler

and transaxle, damage to the inner wall of hose will

occur. To prevent potential leakage, the cooler

hoses must be replaced.

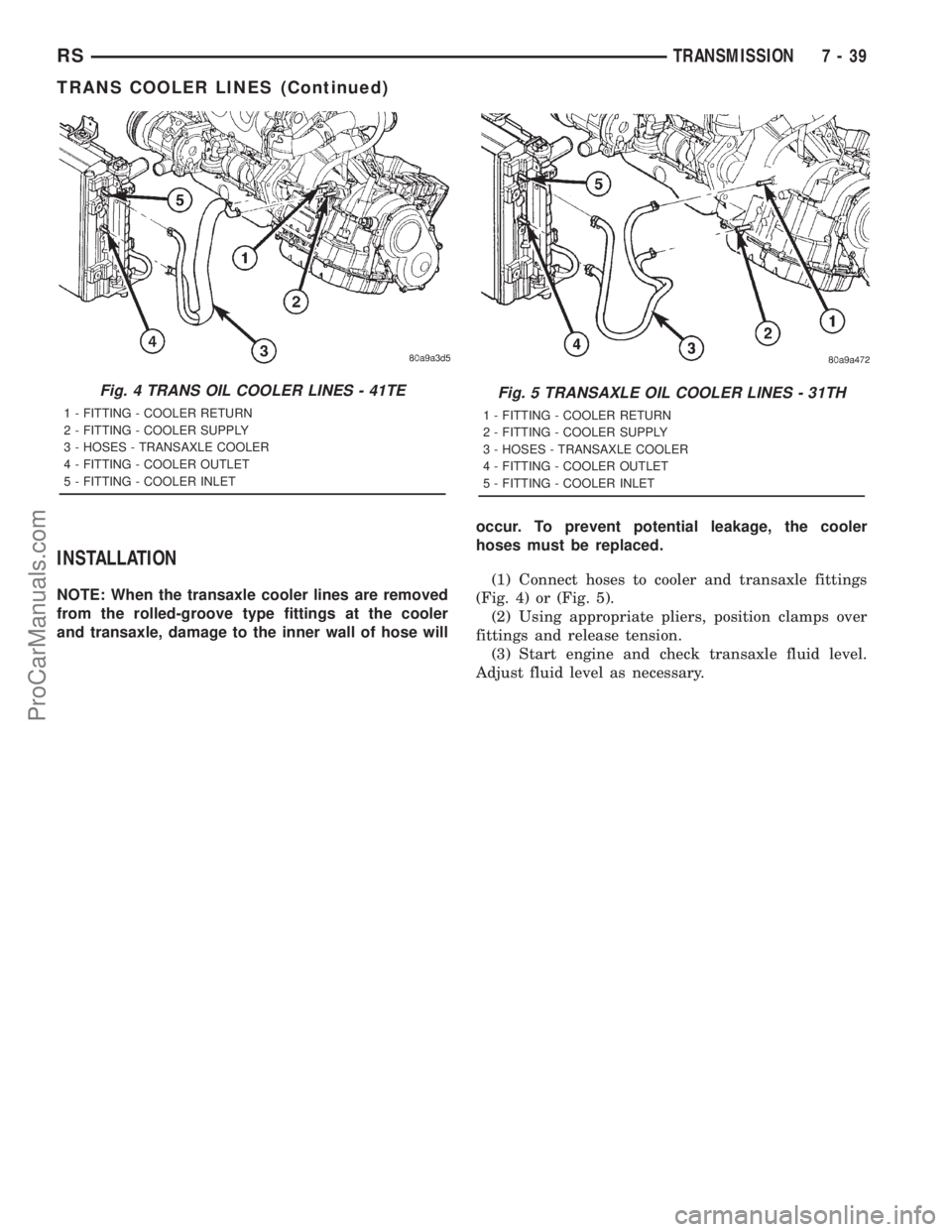

(2) Remove the hoses (Fig. 4) or (Fig. 5).

Fig. 2 TRANSMISSION COOLER HOSES

1 - TRANSAXLE COOLER HOSES

2 - FITTING - COOLER OUTLET

3 - FITTING - COOLER INLET

Fig. 3 Transmission Oil Cooler

1 - TRANSAXLE OIL COOLER

2 - SCREWS

3 - A/C CONDENSOR (REAR SIDE)

7 - 38 TRANSMISSIONRS

ProCarManuals.com

Page 306 of 2321

INSTALLATION

NOTE: When the transaxle cooler lines are removed

from the rolled-groove type fittings at the cooler

and transaxle, damage to the inner wall of hose willoccur. To prevent potential leakage, the cooler

hoses must be replaced.

(1) Connect hoses to cooler and transaxle fittings

(Fig. 4) or (Fig. 5).

(2) Using appropriate pliers, position clamps over

fittings and release tension.

(3) Start engine and check transaxle fluid level.

Adjust fluid level as necessary.

Fig. 4 TRANS OIL COOLER LINES - 41TE

1 - FITTING - COOLER RETURN

2 - FITTING - COOLER SUPPLY

3 - HOSES - TRANSAXLE COOLER

4 - FITTING - COOLER OUTLET

5 - FITTING - COOLER INLET

Fig. 5 TRANSAXLE OIL COOLER LINES - 31TH

1 - FITTING - COOLER RETURN

2 - FITTING - COOLER SUPPLY

3 - HOSES - TRANSAXLE COOLER

4 - FITTING - COOLER OUTLET

5 - FITTING - COOLER INLET

RSTRANSMISSION7-39

TRANS COOLER LINES (Continued)

ProCarManuals.com

Page 366 of 2321

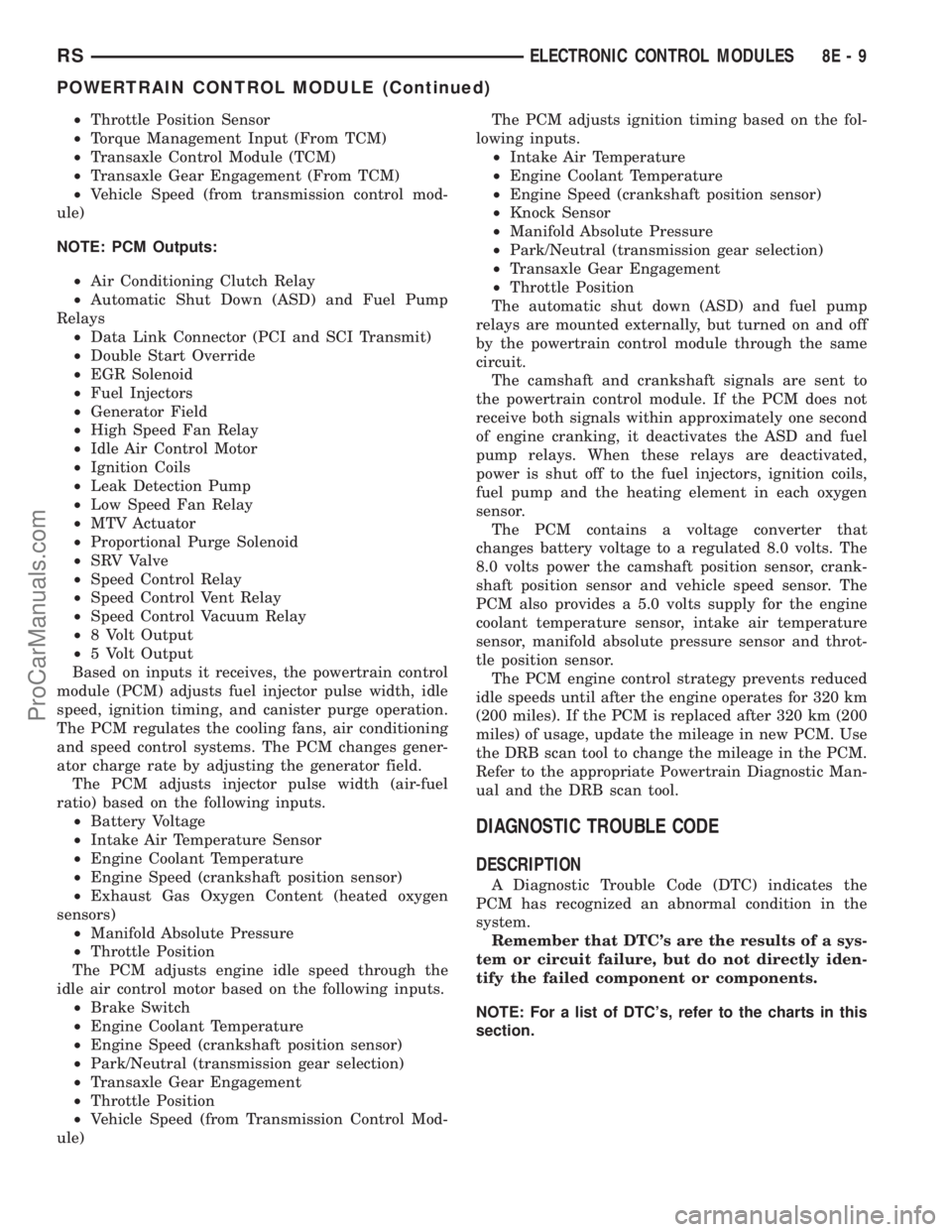

²Throttle Position Sensor

²Torque Management Input (From TCM)

²Transaxle Control Module (TCM)

²Transaxle Gear Engagement (From TCM)

²Vehicle Speed (from transmission control mod-

ule)

NOTE: PCM Outputs:

²Air Conditioning Clutch Relay

²Automatic Shut Down (ASD) and Fuel Pump

Relays

²Data Link Connector (PCI and SCI Transmit)

²Double Start Override

²EGR Solenoid

²Fuel Injectors

²Generator Field

²High Speed Fan Relay

²Idle Air Control Motor

²Ignition Coils

²Leak Detection Pump

²Low Speed Fan Relay

²MTV Actuator

²Proportional Purge Solenoid

²SRV Valve

²Speed Control Relay

²Speed Control Vent Relay

²Speed Control Vacuum Relay

²8 Volt Output

²5 Volt Output

Based on inputs it receives, the powertrain control

module (PCM) adjusts fuel injector pulse width, idle

speed, ignition timing, and canister purge operation.

The PCM regulates the cooling fans, air conditioning

and speed control systems. The PCM changes gener-

ator charge rate by adjusting the generator field.

The PCM adjusts injector pulse width (air-fuel

ratio) based on the following inputs.

²Battery Voltage

²Intake Air Temperature Sensor

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Exhaust Gas Oxygen Content (heated oxygen

sensors)

²Manifold Absolute Pressure

²Throttle Position

The PCM adjusts engine idle speed through the

idle air control motor based on the following inputs.

²Brake Switch

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Park/Neutral (transmission gear selection)

²Transaxle Gear Engagement

²Throttle Position

²Vehicle Speed (from Transmission Control Mod-

ule)The PCM adjusts ignition timing based on the fol-

lowing inputs.

²Intake Air Temperature

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Knock Sensor

²Manifold Absolute Pressure

²Park/Neutral (transmission gear selection)

²Transaxle Gear Engagement

²Throttle Position

The automatic shut down (ASD) and fuel pump

relays are mounted externally, but turned on and off

by the powertrain control module through the same

circuit.

The camshaft and crankshaft signals are sent to

the powertrain control module. If the PCM does not

receive both signals within approximately one second

of engine cranking, it deactivates the ASD and fuel

pump relays. When these relays are deactivated,

power is shut off to the fuel injectors, ignition coils,

fuel pump and the heating element in each oxygen

sensor.

The PCM contains a voltage converter that

changes battery voltage to a regulated 8.0 volts. The

8.0 volts power the camshaft position sensor, crank-

shaft position sensor and vehicle speed sensor. The

PCM also provides a 5.0 volts supply for the engine

coolant temperature sensor, intake air temperature

sensor, manifold absolute pressure sensor and throt-

tle position sensor.

The PCM engine control strategy prevents reduced

idle speeds until after the engine operates for 320 km

(200 miles). If the PCM is replaced after 320 km (200

miles) of usage, update the mileage in new PCM. Use

the DRB scan tool to change the mileage in the PCM.

Refer to the appropriate Powertrain Diagnostic Man-

ual and the DRB scan tool.

DIAGNOSTIC TROUBLE CODE

DESCRIPTION

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.

Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

NOTE: For a list of DTC's, refer to the charts in this

section.

RSELECTRONIC CONTROL MODULES8E-9

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 371 of 2321

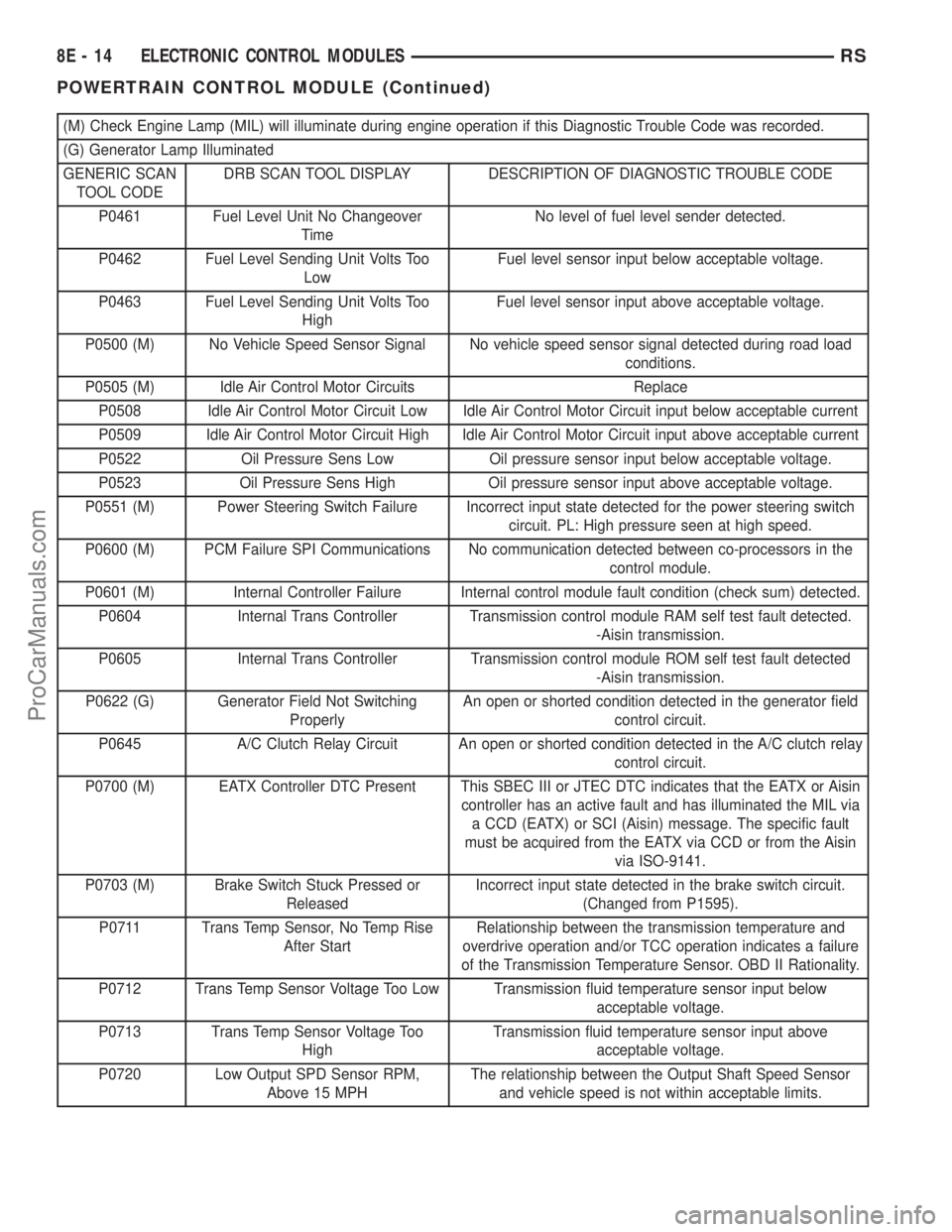

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC SCAN

TOOL CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0461 Fuel Level Unit No Changeover

TimeNo level of fuel level sender detected.

P0462 Fuel Level Sending Unit Volts Too

LowFuel level sensor input below acceptable voltage.

P0463 Fuel Level Sending Unit Volts Too

HighFuel level sensor input above acceptable voltage.

P0500 (M) No Vehicle Speed Sensor Signal No vehicle speed sensor signal detected during road load

conditions.

P0505 (M) Idle Air Control Motor Circuits Replace

P0508 Idle Air Control Motor Circuit Low Idle Air Control Motor Circuit input below acceptable current

P0509 Idle Air Control Motor Circuit High Idle Air Control Motor Circuit input above acceptable current

P0522 Oil Pressure Sens Low Oil pressure sensor input below acceptable voltage.

P0523 Oil Pressure Sens High Oil pressure sensor input above acceptable voltage.

P0551 (M) Power Steering Switch Failure Incorrect input state detected for the power steering switch

circuit. PL: High pressure seen at high speed.

P0600 (M) PCM Failure SPI Communications No communication detected between co-processors in the

control module.

P0601 (M) Internal Controller Failure Internal control module fault condition (check sum) detected.

P0604 Internal Trans Controller Transmission control module RAM self test fault detected.

-Aisin transmission.

P0605 Internal Trans Controller Transmission control module ROM self test fault detected

-Aisin transmission.

P0622 (G) Generator Field Not Switching

ProperlyAn open or shorted condition detected in the generator field

control circuit.

P0645 A/C Clutch Relay Circuit An open or shorted condition detected in the A/C clutch relay

control circuit.

P0700 (M) EATX Controller DTC Present This SBEC III or JTEC DTC indicates that the EATX or Aisin

controller has an active fault and has illuminated the MIL via

a CCD (EATX) or SCI (Aisin) message. The specific fault

must be acquired from the EATX via CCD or from the Aisin

via ISO-9141.

P0703 (M) Brake Switch Stuck Pressed or

ReleasedIncorrect input state detected in the brake switch circuit.

(Changed from P1595).

P0711 Trans Temp Sensor, No Temp Rise

After StartRelationship between the transmission temperature and

overdrive operation and/or TCC operation indicates a failure

of the Transmission Temperature Sensor. OBD II Rationality.

P0712 Trans Temp Sensor Voltage Too Low Transmission fluid temperature sensor input below

acceptable voltage.

P0713 Trans Temp Sensor Voltage Too

HighTransmission fluid temperature sensor input above

acceptable voltage.

P0720 Low Output SPD Sensor RPM,

Above 15 MPHThe relationship between the Output Shaft Speed Sensor

and vehicle speed is not within acceptable limits.

8E - 14 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 383 of 2321

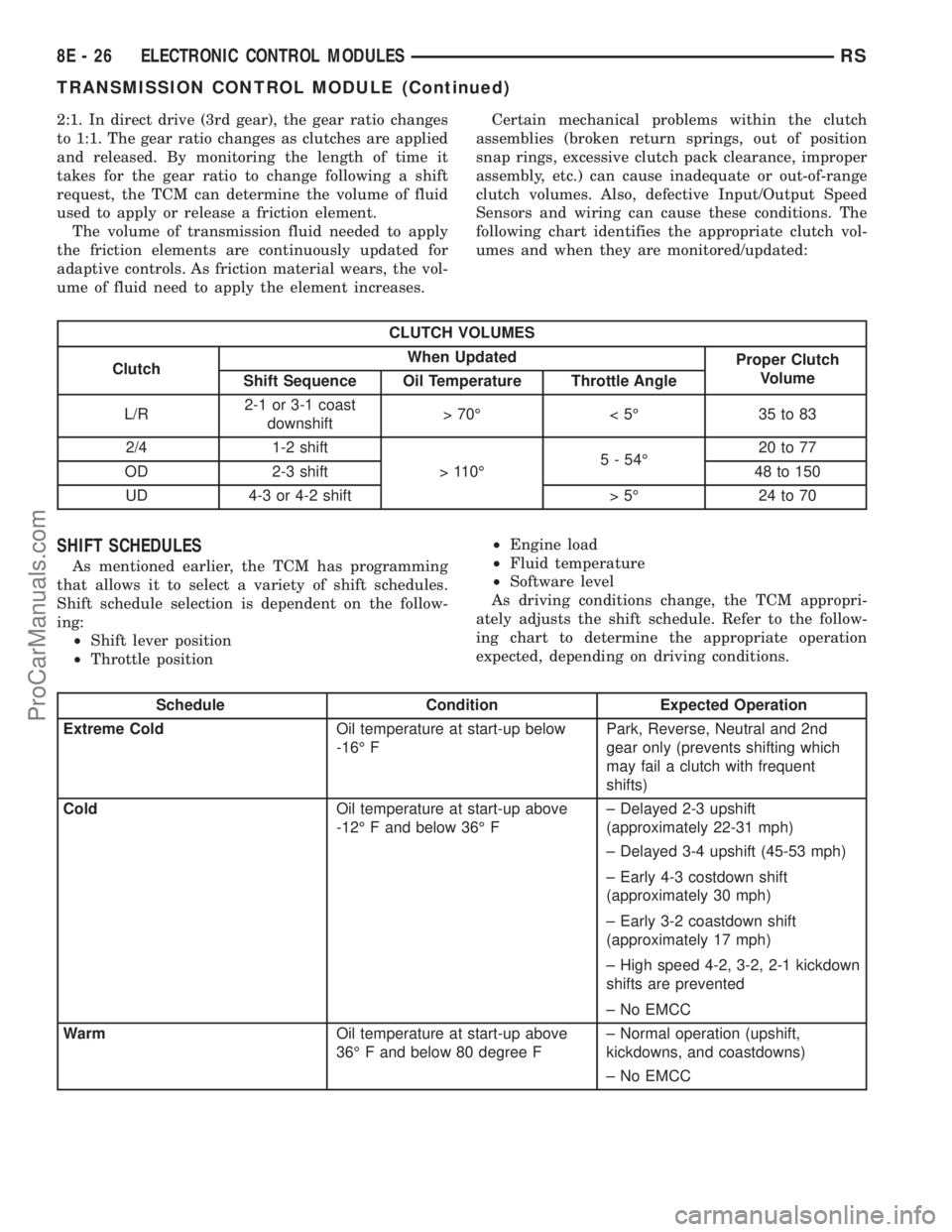

2:1. In direct drive (3rd gear), the gear ratio changes

to 1:1. The gear ratio changes as clutches are applied

and released. By monitoring the length of time it

takes for the gear ratio to change following a shift

request, the TCM can determine the volume of fluid

used to apply or release a friction element.

The volume of transmission fluid needed to apply

the friction elements are continuously updated for

adaptive controls. As friction material wears, the vol-

ume of fluid need to apply the element increases.Certain mechanical problems within the clutch

assemblies (broken return springs, out of position

snap rings, excessive clutch pack clearance, improper

assembly, etc.) can cause inadequate or out-of-range

clutch volumes. Also, defective Input/Output Speed

Sensors and wiring can cause these conditions. The

following chart identifies the appropriate clutch vol-

umes and when they are monitored/updated:

CLUTCH VOLUMES

ClutchWhen Updated

Proper Clutch

Volume

Shift Sequence Oil Temperature Throttle Angle

L/R2-1 or 3-1 coast

downshift>70É <5É 35to83

2/4 1-2 shift

> 110É5 - 54É20 to 77

OD 2-3 shift 48 to 150

UD 4-3 or 4-2 shift > 5É 24 to 70

SHIFT SCHEDULES

As mentioned earlier, the TCM has programming

that allows it to select a variety of shift schedules.

Shift schedule selection is dependent on the follow-

ing:

²Shift lever position

²Throttle position²Engine load

²Fluid temperature

²Software level

As driving conditions change, the TCM appropri-

ately adjusts the shift schedule. Refer to the follow-

ing chart to determine the appropriate operation

expected, depending on driving conditions.

Schedule Condition Expected Operation

Extreme ColdOil temperature at start-up below

-16É FPark, Reverse, Neutral and 2nd

gear only (prevents shifting which

may fail a clutch with frequent

shifts)

ColdOil temperature at start-up above

-12É F and below 36É F± Delayed 2-3 upshift

(approximately 22-31 mph)

± Delayed 3-4 upshift (45-53 mph)

± Early 4-3 costdown shift

(approximately 30 mph)

± Early 3-2 coastdown shift

(approximately 17 mph)

± High speed 4-2, 3-2, 2-1 kickdown

shifts are prevented

± No EMCC

WarmOil temperature at start-up above

36É F and below 80 degree F± Normal operation (upshift,

kickdowns, and coastdowns)

± No EMCC

8E - 26 ELECTRONIC CONTROL MODULESRS

TRANSMISSION CONTROL MODULE (Continued)

ProCarManuals.com

Page 384 of 2321

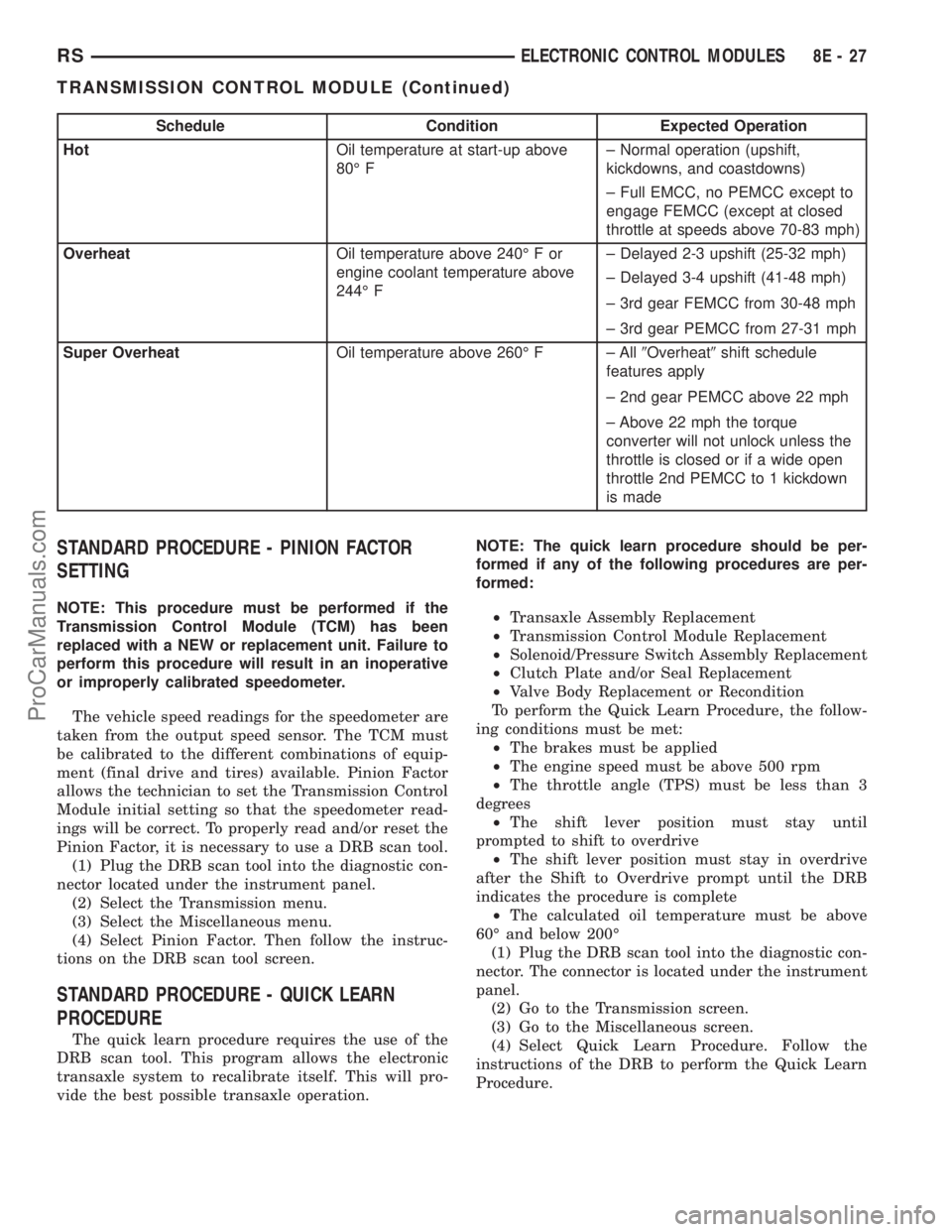

Schedule Condition Expected Operation

HotOil temperature at start-up above

80É F± Normal operation (upshift,

kickdowns, and coastdowns)

± Full EMCC, no PEMCC except to

engage FEMCC (except at closed

throttle at speeds above 70-83 mph)

OverheatOil temperature above 240É F or

engine coolant temperature above

244É F± Delayed 2-3 upshift (25-32 mph)

± Delayed 3-4 upshift (41-48 mph)

± 3rd gear FEMCC from 30-48 mph

± 3rd gear PEMCC from 27-31 mph

Super OverheatOil temperature above 260É F ± All9Overheat9shift schedule

features apply

± 2nd gear PEMCC above 22 mph

± Above 22 mph the torque

converter will not unlock unless the

throttle is closed or if a wide open

throttle 2nd PEMCC to 1 kickdown

is made

STANDARD PROCEDURE - PINION FACTOR

SETTING

NOTE: This procedure must be performed if the

Transmission Control Module (TCM) has been

replaced with a NEW or replacement unit. Failure to

perform this procedure will result in an inoperative

or improperly calibrated speedometer.

The vehicle speed readings for the speedometer are

taken from the output speed sensor. The TCM must

be calibrated to the different combinations of equip-

ment (final drive and tires) available. Pinion Factor

allows the technician to set the Transmission Control

Module initial setting so that the speedometer read-

ings will be correct. To properly read and/or reset the

Pinion Factor, it is necessary to use a DRB scan tool.

(1) Plug the DRB scan tool into the diagnostic con-

nector located under the instrument panel.

(2) Select the Transmission menu.

(3) Select the Miscellaneous menu.

(4) Select Pinion Factor. Then follow the instruc-

tions on the DRB scan tool screen.

STANDARD PROCEDURE - QUICK LEARN

PROCEDURE

The quick learn procedure requires the use of the

DRB scan tool. This program allows the electronic

transaxle system to recalibrate itself. This will pro-

vide the best possible transaxle operation.NOTE: The quick learn procedure should be per-

formed if any of the following procedures are per-

formed:

²Transaxle Assembly Replacement

²Transmission Control Module Replacement

²Solenoid/Pressure Switch Assembly Replacement

²Clutch Plate and/or Seal Replacement

²Valve Body Replacement or Recondition

To perform the Quick Learn Procedure, the follow-

ing conditions must be met:

²The brakes must be applied

²The engine speed must be above 500 rpm

²The throttle angle (TPS) must be less than 3

degrees

²The shift lever position must stay until

prompted to shift to overdrive

²The shift lever position must stay in overdrive

after the Shift to Overdrive prompt until the DRB

indicates the procedure is complete

²The calculated oil temperature must be above

60É and below 200É

(1) Plug the DRB scan tool into the diagnostic con-

nector. The connector is located under the instrument

panel.

(2) Go to the Transmission screen.

(3) Go to the Miscellaneous screen.

(4) Select Quick Learn Procedure. Follow the

instructions of the DRB to perform the Quick Learn

Procedure.

RSELECTRONIC CONTROL MODULES8E-27

TRANSMISSION CONTROL MODULE (Continued)

ProCarManuals.com

Page 418 of 2321

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. It is grounded

through the transmission range sensor only when the

gearshift selector lever is in the Park or Neutral

positions. Check for continuity to ground at the cav-

ity for relay terminal 85. If not OK with an auto-

matic transmission, check for an open or short circuit

to the transmission range sensor and repair.

SAFETY SWITCHES

For diagnostics of the Transmission Range Sensor,

refer to the Transaxle section for more information.

If equipped with Clutch Interlock/Upstop Switch,

refer to Diagnosis and Testing in the Clutch section.

IGNITION SWITCH

After testing starter solenoid and relay, test igni-

tion switch and wiring. Refer to the Ignition Section

or Wiring Diagrams for more information. Check all

wiring for opens or shorts, and all connectors for

being loose or corroded.

BATTERY

For battery diagnosis and testing, refer to the Bat-

tery section for procedures.

ALL RELATED WIRING AND CONNECTORS

Refer to Wiring Diagrams for more information.

FEED CIRCUIT RESISTANCE TEST

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Ignition and Fuel systems must be dis-

abled to prevent engine start while performing the

following tests.

(1) To disable the Ignition and Fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(2) Remove the air cleaner assembly for access to

battery terminals. Refer to the Fuel section for ser-

vice procedures.

(3) With all wiring harnesses and components

properly connected, perform the following:

(a) Connect the negative lead of the voltmeter to

the battery negative post, and positive lead to the

battery negative cable clamp. Rotate and hold the

ignition switch in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between cable clamp and post.(b) Connect positive lead of the voltmeter to the

battery positive post, and negative lead to the bat-

tery positive cable clamp. Rotate and hold the igni-

tion switch key in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between the cable clamp and post.

(c) Connect negative lead of voltmeter to battery

negative terminal, and positive lead to engine

block near the battery cable attaching point.

Rotate and hold the ignition switch in the START

position. If voltage reads above 0.2 volt, correct

poor contact at ground cable attaching point. If

voltage reading is still above 0.2 volt after correct-

ing poor contacts, replace ground cable.

(4) Connect positive voltmeter lead to the starter

motor housing and the negative lead to the battery

negative terminal. Hold the ignition switch key in

the START position. If voltage reads above 0.2 volt,

correct poor starter to engine ground.

(a) Connect the positive voltmeter lead to the

battery positive terminal, and negative lead to bat-

tery cable terminal on starter solenoid. Rotate and

hold the ignition switch in the START position. If

voltage reads above 0.2 volt, correct poor contact at

battery cable to solenoid connection. If reading is

still above 0.2 volt after correcting poor contacts,

replace battery positive cable.

(b) If resistance tests do not detect feed circuit

failures, replace the starter motor.FEED CIRCUIT TEST

NOTE: The following results are based upon the

vehicle being at room temperature.

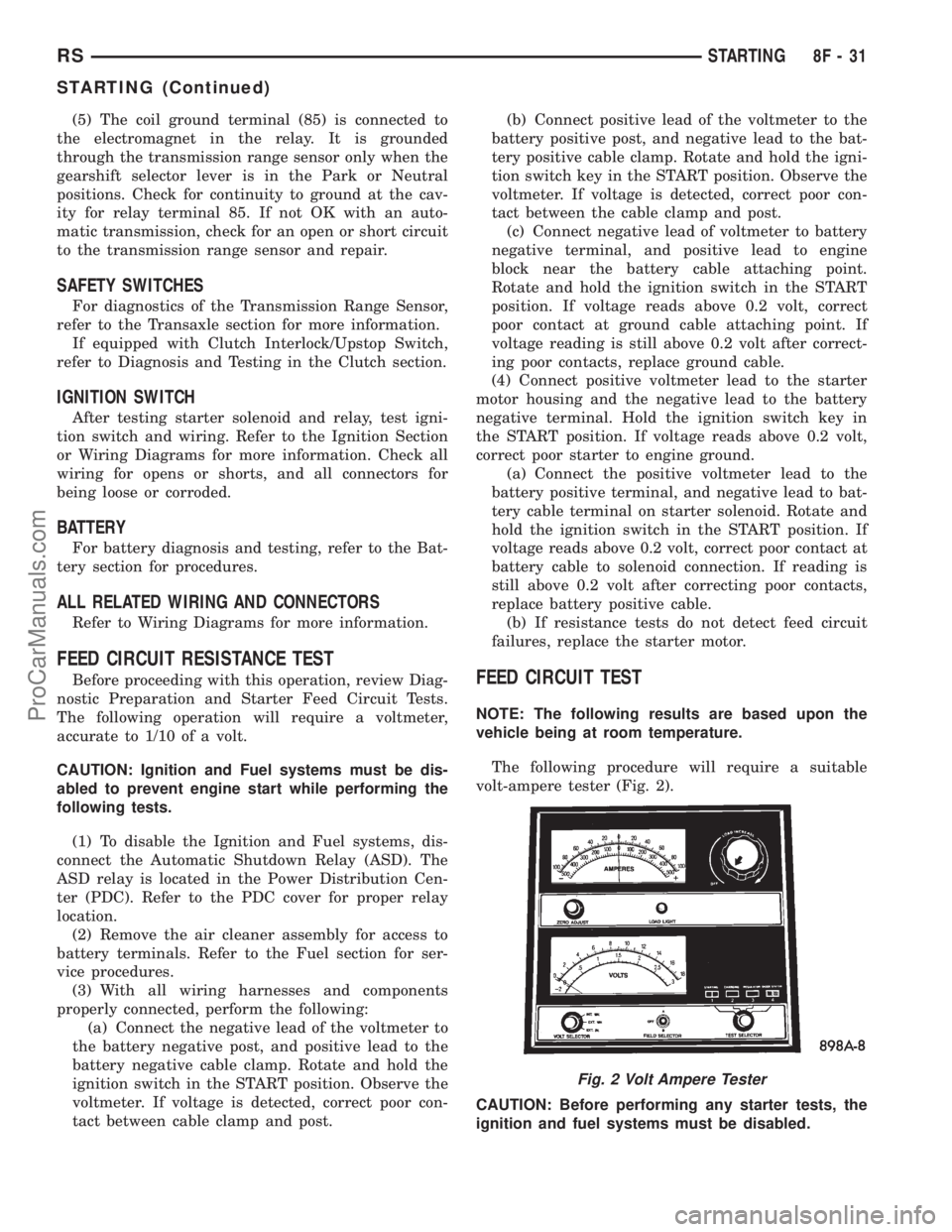

The following procedure will require a suitable

volt-ampere tester (Fig. 2).

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

Fig. 2 Volt Ampere Tester

RSSTARTING8F-31

STARTING (Continued)

ProCarManuals.com

Page 419 of 2321

(1) Check battery before performing this test. Bat-

tery must be fully charged.

(2) Connect a volt-ampere tester to the battery ter-

minals. Refer to the operating instructions provided

with the tester being used.

(3) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(4) Verify that all lights and accessories are OFF,

and the transmission shift selector is in the PARK

and SET parking brake.

CAUTION: Do not overheat the starter motor or

draw the battery voltage below 9.6 volts during

cranking operations.

(5) Rotate and hold the ignition switch in the

START position. Observe the volt-ampere tester (Fig.

2).

²If voltage reads above 9.6 volts, and amperage

draw reads above 280 amps, check for engine seizing

or faulty starter.

²If voltage reads 12.4 volts or greater and amper-

age reads 0 to 10 amps, check for corroded cables

and/or bad connections.

²Voltage below 9.6 volts and amperage draw

above 300 amps, the problem is the starter. Replace

the starter refer to starter removal.

(6) After the starting system problems have been

corrected, verify the battery state-of-charge and

charge battery if necessary. Disconnect all testingequipment and connect ASD relay. Start the vehicle

several times to assure the problem has been cor-

rected.

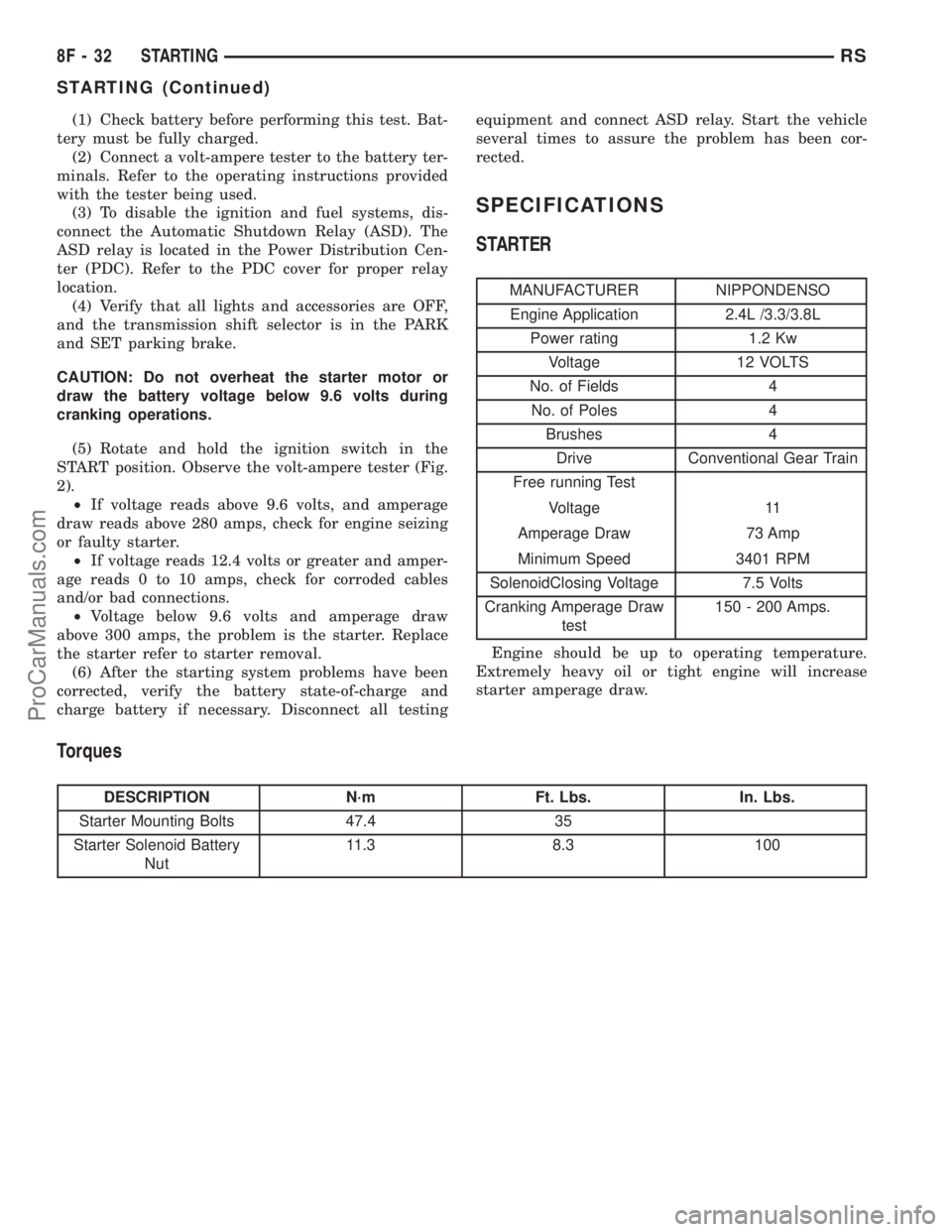

SPECIFICATIONS

STARTER

MANUFACTURER NIPPONDENSO

Engine Application 2.4L /3.3/3.8L

Power rating 1.2 Kw

Voltage 12 VOLTS

No. of Fields 4

No. of Poles 4

Brushes 4

Drive Conventional Gear Train

Free running Test

Voltage 11

Amperage Draw 73 Amp

Minimum Speed 3401 RPM

SolenoidClosing Voltage 7.5 Volts

Cranking Amperage Draw

test150 - 200 Amps.

Engine should be up to operating temperature.

Extremely heavy oil or tight engine will increase

starter amperage draw.

Torques

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Starter Mounting Bolts 47.4 35

Starter Solenoid Battery

Nut11.3 8.3 100

8F - 32 STARTINGRS

STARTING (Continued)

ProCarManuals.com