boot DODGE TOWN AND COUNTRY 2001 Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 1861 of 2321

(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

170).(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

171).

(7) Remove center console support bracket (Fig.

172).

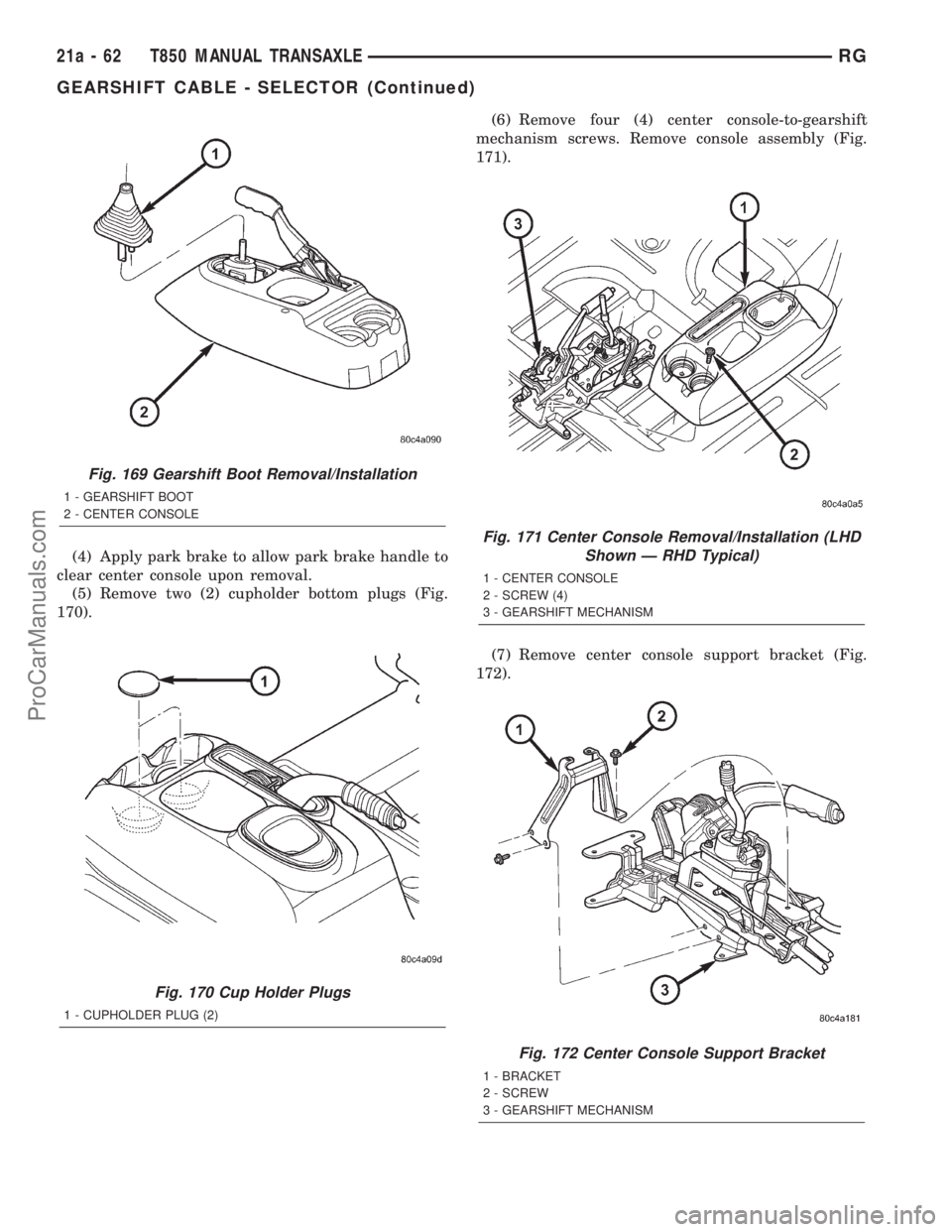

Fig. 169 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 170 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 171 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 172 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

21a - 62 T850 MANUAL TRANSAXLERG

GEARSHIFT CABLE - SELECTOR (Continued)

ProCarManuals.com

Page 1866 of 2321

(13) Install cupholder plugs (Fig. 189).

(14) Install gearshift boot to console (Fig. 190).

Secure with three (3) retainer clips.

(15) Install gearshift knob to gearshift lever (Fig.

191). Orient shift pattern ò-turn clockwise, push

down and rotate ò-turn counter-clockwise and

release. Secure boot to knob.

(16) Connect battery negative cable.

GEARSHIFT KNOB

REMOVAL

(1) Separate gearshift boot from base of knob.

(2) Remove gearshift knob by pushing down and

rotating ò-turn clockwise (Fig. 192).

INSTALLATION

(1) Install gearshift knob pattern ò-turn clock-

wise, press down, and rotate ò-turn counter clock-

wise (Fig. 192).

(2) Secure gearshift boot to base of knob.

Fig. 189 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

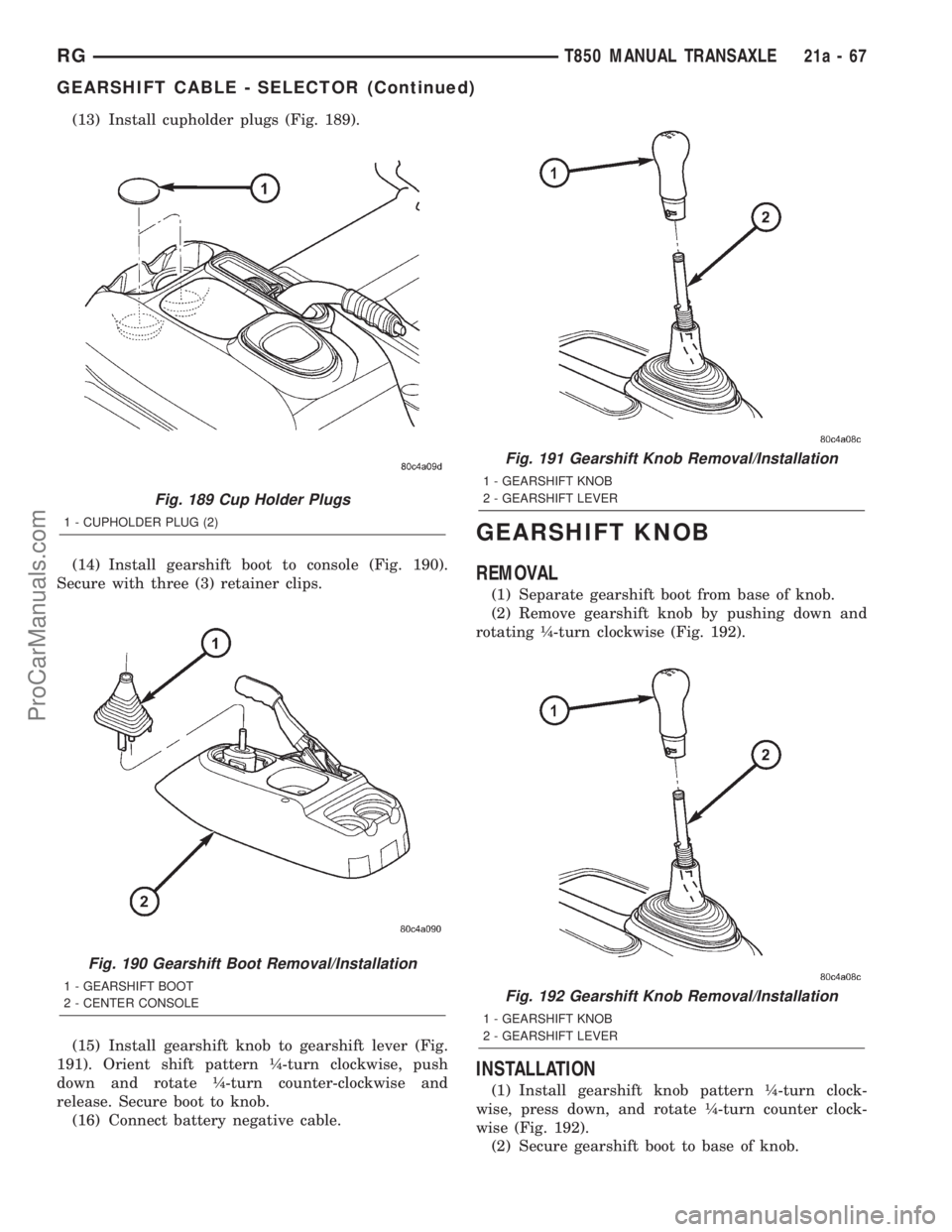

Fig. 190 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 191 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 192 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

RGT850 MANUAL TRANSAXLE21a-67

GEARSHIFT CABLE - SELECTOR (Continued)

ProCarManuals.com

Page 1867 of 2321

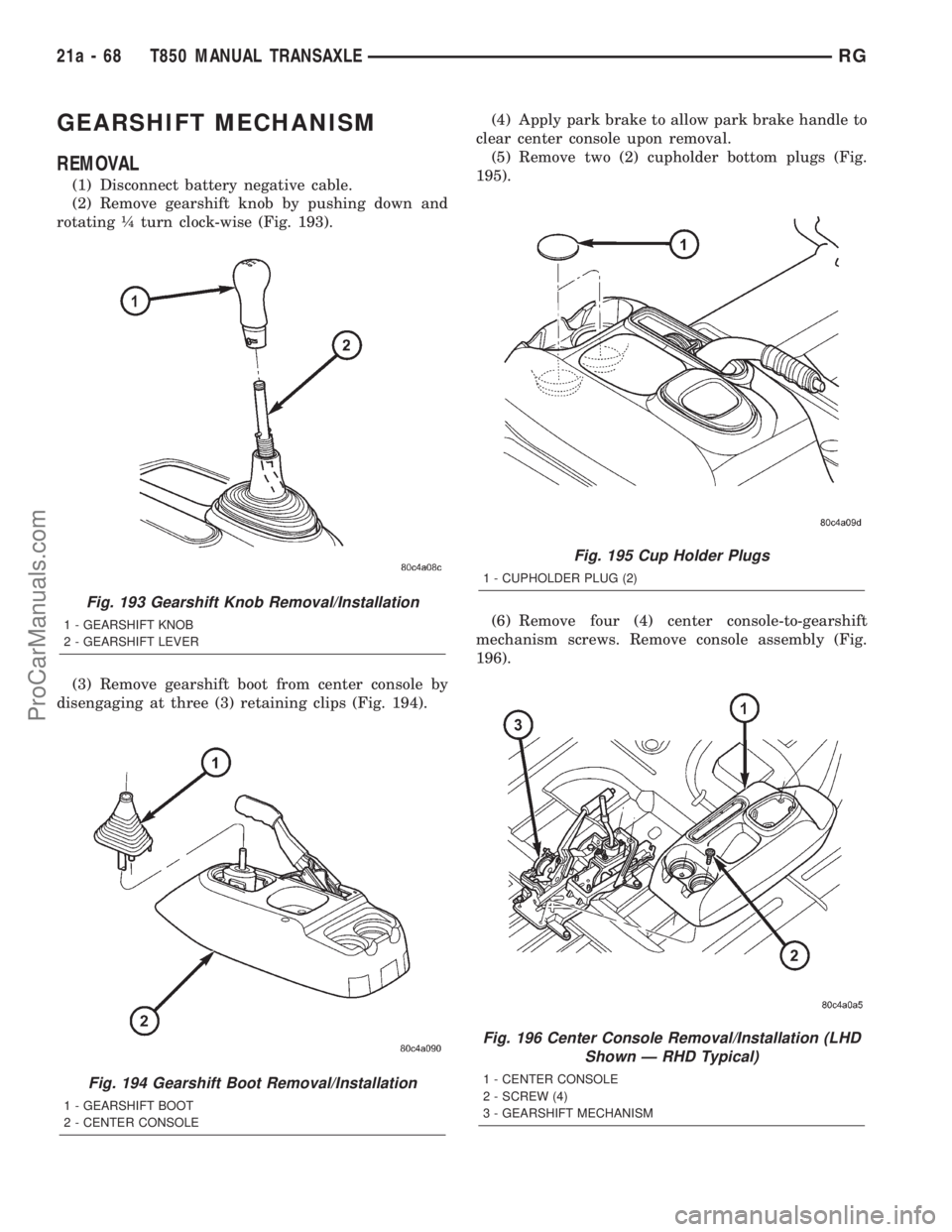

GEARSHIFT MECHANISM

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating ò turn clock-wise (Fig. 193).

(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 194).(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

195).

(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

196).

Fig. 193 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 194 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 195 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 196 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

21a - 68 T850 MANUAL TRANSAXLERG

ProCarManuals.com

Page 1871 of 2321

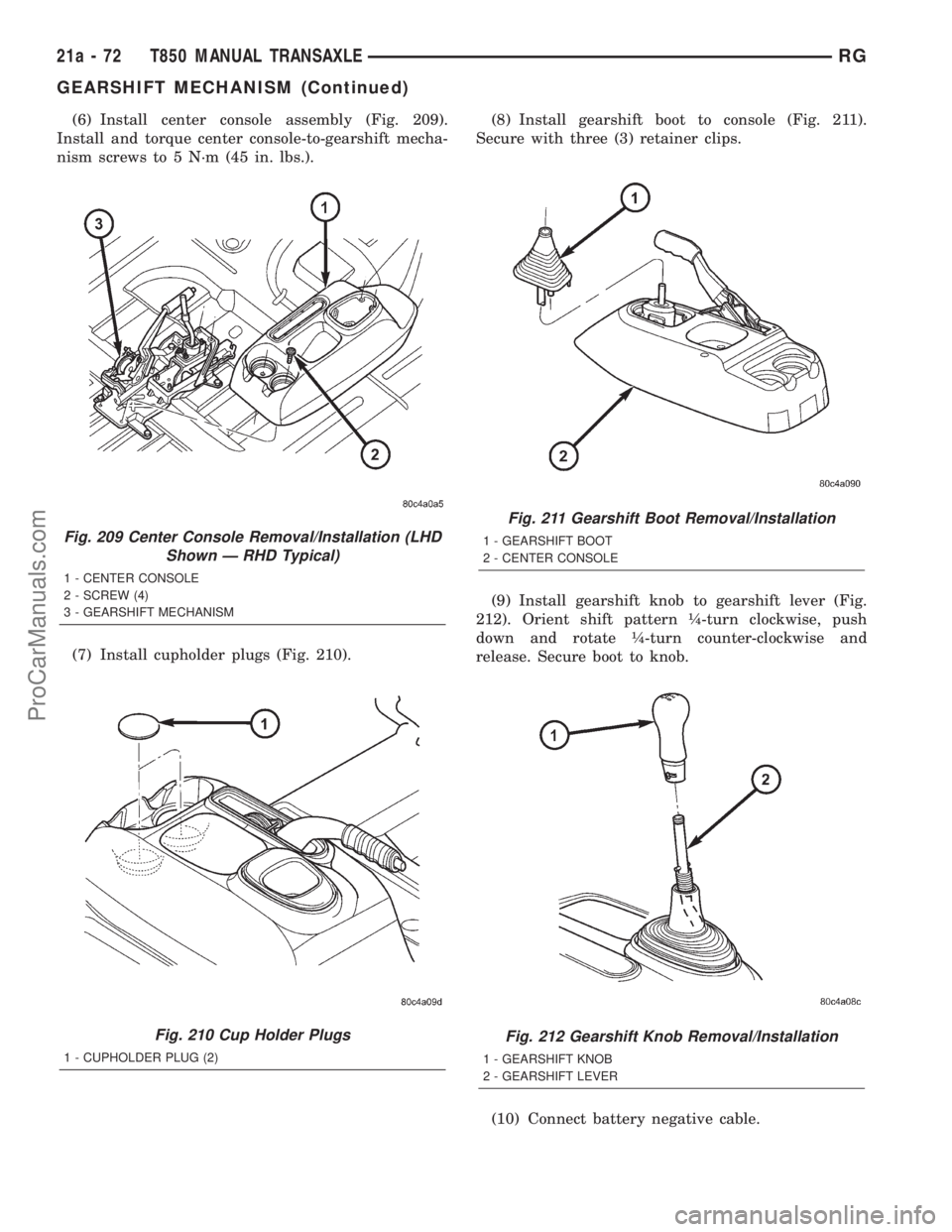

(6) Install center console assembly (Fig. 209).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

(7) Install cupholder plugs (Fig. 210).(8) Install gearshift boot to console (Fig. 211).

Secure with three (3) retainer clips.

(9) Install gearshift knob to gearshift lever (Fig.

212). Orient shift pattern ò-turn clockwise, push

down and rotate ò-turn counter-clockwise and

release. Secure boot to knob.

(10) Connect battery negative cable.

Fig. 209 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 210 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 211 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 212 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

21a - 72 T850 MANUAL TRANSAXLERG

GEARSHIFT MECHANISM (Continued)

ProCarManuals.com

Page 2241 of 2321

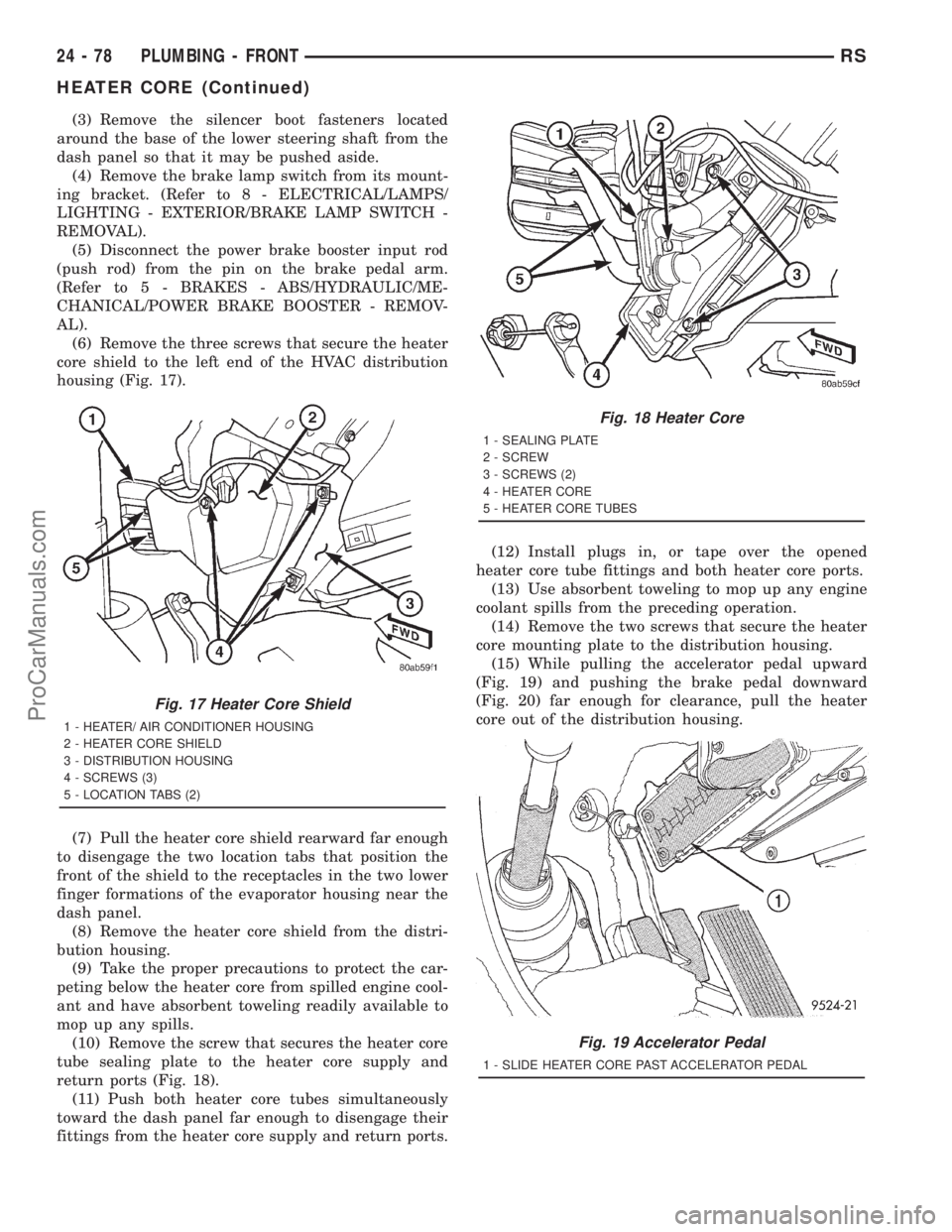

(3) Remove the silencer boot fasteners located

around the base of the lower steering shaft from the

dash panel so that it may be pushed aside.

(4) Remove the brake lamp switch from its mount-

ing bracket. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/BRAKE LAMP SWITCH -

REMOVAL).

(5) Disconnect the power brake booster input rod

(push rod) from the pin on the brake pedal arm.

(Refer to 5 - BRAKES - ABS/HYDRAULIC/ME-

CHANICAL/POWER BRAKE BOOSTER - REMOV-

AL).

(6) Remove the three screws that secure the heater

core shield to the left end of the HVAC distribution

housing (Fig. 17).

(7) Pull the heater core shield rearward far enough

to disengage the two location tabs that position the

front of the shield to the receptacles in the two lower

finger formations of the evaporator housing near the

dash panel.

(8) Remove the heater core shield from the distri-

bution housing.

(9) Take the proper precautions to protect the car-

peting below the heater core from spilled engine cool-

ant and have absorbent toweling readily available to

mop up any spills.

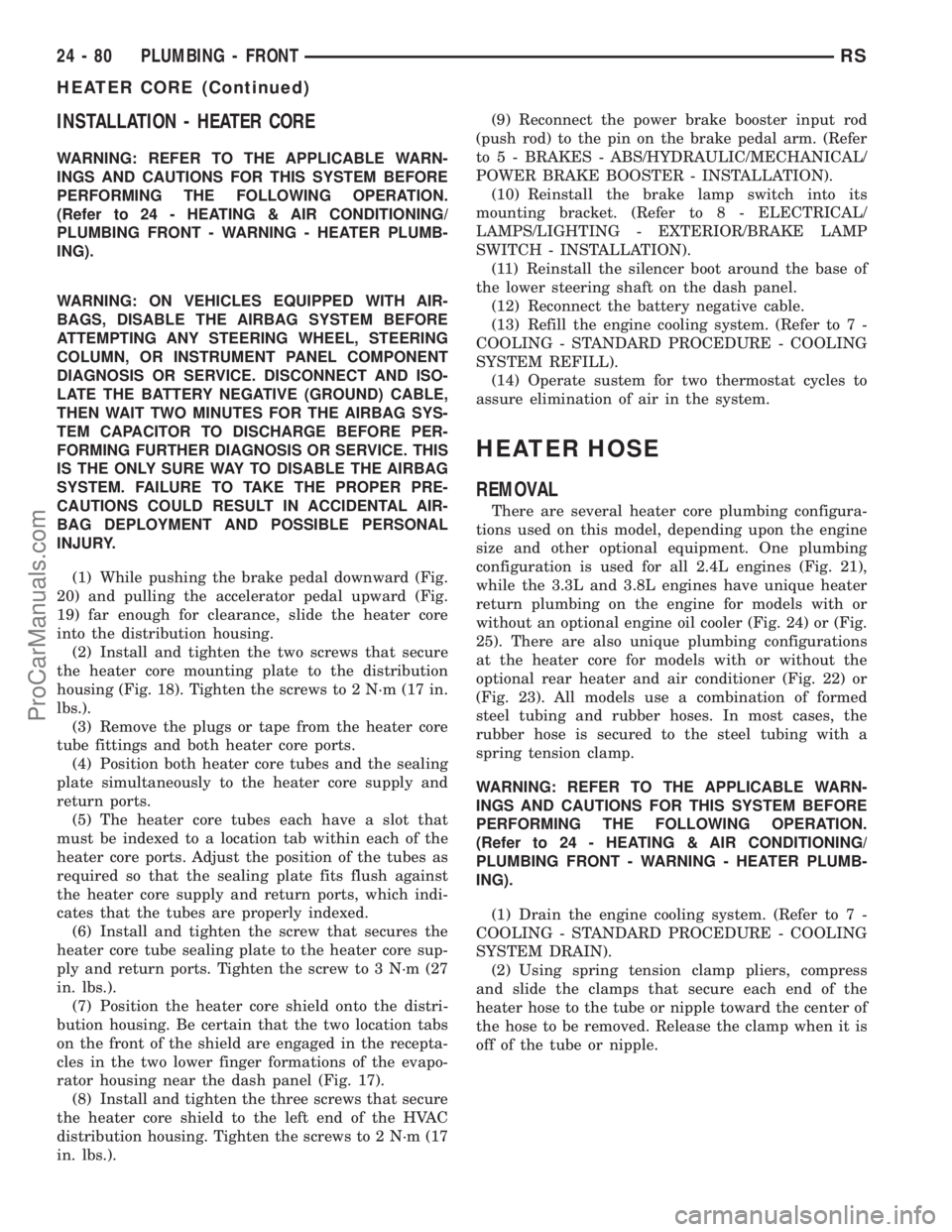

(10) Remove the screw that secures the heater core

tube sealing plate to the heater core supply and

return ports (Fig. 18).

(11) Push both heater core tubes simultaneously

toward the dash panel far enough to disengage their

fittings from the heater core supply and return ports.(12) Install plugs in, or tape over the opened

heater core tube fittings and both heater core ports.

(13) Use absorbent toweling to mop up any engine

coolant spills from the preceding operation.

(14) Remove the two screws that secure the heater

core mounting plate to the distribution housing.

(15) While pulling the accelerator pedal upward

(Fig. 19) and pushing the brake pedal downward

(Fig. 20) far enough for clearance, pull the heater

core out of the distribution housing.

Fig. 17 Heater Core Shield

1 - HEATER/ AIR CONDITIONER HOUSING

2 - HEATER CORE SHIELD

3 - DISTRIBUTION HOUSING

4 - SCREWS (3)

5 - LOCATION TABS (2)

Fig. 18 Heater Core

1 - SEALING PLATE

2 - SCREW

3 - SCREWS (2)

4 - HEATER CORE

5 - HEATER CORE TUBES

Fig. 19 Accelerator Pedal

1 - SLIDE HEATER CORE PAST ACCELERATOR PEDAL

24 - 78 PLUMBING - FRONTRS

HEATER CORE (Continued)

ProCarManuals.com

Page 2243 of 2321

INSTALLATION - HEATER CORE

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING FRONT - WARNING - HEATER PLUMB-

ING).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) While pushing the brake pedal downward (Fig.

20) and pulling the accelerator pedal upward (Fig.

19) far enough for clearance, slide the heater core

into the distribution housing.

(2) Install and tighten the two screws that secure

the heater core mounting plate to the distribution

housing (Fig. 18). Tighten the screws to 2 N´m (17 in.

lbs.).

(3) Remove the plugs or tape from the heater core

tube fittings and both heater core ports.

(4) Position both heater core tubes and the sealing

plate simultaneously to the heater core supply and

return ports.

(5) The heater core tubes each have a slot that

must be indexed to a location tab within each of the

heater core ports. Adjust the position of the tubes as

required so that the sealing plate fits flush against

the heater core supply and return ports, which indi-

cates that the tubes are properly indexed.

(6) Install and tighten the screw that secures the

heater core tube sealing plate to the heater core sup-

ply and return ports. Tighten the screw to 3 N´m (27

in. lbs.).

(7) Position the heater core shield onto the distri-

bution housing. Be certain that the two location tabs

on the front of the shield are engaged in the recepta-

cles in the two lower finger formations of the evapo-

rator housing near the dash panel (Fig. 17).

(8) Install and tighten the three screws that secure

the heater core shield to the left end of the HVAC

distribution housing. Tighten the screws to 2 N´m (17

in. lbs.).(9) Reconnect the power brake booster input rod

(push rod) to the pin on the brake pedal arm. (Refer

to 5 - BRAKES - ABS/HYDRAULIC/MECHANICAL/

POWER BRAKE BOOSTER - INSTALLATION).

(10) Reinstall the brake lamp switch into its

mounting bracket. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION).

(11) Reinstall the silencer boot around the base of

the lower steering shaft on the dash panel.

(12) Reconnect the battery negative cable.

(13) Refill the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

(14) Operate sustem for two thermostat cycles to

assure elimination of air in the system.

HEATER HOSE

REMOVAL

There are several heater core plumbing configura-

tions used on this model, depending upon the engine

size and other optional equipment. One plumbing

configuration is used for all 2.4L engines (Fig. 21),

while the 3.3L and 3.8L engines have unique heater

return plumbing on the engine for models with or

without an optional engine oil cooler (Fig. 24) or (Fig.

25). There are also unique plumbing configurations

at the heater core for models with or without the

optional rear heater and air conditioner (Fig. 22) or

(Fig. 23). All models use a combination of formed

steel tubing and rubber hoses. In most cases, the

rubber hose is secured to the steel tubing with a

spring tension clamp.

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING FRONT - WARNING - HEATER PLUMB-

ING).

(1) Drain the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

(2) Using spring tension clamp pliers, compress

and slide the clamps that secure each end of the

heater hose to the tube or nipple toward the center of

the hose to be removed. Release the clamp when it is

off of the tube or nipple.

24 - 80 PLUMBING - FRONTRS

HEATER CORE (Continued)

ProCarManuals.com