park assist DODGE TOWN AND COUNTRY 2001 Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 26 of 2321

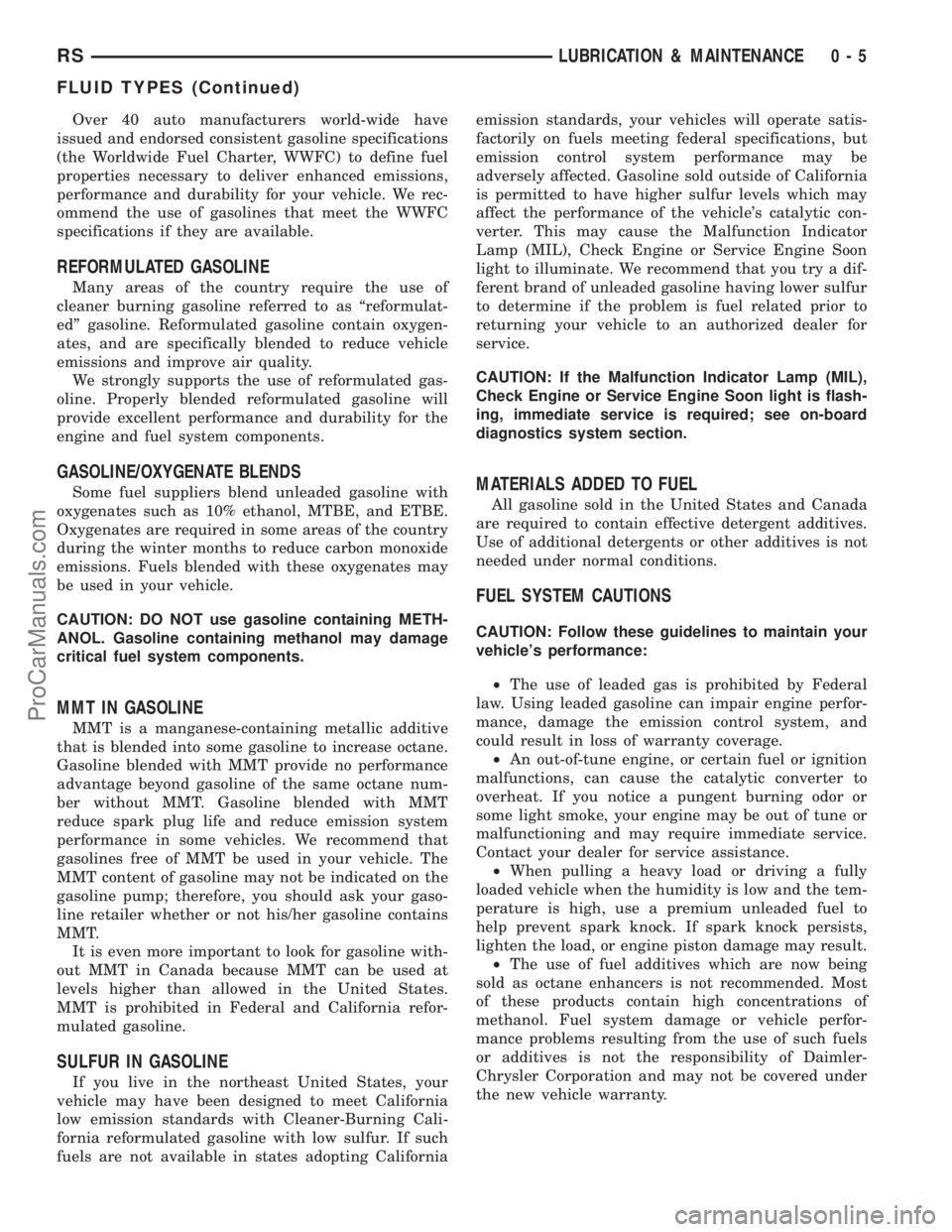

Over 40 auto manufacturers world-wide have

issued and endorsed consistent gasoline specifications

(the Worldwide Fuel Charter, WWFC) to define fuel

properties necessary to deliver enhanced emissions,

performance and durability for your vehicle. We rec-

ommend the use of gasolines that meet the WWFC

specifications if they are available.

REFORMULATED GASOLINE

Many areas of the country require the use of

cleaner burning gasoline referred to as ªreformulat-

edº gasoline. Reformulated gasoline contain oxygen-

ates, and are specifically blended to reduce vehicle

emissions and improve air quality.

We strongly supports the use of reformulated gas-

oline. Properly blended reformulated gasoline will

provide excellent performance and durability for the

engine and fuel system components.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

oxygenates such as 10% ethanol, MTBE, and ETBE.

Oxygenates are required in some areas of the country

during the winter months to reduce carbon monoxide

emissions. Fuels blended with these oxygenates may

be used in your vehicle.

CAUTION: DO NOT use gasoline containing METH-

ANOL. Gasoline containing methanol may damage

critical fuel system components.

MMT IN GASOLINE

MMT is a manganese-containing metallic additive

that is blended into some gasoline to increase octane.

Gasoline blended with MMT provide no performance

advantage beyond gasoline of the same octane num-

ber without MMT. Gasoline blended with MMT

reduce spark plug life and reduce emission system

performance in some vehicles. We recommend that

gasolines free of MMT be used in your vehicle. The

MMT content of gasoline may not be indicated on the

gasoline pump; therefore, you should ask your gaso-

line retailer whether or not his/her gasoline contains

MMT.

It is even more important to look for gasoline with-

out MMT in Canada because MMT can be used at

levels higher than allowed in the United States.

MMT is prohibited in Federal and California refor-

mulated gasoline.

SULFUR IN GASOLINE

If you live in the northeast United States, your

vehicle may have been designed to meet California

low emission standards with Cleaner-Burning Cali-

fornia reformulated gasoline with low sulfur. If such

fuels are not available in states adopting Californiaemission standards, your vehicles will operate satis-

factorily on fuels meeting federal specifications, but

emission control system performance may be

adversely affected. Gasoline sold outside of California

is permitted to have higher sulfur levels which may

affect the performance of the vehicle's catalytic con-

verter. This may cause the Malfunction Indicator

Lamp (MIL), Check Engine or Service Engine Soon

light to illuminate. We recommend that you try a dif-

ferent brand of unleaded gasoline having lower sulfur

to determine if the problem is fuel related prior to

returning your vehicle to an authorized dealer for

service.

CAUTION: If the Malfunction Indicator Lamp (MIL),

Check Engine or Service Engine Soon light is flash-

ing, immediate service is required; see on-board

diagnostics system section.

MATERIALS ADDED TO FUEL

All gasoline sold in the United States and Canada

are required to contain effective detergent additives.

Use of additional detergents or other additives is not

needed under normal conditions.

FUEL SYSTEM CAUTIONS

CAUTION: Follow these guidelines to maintain your

vehicle's performance:

²The use of leaded gas is prohibited by Federal

law. Using leaded gasoline can impair engine perfor-

mance, damage the emission control system, and

could result in loss of warranty coverage.

²An out-of-tune engine, or certain fuel or ignition

malfunctions, can cause the catalytic converter to

overheat. If you notice a pungent burning odor or

some light smoke, your engine may be out of tune or

malfunctioning and may require immediate service.

Contact your dealer for service assistance.

²When pulling a heavy load or driving a fully

loaded vehicle when the humidity is low and the tem-

perature is high, use a premium unleaded fuel to

help prevent spark knock. If spark knock persists,

lighten the load, or engine piston damage may result.

²The use of fuel additives which are now being

sold as octane enhancers is not recommended. Most

of these products contain high concentrations of

methanol. Fuel system damage or vehicle perfor-

mance problems resulting from the use of such fuels

or additives is not the responsibility of Daimler-

Chrysler Corporation and may not be covered under

the new vehicle warranty.

RSLUBRICATION & MAINTENANCE0-5

FLUID TYPES (Continued)

ProCarManuals.com

Page 164 of 2321

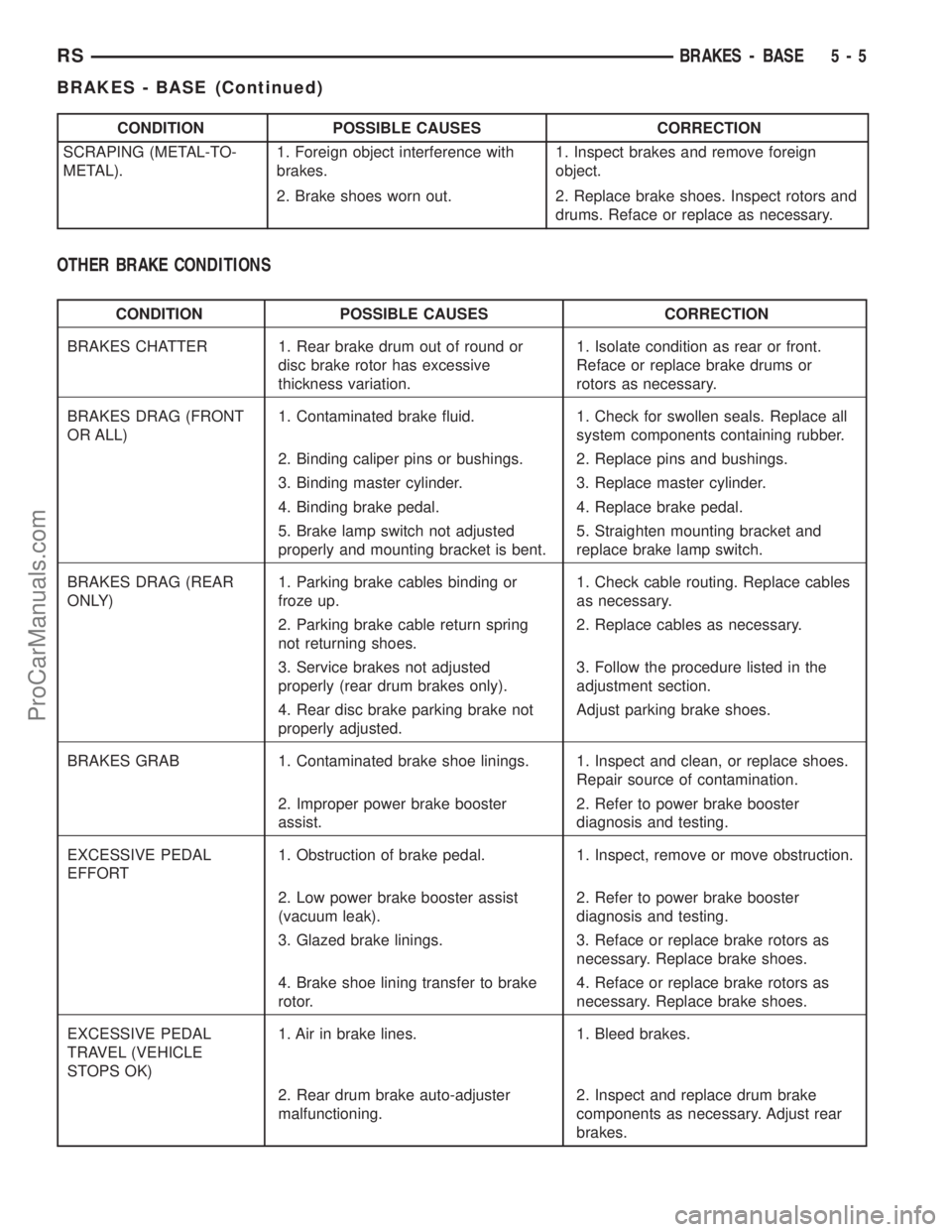

CONDITION POSSIBLE CAUSES CORRECTION

SCRAPING (METAL-TO-

METAL).1. Foreign object interference with

brakes.1. Inspect brakes and remove foreign

object.

2. Brake shoes worn out. 2. Replace brake shoes. Inspect rotors and

drums. Reface or replace as necessary.

OTHER BRAKE CONDITIONS

CONDITION POSSIBLE CAUSES CORRECTION

BRAKES CHATTER 1. Rear brake drum out of round or

disc brake rotor has excessive

thickness variation.1. Isolate condition as rear or front.

Reface or replace brake drums or

rotors as necessary.

BRAKES DRAG (FRONT

OR ALL)1. Contaminated brake fluid. 1. Check for swollen seals. Replace all

system components containing rubber.

2. Binding caliper pins or bushings. 2. Replace pins and bushings.

3. Binding master cylinder. 3. Replace master cylinder.

4. Binding brake pedal. 4. Replace brake pedal.

5. Brake lamp switch not adjusted

properly and mounting bracket is bent.5. Straighten mounting bracket and

replace brake lamp switch.

BRAKES DRAG (REAR

ONLY)1. Parking brake cables binding or

froze up.1. Check cable routing. Replace cables

as necessary.

2. Parking brake cable return spring

not returning shoes.2. Replace cables as necessary.

3. Service brakes not adjusted

properly (rear drum brakes only).3. Follow the procedure listed in the

adjustment section.

4. Rear disc brake parking brake not

properly adjusted.Adjust parking brake shoes.

BRAKES GRAB 1. Contaminated brake shoe linings. 1. Inspect and clean, or replace shoes.

Repair source of contamination.

2. Improper power brake booster

assist.2. Refer to power brake booster

diagnosis and testing.

EXCESSIVE PEDAL

EFFORT1. Obstruction of brake pedal. 1. Inspect, remove or move obstruction.

2. Low power brake booster assist

(vacuum leak).2. Refer to power brake booster

diagnosis and testing.

3. Glazed brake linings. 3. Reface or replace brake rotors as

necessary. Replace brake shoes.

4. Brake shoe lining transfer to brake

rotor.4. Reface or replace brake rotors as

necessary. Replace brake shoes.

EXCESSIVE PEDAL

TRAVEL (VEHICLE

STOPS OK)1. Air in brake lines. 1. Bleed brakes.

2. Rear drum brake auto-adjuster

malfunctioning.2. Inspect and replace drum brake

components as necessary. Adjust rear

brakes.

RSBRAKES - BASE5-5

BRAKES - BASE (Continued)

ProCarManuals.com

Page 165 of 2321

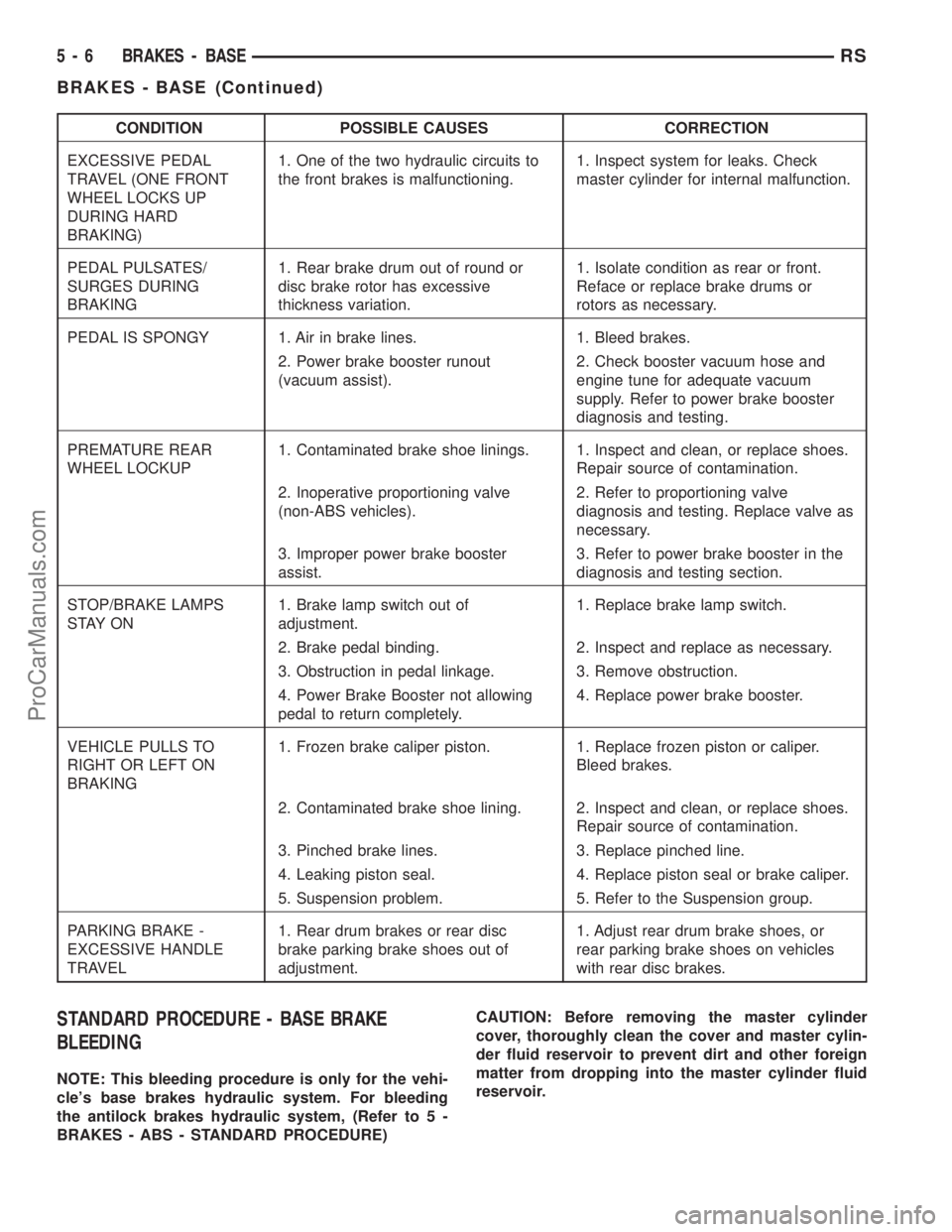

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE PEDAL

TRAVEL (ONE FRONT

WHEEL LOCKS UP

DURING HARD

BRAKING)1. One of the two hydraulic circuits to

the front brakes is malfunctioning.1. Inspect system for leaks. Check

master cylinder for internal malfunction.

PEDAL PULSATES/

SURGES DURING

BRAKING1. Rear brake drum out of round or

disc brake rotor has excessive

thickness variation.1. Isolate condition as rear or front.

Reface or replace brake drums or

rotors as necessary.

PEDAL IS SPONGY 1. Air in brake lines. 1. Bleed brakes.

2. Power brake booster runout

(vacuum assist).2. Check booster vacuum hose and

engine tune for adequate vacuum

supply. Refer to power brake booster

diagnosis and testing.

PREMATURE REAR

WHEEL LOCKUP1. Contaminated brake shoe linings. 1. Inspect and clean, or replace shoes.

Repair source of contamination.

2. Inoperative proportioning valve

(non-ABS vehicles).2. Refer to proportioning valve

diagnosis and testing. Replace valve as

necessary.

3. Improper power brake booster

assist.3. Refer to power brake booster in the

diagnosis and testing section.

STOP/BRAKE LAMPS

S TAY O N1. Brake lamp switch out of

adjustment.1. Replace brake lamp switch.

2. Brake pedal binding. 2. Inspect and replace as necessary.

3. Obstruction in pedal linkage. 3. Remove obstruction.

4. Power Brake Booster not allowing

pedal to return completely.4. Replace power brake booster.

VEHICLE PULLS TO

RIGHT OR LEFT ON

BRAKING1. Frozen brake caliper piston. 1. Replace frozen piston or caliper.

Bleed brakes.

2. Contaminated brake shoe lining. 2. Inspect and clean, or replace shoes.

Repair source of contamination.

3. Pinched brake lines. 3. Replace pinched line.

4. Leaking piston seal. 4. Replace piston seal or brake caliper.

5. Suspension problem. 5. Refer to the Suspension group.

PARKING BRAKE -

EXCESSIVE HANDLE

TRAVEL1. Rear drum brakes or rear disc

brake parking brake shoes out of

adjustment.1. Adjust rear drum brake shoes, or

rear parking brake shoes on vehicles

with rear disc brakes.

STANDARD PROCEDURE - BASE BRAKE

BLEEDING

NOTE: This bleeding procedure is only for the vehi-

cle's base brakes hydraulic system. For bleeding

the antilock brakes hydraulic system, (Refer to 5 -

BRAKES - ABS - STANDARD PROCEDURE)CAUTION: Before removing the master cylinder

cover, thoroughly clean the cover and master cylin-

der fluid reservoir to prevent dirt and other foreign

matter from dropping into the master cylinder fluid

reservoir.

5 - 6 BRAKES - BASERS

BRAKES - BASE (Continued)

ProCarManuals.com

Page 395 of 2321

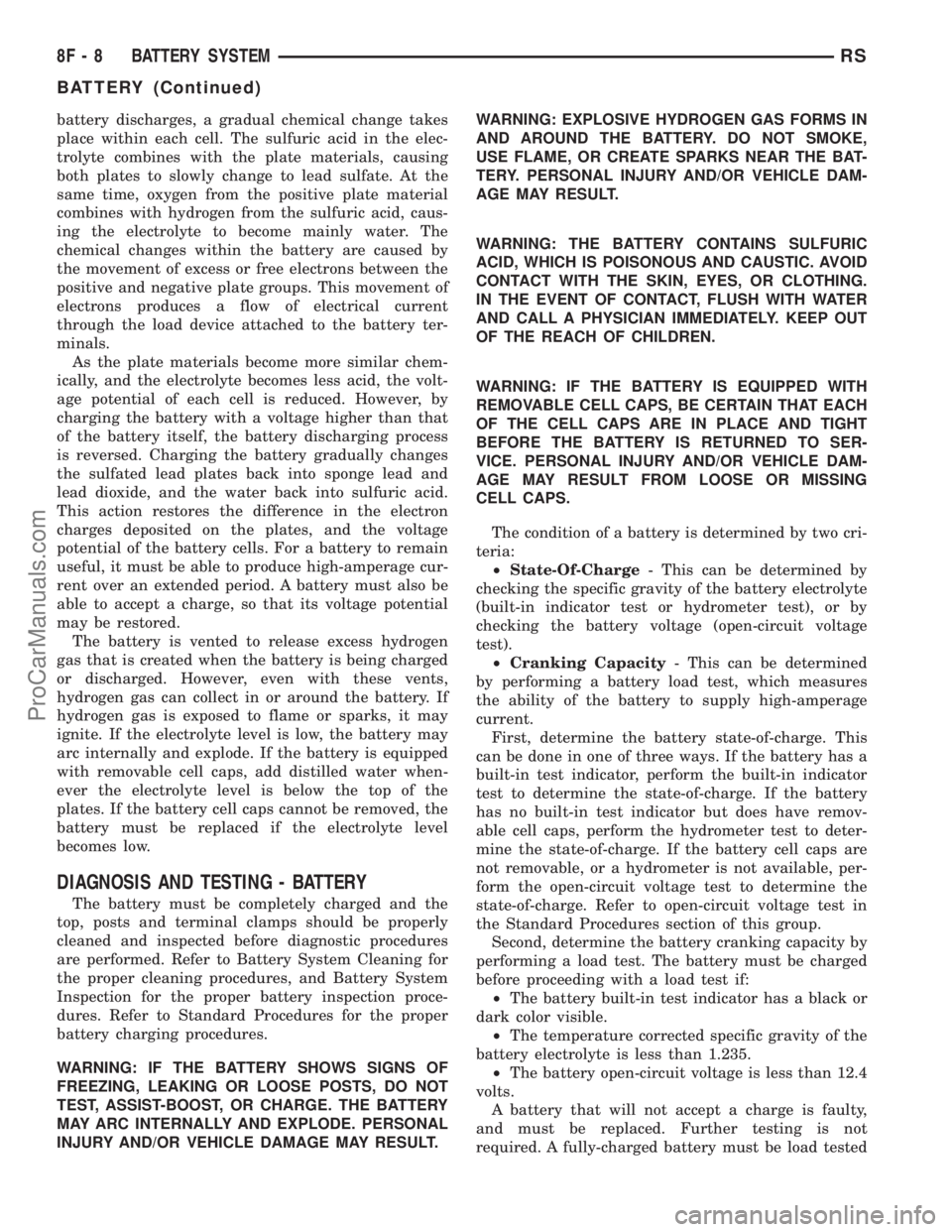

battery discharges, a gradual chemical change takes

place within each cell. The sulfuric acid in the elec-

trolyte combines with the plate materials, causing

both plates to slowly change to lead sulfate. At the

same time, oxygen from the positive plate material

combines with hydrogen from the sulfuric acid, caus-

ing the electrolyte to become mainly water. The

chemical changes within the battery are caused by

the movement of excess or free electrons between the

positive and negative plate groups. This movement of

electrons produces a flow of electrical current

through the load device attached to the battery ter-

minals.

As the plate materials become more similar chem-

ically, and the electrolyte becomes less acid, the volt-

age potential of each cell is reduced. However, by

charging the battery with a voltage higher than that

of the battery itself, the battery discharging process

is reversed. Charging the battery gradually changes

the sulfated lead plates back into sponge lead and

lead dioxide, and the water back into sulfuric acid.

This action restores the difference in the electron

charges deposited on the plates, and the voltage

potential of the battery cells. For a battery to remain

useful, it must be able to produce high-amperage cur-

rent over an extended period. A battery must also be

able to accept a charge, so that its voltage potential

may be restored.

The battery is vented to release excess hydrogen

gas that is created when the battery is being charged

or discharged. However, even with these vents,

hydrogen gas can collect in or around the battery. If

hydrogen gas is exposed to flame or sparks, it may

ignite. If the electrolyte level is low, the battery may

arc internally and explode. If the battery is equipped

with removable cell caps, add distilled water when-

ever the electrolyte level is below the top of the

plates. If the battery cell caps cannot be removed, the

battery must be replaced if the electrolyte level

becomes low.

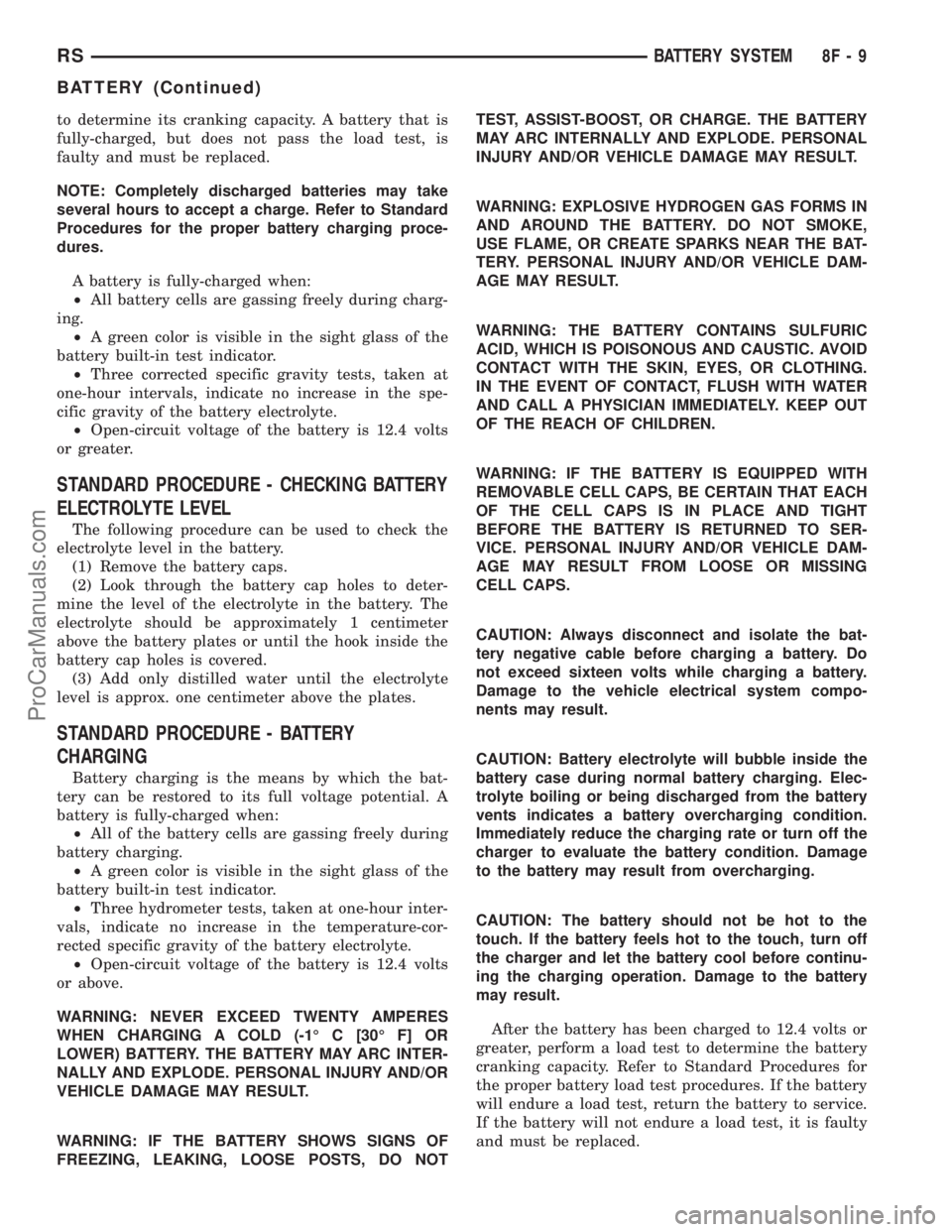

DIAGNOSIS AND TESTING - BATTERY

The battery must be completely charged and the

top, posts and terminal clamps should be properly

cleaned and inspected before diagnostic procedures

are performed. Refer to Battery System Cleaning for

the proper cleaning procedures, and Battery System

Inspection for the proper battery inspection proce-

dures. Refer to Standard Procedures for the proper

battery charging procedures.

WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING OR LOOSE POSTS, DO NOT

TEST, ASSIST-BOOST, OR CHARGE. THE BATTERY

MAY ARC INTERNALLY AND EXPLODE. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BAT-

TERY. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT.

WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

WARNING: IF THE BATTERY IS EQUIPPED WITH

REMOVABLE CELL CAPS, BE CERTAIN THAT EACH

OF THE CELL CAPS ARE IN PLACE AND TIGHT

BEFORE THE BATTERY IS RETURNED TO SER-

VICE. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT FROM LOOSE OR MISSING

CELL CAPS.

The condition of a battery is determined by two cri-

teria:

²State-Of-Charge- This can be determined by

checking the specific gravity of the battery electrolyte

(built-in indicator test or hydrometer test), or by

checking the battery voltage (open-circuit voltage

test).

²Cranking Capacity- This can be determined

by performing a battery load test, which measures

the ability of the battery to supply high-amperage

current.

First, determine the battery state-of-charge. This

can be done in one of three ways. If the battery has a

built-in test indicator, perform the built-in indicator

test to determine the state-of-charge. If the battery

has no built-in test indicator but does have remov-

able cell caps, perform the hydrometer test to deter-

mine the state-of-charge. If the battery cell caps are

not removable, or a hydrometer is not available, per-

form the open-circuit voltage test to determine the

state-of-charge. Refer to open-circuit voltage test in

the Standard Procedures section of this group.

Second, determine the battery cranking capacity by

performing a load test. The battery must be charged

before proceeding with a load test if:

²The battery built-in test indicator has a black or

dark color visible.

²The temperature corrected specific gravity of the

battery electrolyte is less than 1.235.

²The battery open-circuit voltage is less than 12.4

volts.

A battery that will not accept a charge is faulty,

and must be replaced. Further testing is not

required. A fully-charged battery must be load tested

8F - 8 BATTERY SYSTEMRS

BATTERY (Continued)

ProCarManuals.com

Page 396 of 2321

to determine its cranking capacity. A battery that is

fully-charged, but does not pass the load test, is

faulty and must be replaced.

NOTE: Completely discharged batteries may take

several hours to accept a charge. Refer to Standard

Procedures for the proper battery charging proce-

dures.

A battery is fully-charged when:

²All battery cells are gassing freely during charg-

ing.

²A green color is visible in the sight glass of the

battery built-in test indicator.

²Three corrected specific gravity tests, taken at

one-hour intervals, indicate no increase in the spe-

cific gravity of the battery electrolyte.

²Open-circuit voltage of the battery is 12.4 volts

or greater.

STANDARD PROCEDURE - CHECKING BATTERY

ELECTROLYTE LEVEL

The following procedure can be used to check the

electrolyte level in the battery.

(1) Remove the battery caps.

(2) Look through the battery cap holes to deter-

mine the level of the electrolyte in the battery. The

electrolyte should be approximately 1 centimeter

above the battery plates or until the hook inside the

battery cap holes is covered.

(3) Add only distilled water until the electrolyte

level is approx. one centimeter above the plates.

STANDARD PROCEDURE - BATTERY

CHARGING

Battery charging is the means by which the bat-

tery can be restored to its full voltage potential. A

battery is fully-charged when:

²All of the battery cells are gassing freely during

battery charging.

²A green color is visible in the sight glass of the

battery built-in test indicator.

²Three hydrometer tests, taken at one-hour inter-

vals, indicate no increase in the temperature-cor-

rected specific gravity of the battery electrolyte.

²Open-circuit voltage of the battery is 12.4 volts

or above.

WARNING: NEVER EXCEED TWENTY AMPERES

WHEN CHARGING A COLD (-1É C [30É F] OR

LOWER) BATTERY. THE BATTERY MAY ARC INTER-

NALLY AND EXPLODE. PERSONAL INJURY AND/OR

VEHICLE DAMAGE MAY RESULT.

WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING, LOOSE POSTS, DO NOTTEST, ASSIST-BOOST, OR CHARGE. THE BATTERY

MAY ARC INTERNALLY AND EXPLODE. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BAT-

TERY. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT.

WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

WARNING: IF THE BATTERY IS EQUIPPED WITH

REMOVABLE CELL CAPS, BE CERTAIN THAT EACH

OF THE CELL CAPS IS IN PLACE AND TIGHT

BEFORE THE BATTERY IS RETURNED TO SER-

VICE. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT FROM LOOSE OR MISSING

CELL CAPS.

CAUTION: Always disconnect and isolate the bat-

tery negative cable before charging a battery. Do

not exceed sixteen volts while charging a battery.

Damage to the vehicle electrical system compo-

nents may result.

CAUTION: Battery electrolyte will bubble inside the

battery case during normal battery charging. Elec-

trolyte boiling or being discharged from the battery

vents indicates a battery overcharging condition.

Immediately reduce the charging rate or turn off the

charger to evaluate the battery condition. Damage

to the battery may result from overcharging.

CAUTION: The battery should not be hot to the

touch. If the battery feels hot to the touch, turn off

the charger and let the battery cool before continu-

ing the charging operation. Damage to the battery

may result.

After the battery has been charged to 12.4 volts or

greater, perform a load test to determine the battery

cranking capacity. Refer to Standard Procedures for

the proper battery load test procedures. If the battery

will endure a load test, return the battery to service.

If the battery will not endure a load test, it is faulty

and must be replaced.

RSBATTERY SYSTEM8F-9

BATTERY (Continued)

ProCarManuals.com

Page 636 of 2321

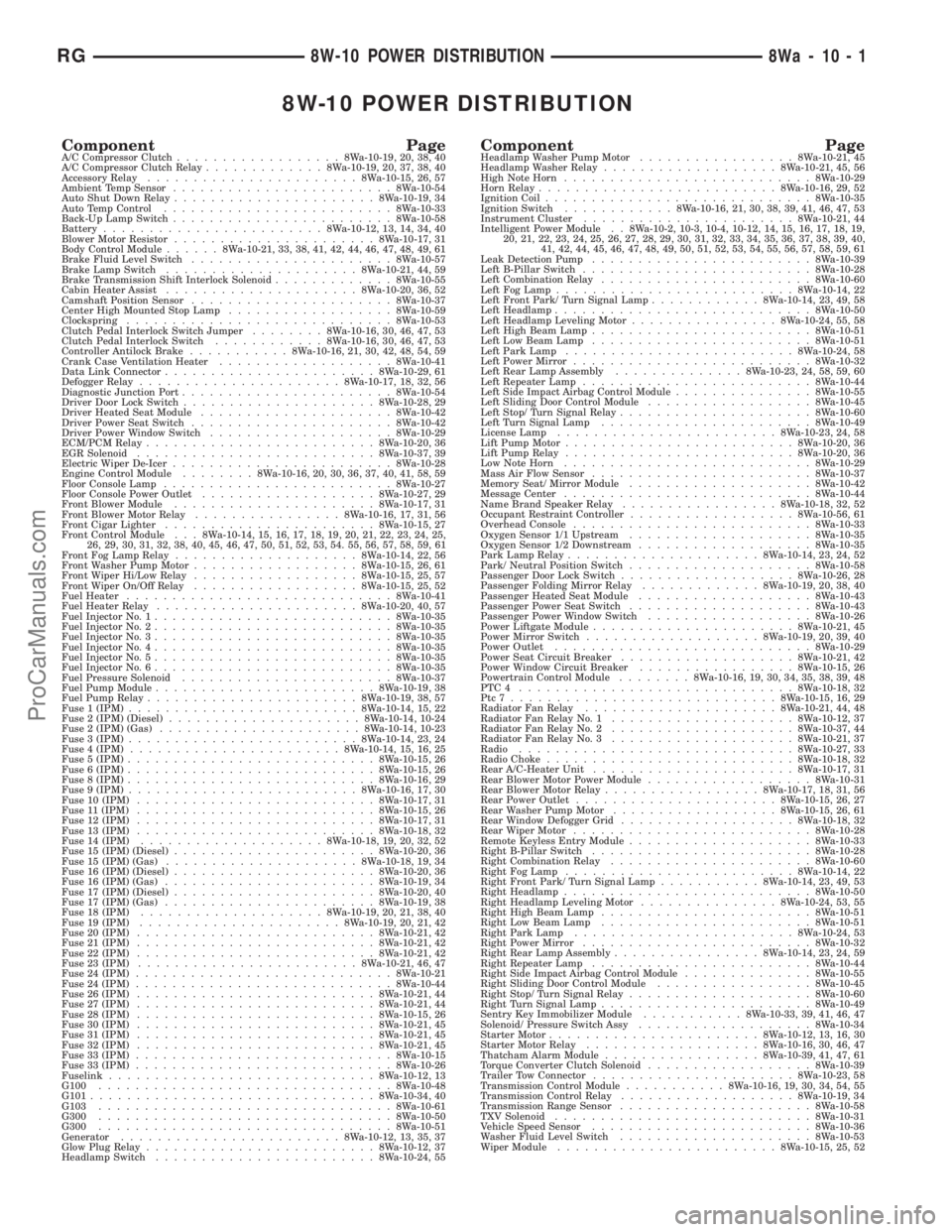

8W-10 POWER DISTRIBUTION

Component PageA/C Compressor Clutch..................8Wa-10-19, 20, 38, 40

A/C Compressor Clutch Relay.............8Wa-10-19, 20, 37, 38, 40

Accessory Relay.......................8Wa-10-15, 26, 57

Ambient Temp Sensor........................8Wa-10-54

Auto Shut Down Relay......................8Wa-10-19, 34

Auto Temp Control.........................8Wa-10-33

Back-Up Lamp Switch........................8Wa-10-58

Battery........................8Wa-10-12, 13, 14, 34, 40

Blower Motor Resistor......................8Wa-10-17, 31

Body Control Module......8Wa-10-21, 33, 38, 41, 42, 44, 46, 47, 48, 49, 61

Brake Fluid Level Switch......................8Wa-10-57

Brake Lamp Switch.....................8Wa-10-21, 44, 59

Brake Transmission Shift Interlock Solenoid.............8Wa-10-55

Cabin Heater Assist.....................8Wa-10-20, 36, 52

Camshaft Position Sensor......................8Wa-10-37

Center High Mounted Stop Lamp..................8Wa-10-59

Clockspring.............................8Wa-10-53

Clutch Pedal Interlock Switch Jumper........8Wa-10-16, 30, 46, 47, 53

Clutch Pedal Interlock Switch............8Wa-10-16, 30, 46, 47, 53

Controller Antilock Brake...........8Wa-10-16, 21, 30, 42, 48, 54, 59

Crank Case Ventilation Heater...................8Wa-10-41

Data Link Connector.......................8Wa-10-29, 61

Defogger Relay......................8Wa-10-17, 18, 32, 56

Diagnostic Junction Port.......................8Wa-10-54

Driver Door Lock Switch.....................8Wa-10-28, 29

Driver Heated Seat Module.....................8Wa-10-42

Driver Power Seat Switch......................8Wa-10-42

Driver Power Window Switch....................8Wa-10-29

ECM/PCM Relay.........................8Wa-10-20, 36

EGR Solenoid..........................8Wa-10-37, 39

Electric Wiper De-Icer........................8Wa-10-28

Engine Control Module........8Wa-10-16, 20, 30, 36, 37, 40, 41, 58, 59

Floor Console Lamp.........................8Wa-10-27

Floor Console Power Outlet...................8Wa-10-27, 29

Front Blower Module......................8Wa-10-17, 31

Front Blower Motor Relay................8Wa-10-16, 17, 31, 56

Front Cigar Lighter.......................8Wa-10-15, 27

Front Control Module . . . 8Wa-10-14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25,

26, 29, 30, 31, 32, 38, 40, 45, 46, 47, 50, 51, 52, 53, 54. 55, 56, 57, 58, 59, 61

Front Fog Lamp Relay....................8Wa-10-14, 22, 56

Front Washer Pump Motor..................8Wa-10-15, 26, 61

Front Wiper Hi/Low Relay..................8Wa-10-15, 25, 57

Front Wiper On/Off Relay..................8Wa-10-15, 25, 52

Fuel Heater.............................8Wa-10-41

Fuel Heater Relay......................8Wa-10-20, 40, 57

Fuel Injector No. 1..........................8Wa-10-35

Fuel Injector No. 2..........................8Wa-10-35

Fuel Injector No. 3..........................8Wa-10-35

Fuel Injector No. 4..........................8Wa-10-35

Fuel Injector No. 5..........................8Wa-10-35

Fuel Injector No. 6..........................8Wa-10-35

Fuel Pressure Solenoid.......................8Wa-10-37

Fuel Pump Module........................8Wa-10-19, 38

Fuel Pump Relay.......................8Wa-10-19, 38, 57

Fuse 1 (IPM).........................8Wa-10-14, 15, 22

Fuse 2 (IPM) (Diesel).....................8Wa-10-14, 10-24

Fuse 2 (IPM) (Gas)......................8Wa-10-14, 10-23

Fuse 3 (IPM).........................8Wa-10-14, 23, 24

Fuse 4 (IPM).......................8Wa-10-14, 15, 16, 25

Fuse 5 (IPM)...........................8Wa-10-15, 26

Fuse 6 (IPM)...........................8Wa-10-15, 26

Fuse 8 (IPM)...........................8Wa-10-16, 29

Fuse 9 (IPM).........................8Wa-10-16, 17, 30

Fuse 10 (IPM)..........................8Wa-10-17, 31

Fuse 11 (IPM)..........................8Wa-10-15, 26

Fuse 12 (IPM)..........................8Wa-10-17, 31

Fuse 13 (IPM)..........................8Wa-10-18, 32

Fuse 14 (IPM)....................8Wa-10-18, 19, 20, 32, 52

Fuse 15 (IPM) (Diesel)......................8Wa-10-20, 36

Fuse 15 (IPM) (Gas).....................8Wa-10-18, 19, 34

Fuse 16 (IPM) (Diesel)......................8Wa-10-20, 36

Fuse 16 (IPM) (Gas).......................8Wa-10-19, 34

Fuse 17 (IPM) (Diesel)......................8Wa-10-20, 40

Fuse 17 (IPM) (Gas).......................8Wa-10-19, 38

Fuse 18 (IPM)....................8Wa-10-19, 20, 21, 38, 40

Fuse 19 (IPM)......................8Wa-10-19, 20, 21, 42

Fuse 20 (IPM)..........................8Wa-10-21, 42

Fuse 21 (IPM)..........................8Wa-10-21, 42

Fuse 22 (IPM)..........................8Wa-10-21, 42

Fuse 23 (IPM)........................8Wa-10-21, 46, 47

Fuse 24 (IPM)............................8Wa-10-21

Fuse 24 (IPM)............................8Wa-10-44

Fuse 26 (IPM)..........................8Wa-10-21, 44

Fuse 27 (IPM)..........................8Wa-10-21, 44

Fuse 28 (IPM)..........................8Wa-10-15, 26

Fuse 30 (IPM)..........................8Wa-10-21, 45

Fuse 31 (IPM)..........................8Wa-10-21, 45

Fuse 32 (IPM)..........................8Wa-10-21, 45

Fuse 33 (IPM)............................8Wa-10-15

Fuse 33 (IPM)............................8Wa-10-26

Fuselink.............................8Wa-10-12, 13

G100................................8Wa-10-48

G101...............................8Wa-10-34, 40

G103................................8Wa-10-61

G300................................8Wa-10-50

G300................................8Wa-10-51

Generator........................8Wa-10-12, 13, 35, 37

Glow Plug Relay.........................8Wa-10-12, 37

Headlamp Switch........................8Wa-10-24, 55Component PageHeadlamp Washer Pump Motor.................8Wa-10-21, 45

Headlamp Washer Relay...................8Wa-10-21, 45, 56

High Note Horn...........................8Wa-10-29

Horn Relay..........................8Wa-10-16, 29, 52

Ignition Coil.............................8Wa-10-35

Ignition Switch............8Wa-10-16, 21, 30, 38, 39, 41, 46, 47, 53

Instrument Cluster.......................8Wa-10-21, 44

Intelligent Power Module . . 8Wa-10-2, 10-3, 10-4, 10-12, 14, 15, 16, 17, 18, 19,

20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38, 39, 40,

41, 42, 44, 45, 46, 47, 48, 49, 50, 51, 52, 53, 54, 55, 56, 57, 58, 59, 61

Leak Detection Pump........................8Wa-10-39

Left B-Pillar Switch.........................8Wa-10-28

Left Combination Relay.......................8Wa-10-60

Left Fog Lamp..........................8Wa-10-14, 22

Left Front Park/ Turn Signal Lamp............8Wa-10-14, 23, 49, 58

Left Headlamp............................8Wa-10-50

Left Headlamp Leveling Motor................8Wa-10-24, 55, 58

Left High Beam Lamp........................8Wa-10-51

Left Low Beam Lamp........................8Wa-10-51

Left Park Lamp.........................8Wa-10-24, 58

Left Power Mirror..........................8Wa-10-32

Left Rear Lamp Assembly..............8Wa-10-23, 24, 58, 59, 60

Left Repeater Lamp.........................8Wa-10-44

Left Side Impact Airbag Control Module...............8Wa-10-55

Left Sliding Door Control Module..................8Wa-10-45

Left Stop/ Turn Signal Relay.....................8Wa-10-60

Left Turn Signal Lamp.......................8Wa-10-49

License Lamp........................8Wa-10-23, 24, 58

Lift Pump Motor.........................8Wa-10-20, 36

Lift Pump Relay.........................8Wa-10-20, 36

Low Note Horn...........................8Wa-10-29

Mass Air Flow Sensor........................8Wa-10-37

Memory Seat/ Mirror Module....................8Wa-10-42

Message Center...........................8Wa-10-44

Name Brand Speaker Relay.................8Wa-10-18, 32, 52

Occupant Restraint Controller..................8Wa-10-56, 61

Overhead Console..........................8Wa-10-33

Oxygen Sensor 1/1 Upstream....................8Wa-10-35

Oxygen Sensor 1/2 Downstream...................8Wa-10-35

Park Lamp Relay.....................8Wa-10-14, 23, 24, 52

Park/ Neutral Position Switch....................8Wa-10-58

Passenger Door Lock Switch...................8Wa-10-26, 28

Passenger Folding Mirror Relay.............8Wa-10-19, 20, 38, 40

Passenger Heated Seat Module...................8Wa-10-43

Passenger Power Seat Switch....................8Wa-10-43

Passenger Power Window Switch..................8Wa-10-26

Power Liftgate Module......................8Wa-10-21, 45

Power Mirror Switch...................8Wa-10-19, 20, 39, 40

Power Outlet............................8Wa-10-29

Power Seat Circuit Breaker...................8Wa-10-21, 42

Power Window Circuit Breaker.................8Wa-10-15, 26

Powertrain Control Module........8Wa-10-16, 19, 30, 34, 35, 38, 39, 48

PTC4 ..............................8Wa-10-18, 32

Ptc7.............................8Wa-10-15, 16, 29

Radiator Fan Relay.....................8Wa-10-21, 44, 48

Radiator Fan Relay No. 1....................8Wa-10-12, 37

Radiator Fan Relay No. 2....................8Wa-10-37, 44

Radiator Fan Relay No. 3....................8Wa-10-21, 37

Radio..............................8Wa-10-27, 33

Radio Choke...........................8Wa-10-18, 32

Rear A/C-Heater Unit......................8Wa-10-17, 31

Rear Blower Motor Power Module..................8Wa-10-31

Rear Blower Motor Relay.................8Wa-10-17, 18, 31, 56

Rear Power Outlet......................8Wa-10-15, 26, 27

Rear Washer Pump Motor..................8Wa-10-15, 26, 61

Rear Window Defogger Grid...................8Wa-10-18, 32

Rear Wiper Motor..........................8Wa-10-28

Remote Keyless Entry Module....................8Wa-10-33

Right B-Pillar Switch........................8Wa-10-28

Right Combination Relay......................8Wa-10-60

Right Fog Lamp.........................8Wa-10-14, 22

Right Front Park/ Turn Signal Lamp...........8Wa-10-14, 23, 49, 53

Right Headlamp...........................8Wa-10-50

Right Headlamp Leveling Motor...............8Wa-10-24, 53, 55

Right High Beam Lamp.......................8Wa-10-51

Right Low Beam Lamp.......................8Wa-10-51

Right Park Lamp........................8Wa-10-24, 53

Right Power Mirror.........................8Wa-10-32

Right Rear Lamp Assembly................8Wa-10-14, 23, 24, 59

Right Repeater Lamp........................8Wa-10-44

Right Side Impact Airbag Control Module..............8Wa-10-55

Right Sliding Door Control Module.................8Wa-10-45

Right Stop/ Turn Signal Relay....................8Wa-10-60

Right Turn Signal Lamp.......................8Wa-10-49

Sentry Key Immobilizer Module...........8Wa-10-33, 39, 41, 46, 47

Solenoid/ Pressure Switch Assy...................8Wa-10-34

Starter Motor.......................8Wa-10-12, 13, 16, 30

Starter Motor Relay...................8Wa-10-16, 30, 46, 47

Thatcham Alarm Module.................8Wa-10-39, 41, 47, 61

Torque Converter Clutch Solenoid..................8Wa-10-39

Trailer Tow Connector......................8Wa-10-23, 58

Transmission Control Module...........8Wa-10-16, 19, 30, 34, 54, 55

Transmission Control Relay...................8Wa-10-19, 34

Transmission Range Sensor.....................8Wa-10-58

TXV Solenoid............................8Wa-10-31

Vehicle Speed Sensor........................8Wa-10-36

Washer Fluid Level Switch.....................8Wa-10-53

Wiper Module........................8Wa-10-15, 25, 52

RG8W-10 POWER DISTRIBUTION8Wa-10-1

ProCarManuals.com

Page 698 of 2321

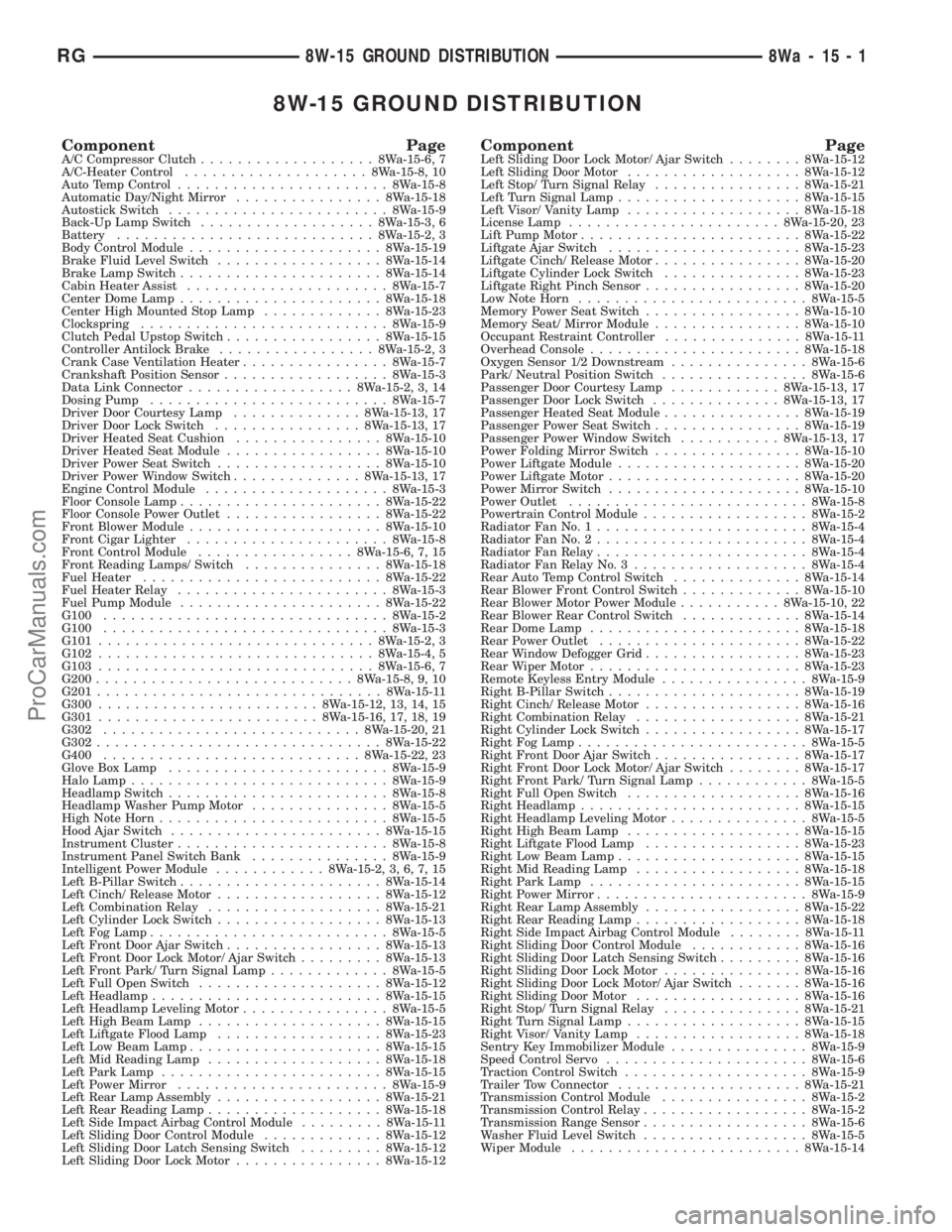

8W-15 GROUND DISTRIBUTION

Component PageA/C Compressor Clutch...................8Wa-15-6, 7

A/C-Heater Control....................8Wa-15-8, 10

Auto Temp Control.......................8Wa-15-8

Automatic Day/Night Mirror................8Wa-15-18

Autostick Switch........................8Wa-15-9

Back-Up Lamp Switch...................8Wa-15-3, 6

Battery............................8Wa-15-2, 3

Body Control Module.....................8Wa-15-19

Brake Fluid Level Switch..................8Wa-15-14

Brake Lamp Switch......................8Wa-15-14

Cabin Heater Assist......................8Wa-15-7

Center Dome Lamp......................8Wa-15-18

Center High Mounted Stop Lamp.............8Wa-15-23

Clockspring...........................8Wa-15-9

Clutch Pedal Upstop Switch.................8Wa-15-15

Controller Antilock Brake.................8Wa-15-2, 3

Crank Case Ventilation Heater................8Wa-15-7

Crankshaft Position Sensor..................8Wa-15-3

Data Link Connector..................8Wa-15-2, 3, 14

Dosing Pump..........................8Wa-15-7

Driver Door Courtesy Lamp..............8Wa-15-13, 17

Driver Door Lock Switch................8Wa-15-13, 17

Driver Heated Seat Cushion................8Wa-15-10

Driver Heated Seat Module.................8Wa-15-10

Driver Power Seat Switch..................8Wa-15-10

Driver Power Window Switch..............8Wa-15-13, 17

Engine Control Module....................8Wa-15-3

Floor Console Lamp......................8Wa-15-22

Floor Console Power Outlet.................8Wa-15-22

Front Blower Module.....................8Wa-15-10

Front Cigar Lighter......................8Wa-15-8

Front Control Module.................8Wa-15-6, 7, 15

Front Reading Lamps/ Switch...............8Wa-15-18

Fuel Heater..........................8Wa-15-22

Fuel Heater Relay.......................8Wa-15-3

Fuel Pump Module......................8Wa-15-22

G100...............................8Wa-15-2

G100...............................8Wa-15-3

G101..............................8Wa-15-2, 3

G102..............................8Wa-15-4, 5

G103..............................8Wa-15-6, 7

G200............................8Wa-15-8, 9, 10

G201...............................8Wa-15-11

G300........................8Wa-15-12, 13, 14, 15

G301........................8Wa-15-16, 17, 18, 19

G302............................8Wa-15-20, 21

G302...............................8Wa-15-22

G400............................8Wa-15-22, 23

Glove Box Lamp........................8Wa-15-9

Halo Lamp............................8Wa-15-9

Headlamp Switch........................8Wa-15-8

Headlamp Washer Pump Motor...............8Wa-15-5

High Note Horn.........................8Wa-15-5

Hood Ajar Switch.......................8Wa-15-15

Instrument Cluster.......................8Wa-15-8

Instrument Panel Switch Bank...............8Wa-15-9

Intelligent Power Module............8Wa-15-2, 3, 6, 7, 15

Left B-Pillar Switch......................8Wa-15-14

Left Cinch/ Release Motor..................8Wa-15-12

Left Combination Relay...................8Wa-15-21

Left Cylinder Lock Switch..................8Wa-15-13

Left Fog Lamp..........................8Wa-15-5

Left Front Door Ajar Switch.................8Wa-15-13

Left Front Door Lock Motor/ Ajar Switch.........8Wa-15-13

Left Front Park/ Turn Signal Lamp.............8Wa-15-5

Left Full Open Switch....................8Wa-15-12

Left Headlamp.........................8Wa-15-15

Left Headlamp Leveling Motor................8Wa-15-5

Left High Beam Lamp....................8Wa-15-15

Left Liftgate Flood Lamp..................8Wa-15-23

Left Low Beam Lamp.....................8Wa-15-15

Left Mid Reading Lamp...................8Wa-15-18

Left Park Lamp........................8Wa-15-15

Left Power Mirror.......................8Wa-15-9

Left Rear Lamp Assembly..................8Wa-15-21

Left Rear Reading Lamp...................8Wa-15-18

Left Side Impact Airbag Control Module.........8Wa-15-11

Left Sliding Door Control Module.............8Wa-15-12

Left Sliding Door Latch Sensing Switch.........8Wa-15-12

Left Sliding Door Lock Motor................8Wa-15-12Component PageLeft Sliding Door Lock Motor/ Ajar Switch........8Wa-15-12

Left Sliding Door Motor...................8Wa-15-12

Left Stop/ Turn Signal Relay................8Wa-15-21

Left Turn Signal Lamp....................8Wa-15-15

Left Visor/ Vanity Lamp...................8Wa-15-18

License Lamp.......................8Wa-15-20, 23

Lift Pump Motor........................8Wa-15-22

Liftgate Ajar Switch.....................8Wa-15-23

Liftgate Cinch/ Release Motor................8Wa-15-20

Liftgate Cylinder Lock Switch...............8Wa-15-23

Liftgate Right Pinch Sensor.................8Wa-15-20

Low Note Horn.........................8Wa-15-5

Memory Power Seat Switch.................8Wa-15-10

Memory Seat/ Mirror Module................8Wa-15-10

Occupant Restraint Controller...............8Wa-15-11

Overhead Console.......................8Wa-15-18

Oxygen Sensor 1/2 Downstream...............8Wa-15-6

Park/ Neutral Position Switch................8Wa-15-6

Passenger Door Courtesy Lamp............8Wa-15-13, 17

Passenger Door Lock Switch..............8Wa-15-13, 17

Passenger Heated Seat Module...............8Wa-15-19

Passenger Power Seat Switch................8Wa-15-19

Passenger Power Window Switch...........8Wa-15-13, 17

Power Folding Mirror Switch................8Wa-15-10

Power Liftgate Module....................8Wa-15-20

Power Liftgate Motor.....................8Wa-15-20

Power Mirror Switch.....................8Wa-15-10

Power Outlet..........................8Wa-15-8

Powertrain Control Module..................8Wa-15-2

Radiator Fan No. 1.......................8Wa-15-4

Radiator Fan No. 2.......................8Wa-15-4

Radiator Fan Relay.......................8Wa-15-4

Radiator Fan Relay No. 3...................8Wa-15-4

Rear Auto Temp Control Switch..............8Wa-15-14

Rear Blower Front Control Switch.............8Wa-15-10

Rear Blower Motor Power Module...........8Wa-15-10, 22

Rear Blower Rear Control Switch.............8Wa-15-14

Rear Dome Lamp.......................8Wa-15-18

Rear Power Outlet......................8Wa-15-22

Rear Window Defogger Grid.................8Wa-15-23

Rear Wiper Motor.......................8Wa-15-23

Remote Keyless Entry Module................8Wa-15-9

Right B-Pillar Switch.....................8Wa-15-19

Right Cinch/ Release Motor.................8Wa-15-16

Right Combination Relay..................8Wa-15-21

Right Cylinder Lock Switch.................8Wa-15-17

Right Fog Lamp.........................8Wa-15-5

Right Front Door Ajar Switch................8Wa-15-17

Right Front Door Lock Motor/ Ajar Switch........8Wa-15-17

Right Front Park/ Turn Signal Lamp............8Wa-15-5

Right Full Open Switch...................8Wa-15-16

Right Headlamp........................8Wa-15-15

Right Headlamp Leveling Motor...............8Wa-15-5

Right High Beam Lamp...................8Wa-15-15

Right Liftgate Flood Lamp.................8Wa-15-23

Right Low Beam Lamp....................8Wa-15-15

Right Mid Reading Lamp..................8Wa-15-18

Right Park Lamp.......................8Wa-15-15

Right Power Mirror.......................8Wa-15-9

Right Rear Lamp Assembly.................8Wa-15-22

Right Rear Reading Lamp..................8Wa-15-18

Right Side Impact Airbag Control Module........8Wa-15-11

Right Sliding Door Control Module............8Wa-15-16

Right Sliding Door Latch Sensing Switch.........8Wa-15-16

Right Sliding Door Lock Motor...............8Wa-15-16

Right Sliding Door Lock Motor/ Ajar Switch.......8Wa-15-16

Right Sliding Door Motor..................8Wa-15-16

Right Stop/ Turn Signal Relay...............8Wa-15-21

Right Turn Signal Lamp...................8Wa-15-15

Right Visor/ Vanity Lamp..................8Wa-15-18

Sentry Key Immobilizer Module...............8Wa-15-9

Speed Control Servo......................8Wa-15-6

Traction Control Switch....................8Wa-15-9

Trailer Tow Connector....................8Wa-15-21

Transmission Control Module................8Wa-15-2

Transmission Control Relay..................8Wa-15-2

Transmission Range Sensor..................8Wa-15-6

Washer Fluid Level Switch..................8Wa-15-5

Wiper Module.........................8Wa-15-14

RG8W-15 GROUND DISTRIBUTION8Wa-15-1

ProCarManuals.com

Page 736 of 2321

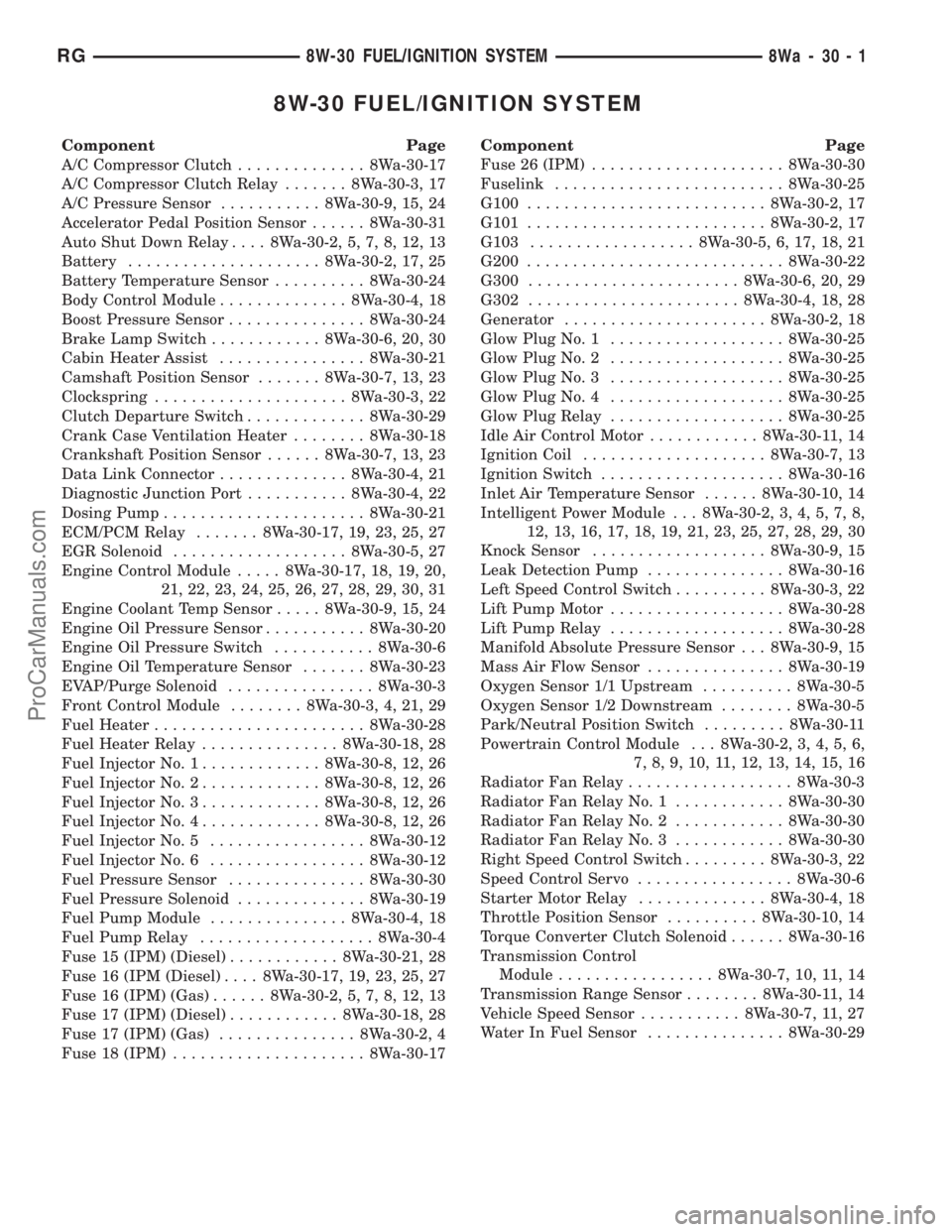

8W-30 FUEL/IGNITION SYSTEM

Component Page

A/C Compressor Clutch.............. 8Wa-30-17

A/C Compressor Clutch Relay....... 8Wa-30-3, 17

A/C Pressure Sensor........... 8Wa-30-9, 15, 24

Accelerator Pedal Position Sensor...... 8Wa-30-31

Auto Shut Down Relay.... 8Wa-30-2, 5, 7, 8, 12, 13

Battery..................... 8Wa-30-2, 17, 25

Battery Temperature Sensor.......... 8Wa-30-24

Body Control Module.............. 8Wa-30-4, 18

Boost Pressure Sensor............... 8Wa-30-24

Brake Lamp Switch............ 8Wa-30-6, 20, 30

Cabin Heater Assist................ 8Wa-30-21

Camshaft Position Sensor....... 8Wa-30-7, 13, 23

Clockspring..................... 8Wa-30-3, 22

Clutch Departure Switch............. 8Wa-30-29

Crank Case Ventilation Heater........ 8Wa-30-18

Crankshaft Position Sensor...... 8Wa-30-7, 13, 23

Data Link Connector.............. 8Wa-30-4, 21

Diagnostic Junction Port........... 8Wa-30-4, 22

Dosing Pump...................... 8Wa-30-21

ECM/PCM Relay....... 8Wa-30-17, 19, 23, 25, 27

EGR Solenoid................... 8Wa-30-5, 27

Engine Control Module..... 8Wa-30-17, 18, 19, 20,

21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31

Engine Coolant Temp Sensor..... 8Wa-30-9, 15, 24

Engine Oil Pressure Sensor........... 8Wa-30-20

Engine Oil Pressure Switch........... 8Wa-30-6

Engine Oil Temperature Sensor....... 8Wa-30-23

EVAP/Purge Solenoid................ 8Wa-30-3

Front Control Module........ 8Wa-30-3, 4, 21, 29

Fuel Heater....................... 8Wa-30-28

Fuel Heater Relay............... 8Wa-30-18, 28

Fuel Injector No. 1............. 8Wa-30-8, 12, 26

Fuel Injector No. 2............. 8Wa-30-8, 12, 26

Fuel Injector No. 3............. 8Wa-30-8, 12, 26

Fuel Injector No. 4............. 8Wa-30-8, 12, 26

Fuel Injector No. 5................. 8Wa-30-12

Fuel Injector No. 6................. 8Wa-30-12

Fuel Pressure Sensor............... 8Wa-30-30

Fuel Pressure Solenoid.............. 8Wa-30-19

Fuel Pump Module............... 8Wa-30-4, 18

Fuel Pump Relay................... 8Wa-30-4

Fuse 15 (IPM) (Diesel)............ 8Wa-30-21, 28

Fuse 16 (IPM (Diesel).... 8Wa-30-17, 19, 23, 25, 27

Fuse 16 (IPM) (Gas)...... 8Wa-30-2, 5, 7, 8, 12, 13

Fuse 17 (IPM) (Diesel)............ 8Wa-30-18, 28

Fuse 17 (IPM) (Gas)............... 8Wa-30-2, 4

Fuse 18 (IPM)..................... 8Wa-30-17Component Page

Fuse 26 (IPM)..................... 8Wa-30-30

Fuselink......................... 8Wa-30-25

G100.......................... 8Wa-30-2, 17

G101.......................... 8Wa-30-2, 17

G103.................. 8Wa-30-5, 6, 17, 18, 21

G200............................ 8Wa-30-22

G300....................... 8Wa-30-6, 20, 29

G302....................... 8Wa-30-4, 18, 28

Generator...................... 8Wa-30-2, 18

Glow Plug No. 1................... 8Wa-30-25

Glow Plug No. 2................... 8Wa-30-25

Glow Plug No. 3................... 8Wa-30-25

Glow Plug No. 4................... 8Wa-30-25

Glow Plug Relay................... 8Wa-30-25

Idle Air Control Motor............ 8Wa-30-11, 14

Ignition Coil.................... 8Wa-30-7, 13

Ignition Switch.................... 8Wa-30-16

Inlet Air Temperature Sensor...... 8Wa-30-10, 14

Intelligent Power Module . . . 8Wa-30-2, 3, 4, 5, 7, 8,

12, 13, 16, 17, 18, 19, 21, 23, 25, 27, 28, 29, 30

Knock Sensor................... 8Wa-30-9, 15

Leak Detection Pump............... 8Wa-30-16

Left Speed Control Switch.......... 8Wa-30-3, 22

Lift Pump Motor................... 8Wa-30-28

Lift Pump Relay................... 8Wa-30-28

Manifold Absolute Pressure Sensor . . . 8Wa-30-9, 15

Mass Air Flow Sensor............... 8Wa-30-19

Oxygen Sensor 1/1 Upstream.......... 8Wa-30-5

Oxygen Sensor 1/2 Downstream........ 8Wa-30-5

Park/Neutral Position Switch......... 8Wa-30-11

Powertrain Control Module . . . 8Wa-30-2, 3, 4, 5, 6,

7, 8, 9, 10, 11, 12, 13, 14, 15, 16

Radiator Fan Relay.................. 8Wa-30-3

Radiator Fan Relay No. 1............ 8Wa-30-30

Radiator Fan Relay No. 2............ 8Wa-30-30

Radiator Fan Relay No. 3............ 8Wa-30-30

Right Speed Control Switch......... 8Wa-30-3, 22

Speed Control Servo................. 8Wa-30-6

Starter Motor Relay.............. 8Wa-30-4, 18

Throttle Position Sensor.......... 8Wa-30-10, 14

Torque Converter Clutch Solenoid...... 8Wa-30-16

Transmission Control

Module................. 8Wa-30-7, 10, 11, 14

Transmission Range Sensor........ 8Wa-30-11, 14

Vehicle Speed Sensor........... 8Wa-30-7, 11, 27

Water In Fuel Sensor............... 8Wa-30-29

RG8W-30 FUEL/IGNITION SYSTEM8Wa-30-1

ProCarManuals.com

Page 1916 of 2321

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-

cle. For hoisting recommendations refer to Group 0,

Lubrication and Maintenance, General Information

section.

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop lightover the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

DIAGNOSIS AND TESTING - WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will not

always seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

noticed in the passenger compartment during high

cross winds. Over compensating on door or glass

adjustments to stop wind noise that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify

noise has stopped before returning vehicle to use.

Wind noise can also be caused by improperly fitted

exterior moldings or body ornamentation. Loose

moldings can flutter, creating a buzzing or chattering

noise. An open cavity or protruding edge can create a

whistling or howling noise. Inspect the exterior of the

vehicle to verify that these conditions do not exist.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and

body components are aligned and sealed. If compo-

nent alignment or sealing is necessary, refer to the

appropriate section of this group for proper proce-

dures.

ROAD TESTING WIND NOISE

(1) Drive the vehicle to verify the general location

of the wind noise.

(2) Apply 50 mm (2 in.) masking tape in 150 mm

(6 in.) lengths along weatherstrips, weld seams or

RSBODY23-3

BODY (Continued)

ProCarManuals.com