DODGE TOWN AND COUNTRY 2001 Service Manual

Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 611 of 2321

CONDITION POSSIBLE CAUSES CORRECTION

WIPER MOTOR WILL NOT

RUN1. BLOWN FUSE.

2. NEW FUSE BLOWS.

3. NEW FUSE BLOWS.

4. NO VOLTAGE AT MOTOR.

5. POOR GROUND.1. REPLACE FUSE, AND RUN SYSTEM.

2. CHECK FOR SHORT IN WIRING OR

SWITCH.

3. REPLACE FUSE, REMOVE MOTOR

CONNECTOR, TURN SWITCH ON, FUSE

DOES NOT BLOW, REPLACE MOTOR.

4. CHECK SWITCH AND WIRING

HARNESS. REFER TO WIRING

DIAGRAMS.

5. REPAIR GROUND WIRE CONNECTION

AS NECESSARY.

FRONT WIPER ARMS

REMOVAL

CAUTION: The driver side wiper arm must be

parked above the passenger side. Failure to do so

will result in damage to the arms, blades or system.

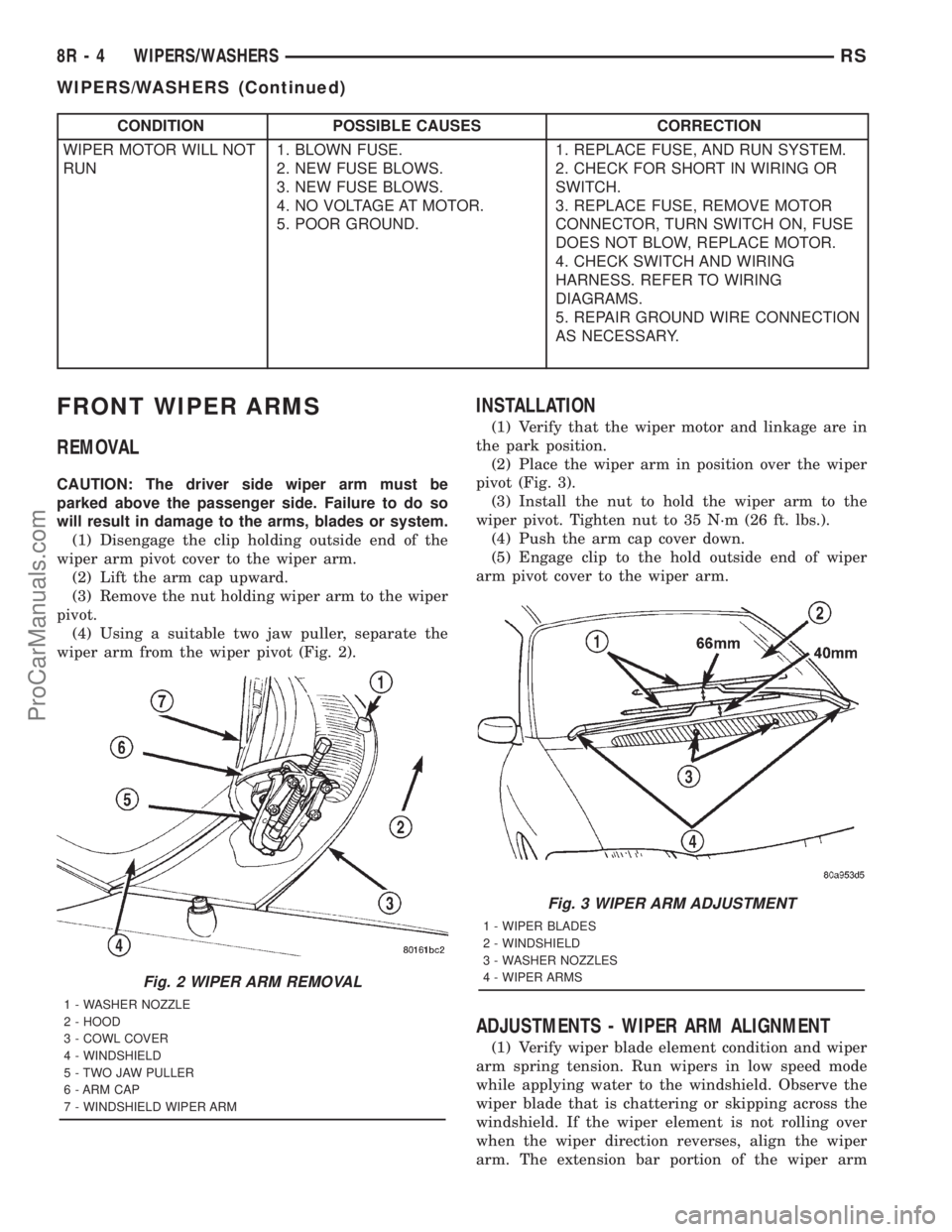

(1) Disengage the clip holding outside end of the

wiper arm pivot cover to the wiper arm.

(2) Lift the arm cap upward.

(3) Remove the nut holding wiper arm to the wiper

pivot.

(4) Using a suitable two jaw puller, separate the

wiper arm from the wiper pivot (Fig. 2).

INSTALLATION

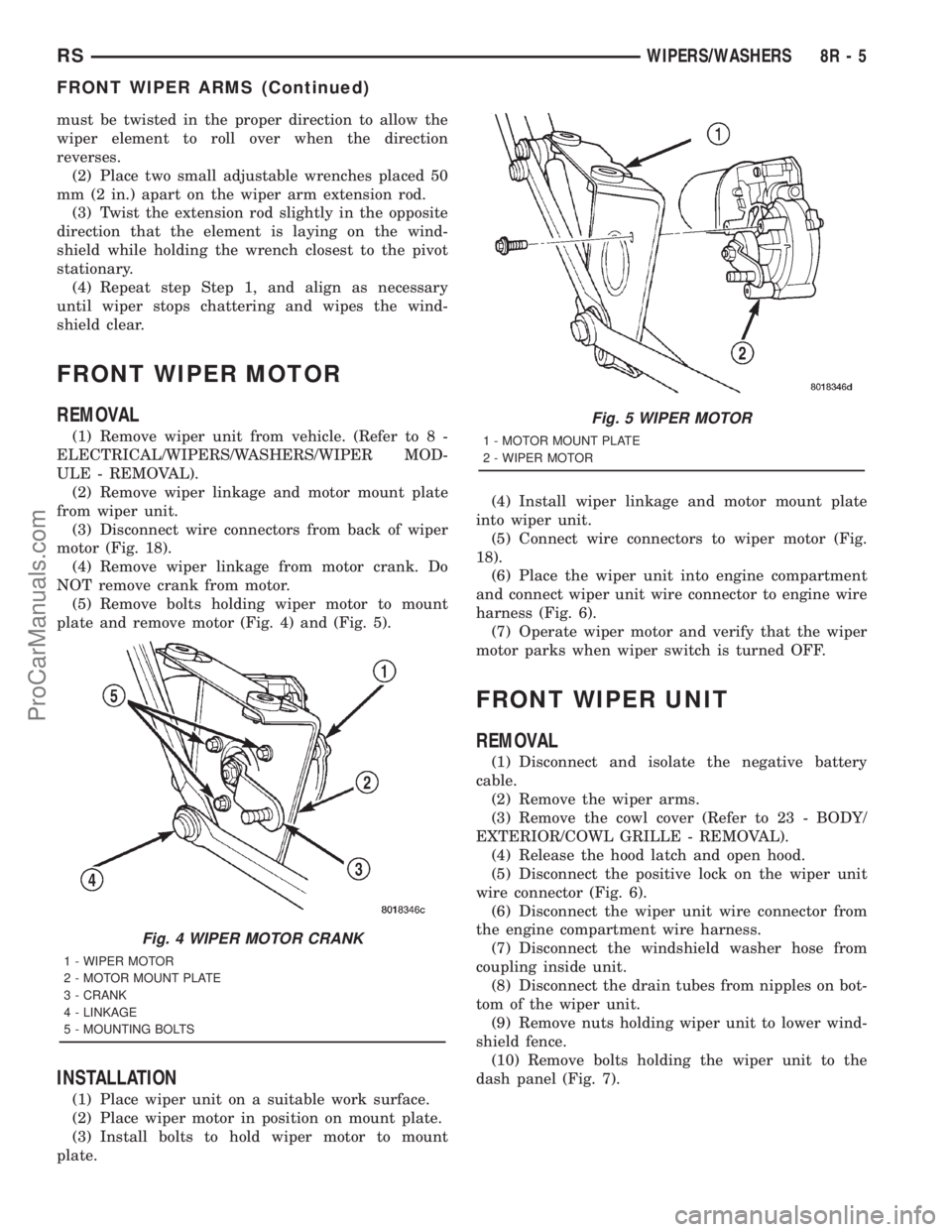

(1) Verify that the wiper motor and linkage are in

the park position.

(2) Place the wiper arm in position over the wiper

pivot (Fig. 3).

(3) Install the nut to hold the wiper arm to the

wiper pivot. Tighten nut to 35 N´m (26 ft. lbs.).

(4) Push the arm cap cover down.

(5) Engage clip to the hold outside end of wiper

arm pivot cover to the wiper arm.

ADJUSTMENTS - WIPER ARM ALIGNMENT

(1) Verify wiper blade element condition and wiper

arm spring tension. Run wipers in low speed mode

while applying water to the windshield. Observe the

wiper blade that is chattering or skipping across the

windshield. If the wiper element is not rolling over

when the wiper direction reverses, align the wiper

arm. The extension bar portion of the wiper arm

Fig. 2 WIPER ARM REMOVAL

1 - WASHER NOZZLE

2 - HOOD

3 - COWL COVER

4 - WINDSHIELD

5 - TWO JAW PULLER

6 - ARM CAP

7 - WINDSHIELD WIPER ARM

Fig. 3 WIPER ARM ADJUSTMENT

1 - WIPER BLADES

2 - WINDSHIELD

3 - WASHER NOZZLES

4 - WIPER ARMS

8R - 4 WIPERS/WASHERSRS

WIPERS/WASHERS (Continued)

ProCarManuals.com

Page 612 of 2321

must be twisted in the proper direction to allow the

wiper element to roll over when the direction

reverses.

(2) Place two small adjustable wrenches placed 50

mm (2 in.) apart on the wiper arm extension rod.

(3) Twist the extension rod slightly in the opposite

direction that the element is laying on the wind-

shield while holding the wrench closest to the pivot

stationary.

(4) Repeat step Step 1, and align as necessary

until wiper stops chattering and wipes the wind-

shield clear.

FRONT WIPER MOTOR

REMOVAL

(1) Remove wiper unit from vehicle. (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - REMOVAL).

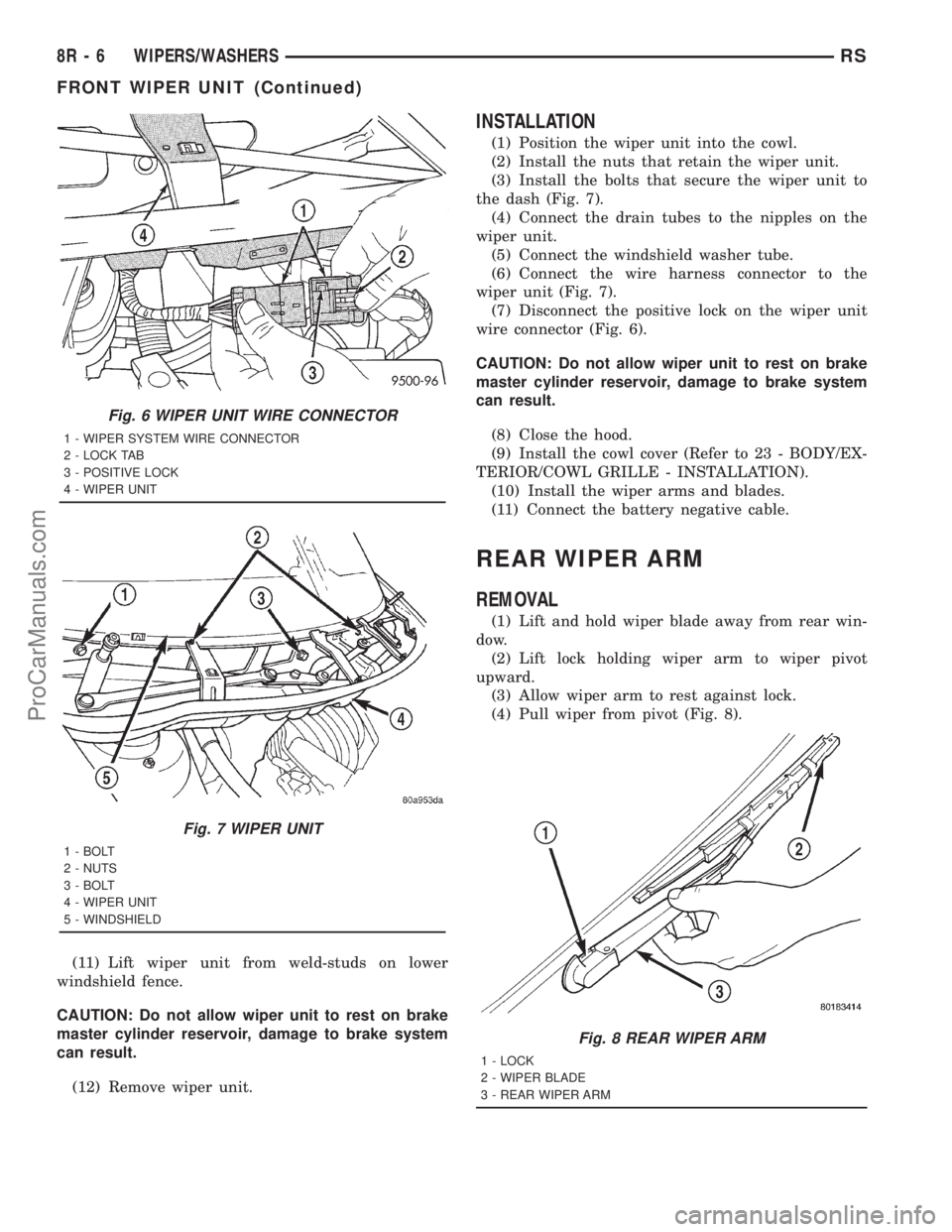

(2) Remove wiper linkage and motor mount plate

from wiper unit.

(3) Disconnect wire connectors from back of wiper

motor (Fig. 18).

(4) Remove wiper linkage from motor crank. Do

NOT remove crank from motor.

(5) Remove bolts holding wiper motor to mount

plate and remove motor (Fig. 4) and (Fig. 5).

INSTALLATION

(1) Place wiper unit on a suitable work surface.

(2) Place wiper motor in position on mount plate.

(3) Install bolts to hold wiper motor to mount

plate.(4) Install wiper linkage and motor mount plate

into wiper unit.

(5) Connect wire connectors to wiper motor (Fig.

18).

(6) Place the wiper unit into engine compartment

and connect wiper unit wire connector to engine wire

harness (Fig. 6).

(7) Operate wiper motor and verify that the wiper

motor parks when wiper switch is turned OFF.

FRONT WIPER UNIT

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the wiper arms.

(3) Remove the cowl cover (Refer to 23 - BODY/

EXTERIOR/COWL GRILLE - REMOVAL).

(4) Release the hood latch and open hood.

(5) Disconnect the positive lock on the wiper unit

wire connector (Fig. 6).

(6) Disconnect the wiper unit wire connector from

the engine compartment wire harness.

(7) Disconnect the windshield washer hose from

coupling inside unit.

(8) Disconnect the drain tubes from nipples on bot-

tom of the wiper unit.

(9) Remove nuts holding wiper unit to lower wind-

shield fence.

(10) Remove bolts holding the wiper unit to the

dash panel (Fig. 7).

Fig. 4 WIPER MOTOR CRANK

1 - WIPER MOTOR

2 - MOTOR MOUNT PLATE

3 - CRANK

4 - LINKAGE

5 - MOUNTING BOLTS

Fig. 5 WIPER MOTOR

1 - MOTOR MOUNT PLATE

2 - WIPER MOTOR

RSWIPERS/WASHERS8R-5

FRONT WIPER ARMS (Continued)

ProCarManuals.com

Page 613 of 2321

(11) Lift wiper unit from weld-studs on lower

windshield fence.

CAUTION: Do not allow wiper unit to rest on brake

master cylinder reservoir, damage to brake system

can result.

(12) Remove wiper unit.

INSTALLATION

(1) Position the wiper unit into the cowl.

(2) Install the nuts that retain the wiper unit.

(3) Install the bolts that secure the wiper unit to

the dash (Fig. 7).

(4) Connect the drain tubes to the nipples on the

wiper unit.

(5) Connect the windshield washer tube.

(6) Connect the wire harness connector to the

wiper unit (Fig. 7).

(7) Disconnect the positive lock on the wiper unit

wire connector (Fig. 6).

CAUTION: Do not allow wiper unit to rest on brake

master cylinder reservoir, damage to brake system

can result.

(8) Close the hood.

(9) Install the cowl cover (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - INSTALLATION).

(10) Install the wiper arms and blades.

(11) Connect the battery negative cable.

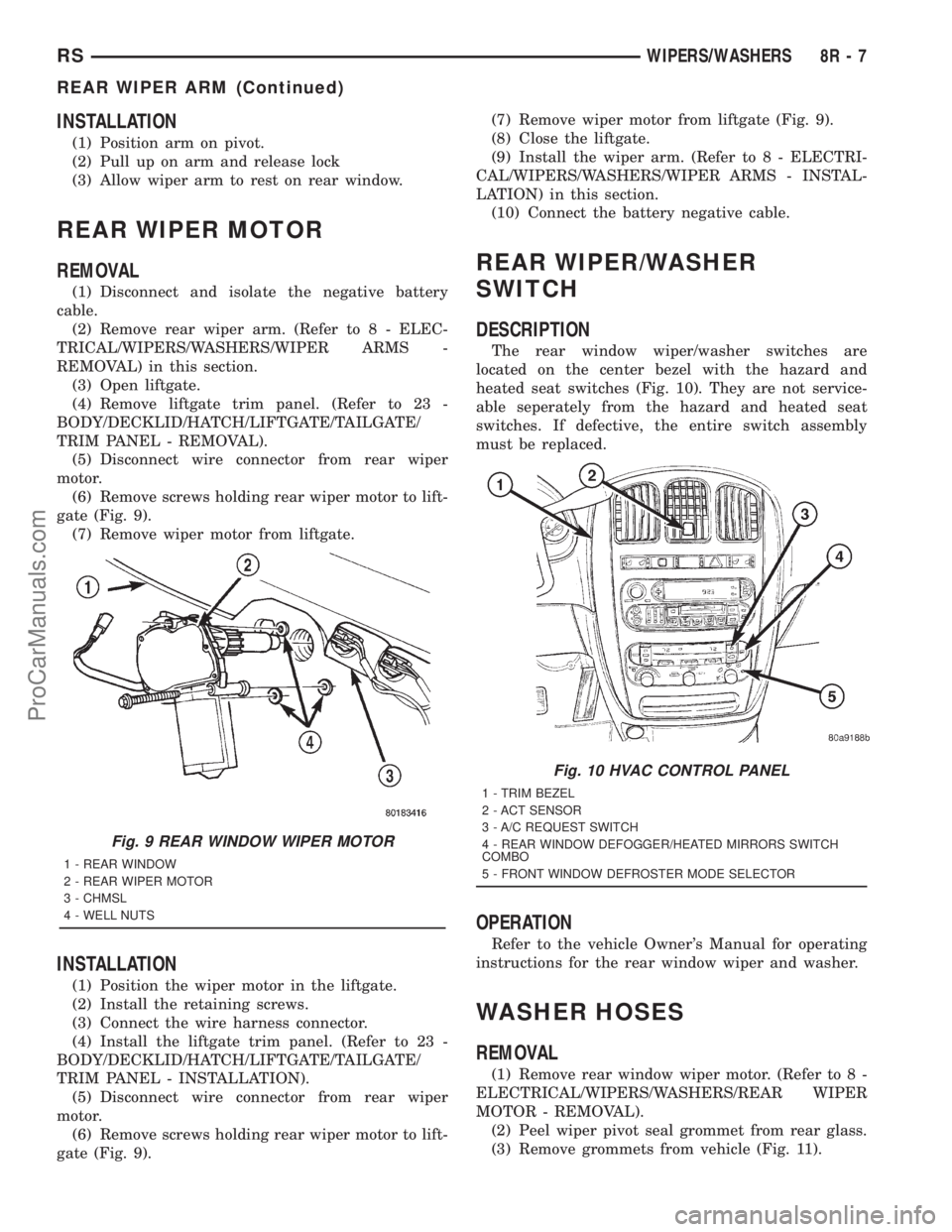

REAR WIPER ARM

REMOVAL

(1) Lift and hold wiper blade away from rear win-

dow.

(2) Lift lock holding wiper arm to wiper pivot

upward.

(3) Allow wiper arm to rest against lock.

(4) Pull wiper from pivot (Fig. 8).

Fig. 6 WIPER UNIT WIRE CONNECTOR

1 - WIPER SYSTEM WIRE CONNECTOR

2 - LOCK TAB

3 - POSITIVE LOCK

4 - WIPER UNIT

Fig. 7 WIPER UNIT

1 - BOLT

2 - NUTS

3 - BOLT

4 - WIPER UNIT

5 - WINDSHIELD

Fig. 8 REAR WIPER ARM

1 - LOCK

2 - WIPER BLADE

3 - REAR WIPER ARM

8R - 6 WIPERS/WASHERSRS

FRONT WIPER UNIT (Continued)

ProCarManuals.com

Page 614 of 2321

INSTALLATION

(1) Position arm on pivot.

(2) Pull up on arm and release lock

(3) Allow wiper arm to rest on rear window.

REAR WIPER MOTOR

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove rear wiper arm. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER ARMS -

REMOVAL) in this section.

(3) Open liftgate.

(4) Remove liftgate trim panel. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL).

(5) Disconnect wire connector from rear wiper

motor.

(6) Remove screws holding rear wiper motor to lift-

gate (Fig. 9).

(7) Remove wiper motor from liftgate.

INSTALLATION

(1) Position the wiper motor in the liftgate.

(2) Install the retaining screws.

(3) Connect the wire harness connector.

(4) Install the liftgate trim panel. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - INSTALLATION).

(5) Disconnect wire connector from rear wiper

motor.

(6) Remove screws holding rear wiper motor to lift-

gate (Fig. 9).(7) Remove wiper motor from liftgate (Fig. 9).

(8) Close the liftgate.

(9) Install the wiper arm. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS - INSTAL-

LATION) in this section.

(10) Connect the battery negative cable.

REAR WIPER/WASHER

SWITCH

DESCRIPTION

The rear window wiper/washer switches are

located on the center bezel with the hazard and

heated seat switches (Fig. 10). They are not service-

able seperately from the hazard and heated seat

switches. If defective, the entire switch assembly

must be replaced.

OPERATION

Refer to the vehicle Owner's Manual for operating

instructions for the rear window wiper and washer.

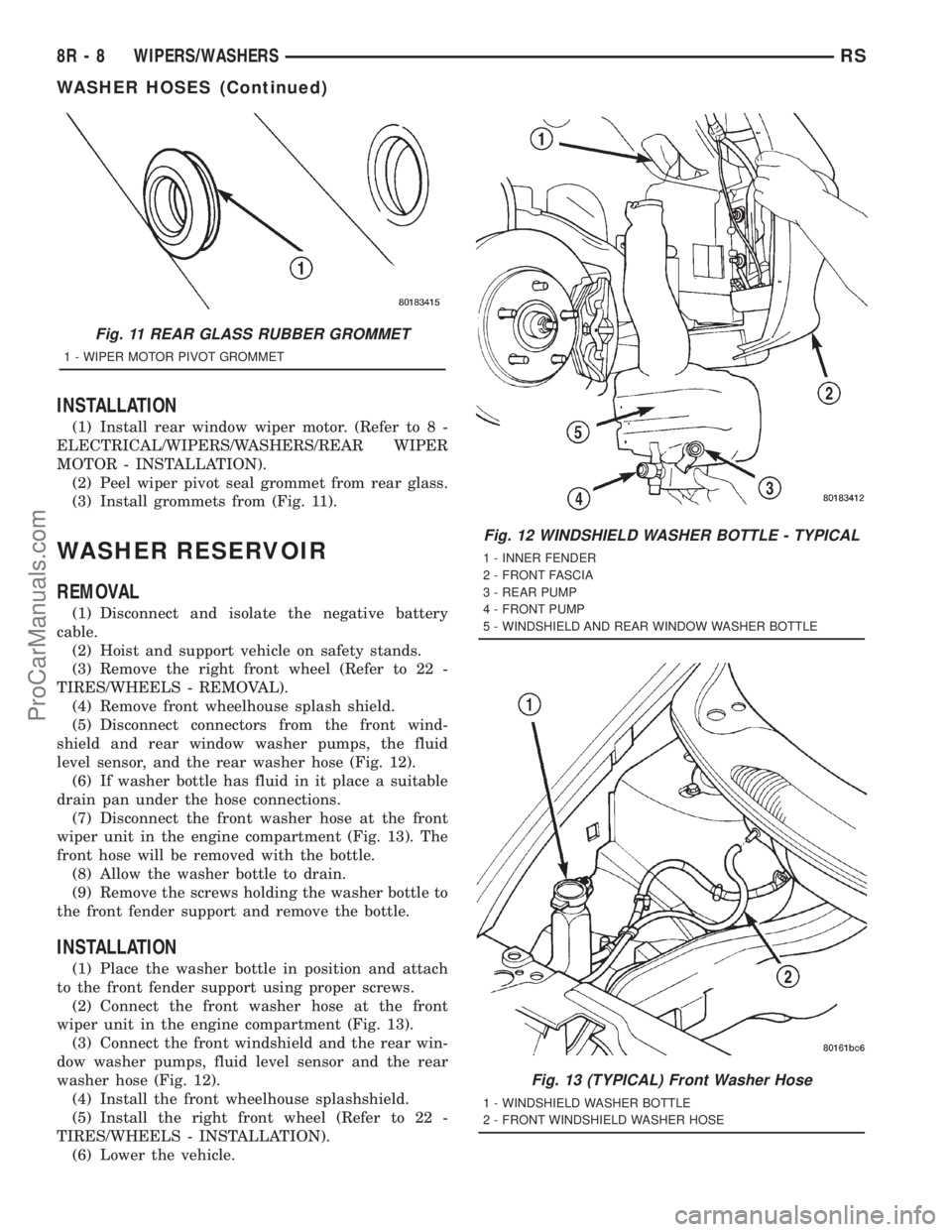

WASHER HOSES

REMOVAL

(1) Remove rear window wiper motor. (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/REAR WIPER

MOTOR - REMOVAL).

(2) Peel wiper pivot seal grommet from rear glass.

(3) Remove grommets from vehicle (Fig. 11).

Fig. 9 REAR WINDOW WIPER MOTOR

1 - REAR WINDOW

2 - REAR WIPER MOTOR

3 - CHMSL

4 - WELL NUTS

Fig. 10 HVAC CONTROL PANEL

1 - TRIM BEZEL

2 - ACT SENSOR

3 - A/C REQUEST SWITCH

4 - REAR WINDOW DEFOGGER/HEATED MIRRORS SWITCH

COMBO

5 - FRONT WINDOW DEFROSTER MODE SELECTOR

RSWIPERS/WASHERS8R-7

REAR WIPER ARM (Continued)

ProCarManuals.com

Page 615 of 2321

INSTALLATION

(1) Install rear window wiper motor. (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/REAR WIPER

MOTOR - INSTALLATION).

(2) Peel wiper pivot seal grommet from rear glass.

(3) Install grommets from (Fig. 11).

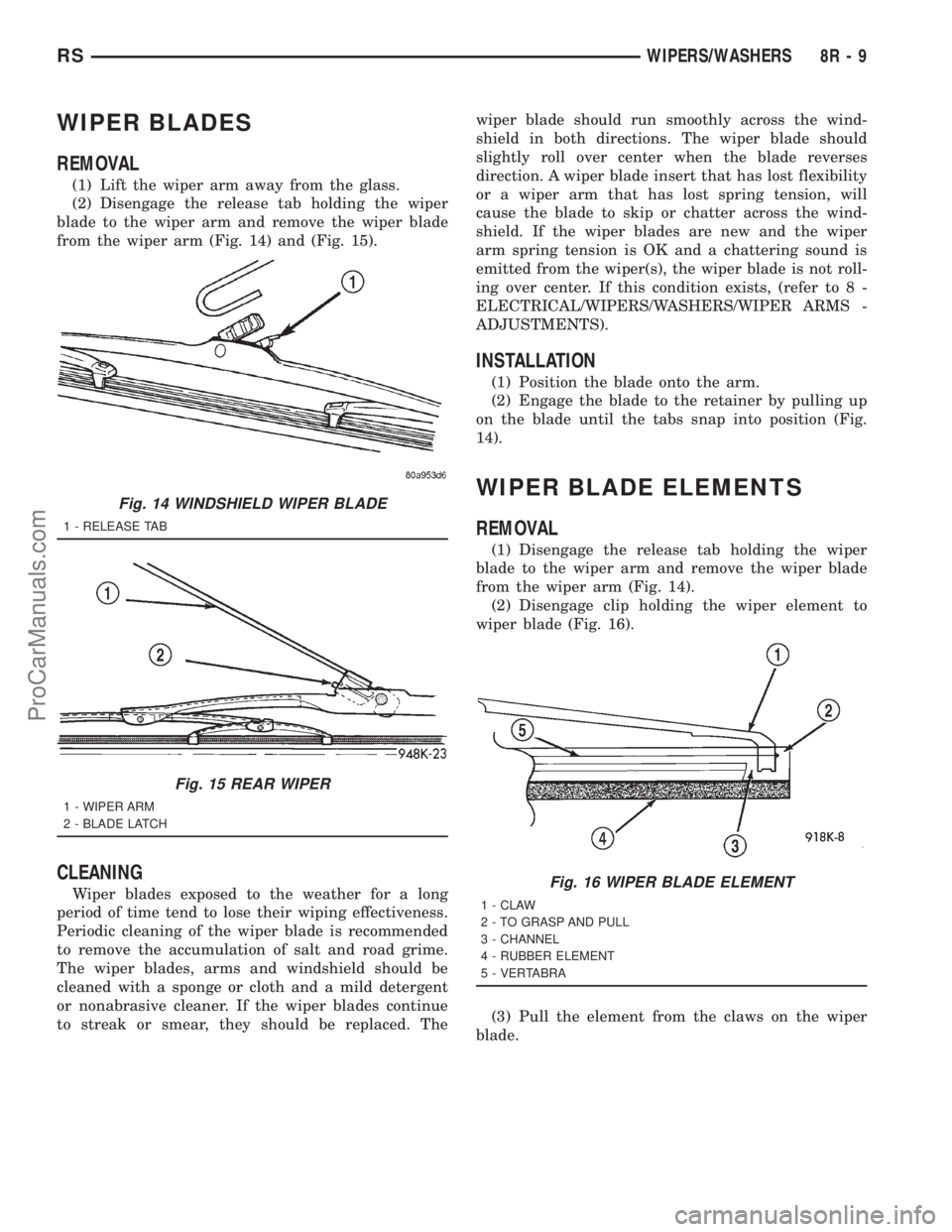

WASHER RESERVOIR

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Hoist and support vehicle on safety stands.

(3) Remove the right front wheel (Refer to 22 -

TIRES/WHEELS - REMOVAL).

(4) Remove front wheelhouse splash shield.

(5) Disconnect connectors from the front wind-

shield and rear window washer pumps, the fluid

level sensor, and the rear washer hose (Fig. 12).

(6) If washer bottle has fluid in it place a suitable

drain pan under the hose connections.

(7) Disconnect the front washer hose at the front

wiper unit in the engine compartment (Fig. 13). The

front hose will be removed with the bottle.

(8) Allow the washer bottle to drain.

(9) Remove the screws holding the washer bottle to

the front fender support and remove the bottle.

INSTALLATION

(1) Place the washer bottle in position and attach

to the front fender support using proper screws.

(2) Connect the front washer hose at the front

wiper unit in the engine compartment (Fig. 13).

(3) Connect the front windshield and the rear win-

dow washer pumps, fluid level sensor and the rear

washer hose (Fig. 12).

(4) Install the front wheelhouse splashshield.

(5) Install the right front wheel (Refer to 22 -

TIRES/WHEELS - INSTALLATION).

(6) Lower the vehicle.

Fig. 11 REAR GLASS RUBBER GROMMET

1 - WIPER MOTOR PIVOT GROMMET

Fig. 12 WINDSHIELD WASHER BOTTLE - TYPICAL

1 - INNER FENDER

2 - FRONT FASCIA

3 - REAR PUMP

4 - FRONT PUMP

5 - WINDSHIELD AND REAR WINDOW WASHER BOTTLE

Fig. 13 (TYPICAL) Front Washer Hose

1 - WINDSHIELD WASHER BOTTLE

2 - FRONT WINDSHIELD WASHER HOSE

8R - 8 WIPERS/WASHERSRS

WASHER HOSES (Continued)

ProCarManuals.com

Page 616 of 2321

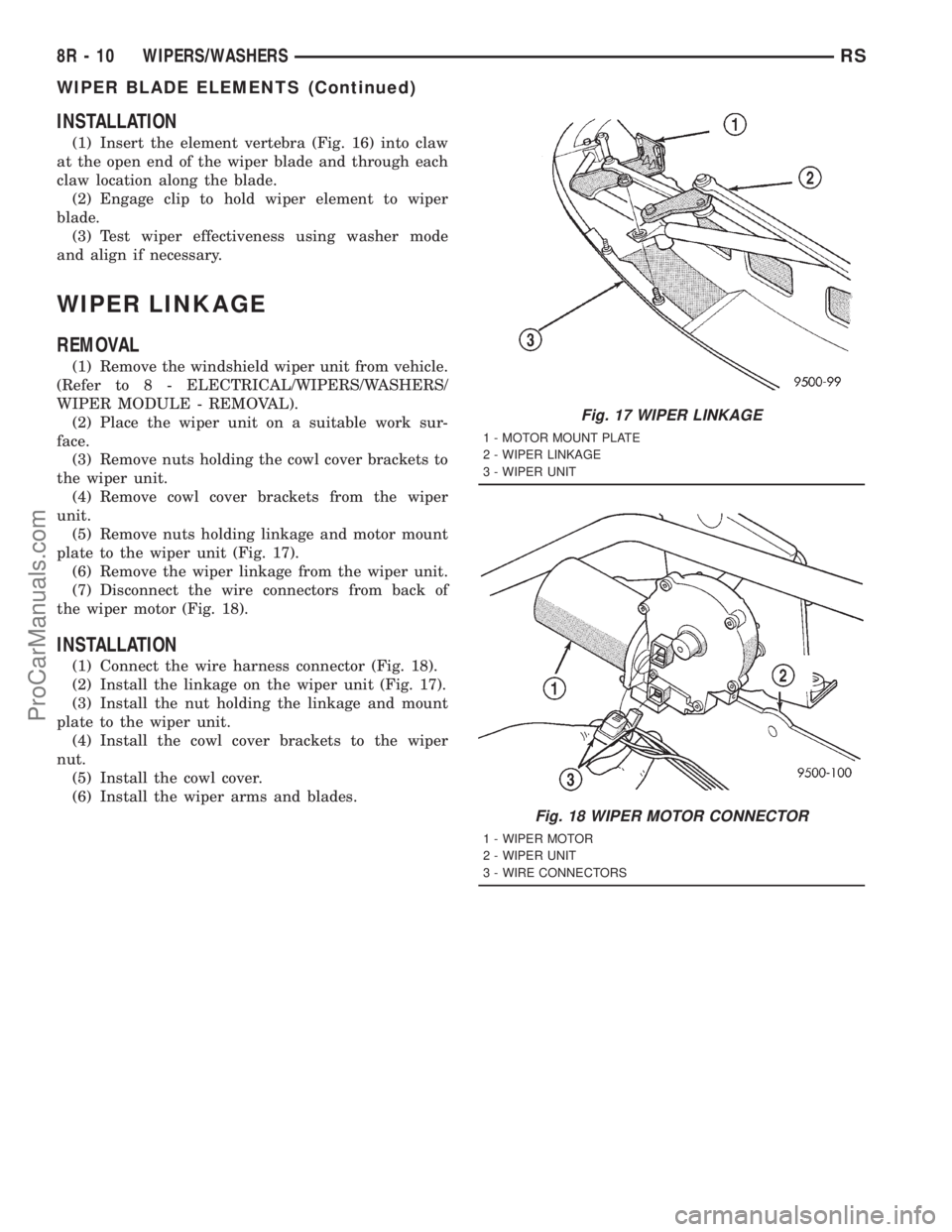

WIPER BLADES

REMOVAL

(1) Lift the wiper arm away from the glass.

(2) Disengage the release tab holding the wiper

blade to the wiper arm and remove the wiper blade

from the wiper arm (Fig. 14) and (Fig. 15).

CLEANING

Wiper blades exposed to the weather for a long

period of time tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is recommended

to remove the accumulation of salt and road grime.

The wiper blades, arms and windshield should be

cleaned with a sponge or cloth and a mild detergent

or nonabrasive cleaner. If the wiper blades continue

to streak or smear, they should be replaced. Thewiper blade should run smoothly across the wind-

shield in both directions. The wiper blade should

slightly roll over center when the blade reverses

direction. A wiper blade insert that has lost flexibility

or a wiper arm that has lost spring tension, will

cause the blade to skip or chatter across the wind-

shield. If the wiper blades are new and the wiper

arm spring tension is OK and a chattering sound is

emitted from the wiper(s), the wiper blade is not roll-

ing over center. If this condition exists, (refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER ARMS -

ADJUSTMENTS).

INSTALLATION

(1) Position the blade onto the arm.

(2) Engage the blade to the retainer by pulling up

on the blade until the tabs snap into position (Fig.

14).

WIPER BLADE ELEMENTS

REMOVAL

(1) Disengage the release tab holding the wiper

blade to the wiper arm and remove the wiper blade

from the wiper arm (Fig. 14).

(2) Disengage clip holding the wiper element to

wiper blade (Fig. 16).

(3) Pull the element from the claws on the wiper

blade.

Fig. 14 WINDSHIELD WIPER BLADE

1 - RELEASE TAB

Fig. 15 REAR WIPER

1 - WIPER ARM

2 - BLADE LATCH

Fig. 16 WIPER BLADE ELEMENT

1 - CLAW

2 - TO GRASP AND PULL

3 - CHANNEL

4 - RUBBER ELEMENT

5 - VERTABRA

RSWIPERS/WASHERS8R-9

ProCarManuals.com

Page 617 of 2321

INSTALLATION

(1) Insert the element vertebra (Fig. 16) into claw

at the open end of the wiper blade and through each

claw location along the blade.

(2) Engage clip to hold wiper element to wiper

blade.

(3) Test wiper effectiveness using washer mode

and align if necessary.

WIPER LINKAGE

REMOVAL

(1) Remove the windshield wiper unit from vehicle.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER MODULE - REMOVAL).

(2) Place the wiper unit on a suitable work sur-

face.

(3) Remove nuts holding the cowl cover brackets to

the wiper unit.

(4) Remove cowl cover brackets from the wiper

unit.

(5) Remove nuts holding linkage and motor mount

plate to the wiper unit (Fig. 17).

(6) Remove the wiper linkage from the wiper unit.

(7) Disconnect the wire connectors from back of

the wiper motor (Fig. 18).

INSTALLATION

(1) Connect the wire harness connector (Fig. 18).

(2) Install the linkage on the wiper unit (Fig. 17).

(3) Install the nut holding the linkage and mount

plate to the wiper unit.

(4) Install the cowl cover brackets to the wiper

nut.

(5) Install the cowl cover.

(6) Install the wiper arms and blades.

Fig. 18 WIPER MOTOR CONNECTOR

1 - WIPER MOTOR

2 - WIPER UNIT

3 - WIRE CONNECTORS

Fig. 17 WIPER LINKAGE

1 - MOTOR MOUNT PLATE

2 - WIPER LINKAGE

3 - WIPER UNIT

8R - 10 WIPERS/WASHERSRS

WIPER BLADE ELEMENTS (Continued)

ProCarManuals.com

Page 618 of 2321

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION...... 8Wa-01-1

COMPONENT INDEX................. 8Wa-02-1

POWER DISTRIBUTION.............. 8Wa-10-1

GROUND DISTRIBUTION............. 8Wa-15-1

BUS COMMUNICATIONS............. 8Wa-18-1

CHARGING SYSTEM................. 8Wa-20-1

STARTING SYSTEM................. 8Wa-21-1

FUEL/IGNITION SYSTEM............. 8Wa-30-1

TRANSMISSION CONTROL SYSTEM.... 8Wa-31-1

VEHICLE SPEED CONTROL........... 8Wa-33-1

ANTILOCK BRAKES.................. 8Wa-35-1

VEHICLE THEFT SECURITY SYSTEM.... 8Wa-39-1

INSTRUMENT CLUSTER.............. 8Wa-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . 8Wa-41-1

AIR CONDITIONING-HEATER.......... 8Wa-42-1

AIRBAG SYSTEM................... 8Wa-43-1

INTERIOR LIGHTING................. 8Wa-44-1

BODY CONTROL MODULE............ 8Wa-45-1MESSAGE CENTER.................. 8Wa-46-1

AUDIO SYSTEM.................... 8Wa-47-1

REAR WINDOW DEFOGGER........... 8Wa-48-1

OVERHEAD CONSOLE................ 8Wa-49-1

FRONT LIGHTING................... 8Wa-50-1

REAR LIGHTING.................... 8Wa-51-1

TURN SIGNALS..................... 8Wa-52-1

WIPERS........................... 8Wa-53-1

TRAILER TOW...................... 8Wa-54-1

POWER WINDOWS.................. 8Wa-60-1

POWER DOOR LOCKS............... 8Wa-61-1

POWER MIRRORS.................. 8Wa-62-1

POWER SEATS..................... 8Wa-63-1

SPLICE INFORMATION............... 8Wa-70-1

CONNECTOR PIN-OUTS.............. 8Wa-80-1

CONNECTOR/GROUND LOCATIONS BUX . 8Wa-90-1

SPLICE LOCATIONS BUX............. 8Wa-95-1 RGWIRING

8Wa-1

ProCarManuals.com

Page 619 of 2321

ProCarManuals.com

Page 620 of 2321

8W-01 WIRING DIAGRAM INFORMATION

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION

DESCRIPTION............................1

WARNING...............................5

DIAGNOSIS AND TESTING..................5

WIRING HARNESS......................5

STANDARD PROCEDURE...................6

TESTING OF VOLTAGE POTENTIAL.........6

TESTING FOR CONTINUITY...............6

TESTING FOR SHORT TO GROUND.........6

TESTING FOR A SHORT TO GROUND ON

FUSES POWERING SEVERAL LOADS........7

TESTING FOR VOLTAGE DROP............7

SPECIAL TOOLS..........................8

CONNECTOR - AUGAT

REMOVAL...............................8

INSTALLATION............................8CONNECTOR - MOLEX

REMOVAL...............................9

INSTALLATION............................9

CONNECTOR - THOMAS AND BETTS

REMOVAL...............................9

INSTALLATION...........................10

DIODE

REMOVAL..............................10

INSTALLATION...........................10

TERMINAL

REMOVAL..............................11

INSTALLATION...........................11

WIRE

STANDARD PROCEDURE..................11

STANDARD PROCEDURE - WIRE SPLICING . . 11

WIRING DIAGRAM

INFORMATION

DESCRIPTION - HOW TO USE WIRING

DIAGRAMS

DaimlerChrysler Corporation wiring diagrams are

designed to provide information regarding the vehi-

cles wiring content. In order to effectively use the

wiring diagrams to diagnose and repair

DaimlerChrysler Corporation vehicles, it is important

to understand all of their features and characteris-

tics.

Diagrams are arranged such that the power (B+)

side of the circuit is placed near the top of the page,

and the ground (B-) side of the circuit is placed near

the bottom of the page (Fig. 1).

All switches, components, and modules are shown

in the at rest position with the doors closed and the

key removed from the ignition (Fig. 2).Components are shown two ways. A solid line

around a component indicates that the component is

complete. A dashed line around the component indi-

cates that the component is being shown is not com-

plete. Incomplete components have a reference

number to indicate the page where the component is

shown complete.

It is important to realize that no attempt is made

on the diagrams to represent components and wiring

as they appear on the vehicle. For example, a short

piece of wire is treated the same as a long one. In

addition, switches and other components are shown

as simply as possible, with regard to function only.

SYMBOLS

International symbols are used throughout the wir-

ing diagrams. These symbols are consistent with

those being used around the world (Fig. 3).

RG8W-01 WIRING DIAGRAM INFORMATION8Wa-01-1

ProCarManuals.com