DODGE TOWN AND COUNTRY 2001 Service Manual

Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 481 of 2321

CAUTION: The switch can only be adjusted once.

That is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

REMOVAL - BRAKE LAMP SWITCH

(1) Disconnect and isolate the battery negative

cable from its post on the battery.

(2) Remove silencer panel below steering column

and knee blocker.

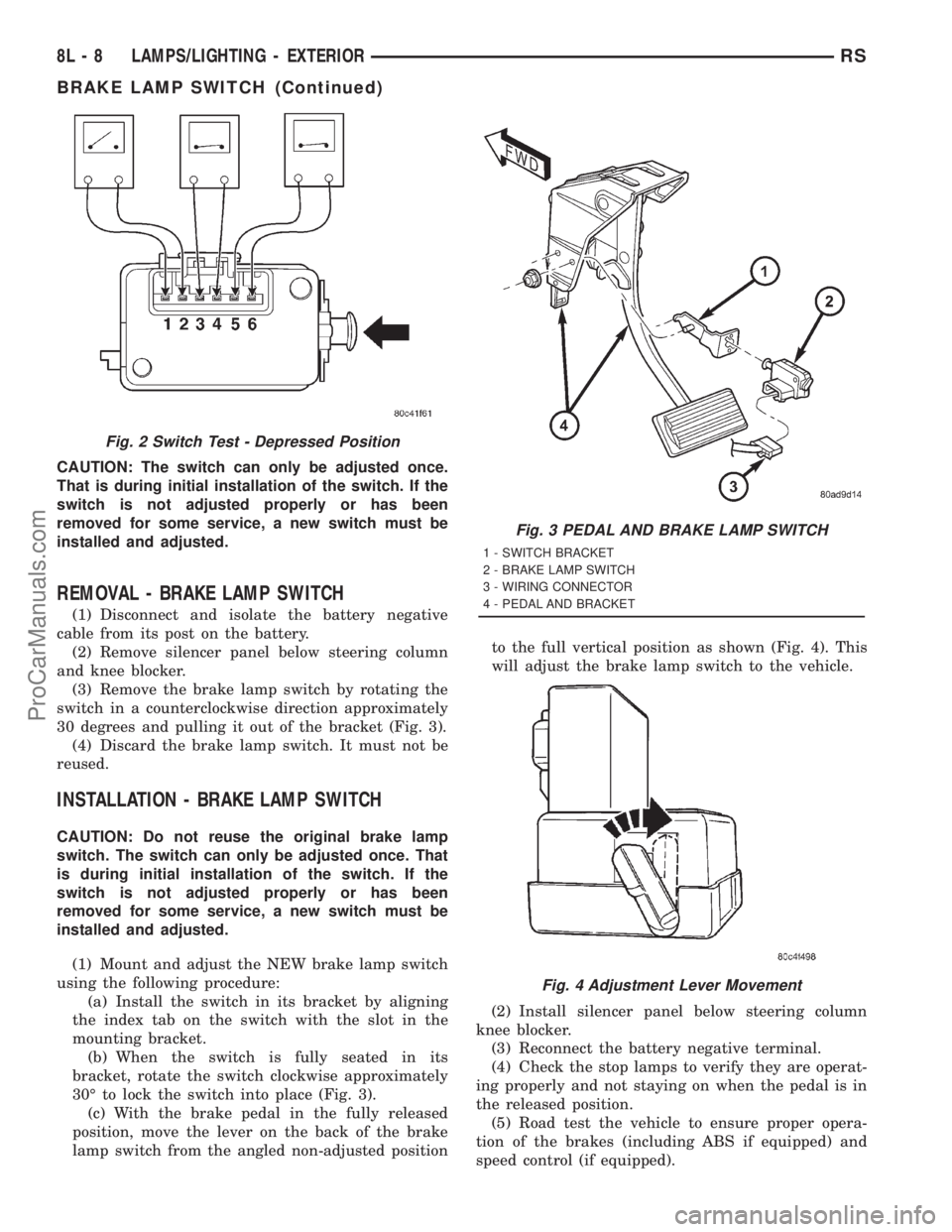

(3) Remove the brake lamp switch by rotating the

switch in a counterclockwise direction approximately

30 degrees and pulling it out of the bracket (Fig. 3).

(4) Discard the brake lamp switch. It must not be

reused.

INSTALLATION - BRAKE LAMP SWITCH

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(1) Mount and adjust the NEW brake lamp switch

using the following procedure:

(a) Install the switch in its bracket by aligning

the index tab on the switch with the slot in the

mounting bracket.

(b) When the switch is fully seated in its

bracket, rotate the switch clockwise approximately

30É to lock the switch into place (Fig. 3).

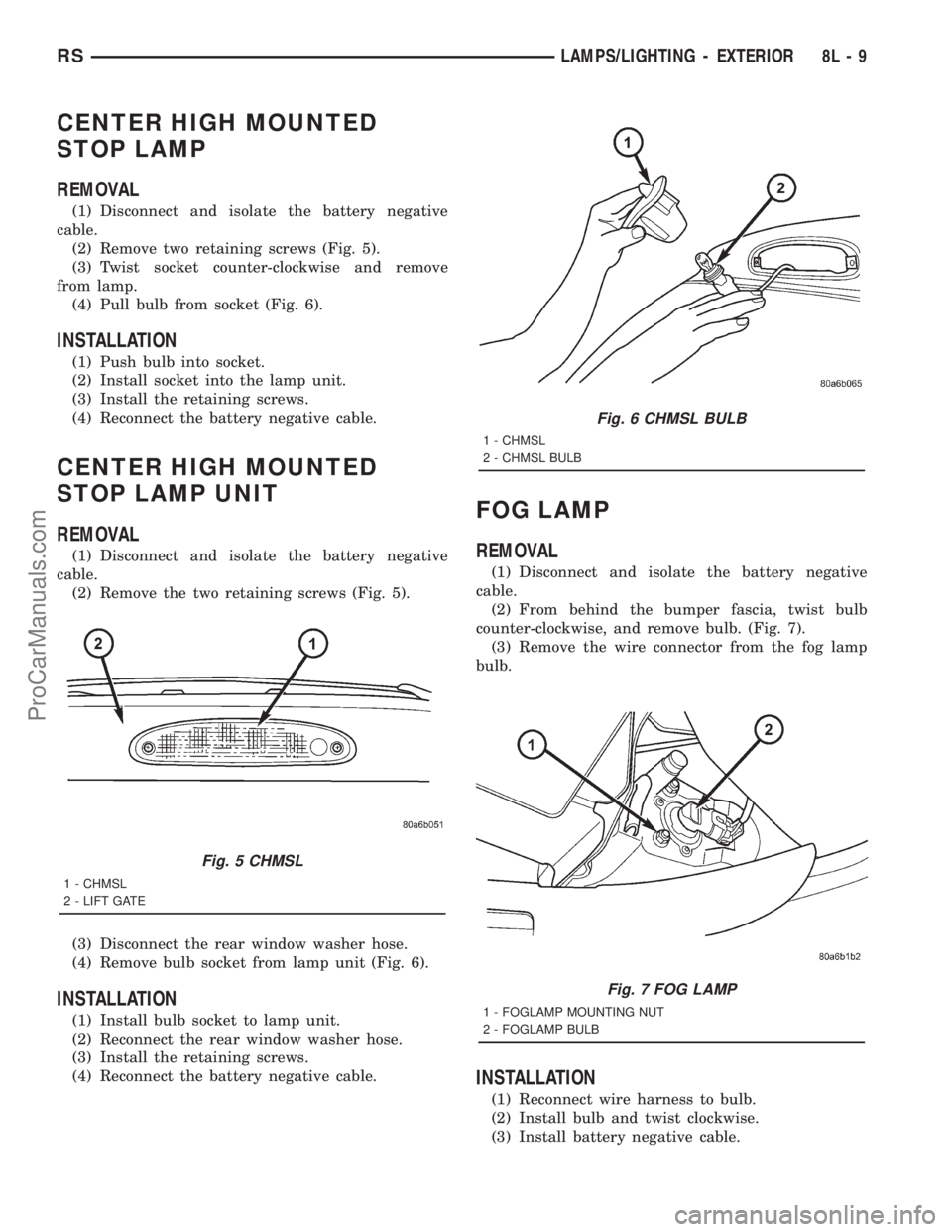

(c) With the brake pedal in the fully released

position, move the lever on the back of the brake

lamp switch from the angled non-adjusted positionto the full vertical position as shown (Fig. 4). This

will adjust the brake lamp switch to the vehicle.

(2) Install silencer panel below steering column

knee blocker.

(3) Reconnect the battery negative terminal.

(4) Check the stop lamps to verify they are operat-

ing properly and not staying on when the pedal is in

the released position.

(5) Road test the vehicle to ensure proper opera-

tion of the brakes (including ABS if equipped) and

speed control (if equipped).

Fig. 2 Switch Test - Depressed Position

Fig. 3 PEDAL AND BRAKE LAMP SWITCH

1 - SWITCH BRACKET

2 - BRAKE LAMP SWITCH

3 - WIRING CONNECTOR

4 - PEDAL AND BRACKET

Fig. 4 Adjustment Lever Movement

8L - 8 LAMPS/LIGHTING - EXTERIORRS

BRAKE LAMP SWITCH (Continued)

ProCarManuals.com

Page 482 of 2321

CENTER HIGH MOUNTED

STOP LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove two retaining screws (Fig. 5).

(3) Twist socket counter-clockwise and remove

from lamp.

(4) Pull bulb from socket (Fig. 6).

INSTALLATION

(1) Push bulb into socket.

(2) Install socket into the lamp unit.

(3) Install the retaining screws.

(4) Reconnect the battery negative cable.

CENTER HIGH MOUNTED

STOP LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the two retaining screws (Fig. 5).

(3) Disconnect the rear window washer hose.

(4) Remove bulb socket from lamp unit (Fig. 6).

INSTALLATION

(1) Install bulb socket to lamp unit.

(2) Reconnect the rear window washer hose.

(3) Install the retaining screws.

(4) Reconnect the battery negative cable.

FOG LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) From behind the bumper fascia, twist bulb

counter-clockwise, and remove bulb. (Fig. 7).

(3) Remove the wire connector from the fog lamp

bulb.

INSTALLATION

(1) Reconnect wire harness to bulb.

(2) Install bulb and twist clockwise.

(3) Install battery negative cable.

Fig. 5 CHMSL

1 - CHMSL

2 - LIFT GATE

Fig. 6 CHMSL BULB

1 - CHMSL

2 - CHMSL BULB

Fig. 7 FOG LAMP

1 - FOGLAMP MOUNTING NUT

2 - FOGLAMP BULB

RSLAMPS/LIGHTING - EXTERIOR8L-9

ProCarManuals.com

Page 483 of 2321

FOG LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) From behind the bumper fascia, disconnect the

wire harness from the fog lamp bulb (Fig. 7).

(3) Remove mounting nuts.

INSTALLATION

(1) Install mounting nuts.

(2) Reconnect the wire harness to the fog lamp

bulb.

(3) Reconnect the battery negative cable.

ADJUSTMENT

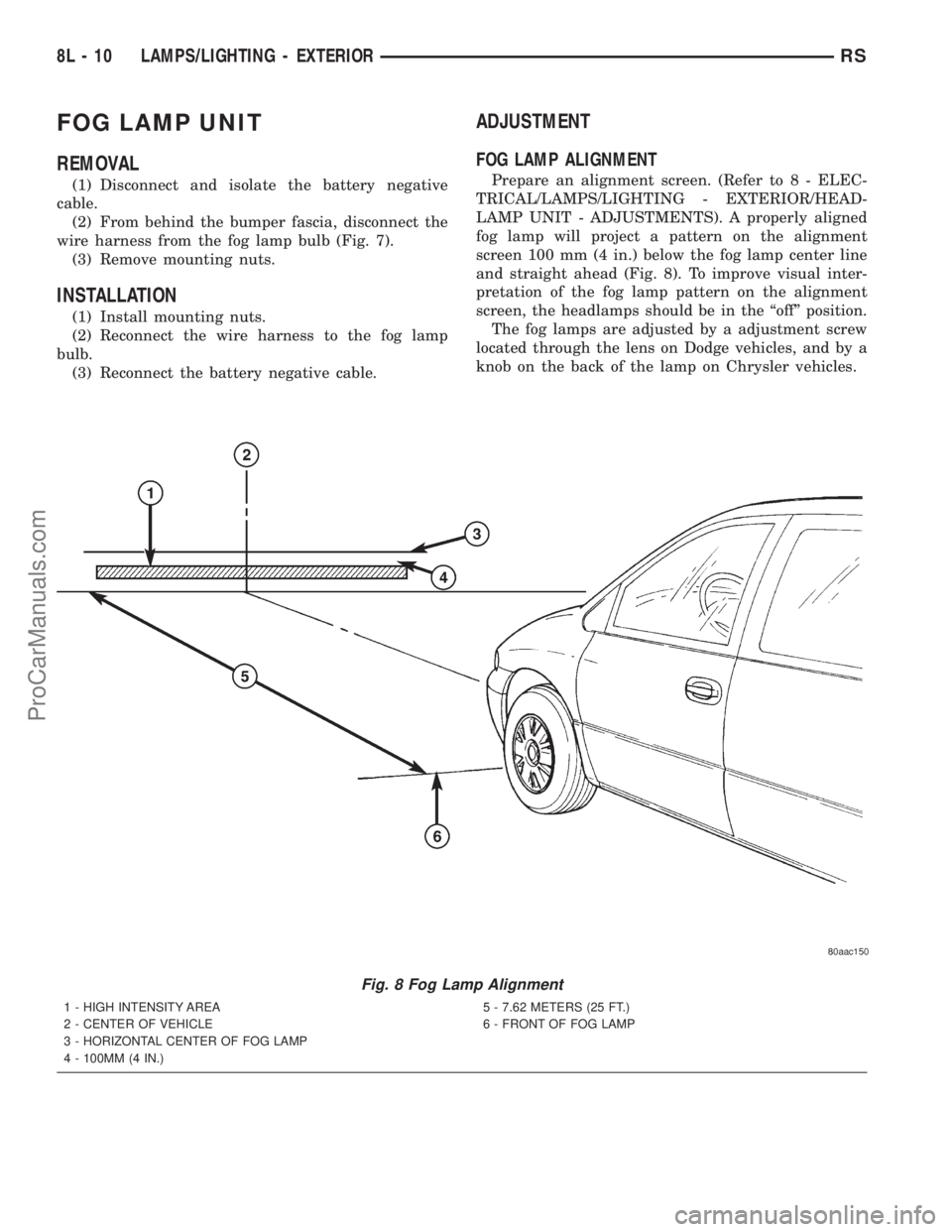

FOG LAMP ALIGNMENT

Prepare an alignment screen. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - ADJUSTMENTS). A properly aligned

fog lamp will project a pattern on the alignment

screen 100 mm (4 in.) below the fog lamp center line

and straight ahead (Fig. 8). To improve visual inter-

pretation of the fog lamp pattern on the alignment

screen, the headlamps should be in the ªoffº position.

The fog lamps are adjusted by a adjustment screw

located through the lens on Dodge vehicles, and by a

knob on the back of the lamp on Chrysler vehicles.

Fig. 8 Fog Lamp Alignment

1 - HIGH INTENSITY AREA

2 - CENTER OF VEHICLE

3 - HORIZONTAL CENTER OF FOG LAMP

4 - 100MM (4 IN.)5 - 7.62 METERS (25 FT.)

6 - FRONT OF FOG LAMP

8L - 10 LAMPS/LIGHTING - EXTERIORRS

ProCarManuals.com

Page 484 of 2321

HEADLAMP

REMOVAL

(1)Disconnect and isolate the battery negative cable.

(2) Remove headlamp unit retaining screws.

(3) Remove headlamp unit to expose back of unit.

(4) Remove wiring connector from bulb.

(5) Rotate headlamp bulb retaining ring counter-

clockwise.

(6) Pull headlamp bulb and remove from headlamp

unit (Fig. 9).

INSTALLATION

(1) Install headlamp bulb to the headlamp unit.

(2) Install headlamp bulb retaining ring.

(3) Connect wiring connector to bulb.

(4) Install the headlamp unit.

(5) Install headlamp unit retaining screws.

(6) Reconnect the battery negative cable.

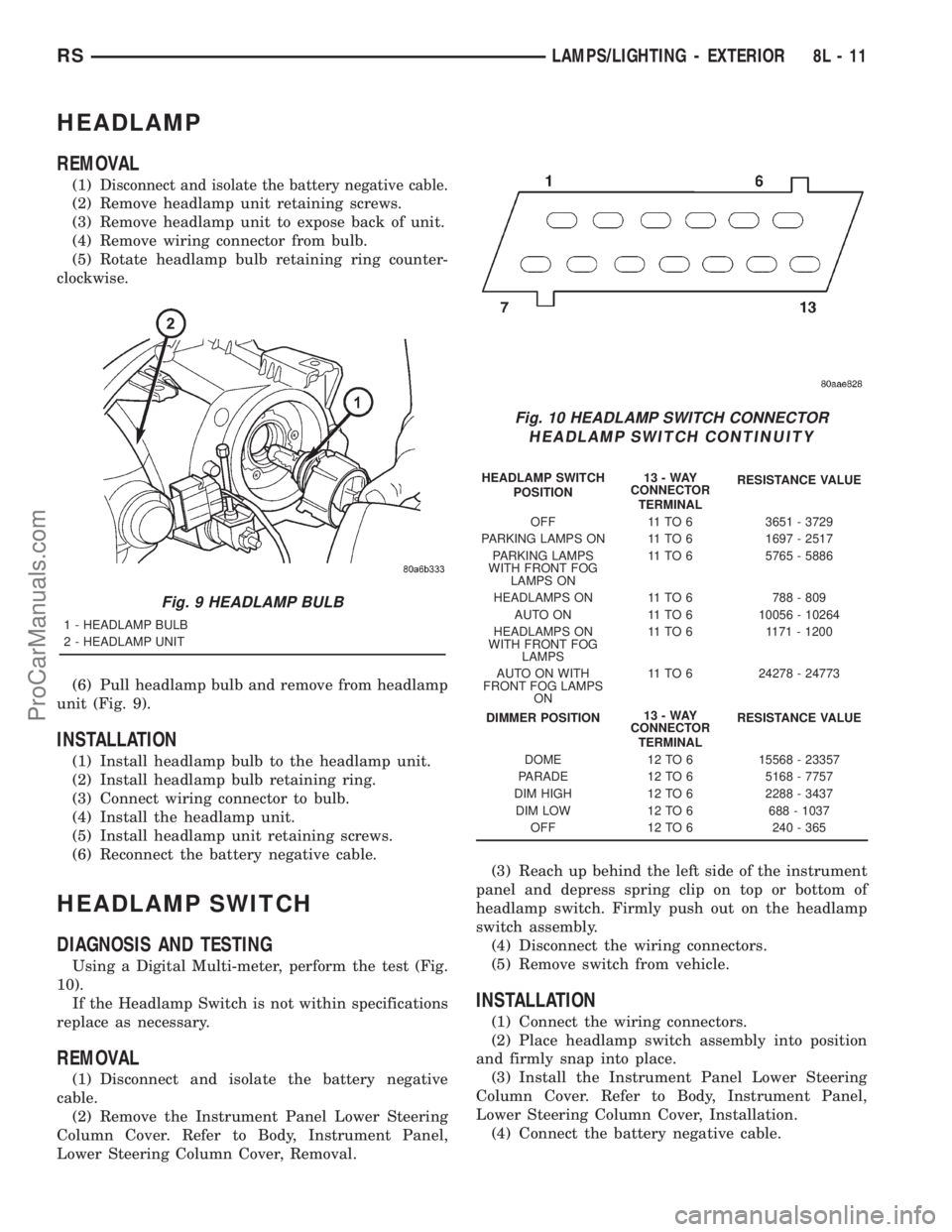

HEADLAMP SWITCH

DIAGNOSIS AND TESTING

Using a Digital Multi-meter, perform the test (Fig.

10).

If the Headlamp Switch is not within specifications

replace as necessary.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the Instrument Panel Lower Steering

Column Cover. Refer to Body, Instrument Panel,

Lower Steering Column Cover, Removal.(3) Reach up behind the left side of the instrument

panel and depress spring clip on top or bottom of

headlamp switch. Firmly push out on the headlamp

switch assembly.

(4) Disconnect the wiring connectors.

(5) Remove switch from vehicle.

INSTALLATION

(1) Connect the wiring connectors.

(2) Place headlamp switch assembly into position

and firmly snap into place.

(3) Install the Instrument Panel Lower Steering

Column Cover. Refer to Body, Instrument Panel,

Lower Steering Column Cover, Installation.

(4) Connect the battery negative cable.

Fig. 9 HEADLAMP BULB

1 - HEADLAMP BULB

2 - HEADLAMP UNIT

Fig. 10 HEADLAMP SWITCH CONNECTOR

HEADLAMP SWITCH CONTINUITY

HEADLAMP SWITCH

POSITION13-WAY

CONNECTOR

TERMINALRESISTANCE VALUE

OFF 11 TO 6 3651 - 3729

PARKING LAMPS ON 11 TO 6 1697 - 2517

PARKING LAMPS

WITH FRONT FOG

LAMPS ON11 TO 6 5765 - 5886

HEADLAMPS ON 11 TO 6 788 - 809

AUTO ON 11 TO 6 10056 - 10264

HEADLAMPS ON

WITH FRONT FOG

LAMPS11 TO 6 1171 - 1200

AUTO ON WITH

FRONT FOG LAMPS

ON11 TO 6 24278 - 24773

DIMMER POSITION13-WAY

CONNECTOR

TERMINALRESISTANCE VALUE

DOME 12 TO 6 15568 - 23357

PARADE 12 TO 6 5168 - 7757

DIM HIGH 12 TO 6 2288 - 3437

DIM LOW 12 TO 6 688 - 1037

OFF 12 TO 6 240 - 365

RSLAMPS/LIGHTING - EXTERIOR8L-11

ProCarManuals.com

Page 485 of 2321

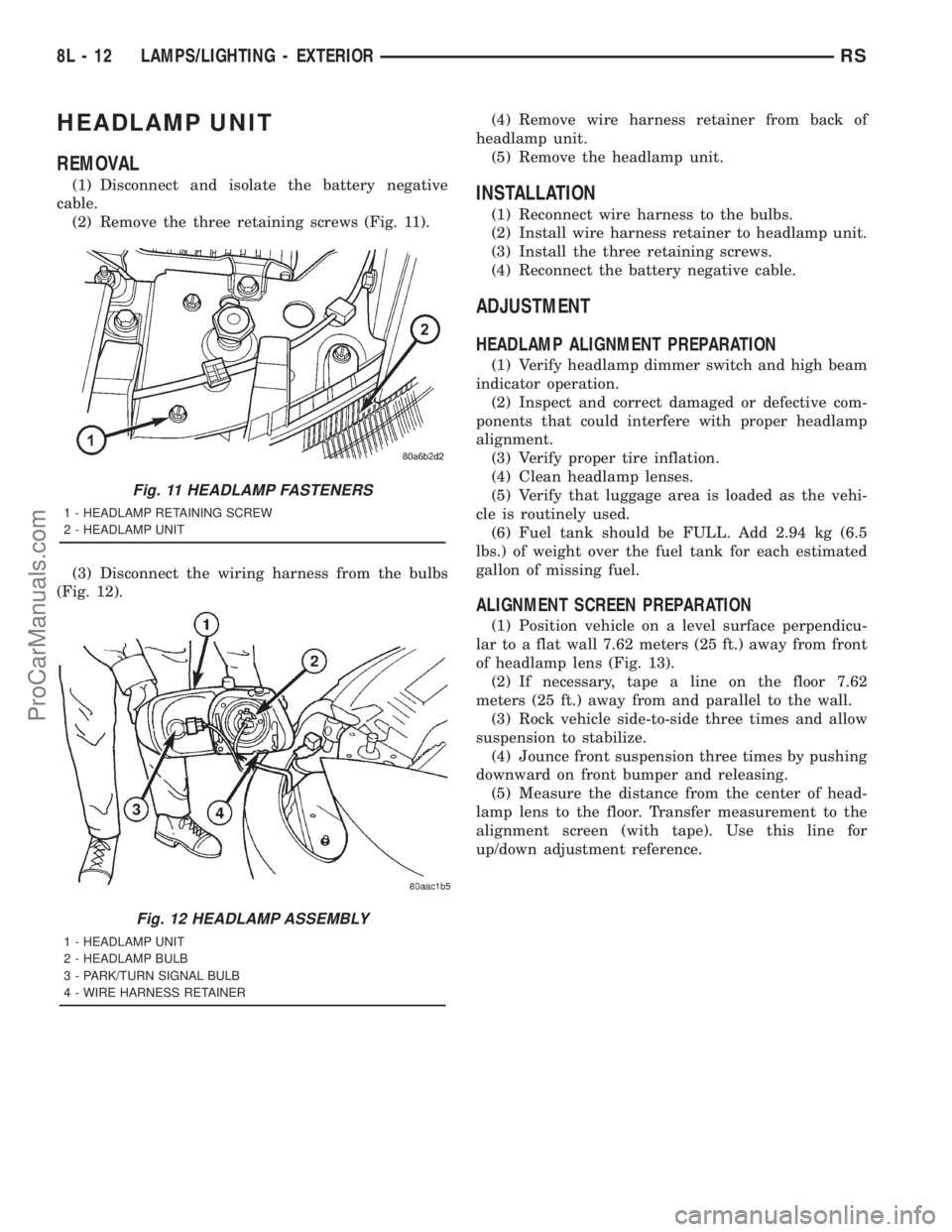

HEADLAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the three retaining screws (Fig. 11).

(3) Disconnect the wiring harness from the bulbs

(Fig. 12).(4) Remove wire harness retainer from back of

headlamp unit.

(5) Remove the headlamp unit.INSTALLATION

(1) Reconnect wire harness to the bulbs.

(2) Install wire harness retainer to headlamp unit.

(3) Install the three retaining screws.

(4) Reconnect the battery negative cable.

ADJUSTMENT

HEADLAMP ALIGNMENT PREPARATION

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Inspect and correct damaged or defective com-

ponents that could interfere with proper headlamp

alignment.

(3) Verify proper tire inflation.

(4) Clean headlamp lenses.

(5) Verify that luggage area is loaded as the vehi-

cle is routinely used.

(6) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

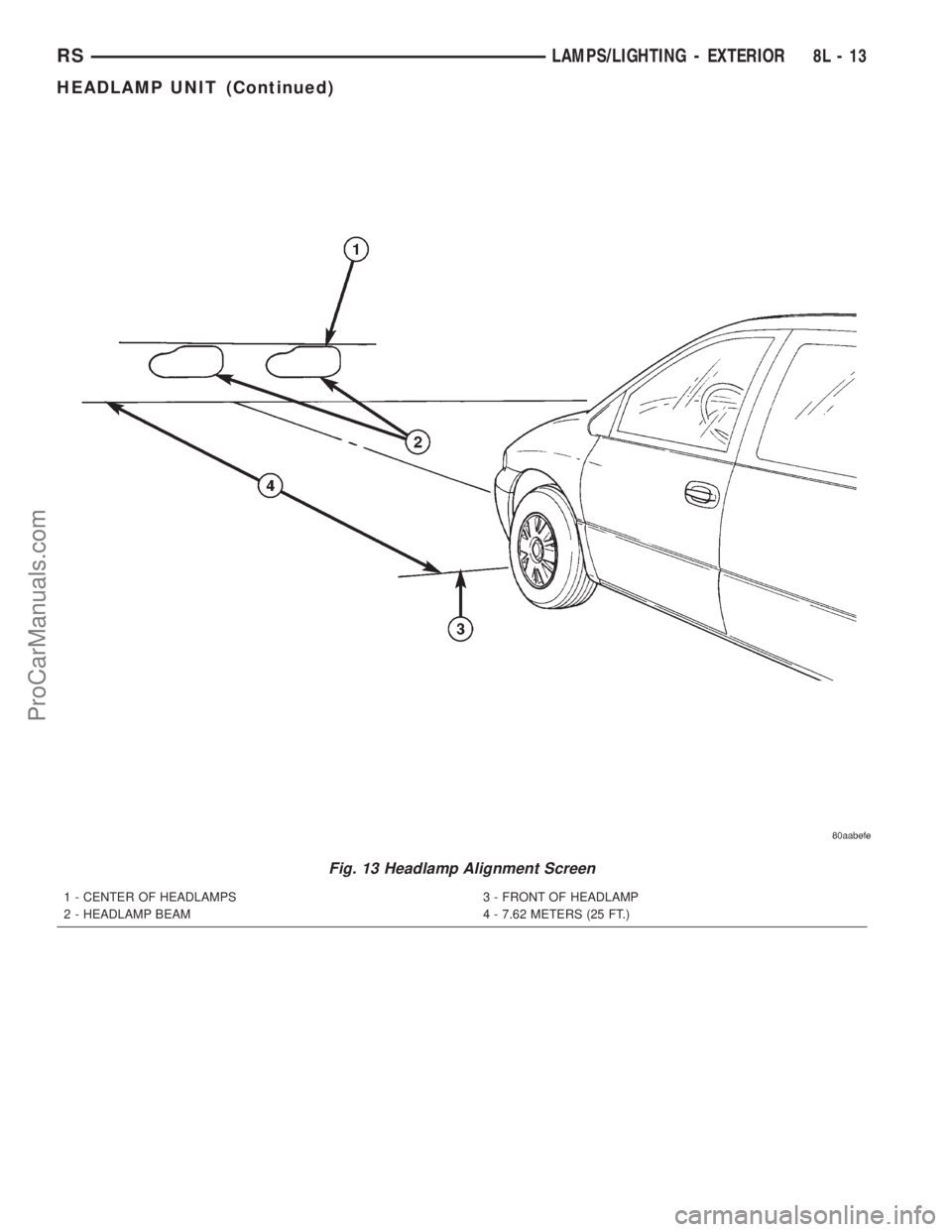

ALIGNMENT SCREEN PREPARATION

(1) Position vehicle on a level surface perpendicu-

lar to a flat wall 7.62 meters (25 ft.) away from front

of headlamp lens (Fig. 13).

(2) If necessary, tape a line on the floor 7.62

meters (25 ft.) away from and parallel to the wall.

(3) Rock vehicle side-to-side three times and allow

suspension to stabilize.

(4) Jounce front suspension three times by pushing

downward on front bumper and releasing.

(5) Measure the distance from the center of head-

lamp lens to the floor. Transfer measurement to the

alignment screen (with tape). Use this line for

up/down adjustment reference.

Fig. 11 HEADLAMP FASTENERS

1 - HEADLAMP RETAINING SCREW

2 - HEADLAMP UNIT

Fig. 12 HEADLAMP ASSEMBLY

1 - HEADLAMP UNIT

2 - HEADLAMP BULB

3 - PARK/TURN SIGNAL BULB

4 - WIRE HARNESS RETAINER

8L - 12 LAMPS/LIGHTING - EXTERIORRS

ProCarManuals.com

Page 486 of 2321

Fig. 13 Headlamp Alignment Screen

1 - CENTER OF HEADLAMPS

2 - HEADLAMP BEAM3 - FRONT OF HEADLAMP

4 - 7.62 METERS (25 FT.)

RSLAMPS/LIGHTING - EXTERIOR8L-13

HEADLAMP UNIT (Continued)

ProCarManuals.com

Page 487 of 2321

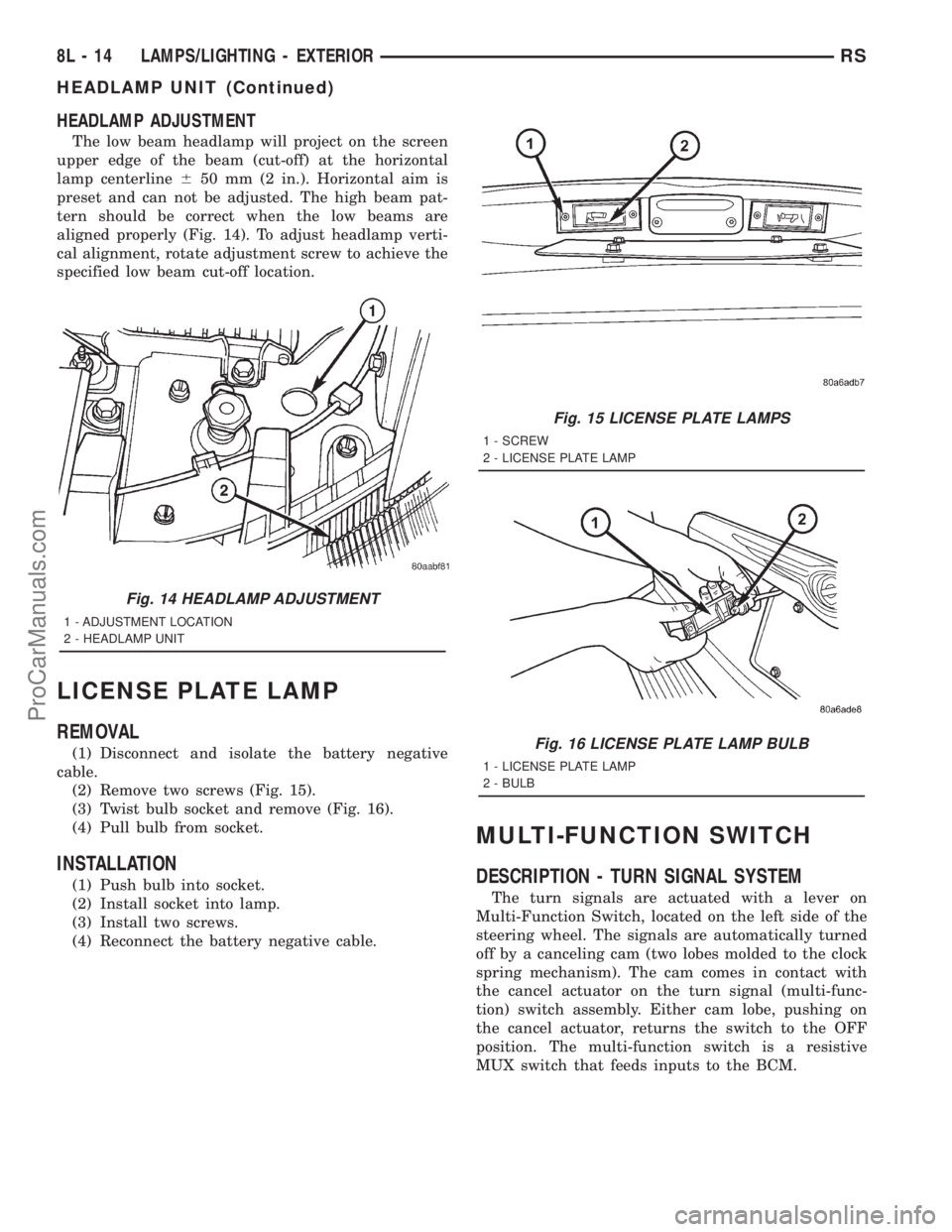

HEADLAMP ADJUSTMENT

The low beam headlamp will project on the screen

upper edge of the beam (cut-off) at the horizontal

lamp centerline650 mm (2 in.). Horizontal aim is

preset and can not be adjusted. The high beam pat-

tern should be correct when the low beams are

aligned properly (Fig. 14). To adjust headlamp verti-

cal alignment, rotate adjustment screw to achieve the

specified low beam cut-off location.

LICENSE PLATE LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove two screws (Fig. 15).

(3) Twist bulb socket and remove (Fig. 16).

(4) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Install socket into lamp.

(3) Install two screws.

(4) Reconnect the battery negative cable.

MULTI-FUNCTION SWITCH

DESCRIPTION - TURN SIGNAL SYSTEM

The turn signals are actuated with a lever on

Multi-Function Switch, located on the left side of the

steering wheel. The signals are automatically turned

off by a canceling cam (two lobes molded to the clock

spring mechanism). The cam comes in contact with

the cancel actuator on the turn signal (multi-func-

tion) switch assembly. Either cam lobe, pushing on

the cancel actuator, returns the switch to the OFF

position. The multi-function switch is a resistive

MUX switch that feeds inputs to the BCM.

Fig. 14 HEADLAMP ADJUSTMENT

1 - ADJUSTMENT LOCATION

2 - HEADLAMP UNIT

Fig. 15 LICENSE PLATE LAMPS

1 - SCREW

2 - LICENSE PLATE LAMP

Fig. 16 LICENSE PLATE LAMP BULB

1 - LICENSE PLATE LAMP

2 - BULB

8L - 14 LAMPS/LIGHTING - EXTERIORRS

HEADLAMP UNIT (Continued)

ProCarManuals.com

Page 488 of 2321

OPERATION - TURN SIGNAL SYSTEM

Lane change signaling is actuated by applying par-

tial turn signal stalk movement toward the direction

desired until the indicator lamps flashes in the

instrument cluster. When the switch stalk is released

the stalk will spring back into the neutral position

turning OFF the turn signal.

With the ignition switch ON and the turn signal

switch stalk actuated left or right, current flows

through the:

²Multi-function switch

²Body Control Module

²Integrated Power Module (IPM)

²Turn indicator lamp

²Front and rear turn signal bulbs.

A chime will sound after the vehicle has traveled a

distance of approximately 0.5 mile and a speed of 15

mph, with the turn signal ON.

DIAGNOSIS AND TESTING - MULTI-FUNCTION

SWITCH

To test turn signal, headlamp beam select and opti-

cal horn portion of the multi-function switch:

(1) Remove the multi-function switch, refer to

Electrical, Lamps/Lighting - Exterior, Multi-Function

Switch, Removal, and Installation.

(2) Using an ohmmeter check the continuity read-

ings between multi-function switch pins. Refer to

Wiring Diagrams for proper pin numbers and the

table.

MULTI-FUNCTION SWITCH CONTINUITY

SWITCH POSITION CONTINUITY BETWEEN

LEFT 2 AND 3

RIGHT 2 AND 3

OPTICAL HORN 2 AND 4

HI BEAM 2 AND 4

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Remove upper and lower steering column

shrouds. Refer to Steering, Column, Shroud,

Removal.

(3) Disconnect wire connector from back of multi-

function switch.

(4) Remove screws holding multi-function switch to

steering column adapter collar.

(5) Remove the multi-function switch.

INSTALLATION

(1) Position the switch on to the steering column.

(2) Install the two retaining screws.

(3) Connect the wire harness connector.

(4) Install the upper and lower steering column

shrouds. Refer to Steering, Column, Shroud, Installa-

tion.

(5) Connect the battery negative cable.

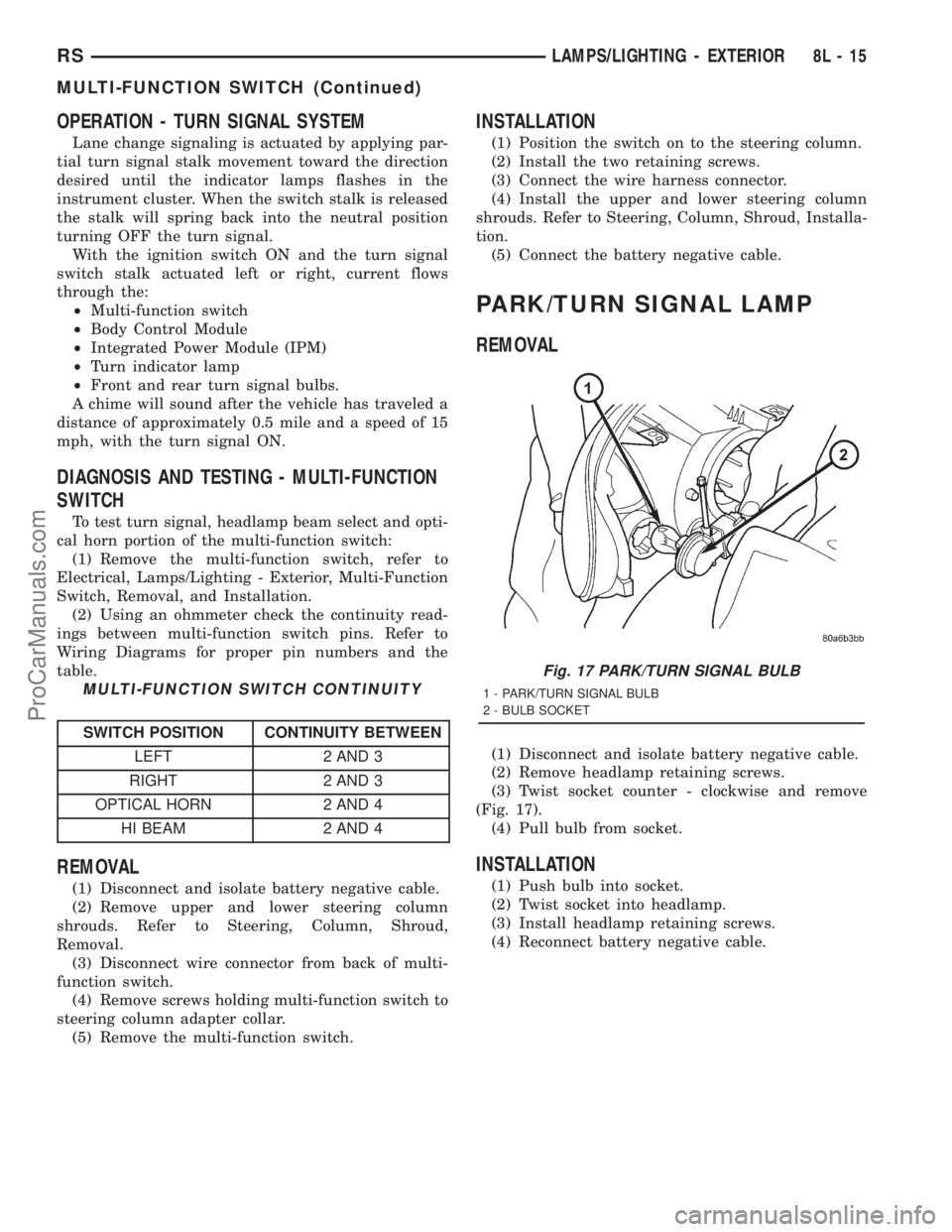

PARK/TURN SIGNAL LAMP

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Remove headlamp retaining screws.

(3) Twist socket counter - clockwise and remove

(Fig. 17).

(4) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Twist socket into headlamp.

(3) Install headlamp retaining screws.

(4) Reconnect battery negative cable.

Fig. 17 PARK/TURN SIGNAL BULB

1 - PARK/TURN SIGNAL BULB

2 - BULB SOCKET

RSLAMPS/LIGHTING - EXTERIOR8L-15

MULTI-FUNCTION SWITCH (Continued)

ProCarManuals.com

Page 489 of 2321

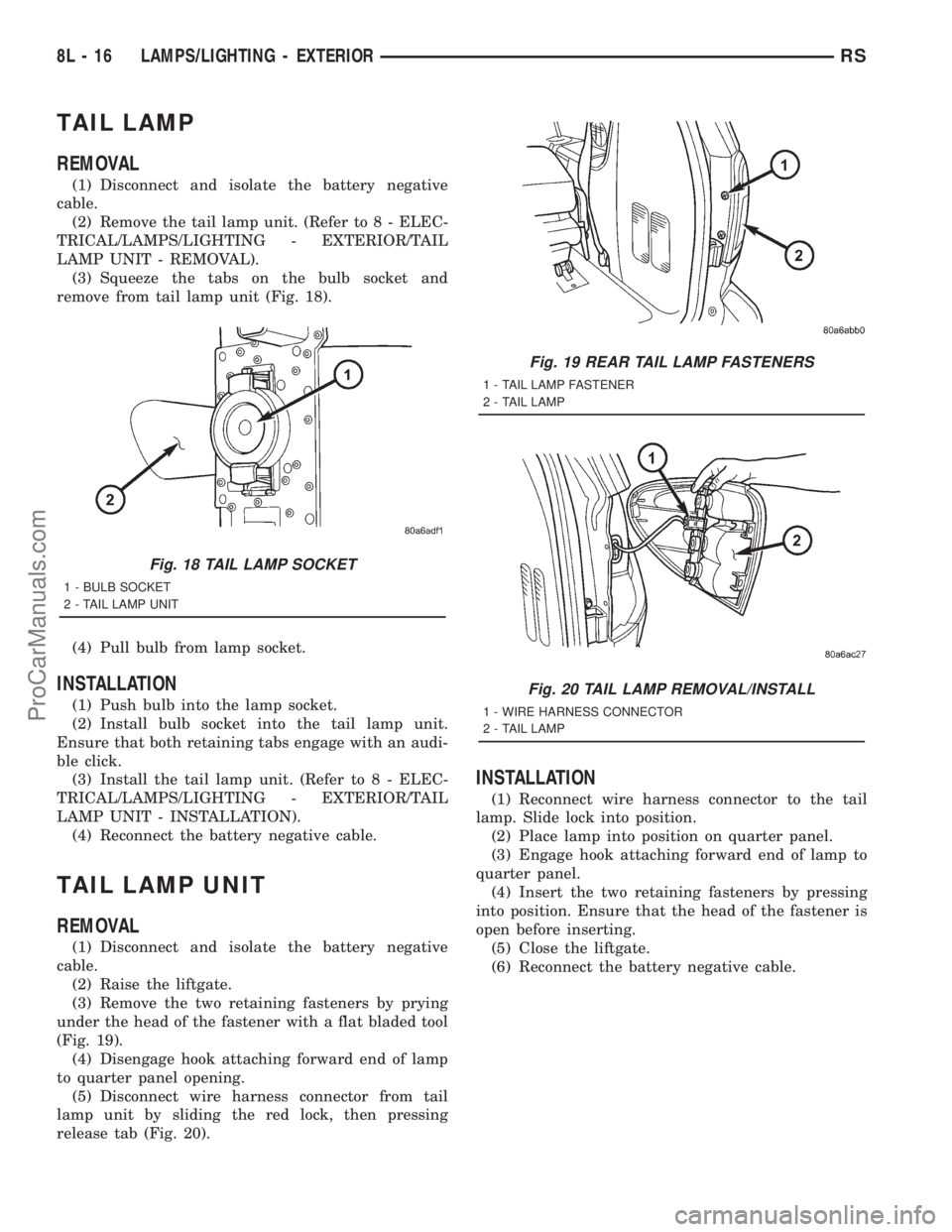

TAIL LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the tail lamp unit. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP UNIT - REMOVAL).

(3) Squeeze the tabs on the bulb socket and

remove from tail lamp unit (Fig. 18).

(4) Pull bulb from lamp socket.

INSTALLATION

(1) Push bulb into the lamp socket.

(2) Install bulb socket into the tail lamp unit.

Ensure that both retaining tabs engage with an audi-

ble click.

(3) Install the tail lamp unit. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP UNIT - INSTALLATION).

(4) Reconnect the battery negative cable.

TAIL LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Raise the liftgate.

(3) Remove the two retaining fasteners by prying

under the head of the fastener with a flat bladed tool

(Fig. 19).

(4) Disengage hook attaching forward end of lamp

to quarter panel opening.

(5) Disconnect wire harness connector from tail

lamp unit by sliding the red lock, then pressing

release tab (Fig. 20).

INSTALLATION

(1) Reconnect wire harness connector to the tail

lamp. Slide lock into position.

(2) Place lamp into position on quarter panel.

(3) Engage hook attaching forward end of lamp to

quarter panel.

(4) Insert the two retaining fasteners by pressing

into position. Ensure that the head of the fastener is

open before inserting.

(5) Close the liftgate.

(6) Reconnect the battery negative cable.

Fig. 18 TAIL LAMP SOCKET

1 - BULB SOCKET

2 - TAIL LAMP UNIT

Fig. 19 REAR TAIL LAMP FASTENERS

1 - TAIL LAMP FASTENER

2 - TAIL LAMP

Fig. 20 TAIL LAMP REMOVAL/INSTALL

1 - WIRE HARNESS CONNECTOR

2 - TAIL LAMP

8L - 16 LAMPS/LIGHTING - EXTERIORRS

ProCarManuals.com

Page 490 of 2321

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS........................17

CENTER CONSOLE LAMP SWITCH

REMOVAL..............................18

INSTALLATION...........................18

CLUSTER ILLUMINATION LAMPS

REMOVAL..............................18

INSTALLATION...........................18

COURTESY LAMP

REMOVAL..............................18

INSTALLATION...........................18

DOME LAMP

REMOVAL..............................18INSTALLATION...........................18

GLOVE BOX LAMP SWITCH

REMOVAL..............................18

INSTALLATION...........................19

LIFTGATE LAMP

REMOVAL..............................19

INSTALLATION...........................19

READING LAMP

REMOVAL..............................19

INSTALLATION...........................20

VANITY LAMP

REMOVAL..............................20

INSTALLATION...........................20

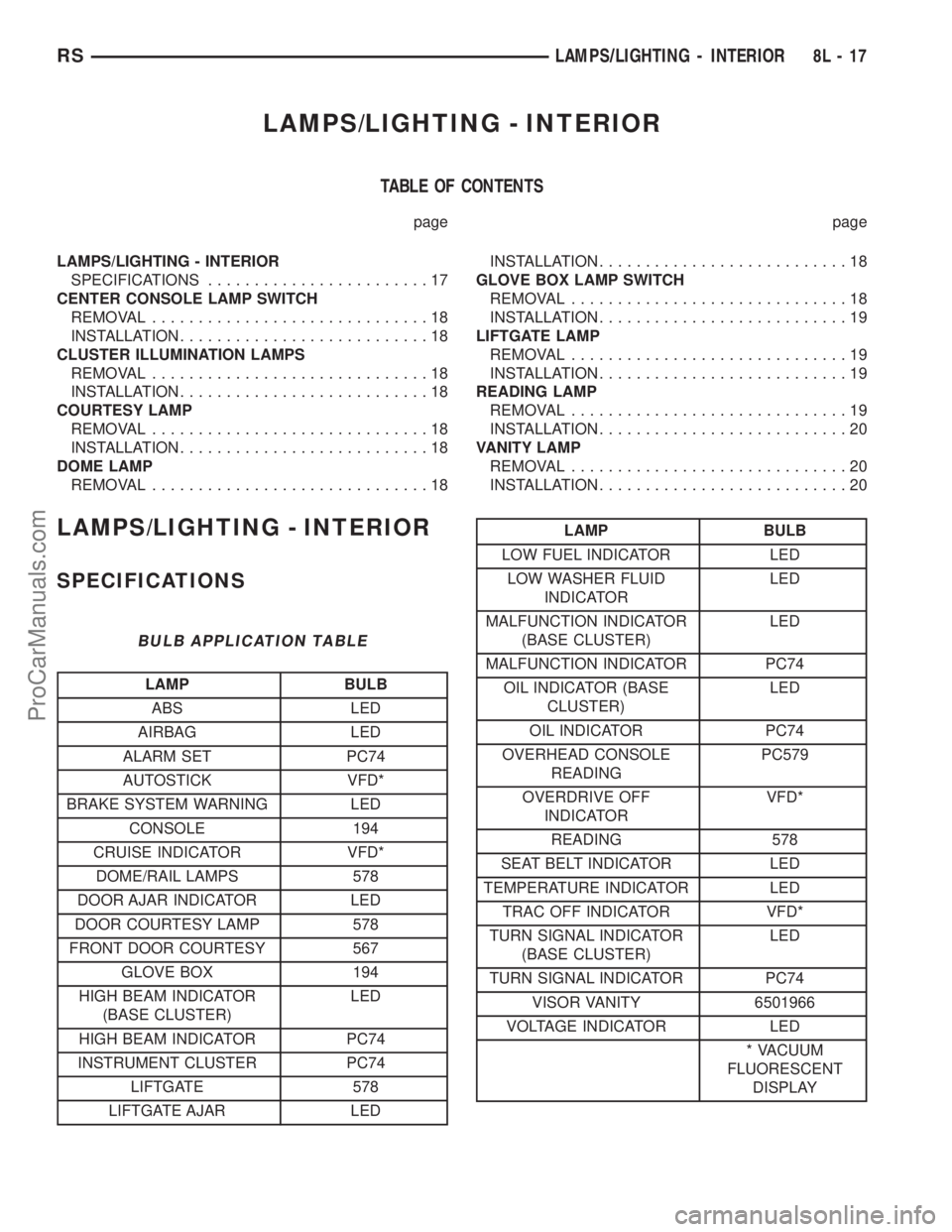

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

BULB APPLICATION TABLE

LAMP BULB

ABS LED

AIRBAG LED

ALARM SET PC74

AUTOSTICK VFD*

BRAKE SYSTEM WARNING LED

CONSOLE 194

CRUISE INDICATOR VFD*

DOME/RAIL LAMPS 578

DOOR AJAR INDICATOR LED

DOOR COURTESY LAMP 578

FRONT DOOR COURTESY 567

GLOVE BOX 194

HIGH BEAM INDICATOR

(BASE CLUSTER)LED

HIGH BEAM INDICATOR PC74

INSTRUMENT CLUSTER PC74

LIFTGATE 578

LIFTGATE AJAR LED

LAMP BULB

LOW FUEL INDICATOR LED

LOW WASHER FLUID

INDICATORLED

MALFUNCTION INDICATOR

(BASE CLUSTER)LED

MALFUNCTION INDICATOR PC74

OIL INDICATOR (BASE

CLUSTER)LED

OIL INDICATOR PC74

OVERHEAD CONSOLE

READINGPC579

OVERDRIVE OFF

INDICATORVFD*

READING 578

SEAT BELT INDICATOR LED

TEMPERATURE INDICATOR LED

TRAC OFF INDICATOR VFD*

TURN SIGNAL INDICATOR

(BASE CLUSTER)LED

TURN SIGNAL INDICATOR PC74

VISOR VANITY 6501966

VOLTAGE INDICATOR LED

* VACUUM

FLUORESCENT

DISPLAY

RSLAMPS/LIGHTING - INTERIOR8L-17

ProCarManuals.com