DODGE TOWN AND COUNTRY 2003 Service Manual

Manufacturer: DODGE, Model Year: 2003, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2003Pages: 2177, PDF Size: 59.81 MB

Page 371 of 2177

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the PDC fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the starter solenoid field coils. There should be

continuity between the cavity for relay terminal 87

and the starter solenoid terminal at all times. If OK,

go to Step 4. If not OK, repair the open circuit to the

starter solenoid as required.

(4) The coil battery terminal (85) is connected to

the electromagnet in the relay. It is energized when

the ignition switch is held in the Start position and

the clutch pedal is depressed (manual trans). Check

for battery voltage at the cavity for relay terminal 86

with the ignition switch in the Start position and the

clutch pedal is depressed (manual trans), and no

voltage when the ignition switch is released to the

On position. If OK, go to Step 5. If not OK, check for

an open or short circuit to the ignition switch and

repair, if required. If the circuit to the ignition switch

is OK, see the Ignition Switch Test procedure in this

group.

(5) The coil ground terminal (86) is connected to

the electromagnet in the relay. It is grounded by the

PCM if the conditions are right to start the car. For

automatic trans. cars the PCM must see Park Neu-

tral switch low and near zero engine speed (rpm).

For manual trans. cars the PCM only needs to see

near zero engine speed (rpm) and low clutch inter-

lock input and see near zero engine speed (rpm). To

diagnose the Park Neutral switch of the trans range

sensor refer to the transaxle section. Check for conti-

nuity to ground while the ignition switch is in the

start position and if equipped the clutch pedal

depressed. If not OK and the vehicle has an auto-

matic trans. verify Park Neutral switch operation. If

that checks OK check for continuity between PCM

and the terminal 86. Repair open circuit as required.

Also check the clutch interlock switch operation if

equipped with a manual transmission. If OK, the

PCM may be defective.

SAFETY SWITCHES

For diagnostics of the Transmission Range Sensor,

refer to the Transaxle section for more information.

If equipped with Clutch Interlock/Upstop Switch,

refer to Diagnosis and Testing in the Clutch section.

IGNITION SWITCH

After testing starter solenoid and relay, test igni-

tion switch and wiring. Refer to the Ignition Section

or Wiring Diagrams for more information. Check all

wiring for opens or shorts, and all connectors for

being loose or corroded.

BATTERY

For battery diagnosis and testing, refer to the Bat-

tery section for procedures.

ALL RELATED WIRING AND CONNECTORS

Refer to Wiring Diagrams for more information.

DIAGNOSIS AND TESTING - FEED CIRCUIT

RESISTANCE TEST

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Ignition and Fuel systems must be dis-

abled to prevent engine start while performing the

following tests.

(1) To disable the Ignition and Fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(2) Gain access to battery terminals.

(3) With all wiring harnesses and components

properly connected, perform the following:

(a) Connect the negative lead of the voltmeter to

the battery negative post, and positive lead to the

battery negative cable clamp. Rotate and hold the

ignition switch in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between cable clamp and post.

(b) Connect positive lead of the voltmeter to the

battery positive post, and negative lead to the bat-

tery positive cable clamp. Rotate and hold the igni-

tion switch key in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between the cable clamp and post.

(c) Connect negative lead of voltmeter to battery

negative terminal, and positive lead to engine

block near the battery cable attaching point.

Rotate and hold the ignition switch in the START

position. If voltage reads above 0.2 volt, correct

poor contact at ground cable attaching point. If

voltage reading is still above 0.2 volt after correct-

ing poor contacts, replace ground cable.

(4) Connect positive voltmeter lead to the starter

motor housing and the negative lead to the battery

negative terminal. Hold the ignition switch key in

8F - 32 STARTINGRS

STARTING (Continued)

ProCarManuals.com

Page 372 of 2177

the START position. If voltage reads above 0.2 volt,

correct poor starter to engine ground.

(a) Connect the positive voltmeter lead to the

battery positive terminal, and negative lead to bat-

tery cable terminal on starter solenoid. Rotate and

hold the ignition switch in the START position. If

voltage reads above 0.2 volt, correct poor contact at

battery cable to solenoid connection. If reading is

still above 0.2 volt after correcting poor contacts,

replace battery positive cable.

(b) If resistance tests do not detect feed circuit

failures, replace the starter motor.

DIAGNOSIS AND TESTING - FEED CIRCUIT

TEST

NOTE: The following results are based upon the

vehicle being at room temperature.

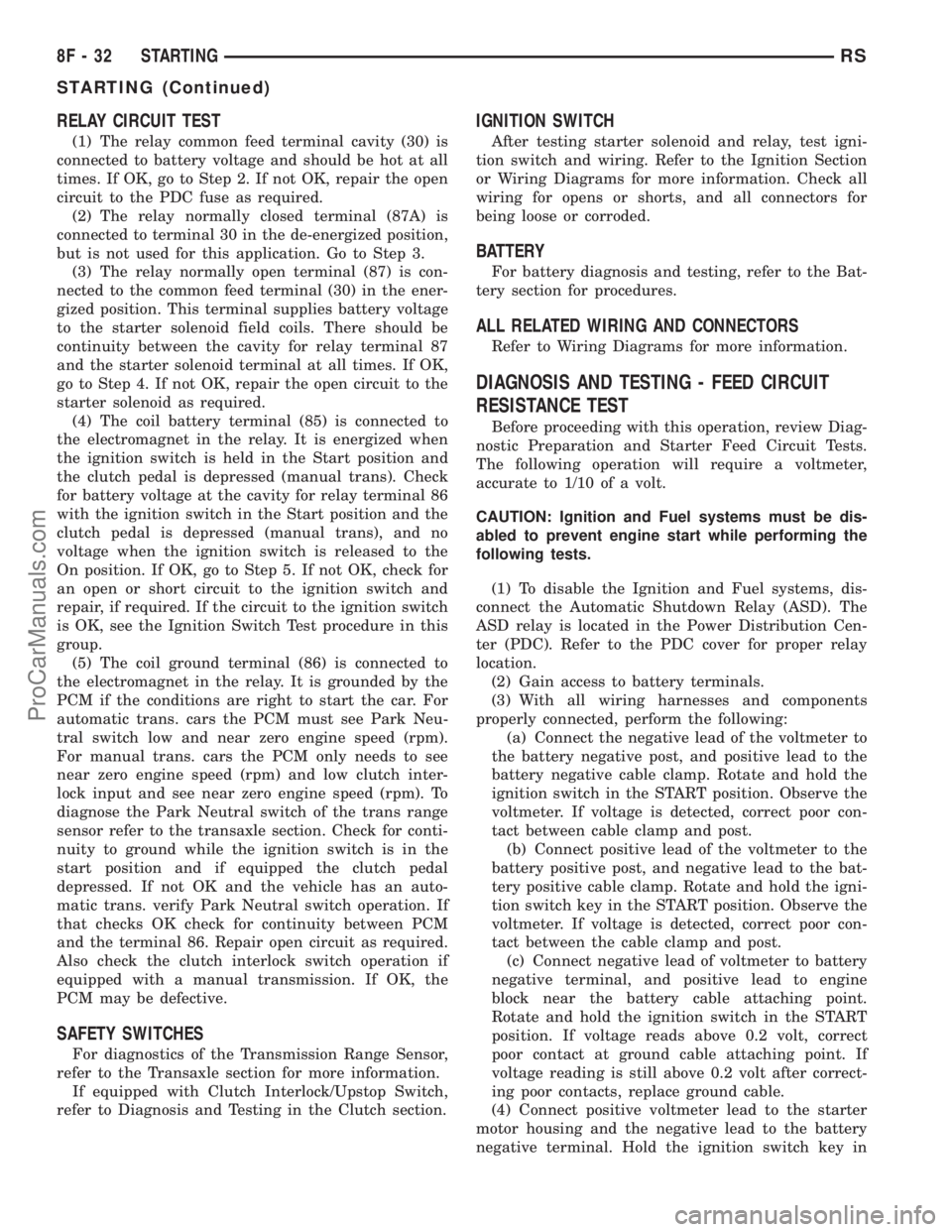

The following procedure will require a suitable

volt-ampere tester (Fig. 1).

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.(1) Check battery before performing this test. Bat-

tery must be fully charged.

(2) Connect a volt-ampere tester to the battery ter-

minals. Refer to the operating instructions provided

with the tester being used.

(3) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(4) Verify that all lights and accessories are OFF,

and the transmission shift selector is in the PARK

and SET parking brake.

CAUTION: Do not overheat the starter motor or

draw the battery voltage below 9.6 volts during

cranking operations.

(5) Rotate and hold the ignition switch in the

START position. Observe the volt-ampere tester (Fig.

1).

²If voltage reads above 9.6 volts, and amperage

draw reads above 280 amps, check for engine seizing

or faulty starter.

²If voltage reads 12.4 volts or greater and amper-

age reads 0 to 10 amps, check for corroded cables

and/or bad connections.

²Voltage below 9.6 volts and amperage draw

above 300 amps, the problem is the starter. Replace

the starter refer to starter removal.

(6) After the starting system problems have been

corrected, verify the battery state-of-charge and

charge battery if necessary. Disconnect all testing

equipment and connect ASD relay. Start the vehicle

several times to assure the problem has been cor-

rected.

SPECIFICATIONS

Torques

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Starter Mounting Bolts 47.4 35

Starter Solenoid Battery

Nut11.3 8.3 100

Fig. 1 Volt Ampere Tester

RSSTARTING8F-33

STARTING (Continued)

ProCarManuals.com

Page 373 of 2177

STARTER

MANUFACTURER NIPPONDENSO

Engine Application 2.4L /3.3/3.8L

Power rating 1.2 Kw

Voltage 12 VOLTS

No. of Fields 4

No. of Poles 4

Brushes 4

Drive Conventional Gear Train

Free running Test

Voltage 11

Amperage Draw 73 Amp

Minimum Speed 3401 RPM

SolenoidClosing Voltage 7.5 Volts

Cranking Amperage Draw

test150 - 200 Amps.

Engine should be up to operating temperature.

Extremely heavy oil or tight engine will increase

starter amperage draw.

STARTER MOTOR

REMOVAL

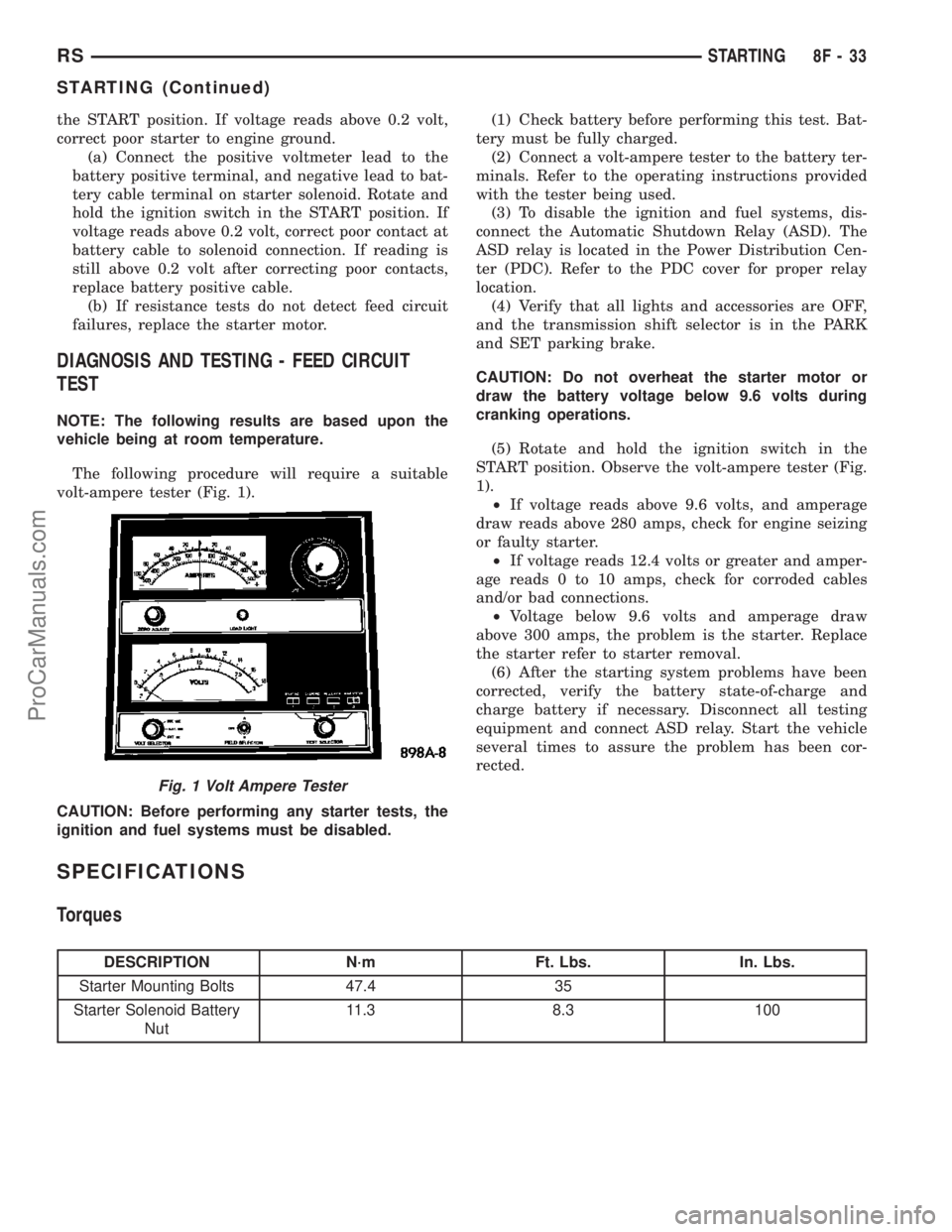

REMOVAL - 2.4L

(1) Release hood latch and open hood (Fig. 2).

(2) Disconnect and isolate the battery negative

cable.

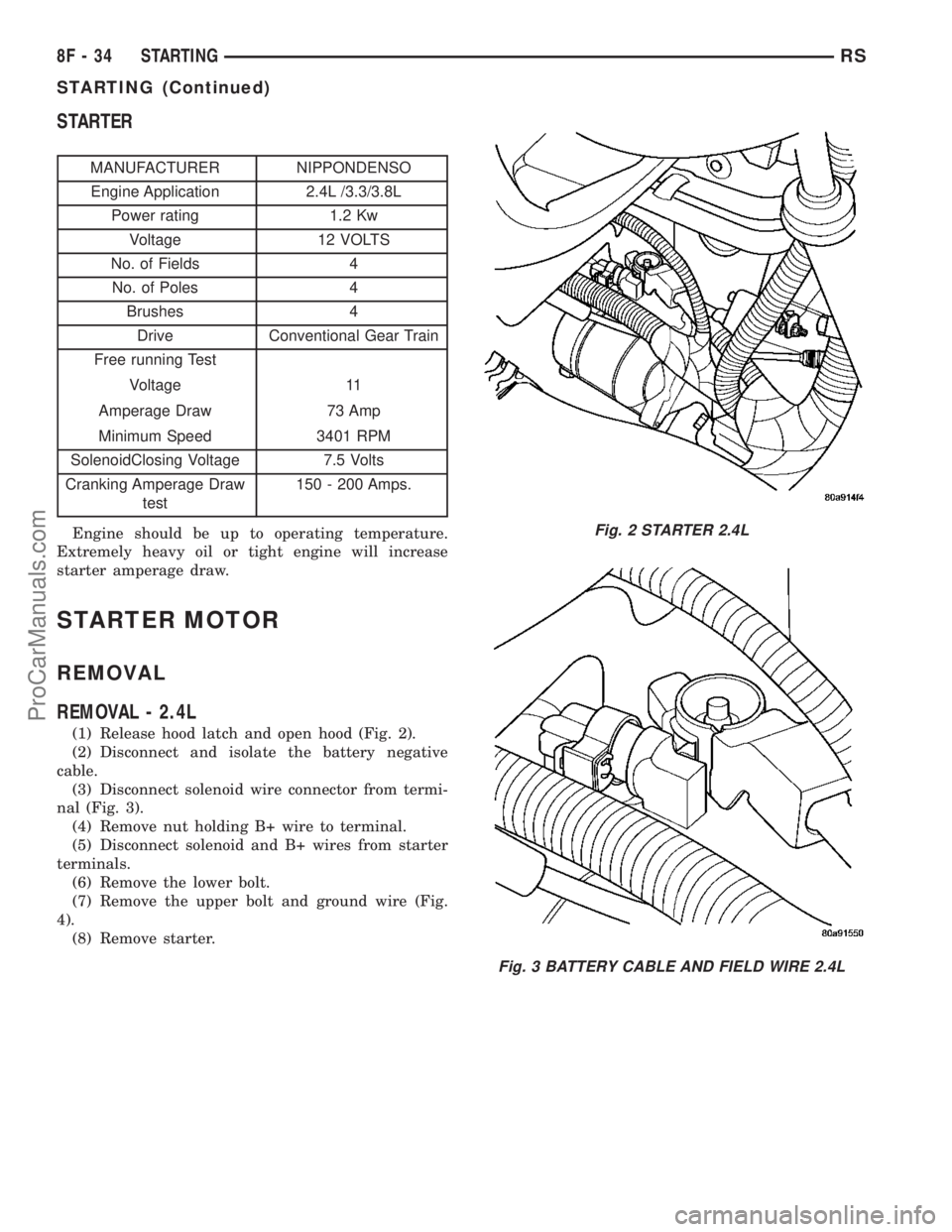

(3) Disconnect solenoid wire connector from termi-

nal (Fig. 3).

(4) Remove nut holding B+ wire to terminal.

(5) Disconnect solenoid and B+ wires from starter

terminals.

(6) Remove the lower bolt.

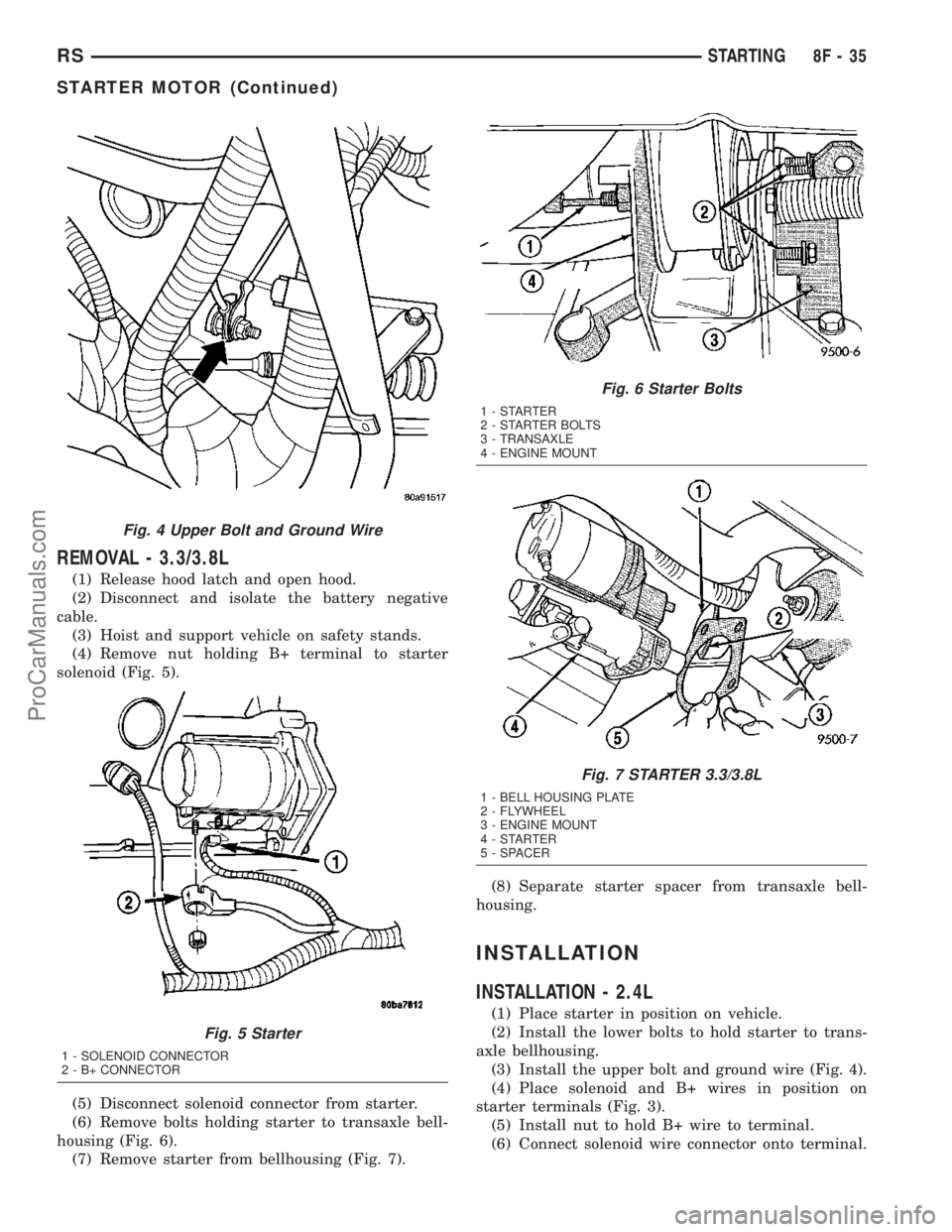

(7) Remove the upper bolt and ground wire (Fig.

4).

(8) Remove starter.

Fig. 2 STARTER 2.4L

Fig. 3 BATTERY CABLE AND FIELD WIRE 2.4L

8F - 34 STARTINGRS

STARTING (Continued)

ProCarManuals.com

Page 374 of 2177

REMOVAL - 3.3/3.8L

(1) Release hood latch and open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Hoist and support vehicle on safety stands.

(4) Remove nut holding B+ terminal to starter

solenoid (Fig. 5).

(5) Disconnect solenoid connector from starter.

(6) Remove bolts holding starter to transaxle bell-

housing (Fig. 6).

(7) Remove starter from bellhousing (Fig. 7).(8) Separate starter spacer from transaxle bell-

housing.

INSTALLATION

INSTALLATION - 2.4L

(1) Place starter in position on vehicle.

(2) Install the lower bolts to hold starter to trans-

axle bellhousing.

(3) Install the upper bolt and ground wire (Fig. 4).

(4) Place solenoid and B+ wires in position on

starter terminals (Fig. 3).

(5) Install nut to hold B+ wire to terminal.

(6) Connect solenoid wire connector onto terminal.

Fig. 4 Upper Bolt and Ground Wire

Fig. 5 Starter

1 - SOLENOID CONNECTOR

2 - B+ CONNECTOR

Fig. 6 Starter Bolts

1-STARTER

2 - STARTER BOLTS

3 - TRANSAXLE

4 - ENGINE MOUNT

Fig. 7 STARTER 3.3/3.8L

1 - BELL HOUSING PLATE

2 - FLYWHEEL

3 - ENGINE MOUNT

4-STARTER

5 - SPACER

RSSTARTING8F-35

STARTER MOTOR (Continued)

ProCarManuals.com

Page 375 of 2177

(7) Connect battery negative cable.

(8) Verify starter operation.

INSTALLATION - 3.3/3.8L

(1) Place starter spacer in position on transaxle

bellhousing, flange toward flywheel.

(2) Place starter in position on bellhousing.(3) Install bolts and ground wire (Fig. 4) to hold

starter to transaxle bellhousing.

(4) Connect solenoid connector into starter.

(5) Install nut to hold B+ terminal to starter sole-

noid.

(6) Lower vehicle.

(7) Connect battery negative cable.

(8) Verify starter operation.

8F - 36 STARTINGRS

STARTER MOTOR (Continued)

ProCarManuals.com

Page 376 of 2177

HEATED SYSTEMS

TABLE OF CONTENTS

page page

HEATED GLASS........................... 1

HEATED MIRRORS......................... 5HEATED SEAT SYSTEM..................... 7

HEATED GLASS

TABLE OF CONTENTS

page page

HEATED GLASS

DESCRIPTION..........................1

OPERATION............................1

DEFOGGER RELAY

DESCRIPTION..........................2

REAR WINDOW DEFOGGER GRID

STANDARD PROCEDURE - GRID LINE

REPAIR REAR.........................2REAR WINDOW DEFOGGER SWITCH

DESCRIPTION..........................2

OPERATION............................2

WINDSHIELD GRID

DIAGNOSIS AND TESTING - SYSTEM TEST . . . 3

STANDARD PROCEDURE - GRID LINE AND

TERMINAL REPAIR.....................3

HEATED GLASS

DESCRIPTION

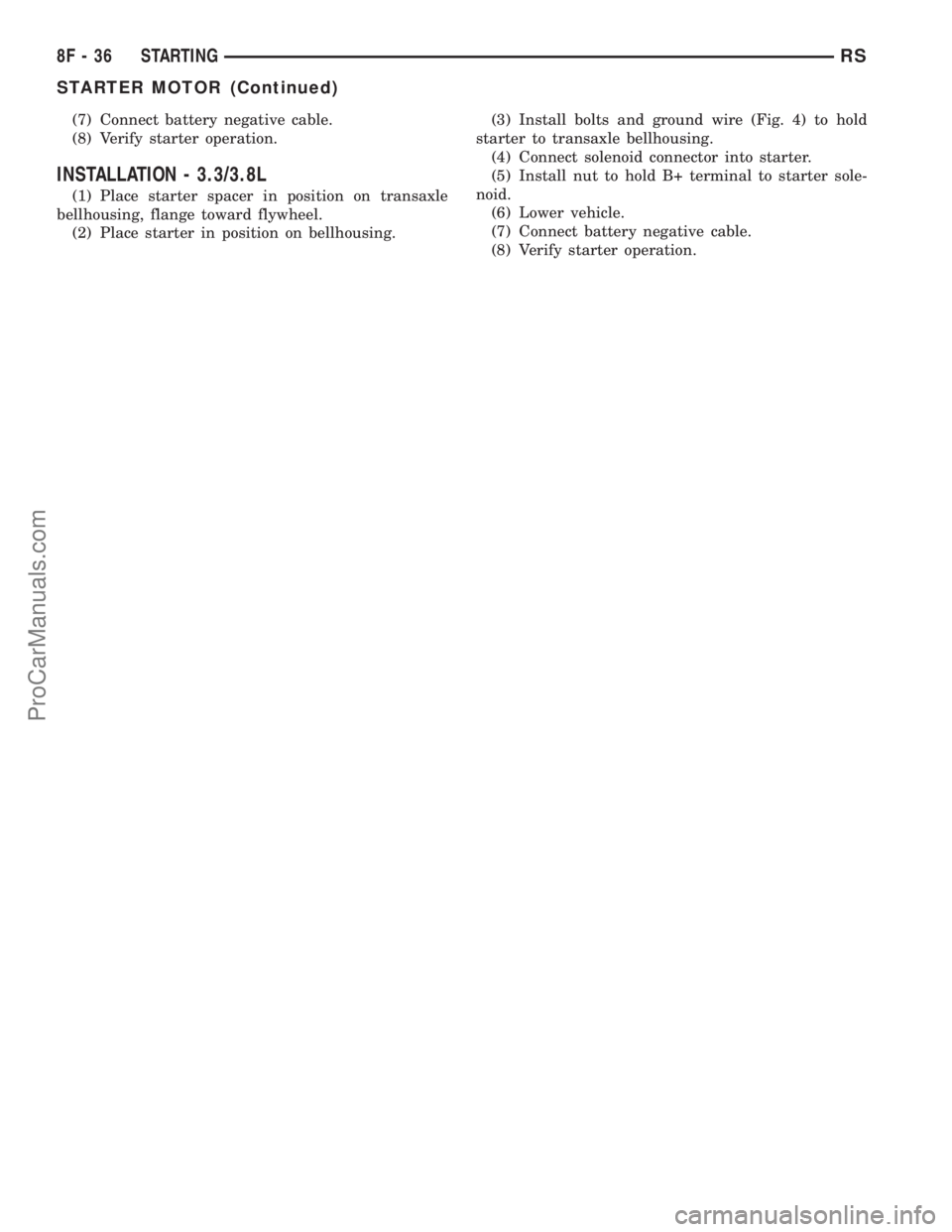

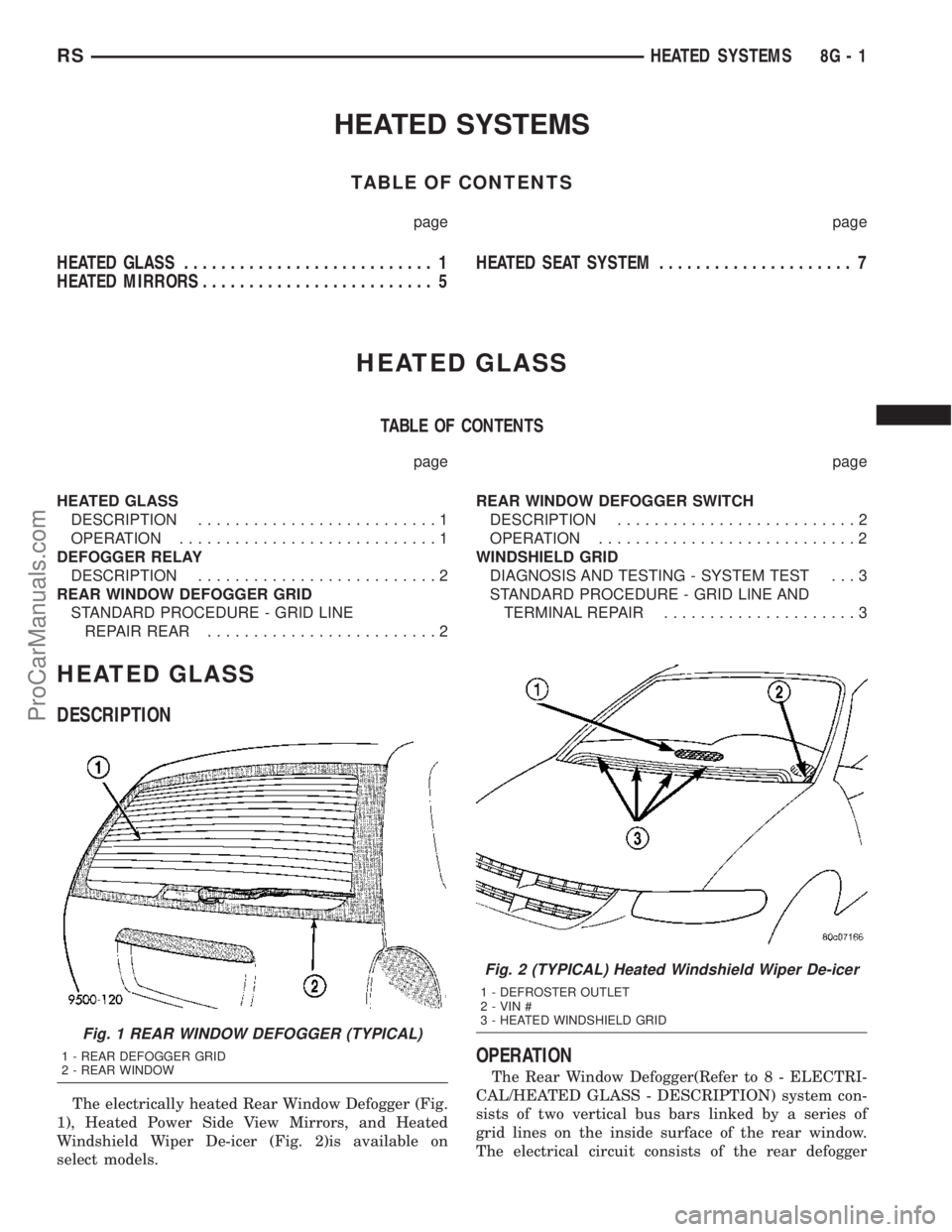

The electrically heated Rear Window Defogger (Fig.

1), Heated Power Side View Mirrors, and Heated

Windshield Wiper De-icer (Fig. 2)is available on

select models.

OPERATION

The Rear Window Defogger(Refer to 8 - ELECTRI-

CAL/HEATED GLASS - DESCRIPTION) system con-

sists of two vertical bus bars linked by a series of

grid lines on the inside surface of the rear window.

The electrical circuit consists of the rear defogger

Fig. 1 REAR WINDOW DEFOGGER (TYPICAL)

1 - REAR DEFOGGER GRID

2 - REAR WINDOW

Fig. 2 (TYPICAL) Heated Windshield Wiper De-icer

1 - DEFROSTER OUTLET

2 - VIN #

3 - HEATED WINDSHIELD GRID

RSHEATED SYSTEMS8G-1

ProCarManuals.com

Page 377 of 2177

switch in the HVAC control assembly and a relay

with timer switch to turn OFF the system after ten

minutes. The main feed circuit is protected by fuse

13 (40 amp) in the Power Distribution Center (PDC)

which is connected directly to the front control mod-

ule (FCM) to form an integrated unit called an Inte-

grated Power Module (IPM). The rear defogger

switch and relay also activates the heated power side

view mirrors. The rear defogger switch also activates

the heated windshield wiper de-icer which is powered

by the RUN/ACC relay in the IPM and feed thru fuse

#11 (20 amp) in the PDC. The heated mirror circuit

is protected by a non-servicable Positive Temperature

Coefficient (PTC) located inside the PDC. The heated

windshield wiper de-icer circuit is protected by fuse

11 (20 amp) in the PDC.

The Heated Windshield Wiper Deicer is also acti-

vated when the DEFROST mode is selected on the

HVAC. In the DEFROST mode the rear defogger

timout is bypassed, the heated windshield wiper de-

icer will stay ON until another mode is selected. For

circuit information and component location refer to

appropriate section for Wiring Diagrams.

CAUTION:

Since grid lines can be damaged or scraped off by

sharp instruments, care should be taken in cleaning

the glass or removing foreign materials, decals or

stickers. Normal glass cleaning solvents or hot

water used with rags or toweling is recommended.

DEFOGGER RELAY

DESCRIPTION

There is no heated windshield wiper de-icer relay.

The grid is powered directly from fuse #11 in the

PDC and is controlled directly from the HVAC con-

trol assembly.

REAR WINDOW DEFOGGER

GRID

STANDARD PROCEDURE - GRID LINE REPAIR

REAR

For Grid repair procedure for the rear window

defogger (Refer to 8 - ELECTRICAL/HEATED

GLASS/WINDSHIELD GRID - STANDARD PROCE-

DURE).

REAR WINDOW DEFOGGER

SWITCH

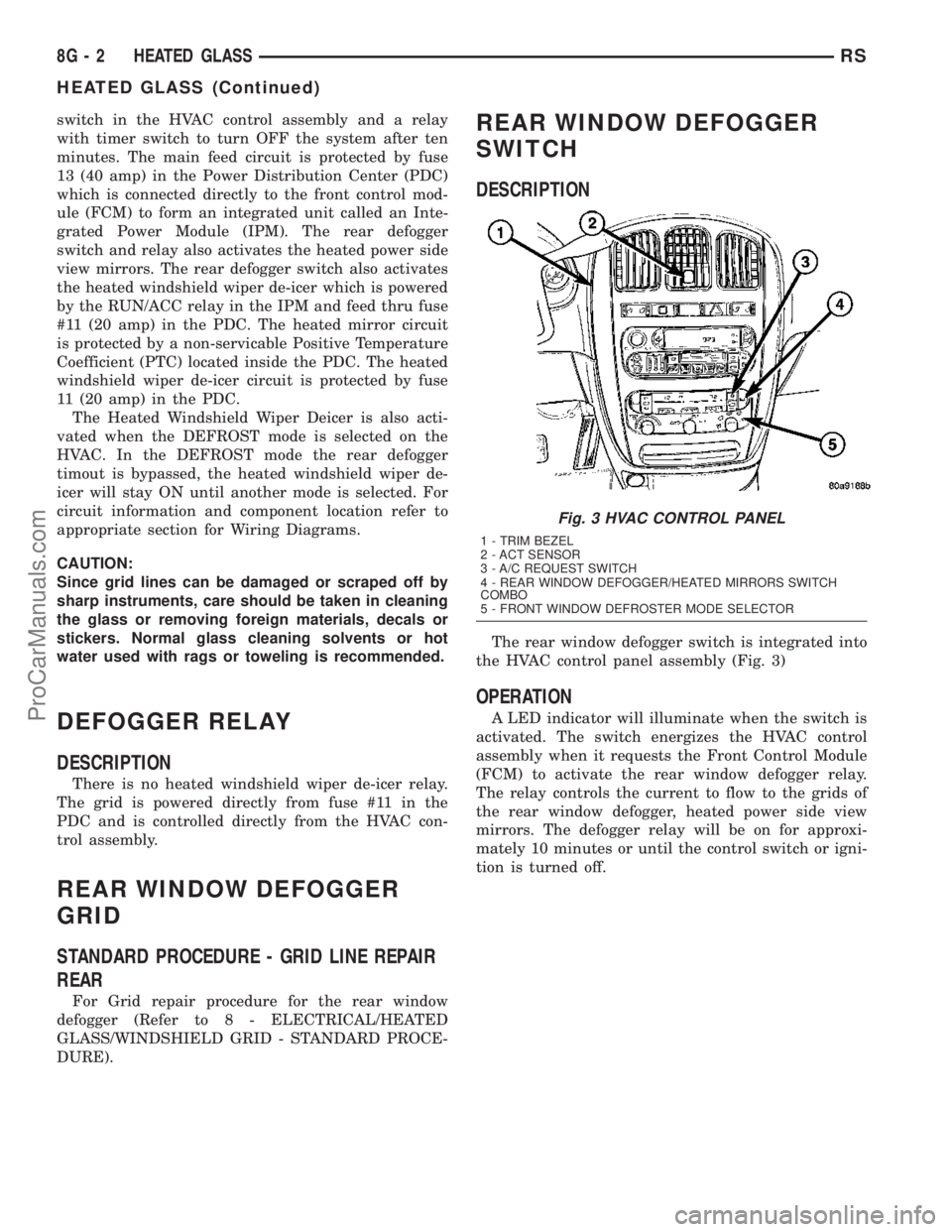

DESCRIPTION

The rear window defogger switch is integrated into

the HVAC control panel assembly (Fig. 3)

OPERATION

A LED indicator will illuminate when the switch is

activated. The switch energizes the HVAC control

assembly when it requests the Front Control Module

(FCM) to activate the rear window defogger relay.

The relay controls the current to flow to the grids of

the rear window defogger, heated power side view

mirrors. The defogger relay will be on for approxi-

mately 10 minutes or until the control switch or igni-

tion is turned off.

Fig. 3 HVAC CONTROL PANEL

1 - TRIM BEZEL

2 - ACT SENSOR

3 - A/C REQUEST SWITCH

4 - REAR WINDOW DEFOGGER/HEATED MIRRORS SWITCH

COMBO

5 - FRONT WINDOW DEFROSTER MODE SELECTOR

8G - 2 HEATED GLASSRS

HEATED GLASS (Continued)

ProCarManuals.com

Page 378 of 2177

WINDSHIELD GRID

DIAGNOSIS AND TESTING - SYSTEM TEST

Electrically heated rear window defogger or the

heated windshield wiper deicer operation can be

checked on the vehicle in the following manner:

(1) Turn the ignition switch to the ON position.

(2) Using a ammeter on the battery, turn the rear

defogger control switch to the ON position, a distinct

increase in amperage draw should be noted.

(3) The rear window defogger or the heated wind-

shield wiper deicer operation can be checked by feel-

ing the glass. A distinct difference in temperature

between the grid lines and adjacent clear glass can

be detected in 3 to 4 minutes of operation.

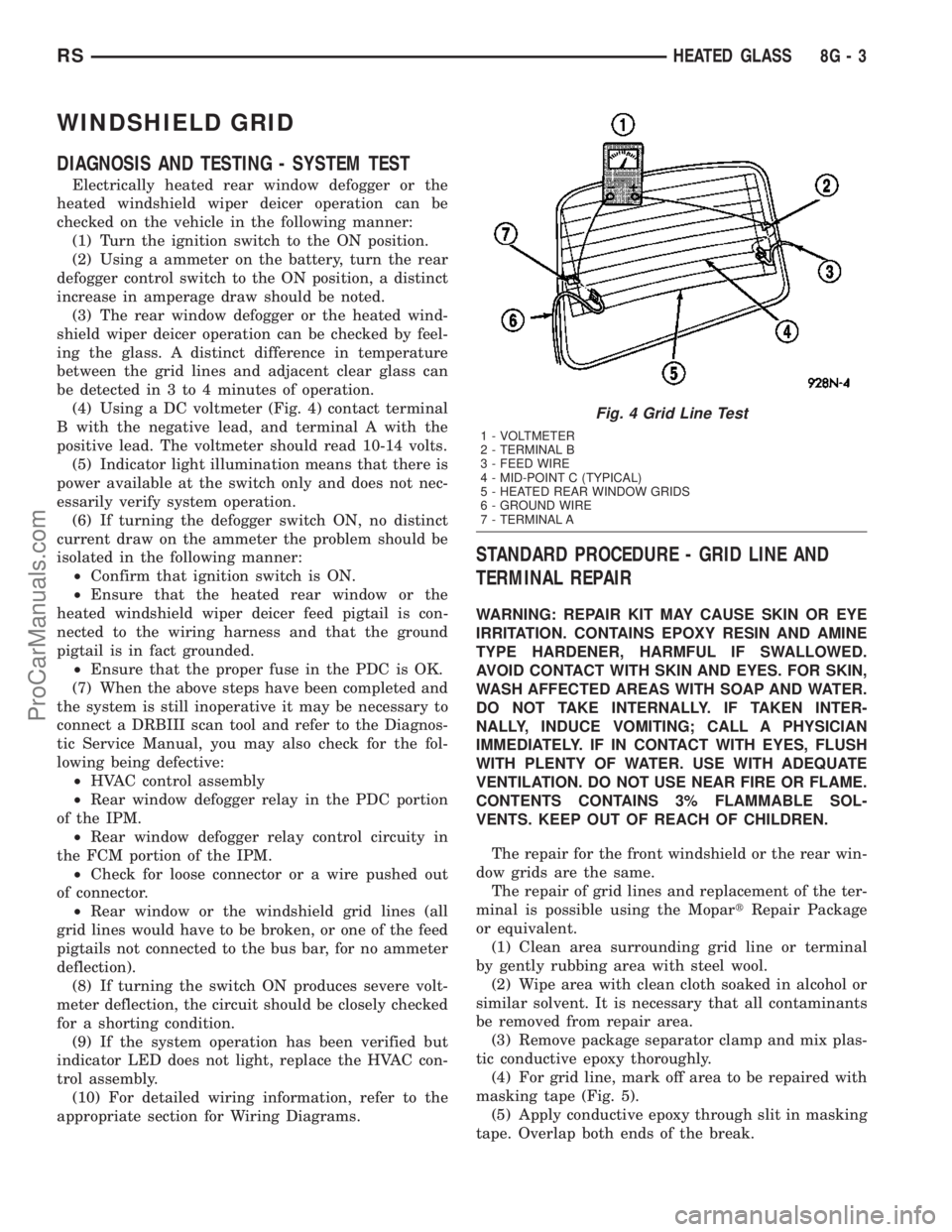

(4) Using a DC voltmeter (Fig. 4) contact terminal

B with the negative lead, and terminal A with the

positive lead. The voltmeter should read 10-14 volts.

(5) Indicator light illumination means that there is

power available at the switch only and does not nec-

essarily verify system operation.

(6) If turning the defogger switch ON, no distinct

current draw on the ammeter the problem should be

isolated in the following manner:

²Confirm that ignition switch is ON.

²Ensure that the heated rear window or the

heated windshield wiper deicer feed pigtail is con-

nected to the wiring harness and that the ground

pigtail is in fact grounded.

²Ensure that the proper fuse in the PDC is OK.

(7) When the above steps have been completed and

the system is still inoperative it may be necessary to

connect a DRBIII scan tool and refer to the Diagnos-

tic Service Manual, you may also check for the fol-

lowing being defective:

²HVAC control assembly

²Rear window defogger relay in the PDC portion

of the IPM.

²Rear window defogger relay control circuity in

the FCM portion of the IPM.

²Check for loose connector or a wire pushed out

of connector.

²Rear window or the windshield grid lines (all

grid lines would have to be broken, or one of the feed

pigtails not connected to the bus bar, for no ammeter

deflection).

(8) If turning the switch ON produces severe volt-

meter deflection, the circuit should be closely checked

for a shorting condition.

(9) If the system operation has been verified but

indicator LED does not light, replace the HVAC con-

trol assembly.

(10) For detailed wiring information, refer to the

appropriate section for Wiring Diagrams.

STANDARD PROCEDURE - GRID LINE AND

TERMINAL REPAIR

WARNING: REPAIR KIT MAY CAUSE SKIN OR EYE

IRRITATION. CONTAINS EPOXY RESIN AND AMINE

TYPE HARDENER, HARMFUL IF SWALLOWED.

AVOID CONTACT WITH SKIN AND EYES. FOR SKIN,

WASH AFFECTED AREAS WITH SOAP AND WATER.

DO NOT TAKE INTERNALLY. IF TAKEN INTER-

NALLY, INDUCE VOMITING; CALL A PHYSICIAN

IMMEDIATELY. IF IN CONTACT WITH EYES, FLUSH

WITH PLENTY OF WATER. USE WITH ADEQUATE

VENTILATION. DO NOT USE NEAR FIRE OR FLAME.

CONTENTS CONTAINS 3% FLAMMABLE SOL-

VENTS. KEEP OUT OF REACH OF CHILDREN.

The repair for the front windshield or the rear win-

dow grids are the same.

The repair of grid lines and replacement of the ter-

minal is possible using the MopartRepair Package

or equivalent.

(1) Clean area surrounding grid line or terminal

by gently rubbing area with steel wool.

(2) Wipe area with clean cloth soaked in alcohol or

similar solvent. It is necessary that all contaminants

be removed from repair area.

(3) Remove package separator clamp and mix plas-

tic conductive epoxy thoroughly.

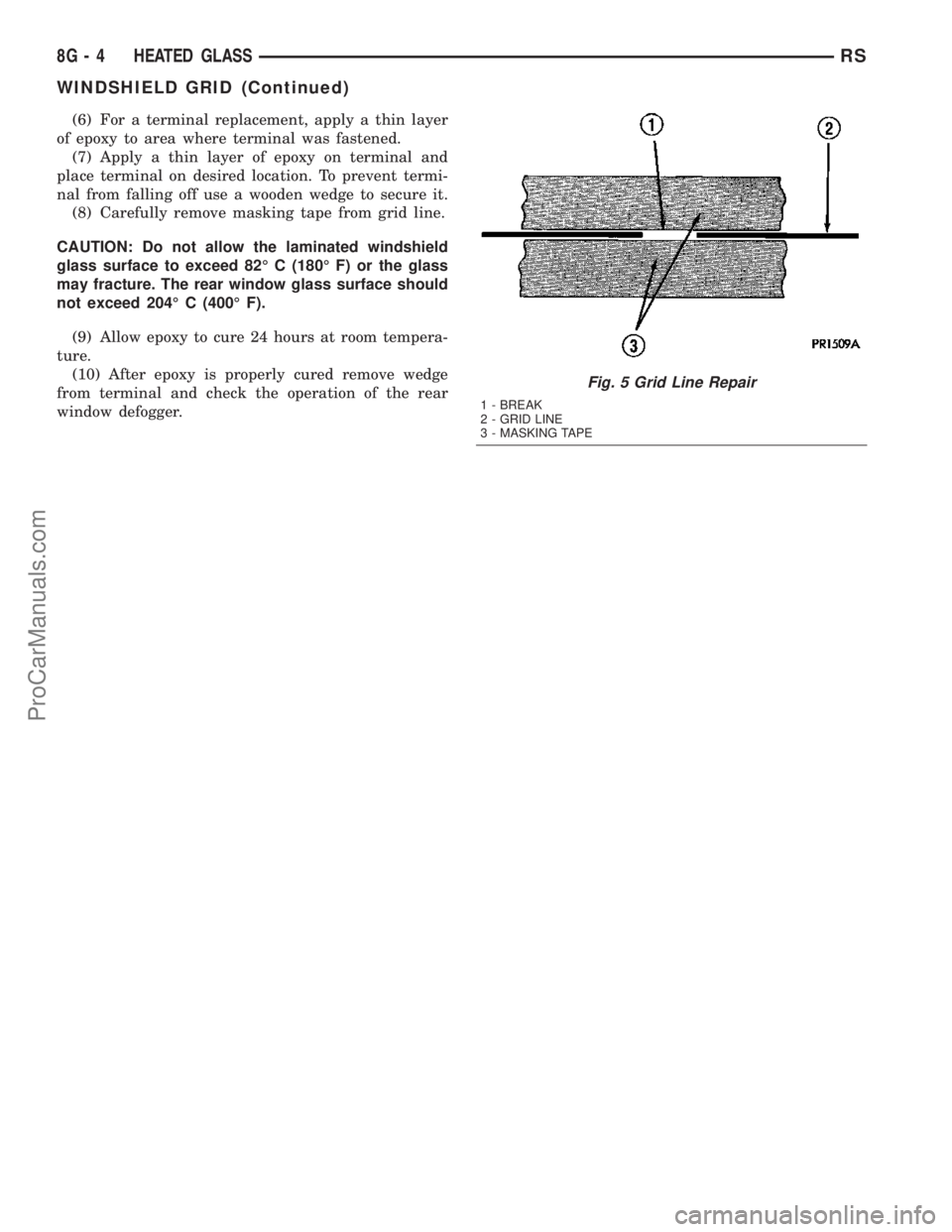

(4) For grid line, mark off area to be repaired with

masking tape (Fig. 5).

(5) Apply conductive epoxy through slit in masking

tape. Overlap both ends of the break.

Fig. 4 Grid Line Test

1 - VOLTMETER

2 - TERMINAL B

3 - FEED WIRE

4 - MID-POINT C (TYPICAL)

5 - HEATED REAR WINDOW GRIDS

6 - GROUND WIRE

7 - TERMINAL A

RSHEATED GLASS8G-3

ProCarManuals.com

Page 379 of 2177

(6) For a terminal replacement, apply a thin layer

of epoxy to area where terminal was fastened.

(7) Apply a thin layer of epoxy on terminal and

place terminal on desired location. To prevent termi-

nal from falling off use a wooden wedge to secure it.

(8) Carefully remove masking tape from grid line.

CAUTION: Do not allow the laminated windshield

glass surface to exceed 82É C (180É F) or the glass

may fracture. The rear window glass surface should

not exceed 204É C (400É F).

(9) Allow epoxy to cure 24 hours at room tempera-

ture.

(10) After epoxy is properly cured remove wedge

from terminal and check the operation of the rear

window defogger.

Fig. 5 Grid Line Repair

1 - BREAK

2 - GRID LINE

3 - MASKING TAPE

8G - 4 HEATED GLASSRS

WINDSHIELD GRID (Continued)

ProCarManuals.com

Page 380 of 2177

HEATED MIRRORS

TABLE OF CONTENTS

page page

HEATED MIRRORS

DESCRIPTION..........................5

OPERATION............................5

DIAGNOSIS AND TESTING - HEATED

MIRROR TEST........................5

MIRROR SWITCH

DESCRIPTION..........................5OPERATION............................5

HEATED MIRROR GRID

STANDARD PROCEDURE - HEATED MIRROR . . 6

RELAY

DESCRIPTION..........................6

HEATED MIRRORS

DESCRIPTION

Heated mirrors are available on models with

Power Mirrors and Rear Window Defogger only.

OPERATION

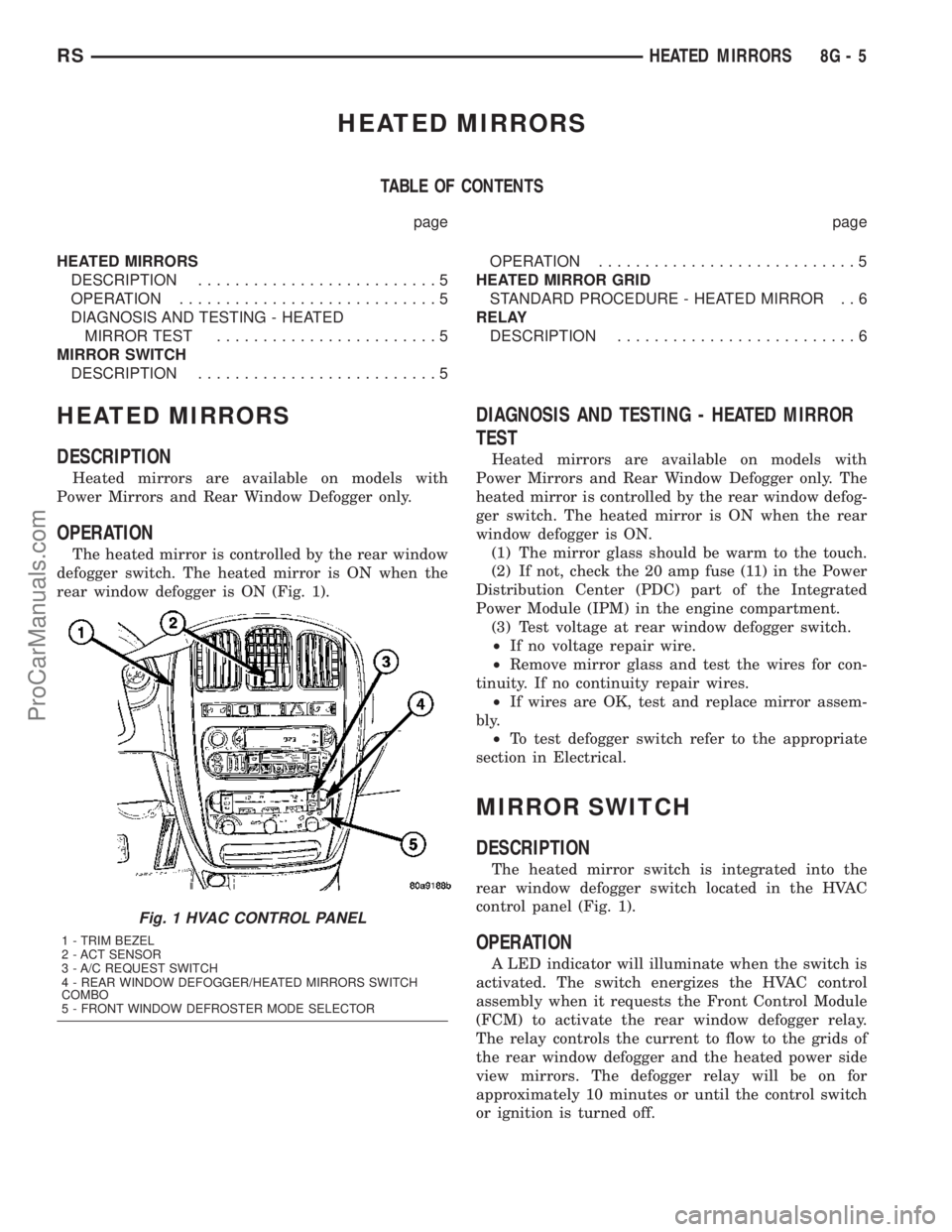

The heated mirror is controlled by the rear window

defogger switch. The heated mirror is ON when the

rear window defogger is ON (Fig. 1).

DIAGNOSIS AND TESTING - HEATED MIRROR

TEST

Heated mirrors are available on models with

Power Mirrors and Rear Window Defogger only. The

heated mirror is controlled by the rear window defog-

ger switch. The heated mirror is ON when the rear

window defogger is ON.

(1) The mirror glass should be warm to the touch.

(2) If not, check the 20 amp fuse (11) in the Power

Distribution Center (PDC) part of the Integrated

Power Module (IPM) in the engine compartment.

(3) Test voltage at rear window defogger switch.

²If no voltage repair wire.

²Remove mirror glass and test the wires for con-

tinuity. If no continuity repair wires.

²If wires are OK, test and replace mirror assem-

bly.

²To test defogger switch refer to the appropriate

section in Electrical.

MIRROR SWITCH

DESCRIPTION

The heated mirror switch is integrated into the

rear window defogger switch located in the HVAC

control panel (Fig. 1).

OPERATION

A LED indicator will illuminate when the switch is

activated. The switch energizes the HVAC control

assembly when it requests the Front Control Module

(FCM) to activate the rear window defogger relay.

The relay controls the current to flow to the grids of

the rear window defogger and the heated power side

view mirrors. The defogger relay will be on for

approximately 10 minutes or until the control switch

or ignition is turned off.

Fig. 1 HVAC CONTROL PANEL

1 - TRIM BEZEL

2 - ACT SENSOR

3 - A/C REQUEST SWITCH

4 - REAR WINDOW DEFOGGER/HEATED MIRRORS SWITCH

COMBO

5 - FRONT WINDOW DEFROSTER MODE SELECTOR

RSHEATED MIRRORS8G-5

ProCarManuals.com