boot DODGE TOWN AND COUNTRY 2001 Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 496 of 2321

FRONT POSITION LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

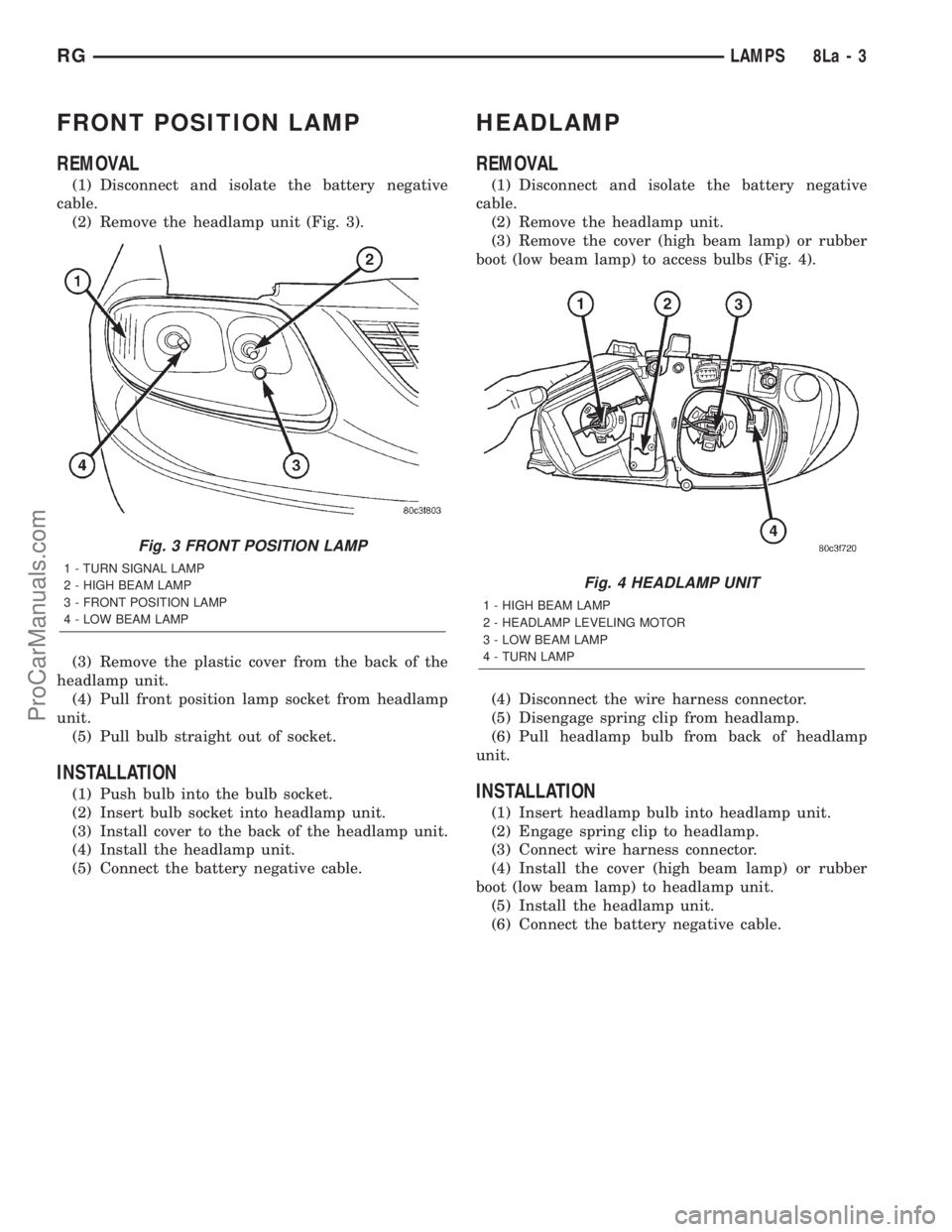

(2) Remove the headlamp unit (Fig. 3).

(3) Remove the plastic cover from the back of the

headlamp unit.

(4) Pull front position lamp socket from headlamp

unit.

(5) Pull bulb straight out of socket.

INSTALLATION

(1) Push bulb into the bulb socket.

(2) Insert bulb socket into headlamp unit.

(3) Install cover to the back of the headlamp unit.

(4) Install the headlamp unit.

(5) Connect the battery negative cable.

HEADLAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the headlamp unit.

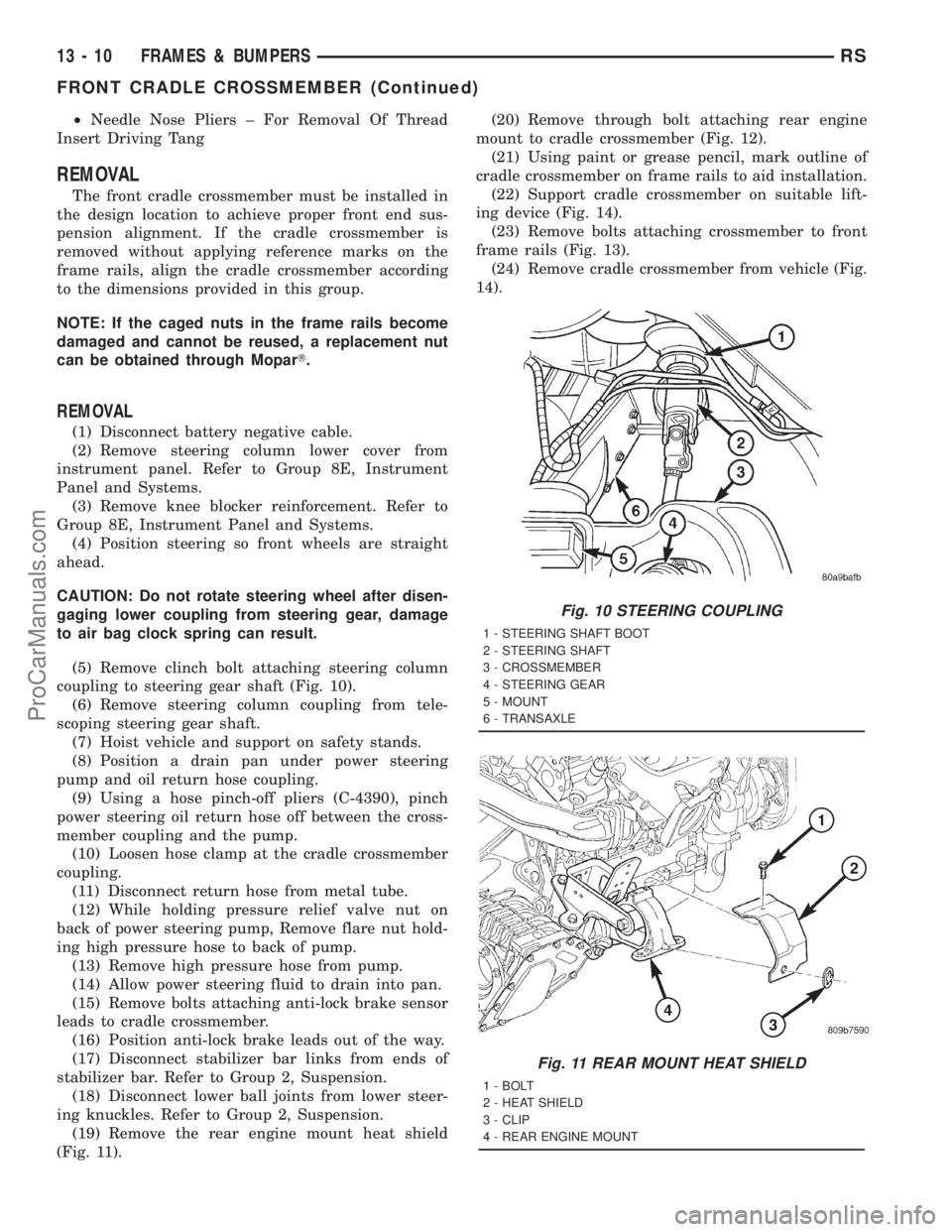

(3) Remove the cover (high beam lamp) or rubber

boot (low beam lamp) to access bulbs (Fig. 4).

(4) Disconnect the wire harness connector.

(5) Disengage spring clip from headlamp.

(6) Pull headlamp bulb from back of headlamp

unit.

INSTALLATION

(1) Insert headlamp bulb into headlamp unit.

(2) Engage spring clip to headlamp.

(3) Connect wire harness connector.

(4) Install the cover (high beam lamp) or rubber

boot (low beam lamp) to headlamp unit.

(5) Install the headlamp unit.

(6) Connect the battery negative cable.

Fig. 3 FRONT POSITION LAMP

1 - TURN SIGNAL LAMP

2 - HIGH BEAM LAMP

3 - FRONT POSITION LAMP

4 - LOW BEAM LAMP

Fig. 4 HEADLAMP UNIT

1 - HIGH BEAM LAMP

2 - HEADLAMP LEVELING MOTOR

3 - LOW BEAM LAMP

4 - TURN LAMP

RGLAMPS8La-3

ProCarManuals.com

Page 1403 of 2321

²Needle Nose Pliers ± For Removal Of Thread

Insert Driving Tang

REMOVAL

The front cradle crossmember must be installed in

the design location to achieve proper front end sus-

pension alignment. If the cradle crossmember is

removed without applying reference marks on the

frame rails, align the cradle crossmember according

to the dimensions provided in this group.

NOTE: If the caged nuts in the frame rails become

damaged and cannot be reused, a replacement nut

can be obtained through MoparT.

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove steering column lower cover from

instrument panel. Refer to Group 8E, Instrument

Panel and Systems.

(3) Remove knee blocker reinforcement. Refer to

Group 8E, Instrument Panel and Systems.

(4) Position steering so front wheels are straight

ahead.

CAUTION: Do not rotate steering wheel after disen-

gaging lower coupling from steering gear, damage

to air bag clock spring can result.

(5) Remove clinch bolt attaching steering column

coupling to steering gear shaft (Fig. 10).

(6) Remove steering column coupling from tele-

scoping steering gear shaft.

(7) Hoist vehicle and support on safety stands.

(8) Position a drain pan under power steering

pump and oil return hose coupling.

(9) Using a hose pinch-off pliers (C-4390), pinch

power steering oil return hose off between the cross-

member coupling and the pump.

(10) Loosen hose clamp at the cradle crossmember

coupling.

(11) Disconnect return hose from metal tube.

(12) While holding pressure relief valve nut on

back of power steering pump, Remove flare nut hold-

ing high pressure hose to back of pump.

(13) Remove high pressure hose from pump.

(14) Allow power steering fluid to drain into pan.

(15) Remove bolts attaching anti-lock brake sensor

leads to cradle crossmember.

(16) Position anti-lock brake leads out of the way.

(17) Disconnect stabilizer bar links from ends of

stabilizer bar. Refer to Group 2, Suspension.

(18) Disconnect lower ball joints from lower steer-

ing knuckles. Refer to Group 2, Suspension.

(19) Remove the rear engine mount heat shield

(Fig. 11).(20) Remove through bolt attaching rear engine

mount to cradle crossmember (Fig. 12).

(21) Using paint or grease pencil, mark outline of

cradle crossmember on frame rails to aid installation.

(22) Support cradle crossmember on suitable lift-

ing device (Fig. 14).

(23) Remove bolts attaching crossmember to front

frame rails (Fig. 13).

(24) Remove cradle crossmember from vehicle (Fig.

14).

Fig. 10 STEERING COUPLING

1 - STEERING SHAFT BOOT

2 - STEERING SHAFT

3 - CROSSMEMBER

4 - STEERING GEAR

5 - MOUNT

6 - TRANSAXLE

Fig. 11 REAR MOUNT HEAT SHIELD

1 - BOLT

2 - HEAT SHIELD

3 - CLIP

4 - REAR ENGINE MOUNT

13 - 10 FRAMES & BUMPERSRS

FRONT CRADLE CROSSMEMBER (Continued)

ProCarManuals.com

Page 1474 of 2321

GEAR

TABLE OF CONTENTS

page page

GEAR

DESCRIPTION...........................17

OPERATION.............................17

CAUTION...............................18

REMOVAL..............................18INSTALLATION...........................20

SPECIAL TOOLS.........................21

OUTER TIE ROD END

REMOVAL..............................22

INSTALLATION...........................22

GEAR

DESCRIPTION

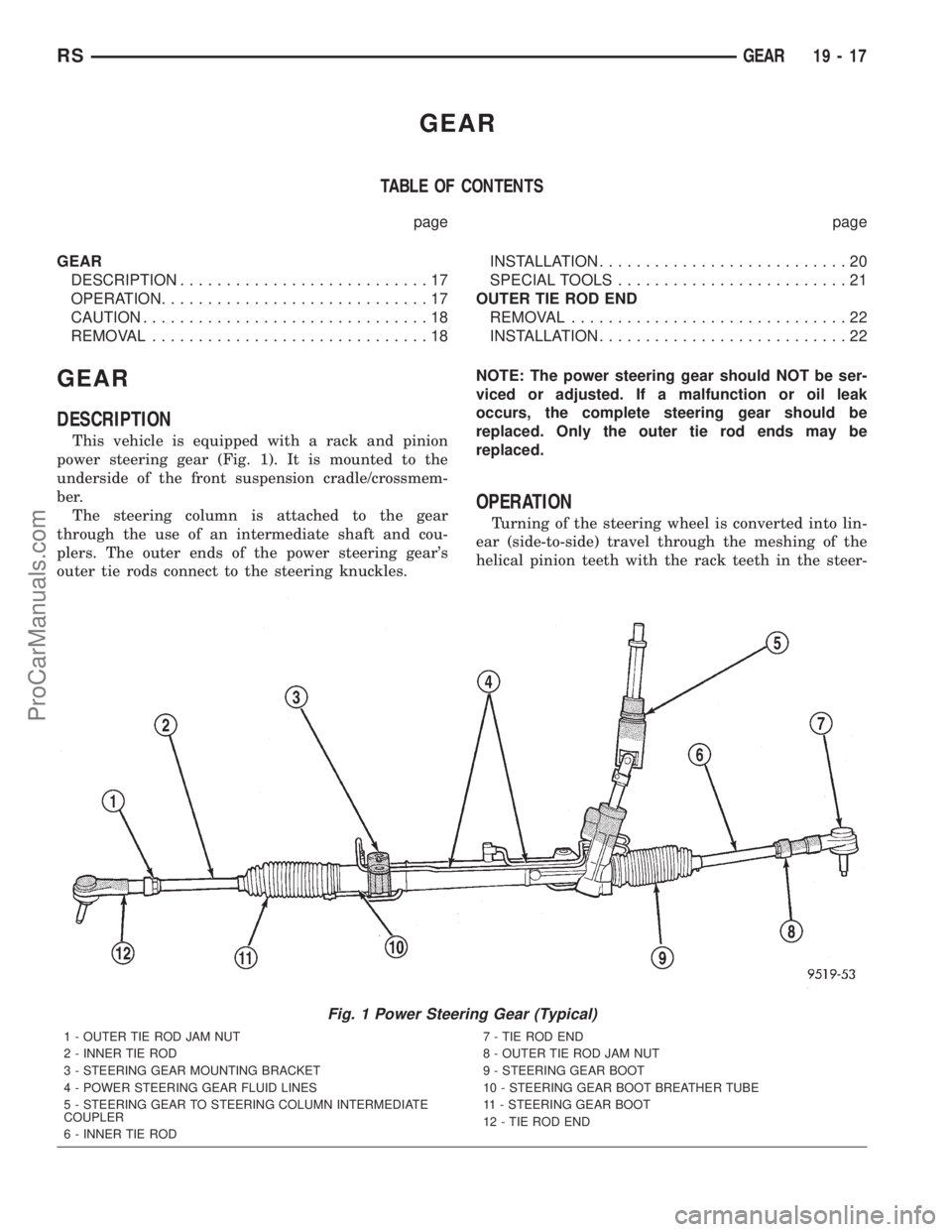

This vehicle is equipped with a rack and pinion

power steering gear (Fig. 1). It is mounted to the

underside of the front suspension cradle/crossmem-

ber.

The steering column is attached to the gear

through the use of an intermediate shaft and cou-

plers. The outer ends of the power steering gear's

outer tie rods connect to the steering knuckles.NOTE: The power steering gear should NOT be ser-

viced or adjusted. If a malfunction or oil leak

occurs, the complete steering gear should be

replaced. Only the outer tie rod ends may be

replaced.

OPERATION

Turning of the steering wheel is converted into lin-

ear (side-to-side) travel through the meshing of the

helical pinion teeth with the rack teeth in the steer-

Fig. 1 Power Steering Gear (Typical)

1 - OUTER TIE ROD JAM NUT

2 - INNER TIE ROD

3 - STEERING GEAR MOUNTING BRACKET

4 - POWER STEERING GEAR FLUID LINES

5 - STEERING GEAR TO STEERING COLUMN INTERMEDIATE

COUPLER

6 - INNER TIE ROD7 - TIE ROD END

8 - OUTER TIE ROD JAM NUT

9 - STEERING GEAR BOOT

10 - STEERING GEAR BOOT BREATHER TUBE

11 - STEERING GEAR BOOT

12 - TIE ROD END

RSGEAR19-17

ProCarManuals.com

Page 1480 of 2321

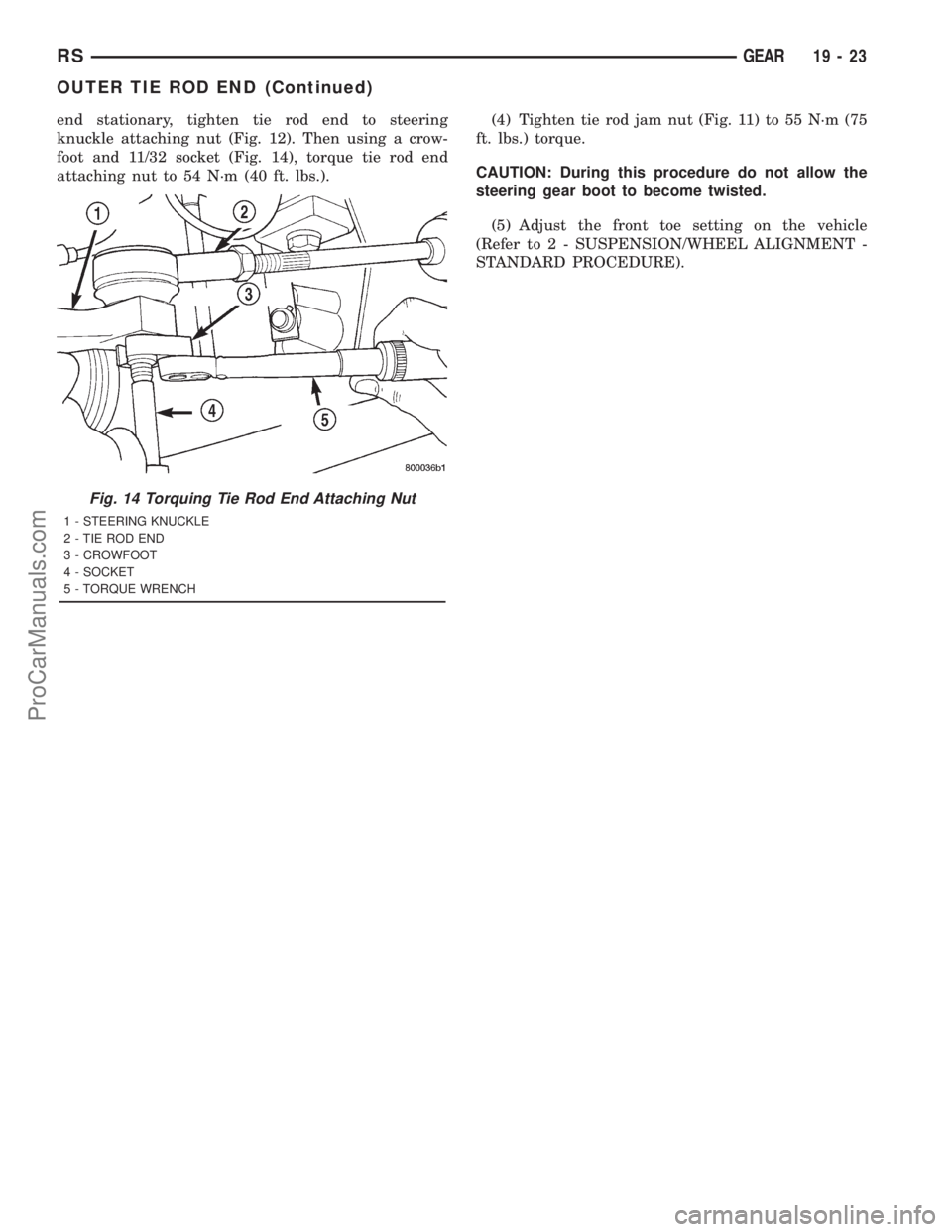

end stationary, tighten tie rod end to steering

knuckle attaching nut (Fig. 12). Then using a crow-

foot and 11/32 socket (Fig. 14), torque tie rod end

attaching nut to 54 N´m (40 ft. lbs.).(4) Tighten tie rod jam nut (Fig. 11) to 55 N´m (75

ft. lbs.) torque.

CAUTION: During this procedure do not allow the

steering gear boot to become twisted.

(5) Adjust the front toe setting on the vehicle

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT -

STANDARD PROCEDURE).

Fig. 14 Torquing Tie Rod End Attaching Nut

1 - STEERING KNUCKLE

2 - TIE ROD END

3 - CROWFOOT

4 - SOCKET

5 - TORQUE WRENCH

RSGEAR19-23

OUTER TIE ROD END (Continued)

ProCarManuals.com

Page 1800 of 2321

T850 MANUAL TRANSAXLE

TABLE OF CONTENTS

page

T850 MANUAL TRANSAXLE.................1

T850 MANUAL TRANSAXLE

TABLE OF CONTENTS

page page

T850 MANUAL TRANSAXLE

DESCRIPTION............................2

OPERATION.............................4

DIAGNOSIS AND TESTING.................11

DIAGNOSIS AND TESTING - COMMON

PROBLEM CAUSES.....................11

REMOVAL..............................11

DISASSEMBLY...........................17

ASSEMBLY.............................22

INSTALLATION...........................31

SPECIFICATIONS........................37

SPECIAL TOOLS.........................39

AXLE SEALS

REMOVAL..............................42

INSTALLATION...........................42

BACK-UP LAMP SWITCH

REMOVAL..............................43

INSTALLATION...........................43

DIFFERENTIAL

DESCRIPTION...........................43

OPERATION.............................43

DISASSEMBLY...........................44

ASSEMBLY.............................47

ADJUSTMENTS..........................50

FLUID

STANDARD PROCEDURE..................52

STANDARD PROCEDURE - FLUID LEVEL

CHECK...............................52

STANDARD PROCEDURE - FLUID DRAIN

AND FILL.............................53

GEARSHIFT BOOT

REMOVAL..............................53

INSTALLATION...........................53

GEARSHIFT CABLE - CROSSOVER

REMOVAL..............................54INSTALLATION...........................56

ADJUSTMENTS..........................60

GEARSHIFT CABLE - SELECTOR

REMOVAL..............................61

INSTALLATION...........................64

GEARSHIFT KNOB

REMOVAL..............................67

INSTALLATION...........................67

GEARSHIFT MECHANISM

REMOVAL..............................68

INSTALLATION...........................70

INPUT SHAFT

DESCRIPTION...........................73

DISASSEMBLY...........................74

ASSEMBLY.............................77

INTERMEDIATE SHAFT

DESCRIPTION...........................81

DISASSEMBLY...........................81

ASSEMBLY.............................88

SHIFT COVER

DESCRIPTION...........................94

SHIFT FORK AND SHAFT

DESCRIPTION...........................95

SYNCHRONIZER

DESCRIPTION...........................95

DISASSEMBLY...........................95

CLEANING..............................95

INSPECTION............................95

ASSEMBLY.............................95

VEHICLE SPEED SENSOR

REMOVAL..............................96

INSTALLATION...........................96

RGT850 MANUAL TRANSAXLE21a-1

ProCarManuals.com

Page 1852 of 2321

STANDARD PROCEDURE - FLUID DRAIN AND

FILL

NOTE: For proper fluid change intervals, (Refer to

LUBRICATION & MAINTENANCE/MAINTENANCE

SCHEDULES - DESCRIPTION)

The fluid required in this transaxle is Mopart

ATF+4 (Automatic Transmission FluidÐType 9602).

Use of substitute fluids may result in improper

transaxle operation and/or failure.

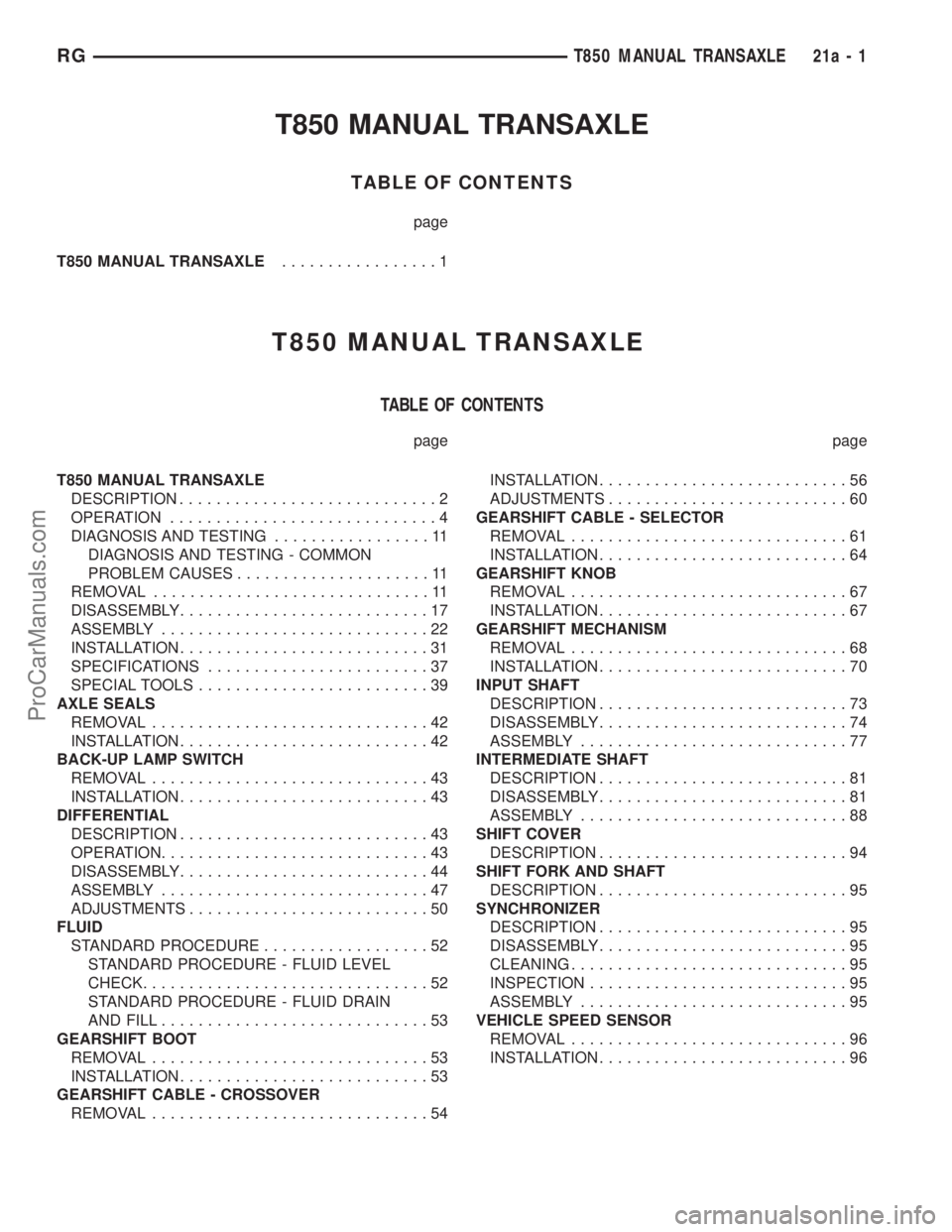

FLUID DRAIN

(1) Raise vehicle on hoist.

(2) Remove transaxle drain plug (Fig. 135) and

drain fluid into suitable container.

(3) Install drain plug and torque to 14 N´m (120

in. lbs.).

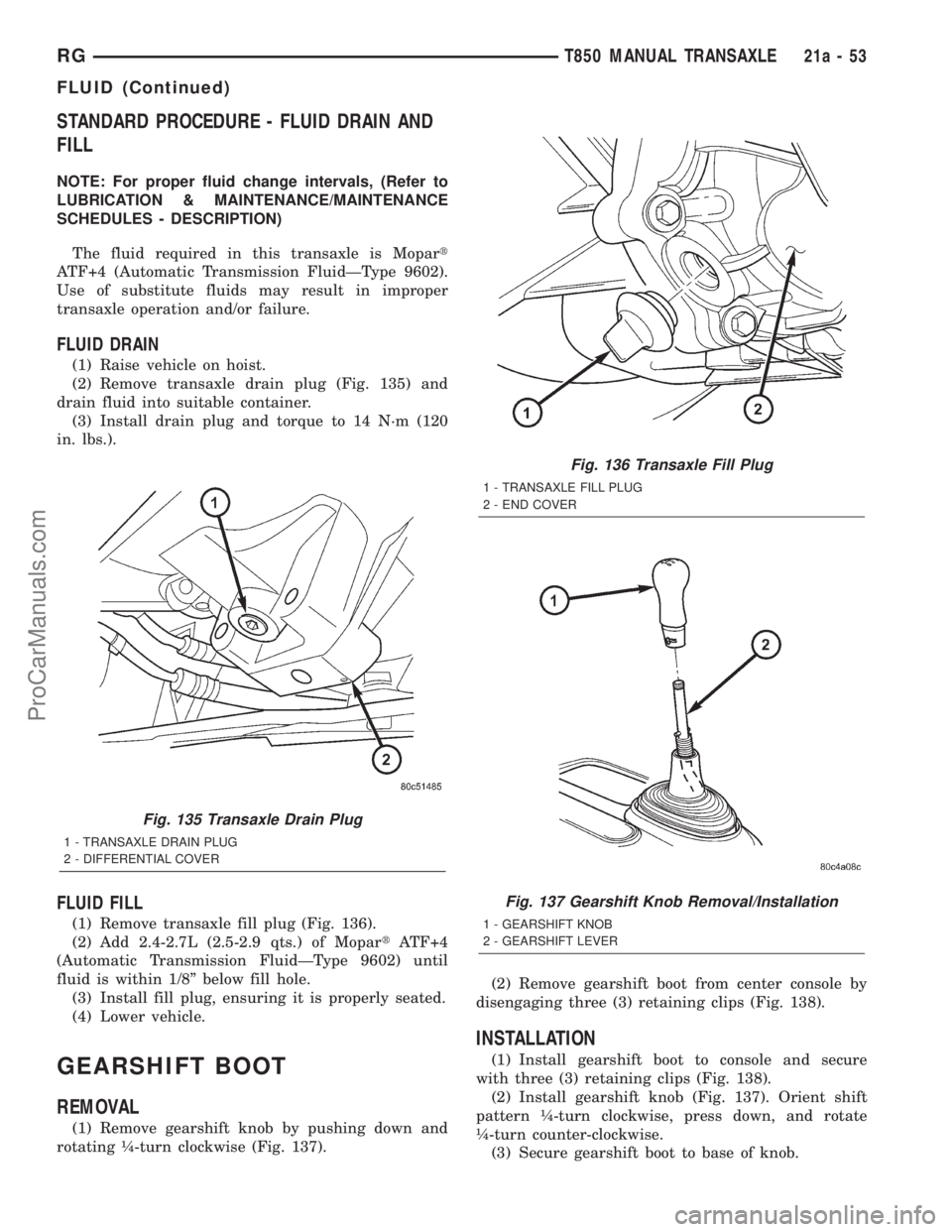

FLUID FILL

(1) Remove transaxle fill plug (Fig. 136).

(2) Add 2.4-2.7L (2.5-2.9 qts.) of MopartATF+4

(Automatic Transmission FluidÐType 9602) until

fluid is within 1/8º below fill hole.

(3) Install fill plug, ensuring it is properly seated.

(4) Lower vehicle.

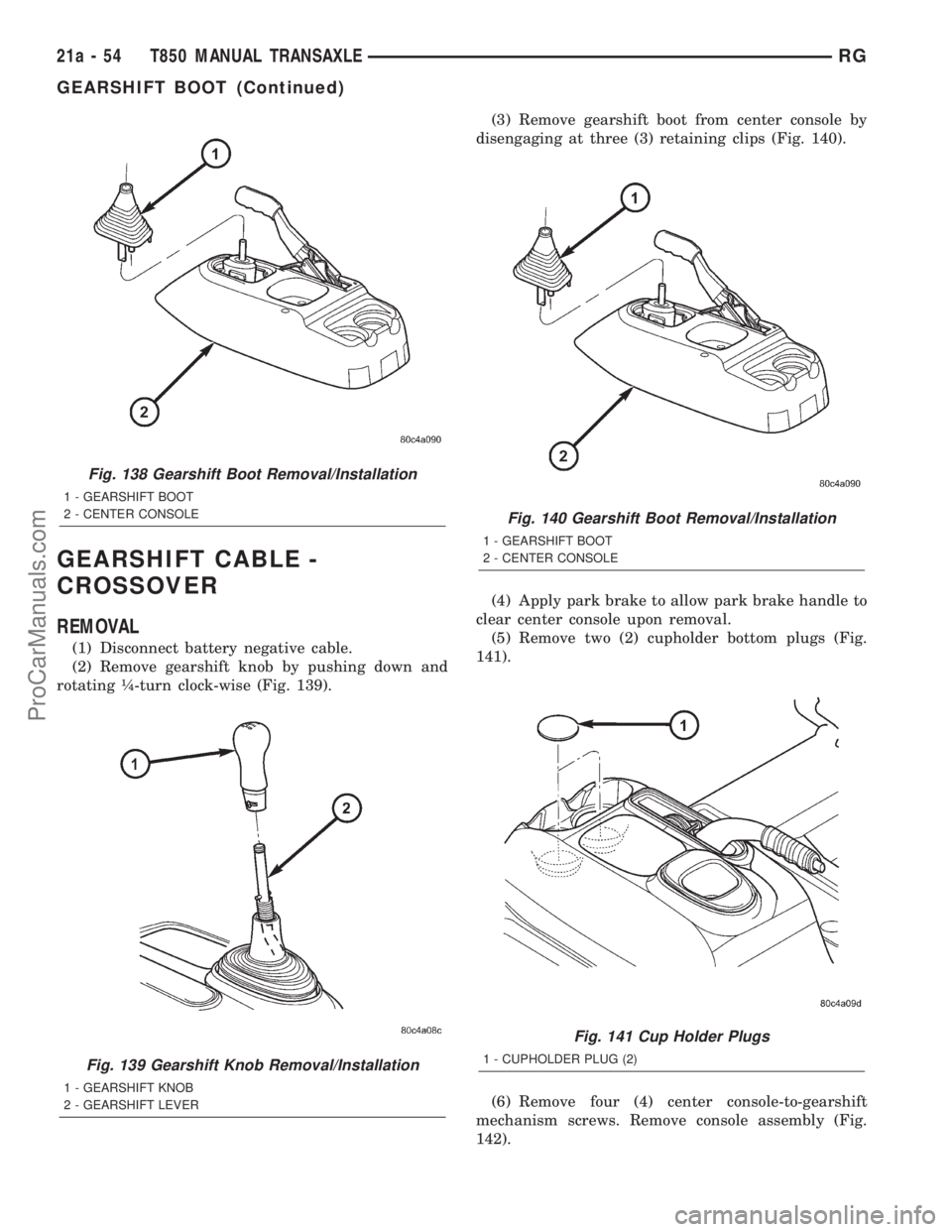

GEARSHIFT BOOT

REMOVAL

(1) Remove gearshift knob by pushing down and

rotating ò-turn clockwise (Fig. 137).(2) Remove gearshift boot from center console by

disengaging three (3) retaining clips (Fig. 138).

INSTALLATION

(1) Install gearshift boot to console and secure

with three (3) retaining clips (Fig. 138).

(2) Install gearshift knob (Fig. 137). Orient shift

pattern ò-turn clockwise, press down, and rotate

ò-turn counter-clockwise.

(3) Secure gearshift boot to base of knob.

Fig. 135 Transaxle Drain Plug

1 - TRANSAXLE DRAIN PLUG

2 - DIFFERENTIAL COVER

Fig. 136 Transaxle Fill Plug

1 - TRANSAXLE FILL PLUG

2 - END COVER

Fig. 137 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

RGT850 MANUAL TRANSAXLE21a-53

FLUID (Continued)

ProCarManuals.com

Page 1853 of 2321

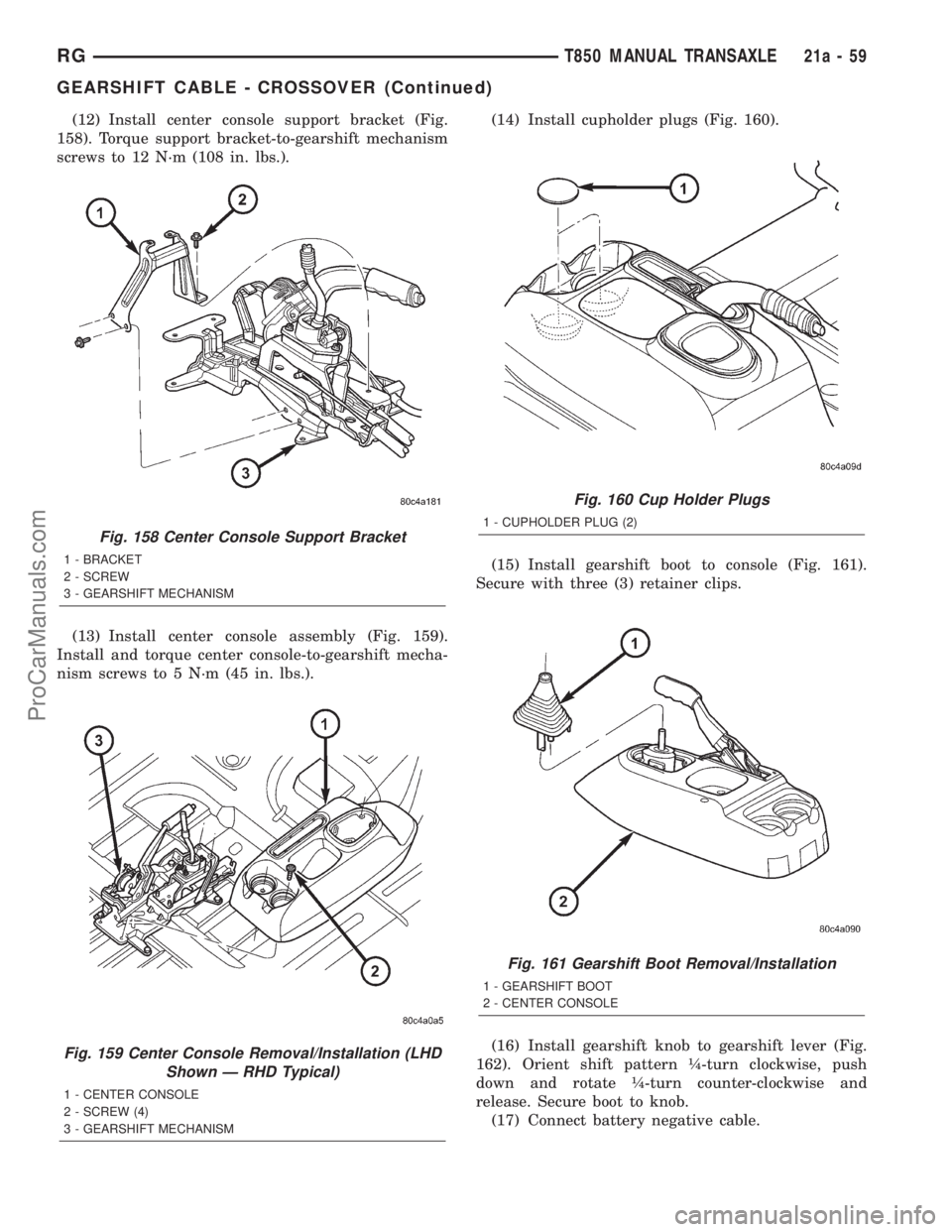

GEARSHIFT CABLE -

CROSSOVER

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating ò-turn clock-wise (Fig. 139).(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 140).

(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

141).

(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

142).

Fig. 138 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 139 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 140 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 141 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

21a - 54 T850 MANUAL TRANSAXLERG

GEARSHIFT BOOT (Continued)

ProCarManuals.com

Page 1858 of 2321

(12) Install center console support bracket (Fig.

158). Torque support bracket-to-gearshift mechanism

screws to 12 N´m (108 in. lbs.).

(13) Install center console assembly (Fig. 159).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).(14) Install cupholder plugs (Fig. 160).

(15) Install gearshift boot to console (Fig. 161).

Secure with three (3) retainer clips.

(16) Install gearshift knob to gearshift lever (Fig.

162). Orient shift pattern ò-turn clockwise, push

down and rotate ò-turn counter-clockwise and

release. Secure boot to knob.

(17) Connect battery negative cable.

Fig. 158 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 159 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 160 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 161 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

RGT850 MANUAL TRANSAXLE21a-59

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com

Page 1859 of 2321

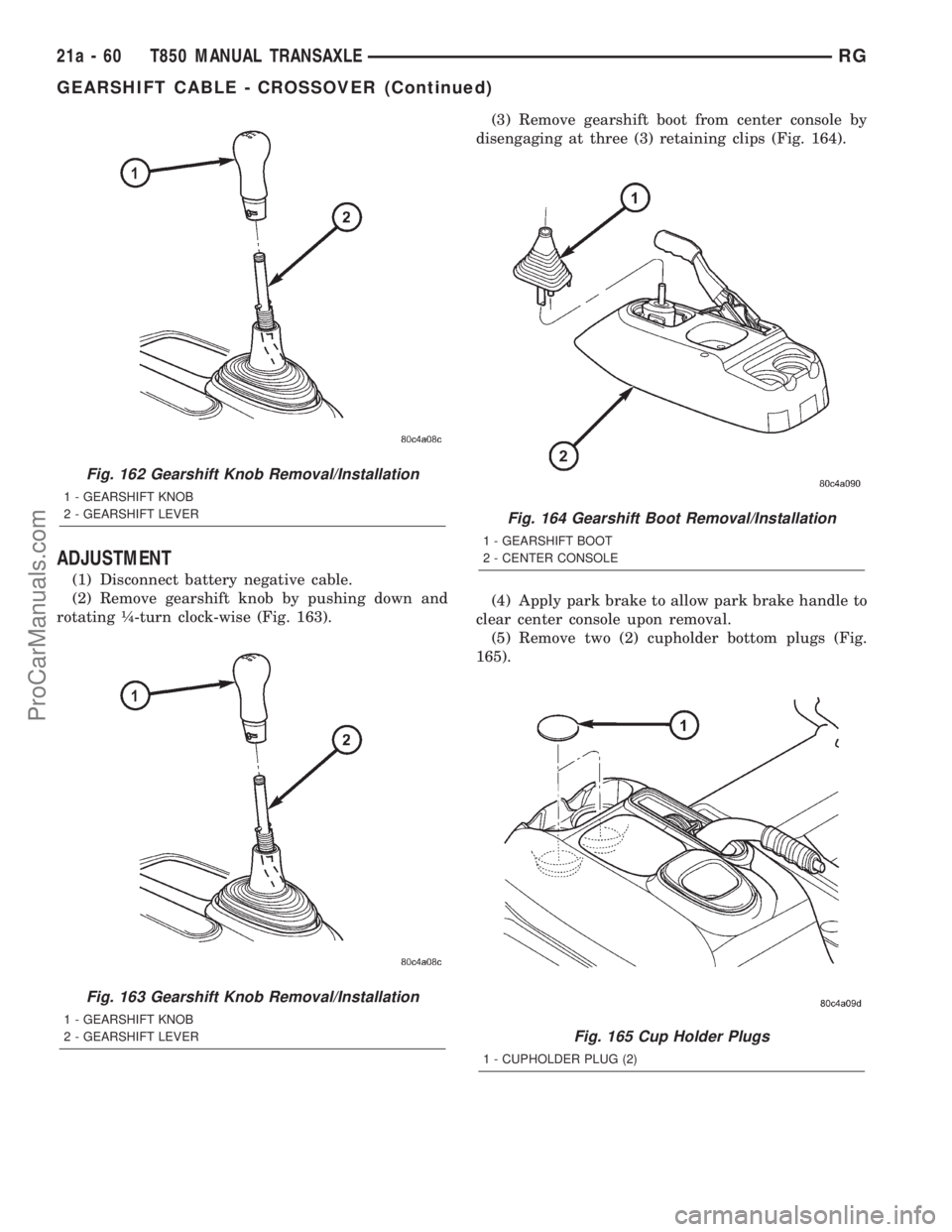

ADJUSTMENT

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating ò-turn clock-wise (Fig. 163).(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 164).

(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

165).

Fig. 162 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 163 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 164 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 165 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

21a - 60 T850 MANUAL TRANSAXLERG

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com

Page 1860 of 2321

(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

166).

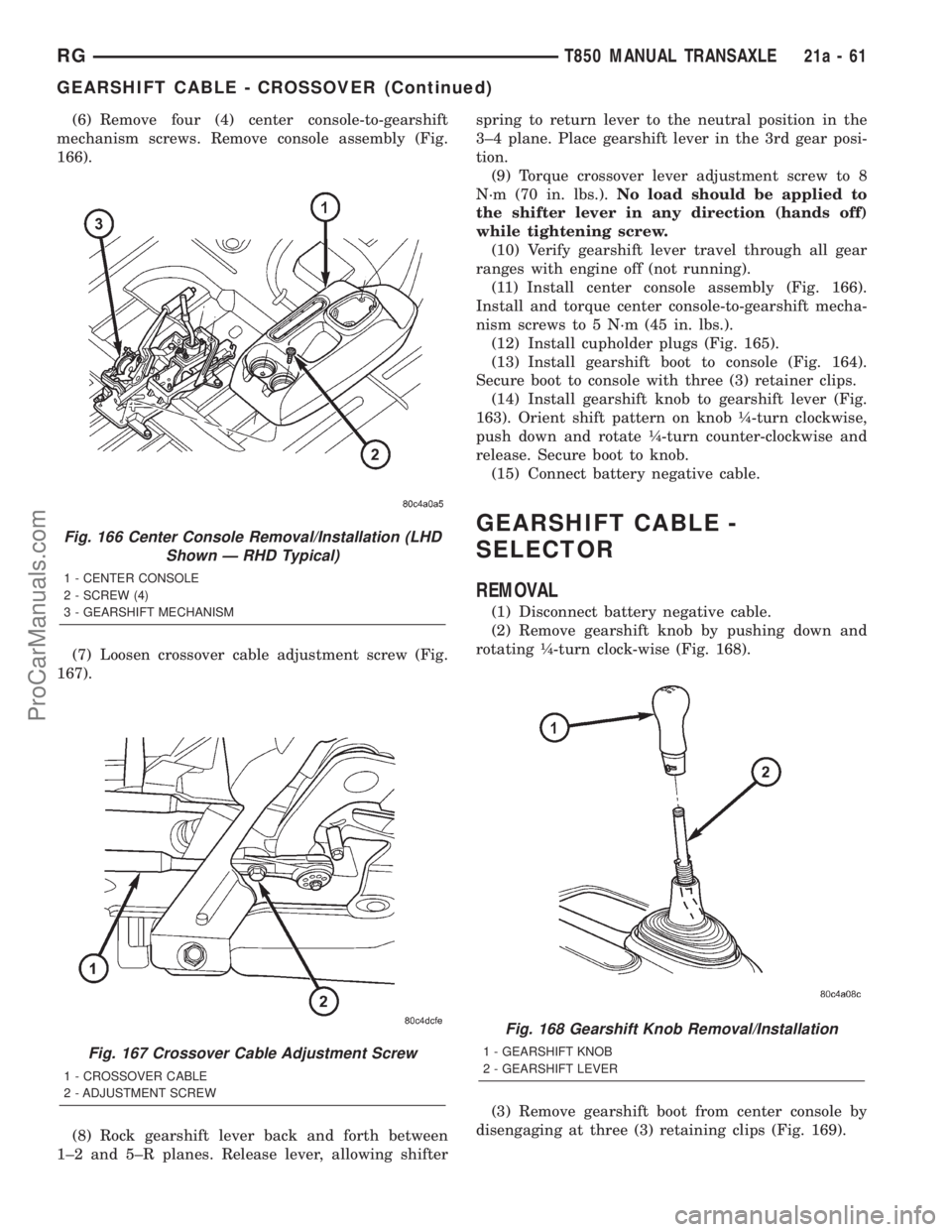

(7) Loosen crossover cable adjustment screw (Fig.

167).

(8) Rock gearshift lever back and forth between

1±2 and 5±R planes. Release lever, allowing shifterspring to return lever to the neutral position in the

3±4 plane. Place gearshift lever in the 3rd gear posi-

tion.

(9) Torque crossover lever adjustment screw to 8

N´m (70 in. lbs.).No load should be applied to

the shifter lever in any direction (hands off)

while tightening screw.

(10) Verify gearshift lever travel through all gear

ranges with engine off (not running).

(11) Install center console assembly (Fig. 166).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

(12) Install cupholder plugs (Fig. 165).

(13) Install gearshift boot to console (Fig. 164).

Secure boot to console with three (3) retainer clips.

(14) Install gearshift knob to gearshift lever (Fig.

163). Orient shift pattern on knob ò-turn clockwise,

push down and rotate ò-turn counter-clockwise and

release. Secure boot to knob.

(15) Connect battery negative cable.

GEARSHIFT CABLE -

SELECTOR

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating ò-turn clock-wise (Fig. 168).

(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 169).

Fig. 166 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 167 Crossover Cable Adjustment Screw

1 - CROSSOVER CABLE

2 - ADJUSTMENT SCREW

Fig. 168 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

RGT850 MANUAL TRANSAXLE21a-61

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com