seat adjustment DODGE TOWN AND COUNTRY 2001 Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 171 of 2321

The outboard rear disc brake shoes (pads) are side-

oriented. The shoes are marked indicating which side

they belong on.

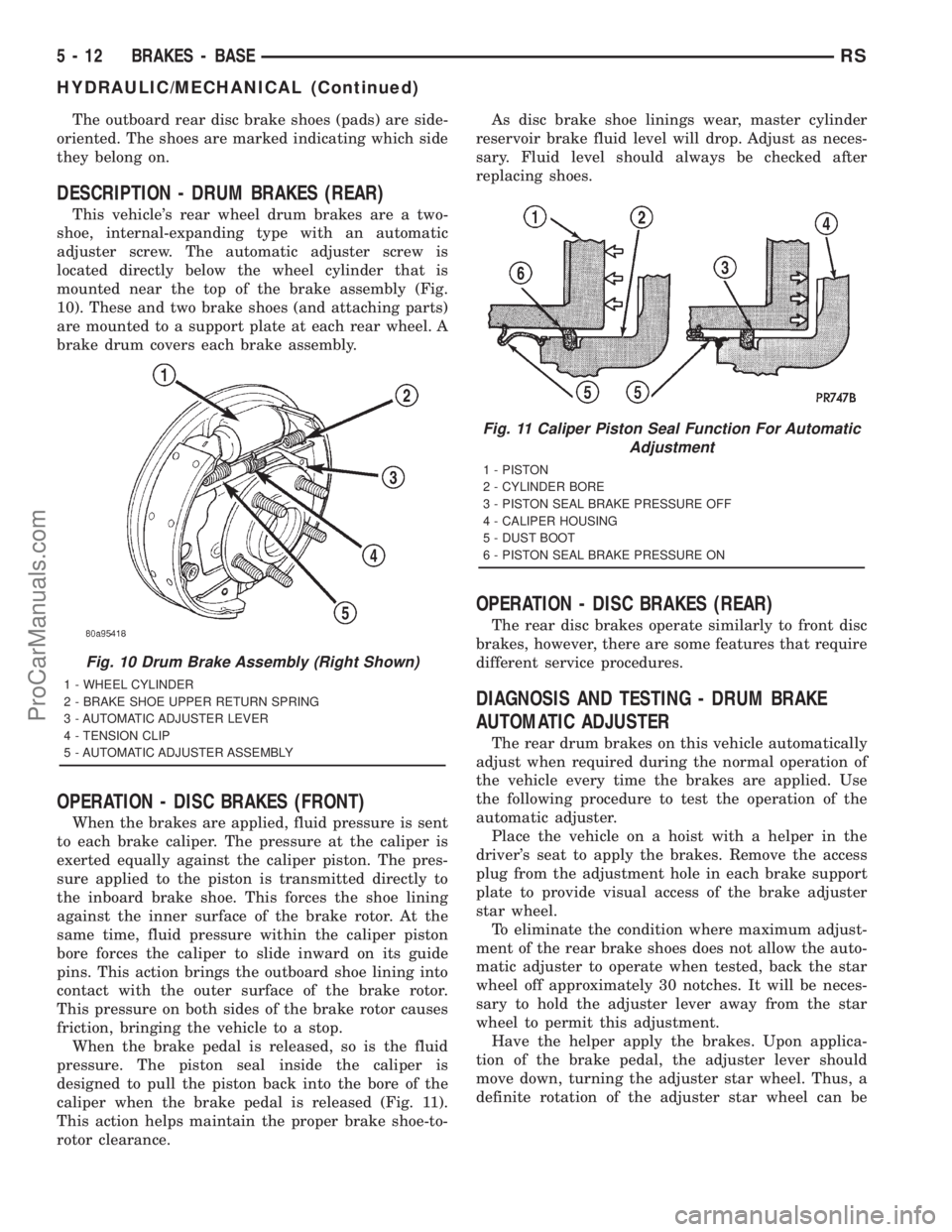

DESCRIPTION - DRUM BRAKES (REAR)

This vehicle's rear wheel drum brakes are a two-

shoe, internal-expanding type with an automatic

adjuster screw. The automatic adjuster screw is

located directly below the wheel cylinder that is

mounted near the top of the brake assembly (Fig.

10). These and two brake shoes (and attaching parts)

are mounted to a support plate at each rear wheel. A

brake drum covers each brake assembly.

OPERATION - DISC BRAKES (FRONT)

When the brakes are applied, fluid pressure is sent

to each brake caliper. The pressure at the caliper is

exerted equally against the caliper piston. The pres-

sure applied to the piston is transmitted directly to

the inboard brake shoe. This forces the shoe lining

against the inner surface of the brake rotor. At the

same time, fluid pressure within the caliper piston

bore forces the caliper to slide inward on its guide

pins. This action brings the outboard shoe lining into

contact with the outer surface of the brake rotor.

This pressure on both sides of the brake rotor causes

friction, bringing the vehicle to a stop.

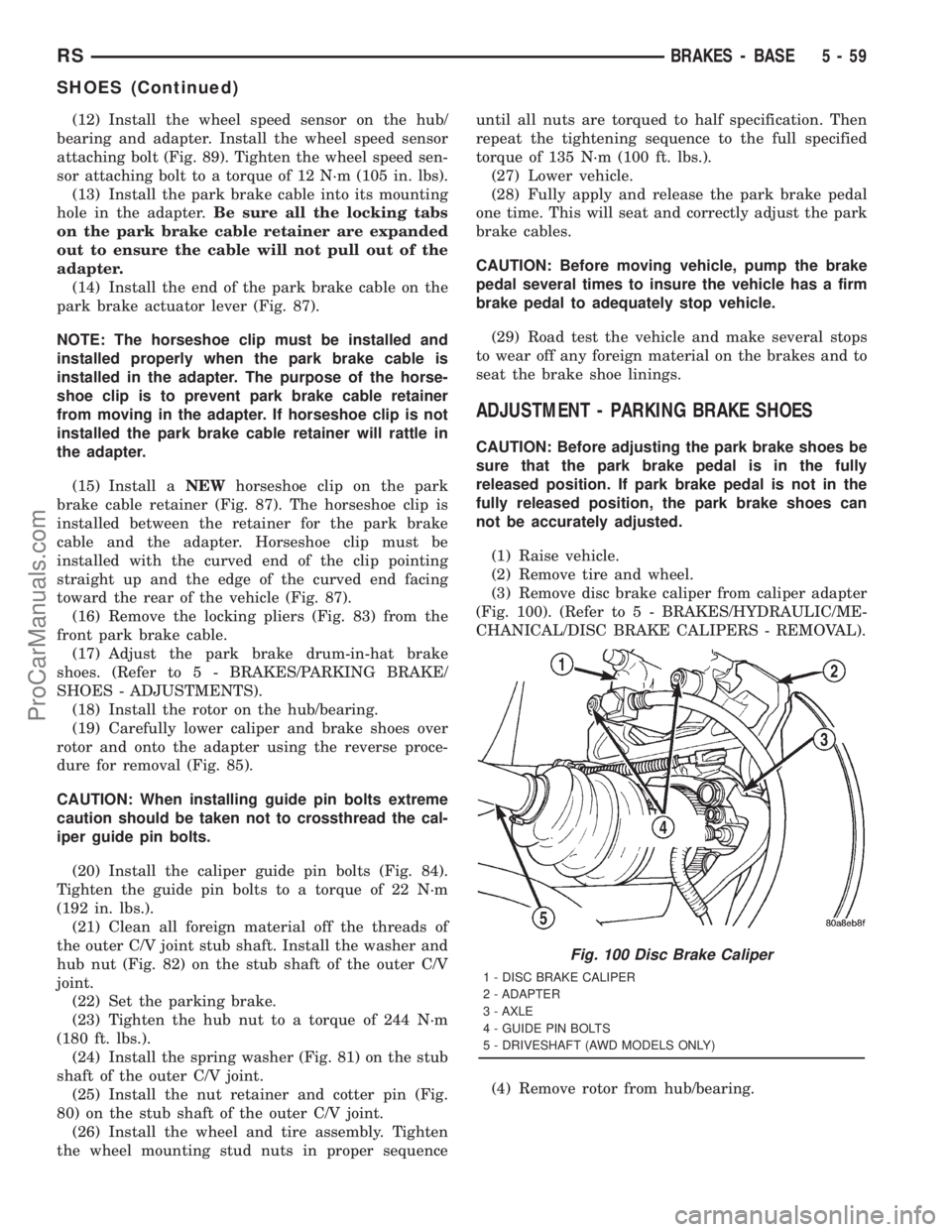

When the brake pedal is released, so is the fluid

pressure. The piston seal inside the caliper is

designed to pull the piston back into the bore of the

caliper when the brake pedal is released (Fig. 11).

This action helps maintain the proper brake shoe-to-

rotor clearance.As disc brake shoe linings wear, master cylinder

reservoir brake fluid level will drop. Adjust as neces-

sary. Fluid level should always be checked after

replacing shoes.

OPERATION - DISC BRAKES (REAR)

The rear disc brakes operate similarly to front disc

brakes, however, there are some features that require

different service procedures.

DIAGNOSIS AND TESTING - DRUM BRAKE

AUTOMATIC ADJUSTER

The rear drum brakes on this vehicle automatically

adjust when required during the normal operation of

the vehicle every time the brakes are applied. Use

the following procedure to test the operation of the

automatic adjuster.

Place the vehicle on a hoist with a helper in the

driver's seat to apply the brakes. Remove the access

plug from the adjustment hole in each brake support

plate to provide visual access of the brake adjuster

star wheel.

To eliminate the condition where maximum adjust-

ment of the rear brake shoes does not allow the auto-

matic adjuster to operate when tested, back the star

wheel off approximately 30 notches. It will be neces-

sary to hold the adjuster lever away from the star

wheel to permit this adjustment.

Have the helper apply the brakes. Upon applica-

tion of the brake pedal, the adjuster lever should

move down, turning the adjuster star wheel. Thus, a

definite rotation of the adjuster star wheel can be

Fig. 10 Drum Brake Assembly (Right Shown)

1 - WHEEL CYLINDER

2 - BRAKE SHOE UPPER RETURN SPRING

3 - AUTOMATIC ADJUSTER LEVER

4 - TENSION CLIP

5 - AUTOMATIC ADJUSTER ASSEMBLY

Fig. 11 Caliper Piston Seal Function For Automatic

Adjustment

1 - PISTON

2 - CYLINDER BORE

3 - PISTON SEAL BRAKE PRESSURE OFF

4 - CALIPER HOUSING

5 - DUST BOOT

6 - PISTON SEAL BRAKE PRESSURE ON

5 - 12 BRAKES - BASERS

HYDRAULIC/MECHANICAL (Continued)

ProCarManuals.com

Page 218 of 2321

(12) Install the wheel speed sensor on the hub/

bearing and adapter. Install the wheel speed sensor

attaching bolt (Fig. 89). Tighten the wheel speed sen-

sor attaching bolt to a torque of 12 N´m (105 in. lbs).

(13) Install the park brake cable into its mounting

hole in the adapter.Be sure all the locking tabs

on the park brake cable retainer are expanded

out to ensure the cable will not pull out of the

adapter.

(14) Install the end of the park brake cable on the

park brake actuator lever (Fig. 87).

NOTE: The horseshoe clip must be installed and

installed properly when the park brake cable is

installed in the adapter. The purpose of the horse-

shoe clip is to prevent park brake cable retainer

from moving in the adapter. If horseshoe clip is not

installed the park brake cable retainer will rattle in

the adapter.

(15) Install aNEWhorseshoe clip on the park

brake cable retainer (Fig. 87). The horseshoe clip is

installed between the retainer for the park brake

cable and the adapter. Horseshoe clip must be

installed with the curved end of the clip pointing

straight up and the edge of the curved end facing

toward the rear of the vehicle (Fig. 87).

(16) Remove the locking pliers (Fig. 83) from the

front park brake cable.

(17) Adjust the park brake drum-in-hat brake

shoes. (Refer to 5 - BRAKES/PARKING BRAKE/

SHOES - ADJUSTMENTS).

(18) Install the rotor on the hub/bearing.

(19) Carefully lower caliper and brake shoes over

rotor and onto the adapter using the reverse proce-

dure for removal (Fig. 85).

CAUTION: When installing guide pin bolts extreme

caution should be taken not to crossthread the cal-

iper guide pin bolts.

(20) Install the caliper guide pin bolts (Fig. 84).

Tighten the guide pin bolts to a torque of 22 N´m

(192 in. lbs.).

(21) Clean all foreign material off the threads of

the outer C/V joint stub shaft. Install the washer and

hub nut (Fig. 82) on the stub shaft of the outer C/V

joint.

(22) Set the parking brake.

(23) Tighten the hub nut to a torque of 244 N´m

(180 ft. lbs.).

(24) Install the spring washer (Fig. 81) on the stub

shaft of the outer C/V joint.

(25) Install the nut retainer and cotter pin (Fig.

80) on the stub shaft of the outer C/V joint.

(26) Install the wheel and tire assembly. Tighten

the wheel mounting stud nuts in proper sequenceuntil all nuts are torqued to half specification. Then

repeat the tightening sequence to the full specified

torque of 135 N´m (100 ft. lbs.).

(27) Lower vehicle.

(28) Fully apply and release the park brake pedal

one time. This will seat and correctly adjust the park

brake cables.

CAUTION: Before moving vehicle, pump the brake

pedal several times to insure the vehicle has a firm

brake pedal to adequately stop vehicle.

(29) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake shoe linings.

ADJUSTMENT - PARKING BRAKE SHOES

CAUTION: Before adjusting the park brake shoes be

sure that the park brake pedal is in the fully

released position. If park brake pedal is not in the

fully released position, the park brake shoes can

not be accurately adjusted.

(1) Raise vehicle.

(2) Remove tire and wheel.

(3) Remove disc brake caliper from caliper adapter

(Fig. 100). (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/DISC BRAKE CALIPERS - REMOVAL).

(4) Remove rotor from hub/bearing.

Fig. 100 Disc Brake Caliper

1 - DISC BRAKE CALIPER

2 - ADAPTER

3 - AXLE

4 - GUIDE PIN BOLTS

5 - DRIVESHAFT (AWD MODELS ONLY)

RSBRAKES - BASE5-59

SHOES (Continued)

ProCarManuals.com

Page 225 of 2321

INSTALLATION - PARKING BRAKE CABLE

(LEFT REAR)

(1) Install the rear parking brake cable in the

brake support plate. Insert cable housing retainer

into brake support plate making certain that cable

housing retainer fingers lock the housing and

retainer firmly into place.

(2) Attach the parking brake cable onto the park

brake actuator lever.

(3) Install the brake shoes on the rear brake sup-

port plate. (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/BRAKE PADS/SHOES -

INSTALLATION).

(4) Insert cable housing retainer into body outrig-

ger bracket making certain that cable housing

retainer fingers lock the housing firmly into place.

(5) Connect rear parking brake cable to the equal-

izer bracket (Fig. 114).

(6) Install brake drum, and wheel and tire assem-

bly.

(7) Remove the locking pliers from the front park

brake cable. This will automatically adjust the park

brake cables.

(8) Apply and release park brake pedal 1 time.

This will seat the park brake cables.

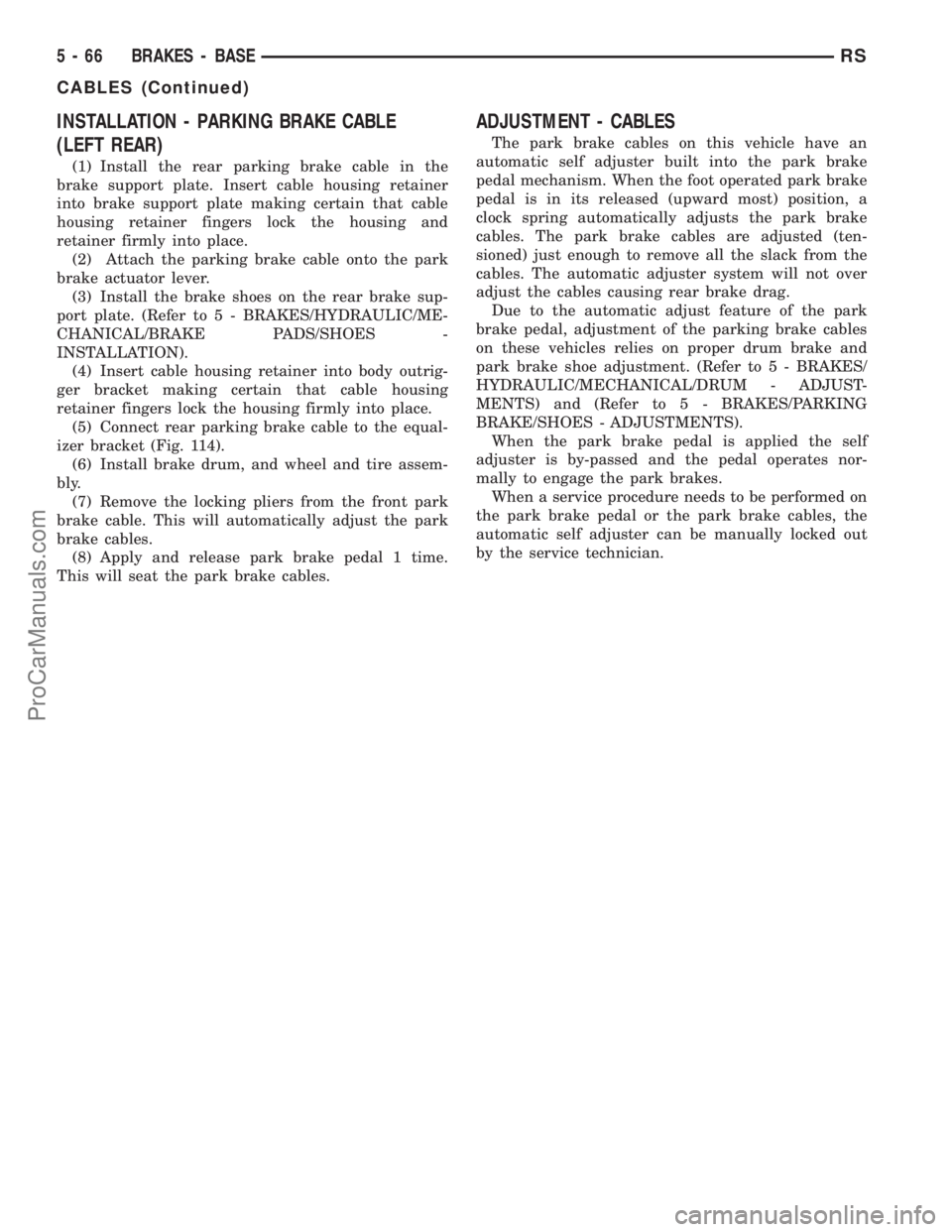

ADJUSTMENT - CABLES

The park brake cables on this vehicle have an

automatic self adjuster built into the park brake

pedal mechanism. When the foot operated park brake

pedal is in its released (upward most) position, a

clock spring automatically adjusts the park brake

cables. The park brake cables are adjusted (ten-

sioned) just enough to remove all the slack from the

cables. The automatic adjuster system will not over

adjust the cables causing rear brake drag.

Due to the automatic adjust feature of the park

brake pedal, adjustment of the parking brake cables

on these vehicles relies on proper drum brake and

park brake shoe adjustment. (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/DRUM - ADJUST-

MENTS) and (Refer to 5 - BRAKES/PARKING

BRAKE/SHOES - ADJUSTMENTS).

When the park brake pedal is applied the self

adjuster is by-passed and the pedal operates nor-

mally to engage the park brakes.

When a service procedure needs to be performed on

the park brake pedal or the park brake cables, the

automatic self adjuster can be manually locked out

by the service technician.

5 - 66 BRAKES - BASERS

CABLES (Continued)

ProCarManuals.com

Page 340 of 2321

CONDITION POSSIBLE CAUSE CORRECTION

4. POOR ANTENNA

CONNECTION AT

RADIO OR IN LINE.4. SEAT CONNECTOR.

NO/POOR TAPE

OPERATION.1. FAULTY TAPE. 1. INSERT KNOWN GOOD TAPE AND TEST OPERATION.

2. FOREIGN OBJECTS

BEHIND TAPE DOOR.2. REMOVE FOREIGN OBJECTS AND TEST OPERATION.

3. DIRTY CASSETTE

TAPE HEAD.3. CLEAN HEAD WITH MOPAR CASSETTE HEAD CLEANER.

4. FAULTY TAPE DECK. 4. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

NO COMPACT

DISC

OPERATION1. FAULTY CD. 1. INSERT KNOWN GOOD CD AND TEST OPERATION.

2. FOREIGN MATERIAL

ON CD.2. CLEAN CD AND TEST OPERATION.

3. CONDENSATION ON

CD OR OPTICS.3. ALLOW TEMPERATURE OF VEHICLE INTERIOR TO

STABILIZE AND TEST OPERATION.

4. FAULTY CD PLAYER. 4. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

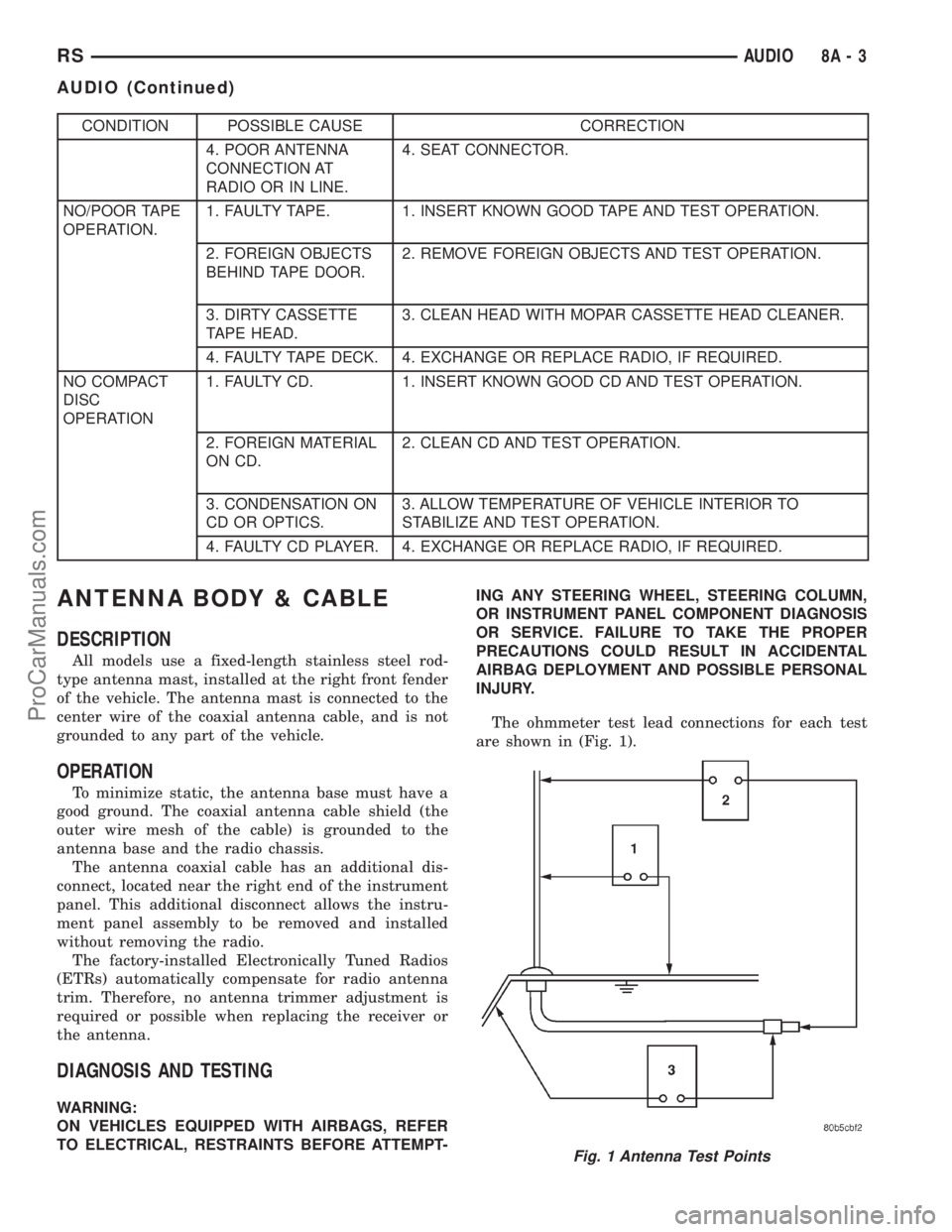

ANTENNA BODY & CABLE

DESCRIPTION

All models use a fixed-length stainless steel rod-

type antenna mast, installed at the right front fender

of the vehicle. The antenna mast is connected to the

center wire of the coaxial antenna cable, and is not

grounded to any part of the vehicle.

OPERATION

To minimize static, the antenna base must have a

good ground. The coaxial antenna cable shield (the

outer wire mesh of the cable) is grounded to the

antenna base and the radio chassis.

The antenna coaxial cable has an additional dis-

connect, located near the right end of the instrument

panel. This additional disconnect allows the instru-

ment panel assembly to be removed and installed

without removing the radio.

The factory-installed Electronically Tuned Radios

(ETRs) automatically compensate for radio antenna

trim. Therefore, no antenna trimmer adjustment is

required or possible when replacing the receiver or

the antenna.

DIAGNOSIS AND TESTING

WARNING:

ON VEHICLES EQUIPPED WITH AIRBAGS, REFER

TO ELECTRICAL, RESTRAINTS BEFORE ATTEMPT-ING ANY STEERING WHEEL, STEERING COLUMN,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The ohmmeter test lead connections for each test

are shown in (Fig. 1).

Fig. 1 Antenna Test Points

RSAUDIO8A-3

AUDIO (Continued)

ProCarManuals.com

Page 481 of 2321

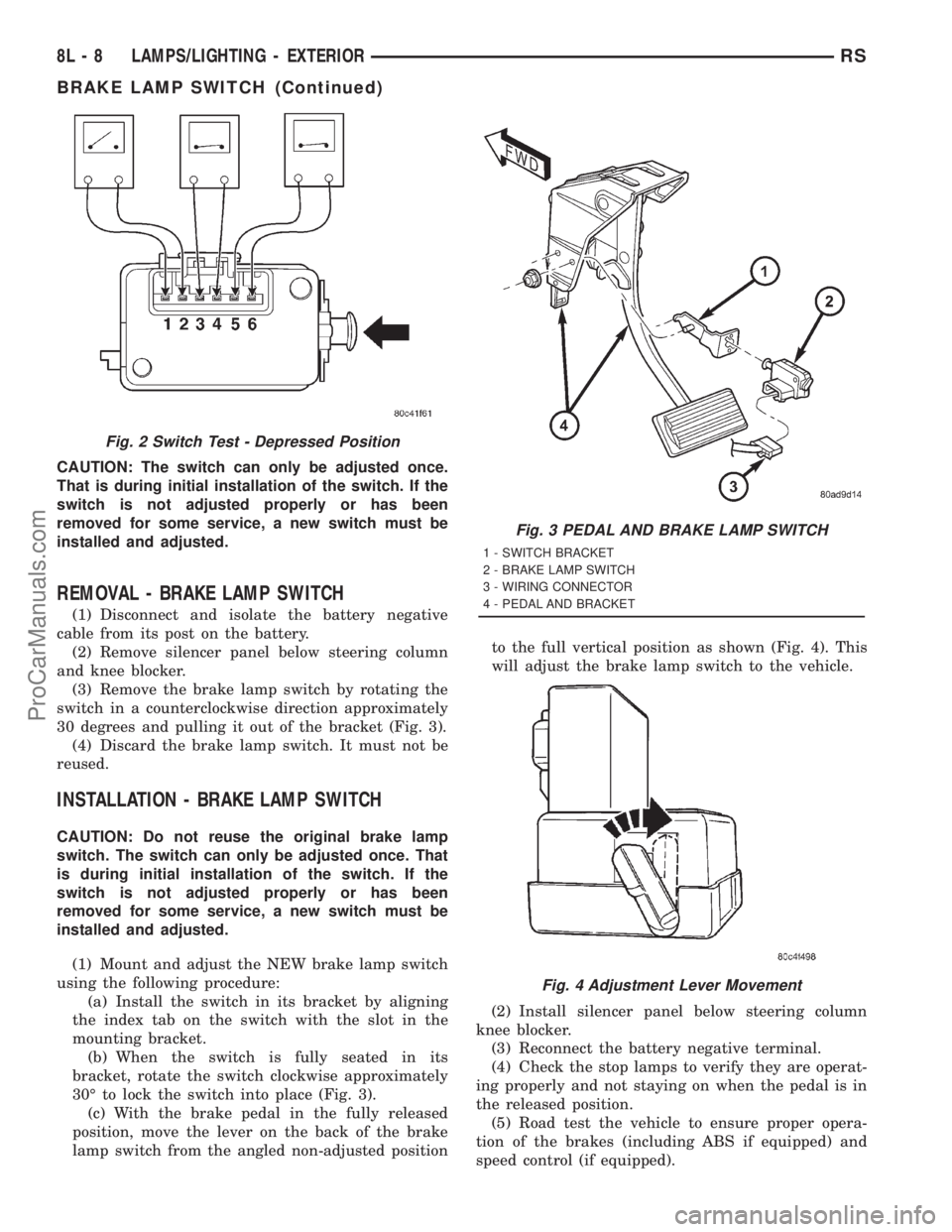

CAUTION: The switch can only be adjusted once.

That is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

REMOVAL - BRAKE LAMP SWITCH

(1) Disconnect and isolate the battery negative

cable from its post on the battery.

(2) Remove silencer panel below steering column

and knee blocker.

(3) Remove the brake lamp switch by rotating the

switch in a counterclockwise direction approximately

30 degrees and pulling it out of the bracket (Fig. 3).

(4) Discard the brake lamp switch. It must not be

reused.

INSTALLATION - BRAKE LAMP SWITCH

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(1) Mount and adjust the NEW brake lamp switch

using the following procedure:

(a) Install the switch in its bracket by aligning

the index tab on the switch with the slot in the

mounting bracket.

(b) When the switch is fully seated in its

bracket, rotate the switch clockwise approximately

30É to lock the switch into place (Fig. 3).

(c) With the brake pedal in the fully released

position, move the lever on the back of the brake

lamp switch from the angled non-adjusted positionto the full vertical position as shown (Fig. 4). This

will adjust the brake lamp switch to the vehicle.

(2) Install silencer panel below steering column

knee blocker.

(3) Reconnect the battery negative terminal.

(4) Check the stop lamps to verify they are operat-

ing properly and not staying on when the pedal is in

the released position.

(5) Road test the vehicle to ensure proper opera-

tion of the brakes (including ABS if equipped) and

speed control (if equipped).

Fig. 2 Switch Test - Depressed Position

Fig. 3 PEDAL AND BRAKE LAMP SWITCH

1 - SWITCH BRACKET

2 - BRAKE LAMP SWITCH

3 - WIRING CONNECTOR

4 - PEDAL AND BRACKET

Fig. 4 Adjustment Lever Movement

8L - 8 LAMPS/LIGHTING - EXTERIORRS

BRAKE LAMP SWITCH (Continued)

ProCarManuals.com

Page 500 of 2321

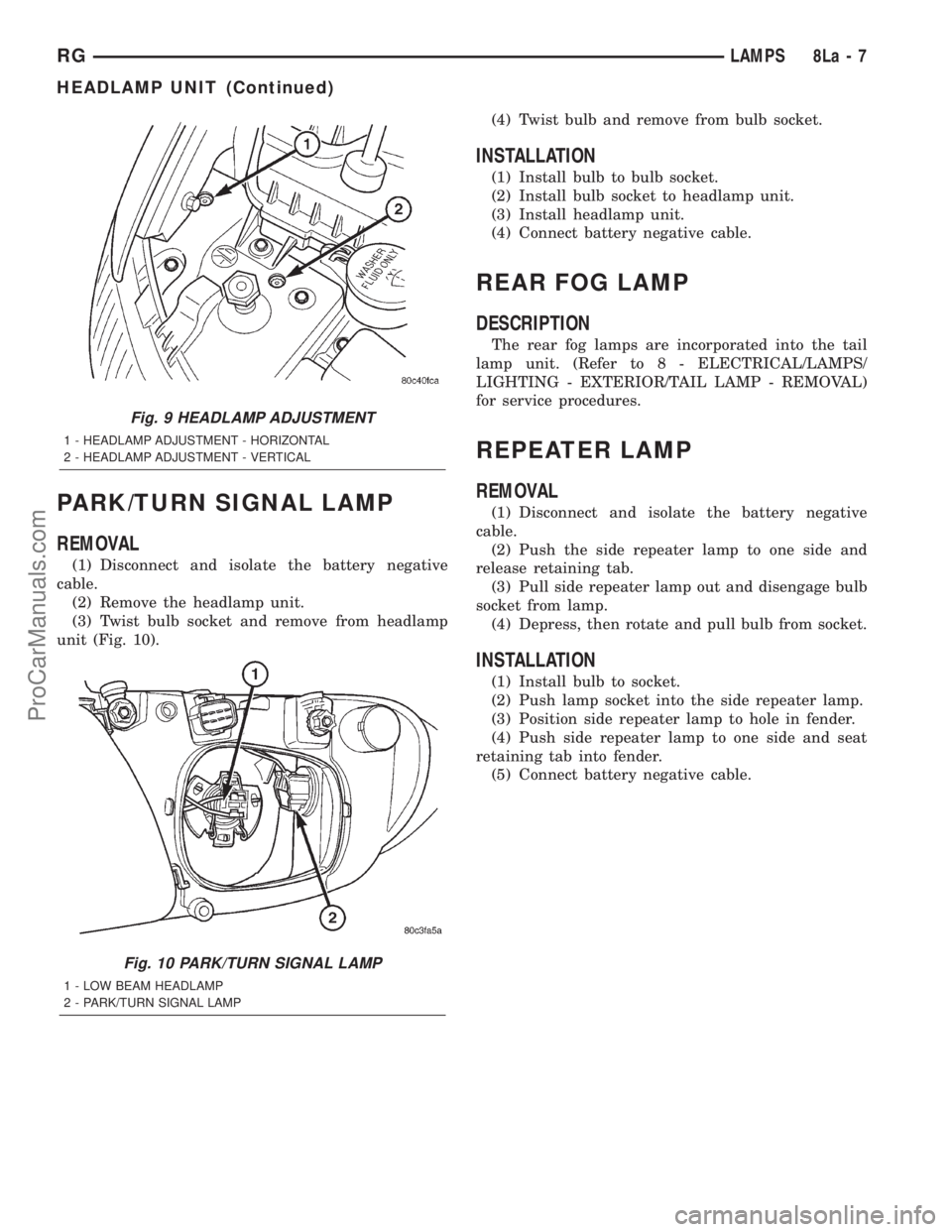

PARK/TURN SIGNAL LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the headlamp unit.

(3) Twist bulb socket and remove from headlamp

unit (Fig. 10).(4) Twist bulb and remove from bulb socket.

INSTALLATION

(1) Install bulb to bulb socket.

(2) Install bulb socket to headlamp unit.

(3) Install headlamp unit.

(4) Connect battery negative cable.

REAR FOG LAMP

DESCRIPTION

The rear fog lamps are incorporated into the tail

lamp unit. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/TAIL LAMP - REMOVAL)

for service procedures.

REPEATER LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Push the side repeater lamp to one side and

release retaining tab.

(3) Pull side repeater lamp out and disengage bulb

socket from lamp.

(4) Depress, then rotate and pull bulb from socket.

INSTALLATION

(1) Install bulb to socket.

(2) Push lamp socket into the side repeater lamp.

(3) Position side repeater lamp to hole in fender.

(4) Push side repeater lamp to one side and seat

retaining tab into fender.

(5) Connect battery negative cable.

Fig. 9 HEADLAMP ADJUSTMENT

1 - HEADLAMP ADJUSTMENT - HORIZONTAL

2 - HEADLAMP ADJUSTMENT - VERTICAL

Fig. 10 PARK/TURN SIGNAL LAMP

1 - LOW BEAM HEADLAMP

2 - PARK/TURN SIGNAL LAMP

RGLAMPS8La-7

HEADLAMP UNIT (Continued)

ProCarManuals.com

Page 514 of 2321

POWER SYSTEMS

TABLE OF CONTENTS

page page

POWER LIFTGATE SYSTEM.................. 1

POWER SLIDING DOOR SYSTEM............ 19

POWER LOCKS........................... 39POWER MIRRORS........................ 45

POWER SEATS........................... 49

POWER WINDOWS........................ 60

POWER LIFTGATE SYSTEM

TABLE OF CONTENTS

page page

POWER LIFTGATE SYSTEM

DESCRIPTION............................2

OPERATION.............................3

DIAGNOSIS AND TESTING..................4

DIAGNOSIS AND TESTING - POWER

LIFTGATE SYSTEM......................4

STANDARD PROCEDURE...................9

LIFTGATE ADJUSTMENT..................9

POWER LIFTGATE LEARN CYCLE..........9

PINCH SENSOR

DESCRIPTION............................9

OPERATION.............................9

REMOVAL...............................9

INSTALLATION...........................10

FULL OPEN SWITCH

DESCRIPTION...........................10

OPERATION.............................10

REMOVAL..............................10

INSTALLATION...........................10

LIFTGATE MOTOR

DESCRIPTION...........................11

OPERATION.............................11

REMOVAL..............................11

INSTALLATION...........................11

ENGAGE ACTUATOR

DESCRIPTION...........................12

OPERATION.............................12

REMOVAL..............................12

INSTALLATION...........................12TRANSVERSE BRACKET

DESCRIPTION...........................13

OPERATION.............................13

REMOVAL..............................13

INSTALLATION...........................13

LIFT GEAR & LINK ROD

DESCRIPTION...........................14

OPERATION.............................14

REMOVAL..............................14

INSTALLATION...........................14

LATCH

DESCRIPTION...........................15

OPERATION.............................15

REMOVAL..............................15

INSTALLATION...........................15

LATCH ACTUATOR

DESCRIPTION...........................16

OPERATION.............................16

REMOVAL..............................16

INSTALLATION...........................16

EXTERIOR HANDLE SWITCH

DESCRIPTION...........................17

OPERATION.............................17

REMOVAL..............................17

INSTALLATION...........................17

CHIME/THERMISTOR

DESCRIPTION...........................18

OPERATION.............................18

REMOVAL..............................18

INSTALLATION...........................18

RSPOWER SYSTEMS8N-1

ProCarManuals.com

Page 571 of 2321

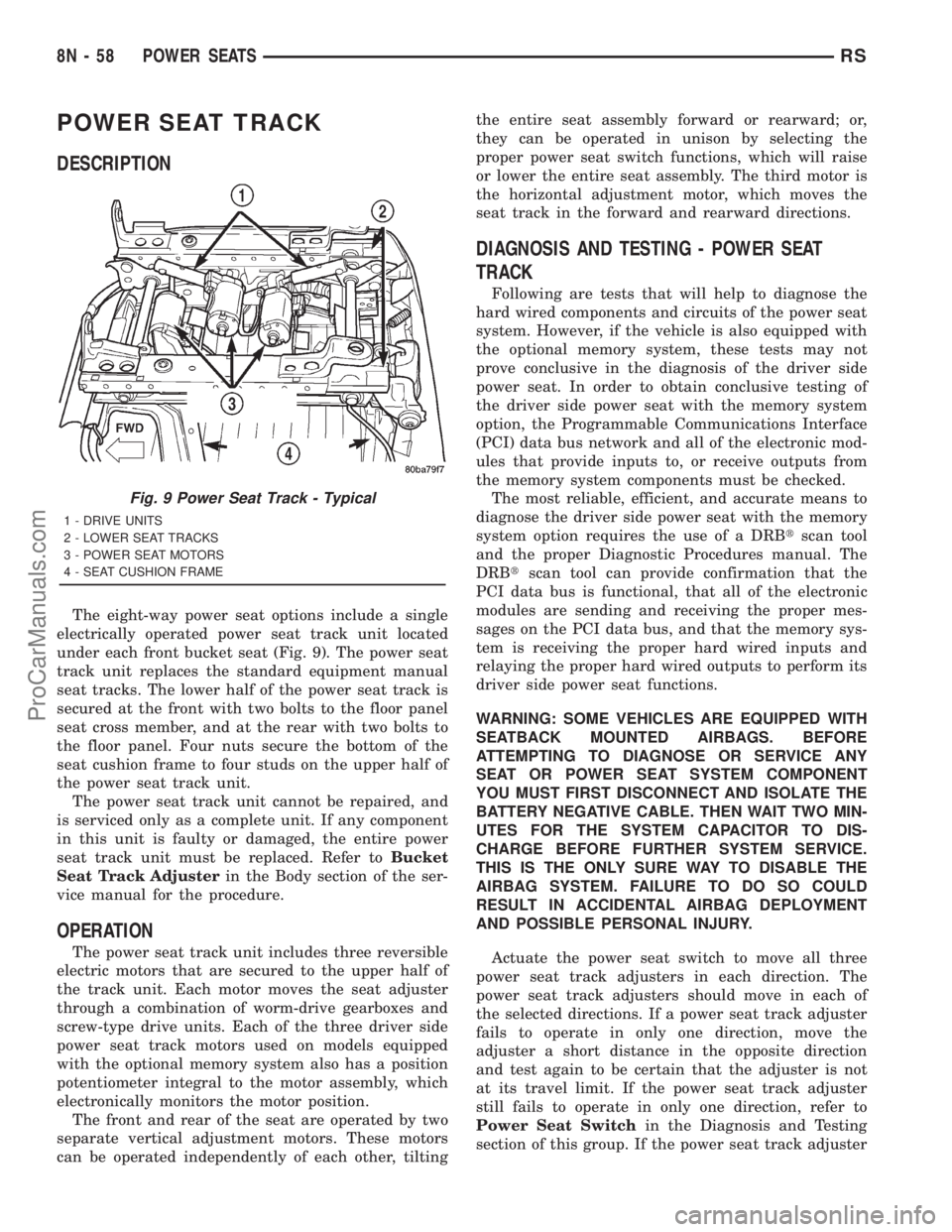

POWER SEAT TRACK

DESCRIPTION

The eight-way power seat options include a single

electrically operated power seat track unit located

under each front bucket seat (Fig. 9). The power seat

track unit replaces the standard equipment manual

seat tracks. The lower half of the power seat track is

secured at the front with two bolts to the floor panel

seat cross member, and at the rear with two bolts to

the floor panel. Four nuts secure the bottom of the

seat cushion frame to four studs on the upper half of

the power seat track unit.

The power seat track unit cannot be repaired, and

is serviced only as a complete unit. If any component

in this unit is faulty or damaged, the entire power

seat track unit must be replaced. Refer toBucket

Seat Track Adjusterin the Body section of the ser-

vice manual for the procedure.

OPERATION

The power seat track unit includes three reversible

electric motors that are secured to the upper half of

the track unit. Each motor moves the seat adjuster

through a combination of worm-drive gearboxes and

screw-type drive units. Each of the three driver side

power seat track motors used on models equipped

with the optional memory system also has a position

potentiometer integral to the motor assembly, which

electronically monitors the motor position.

The front and rear of the seat are operated by two

separate vertical adjustment motors. These motors

can be operated independently of each other, tiltingthe entire seat assembly forward or rearward; or,

they can be operated in unison by selecting the

proper power seat switch functions, which will raise

or lower the entire seat assembly. The third motor is

the horizontal adjustment motor, which moves the

seat track in the forward and rearward directions.

DIAGNOSIS AND TESTING - POWER SEAT

TRACK

Following are tests that will help to diagnose the

hard wired components and circuits of the power seat

system. However, if the vehicle is also equipped with

the optional memory system, these tests may not

prove conclusive in the diagnosis of the driver side

power seat. In order to obtain conclusive testing of

the driver side power seat with the memory system

option, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the memory system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the driver side power seat with the memory

system option requires the use of a DRBtscan tool

and the proper Diagnostic Procedures manual. The

DRBtscan tool can provide confirmation that the

PCI data bus is functional, that all of the electronic

modules are sending and receiving the proper mes-

sages on the PCI data bus, and that the memory sys-

tem is receiving the proper hard wired inputs and

relaying the proper hard wired outputs to perform its

driver side power seat functions.

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Actuate the power seat switch to move all three

power seat track adjusters in each direction. The

power seat track adjusters should move in each of

the selected directions. If a power seat track adjuster

fails to operate in only one direction, move the

adjuster a short distance in the opposite direction

and test again to be certain that the adjuster is not

at its travel limit. If the power seat track adjuster

still fails to operate in only one direction, refer to

Power Seat Switchin the Diagnosis and Testing

section of this group. If the power seat track adjuster

Fig. 9 Power Seat Track - Typical

1 - DRIVE UNITS

2 - LOWER SEAT TRACKS

3 - POWER SEAT MOTORS

4 - SEAT CUSHION FRAME

8N - 58 POWER SEATSRS

ProCarManuals.com

Page 1593 of 2321

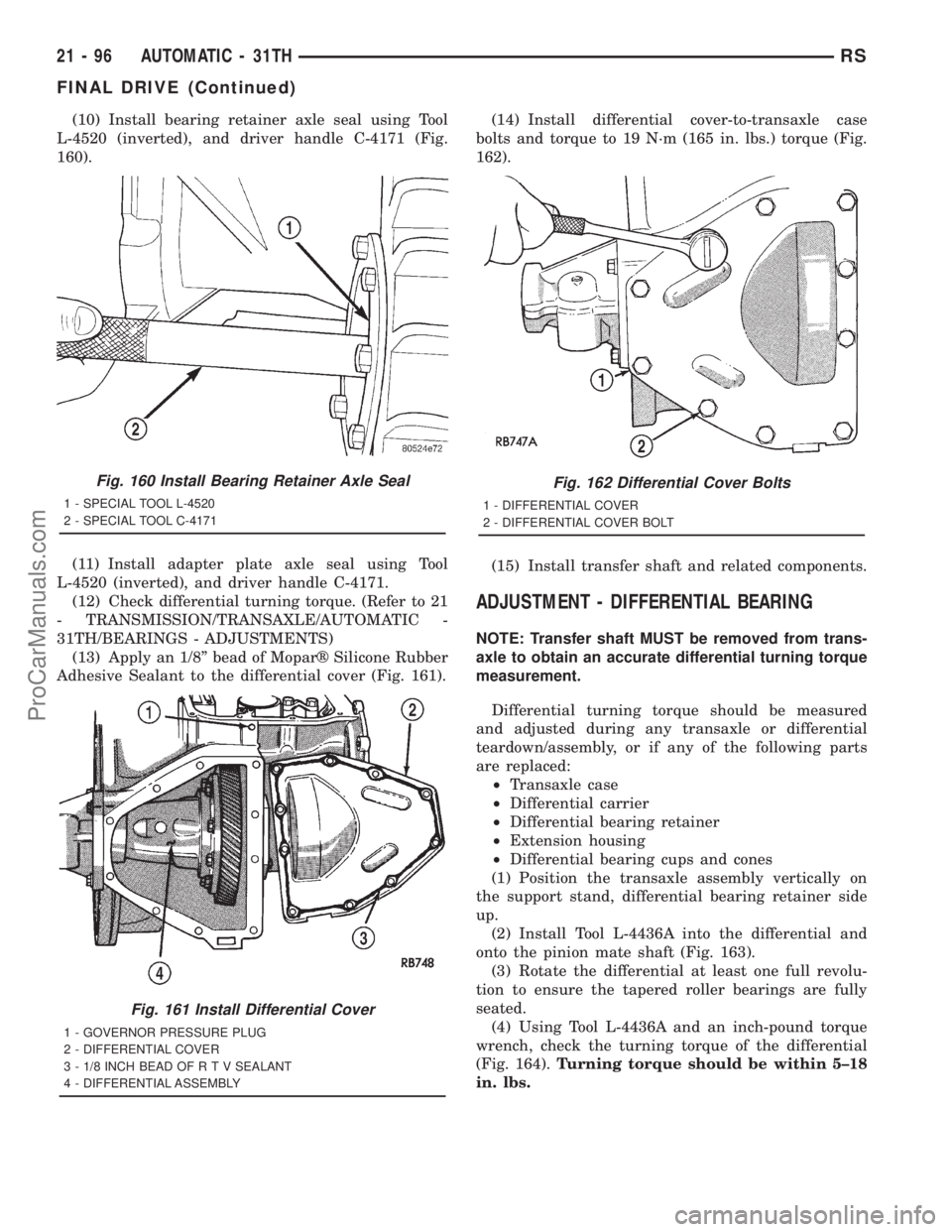

(10) Install bearing retainer axle seal using Tool

L-4520 (inverted), and driver handle C-4171 (Fig.

160).

(11) Install adapter plate axle seal using Tool

L-4520 (inverted), and driver handle C-4171.

(12) Check differential turning torque. (Refer to 21

- TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH/BEARINGS - ADJUSTMENTS)

(13) Apply an 1/8º bead of Moparž Silicone Rubber

Adhesive Sealant to the differential cover (Fig. 161).(14) Install differential cover-to-transaxle case

bolts and torque to 19 N´m (165 in. lbs.) torque (Fig.

162).

(15) Install transfer shaft and related components.

ADJUSTMENT - DIFFERENTIAL BEARING

NOTE: Transfer shaft MUST be removed from trans-

axle to obtain an accurate differential turning torque

measurement.

Differential turning torque should be measured

and adjusted during any transaxle or differential

teardown/assembly, or if any of the following parts

are replaced:

²Transaxle case

²Differential carrier

²Differential bearing retainer

²Extension housing

²Differential bearing cups and cones

(1) Position the transaxle assembly vertically on

the support stand, differential bearing retainer side

up.

(2) Install Tool L-4436A into the differential and

onto the pinion mate shaft (Fig. 163).

(3) Rotate the differential at least one full revolu-

tion to ensure the tapered roller bearings are fully

seated.

(4) Using Tool L-4436A and an inch-pound torque

wrench, check the turning torque of the differential

(Fig. 164).Turning torque should be within 5±18

in. lbs.

Fig. 160 Install Bearing Retainer Axle Seal

1 - SPECIAL TOOL L-4520

2 - SPECIAL TOOL C-4171

Fig. 161 Install Differential Cover

1 - GOVERNOR PRESSURE PLUG

2 - DIFFERENTIAL COVER

3 - 1/8 INCH BEAD OF R T V SEALANT

4 - DIFFERENTIAL ASSEMBLY

Fig. 162 Differential Cover Bolts

1 - DIFFERENTIAL COVER

2 - DIFFERENTIAL COVER BOLT

21 - 96 AUTOMATIC - 31THRS

FINAL DRIVE (Continued)

ProCarManuals.com

Page 1629 of 2321

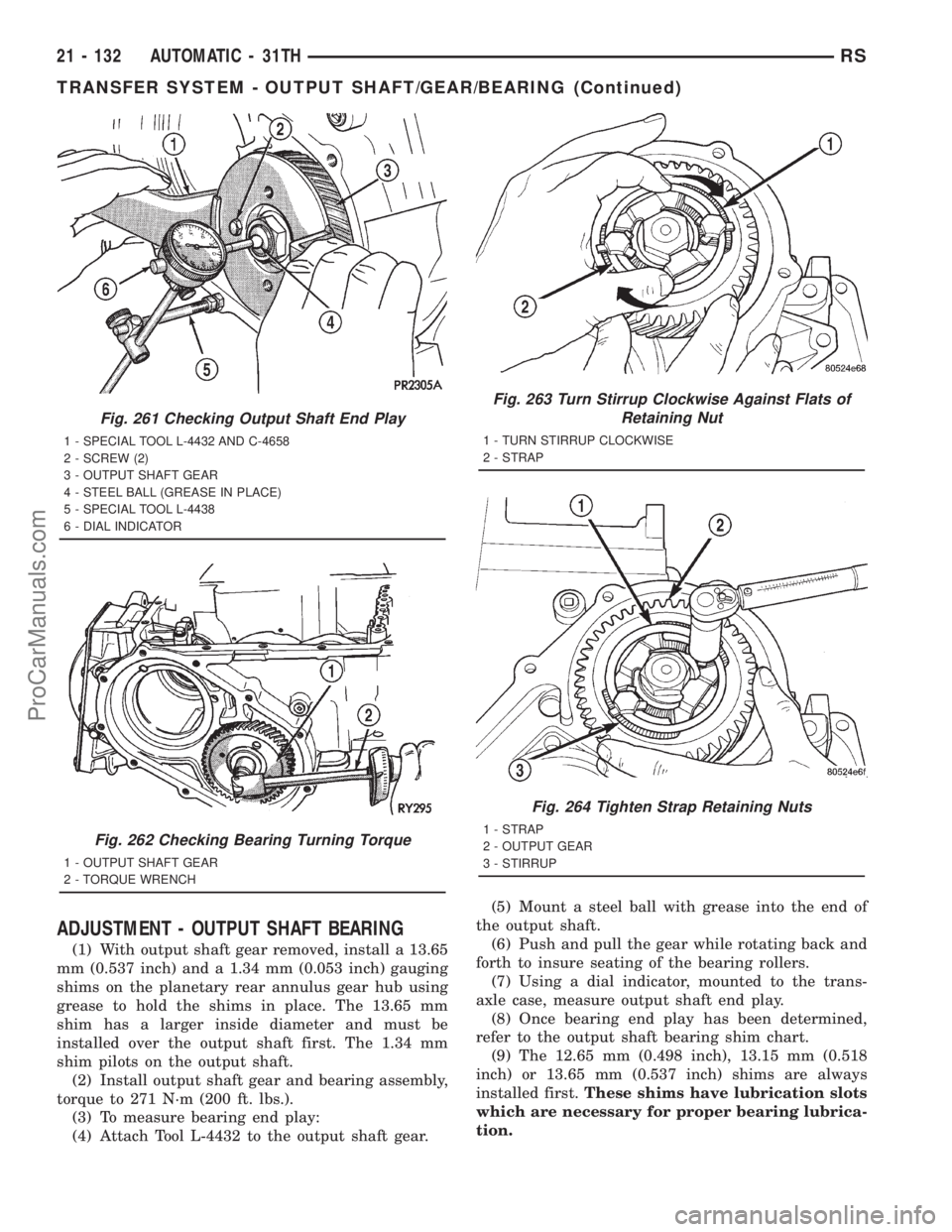

ADJUSTMENT - OUTPUT SHAFT BEARING

(1) With output shaft gear removed, install a 13.65

mm (0.537 inch) and a 1.34 mm (0.053 inch) gauging

shims on the planetary rear annulus gear hub using

grease to hold the shims in place. The 13.65 mm

shim has a larger inside diameter and must be

installed over the output shaft first. The 1.34 mm

shim pilots on the output shaft.

(2) Install output shaft gear and bearing assembly,

torque to 271 N´m (200 ft. lbs.).

(3) To measure bearing end play:

(4) Attach Tool L-4432 to the output shaft gear.(5) Mount a steel ball with grease into the end of

the output shaft.

(6) Push and pull the gear while rotating back and

forth to insure seating of the bearing rollers.

(7) Using a dial indicator, mounted to the trans-

axle case, measure output shaft end play.

(8) Once bearing end play has been determined,

refer to the output shaft bearing shim chart.

(9) The 12.65 mm (0.498 inch), 13.15 mm (0.518

inch) or 13.65 mm (0.537 inch) shims are always

installed first.These shims have lubrication slots

which are necessary for proper bearing lubrica-

tion.

Fig. 261 Checking Output Shaft End Play

1 - SPECIAL TOOL L-4432 AND C-4658

2 - SCREW (2)

3 - OUTPUT SHAFT GEAR

4 - STEEL BALL (GREASE IN PLACE)

5 - SPECIAL TOOL L-4438

6 - DIAL INDICATOR

Fig. 262 Checking Bearing Turning Torque

1 - OUTPUT SHAFT GEAR

2 - TORQUE WRENCH

Fig. 263 Turn Stirrup Clockwise Against Flats of

Retaining Nut

1 - TURN STIRRUP CLOCKWISE

2 - STRAP

Fig. 264 Tighten Strap Retaining Nuts

1 - STRAP

2 - OUTPUT GEAR

3 - STIRRUP

21 - 132 AUTOMATIC - 31THRS

TRANSFER SYSTEM - OUTPUT SHAFT/GEAR/BEARING (Continued)

ProCarManuals.com