boot DODGE TRUCK 1993 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 227 of 1502

5

- 40

BRAKES

•

Fig.

6 Removing/Installing

Support

Key Retaining

Screw

If the shoe lining will be reused, do not intermix

the shoes. Keep them with the caliper they were re moved from.

Examine the caliper piston area for evidence of

leaks.

Also check condition of the piston boot. Over

haul the caliper if leakage is evident or the boot is

cut or torn.

Clean rust and corrosion from the support key and

the caliper and adapter slide surfaces (machined

ways) with a wire brush. Then lubricate the slide surfaces with Mopar multi-mileage grease, or equiv

alent.

DISC

BRAKESHOE

INSTALLATION

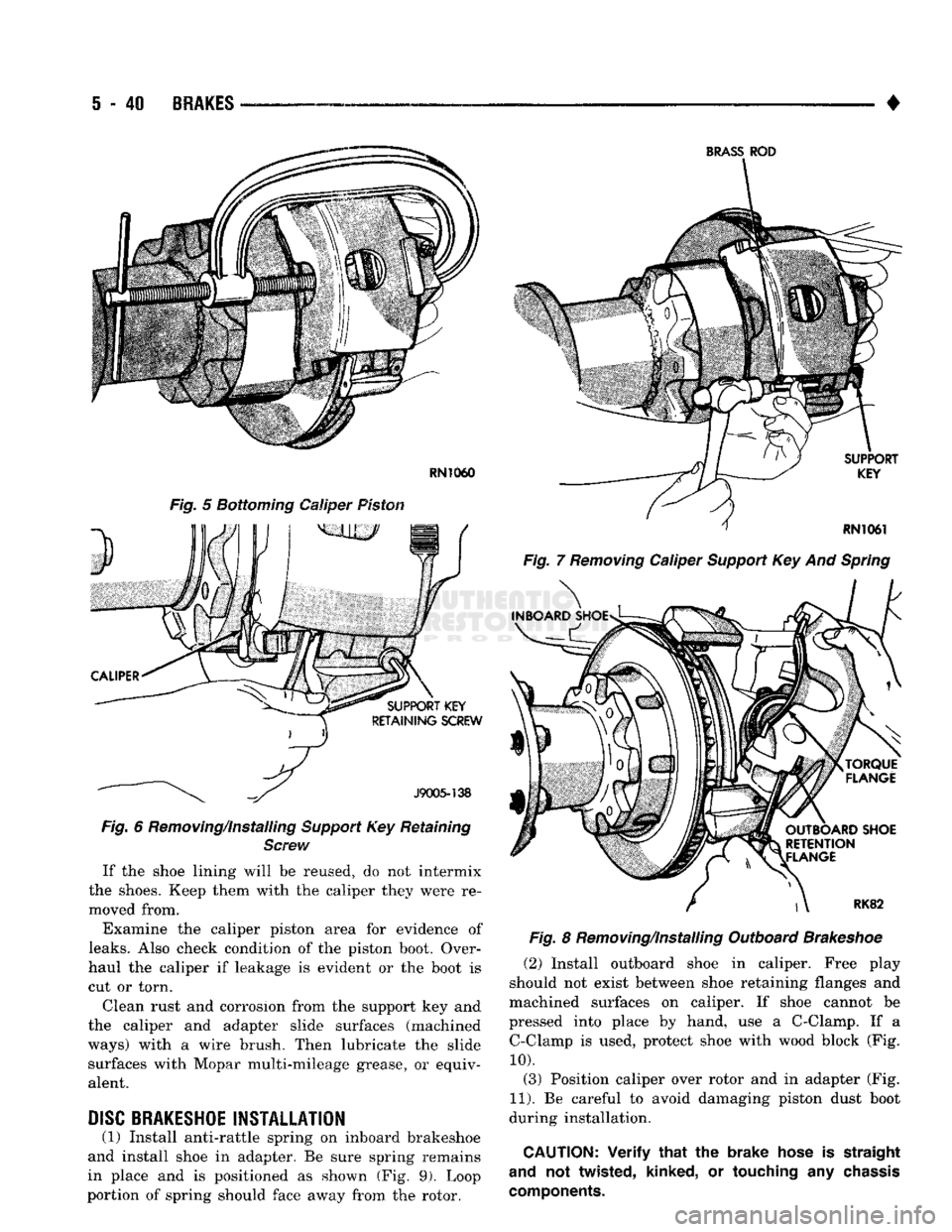

(1) Install anti-rattle spring on inboard brakeshoe

and install shoe in adapter. Be sure spring remains

in place and is positioned as shown (Fig. 9). Loop

portion of spring should face away from the rotor.

BRASS

ROD

Fig.

7

Removing

Caliper

Support

Key And

Spring

Fig.

8 Removing/Installing Outboard

Brakeshoe

(2) Install outboard shoe in caliper. Free play

should not exist between shoe retaining flanges and

machined surfaces on caliper. If shoe cannot be

pressed into place by hand, use a C-Clamp. If a C-Clamp is used, protect shoe with wood block (Fig.

10).

(3) Position caliper over rotor and in adapter (Fig.

11).

Be careful to avoid damaging piston dust boot

during installation.

CAUTION:

Verify

that

the brake

hose

is straight

and

not twisted, kinked, or

touching

any

chassis

components.

Page 229 of 1502

5

- 42

BRAKES

•

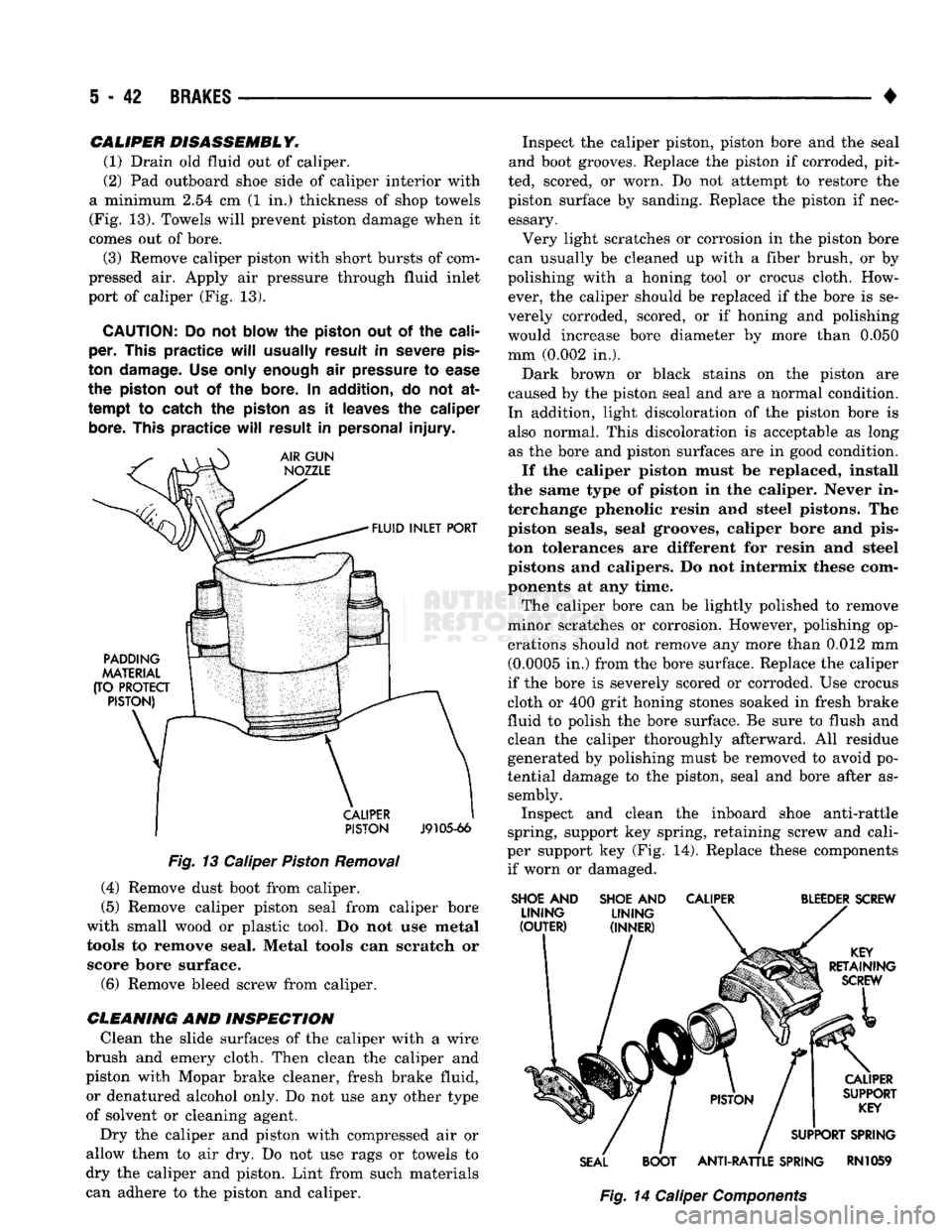

CALIPER

DISASSEMBLY.

(1) Drain old fluid out of caliper.

(2) Pad outboard shoe side of caliper interior with

a minimum 2.54 cm (1 in.) thickness of shop towels

(Fig. 13). Towels will prevent piston damage when it

comes out of bore.

(3) Remove caliper piston with short bursts of com

pressed air. Apply air pressure through fluid inlet

port of caliper (Fig. 13).

CAUTION:

Do not

blow

the

piston

out of the

cali

per.

This

practice

will

usually

result

in

severe

pis

ton

damage.

Use only

enough

air

pressure

to

ease

the

piston

out of the

bore.

In

addition,

do not at

tempt

to catch the

piston

as it

leaves

the

caliper

bore.

This

practice

will

result

in

personal

injury.

PISTON

J9105-66

Fig.

13 Caliper

Piston

Removal (4) Remove dust boot from caliper.

(5) Remove caliper piston seal from caliper bore

with small wood or plastic tool. Do not use metal tools to remove seal. Metal tools can scratch or score bore surface. (6) Remove bleed screw from caliper.

CLEANING

AND INSPECTION Clean the slide surfaces of the caliper with a wire

brush and emery cloth. Then clean the caliper and

piston with Mopar brake cleaner, fresh brake fluid, or denatured alcohol only. Do not use any other type

of solvent or cleaning agent.

Dry the caliper and piston with compressed air or

allow them to air dry. Do not use rags or towels to

dry the caliper and piston. Lint from such materials

can adhere to the piston and caliper. Inspect the caliper piston, piston bore and the seal

and boot grooves. Replace the piston if corroded, pit

ted, scored, or worn. Do not attempt to restore the

piston surface by sanding. Replace the piston if nec essary.

Very light scratches or corrosion in the piston bore

can usually be cleaned up with a fiber brush, or by

polishing with a honing tool or crocus cloth. How ever, the caliper should be replaced if the bore is se

verely corroded, scored, or if honing and polishing

would increase bore diameter by more than 0.050

mm (0.002 in.).

Dark brown or black stains on the piston are

caused by the piston seal and are a normal condition.

In addition, light discoloration of the piston bore is also normal. This discoloration is acceptable as long as the bore and piston surfaces are in good condition.

If the caliper piston must be replaced, install

the same type of piston in the caliper. Never in

terchange phenolic resin and steel pistons. The piston seals, seal grooves, caliper bore and pis

ton tolerances are different for resin and steel

pistons and calipers. Do not intermix these com ponents at any time.

The caliper bore can be lightly polished to remove

minor scratches or corrosion. However, polishing op

erations should not remove any more than 0.012 mm (0.0005 in.) from the bore surface. Replace the caliper

if the bore is severely scored or corroded. Use crocus

cloth or 400 grit honing stones soaked in fresh brake

fluid to polish the bore surface. Be sure to flush and

clean the caliper thoroughly afterward. All residue generated by polishing must be removed to avoid po

tential damage to the piston, seal and bore after as sembly. Inspect and clean the inboard shoe anti-rattle

spring, support key spring, retaining screw and cali

per support key (Fig. 14). Replace these components if worn or damaged.

SHOE

AND

SHOE

AND

CALIPER

BLEEDER

SCREW

SEAL

BOOT

ANTI-RATTLE

SPRING

RN1059

Fig.

14 Caliper

Components

Page 230 of 1502

•

BRAKES

5 - 43

CAMPER

ASSEMBLY

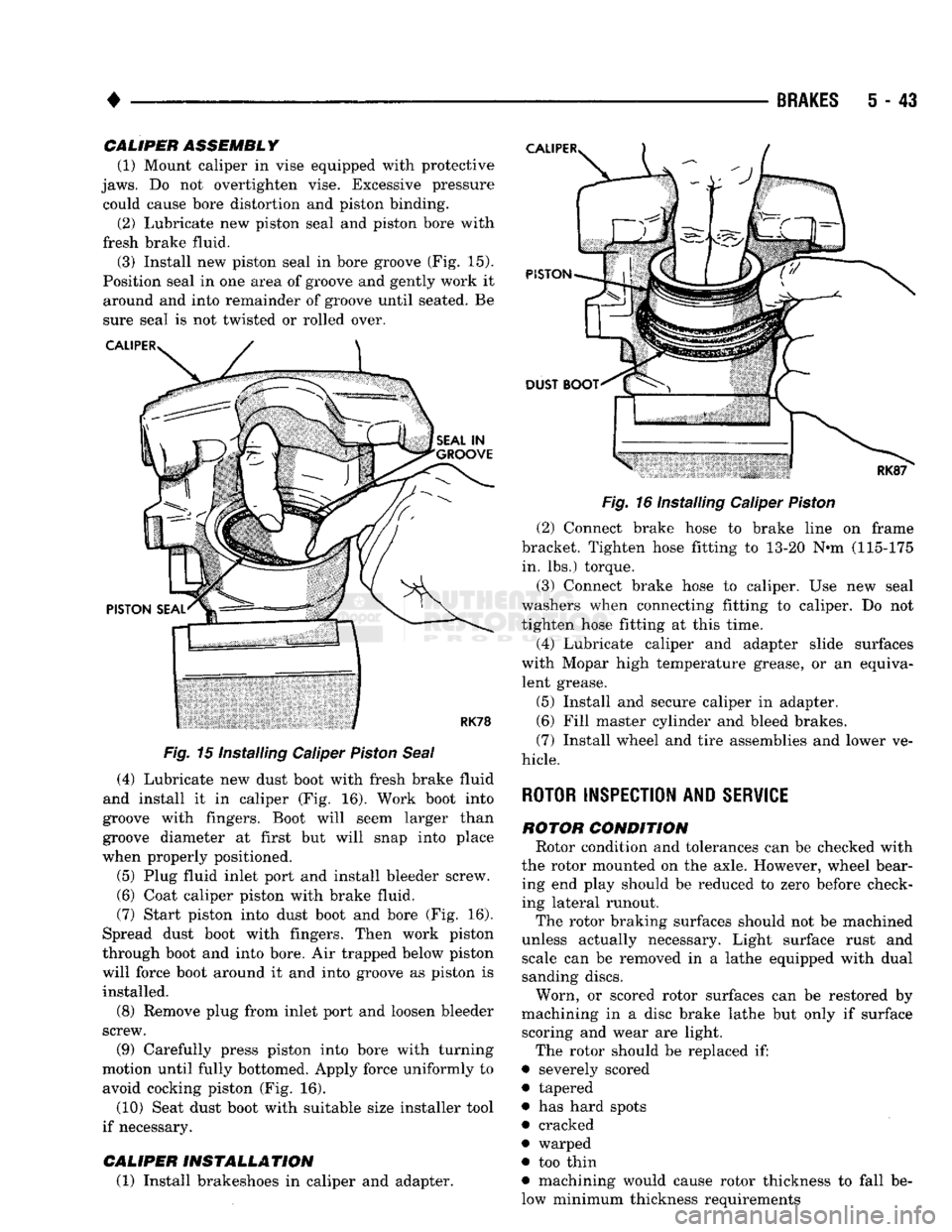

(1) Mount caliper in vise equipped with protective

jaws.

Do not overtighten vise. Excessive pressure could cause bore distortion and piston binding. (2) Lubricate new piston seal and piston bore with

fresh brake fluid. (3) Install new piston seal in bore groove (Fig. 15).

Position seal in one area of groove and gently work it around and into remainder of groove until seated. Be

sure seal is not twisted or rolled over.

Fig.

15 Installing Caliper

Piston

Seal

(4) Lubricate new dust boot with fresh brake fluid

and install it in caliper (Fig. 16). Work boot into

groove with fingers. Boot will seem larger than

groove diameter at first but will snap into place

when properly positioned.

(5) Plug fluid inlet port and install bleeder screw. (6) Coat caliper piston with brake fluid.

(7) Start piston into dust boot and bore (Fig. 16).

Spread dust boot with fingers. Then work piston

through boot and into bore. Air trapped below piston

will force boot around it and into groove as piston is installed.

(8) Remove plug from inlet port and loosen bleeder

screw.

(9) Carefully press piston into bore with turning

motion until fully bottomed. Apply force uniformly to avoid cocking piston (Fig. 16).

(10) Seat dust boot with suitable size installer tool

if necessary.

CALIPER

INSTALLATION

(1) Install brakeshoes in caliper and adapter.

Fig.

16 Installing Caliper

Piston

(2) Connect brake hose to brake line on frame

bracket. Tighten hose fitting to 13-20 N«m (115-175 in. lbs.) torque.

(3) Connect brake hose to caliper. Use new seal

washers when connecting fitting to caliper. Do not

tighten hose fitting at this time.

(4) Lubricate caliper and adapter slide surfaces

with Mopar high temperature grease, or an equiva lent grease.

(5) Install and secure caliper in adapter.

(6) Fill master cylinder and bleed brakes.

(7) Install wheel and tire assemblies and lower ve

hicle.

ROTOR INSPECTION AND

SERVICE

ROTOR

CONDITION

Rotor condition and tolerances can be checked with

the rotor mounted on the axle. However, wheel bear ing end play should be reduced to zero before check

ing lateral runout.

The rotor braking surfaces should not be machined

unless actually necessary. Light surface rust and scale can be removed in a lathe equipped with dual

sanding discs.

Worn, or scored rotor surfaces can be restored by

machining in a disc brake lathe but only if surface scoring and wear are light.

The rotor should be replaced if:

• severely scored

• tapered

• has hard spots

• cracked

• warped

• too thin

• machining would cause rotor thickness to fall be

low minimum thickness requirements

Page 236 of 1502

•

BRAKES

5 - 49 (2) Adjust brake shoes to drum with a brake

gauge. (3) Install and secure drum to wheel studs with

new retaining nuts/clips.

(4) Install rubber access plugs in support plate if

removed.

(5) Install wheel and tire.

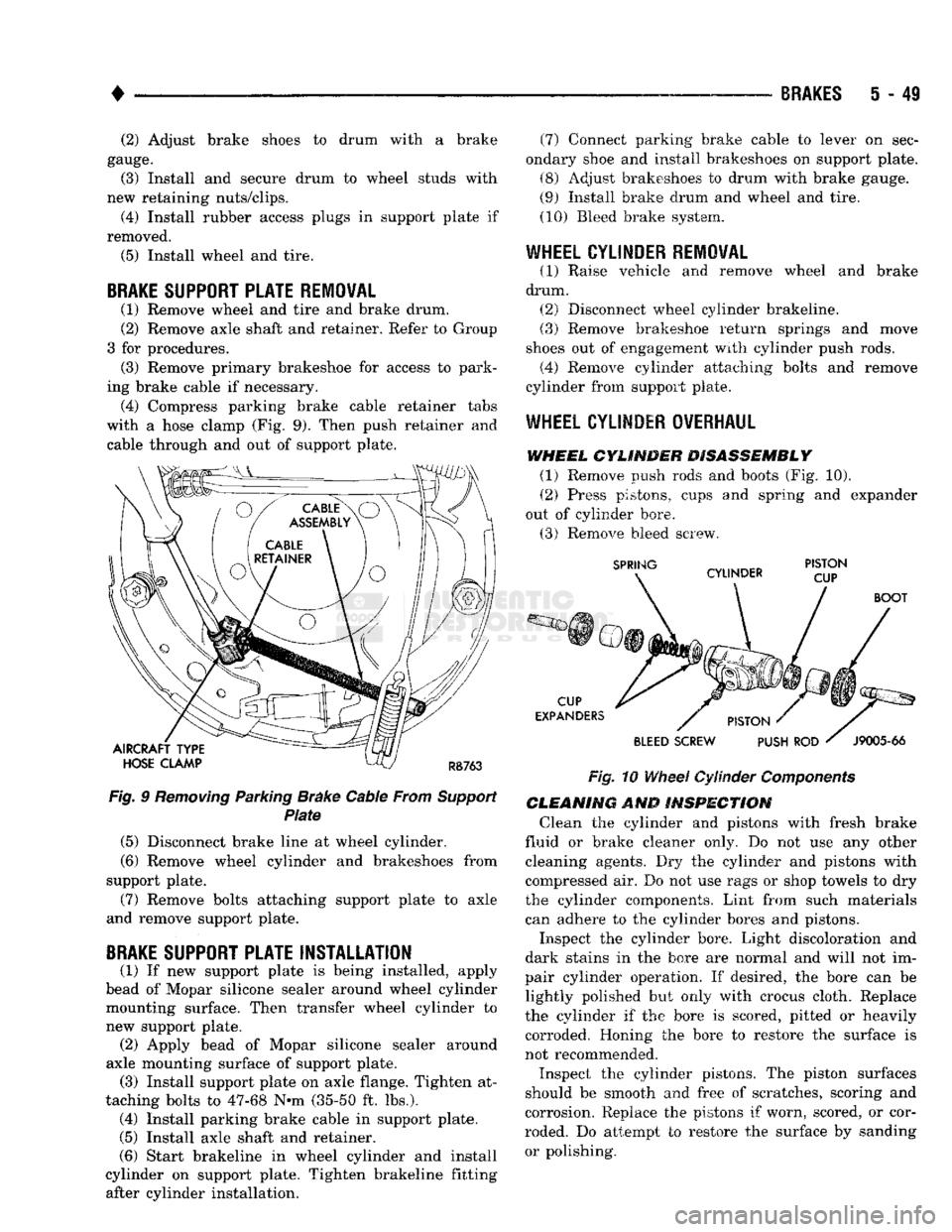

BRAKE

SUPPORT PLATE REMOVAL

(1) Remove wheel and tire and brake drum.

(2) Remove axle shaft and retainer. Refer to Group

3 for procedures. (3) Remove primary brakeshoe for access to park

ing brake cable if necessary. (4) Compress parking brake cable retainer tabs

with a hose clamp (Fig. 9). Then push retainer and cable through and out of support plate.

AIRCRAFT TYPE

HOSE

CLAMP

RB763

Fig.

9

Removing

Parking Brake Cable From

Support

Plate

(5) Disconnect brake line at wheel cylinder.

(6) Remove wheel cylinder and brakeshoes from

support plate.

(7) Remove bolts attaching support plate to axle

and remove support plate.

BRAKE

SUPPORT PLATE INSTALLATION

(1) If new support plate is being installed, apply

bead of Mopar silicone sealer around wheel cylinder mounting surface. Then transfer wheel cylinder to

new support plate. (2) Apply bead of Mopar silicone sealer around

axle mounting surface of support plate. (3) Install support plate on axle flange. Tighten at

taching bolts to 47-68 N-m (35-50 ft. lbs.). (4) Install parking brake cable in support plate.

(5) Install axle shaft and retainer.

(6) Start brakeline in wheel cylinder and install

cylinder on support plate. Tighten brakeline fitting after cylinder installation. (7) Connect parking brake cable to lever on sec

ondary shoe and install brakeshoes on support plate.

(8) Adjust brakeshoes to drum with brake gauge.

(9) Install brake drum and wheel and tire.

(10) Bleed brake system.

WHEEL CYLINDER REMOVAL

(1) Raise vehicle and remove wheel and brake

drum. (2) Disconnect wheel cylinder brakeline.

(3) Remove brakeshoe return springs and move

shoes out of engagement with cylinder push rods. (4) Remove cylinder attaching bolts and remove

cylinder from support plate.

WHEEL

CYLINDER OVERHAUL

WHEEL

CYLINDER DISASSEMBLY

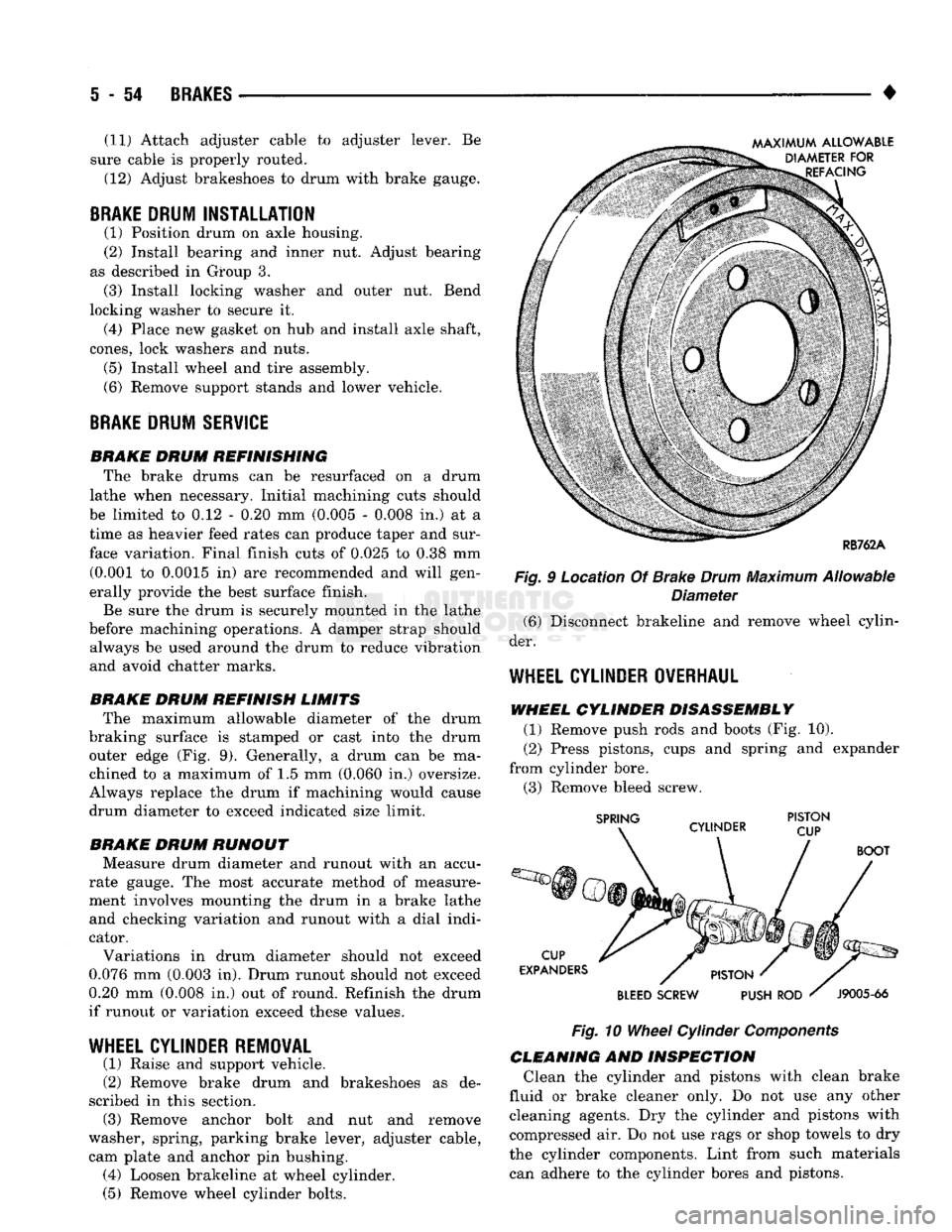

(1) Remove push rods and boots (Fig. 10).

(2) Press pistons, cups and spring and expander

out of cylinder bore.

(3) Remove bleed screw.

SPRING

CYLINDER PISTON

CUP

CUP

EXPANDERS

BOOT

PISTON

'

BLEED

SCREW PUSH

ROD '

J9005-66

Fig.

10

Wheel

Cylinder

Components

CLEANING

AND

INSPECTION

Clean the cylinder and pistons with fresh brake

fluid or brake cleaner only. Do not use any other cleaning agents. Dry the cylinder and pistons with

compressed air. Do not use rags or shop towels to dry

the cylinder components. Lint from such materials

can adhere to the cylinder bores and pistons.

Inspect the cylinder bore. Light discoloration and

dark stains in the bore are normal and will not im

pair cylinder operation. If desired, the bore can be lightly polished but only with crocus cloth. Replace

the cylinder if the bore is scored, pitted or heavily

corroded. Honing the bore to restore the surface is

not recommended.

Inspect the cylinder pistons. The piston surfaces

should be smooth and free of scratches, scoring and

corrosion. Replace the pistons if worn, scored, or cor

roded. Do attempt to restore the surface by sanding or polishing.

Page 237 of 1502

5

- 50

BRAKES

• Discard

the old

piston cups

and the

spring

and ex

pander. These parts

are not

reusable.

The

original

dust boots

may be

reused

but

only

if

they

are in

good condition.

ASSEMBLING

WHEEL

CYLINDER

(1) Lubricate wheel cylinder bore, pistons, piston

cups

and

spring

and

expander with clean brake fluid. (2) Install first piston

in

cylinder bore. Then

in

stall

cup in

bore

and

against piston.

Be

sure

lip of

piston

cup is

facing inward (toward spring

and

expander)

and

flat side

is

against piston.

(3) Install spring

and

expanders followed

by re

maining piston

cup and

piston.

(4) Install boots

on

each

end of

cylinder

and

insert

push rods

in

boots.

(5)

Install cylinder bleed screw.

WHEEL

CYLINDER INSTALLATION

(1) Apply bead

of

Mopar silicone sealer around cyl

inder mounting surface

of

support plate. (2) Connect brake line

to

cylinder. Mount cylinder

on support plate

and

install cylinder attaching bolts. (3) Install wheel brake components.

(4) Install brake drum

and

wheel

and

bleed

brakes.

DRUM

BRAKES—TWELVE INCH

INDEX

page

Brake Drum

Installation

54

Brake Drum Removal

52

Brake Drum Service

54

Brake

Shoe

Installation

53

Brakeshoe

Removal

52

Cleaning

and

Inspection

52

GENERAL

INFORMATION

Twelve inch rear drum brakes

are

used

on D and

W 250/350 models

(Fig. 1). All

applications

are

dual

shoe,

internal expanding units with

a

self adjusting

mechanism.

A

single wheel cylinder

is

used

to ex-

page

General

Information

50

Support

Plate

Installation

55

Support

Plate

Removal

55

Wheel

Cylinder

Installation

55

Wheel

Cylinder

Overhaul

...................

54

Wheel

Cylinder

Removal

. 54

pand

the

dual brakeshoes.

The

lower ends

of the

brake shoes

are

connected

by a

star wheel adjuster screw which

is

part

of the

self adjusting mechanism

(Fig.

1).

Page 241 of 1502

5

- 54

BRAKES

• (11) Attach adjuster cable to adjuster lever. Be

sure cable is properly routed.

(12) Adjust brakeshoes to drum with brake gauge.

BRAKE

DRUM INSTALLATION

(1) Position drum on axle housing.

(2) Install bearing and inner nut. Adjust bearing

as described in Group 3. (3) Install locking washer and outer nut. Bend

locking washer to secure it. (4) Place new gasket on hub and install axle shaft,

cones,

lock washers and nuts. (5) Install wheel and tire assembly.

(6) Remove support stands and lower vehicle.

BRAKE

DRUM

SERVICE

BRAKE DRUM REFINISHING The brake drums can be resurfaced on a drum

lathe when necessary. Initial machining cuts should

be limited to 0.12 - 0.20 mm (0.005 - 0.008 in.) at a time as heavier feed rates can produce taper and sur

face variation. Final finish cuts of 0.025 to 0.38 mm (0.001 to 0.0015 in) are recommended and will gen

erally provide the best surface finish.

Be sure the drum is securely mounted in the lathe

before machining operations. A damper strap should always be used around the drum to reduce vibration

and avoid chatter marks.

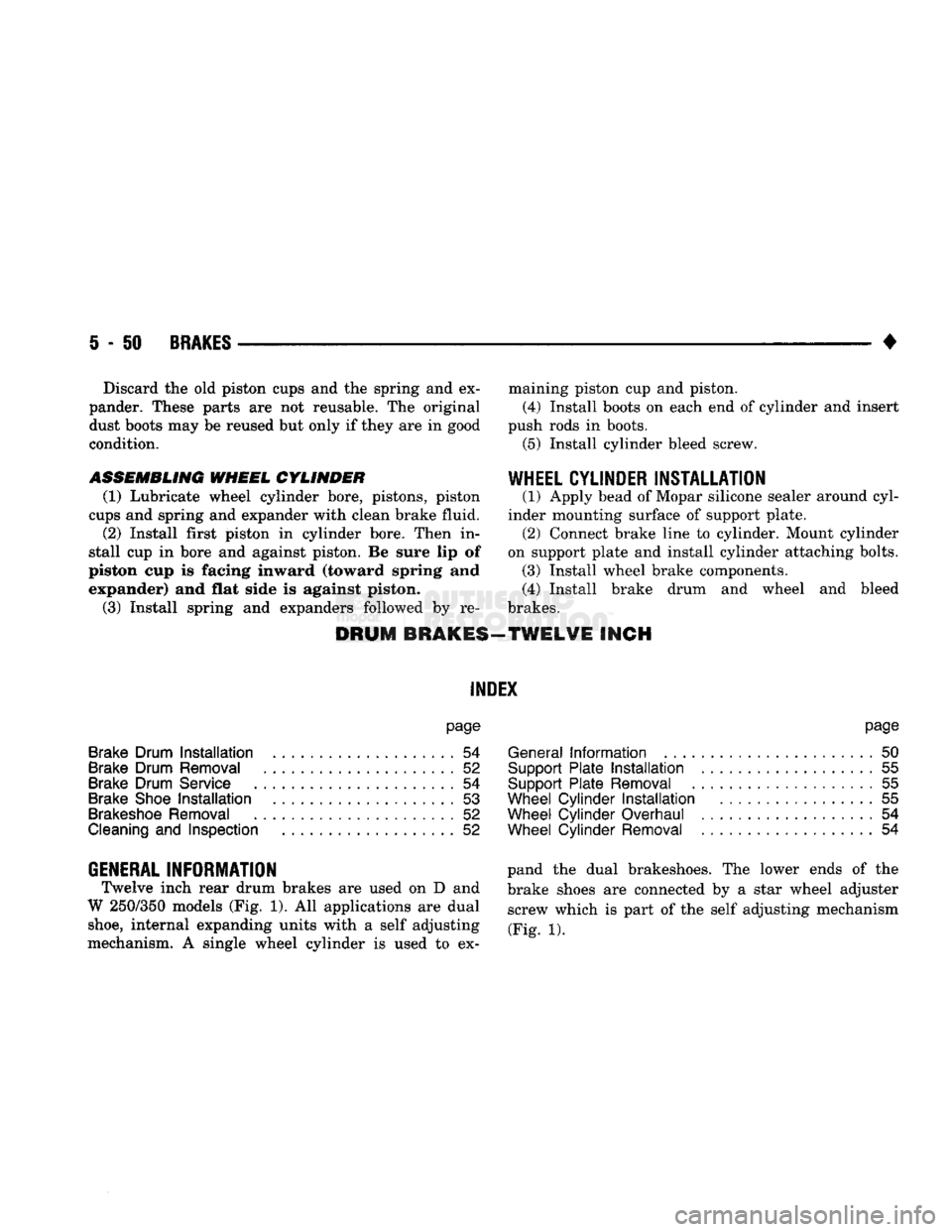

BRAKE DRUM REFINISH LIMITS The maximum allowable diameter of the drum

braking surface is stamped or cast into the drum outer edge (Fig. 9). Generally, a drum can be ma

chined to a maximum of 1.5 mm (0.060 in.) oversize.

Always replace the drum if machining would cause

drum diameter to exceed indicated size limit.

BRAKE DRUM RUNOUT Measure drum diameter and runout with an accu

rate gauge. The most accurate method of measure

ment involves mounting the drum in a brake lathe and checking variation and runout with a dial indi

cator.

Variations in drum diameter should not exceed

0.076 mm (0.003 in). Drum runout should not exceed

0.20 mm (0.008 in.) out of round. Refinish the drum

if runout or variation exceed these values.

WHEEL

CYLINDER REMOVAL

(1) Raise and support vehicle.

(2) Remove brake drum and brakeshoes as de

scribed in this section. (3) Remove anchor bolt and nut and remove

washer, spring, parking brake lever, adjuster cable, cam plate and anchor pin bushing. (4) Loosen brakeline at wheel cylinder.

(5) Remove wheel cylinder bolts. Fig. 9 Location Of Brake

Drum

Maximum Allowable

Diameter (6) Disconnect brakeline and remove wheel cylin

der.

WHEEL

CYLINDER OVERHAUL

WHEEL CYLINDER DISASSEMBLY (1) Remove push rods and boots (Fig. 10).

(2) Press pistons, cups and spring and expander

from cylinder bore. (3) Remove bleed screw.

Fig.

10

Wheel

Cylinder

Components

CLEANING AND INSPECTION Clean the cylinder and pistons with clean brake

fluid or brake cleaner only. Do not use any other cleaning agents. Dry the cylinder and pistons with

compressed air. Do not use rags or shop towels to dry

the cylinder components. Lint from such materials can adhere to the cylinder bores and pistons.

Page 242 of 1502

•

BRAKES

5 - 55 Inspect the cylinder bore. Light discoloration and

dark stains in the bore are normal and will not im

pair cylinder operation. If desired, the bore can be lightly polished but only with crocus cloth. Replace

the cylinder if the bore is scored, pitted or heavily corroded. Honing the bore to restore the surface is not recommended.

Inspect the cylinder pistons. The piston surfaces

should be smooth and free of scratches, scoring and

corrosion. Replace the pistons if worn, scored, or cor

roded. Do attempt to restore the surface by sanding or polishing.

Discard the old piston cups and the spring and ex

pander. These parts are not reusable. The original

dust boots may be reused but only if they are in good condition.

ASSEMBLING

WHEEL CYLINDER

(1) Lubricate wheel cylinder bore, pistons, piston

cups and spring and expander with ^clean brake fluid. (2) Install first piston in cylinder bore. Then in

stall cup in bore and against piston. Be sure lip of

piston cup is facing inward (toward spring and

expander) and flat side is against piston.

(3) Install spring and expanders followed by re

maining piston cup and piston.

(4) Install boots on each end of cylinder and insert

push rods in boots.

(5)

Install cylinder bleed screw.

WHEEL

CYLINDER INSTALLATION

(1) Start brakeline into cylinder.

(2) Position cylinder on support plate and install

cylinder attaching bolts. (3) Tighten brakeline fitting and cylinder attach

ing bolts. (4) Install anchor pin bushing, cam plate, adjuster

cable, parking brake lever, spring washer and anchor

bolt and nut.

(5) Install brakeshoes and brake drum as described

in this section. (6) Install axle shaft.

(7) Install wheel and tire.

(8) Remove supports and lower vehicle.

SUPPORT

PLATE REMOVAL

(1) Raise and support vehicle.

(2) Remove wheel and tire.

(3) Remove axle shaft.

(4) Remove brake drum, brake shoes and wheel

cylinder as described in this section. (5) Remove bolts/nuts attaching support plate to

axle and remove support plate.

SUPPORT PLATE INSTALLATION

(1) Transfer wheel cylinder and parking brake le

ver components to replacement support plate. (2) Position support plate on axle and install at

taching bolts/nuts. (3) Lubricate shoe contact surfaces of support plate

with Mopar multi-purpose, or high temperature bear ing grease. (4) Install brakeshoes. Adjust shoes to drum with

brake gauge. (5) Install brake drum.

(6) Install axle shaft.

(7) Install wheel and tire.

(8) Remove supports and lower vehicle.

Page 266 of 1502

•

CLUTCH

6 - 13

APPLY

LIGHT

COAT

OF

HI-TEMP

GREASE

TO

THESE

SURFACES

BEFORE

INSTALLATION

J9106-15

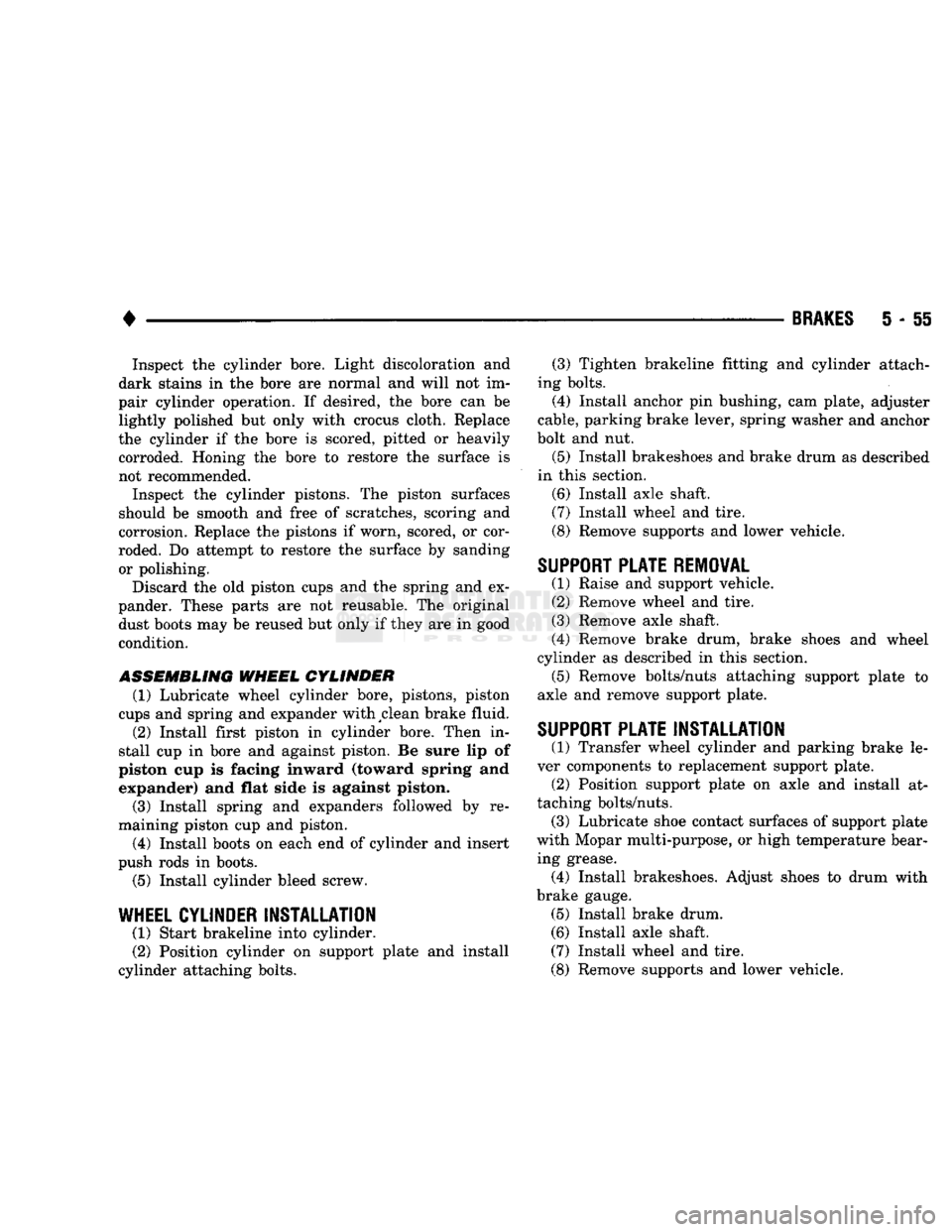

Fig.

7 Input Shaft Lubrication

Points

(Typical)

ENGINE BLOCK

CLUTCH

DISC AND COVER

J9006-32

Fig.

8

Clutch

Housing

Installation—Gas

Engine

(4)

Verify that clutch housing alignment dowels

are in good condition and properly seated. (5) Transfer slave cylinder, release fork and boot,

fork pivot stud and wire/hose brackets to new hous ing.

CLUTCH HOUSING INSTALLATION

(1) Lubricate release fork and pivot contact sur

faces with Mopar High Temperature wheel bearing grease before installation.

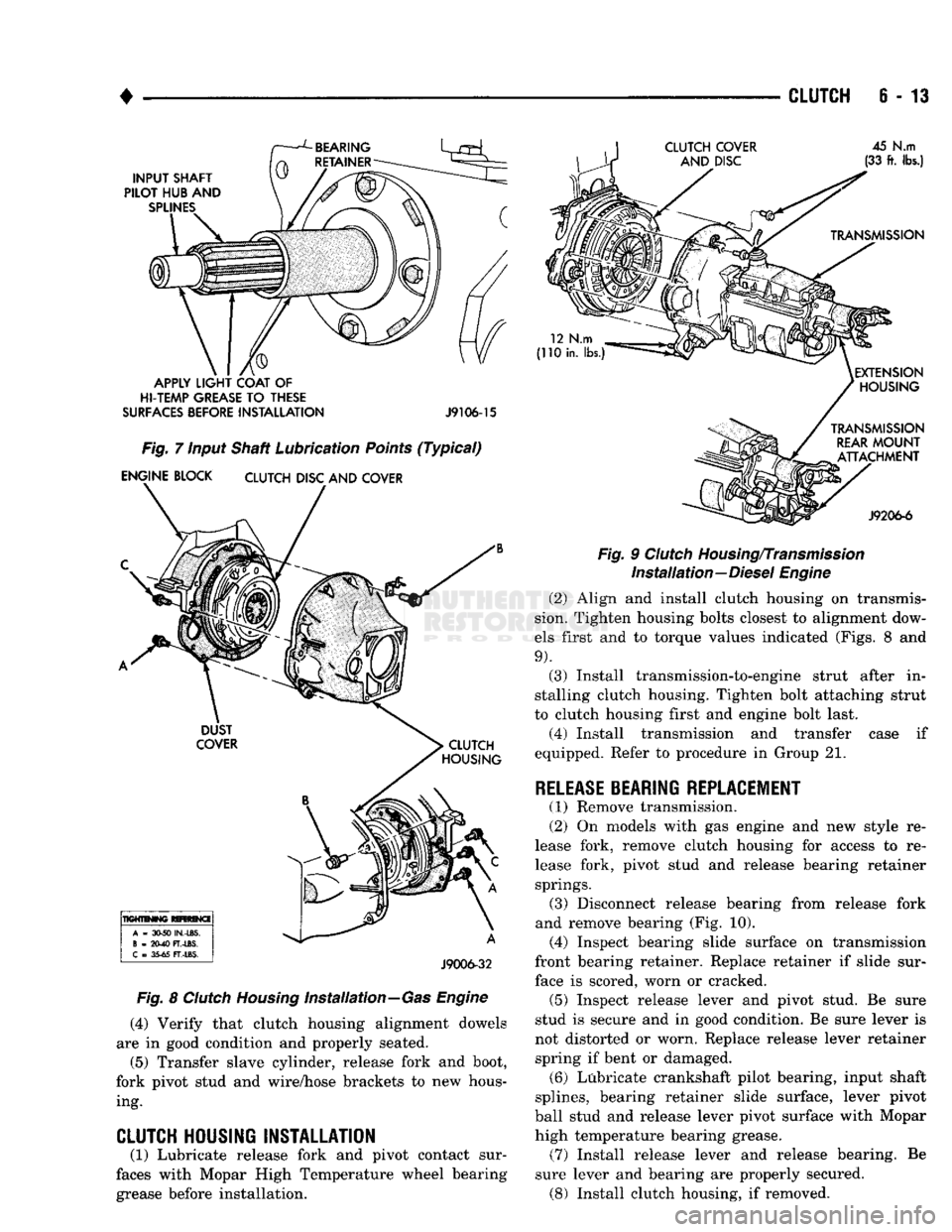

Fig.

9

Clutch

Housing/Transmission

Installation—Diesel

Engine

(2) Align and install clutch housing on transmis

sion. Tighten housing bolts closest to alignment dow

els first and to torque values indicated (Figs. 8 and

9).

(3) Install transmission-to-engine strut after in

stalling clutch housing. Tighten bolt attaching strut

to clutch housing first and engine bolt last.

(4) Install transmission and transfer case if

equipped. Refer to procedure in Group 21.

RELEASE

BEARING REPLACEMENT

(1) Remove transmission.

(2) On models with gas engine and new style re

lease fork, remove clutch housing for access to re

lease fork, pivot stud and release bearing retainer springs. (3) Disconnect release bearing from release fork

and remove bearing (Fig. 10). (4) Inspect bearing slide surface on transmission

front bearing retainer. Replace retainer if slide sur face is scored, worn or cracked. (5) Inspect release lever and pivot stud. Be sure

stud is secure and in good condition. Be sure lever is

not distorted or worn. Replace release lever retainer spring if bent or damaged. (6) Lubricate crankshaft pilot bearing, input shaft

splines, bearing retainer slide surface, lever pivot

ball stud and release lever pivot surface with Mopar

high temperature bearing grease. (7) Install release lever and release bearing. Be

sure lever and bearing are properly secured. (8) Install clutch housing, if removed.

Page 346 of 1502

•

Fig.

3

Remove

or Install

Starter

Motor

STARTER

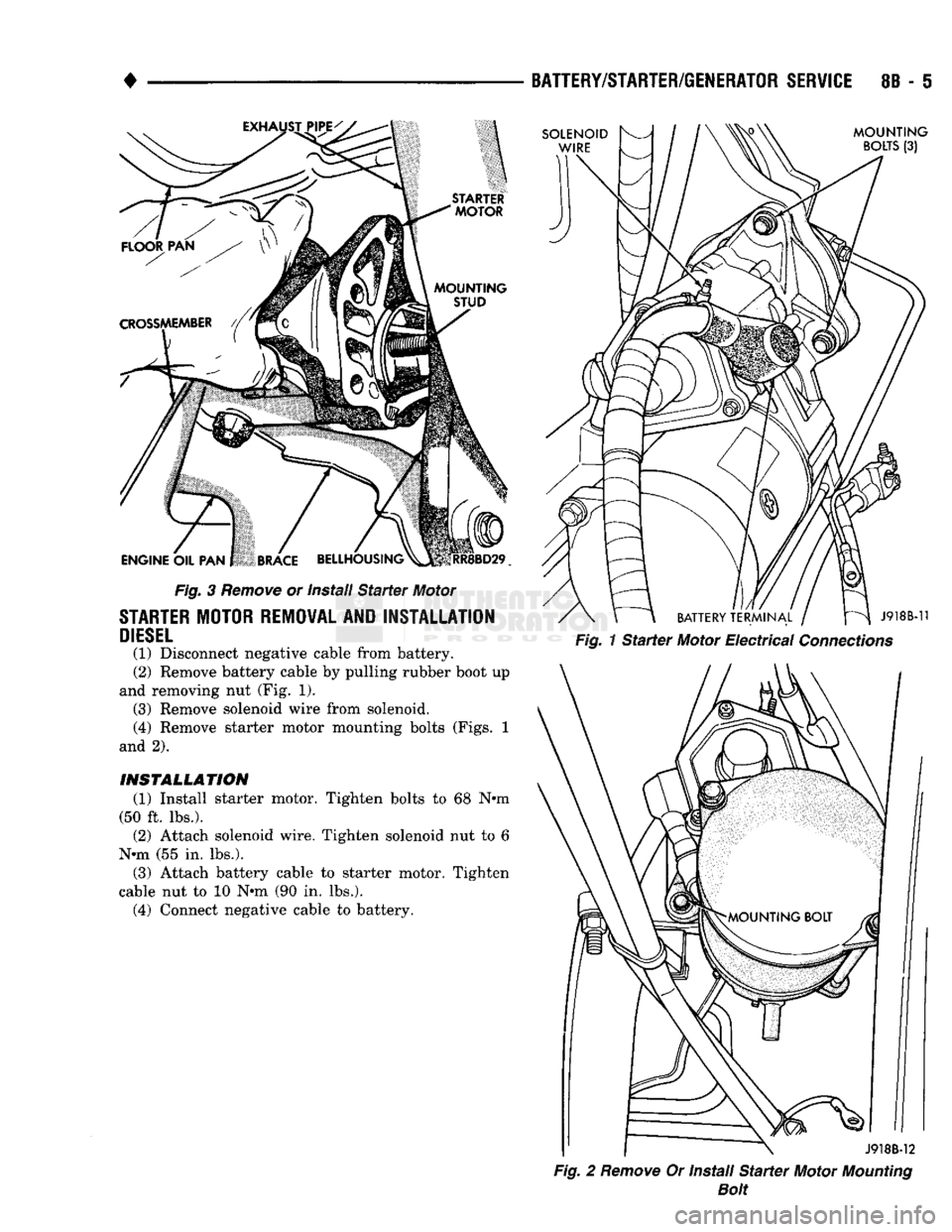

MOTOR REMOVAL AND INSTALLATION

DIESEL

(1) Disconnect negative cable from battery.

(2) Remove battery cable by pulling rubber boot up

and removing nut (Fig. 1). (3) Remove solenoid wire from solenoid.

(4) Remove starter motor mounting bolts (Figs. 1

and 2).

INSTALLATION

(1) Install starter motor. Tighten bolts to 68 N»m

(50 ft. lbs.). (2) Attach solenoid wire. Tighten solenoid nut to 6

N»m (55 in. lbs.). (3) Attach battery cable to starter motor. Tighten

cable nut to 10 N*m (90 in. lbs.). (4) Connect negative cable to battery.

BATTERY/STARTER/GENERATOR SERVICE

8B - 5

Fig.

2

Remove

Or Install

Starter

Motor

Mounting

Bolt

Page 361 of 1502

8D

- 10

IGNITION

SYSTEMS

• Arcing at the tower will carbonize the cable boot,

which if it is connected to a new ignition coil, will cause the coil to fail. If the secondary coil cable shows any signs of dam

age,

it should be replaced with a new cable and new

terminal. Carbon tracking on the old cable can cause

arcing and the failure of a new ignition coil.

ENGINE

COOLANT

TEMPERATURE

SENSOR

TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB II diagnostic scan tool.

Also refer to the appropriate Powertrain Diagnostics

Procedures manual. To test the sensor only, refer to

the following: The sensor is located in a water passage of the in

take manifold next to the thermostat housing (Fig.

8).

(1) Disconnect wire harness connector from sensor

(Fig. 8). On engines with air conditioning, do not pull

directly on wiring harness. Fabricate an L-shaped

hook tool from a coat hanger (approximately eight inches long). Place the hook part of tool under the

connector for removal. The connector is snapped onto

the sensor. It is not equipped with a lock type tab.

COOLANT

TEMPERATURE

SENSOR

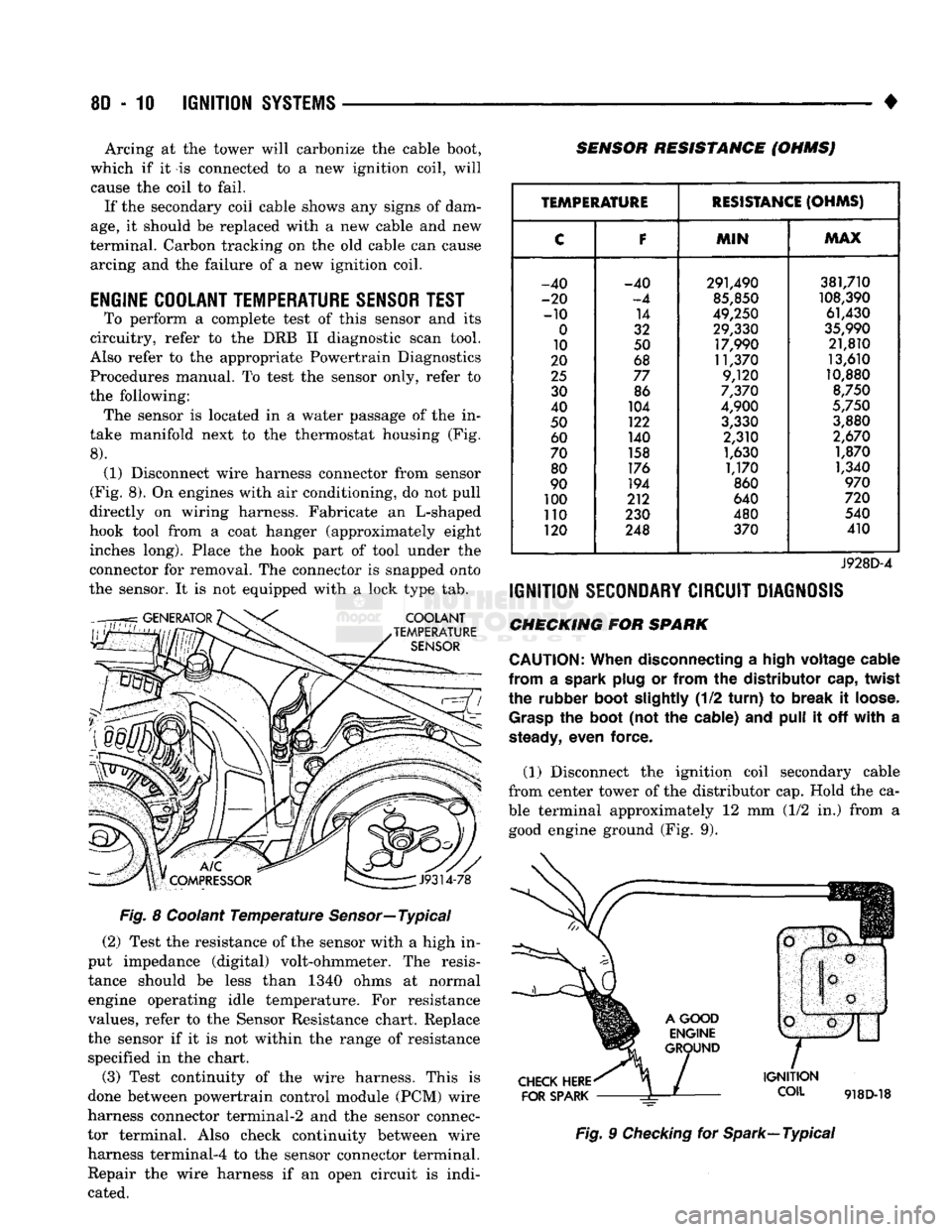

SENSOR RESISTANCE (OHMSJ

V

J9314-78

Fig. 8 Coolant Temperature Sensor—Typical (2) Test the resistance of the sensor with a high in

put impedance (digital) volt-ohmmeter. The resis tance should be less than 1340 ohms at normal

engine operating idle temperature. For resistance

values, refer to the Sensor Resistance chart. Replace

the sensor if it is not within the range of resistance specified in the chart.

(3) Test continuity of the wire harness. This is

done between powertrain control module (PCM) wire

harness connector terminal-2 and the sensor connec

tor terminal. Also check continuity between wire harness terminal-4 to the sensor connector terminal. Repair the wire harness if an open circuit is indi

cated.

TEMPERATURE

RESISTANCE

(OHMS)

C

F

MIN

MAX

-40 -40 291,490 381,710

-20

-4

85,850

108,390

-10 14

49,250 61,430

0

32 29,330

35,990

10 50 17,990 21,810

20 68 11,370 13,610

25

77 9,120 10,880

30 86

7,370

8,750

40 104

4,900

5,750

50 122

3,330 3,880

60 140 2,310

2,670

70 158

1,630 1,870

80 176

1,170 1,340

90 194

860

970

100 212 640

720

110 230 480 540

120 248 370 410

J928D-4

IGNITION

SECONDARY

CIRCUIT

DIAGNOSIS

CHECKING FOR SPARK

CAUTION:

When

disconnecting a

high

voltage

cable

from

a spark

plug

or

from

the

distributor

cap,

twist

the rubber

boot

slightly

(1/2

turn)

to

break

it

loose.

Grasp

the

boot

(not the cable) and

pull

it off

with

a

steady,

even force.

(1) Disconnect the ignition coil secondary cable

from center tower of the distributor cap. Hold the ca

ble terminal approximately 12 mm (1/2 in.) from a good engine ground (Fig. 9).

CHECK

HERE

FOR

SPARK

IGNITION

COIL

918D-18

Fig. 9 Checking for Spark—Typical