height adjustment DODGE TOWN AND COUNTRY 2004 Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2004Pages: 2585, PDF Size: 62.54 MB

Page 90 of 2585

WHEEL ALIGNMENT

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT

DESCRIPTION - WHEEL ALIGNMENT.......47

DIAGNOSIS AND TESTING - SUSPENSION

AND STEERING......................50

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL

ALIGNMENT.........................52STANDARD PROCEDURE - CURB HEIGHT

MEASUREMENT......................55

SPECIFICATIONS

WHEEL ALIGNMENT...................56

WHEEL ALIGNMENT

DESCRIPTION - WHEEL ALIGNMENT

Vehicle wheel alignment is the positioning of all

interrelated front and rear suspension angles. These

angles affect the handling and steering of the vehicle

when it is in motion. Proper wheel alignment is

essential for efficient steering, good directional stabil-

ity, and proper tire wear.

The method of checking a vehicle's front and rear

wheel alignment varies depending on the manufac-

turer and type of equipment used. The manufactur-

er's instructions should always be followed to ensure

accuracy of the alignment, except when

DaimlerChrysler Corporation's wheel alignment spec-

ifications differ.

On this vehicle, the suspension angles that can be

adjusted are as follows:

²Front Camber (with camber bolt package and

standard procedure)

²Front Toe

Check the wheel alignment and make all wheel

alignment adjustments with the vehicle standing at

its proper curb height specification. Curb height is

the normal riding height of the vehicle. It is mea-

sured from a certain point on the vehicle to the

ground or a designated area while the vehicle is sit-

ting on a flat, level surface. Refer to Curb Height

Measurement in this section for additional informa-

tion.

Typical wheel alignment angles and measurements

are described in the following paragraphs.

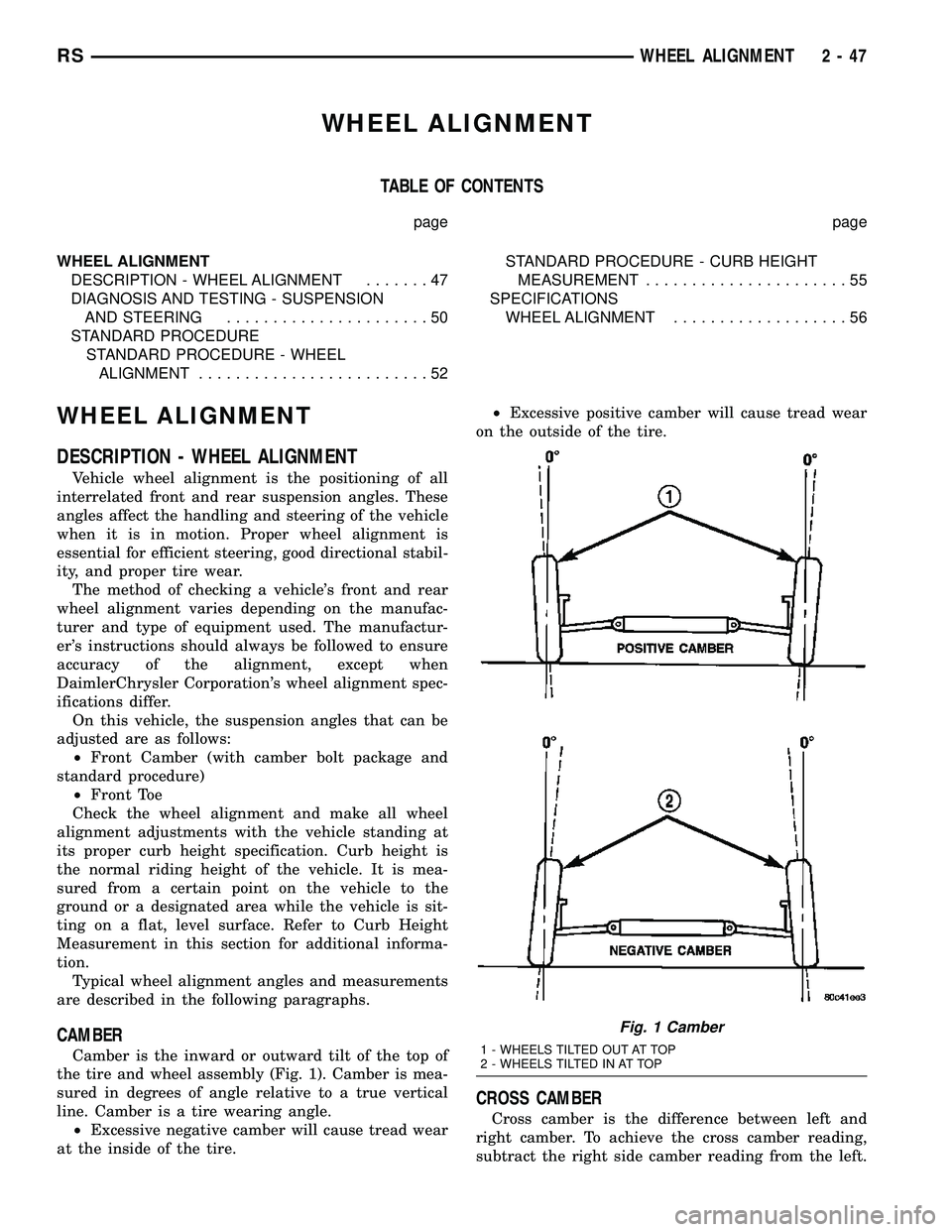

CAMBER

Camber is the inward or outward tilt of the top of

the tire and wheel assembly (Fig. 1). Camber is mea-

sured in degrees of angle relative to a true vertical

line. Camber is a tire wearing angle.

²Excessive negative camber will cause tread wear

at the inside of the tire.²Excessive positive camber will cause tread wear

on the outside of the tire.

CROSS CAMBER

Cross camber is the difference between left and

right camber. To achieve the cross camber reading,

subtract the right side camber reading from the left.

Fig. 1 Camber

1 - WHEELS TILTED OUT AT TOP

2 - WHEELS TILTED IN AT TOP

RSWHEEL ALIGNMENT2-47

Page 95 of 2585

CONDITION POSSIBLE CAUSES CORRECTION

Excessive Steering Free

Play1. Incorrect Steering Gear Adjustment 1. Adjust Or Replace Steering Gear

2. Worn or loose tie rod ends 2. Replace or tighten tie rod ends

3. Loose steering gear mounting bolts 3. Tighten steering gear bolts to specified

torque

4. Loose or worn steering shaft coupler 4. Replace steering shaft coupler

Excessive Steering Effort 1. Low tire pressure 1. Inflate all tires to recommended

pressure

2. Lack of lubricant in steering gear 2. Replace steering gear

3. Low power steering fluid level 3. Fill power steering fluid reservoir to

correct level

4. Loose power steering pump drive

belt4. Correctly adjust power steering pump

drive belt

5. Lack of lubricant in ball joints 5. Lubricate or replace ball joints

6. Steering gear malfunction 6. Replace steering gear

7. Lack of lubricant in steering coupler 7. Replace steering coupler

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL ALIGNMENT

PRE-WHEEL ALIGNMENT INSPECTION

Before any attempt is made to change or correct

the wheel alignment, the following inspection and

necessary corrections must be made to ensure proper

alignment.

(1) Verify that the fuel tank is full of fuel. If the

tank is not full, the reduction in weight will affect

the curb height of the vehicle and the alignment

angles.

(2) The passenger and luggage compartments of

the vehicle should be free of any load that is not fac-

tory equipment.

(3) Check the tires on the vehicle. All tires must be

the same size and in good condition with approxi-

mately the same amount of tread wear. Inflate all

the tires to the recommended air pressure.

(4) Check the front wheel and tire assemblies for

excessive radial runout.

(5) Inspect lower ball joints and all steering link-

age for looseness, binding, wear or damage. Repair as

necessary.

(6) Check suspension fasteners for proper torque

and retighten as necessary.

(7) Inspect all suspension component rubber bush-

ings for signs of wear or deterioration. Replace any

faulty bushings or components before aligning the

vehicle.

(8) Check the vehicle's curb height to verify it is

within specifications. Refer to Curb Height Measure-

ment.

WHEEL ALIGNMENT SETUP

(1) Position the vehicle on an alignment rack.

(2) Install all required alignment equipment on

the vehicle per the alignment equipment manufactur-

er's instructions. On this vehicle, a four-wheel align-

ment is recommended.

NOTE: Prior to reading the vehicle's alignment

readouts, the front and rear of vehicle should be

jounced. Induce jounce (rear first, then front) by

grasping the center of the bumper and jouncing

each end of vehicle an equal number of times. The

bumper should always be released when vehicle is

at the bottom of the jounce cycle.

(3) Read the vehicle's current front and rear align-

ment settings. Compare the vehicle's current align-

ment settings to the vehicle specifications for camber,

caster and toe-in. (Refer to 2 - SUSPENSION/

WHEEL ALIGNMENT - SPECIFICATIONS)

(4) If front camber and caster are not within spec-

ifications, proceed to CAMBER AND CASTER below.

If caster and camber are within specifications, pro-

ceed to TOE which can be found following CAMBER

AND CASTER. Rear camber, caster and toe are not

adjustable. If found not to be within specifications,

reinspect for damaged suspension or body compo-

nents and replace as necessary.

CAMBER AND CASTER

Camber and caster settings on this vehicle are

determined at the time the vehicle is designed, by

the location of the vehicle's suspension components.

This is referred to as NET BUILD. The result is no

2 - 52 WHEEL ALIGNMENTRS

WHEEL ALIGNMENT (Continued)

Page 98 of 2585

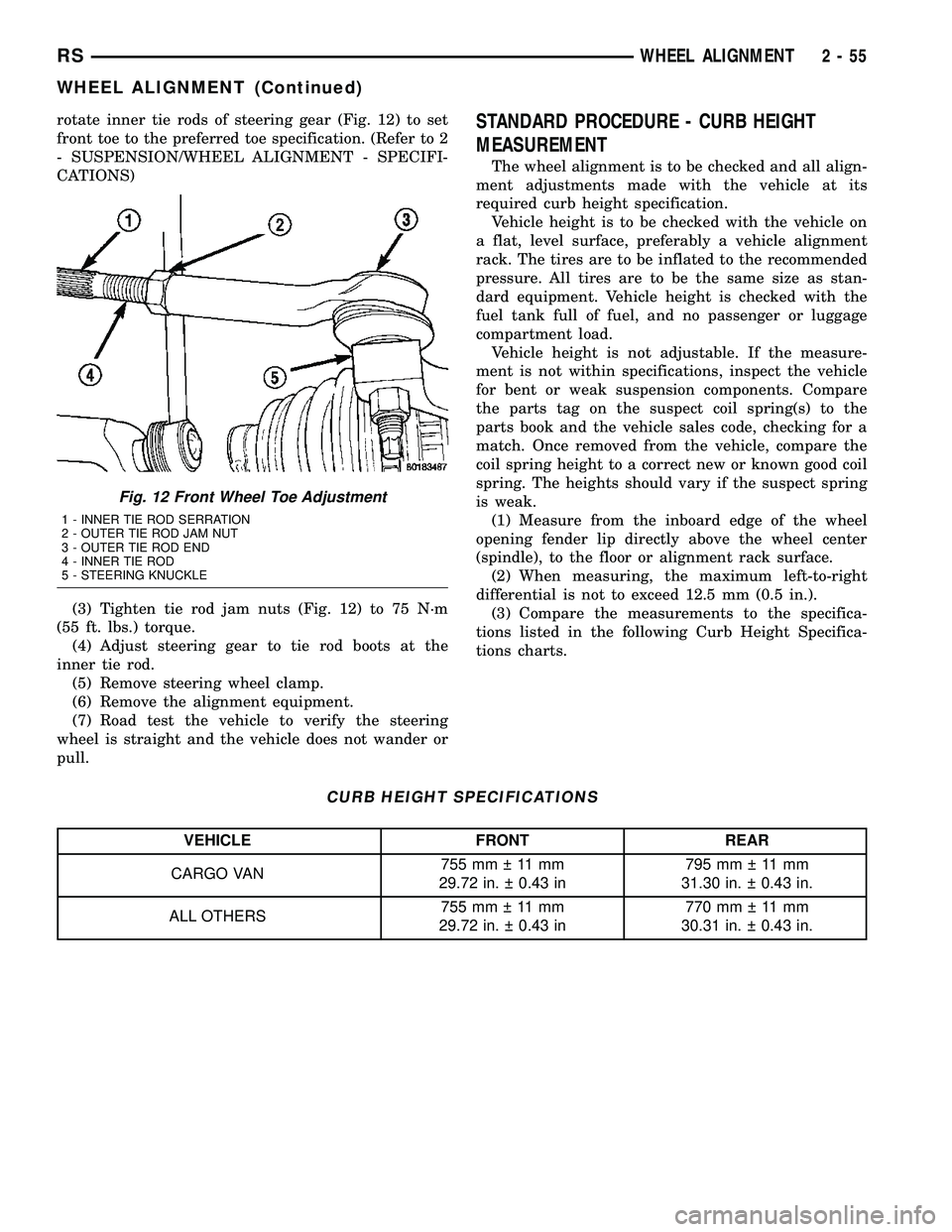

rotate inner tie rods of steering gear (Fig. 12) to set

front toe to the preferred toe specification. (Refer to 2

- SUSPENSION/WHEEL ALIGNMENT - SPECIFI-

CATIONS)

(3) Tighten tie rod jam nuts (Fig. 12) to 75 N´m

(55 ft. lbs.) torque.

(4) Adjust steering gear to tie rod boots at the

inner tie rod.

(5) Remove steering wheel clamp.

(6) Remove the alignment equipment.

(7) Road test the vehicle to verify the steering

wheel is straight and the vehicle does not wander or

pull.STANDARD PROCEDURE - CURB HEIGHT

MEASUREMENT

The wheel alignment is to be checked and all align-

ment adjustments made with the vehicle at its

required curb height specification.

Vehicle height is to be checked with the vehicle on

a flat, level surface, preferably a vehicle alignment

rack. The tires are to be inflated to the recommended

pressure. All tires are to be the same size as stan-

dard equipment. Vehicle height is checked with the

fuel tank full of fuel, and no passenger or luggage

compartment load.

Vehicle height is not adjustable. If the measure-

ment is not within specifications, inspect the vehicle

for bent or weak suspension components. Compare

the parts tag on the suspect coil spring(s) to the

parts book and the vehicle sales code, checking for a

match. Once removed from the vehicle, compare the

coil spring height to a correct new or known good coil

spring. The heights should vary if the suspect spring

is weak.

(1) Measure from the inboard edge of the wheel

opening fender lip directly above the wheel center

(spindle), to the floor or alignment rack surface.

(2) When measuring, the maximum left-to-right

differential is not to exceed 12.5 mm (0.5 in.).

(3) Compare the measurements to the specifica-

tions listed in the following Curb Height Specifica-

tions charts.

CURB HEIGHT SPECIFICATIONS

VEHICLE FRONT REAR

CARGO VAN755mm 11mm

29.72 in. 0.43 in795mm 11mm

31.30 in. 0.43 in.

ALL OTHERS755mm 11mm

29.72 in. 0.43 in770mm 11mm

30.31 in. 0.43 in.

Fig. 12 Front Wheel Toe Adjustment

1 - INNER TIE ROD SERRATION

2 - OUTER TIE ROD JAM NUT

3 - OUTER TIE ROD END

4 - INNER TIE ROD

5 - STEERING KNUCKLE

RSWHEEL ALIGNMENT2-55

WHEEL ALIGNMENT (Continued)

Page 2142 of 2585

point must not affect alignment. Striker should go

straight into the latching mechanism.

(2) On vehicles with left sliding doors, check the

fuel door blocker striker entry into latch. Striker at

this point must not affect alignment.

(3) Check C-post and B-post for door to aperture

gaps and door to door gaps. All gaps should be 5 mm

1 mm.

(4) Check door for height using character lines as

a reference. Also check roof contour as a controlling

factor.

Using the procedures noted below, adjust the side

door in the order the individual steps are called out.

DOOR FLUSHNESS ADJUSTMENT

(1) Check sliding door flushness at the C-pillar

striker.

(2) If the sliding door is under or over flush,

remove striker assembly and move thread plate over

keeping one bolt in plate so it will not fall between

inner and outer panels.

(3) Adjust the C-pillar striker in or out until the

door is flush. Then, the on size hole can be elongated

in the direction required. This can be done by grind-

ing or filing the sheet metal and then painting raw

edge to prevent rusting.

(4) Check upper B-pillar flushness to A-pillar

cover.

(5) The sliding door upper hinge can only be

moved outboard by addinga1mmshim behind the

hinge mounting area once the too attachment bolts

are removed and reinstalled.

(6) Check flushness at upper C-pillar.

(7) If upper C-pillar flushness is out of specifica-

tion use a heavy rubber mallet on the door assembly

until door is in specifications.

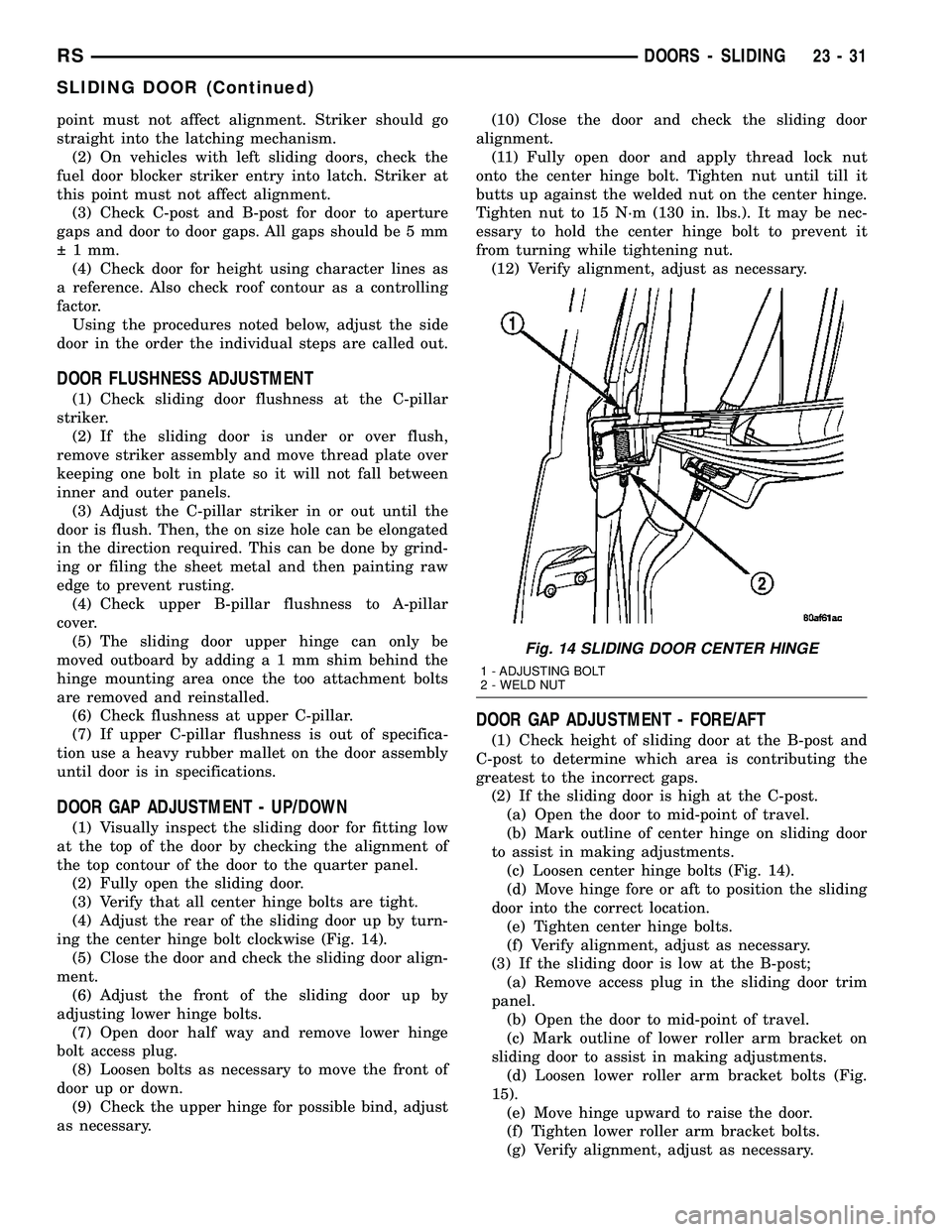

DOOR GAP ADJUSTMENT - UP/DOWN

(1) Visually inspect the sliding door for fitting low

at the top of the door by checking the alignment of

the top contour of the door to the quarter panel.

(2) Fully open the sliding door.

(3) Verify that all center hinge bolts are tight.

(4) Adjust the rear of the sliding door up by turn-

ing the center hinge bolt clockwise (Fig. 14).

(5) Close the door and check the sliding door align-

ment.

(6) Adjust the front of the sliding door up by

adjusting lower hinge bolts.

(7) Open door half way and remove lower hinge

bolt access plug.

(8) Loosen bolts as necessary to move the front of

door up or down.

(9) Check the upper hinge for possible bind, adjust

as necessary.(10) Close the door and check the sliding door

alignment.

(11) Fully open door and apply thread lock nut

onto the center hinge bolt. Tighten nut until till it

butts up against the welded nut on the center hinge.

Tighten nut to 15 N´m (130 in. lbs.). It may be nec-

essary to hold the center hinge bolt to prevent it

from turning while tightening nut.

(12) Verify alignment, adjust as necessary.

DOOR GAP ADJUSTMENT - FORE/AFT

(1) Check height of sliding door at the B-post and

C-post to determine which area is contributing the

greatest to the incorrect gaps.

(2) If the sliding door is high at the C-post.

(a) Open the door to mid-point of travel.

(b) Mark outline of center hinge on sliding door

to assist in making adjustments.

(c) Loosen center hinge bolts (Fig. 14).

(d) Move hinge fore or aft to position the sliding

door into the correct location.

(e) Tighten center hinge bolts.

(f) Verify alignment, adjust as necessary.

(3) If the sliding door is low at the B-post;

(a) Remove access plug in the sliding door trim

panel.

(b) Open the door to mid-point of travel.

(c) Mark outline of lower roller arm bracket on

sliding door to assist in making adjustments.

(d) Loosen lower roller arm bracket bolts (Fig.

15).

(e) Move hinge upward to raise the door.

(f) Tighten lower roller arm bracket bolts.

(g) Verify alignment, adjust as necessary.

Fig. 14 SLIDING DOOR CENTER HINGE

1 - ADJUSTING BOLT

2 - WELD NUT

RSDOORS - SLIDING23-31

SLIDING DOOR (Continued)

Page 2546 of 2585

BASE COAT/CLEARCOAT FINISH -

DESCRIPTION.......................23-85

BATTERY - DESCRIPTION...............8F-7

BATTERY - DIAGNOSIS AND TESTING.....8F-9

BATTERY - OPERATION.................8F-9

BATTERY - REMOVAL............8F-14,8F-15

BATTERY - SPECIFICATIONS.............8N-5

BATTERY CABLE - DIAGNOSIS AND

TESTING...........................8F-16

BATTERY CABLES - DESCRIPTION.......8F-16

BATTERY CABLES - INSTALLATION.......8F-18

BATTERY CABLES - OPERATION.........8F-16

BATTERY CABLES - REMOVAL..........8F-18

BATTERY CHARGING - STANDARD

PROCEDURE, CONVENTIONAL..........8F-11

BATTERY CHARGING - STANDARD

PROCEDURE, SPIRAL PLATE............8F-10

BATTERY ELECTROLYTE LEVEL -

STANDARD PROCEDURE, CHECKING.....8F-14

BATTERY HOLDDOWN - DESCRIPTION....8F-15

BATTERY HOLDDOWN - INSTALLATION . . . 8F-16

BATTERY HOLDDOWN - OPERATION.....8F-15

BATTERY HOLDDOWN - REMOVAL . . 8F-15,8F-16

BATTERY REPLACEMENT - STANDARD

PROCEDURE....................8N-42,8N-5

BATTERY, SPECIFICATIONS.............8N-43

BATTERY SYSTEM - CLEANING.......8F-4,8F-5

BATTERY SYSTEM - DESCRIPTION........8F-1

BATTERY SYSTEM - DIAGNOSIS AND

TESTING............................8F-2

BATTERY SYSTEM - INSPECTION.....8F-5,8F-6

BATTERY SYSTEM - OPERATION.........8F-2

BATTERY SYSTEM - SPECIFICATIONS......8F-6

BATTERY SYSTEM SPECIAL TOOLS,

SPECIAL TOOLS......................8F-7

BATTERY TEMPERATURE SENSOR -

DESCRIPTION.......................8F-23

BATTERY TEMPERATURE SENSOR -

OPERATION.........................8F-23

BATTERY TEMPERATURE SENSOR -

REMOVAL..........................8F-23

BATTERY TEMPERATURE SENSOR -

SPECIFICATIONS.....................8F-22

BATTERY TRAY - DESCRIPTION.........8F-18

BATTERY TRAY - INSTALLATION.........8F-19

BATTERY TRAY - OPERATION......8F-18,8F-19

BATTERY TRAY - REMOVAL............8F-19

BEARING - DESCRIPTION, HUB.......2-30,2-4

BEARING - DIAGNOSIS AND TESTING,

HUB.............................2-31,2-5

BEARING - INSTALLATION, CLUTCH

RELEASE LEVER.......................6-7

BEARING - INSTALLATION, END COVER

BALL..............................21-10

BEARING - INSTALLATION, HUB.......2-33,2-6

BEARING - OPERATION, HUB.........2-30,2-4

BEARING - REMOVAL, CLUTCH RELEASE

LEVER...............................6-6

BEARING - REMOVAL, END COVER BALL . . . 21-9

BEARING - REMOVAL, HUB..........2-31,2-5

BEARING CLEARANCE - STANDARD

PROCEDURE, MEASURING

CONNECTING ROD...................9-120

BEARING CLEARANCE USING

PLASTIGAGE - STANDARD

PROCEDURE, MEASURING..........9-12,9-84

BEARING FITTING - STANDARD

PROCEDURE, MAIN...................9-123

BEARING PRELOAD - ADJUSTMENT,

DIFFERENTIAL......................21-199

BEARING PRELOAD MEASUREMENT

AND ADJUSTMENT, ADJUSTMENTS -

DIFFERENTIAL.....................21s-100

BEARINGS - INSTALLATION,

CRANKSHAFT MAIN..................9-124

BEARINGS - REMOVAL, CRANKSHAFT

MAIN..............................9-124

BEARINGS (IN BLOCK) - DESCRIPTION,

CAMSHAFT.........................9-115

BEARINGS (IN BLOCK) - INSPECTION,

CAMSHAFT

.........................9-115

BEARINGS (IN BLOCK) - INSTALLATION,

CAMSHAFT

.........................9-115

BEARINGS (IN BLOCK) - OPERATION,

CAMSHAFT

.........................9-115

BEARINGS (IN BLOCK) - REMOVAL,

CAMSHAFT

.........................9-115

BELLCRANK - INSTALLATION

...........23-35BELLCRANK - REMOVAL...............23-35

BELT - DIAGNOSIS AND TESTING,

ACCESSORY DRIVE.....................7-7

BELT - INSTALLATION, TIMING...........9-65

BELT - REMOVAL, TIMING..............9-63

BELT & RETRACTOR - FIRST ROW -

OUTBOARD - INSTALLATION, SEAT......8O-14

BELT & RETRACTOR - FIRST ROW -

OUTBOARD - REMOVAL, SEAT..........8O-14

BELT & RETRACTOR - OUTBOARD -

FRONT - INSTALLATION, SEAT..........8O-14

BELT & RETRACTOR - OUTBOARD -

FRONT - REMOVAL, SEAT..............8O-14

BELT & RETRACTOR - SECOND ROW -

LEFT OUTBOARD - INSTALLATION,

SEAT ..............................8O-17

BELT & RETRACTOR - SECOND ROW -

LEFT OUTBOARD - REMOVAL, SEAT.....8O-17

BELT & RETRACTOR - SECOND ROW -

RIGHT OUTBOARD - INSTALLATION,

SEAT ..............................8O-15

BELT & RETRACTOR - SECOND ROW -

RIGHT OUTBOARD - REMOVAL, SEAT....8O-15

BELT & RETRACTOR - SECOND ROW -

RIGHT OUTBOARD WITH REAR HVAC -

LWB - INSTALLATION, SEAT............8O-16

BELT & RETRACTOR - SECOND ROW -

RIGHT OUTBOARD WITH REAR HVAC -

LWB - REMOVAL, SEAT...............8O-16

BELT BUCKLE - FIRST ROW - BENCH -

INSTALLATION, SEAT.................8O-13

BELT BUCKLE - FIRST ROW - BENCH -

REMOVAL, SEAT.....................8O-13

BELT BUCKLE - FIRST ROW INBOARD -

QUAD BUCKET - INSTALLATION, SEAT....8O-12

BELT BUCKLE - FIRST ROW INBOARD -

QUAD BUCKET - REMOVAL, SEAT.......8O-12

BELT BUCKLE - FRONT INBOARD -

INSTALLATION, SEAT.................8O-12

BELT BUCKLE - FRONT INBOARD -

REMOVAL, SEAT.....................8O-12

BELT BUCKLE - SECOND ROW - THREE

PASSENGER BENCH - INSTALLATION,

SEAT ..............................8O-15

BELT BUCKLE - SECOND ROW - THREE

PASSENGER BENCH - REMOVAL, SEAT . . . 8O-15

BELT BUCKLE - SECOND ROW INBOARD

- 50/50 BENCH - INSTALLATION, SEAT . . . 8O-13

BELT BUCKLE - SECOND ROW INBOARD

- 50/50 BENCH - REMOVAL, SEAT.......8O-13

BELT COVER(S) - INSTALLATION,

TIMING.............................9-62

BELT COVER(S) - REMOVAL, TIMING......9-61

BELT HEIGHT ADJUSTER-BOR

C-PILLAR - INSTALLATION, SEAT........8O-13

BELT HEIGHT ADJUSTER-BOR

C-PILLAR - REMOVAL, SEAT...........8O-13

BELT HEIGHT ADJUSTER KNOB -

INSTALLATION, SEAT.................8O-14

BELT HEIGHT ADJUSTER KNOB -

REMOVAL, SEAT.....................8O-14

BELT MOLDING - INSTALLATION, FRONT

DOOR INNER.......................23-115

BELT MOLDING - INSTALLATION, FRONT

DOOR OUTER......................23-113

BELT MOLDING - REMOVAL, FRONT

DOOR INNER.......................23-115

BELT MOLDING - REMOVAL, FRONT

DOOR OUTER......................23-113

BELT TENSION - STANDARD

PROCEDURE, CHECKING POWER

STEERING............................7-8

BELT TENSION, SPECIFICATIONS -

ACCESSORY DRIVE.....................7-5

BELT TENSIONER - 2.4L - INSTALLATION . . 7-10

BELT TENSIONER - 2.4L - REMOVAL......7-10

BELT TENSIONER - 3.3/3.8L -

INSTALLATION........................7-12

BELT TENSIONER - 3.3/3.8L - REMOVAL . . . 7-12

BELT TENSIONER - DESCRIPTION, SEAT . . 8O-17

BELT TENSIONER - OPERATION, SEAT....8O-17

BELT TENSIONER & PULLEY -

INSTALLATION, TIMING

.................9-69

BELT TENSIONER & PULLEY -

REMOVAL, TIMING

....................9-68

BELTS - 2.4L - ADJUSTMENTS, DRIVE

.....7-10

BELTS - 2.4L - CLEANING, DRIVE

..........7-9

BELTS - 2.4L - INSPECTION, DRIVE

........7-9BELTS - 2.4L - INSTALLATION, DRIVE.....7-10

BELTS - 2.4L - REMOVAL, DRIVE..........7-8

BELTS - 3.3/3.8L - CLEANING, DRIVE......7-11

BELTS - 3.3/3.8L - INSPECTION, DRIVE....7-11

BELTS - 3.3/3.8L - INSTALLATION, DRIVE . . 7-12

BELTS - 3.3/3.8L - REMOVAL, DRIVE......7-11

BENCH - INSTALLATION, SEAT BACK

HINGE COVERS - QUAD BUCKET, 50/50

SPLIT.............................23-101

BENCH - INSTALLATION, SEAT BELT

BUCKLE - FIRST ROW................8O-13

BENCH - INSTALLATION, SEAT BELT

BUCKLE - SECOND ROW - THREE

PASSENGER........................8O-15

BENCH - INSTALLATION, SEAT BELT

BUCKLE - SECOND ROW INBOARD -

50/50..............................8O-13

BENCH - INSTALLATION, SEAT CUSHION

COVER - QUAD BUCKET, 50/50 SPLIT . . . 23-100

BENCH - REMOVAL, SEAT BACK HINGE

COVERS - QUAD BUCKET, 50/50 SPLIT . . 23-101

BENCH - REMOVAL, SEAT BELT BUCKLE

- FIRST ROW.......................8O-13

BENCH - REMOVAL, SEAT BELT BUCKLE

- SECOND ROW - THREE PASSENGER....8O-15

BENCH - REMOVAL, SEAT BELT BUCKLE

- SECOND ROW INBOARD - 50/50.......8O-13

BENCH - REMOVAL, SEAT CUSHION

COVER - QUAD BUCKET, 50/50 SPLIT . . . 23-100

BENCH SEAT - REMOVAL, CHILD SEAT

MODULE...........................23-87

BENCH SEAT BACK - INSTALLATION.....23-103

BENCH SEAT BACK - REMOVAL........23-103

BENCH SEAT BACK COVER -

INSTALLATION......................23-103

BENCH SEAT BACK COVER - REMOVAL . . 23-103

BENCH SEAT BACK HINGE - REMOVAL . . 23-102

BENCH SEAT RISER - 50/50 SPLIT -

INSTALLATION......................23-100

BENCH SEAT RISER - 50/50 SPLIT -

REMOVAL.........................23-100

BENCH SEAT RISER - SECOND ROW -

INSTALLATION......................23-101

BENCH SEAT RISER - SECOND ROW -

REMOVAL.........................23-101

BENCH SEAT RISER - THIRD ROW -

INSTALLATION......................23-101

BENCH SEAT RISER - THIRD ROW -

REMOVAL.........................23-101

BENCH SEAT TRACK - INSTALLATION . . . 23-104

BENCH SEAT TRACK - REMOVAL.......23-104

BENCH SEATBACK PANEL -

INSTALLATION.......................23-99

BENCH SEATBACK PANEL - REMOVAL....23-99

BEZEL - INSTALLATION, CLUSTER.......23-63

BEZEL - INSTALLATION, INSTRUMENT

PANEL CENTER......................23-68

BEZEL - INSTALLATION, SLIDING DOOR

STOP BUMPER......................23-25

BEZEL - REMOVAL, CLUSTER...........23-63

BEZEL - REMOVAL, INSTRUMENT PANEL

CENTER............................23-68

BEZEL - REMOVAL, SLIDING DOOR

STOP BUMPER......................23-25

BEZEL OUTLETS - INSTALLATION,

CENTER............................24-45

BEZEL OUTLETS - REMOVAL, CENTER

....24-44

BI-DIRECTIONAL OVERRUNNING

CLUTCH - DESCRIPTION

................3-34

BI-DIRECTIONAL OVERRUNNING

CLUTCH - OPERATION

.................3-36

BIN - INSTALLATION, UNDER SEAT

STORAGE

..........................23-105

BIN - REMOVAL, UNDER SEAT STORAGE

. 23-105

BIN GUIDE - INSTALLATION, UNDER

SEAT STORAGE

.....................23-105

BIN GUIDE - REMOVAL, UNDER SEAT

STORAGE

..........................23-105

BIN LOCK/LATCH - INSTALLATION,

UNDER SEAT STORAGE

...............23-105

BIN LOCK/LATCH - REMOVAL, UNDER

SEAT STORAGE

.....................23-105

BLADES - CLEANING, WIPER

...........8R-14

BLADES - INSTALLATION, WIPER

........8R-14

BLADES - REMOVAL, WIPER

...........8R-14

BLEEDING - STANDARD PROCEDURE,

ANTILOCK BRAKE SYSTEM

..............5-78

RSINDEX3

Description Group-Page Description Group-Page Description Group-Page

Page 2564 of 2585

LOWER HINGE - REMOVAL.............23-28

LOWER INSTRUMENT PANEL -

INSTALLATION.......................23-69

LOWER INSTRUMENT PANEL -

REMOVAL..........................23-69

LOWER INTAKE MANIFOLD -

INSTALLATION.......................9-149

LOWER INTAKE MANIFOLD - REMOVAL . . . 9-148

LOWER STEERING COLUMN COVER -

INSTALLATION.......................23-70

LOWER STEERING COLUMN COVER -

REMOVAL..........................23-70

LOWER TRIM - INSTALLATION,

B-PILLAR...........................23-75

LOWER TRIM - REMOVAL, B-PILLAR.....23-74

LUBRICANTS - DESCRIPTION, ENGINE

OIL .................................0-1

LUBRICATION - DESCRIPTION......9-136,9-52

LUBRICATION - OPERATION........9-136,9-52

LUBRICATION - STANDARD PROCEDURE....2-2

LUBRICATION POINTS - DESCRIPTION......0-7

LUBRICATION, SPECIFICATIONS - BODY . . 23-12

LUGGAGE RACK CROSSBAR -

INSTALLATION.......................23-57

LUGGAGE RACK CROSSBAR - REMOVAL . . 23-56

LUGGAGE RACK RISER - INSTALLATION . . 23-56

LUGGAGE RACK RISER - REMOVAL......23-55

LUMBAR SUPPORT - INSTALLATION....23-106

LUMBAR SUPPORT - REMOVAL........23-106

LWB - INSTALLATION, SEAT BELT &

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD WITH REAR HVAC..........8O-16

LWB - REMOVAL, SEAT BELT &

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD WITH REAR HVAC..........8O-16

MACHINING - STANDARD PROCEDURE,

BRAKE ROTOR..................5-53,5s-56

MAIN BEARING FITTING - STANDARD

PROCEDURE........................9-123

MAIN BEARINGS - INSTALLATION,

CRANKSHAFT.......................9-124

MAIN BEARINGS - REMOVAL,

CRANKSHAFT.......................9-124

MANAGER - DESCRIPTION, TASK........25-24

MANAGER - OPERATION, TASK.........25-24

MANIFOLD - CLEANING, EXHAUST........9-61

MANIFOLD - DESCRIPTION, INTAKE . . 9-144,9-58

MANIFOLD - INSPECTION, EXHAUST......9-61

MANIFOLD - INSTALLATION, EXHAUST....9-61

MANIFOLD - INSTALLATION, LOWER

INTAKE ............................9-149

MANIFOLD - INSTALLATION, UPPER

INTAKE ............................9-147

MANIFOLD - LEFT - CLEANING,

EXHAUST...........................9-152

MANIFOLD - LEFT - INSPECTION,

EXHAUST...........................9-152

MANIFOLD - LEFT - INSTALLATION,

EXHAUST...........................9-152

MANIFOLD - LEFT - REMOVAL, EXHAUST . 9-152

MANIFOLD - LOWER - CLEANING,

INTAKE ............................9-148

MANIFOLD - LOWER - INSPECTION,

INTAKE ........................9-148,9-60

MANIFOLD - LOWER - INSTALLATION,

INTAKE .............................9-60

MANIFOLD - LOWER - REMOVAL,

INTAKE .............................9-60

MANIFOLD - REMOVAL, EXHAUST........9-61

MANIFOLD - REMOVAL, LOWER INTAKE . . 9-148

MANIFOLD - REMOVAL, UPPER INTAKE . . . 9-145

MANIFOLD - RIGHT - CLEANING,

EXHAUST...........................9-151

MANIFOLD - RIGHT - INSPECTION,

EXHAUST...........................9-151

MANIFOLD - RIGHT - INSTALLATION,

EXHAUST...........................9-151

MANIFOLD - RIGHT - REMOVAL,

EXHAUST...........................9-150

MANIFOLD - UPPER - INSPECTION,

INTAKE

.............................9-59

MANIFOLD - UPPER - INSTALLATION,

INTAKE

.............................9-59

MANIFOLD - UPPER - REMOVAL, INTAKE

. . 9-58

MANIFOLD LEAKS - DIAGNOSIS AND

TESTING, INTAKE

................9-145,9-58

MANIFOLD STRIPPED THREAD REPAIR -

STANDARD PROCEDURE

...............9-145MANIFOLD VACUUM PORT REPAIR -

STANDARD PROCEDURE, INTAKE........9-145

MANUAL - INSTALLATION, WINDOW

REGULATOR........................23-23

MANUAL - REMOVAL, WINDOW

REGULATOR........................23-22

MANUAL ADJUSTER - INSTALLATION,

FRONT SEAT TRACK..................23-95

MANUAL ADJUSTER - REMOVAL, FRONT

SEAT TRACK........................23-95

MANUAL TEMPERATURE CONTROL

(MTC) - INSTALLATION................24-29

MANUAL TEMPERATURE CONTROL

(MTC) - REMOVAL...................24-29

MANUAL TEMPERATURE CONTROL

SYSTEM - OPERATION...............24-112

MANUAL THREE ZONE - DESCRIPTION....24-2

MANUAL THREE ZONE - OPERATION......24-5

MANUAL TRACK - INSTALLATION,

FRONT SEAT RISER...................23-95

MANUAL TRACK - REMOVAL, FRONT

SEAT RISER.........................23-94

MANUAL TRANSAXLE - ASSEMBLY, T850 . 21-42

MANUAL TRANSAXLE - DESCRIPTION,

T850..............................21-21

MANUAL TRANSAXLE - DISASSEMBLY,

T850..............................21-35

MANUAL TRANSAXLE - INSTALLATION,

T850..............................21-51

MANUAL TRANSAXLE - OPERATION,

T850..............................21-24

MANUAL TRANSAXLE - REMOVAL, T850 . . 21-31

MANUAL TRANSAXLE - SPECIFICATIONS,

T850..............................21-56

MANUFACTURER PLATE - DESCRIPTION . Intro.-11

MAP SENSOR - DESCRIPTION..........14-30

MAP SENSOR - OPERATION............14-30

MASTER CYLINDER - LHD -

INSTALLATION........................6-10

MASTER CYLINDER - LHD - REMOVAL.....6-9

MASTER CYLINDER - RHD -

INSTALLATION.........................6-9

MASTER CYLINDER - RHD - REMOVAL.....6-8

MASTER CYLINDER BLEEDING -

STANDARD PROCEDURE...........5-35,5s-34

MASTER CYLINDER (FLUID RESERVOIR)

- ASSEMBLY....................5-38,5s-37

MASTER CYLINDER (FLUID RESERVOIR)

- DISASSEMBLY.................5-37,5s-36

MATCH MOUNTING - STANDARD

PROCEDURE, TIRE AND WHEEL..........22-7

MATS - INSTALLATION, CARPETS AND

FLOOR.............................23-76

MATS - REMOVAL, CARPETS AND

FLOOR.............................23-75

MEASUREMENT - STANDARD

PROCEDURE, CURB HEIGHT.............2-55

MEASUREMENT AND ADJUSTMENT,

ADJUSTMENTS - DIFFERENTIAL

BEARING PRELOAD.................21s-100

MEASUREMENTS - SPECIFICATIONS,

GAP AND FLUSH

....................23-124

MEASURING BEARING CLEARANCE

USING PLASTIGAGE - STANDARD

PROCEDURE

.....................9-12,9-84

MEASURING CAMSHAFT END PLAY -

STANDARD PROCEDURE

................9-29

MEASURING CONNECTING ROD

BEARING CLEARANCE - STANDARD

PROCEDURE

........................9-120

MEASURING CRANKSHAFT END PLAY -

STANDARD PROCEDURE

...............9-125

MEASURING TIMING CHAIN WEAR -

STANDARD PROCEDURE

...............9-153

MECHANICAL - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS

........9-6,9-80

MECHANISM - INSTALLATION,

GEARSHIFT

.........................21-89

MECHANISM - REMOVAL, GEARSHIFT

....21-87

MEMORIES, OPERATION - FUEL

CORRECTION OR ADAPTIVE

............14-20

MEMORY SEAT/MIRROR MODULE -

DESCRIPTION

.......................8E-10

MEMORY SEAT/MIRROR MODULE -

DIAGNOSIS AND TESTING

.............8E-10

MEMORY SEAT/MIRROR MODULE -

INSTALLATION

.......................8E-10MEMORY SEAT/MIRROR MODULE -

OPERATION.........................8E-10

MEMORY SEAT/MIRROR MODULE -

REMOVAL..........................8E-10

MEMORY SET SWITCH - DESCRIPTION . . 8N-12,

8N-55

MEMORY SET SWITCH - INSTALLATION . . 8N-13,

8N-56

MEMORY SET SWITCH - OPERATION....8N-13,

8N-56

MEMORY SET SWITCH - REMOVAL . 8N-13,8N-56

MEMORY SWITCH - DIAGNOSIS AND

TESTING......................8N-13,8N-56

MEMORY SYSTEM - DESCRIPTION . . 8N-51,8N-8

MEMORY SYSTEM - DIAGNOSIS AND

TESTING......................8N-10,8N-53

MEMORY SYSTEM - OPERATION....8N-52,8N-9

METRIC SYSTEM - DESCRIPTION......Intro.-6

MINI-TRIP COMPUTER - DIAGNOSIS

AND TESTING, COMPASS.............8M-10

MIRROR - DESCRIPTION, AUTOMATIC

DAY / NIGHT........................8N-47

MIRROR - DIAGNOSIS AND TESTING,

AUTOMATIC DAY / NIGHT..............8N-47

MIRROR - INSTALLATION, REAR VIEW . . . 23-81

MIRROR - INSTALLATION, SIDE VIEW....23-59

MIRROR - OPERATION, AUTOMATIC DAY

/ NIGHT............................8N-47

MIRROR - REMOVAL, REAR VIEW.......23-81

MIRROR - REMOVAL, SIDE VIEW........23-59

MIRROR - REMOVAL, SIDEVIEW..........8N-49

MIRROR GLASS - INSTALLATION, SIDE

VIEW..............................23-59

MIRROR GLASS - REMOVAL, SIDE VIEW . . 23-59

MIRROR SWITCH - EXPORT -

DESCRIPTION, POWER FOLDAWAY......8N-48

MIRROR SWITCH - EXPORT -

INSTALLATION, POWER FOLDAWAY......8N-49

MIRROR SWITCH - EXPORT -

OPERATION, POWER FOLDAWAY........8N-48

MIRROR SWITCH - EXPORT - REMOVAL,

POWER FOLDAWAY..................8N-48

MIRRORS - DESCRIPTION, HEATED.......8G-6

MIRRORS - DESCRIPTION, POWER......8N-45

MIRRORS - DIAGNOSIS AND TESTING,

POWER............................8N-46

MIRRORS - OPERATION, HEATED........8G-6

MIRRORS - OPERATION, POWER........8N-45

MISALIGNMENT - DIAGNOSIS AND

TESTING, DRIVE PLATE.................6-6

MODE DOOR ACTUATOR - DESCRIPTION . . 24-30

MODE DOOR ACTUATOR -

INSTALLATION.......................24-31

MODE DOOR ACTUATOR - OPERATION . . . 24-30

MODE DOOR ACTUATOR - REAR -

DESCRIPTION.......................24-39

MODE DOOR ACTUATOR - REAR -

INSTALLATION.......................24-40

MODE DOOR ACTUATOR - REAR -

OPERATION.........................24-40

MODE DOOR ACTUATOR - REAR -

REMOVAL..........................24-40

MODE DOOR ACTUATOR - REMOVAL.....24-30

MODE, OPERATION - DRB IIITS TAT E

DISPLAY TEST........................25-9

MODES OF OPERATION - OPERATION....14-18

MODULAR CLUTCH ASSY - 2.4L GAS -

INSTALLATION........................6-11

MODULAR CLUTCH ASSY - 2.4L GAS -

REMOVAL...........................6-11

MODULE - BLOWER MOTOR -

DESCRIPTION, POWER................24-31

MODULE - BLOWER MOTOR -

INSTALLATION, POWER...............24-32

MODULE - BLOWER MOTOR -

OPERATION, POWER..................24-31

MODULE - BLOWER MOTOR -

REMOVAL, POWER...................24-31

MODULE - DESCRIPTION, BODY

CONTROL............................8s-1

MODULE - DESCRIPTION, BODY

CONTROL

...........................8E-3

MODULE - DESCRIPTION, FRONT

CONTROL

...........................8E-7

MODULE - DESCRIPTION, FUEL PUMP

....14-8

MODULE - DESCRIPTION, HEATED SEAT

. . . 8E-8

MODULE - DESCRIPTION, INTEGRATED

POWER

..........................8W-97-2

RSINDEX21

Description Group-Page Description Group-Page Description Group-Page

Page 2569 of 2585

POWER TRANSFER UNIT, SPECIAL

TOOLS - SDP........................21-8

POWER WINDOWS - DESCRIPTION......8N-62

POWER WINDOWS - DIAGNOSIS AND

TESTING...........................8N-62

POWER WINDOWS - OPERATION........8N-62

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON FUSES . 8W-01-10

PRECAUTIONS AND WARNINGS,

WARNING - SAFETY...................23-1

PRECAUTIONS, WARNING -

WINDSHIELD SAFETY................23-108

PREFERENCE - STANDARD PROCEDURE,

HORN CHIRP...................8N-42,8N-5

PRELOAD - ADJUSTMENT,

DIFFERENTIAL BEARING..............21-199

PRELOAD MEASUREMENT AND

ADJUSTMENT, ADJUSTMENTS -

DIFFERENTIAL BEARING.............21s-100

PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET

SURFACE........................9-11,9-85

PRESSURE - DIAGNOSIS AND TESTING,

CHECKING ENGINE OIL.................9-52

PRESSURE - DIAGNOSIS AND TESTING,

ENGINE OIL.........................9-136

PRESSURE CAP - DESCRIPTION,

RADIATOR...........................7-26

PRESSURE CAP - OPERATION,

RADIATOR...........................7-27

PRESSURE CAP TESTING - DIAGNOSIS

AND TESTING, COOLING SYSTEM........7-27

PRESSURE FOR HIGH SPEED

OPERATION - STANDARD PROCEDURE,

TIRE..........................22-17,22s-9

PRESSURE LEAKAGE TEST - DIAGNOSIS

AND TESTING, CYLINDER

COMBUSTION.....................9-83,9-9

PRESSURE MONITORING -

DESCRIPTION, TIRE..............22-9,22s-1

PRESSURE MONITORING - OPERATION,

TIRE...........................22-9,22s-1

PRESSURE PLATE - 2.5L TD -

INSTALLATION, CLUTCH DISC...........6-12

PRESSURE PLATE - 2.5L TD - REMOVAL,

CLUTCH DISC........................6-11

PRESSURE REGULATOR -

INSTALLATION, FUEL..................14-7

PRESSURE REGULATOR - OPERATION,

FUEL...............................14-7

PRESSURE REGULATOR - REMOVAL,

FUEL...............................14-7

PRESSURE RELEASE PROCEDURE -

STANDARD PROCEDURE, FUEL

SYSTEM............................14-2

PRESSURE RELIEF VALVE -

DESCRIPTION, HIGH..................24-73

PRESSURE RELIEF VALVE -

INSTALLATION, OIL...................9-141

PRESSURE RELIEF VALVE - OPERATION,

HIGH..............................24-73

PRESSURE RELIEF VALVE - REMOVAL,

OIL

................................9-141

PRESSURE SENSOR - DIAGNOSIS AND

TESTING, TIRE

..................22-10,22s-2

PRESSURE SENSOR RETRAIN -

STANDARD PROCEDURE, TIRE

.....22-10,22s-2

PRESSURE, SPECIFICATIONS - FUEL

SYSTEM

............................14-3

PRESSURE SWITCH - DESCRIPTION, OIL

. 9-141

PRESSURE SWITCH - INSTALLATION,

OIL

...........................9-141,9-54

PRESSURE SWITCH - OPERATION, OIL

. . . 9-141

PRESSURE SWITCH - REMOVAL, OIL

....9-141,

9-54

PRESSURE TEST - DIAGNOSIS AND

TESTING, CYLINDER COMPRESSION

. . . 9-83,9-9

PRESSURE TEST - DIAGNOSIS AND

TESTING, POWER STEERING SYSTEM

FLOW

...............................19-1

PRESSURE TESTS - DIAGNOSIS AND

TESTING, CLUTCH AIR

.........21-122,21s-30

PRESSURE TESTS - DIAGNOSIS AND

TESTING, HYDRAULIC

..........21-120,21s-28

PRESSURE TRANSDUCER -

DESCRIPTION, A/C

...................24-21PRESSURE TRANSDUCER - DIAGNOSIS

AND TESTING, A/C...................24-22

PRESSURE TRANSDUCER -

INSTALLATION, A/C...................24-22

PRESSURE TRANSDUCER - OPERATION,

A/C................................24-21

PRESSURE TRANSDUCER - REMOVAL,

A/C................................24-22

PRESSURES - STANDARD PROCEDURE,

TIRE INFLATION.................22-16,22s-8

PROBLEM CAUSES - DIAGNOSIS AND

TESTING, COMMON..................21-30

PROGRAMING - STANDARD

PROCEDURE, RKE TRANSMITTER.......8N-43

PROGRAMMABLE COMMUNICATIONS

INTERFACE (PCI) BUS, OPERATION......14-21

PROGRAMMING - STANDARD

PROCEDURE, ELECTRONIC VEHICLE

INFORMATION CENTER................8M-7

PROGRAMMING - STANDARD

PROCEDURE, PCM/SKIM................8E-2

PROGRAMMING - STANDARD

PROCEDURE, REMOTE KEYLESS

ENTRY TRANSMITTER.................8N-5

PROGRAMMING - STANDARD

PROCEDURE, TRANSPONDER...........8Q-6

PROPELLER SHAFT - DESCRIPTION.......3-21

PROPELLER SHAFT - INSTALLATION......3-22

PROPELLER SHAFT - OPERATION........3-21

PROPELLER SHAFT - REMOVAL..........3-21

PROPELLER SHAFT - SPECIFICATIONS.....3-22

PROPORTIONING - DESCRIPTION,

ELECTRONIC VARIABLE BRAKE............5-75

PROPORTIONING - OPERATION,

ELECTRONIC VARIABLE BRAKE..........5-77

PROPORTIONING VALVE (HEIGHT

SENSING) - DESCRIPTION.........5-48,5s-51

PROPORTIONING VALVE (HEIGHT

SENSING) - DIAGNOSIS AND TESTING....5-49,

5s-52

PROPORTIONING VALVE (HEIGHT

SENSING) - INSTALLATION.........5-51,5s-53

PROPORTIONING VALVE (HEIGHT

SENSING) - OPERATION...........5-48,5s-51

PROPORTIONING VALVE (HEIGHT

SENSING) - REMOVAL............5-50,5s-53

PTU FLUID CHANGE - STANDARD

PROCEDURE.........................21-5

PULLEY - DESCRIPTION, GENERATOR

DECOUPLER....................8F-25,8F-27

PULLEY - DIAGNOSIS AND TESTING,

GENERATOR DECOUPLER.........8F-25,8F-27

PULLEY - INSTALLATION, GENERATOR

DECOUPLER....................8F-26,8F-28

PULLEY - INSTALLATION, TIMING BELT

TENSIONER..........................9-69

PULLEY - OPERATION, GENERATOR

DECOUPLER....................8F-25,8F-27

PULLEY - REMOVAL, GENERATOR

DECOUPLER....................8F-26,8F-28

PULLEY - REMOVAL, TIMING BELT

TENSIONER..........................9-68

PUMP - 2.4L - CLEANING, WATER........7-32

PUMP - 2.4L - DESCRIPTION, WATER.....7-31

PUMP - 2.4L - INSPECTION, WATER......7-32

PUMP - 2.4L - INSTALLATION, WATER.....7-32

PUMP - 2.4L - REMOVAL, WATER........7-31

PUMP - 3.3/3.8L - CLEANING, WATER.....7-34

PUMP - 3.3/3.8L - DESCRIPTION,

WATER .............................7-33

PUMP - 3.3/3.8L - INSPECTION, WATER . . . 7-34

PUMP - 3.3/3.8L - INSTALLATION,

WATER .............................7-34

PUMP - 3.3/3.8L - REMOVAL, WATER.....7-33

PUMP - ASSEMBLY, OIL...........9-143,9-56

PUMP - ASSEMBLY, OIL.......21-232,21s-132

PUMP - CLEANING, OIL...........9-142,9-56

PUMP - DESCRIPTION, FUEL............14-8

PUMP - DESCRIPTION, FUEL DOSING . . . 24-115

PUMP - DESCRIPTION, OIL.............9-142

PUMP - DESCRIPTION, OIL.....21-230,21s-131

PUMP - DISASSEMBLY, OIL........9-142,9-55

PUMP - DISASSEMBLY, OIL

....21-230,21s-131

PUMP - INSPECTION, OIL

..........9-142,9-56

PUMP - INSTALLATION, FUEL DOSING

. . . 24-116

PUMP - INSTALLATION, LEAK

DETECTION

.........................25-13

PUMP - INSTALLATION, OIL

........9-144,9-57PUMP - INSTALLATION, SEAL - OIL....21-233,

21s-133

PUMP - OPERATION, FUEL..............14-8

PUMP - OPERATION, FUEL DOSING.....24-115

PUMP - OPERATION, OIL......21-230,21s-131

PUMP - REMOVAL, FUEL DOSING......24-115

PUMP - REMOVAL, LEAK DETECTION....25-13

PUMP - REMOVAL, OIL............9-142,9-55

PUMP - REMOVAL, SEAL - OIL . . 21-232,21s-133

PUMP (2.4L ENGINE) - INSTALLATION....19-42

PUMP (2.4L ENGINE) - REMOVAL.......19-38

PUMP (2.4L/3.3L/3.8L ENGINE) -

DESCRIPTION.......................19-36

PUMP (2.5L DIESEL) - DESCRIPTION.....19-36

PUMP (2.5L DIESEL) - INSTALLATION....19-43

PUMP (2.5L DIESEL) - REMOVAL........19-40

PUMP (3.3L/3.8L ENGINE) -

INSTALLATION.......................19-43

PUMP (3.3L/3.8L ENGINE) - REMOVAL . . . 19-40

PUMP INITIAL OPERATION - STANDARD

PROCEDURE, POWER STEERING........19-37

PUMP INLET TUBE - 2.4L -

DESCRIPTION, WATER.................7-35

PUMP INLET TUBE - 2.4L -

INSTALLATION, WATER.................7-35

PUMP INLET TUBE - 2.4L - REMOVAL,

WATER .............................7-35

PUMP INLET TUBE - 3.3/3.8L -

INSTALLATION, WATER.................7-36

PUMP INLET TUBE - 3.3/3.8L -

REMOVAL, WATER....................7-36

PUMP MODULE - DESCRIPTION, FUEL....14-8

PUMP MODULE - INSTALLATION, FUEL....14-9

PUMP MODULE - OPERATION, FUEL......14-8

PUMP MODULE - REMOVAL, FUEL........14-8

PUMP MOTOR - INSTALLATION, FRONT

WASHER............................8R-8

PUMP MOTOR - INSTALLATION, REAR

WASHER...........................8R-10

PUMP MOTOR - REMOVAL, FRONT

WASHER............................8R-8

PUMP MOTOR - REMOVAL, REAR

WASHER...........................8R-10

PUMP (PULLEY) - ASSEMBLY..........19-41

PUMP (PULLEY) - DISASSEMBLY........19-41

PUMP RELAY - DESCRIPTION, FUEL.....14-28

PUMP RELAY - OPERATION, FUEL.......14-28

PUMP, SPECIAL TOOLS - POWER

STEERING..........................19-43

PUSH-PIN GROMMET REPLACEMENT -

STANDARD PROCEDURE..............8N-28

PUSHRODS - DESCRIPTION.......9-109,9s-26

PUSHRODS - OPERATION.........9-109,9s-26

QUAD BUCKET - INSTALLATION, BUCKET

SEAT BACK.........................23-99

QUAD BUCKET - INSTALLATION, SEAT

BELT BUCKLE - FIRST ROW INBOARD....8O-12

QUAD BUCKET - REMOVAL, BUCKET

SEAT BACK.........................23-98

QUAD BUCKET - REMOVAL, SEAT BELT

BUCKLE - FIRST ROW INBOARD........8O-12

QUAD BUCKET, 50/50 SPLIT, BENCH -

INSTALLATION, SEAT BACK HINGE

COVERS...........................23-101

QUAD BUCKET, 50/50 SPLIT, BENCH -

INSTALLATION, SEAT CUSHION COVER . . 23-100

QUAD BUCKET, 50/50 SPLIT, BENCH -

REMOVAL, SEAT BACK HINGE COVERS . . 23-101

QUAD BUCKET, 50/50 SPLIT, BENCH -

REMOVAL, SEAT CUSHION COVER......23-100

QUAD BUCKET SEAT RISER -

INSTALLATION.......................23-98

QUAD BUCKET SEAT RISER - REMOVAL . . 23-98

QUAD BUCKET SEAT SIDE SHIELD - NO

CUPHOLDER - INSTALLATION...........23-97

QUAD BUCKET SEAT SIDE SHIELD - NO

CUPHOLDER - REMOVAL..............23-97

QUAD BUCKET SEAT SIDE SHIELD/

CUPHOLDER - FLAP AND SPRING

ASSEMBLY - INSTALLATION

...........23-107

QUAD BUCKET SEAT SIDE SHIELD/

CUPHOLDER - FLAP AND SPRING

ASSEMBLY - REMOVAL

...............23-107

QUAD BUCKET SEAT SIDE SHIELD/

CUPHOLDER - INSTALLATION

...........23-96

QUAD BUCKET SEAT SIDE SHIELD/

CUPHOLDER - REMOVAL

..............23-96

QUAD CHILD SEAT - INSTALLATION

......23-89

26 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2581 of 2585

VALVE (HEIGHT SENSING) -

DESCRIPTION, PROPORTIONING....5-48,5s-51

VALVE (HEIGHT SENSING) - DIAGNOSIS

AND TESTING, PROPORTIONING....5-49,5s-52

VALVE (HEIGHT SENSING) -

INSTALLATION, PROPORTIONING....5-51,5s-53

VALVE (HEIGHT SENSING) - OPERATION,

PROPORTIONING.................5-48,5s-51

VALVE (HEIGHT SENSING) - REMOVAL,

PROPORTIONING.................5-50,5s-53

VALVE SEATS - STANDARD PROCEDURE,

REFACING VALVES...............9-104,9s-21

VALVE SPRINGS - DESCRIPTION . . . 9-106,9s-23

VALVE SPRINGS - OPERATION.....9-106,9s-23

VALVE STEM SEALS - DESCRIPTION.....9-111,

9s-29

VALVE STEM SEALS - INSTALLATION....9-112,

9s-29

VALVE STEM SEALS - REMOVAL . . . 9-112,9s-29

VALVE TIMING VERIFICATION -

STANDARD PROCEDURE...............9-153

VALVES - OPERATION, HYDRAULIC

CIRCUITS............................5-83

VALVES & SEATS - CLEANING,

INTAKE/EXHAUST...........9-105,9-32,9s-22

VALVES & SEATS - DESCRIPTION,

INTAKE/EXHAUST...........9-104,9-32,9s-21

VALVES & SEATS - INSPECTION,

INTAKE/EXHAUST...............9-105,9s-22

VALVES & SEATS - INSTALLATION,

INTAKE/EXHAUST...............9-106,9s-23

VALVES & SEATS - OPERATION,

INTAKE/EXHAUST.................9-104,9s-21

VALVES & SEATS - REMOVAL,

INTAKE/EXHAUST...............9-105,9s-22

VALVES AND VALVE SEATS - STANDARD

PROCEDURE, REFACING..........9-104,9s-21

VANITY LAMP - INSTALLATION.........8L-24

VANITY LAMP - REMOVAL.............8L-24

VAPOR CANISTER - DESCRIPTION.......25-18

VAPOR CANISTER - OPERATION.........25-18

VARIABLE BRAKE PROPORTIONING -

DESCRIPTION, ELECTRONIC.............5-75

VARIABLE BRAKE PROPORTIONING -

OPERATION, ELECTRONIC...............5-77

VARIATION ADJUSTMENT - STANDARD

PROCEDURE, COMPASS...............8M-5

VECI LABEL - DESCRIPTION..........Intro.-11

VEHICLE CERTIFICATION LABEL -

DESCRIPTION.....................Intro.-11

VEHICLE DOES NOT FILL - DIAGNOSIS

AND TESTING.......................25-16

VEHICLE EMISSION CONTROL

INFORMATION LABEL - DESCRIPTION.....25-1

VEHICLE IDENTIFICATION -

DESCRIPTION........................23-1

VEHICLE IDENTIFICATION NUMBER -

DESCRIPTION......................Intro.-9

VEHICLE INFO CENTER - DESCRIPTION,

ELECTRONIC........................8M-6

VEHICLE INFO CENTER - INSTALLATION,

ELECTRONIC........................8M-9

VEHICLE INFO CENTER - OPERATION,

ELECTRONIC........................8M-7

VEHICLE INFO CENTER - REMOVAL,

ELECTRONIC........................8M-9

VEHICLE INFORMATION CENTER -

DIAGNOSIS AND TESTING,

ELECTRONIC........................8M-7

VEHICLE INFORMATION CENTER

PROGRAMMING - STANDARD

PROCEDURE, ELECTRONIC.............8M-7

VEHICLE SPEED SENSOR -

INSTALLATION......................21-115

VEHICLE SPEED SENSOR - REMOVAL . . . 21-115

VEHICLE THEFT SECURITY -

DESCRIPTION........................8Q-1

VEHICLE THEFT SECURITY - OPERATION . . 8Q-1

VEHICLE THEFT SECURITY SYSTEM -

DIAGNOSIS AND TESTING..............8Q-3

VENT WINDOW MOTOR - DIAGNOSIS

AND TESTING

.......................8N-63

VENT WINDOW MOTOR - INSTALLATION

. . 8N-64

VENT WINDOW MOTOR - REMOVAL

.....8N-63

VERIFICATION - STANDARD

PROCEDURE, VALVE TIMING

...........9-153

VIBRATION - DIAGNOSIS AND TESTING,

TIRE AND WHEEL

.....................22-1VIBRATION DAMPER - INSTALLATION....9-130,

9-47

VIBRATION DAMPER - REMOVAL....9-130,9-47

VIDEO SCREEN - DESCRIPTION.........8A-16

VIDEO SCREEN - INSTALLATION........8A-16

VIDEO SCREEN - OPERATION...........8A-16

VIDEO SCREEN - REMOVAL............8A-16

VIEW MIRROR - INSTALLATION, REAR . . . 23-81

VIEW MIRROR - INSTALLATION, SIDE....23-59

VIEW MIRROR - REMOVAL, REAR.......23-81

VIEW MIRROR - REMOVAL, SIDE........23-59

VIEW MIRROR GLASS - INSTALLATION,

SIDE..............................23-59

VIEW MIRROR GLASS - REMOVAL, SIDE . . 23-59

VISCOUS COUPLER - DESCRIPTION.......3-41

VISCOUS COUPLER - OPERATION........3-42

VISOR - INSTALLATION, SUN...........23-82

VISOR - REMOVAL, SUN...............23-82

VISOR SUPPORT - INSTALLATION, SUN . . . 23-83

VISOR SUPPORT - REMOVAL, SUN......23-83

VOLT SUPPLY - PCM OUTPUT -

OPERATION, 5.......................8E-15

VOLTAGE DROP - STANDARD

PROCEDURE, TESTING FOR A.......8W-01-10

VOLTAGE POTENTIAL - STANDARD

PROCEDURE, TESTING OF...........8W-01-9

VOLTAGE REGULATOR - DESCRIPTION . . . 8F-27,

8F-29

VOLTAGE REGULATOR - OPERATION.....8F-27,

8F-29

VOLTAGE TEST - STANDARD

PROCEDURE, OPEN-CIRCUIT...........8F-13

VTSS/SKIS INDICATOR LAMP -

DESCRIPTION........................8Q-7

VTSS/SKIS INDICATOR LAMP -

OPERATION..........................8Q-8

WARNING - A/C SYSTEM..............24-65

WARNING - ENGINE COOLING SYSTEM . . . 24-65

WARNING - INSTALLATION............23-109

WARNING - INSTALLATION.............19-13

WARNING - REMOVAL...............23-108

WARNING - REMOVAL................19-12

WARNING - SAFETY PRECAUTIONS AND

WARNINGS..........................23-1

WARNING - WARNINGS AND CAUTIONS . . 19-10,

19-27

WARNING - WINDSHIELD SAFETY

PRECAUTIONS......................23-108

WARNING, CHIME/BUZZER..............8B-1

WARNING, DESCRIPTION............5-4,5s-3

WARNING, DESCRIPTION..............19-37

WARNING, LAMPS/LIGHTING -

EXTERIOR...........................8L-3

WARNING, RESTRAINTS................8O-2

WARNINGS AND CAUTIONS, WARNING . . 19-10,

19-27

WARNINGS, GENERAL..............8W-01-7

WARNINGS, WARNING - SAFETY

PRECAUTIONS........................23-1

WASHER FLUID LEVEL SWITCH -

INSTALLATION......................8R-12

WASHER FLUID LEVEL SWITCH -

REMOVAL..........................8R-12

WASHER HOSES - INSTALLATION.......8R-13

WASHER HOSES - REMOVAL...........8R-13

WASHER PUMP MOTOR -

INSTALLATION, FRONT.................8R-8

WASHER PUMP MOTOR -

INSTALLATION, REAR.................8R-10

WASHER PUMP MOTOR - REMOVAL,

FRONT..............................8R-8

WASHER PUMP MOTOR - REMOVAL,

REAR..............................8R-10

WASHER RESERVOIR - INSTALLATION . . . 8R-13

WASHER RESERVOIR - REMOVAL.......8R-13

WASHER SYSTEM - DIAGNOSIS AND

TESTING............................8R-4

WATER CHANNEL - INSTALLATION......23-121

WATER CHANNEL - REMOVAL.........23-121

WATER LEAKS - DIAGNOSIS AND

TESTING............................23-1

WATER PUMP - 2.4L - CLEANING........7-32

WATER PUMP - 2.4L - DESCRIPTION......7-31

WATER PUMP - 2.4L - INSPECTION

.......7-32

WATER PUMP - 2.4L - INSTALLATION

.....7-32

WATER PUMP - 2.4L - REMOVAL

.........7-31

WATER PUMP - 3.3/3.8L - CLEANING

.....7-34

WATER PUMP - 3.3/3.8L - DESCRIPTION

. . . 7-33WATER PUMP - 3.3/3.8L - INSPECTION....7-34

WATER PUMP - 3.3/3.8L -

INSTALLATION........................7-34

WATER PUMP - 3.3/3.8L - REMOVAL......7-33

WATER PUMP INLET TUBE - 2.4L -

DESCRIPTION........................7-35

WATER PUMP INLET TUBE - 2.4L -

INSTALLATION........................7-35

WATER PUMP INLET TUBE - 2.4L -

REMOVAL...........................7-35

WATER PUMP INLET TUBE - 3.3/3.8L -

INSTALLATION........................7-36

WATER PUMP INLET TUBE - 3.3/3.8L -

REMOVAL...........................7-36

WATERSHIELD - INSTALLATION.........23-21

WATERSHIELD - REMOVAL.............23-21

WEAR - STANDARD PROCEDURE,

MEASURING TIMING CHAIN............9-153

WEAR INDICATORS - DIAGNOSIS AND

TESTING, TREAD................22-16,22s-8

WEAR PATTERNS - DIAGNOSIS AND

TESTING, TIRE..................22-16,22s-8

WEATHERSTRIP - INSTALLATION, FRONT

DOOR............................23-114

WEATHERSTRIP - INSTALLATION, FRONT

DOOR GLASS RUN..................23-113

WEATHERSTRIP - INSTALLATION,

SLIDING DOOR.....................23-115

WEATHERSTRIP - REMOVAL, FRONT

DOOR............................23-114

WEATHERSTRIP - REMOVAL, FRONT

DOOR GLASS RUN..................23-113

WEATHERSTRIP - REMOVAL, SLIDING

DOOR............................23-115

WELD LOCATIONS - SPECIFICATIONS . . . 23-166

WHEEL - DESCRIPTION...............22-18

WHEEL - INSPECTION, TONE............5-82

WHEEL - INSTALLATION, STEERING......19-24

WHEEL - REMOVAL, STEERING.........19-23

WHEEL ALIGNMENT - DESCRIPTION......2-47

WHEEL ALIGNMENT - STANDARD

PROCEDURE.........................2-52

WHEEL ALIGNMENT, SPECIFICATIONS.....2-56

WHEEL ASSEMBLY (ALUMINUM WHEEL)

- INSTALLATION, TIRE.................22-8

WHEEL ASSEMBLY (ALUMINUM WHEEL)

- REMOVAL, TIRE.....................22-7

WHEEL ASSEMBLY (STEEL WHEEL) -

INSTALLATION, TIRE...................22-8

WHEEL ASSEMBLY (STEEL WHEEL) -

REMOVAL, TIRE......................22-8

WHEEL BALANCE - STANDARD

PROCEDURE, TIRE....................22-5

WHEEL CARE - CLEANING, ALUMINUM . . . 22-18

WHEEL COVER - DESCRIPTION.........22-19

WHEEL COVER - INSTALLATION.........22-19

WHEEL COVER - REMOVAL............22-19

WHEEL CYLINDERS - INSPECTION . . . 5-57,5s-59

WHEEL CYLINDERS - INSTALLATION . 5-57,5s-60

WHEEL CYLINDERS - REMOVAL.....5-57,5s-59

WHEEL INSPECTION - DIAGNOSIS AND

TESTING...........................22-18

WHEEL MATCH MOUNTING - STANDARD

PROCEDURE, TIRE

....................22-7

WHEEL MOUNTING STUDS - FRONT -

INSTALLATION

.......................22-21

WHEEL MOUNTING STUDS - FRONT -

REMOVAL

..........................22-20

WHEEL MOUNTING STUDS - REAR -

INSTALLATION

.......................22-22

WHEEL MOUNTING STUDS - REAR -

REMOVAL

..........................22-21

WHEEL ROTATION - STANDARD

PROCEDURE, TIRE

....................22-7

WHEEL RUNOUT, SPECIFICATIONS -

TONE

...............................5-79

WHEEL, SPECIFICATIONS

..............22-19

WHEEL SPEED SENSOR - AWD -

INSTALLATION, REAR

..................5-80

WHEEL SPEED SENSOR - AWD -

REMOVAL, REAR

......................5-80

WHEEL SPEED SENSOR - FWD -

INSTALLATION, REAR

..................5-81

WHEEL SPEED SENSOR - FWD -

REMOVAL, REAR

......................5-81

WHEEL SPEED SENSOR -

INSTALLATION, FRONT

.................5-80

38 INDEXRS

Description Group-Page Description Group-Page Description Group-Page