ABS DODGE TRUCK 1993 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 66 of 1502

•

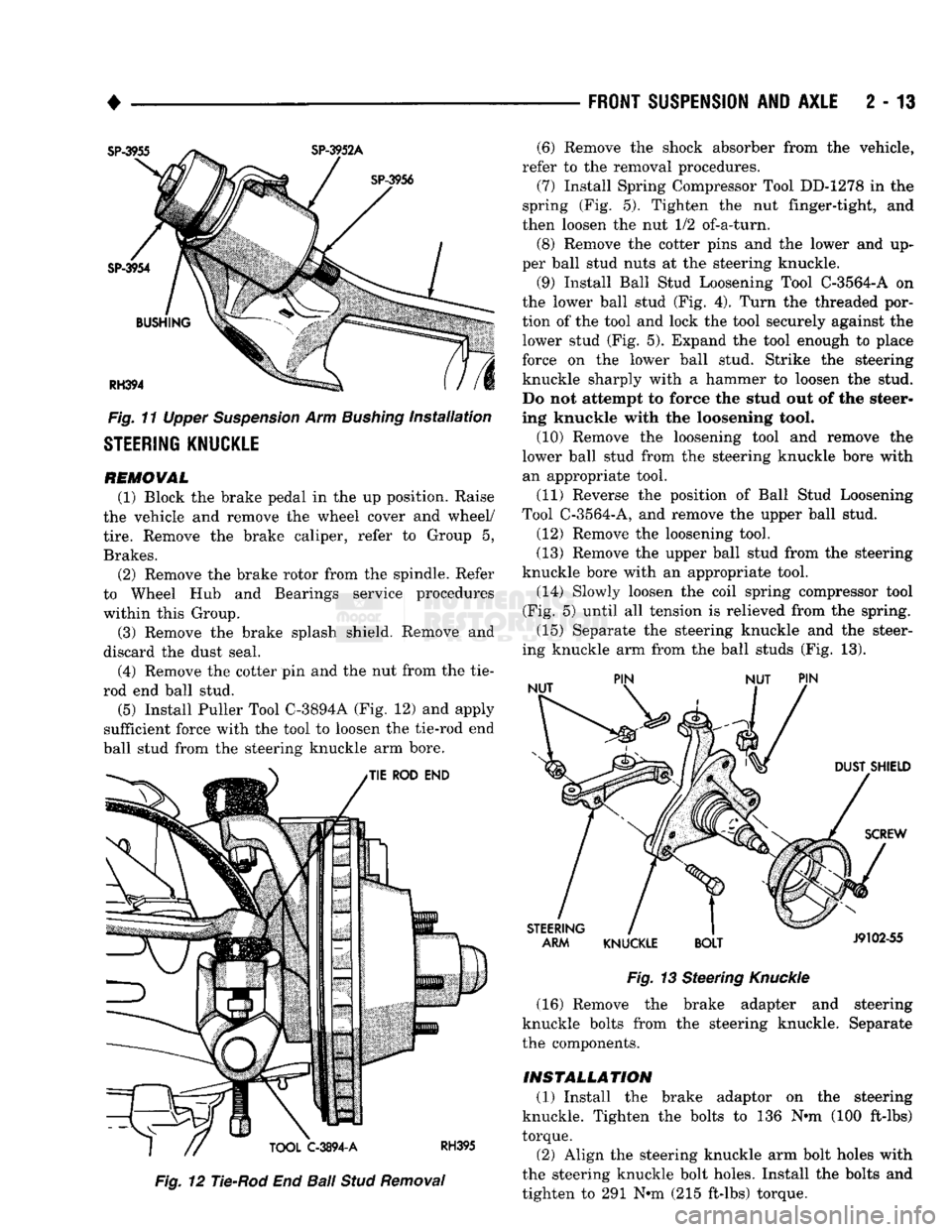

Fig.

11 Upper Suspension Arm Bushing installation

STEERING KNUCKLE

REMOVAL

(1) Block the brake pedal in the up position. Raise

the vehicle and remove the wheel cover and wheel/

tire.

Remove the brake caliper, refer to Group 5,

Brakes. (2) Remove the brake rotor from the spindle. Refer

to Wheel Hub and Bearings service procedures

within this Group.

(3) Remove the brake splash shield. Remove and

discard the dust seal.

(4) Remove the cotter pin and the nut from the tie-

rod end ball stud.

(5)

Install Puller Tool C-3894A (Fig. 12) and apply

sufficient force with the tool to loosen the tie-rod end

ball stud from the steering knuckle arm bore.

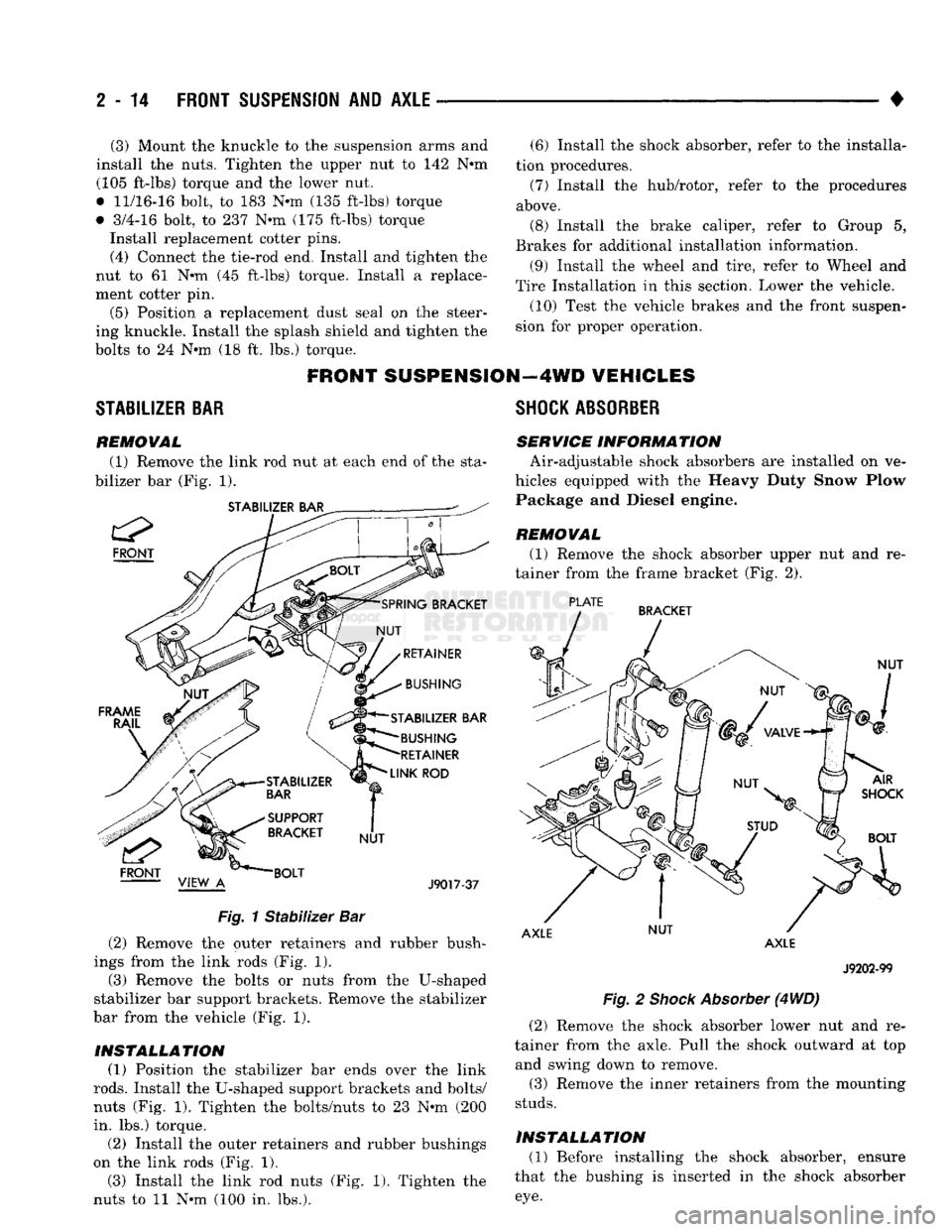

Fig.

12 Tie-Rod End

Ball

Stud

Removal

FRONT SUSPENSION

AND

AXLE

2 - 13

Fig.

13 Steering

Knuckle

(16) Remove the brake adapter and steering

knuckle bolts from the steering knuckle. Separate

the components.

INSTALLATION (1) Install the brake adaptor on the steering

knuckle. Tighten the bolts to 136 Nnn (100 ft-lbs)

torque.

(2) Align the steering knuckle arm bolt holes with

the steering knuckle bolt holes. Install the bolts and

tighten to 291 Nnn (215 ft-lbs) torque. (6) Remove the shock absorber from the vehicle,

refer to the removal procedures. (7) Install Spring Compressor Tool DD-1278 in the

spring (Fig. 5). Tighten the nut finger-tight, and

then loosen the nut 1/2 of-a-turn.

(8) Remove the cotter pins and the lower and up

per ball stud nuts at the steering knuckle.

(9) Install Ball Stud Loosening Tool C-3564-A on

the lower ball stud (Fig. 4). Turn the threaded por

tion of the tool and lock the tool securely against the lower stud (Fig. 5). Expand the tool enough to place

force on the lower ball stud. Strike the steering

knuckle sharply with a hammer to loosen the stud.

Do not attempt to force the stud out of the steer

ing knuckle with the loosening tool.

(10) Remove the loosening tool and remove the

lower ball stud from the steering knuckle bore with an appropriate tool.

(11) Reverse the position of Ball Stud Loosening

Tool C-3564-A, and remove the upper ball stud.

(12) Remove the loosening tool.

(13) Remove the upper ball stud from the steering

knuckle bore with an appropriate tool. (14) Slowly loosen the coil spring compressor tool

(Fig. 5) until all tension is relieved from the spring.

(15) Separate the steering knuckle and the steer

ing knuckle arm from the ball studs (Fig. 13).

Page 67 of 1502

2

- 14

FRONT SUSPENSION

AND

AXLE

• (3) Mount the knuckle to the suspension arms and

install the nuts. Tighten the upper nut to 142 Nnn (105 ft-lbs) torque and the lower nut.

• 11/16-16 bolt, to 183 Nnn (135 ft-lbs) torque

• 3/4-16 bolt, to 237 Nnn (175 ft-lbs) torque Install replacement cotter pins. (4) Connect the tie-rod end. Install and tighten the

nut to 61 Nnn (45 ft-lbs) torque. Install a replace

ment cotter pin. (5) Position a replacement dust seal on the steer

ing knuckle. Install the splash shield and tighten the

bolts to 24 Nnn (18 ft. lbs.) torque. (6) Install the shock absorber, refer to the installa

tion procedures.

(7) Install the hub/rotor, refer to the procedures

above.

(8) Install the brake caliper, refer to Group 5,

Brakes for additional installation information.

(9)

Install the wheel and tire, refer to Wheel and

Tire Installation in this section. Lower the vehicle.

(10) Test the vehicle brakes and the front suspen

sion for proper operation.

FRONT

SUSPENSION—4WD VEHICLES

STABILIZER

BAR REMOVAL

(1) Remove the link rod nut at each end of the sta

bilizer bar (Fig. 1).

STABILIZER BAR

FRONT

STABILIZER BAR BUSHING

RETAINER

LINK

ROD

J9017-37

Fig.

1

Stabilizer

Bar (2) Remove the outer retainers and rubber bush

ings from the link rods (Fig. 1). (3) Remove the bolts or nuts from the U-shaped

stabilizer bar support brackets. Remove the stabilizer

bar from the vehicle (Fig. 1).

INSTALLATION (1) Position the stabilizer bar ends over the link

rods.

Install the U-shaped support brackets and bolts/

nuts (Fig. 1). Tighten the bolts/nuts to 23 Nnn (200

in. lbs.) torque.

(2) Install the outer retainers and rubber bushings

on the link rods (Fig. 1). (3) Install the link rod nuts (Fig. 1). Tighten the

nuts to 11 Nnn (100 in. lbs.).

SHOCK

ABSORBER

SERVICE INFORM

A TION Air-adjustable shock absorbers are installed on ve

hicles equipped with the Heavy Duty Snow Plow Package and Diesel engine.

REMOVAL

(1) Remove the shock absorber upper nut and re

tainer from the frame bracket (Fig. 2).

PLATE

BRACKET

NUT

AXLE NUT

AXLE

J9202-99

Fig.

2

Shock

Absorber

(4

WD)

(2) Remove the shock absorber lower nut and re

tainer from the axle. Pull the shock outward at top and swing down to remove.

(3) Remove the inner retainers from the mounting

studs.

INSTALLATION (1) Before installing the shock absorber, ensure

that the bushing is inserted in the shock absorber

eye.

Page 68 of 1502

•

FRONT

SUSPENSION

AND

AXLE

2 - 15 Ensure the shock absorber is positioned on the

stud with retainers correctly located (Fig. 2).

(2)

Position the inner retainers on the mounting

studs.

(3) Install the shock on the upper and lower stud

and install the outer retainers.

(4) Install the nuts on the frame bracket and axle

(Fig. 2). (5) Tighten the shock absorber upper and lower

nuts;

• Standard shock upper and lower nut to 75 Nnn (55

ft. lbs.) torque

• Air-adjustable shock upper nut to 75 N»m (55 ft. lbs.) torque, lower nut to 271 Nnn (200 ft. lbs.)

torque

CAUTION:

Vehicles

with

air

shocks MUST

maintain

a

minimum

pressure

of 10 to 15 psi (70 to 105 kPa). Operation below the specified minimum

pressures

may cause damage.

(6) Remove the supports and lower the vehicle.

LEAF

SPRINGS

REMOVAL

(1) Raise and support the frame until all weight is

removed from the front springs. (2) With the front tires in contact with the surface,

position support stands under the frame side rails. (3) Remove the nuts, lockwashers, U-bolts that at

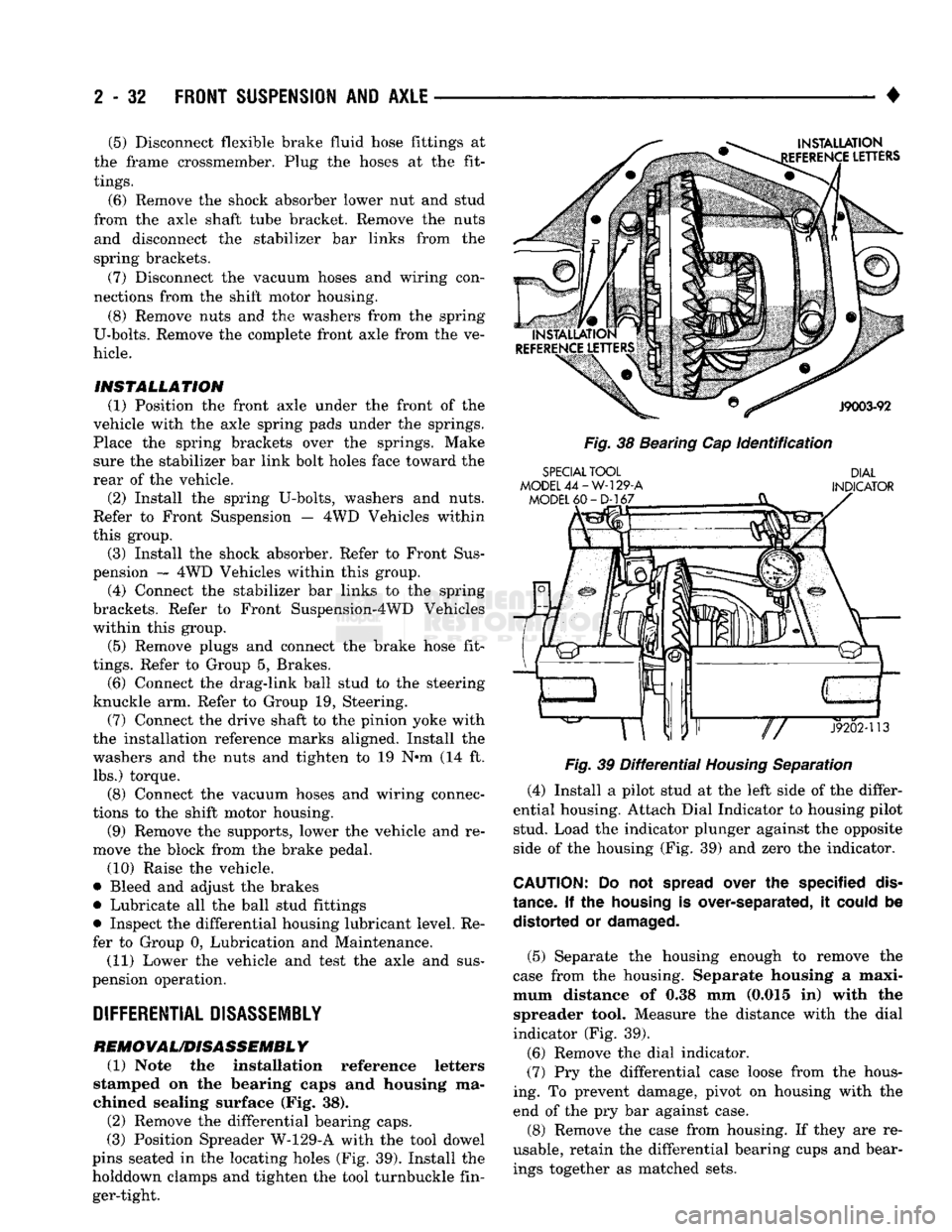

tach the spring to the axle shaft tubes (Fig. 3).

SPRING

BRACKET SPRING

BRACKET SPRING

SHACKLE

PLATE

FRONT

SPRING

AXLE

TUBE U-BOLT LEFT

SIDE

J9017-33

Fig.

3 Front

Suspension

(4) Remove the spring front eye pivot nut and bolt,

rear spring shackle nuts, shackle plates. Remove the spring from the vehicle (Fig. 3).

INSTALLATION

(1) Align the spring front eye with the bolt hole in

the frame bracket and install the pivot bolt and nut (Fig. 3). (2) Position the shackle plates at the spring rear

eye and frame rail bracket. Install the nuts (Fig. 3). (3) Tighten the shackle plate nuts and front pivot

bolt nut until all slack is taken up. (4) Position the spring on the axle tube with the

spring center bolt seated in locating hole in axle tube

pad (Fig. 3).

(5) Install the U-bolts, new lockwashers and nuts.

(6) Tighten the nuts snug against the spring

bracket.

(7) Remove the supports and lower the vehicle

with the weight being supported by the tires. (8) Tighten the spring nuts according to the follow

ing specifications:

• Model 44 Axle: U-bolt/Stud nuts - 115 Nnn (85 ft. lbs.) torque

Front pivot bolt/nut — 135 Nnn (100 ft. lbs.) torque

Rear shackle bolt/nut — 81 Nnn (60 ft. lbs.) torque

• Model 60 Axle: U-bolt nuts - 129 Nnn (95 ft. lbs.) torque Front pivot bolt/nut - 135 Nnn (100 ft. lbs.) torque

Rear shackle bolt/nut - 108 Nnn (80 ft. lbs.)

torque

SPRING LEAF-REPLACEMENT

If a spring has acquired a set (lost significant

height), it should be replaced. (1) Remove the spring from the vehicle. If neces

sary, refer to the removal procedure. (2) Remove the spring leaf alignment clips.

(3) Clamp the spring in a vise. Remove the nut

and center bolt (Fig. 4).

SPRING

CENTER

RATCHET

AND

SOCKET

WRENCH

Fig.

4 Leaf

Spring

Disassembly

(4) Insert a long drift or punch into the center bolt

hole and slowly release the vise jaws.

Page 85 of 1502

2

- 32

FRONT

SUSPENSION

AND

AXLE

• (5) Disconnect flexible brake fluid hose fittings at

the frame crossmember. Plug the hoses at the fit

tings.

(6) Remove the shock absorber lower nut and stud

from the axle shaft tube bracket. Remove the nuts and disconnect the stabilizer bar links from the

spring brackets.

(7) Disconnect the vacuum hoses and wiring con

nections from the shift motor housing.

(8) Remove nuts and the washers from the spring

U-bolts. Remove the complete front axle from the ve

hicle.

INSTALLATION

(1) Position the front axle under the front of the

vehicle with the axle spring pads under the springs.

Place the spring brackets over the springs. Make sure the stabilizer bar link bolt holes face toward the

rear of the vehicle.

(2) Install the spring U-bolts, washers and nuts.

Refer to Front Suspension — 4WD Vehicles within

this group. (3) Install the shock absorber. Refer to Front Sus

pension — 4WD Vehicles within this group. (4) Connect the stabilizer bar links to the spring

brackets. Refer to Front Suspension-4WD Vehicles

within this group.

(5) Remove plugs and connect the brake hose fit

tings.

Refer to Group 5, Brakes. (6) Connect the drag-link ball stud to the steering

knuckle arm. Refer to Group 19, Steering. (7) Connect the drive shaft to the pinion yoke with

the installation reference marks aligned. Install the

washers and the nuts and tighten to 19 N*m (14 ft. lbs.) torque.

(8) Connect the vacuum hoses and wiring connec

tions to the shift motor housing. (9) Remove the supports, lower the vehicle and re

move the block from the brake pedal.

(10) Raise the vehicle.

• Bleed and adjust the brakes

• Lubricate all the ball stud fittings

• Inspect the differential housing lubricant level. Re

fer to Group 0, Lubrication and Maintenance. (11) Lower the vehicle and test the axle and sus

pension operation.

DIFFERENTIAL

DISASSEMBLY

REMOVAL/DISASSEMBLY (1) Note the installation reference letters

stamped on the bearing caps and housing ma

chined sealing surface (Fig. 38). (2) Remove the differential bearing caps.

(3) Position Spreader W-129-A with the tool dowel

pins seated in the locating holes (Fig. 39). Install the

holddown clamps and tighten the tool turnbuckle fin ger-tight.

INSTALLATION

EFERENCE

LETTERS

J9003-92

Fig.

38 Bearing Cap

Identification

SPECIAL

TOOL

MODEL

44-W-129-A

MODEL

60-D-167

DIAL

INDICATOR

«ar"P—

J9202-113

Fig.

39

Differential

Housing

Separation

(4) Install a pilot stud at the left side of the differ

ential housing. Attach Dial Indicator to housing pilot stud. Load the indicator plunger against the opposite

side of the housing (Fig. 39) and zero the indicator.

CAUTION:

Do not

spread

over the specified

dis

tance.

If the

housing

is over-separated, it

could

be distorted or

damaged.

(5) Separate the housing enough to remove the

case from the housing. Separate housing a maxi

mum distance of 0.38 mm (0.015 in) with the spreader tool. Measure the distance with the dial

indicator (Fig. 39).

(6) Remove the dial indicator.

(7) Pry the differential case loose from the hous

ing. To prevent damage, pivot on housing with the end of the pry bar against case.

(8) Remove the case from housing. If they are re

usable, retain the differential bearing cups and bear ings together as matched sets.

Page 112 of 1502

•

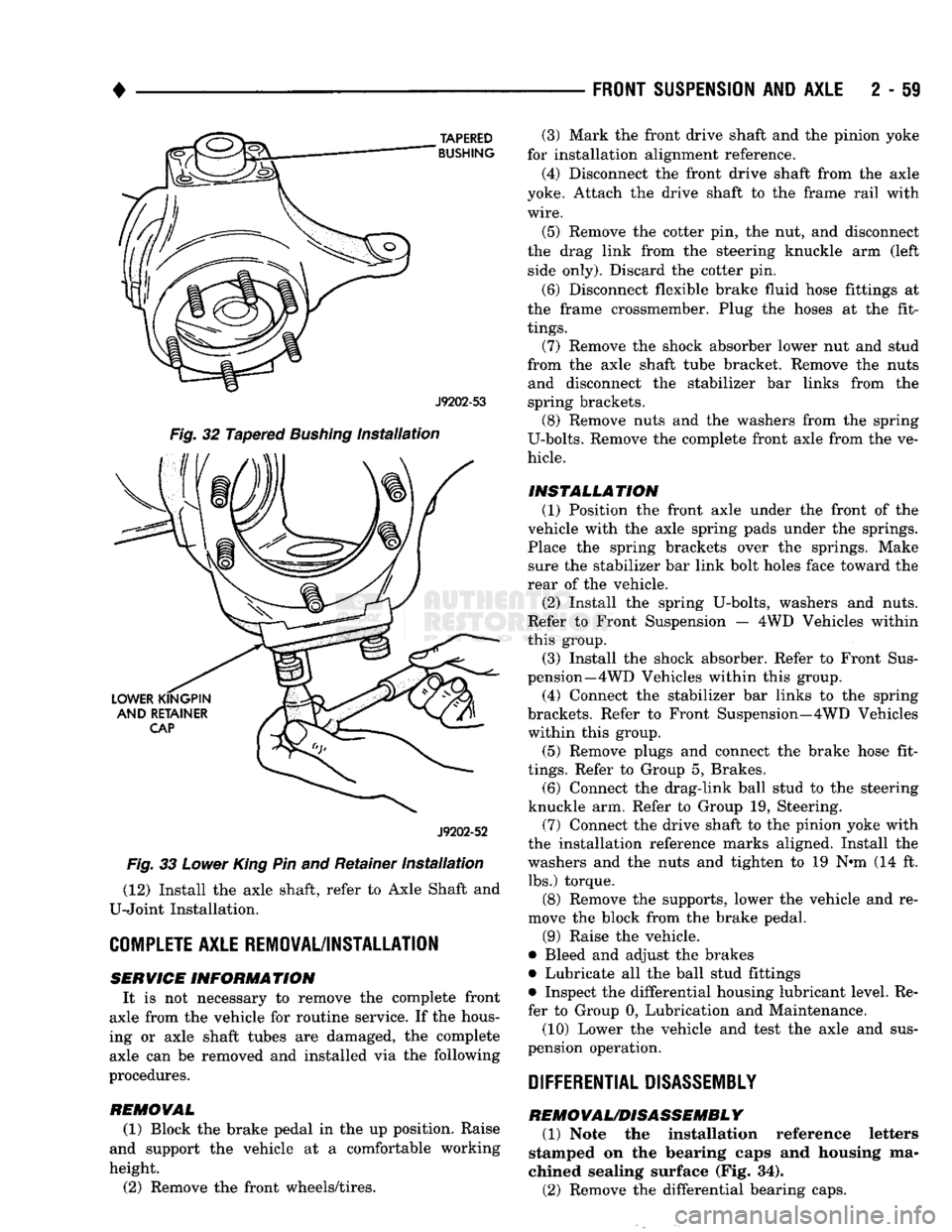

TAPERED

BUSHING

J9202-53

Fig.

32 Tapered

Bushing

Installation

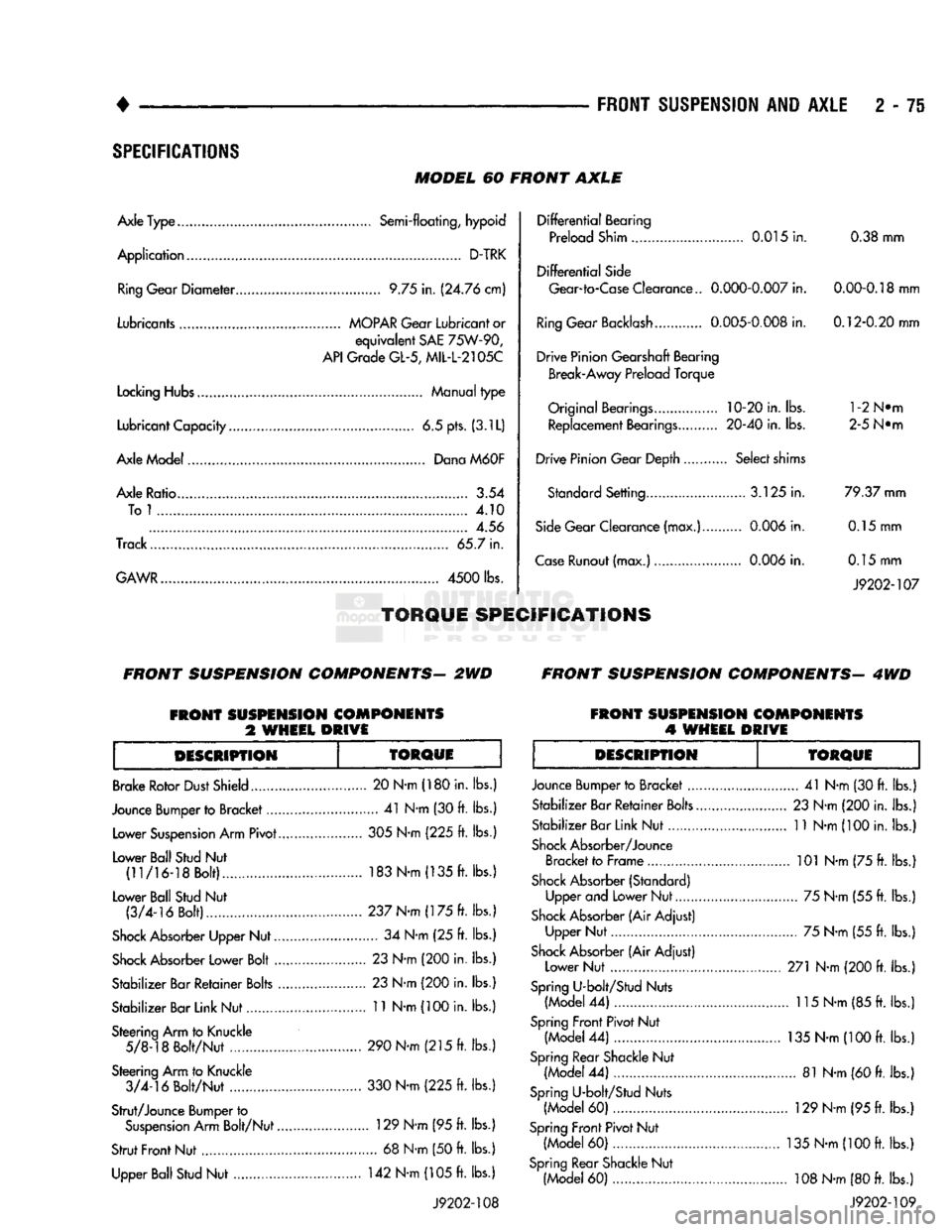

J9202-52

Fig.

33

Lower

King

Pin and Retainer

Installation

(12) Install the axle shaft, refer to Axle Shaft and

U-Joint Installation.

COMPLETE

AXLE REMOVAL/INSTALLATION SERVICE

INFORMATION

It is not necessary to remove the complete front

axle from the vehicle for routine service. If the hous

ing or axle shaft tubes are damaged, the complete axle can be removed and installed via the following

procedures.

REMOVAL

(1) Block the brake pedal in the up position. Raise

and support the vehicle at a comfortable working

height.

(2) Remove the front wheels/tires.

FRONT SUSPENSION

AND

AXLE

2 - 59

(3) Mark the front drive shaft and the pinion yoke

for installation alignment reference.

(4) Disconnect the front drive shaft from the axle

yoke. Attach the drive shaft to the frame rail with

wire.

(5) Remove the cotter pin, the nut, and disconnect

the drag link from the steering knuckle arm (left side only). Discard the cotter pin.

(6) Disconnect flexible brake fluid hose fittings at

the frame crossmember. Plug the hoses at the fit

tings.

(7) Remove the shock absorber lower nut and stud

from the axle shaft tube bracket. Remove the nuts and disconnect the stabilizer bar links from the

spring brackets. (8) Remove nuts and the washers from the spring

U-bolts. Remove the complete front axle from the ve

hicle.

INSTALLATION (1) Position the front axle under the front of the

vehicle with the axle spring pads under the springs.

Place the spring brackets over the springs. Make sure the stabilizer bar link bolt holes face toward the

rear of the vehicle.

(2) Install the spring U-bolts, washers and nuts.

Refer to Front Suspension — 4WD Vehicles within

this group. (3) Install the shock absorber. Refer to Front Sus

pension—4 WD Vehicles within this group.

(4) Connect the stabilizer bar links to the spring

brackets. Refer to Front Suspension—4WD Vehicles within this group.

(5) Remove plugs and connect the brake hose fit

tings.

Refer to Group 5, Brakes. (6) Connect the drag-link ball stud to the steering

knuckle arm. Refer to Group 19, Steering. (7) Connect the drive shaft to the pinion yoke with

the installation reference marks aligned. Install the

washers and the nuts and tighten to 19 N-m (14 ft. lbs.) torque.

(8) Remove the supports, lower the vehicle and re

move the block from the brake pedal.

(9) Raise the vehicle.

• Bleed and adjust the brakes

• Lubricate all the ball stud fittings

• Inspect the differential housing lubricant level. Re

fer to Group 0, Lubrication and Maintenance.

(10) Lower the vehicle and test the axle and sus

pension operation.

DIFFERENTIAL DISASSEMBLY

REMOVAL/DISASSEMBLY

(1) Note the installation reference letters

stamped on the bearing caps and housing ma

chined sealing surface (Fig. 34).

(2) Remove the differential bearing caps.

Page 128 of 1502

FRONT

SUSPENSION

AND

AXLE

2 - 75

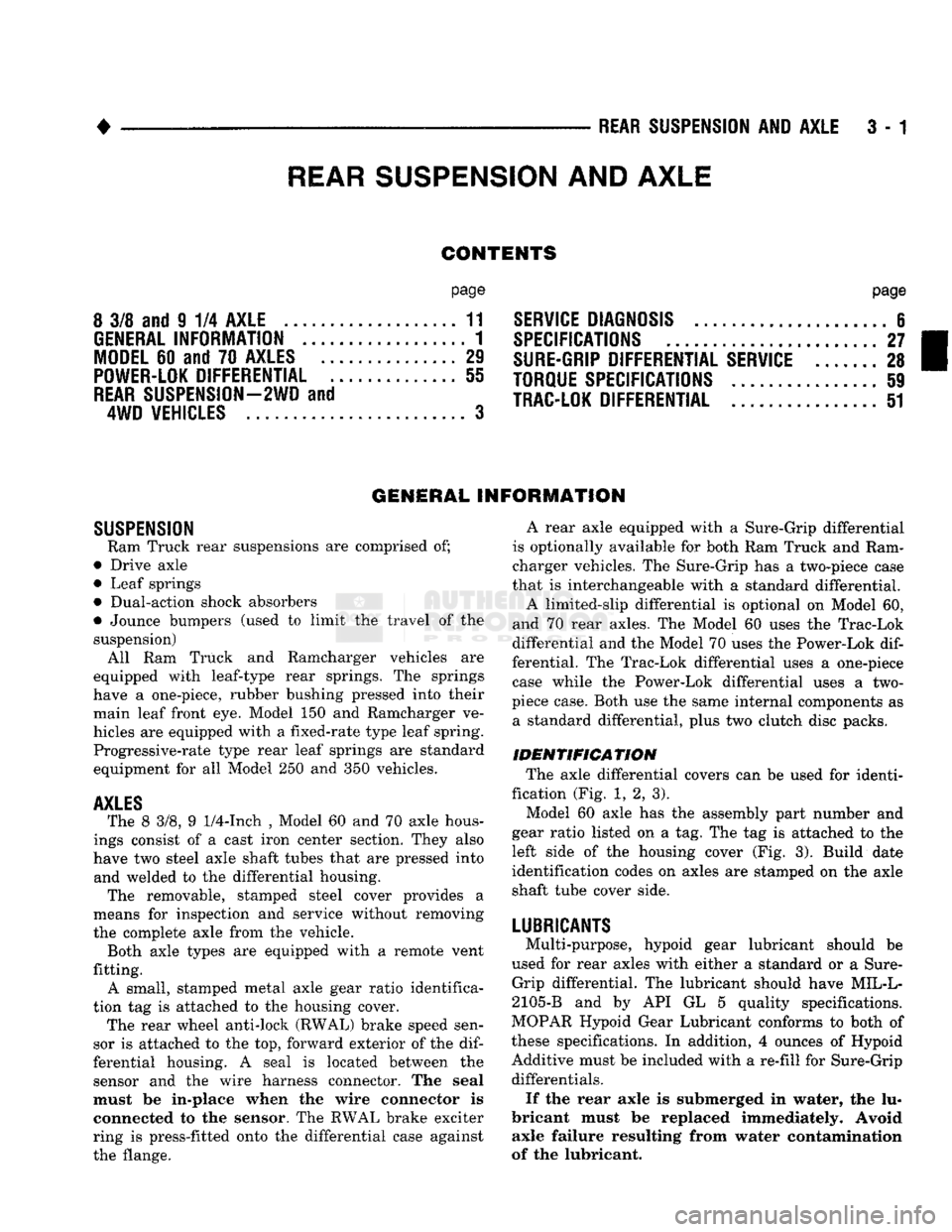

SPECIFICATIONS

MODEL

60

FRONT

AXLE

Axle Type........

Semi-floating,

hypoid

Application

D-TRK Ring Gear

Diameter

9.75

in.

(24.76 cm)

Lubricants

MOPAR

Gear

Lubricant

or

equivalent

SAE

75W-90,

API

Grade

GL-5,

MIL-L-2105C

Locking

Hubs Manual

type

Lubricant Capacity

6.5

pts. (3.1L)

Axle Model Dana

M60F

Axle Ratio.........

3.54

Tol

4.10

4.56

Track... 65.7

in.

GAWR....................

4500

lbs.

TORQUE

SPECIFICATIONS

Differential

Bearing

Preload Shim 0.015

in.

0.38

mm

Differential

Side Gear-to-Case Clearance..

0.000-0.007

in.

0.00-0.18

mm

Ring

Gear Backlash 0.005-0,008

in.

0.12-0.20 mm

Drive Pinion Gearshaft Bearing Break-Away Preload Torque

Original

Bearings....

10-20

in. lbs. l-2N®m Replacement Bearings. 20-40

in.

lbs. 2-5 N®m

Drive Pinion Gear Depth Select shims Standard Setting.... 3.125

in.

79.37 mm

Side

Gear Clearance (max.) 0.006

in.

0.15

mm

Case

Runout (max.) 0.006

in.

0.15

mm

J9202-107

FRONT

SUSPENSION

COMPONENTS-

2WD

FRONT

SUSPENSION

COMPONENTS-

4WD

FRONT

SUSPENSION

COMPONENTS

%

WHEEL

DRIVE

FRONT

SUSPENSION

COMPONENTS

4

WHEEL

DRIVE

DESCRIPTION

TOROUE

Brake Rotor

Dust

Shield

Jounce Bumper to Bracket.... Lower

Suspension

Arm Pivot.

Lower Ball Stud

Nut

(11/16-18 Bolt)...............

Lower Ball Stud

Nut

(3/4-16 Bolt).....

Shock

Absorber Upper Nut..

Shock

Absorber Lower Bolt

..

Stabilizer Bar Retainer

Bolts

.

Stabilizer Bar Link Nut

Steering Arm to Knuckle 5/8-18 Bolt/Nut

.............

Steering Arm to Knuckle 3/4-16 Bolt/Nut . 20 N-m (180 in.

lbs.

....

41

N-m

(30

ft. lbs.

305

N-m (225

ft. lbs.

183

N-m (135

ft. lbs.

237 N-m (175

ft. lbs.

....

34

N-m

(25 ft.

lbs. .

23

N-m

(200

in. lbs.

.

23

N-m

(200

in. lbs.

. 11 N-m

(100

in. lbs.

Strut/Jounce Bumper to

Suspension

Arm Bolt/Nut.

Strut

Front

Nut Upper Ball Stud

Nut

290 N-m (215

ft. lbs.

330 N-m (225

ft.

lbs.

.. 129 N-m (95

ft.

lbs.

....

68

N-m

(50

ft.

lbs.

142

N-m

(105

ft.

lbs.

J9202-108

DESCRIPTION

TORQUE

Jounce Bumper to Bracket

....

Stabilizer Bar Retainer

Bolts..

Stabilizer Bar Link Nut

Shock

Absorber/Jounce Bracket to Frame

Shock

Absorber (Standard) Upper and Lower Nut

Shock

Absorber (Air Adjust) Upper Nut

Shock

Absorber (Air Adjust) Lower Nut

Spring

U-bolt/Stud Nuts (Model

44) ...

Spring

Front Pivot Nut (Model

44)

Spring

Rear Shackle

Nut

(Model

44)

Spring

U-bolt/Stud Nuts (Model

60)

Spring

Front

Pivot Nut (Model

60)

Spring

Rear Shackle Nut (Model

60)

...

41

N-m (30

ft.

lbs.)

23

N-m (200 in.

lbs.)

11

N-m

(100

in.

lbs.)

.. 101 N-m (75

ft.

lbs.)

.... 75 N-m (55

ft.

lbs.)

.... 75 N-m (55

ft.

lbs.)

271 N-m

(200

ft.

lbs.)

.. 115 N-m (85

ft.

lbs.)

135

N-m (100

ft.

lbs.)

.... 81 N-m

(60

ft.

lbs.)

..

129

N-m

(95

ft.

lbs.)

135

N-m (100

ft.

lbs.)

,.

108

N-m

(80

ft.

lbs.)

J9202-109

Page 130 of 1502

•

REAR

SUSPENSION

AND

AXLE

3 - 1

CONTENTS

page

8

3/8 and 9 1/4

AXLE

11

GENERAL

INFORMATION

1

MODEL

60 and 70

AXLES

29

POWER-LOK DIFFERENTIAL

55

REAR

SUSPENSION—2WD

and

4WD VEHICLES

3

page

SERVICE

DIAGNOSIS

6

SPECIFICATIONS

27

SURE-GRIP

DIFFERENTIAL SERVICE

28

TORQUE SPECIFICATIONS

59

TRAC-LOK DIFFERENTIAL

51

GENERAL INFORMATION

SUSPENSION

Ram Truck rear suspensions

are

comprised

of;

• Drive axle

• Leaf springs

• Dual-action shock absorbers

• Jounce bumpers (used

to

limit

the

travel

of the

suspension) All

Ram

Truck

and

Ramcharger vehicles

are

equipped with leaf-type rear springs.

The

springs

have

a

one-piece, rubber bushing pressed into their main leaf front

eye.

Model

150 and

Ramcharger

ve

hicles

are

equipped with

a

fixed-rate type leaf spring. Progressive-rate type rear leaf springs

are

standard equipment

for all

Model

250 and 350

vehicles.

AXLES

The

8 3/8, 9

1/4-Inch

,

Model

60 and 70

axle hous

ings consist

of a

cast iron center section. They also

have

two

steel axle shaft tubes that

are

pressed into and welded

to the

differential housing. The removable, stamped steel cover provides

a

means

for

inspection

and

service without removing

the complete axle from

the

vehicle. Both axle types

are

equipped with

a

remote vent

fitting. A small, stamped metal axle gear ratio identifica

tion

tag is

attached

to the

housing cover. The rear wheel anti-lock (RWAL) brake speed sen

sor

is

attached

to the top,

forward exterior

of the dif

ferential housing.

A

seal

is

located between

the

sensor

and the

wire harness connector.

The

seal

must

be

in-plaee when

the

wire connector

is

connected

to the

sensor.

The

RWAL brake exciter

ring

is

press-fitted onto

the

differential case against

the flange. A rear axle equipped with

a

Sure-Grip differential

is optionally available

for

both

Ram

Truck

and

Ram

charger vehicles.

The

Sure-Grip

has a

two-piece case

that

is

interchangeable with

a

standard differential.

A limited-slip differential

is

optional

on

Model

60,

and

70

rear axles.

The

Model

60

uses

the

Trac-Lok

differential

and the

Model

70

uses

the

Power-Lok

dif

ferential.

The

Trac-Lok differential uses

a

one-piece case while

the

Power-Lok differential uses

a two-

piece case. Both

use the

same internal components

as

a standard differential, plus

two

clutch disc packs.

IDENTIFICATION The axle differential covers

can be

used

for

identi

fication (Fig.

1, 2, 3).

Model

60

axle

has the

assembly part number

and

gear ratio listed

on a tag. The tag is

attached

to the

left side

of the

housing cover

(Fig. 3).

Build date

identification codes

on

axles

are

stamped

on the

axle

shaft tube cover side.

LUBRICANTS

Multi-purpose, hypoid gear lubricant should

be

used

for

rear axles with either

a

standard

or a

Sure- Grip differential.

The

lubricant should have MIL-L-

2105-B

and by API GL 5

quality specifications.

MOPAR Hypoid Gear Lubricant conforms

to

both

of

these specifications.

In

addition,

4

ounces

of

Hypoid Additive must

be

included with

a

re-fill

for

Sure-Grip differentials.

If

the

rear axle

is

submerged

in

water,

the lu

bricant must

be

replaced immediately. Avoid axle failure resulting from water contamination

of

the

lubricant.

REAR

SUSPENSION

AND

AXLE

Page 132 of 1502

•

REAR

SUSPENSION

AND

AXLE

3 - 3

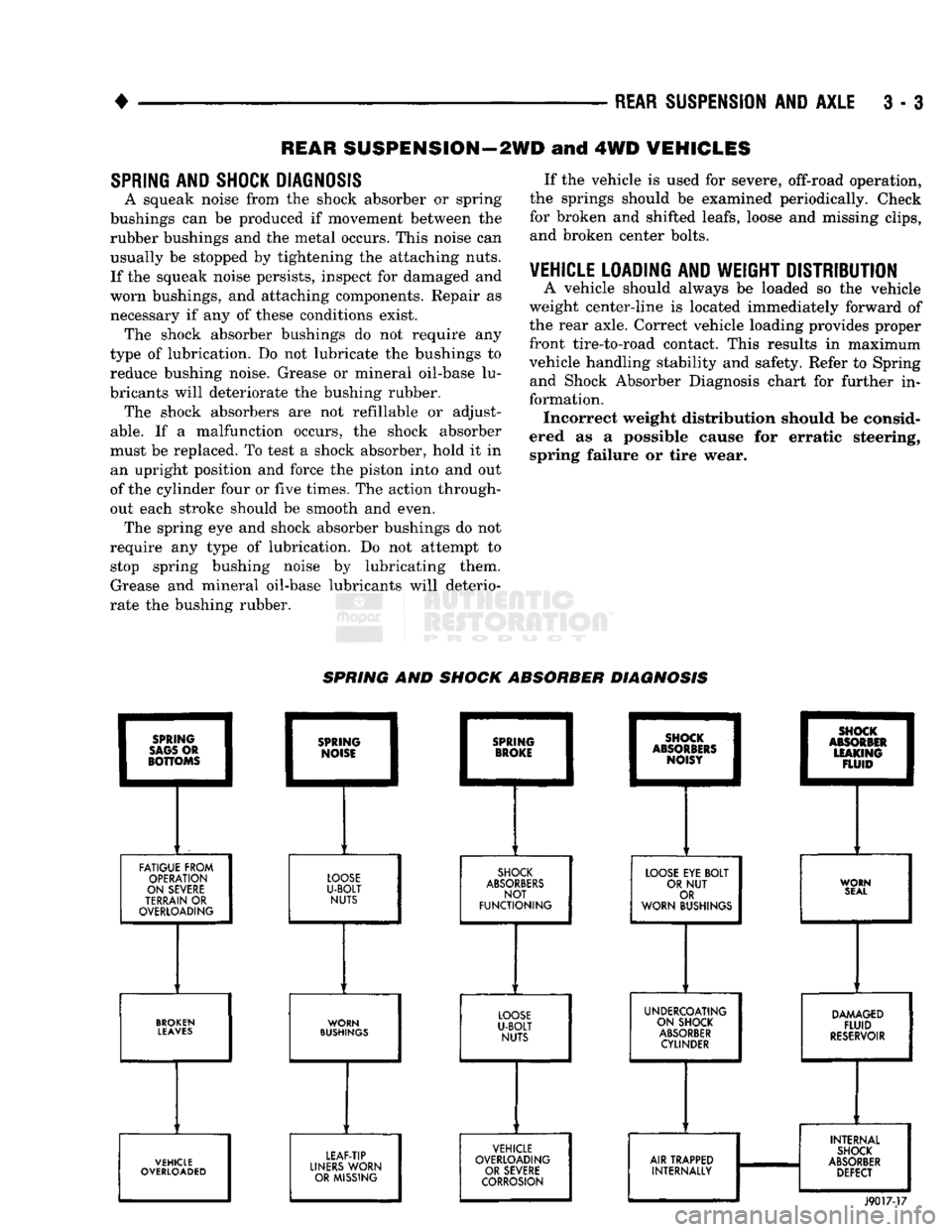

REAR SUSPENSION—2WD

and 4WD

VEHICLES

SPRING

AND

SHOCK DIAGNOSIS

A squeak noise from the shock absorber or spring

bushings can be produced if movement between the

rubber bushings and the metal occurs. This noise can usually be stopped by tightening the attaching nuts.

If the squeak noise persists, inspect for damaged and

worn bushings, and attaching components. Repair as

necessary if any of these conditions exist. The shock absorber bushings do not require any

type of lubrication. Do not lubricate the bushings to reduce bushing noise. Grease or mineral oil-base lu

bricants will deteriorate the bushing rubber. The shock absorbers are not reflllable or adjust

able.

If a malfunction occurs, the shock absorber

must be replaced. To test a shock absorber, hold it in an upright position and force the piston into and out

of the cylinder four or five times. The action through

out each stroke should be smooth and even. The spring eye and shock absorber bushings do not

require any type of lubrication. Do not attempt to stop spring bushing noise by lubricating them.

Grease and mineral oil-base lubricants will deterio

rate the bushing rubber. If the vehicle is used for severe, off-road operation,

the springs should be examined periodically. Check for broken and shifted leafs, loose and missing clips, and broken center bolts.

VEHICLE LOADING

AND

WEIGHT DISTRIBUTION

A vehicle should always be loaded so the vehicle

weight center-line is located immediately forward of

the rear axle. Correct vehicle loading provides proper

front tire-to-road contact. This results in maximum

vehicle handling stability and safety. Refer to Spring and Shock Absorber Diagnosis chart for further in

formation. Incorrect weight distribution should be consid

ered as a possible cause for erratic steering, spring failure or tire wear. SPRING AND SHOCK ABSORBER DIAGNOSIS

FATIGUE FROM

OPERATION

ON SEVERE

TERRAIN

OR

OVERLOADING

LOOSE

U-BOLT

NUTS

SHOCK

ABSORBERS

NOT

FUNCTIONING

LOOSE

EYE

BOLT

OR

NUT

OR

WORN BUSHINGS WORN

SEAL

BROKEN

LEAVES

WORN

BUSHINGS

UNDERCOATING

ON SHOCK

ABSORBER

CYLINDER

DAMAGED

FLUID

RESERVOIR

VEHICLE

OVERLOADED LEAF-TIP

LINERS

WORN OR MISSING VEHICLE

OVERLOADING OR SEVERE

CORROSION

AIR TRAPPED

INTERNALLY INTERNAL

SHOCK

ABSORBER

DEFECT

J9017-17

Page 133 of 1502

3

- 4

REAR SUSPENSION

AND

AXLE

•

SHOCK

ABSORBER

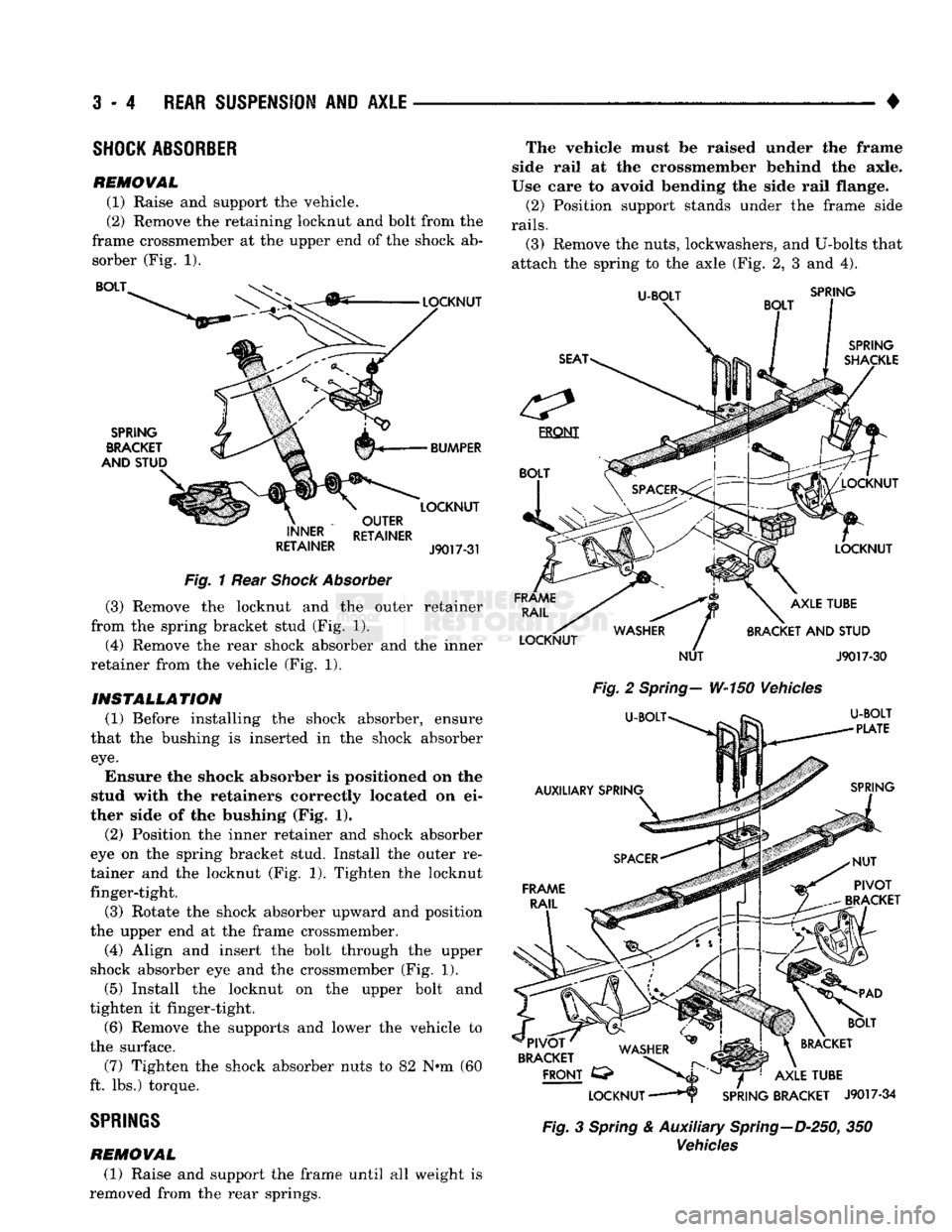

REMOVAL (1) Raise and support the vehicle.

(2) Remove the retaining locknut and bolt from the

frame crossmember at the upper end of the shock ab sorber (Fig. 1). BOLT

SPRING

BRACKET

AND STUD LOCKNUT

BUMPER LOCKNUT

OUTER

INNER RETAINER

RETAINER

J90T7-31

Fig.

1 Rear

Shock

Absorber

(3) Remove the locknut and the outer retainer

from the spring bracket stud (Fig. 1).

(4) Remove the rear shock absorber and the inner

retainer from the vehicle (Fig. 1).

INSTALLATION (1) Before installing the shock absorber, ensure

that the bushing is inserted in the shock absorber

eye.

Ensure the shock absorber is positioned on the

stud with the retainers correctly located on ei

ther side of the bushing (Fig. 1).

(2) Position the inner retainer and shock absorber

eye on the spring bracket stud. Install the outer re

tainer and the locknut (Fig. 1). Tighten the locknut finger-tight.

(3) Rotate the shock absorber upward and position

the upper end at the frame crossmember.

(4) Align and insert the bolt through the upper

shock absorber eye and the crossmember (Fig. 1).

(5) Install the locknut on the upper bolt and

tighten it finger-tight.

(6) Remove the supports and lower the vehicle to

the surface. (7) Tighten the shock absorber nuts to 82 N*m (60

ft. lbs.) torque.

SPRINGS

REMOVAL (1) Raise and support the frame until all weight is

removed from the rear springs. The vehicle must be raised under the frame

side rail at the crossmember behind the axle.

Use care to avoid bending the side rail flange.

(2) Position support stands under the frame side

rails.

(3) Remove the nuts, lockwashers, and U-bolts that

attach the spring to the axle (Fig. 2, 3 and 4).

U-BOLT

SPRING

SPRING

SHACKLE

FRAME

RAIL

LOCKNUT LOCKNUT

LOCKNUT AXLE TUBE

BRACKET

AND

STUD

NUT

J9017-3Q

Fig.

2

Spring—

W-150 Vehicles

U-BOLT^

U-BOLT

~ '

PLATE

IB*

AUXILIARY SPRING

SPRING

FRAME

RAIL

PIVOT

BRACKET

^ . , _

BOLT

'PIVOT'

WA^HFP

^

in^gJ

\

BRACKET

BRACKET WASHER

^

FRONT

C3>

>>JL

^ T^1

AXLE TUBE

LOCKNUT

——Hr

SPRING BRACKET

J9017-34

Fig.

3

Spring

& Auxiliary

Spring—D-250,

350

Vehicles

Page 143 of 1502

3

- 14

REAR SUSPENSION

AND

AXLE

3

- 18

REAR SUSPENSION Fig.

6 Bearing

Removal

(9

1/4-Axle)

(4) Inspect the axle shaft tube bore for roughness

and burrs. Remove as necessary.

CAUTION:

Inspect

the

housing

bore for

burrs.

Re

move

as

necessary.

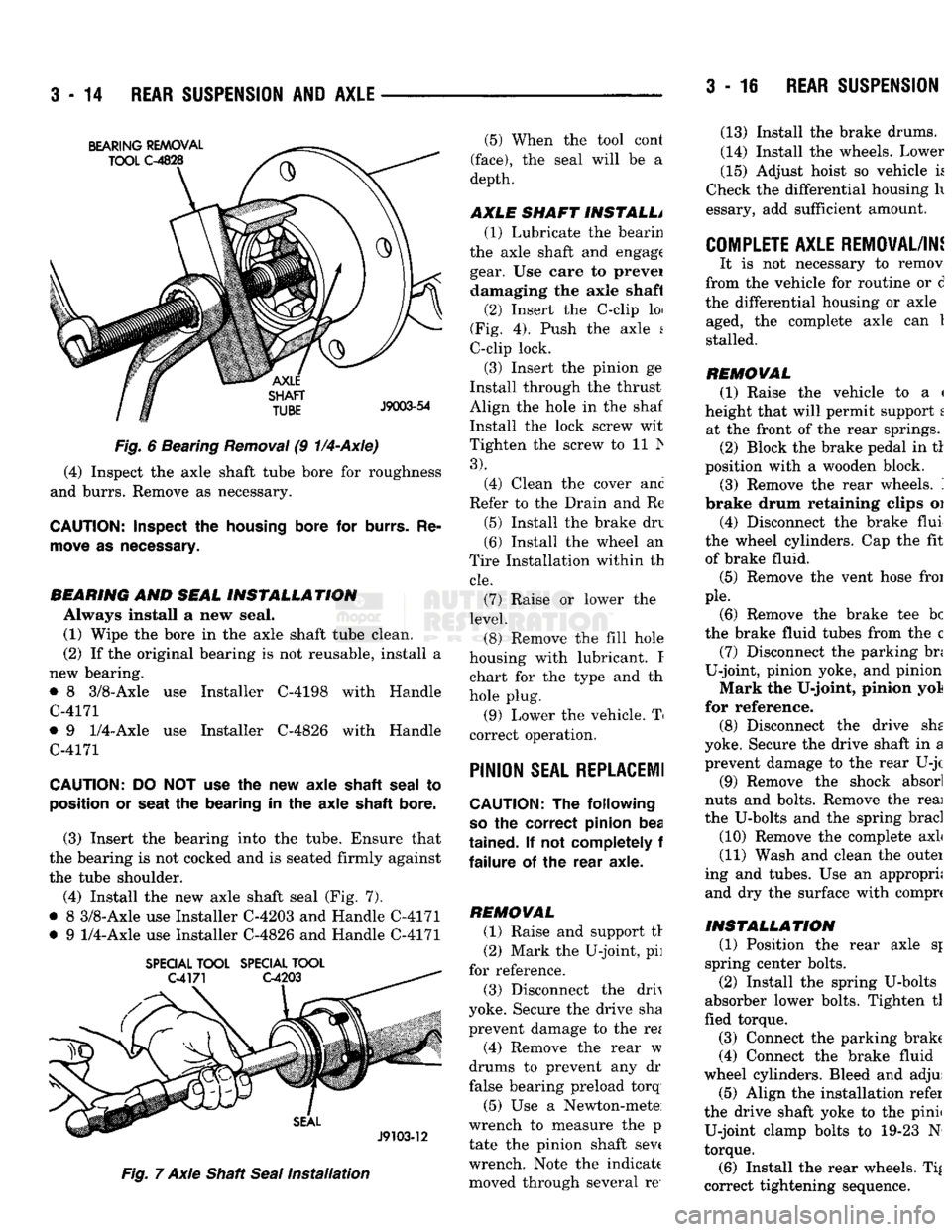

BEARING

AND

SEAL

INSTALLATION

Always install a new seal. (1) Wipe the bore in the axle shaft tube clean.

(2) If the original bearing is not reusable, install a

new bearing.

• 8 3/8-Axle use Installer C-4198 with Handle

C-4171

• 9

1/4-Axle

use Installer C-4826 with Handle

C-4171

CAUTION:

DO NOT use the new axle

shaft

seal

to

position

or

seat

the bearing in the axle

shaft

bore.

(3) Insert the bearing into the tube. Ensure that

the bearing is not cocked and is seated firmly against

the tube shoulder.

(4) Install the new axle shaft seal (Fig. 7).

• 8 3/8-Axle use Installer C-4203 and Handle C-4171

• 9

1/4-Axle

use Installer C-4826 and Handle C-4171

SPECIAL

TOOL

SPECIAL

TOOL

Fig.

7 Axle Shaft

Seal

Installation

(5) When the tool cont

(face),

the seal will be a

depth.

AXLE SHAFT INSTALL* (1) Lubricate the bearin

the axle shaft and engage gear. Use care to prevei damaging the axle shaft

(2) Insert the C-clip loi

(Fig. 4). Push the axle s

C-clip lock.

(3) Insert the pinion ge

Install through the thrust

Align the hole in the shaf

Install the lock screw wit

Tighten the screw to 11 Is

3).

(4) Clean the cover anc

Refer to the Drain and Re

(5) Install the brake drv

(6) Install the wheel an

Tire Installation within th

cle.

(7) Raise or lower the

level.

(8) Remove the fill hole

housing with lubricant. I chart for the type and th

hole plug.

(9) Lower the vehicle. T

correct operation.

PINION

SEAL REPLACE!!

CAUTION:

The following

so

the correct pinion bea

tained.

If not completely f

failure

of the rear axle.

REMOVAL (1) Raise and support tr

(2) Mark the U-joint, pi]

for reference.

(3) Disconnect the drh

yoke. Secure the drive sha

prevent damage to the re*

(4) Remove the rear w

drums to prevent any dr

false bearing preload torq

(5) Use a Newton-mete

wrench to measure the p

tate the pinion shaft sev( wrench. Note the indicate moved through several re' (13) Install the brake drums.

(14) Install the wheels. Lower

(15) Adjust hoist so vehicle k

Check the differential housing h

essary, add sufficient amount.

COMPLETE AXLE REMOVAL/IN!

It is not necessary to remov

from the vehicle for routine or d

the differential housing or axle aged, the complete axle can 1

stalled.

REMOVAL (1) Raise the vehicle to a <

height that will permit support t at the front of the rear springs. (2) Block the brake pedal in tl

position with a wooden block. (3) Remove the rear wheels. '.

brake drum retaining clips oi

(4) Disconnect the brake flui

the wheel cylinders. Cap the fit of brake fluid.

(5) Remove the vent hose froi

pie.

(6) Remove the brake tee be

the brake fluid tubes from the c (7) Disconnect the parking bn

U-joint, pinion yoke, and pinion

Mark the U-joint, pinion yol

for reference. (8) Disconnect the drive she

yoke. Secure the drive shaft in a prevent damage to the rear U-jc

(9) Remove the shock absorl

nuts and bolts. Remove the reai

the U-bolts and the spring brad

(10) Remove the complete axL

(11) Wash and clean the outei

ing and tubes. Use an appropri; and dry the surface with comprc

INSTALLATION

(1) Position the rear axle sj

spring center bolts.

(2) Install the spring U-bolts

absorber lower bolts. Tighten tl

fled torque.

(3) Connect the parking brake

(4) Connect the brake fluid

wheel cylinders. Bleed and adjui (5) Align the installation refer

the drive shaft yoke to the pinii U-joint clamp bolts to 19-23 N

torque.

(6) Install the rear wheels. Ti|

correct tightening sequence.