Freeze plugs DODGE TOWN AND COUNTRY 2001 Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 271 of 2321

- 124 kPa (14 - 18 psi). This air is replaced with cool-

ant from the coolant bottle.

NOTE: Deaeration does not occur at engine idleÐ

higher engine speeds are required. Normal driving

will deaerate cooling system.

To effectively deaerate the system, multiple ther-

mal cycles of the system may be required.

STANDARD PROCEDURE - COOLING SYSTEM

DRAINING

WARNING: DO NOT REMOVE OR LOOSEN THE

COOLANT PRESSURE CAP, CYLINDER BLOCK

DRAIN PLUGS, OR THE DRAINCOCK WHEN THE

SYSTEM IS HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

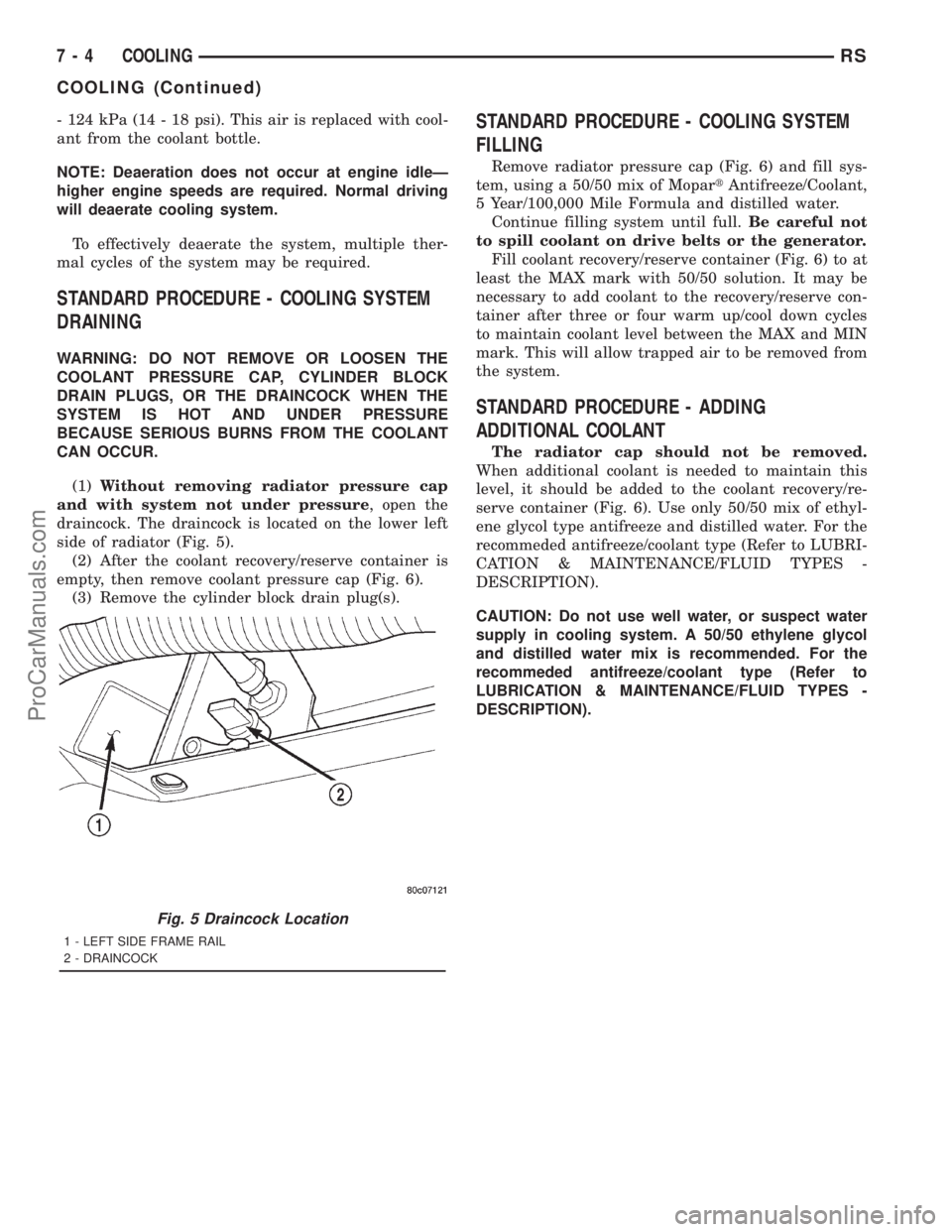

(1)Without removing radiator pressure cap

and with system not under pressure, open the

draincock. The draincock is located on the lower left

side of radiator (Fig. 5).

(2) After the coolant recovery/reserve container is

empty, then remove coolant pressure cap (Fig. 6).

(3) Remove the cylinder block drain plug(s).

STANDARD PROCEDURE - COOLING SYSTEM

FILLING

Remove radiator pressure cap (Fig. 6) and fill sys-

tem, using a 50/50 mix of MopartAntifreeze/Coolant,

5 Year/100,000 Mile Formula and distilled water.

Continue filling system until full.Be careful not

to spill coolant on drive belts or the generator.

Fill coolant recovery/reserve container (Fig. 6) to at

least the MAX mark with 50/50 solution. It may be

necessary to add coolant to the recovery/reserve con-

tainer after three or four warm up/cool down cycles

to maintain coolant level between the MAX and MIN

mark. This will allow trapped air to be removed from

the system.

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT

The radiator cap should not be removed.

When additional coolant is needed to maintain this

level, it should be added to the coolant recovery/re-

serve container (Fig. 6). Use only 50/50 mix of ethyl-

ene glycol type antifreeze and distilled water. For the

recommeded antifreeze/coolant type (Refer to LUBRI-

CATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

CAUTION: Do not use well water, or suspect water

supply in cooling system. A 50/50 ethylene glycol

and distilled water mix is recommended. For the

recommeded antifreeze/coolant type (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

Fig. 5 Draincock Location

1 - LEFT SIDE FRAME RAIL

2 - DRAINCOCK

7 - 4 COOLINGRS

COOLING (Continued)

ProCarManuals.com

Page 323 of 2321

STANDARD PROCEDURE - COOLANT LEVEL

CHECK

NOTE: Do not remove pressure/vent cap for routine

coolant level inspections.

The coolant reserve system provides a quick visual

method for determining the coolant level without

removing the pressure/vent cap.With the engine

cold and not running,simply observe the level of

the coolant in the coolant recovery pressure container

(Fig. 2). The coolant level should be between the MIN

and MAX marks.

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM

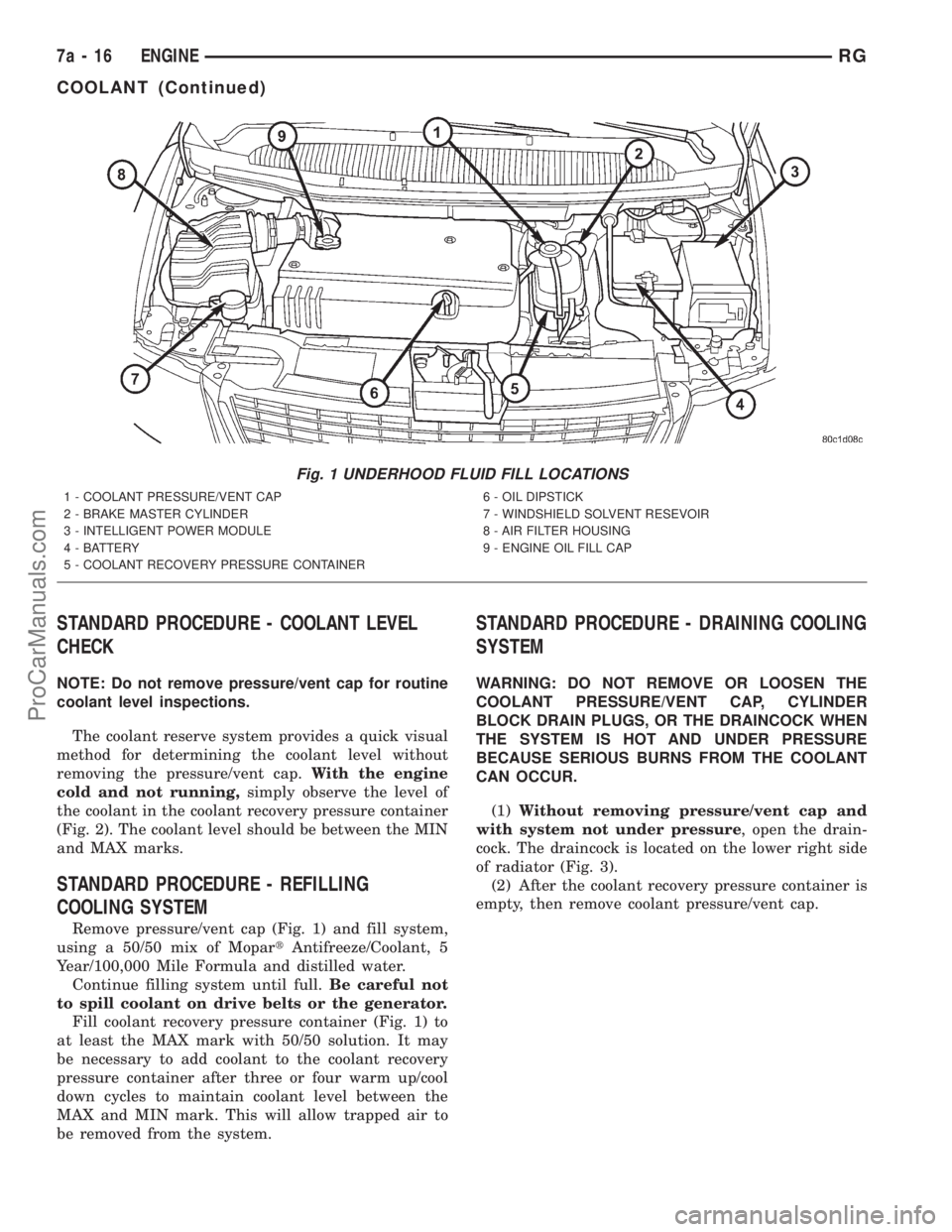

Remove pressure/vent cap (Fig. 1) and fill system,

using a 50/50 mix of MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula and distilled water.

Continue filling system until full.Be careful not

to spill coolant on drive belts or the generator.

Fill coolant recovery pressure container (Fig. 1) to

at least the MAX mark with 50/50 solution. It may

be necessary to add coolant to the coolant recovery

pressure container after three or four warm up/cool

down cycles to maintain coolant level between the

MAX and MIN mark. This will allow trapped air to

be removed from the system.

STANDARD PROCEDURE - DRAINING COOLING

SYSTEM

WARNING: DO NOT REMOVE OR LOOSEN THE

COOLANT PRESSURE/VENT CAP, CYLINDER

BLOCK DRAIN PLUGS, OR THE DRAINCOCK WHEN

THE SYSTEM IS HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

(1)Without removing pressure/vent cap and

with system not under pressure, open the drain-

cock. The draincock is located on the lower right side

of radiator (Fig. 3).

(2) After the coolant recovery pressure container is

empty, then remove coolant pressure/vent cap.

Fig. 1 UNDERHOOD FLUID FILL LOCATIONS

1 - COOLANT PRESSURE/VENT CAP

2 - BRAKE MASTER CYLINDER

3 - INTELLIGENT POWER MODULE

4 - BATTERY

5 - COOLANT RECOVERY PRESSURE CONTAINER6 - OIL DIPSTICK

7 - WINDSHIELD SOLVENT RESEVOIR

8 - AIR FILTER HOUSING

9 - ENGINE OIL FILL CAP

7a - 16 ENGINERG

COOLANT (Continued)

ProCarManuals.com

Page 2262 of 2321

through the rear evaporator when the rear air condi-

tioner is turned Off.

DIAGNOSIS AND TESTING - EXPANSION VALVE

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

NOTE: The expansion valve should only be tested

following testing of the compressor.

NOTE: Liquid CO

2is required to test the expansion

valve. This material is available from most welding

supply facilities. Liquid CO

2is also available from

companies which service and sell fire extinguish-

ers.

When testing the expansion valve, the work area

and the vehicle temperature must be 21É to 27É C

(70É to 85É F). To test the expansion valve:

(1) Connect a charging station or manifold gauge

set to the refrigerant system service ports. Verify the

refrigerant charge level.

(2) Close all doors, windows and vents to the pas-

senger compartment.

(3) Set the heater-air conditioner controls so that

the compressor is operating, the temperature control

is in the highest temperature position, the mode door

is directing the output to the floor outlets, and the

blower is operating at the highest speed setting.

(4) Start the engine and allow it to idle at 1000

rpm. After the engine has reached normal operating

temperature, allow the passenger compartment to

heat up. This will create the need for maximum

refrigerant flow into the evaporator.

(5) If the refrigerant charge is sufficient, the dis-

charge (high pressure) gauge should read 965 to 1655

kPa (140 to 240 psi). The suction (low pressure)

gauge should read 140 kPa to 207 kPa (20 psi to 30

psi). If OK, go to Step 6. If not OK, replace the faulty

expansion valve.

WARNING:

PROTECT THE SKIN AND EYES FROM EXPOSURE

TO LIQUID CO

2. PERSONAL INJURY CAN RESULT.

(6) If the suction (low pressure) gauge reads

within the specified range, freeze the expansion valve

control head for 30 seconds using liquid CO

2or

another suitable super-cold material.Do not spray

R-134a or R-12 refrigerant on the expansionvalve control head for this test.The suction (low

pressure) gauge reading should drop by 10 psi. If OK,

go to Step 7 If not OK, replace the faulty expansion

valve.

(7) Allow the expansion valve control head to thaw.

The suction (low pressure) gauge reading should sta-

bilize at 140 kPa to 240 kPa (20 psi to 30 psi). If not

OK, replace the faulty expansion valve.

(8) When expansion valve testing is complete, test

the overall air conditioner performance. (Refer to 24 -

HEATING & AIR CONDITIONING - DIAGNOSIS

AND TESTING - A/C PERFORMANCE TEST).

Remove all test equipment before returning the vehi-

cle to service.

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING),

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING),

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - HEATER PLUMB-

ING).

(1) Remove the rear heater-A/C unit housing from

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/REAR HEATER-

A/C HOUSING - REMOVAL).

(2) Carefully remove the foam insulator wrap from

the rear expansion valve.

(3) Remove the rear evaporator line extension from

the expansion valve. (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - REAR/EVAPORA-

TOR - REMOVAL - EVAPORATOR LINE EXTEN-

SION).

(4) If the vehicle is equipped with the optional

Automatic Temperature Control (ATC) system, dis-

connect the expansion valve solenoid pigtail wire con-

nector from the rear HVAC wire harness connector

(Fig. 4).

(5) Remove the two screws that secure the expan-

sion valve to the evaporator tube sealing plate.

(6) Remove the expansion valve from the evapora-

tor tubes.

(7) Remove the seals from the evaporator tube fit-

tings and discard.

(8) Install plugs in, or tape over the opened evap-

orator tube fittings and both expansion valve ports.

INSTALLATION

(1) Remove the tape or plugs from the evaporator

tube fittings and both expansion valve ports.

RSPLUMBING - REAR24-99

EXPANSION VALVE (Continued)

ProCarManuals.com