washer fluid DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 21 of 1502

0 - 2

LUBRICATION

AND

MAINTENANCE

• Commercial service

When a vehicle is continuously subjected to severe

driving conditions, lubricate:

• Body components

• All the driveline coupling joints

• Steering linkage More often than normal driving conditions

DUSTY

AREAS

With this type of severe driving condition, special

care should be given to the:

• Engine air cleaner filter

• PCV filter

• Crankcase ventilation system

• Brake booster control valve air filter. Verify that the filters and the associated compo

nents are clean. Also verify that they are functioning

effectively. This will minimize the amount of abra sive particles that enter the engine.

OFF-ROAD

(4WD)

OPERATION

After off-road (4WD) operation, inspect the under

side of the vehicle. Inspect the:

• Tires

• Body structure

• Steering components

• Suspension components • Exhaust system

• Threaded fasteners

HARSH

SURFACE ENVIRONMENTS

After extended operation in harsh environments,

the brake drums, brake linings, and rear wheel bear ings should be inspected and cleaned. This will pre

vent wear and erratic brake action.

ROUTINE MAINTENANCE

The following routine maintenance is recommended

on a monthly basis: TIRES—Inspect the tires for unusual wear/damage.

Determine if the inflation pressure is adequate for

the vehicle load. BATTERY—Inspect and clean the terminals.

Tighten the terminals if necessary. FLUIDS—Determine if the component fluid levels

are acceptable. Add fluid, if necessary. LIGHTS/ELECTRICAL—Test all the electrical sys

tems in the vehicle for proper operation. It is also recommended that the engine oil and the

washer fluid level be determined at each fuel fill-up.

VEHICLE

NOISE CONTROL

Vehicles with a GVWR of 4 535 kg (10,000 lbs), or

more, are required to comply with Federal Exterior Noise Regulations (Fig. 2).

VEHICLE

NOISE

EMISSION

CONTROL INFORMATION

DATE

OF

VEHICLE

MANUFACTURE

THIS

VEHICLE CONFORMS

TO

U.S. EPA REGULATIONS FOR NOISE EMISSION

APPLICABLE

TO

MEDIUM

AND HEAVY

DUTY

TRUCKS. THE

FOLLOWING

ACTS OR THE CAUSING THEREOF BY ANY PERSON ARE PROHIBITED BY THE NOISE CONTROL ACT

OF 1972. (A) THE

REMOVAL

OR

RENDERING

INOPERATIVE, OTHER

THAN

FOR

PURPOSES

OF

MAINTENANCE,

REPAIR.

OR REPLACEMENT, OF ANY NOISE CONTROL DEVICE OR ELEMENT OF

DESIGN

(LISTED

IN

THE

OWNERS

MANUAL)

INCORPORATED

INTO

THIS

VEHICLE

IN COMPLIANCE

WITH

THE NOISE CONTROL

ACT:

(B) THE

USE

OF

THIS

VEHICLE

AFTER SUCH DEVICE

OR

ELEMENT

OF

DESIGN HAS BEEN REMOVED

OR

RENDERED

INOPERATIVE.

PU626D

Fig.

2 Vehicle

Noise

Emission

Control Information

Label

UNAUTHORIZED

DEFEAT

OF

NOISE

CONTROL COMPONENTS

Federal law prohibits removal, altering or other

wise defeating any noise control component. This in

cludes before or after the vehicle is in use. Federal

law also prohibits the use of a vehicle after a noise

control component is defeated.

REQUIRED MAINTENANCE/SERVICE

FOR

NOISE

CONTROL

The following maintenance is required after each

6-month or 9 600 km (6,000 miles) interval. This will

ensure that the vehicle noise control components are

operating properly.

EXHAUST SYSTEM

Inspect exhaust system for exhaust leaks and dam

aged components. The exhaust hangers, clamps and

U-bolts should be attached and in good condition.

Burned or ruptured mufflers, damaged exhaust pipes should be replaced. Refer to Group 11—Exhaust Sys

tem/Intake Manifold for service information.

AIR

FILTER

HOUSING/CANISTER

Inspect the air filter assembly for proper fit. Verify

the cover is securely attached to the housing/canis

ter. Inspect all the air filter housing hoses for con nections. The gasket between the air filter housing and throttle body must be in good condition. The air

filter element should be clean and serviced according

to the maintenance schedule.

FUEL

REQUIREMENTS

GASOLINE

ENGINES

All engines require the use of unleaded gasoline to

reduce the effects of lead to the environment. Also unleaded fuel is necessary to prevent damage to the

catalytic converter/02 sensor. The fuel must have a

minimum octane rating of 87 based on the (R + M)/2

calculation method.

Page 41 of 1502

0

- 22

LUBRICATION

AND

MAINTENANCE

DRIVETRAIN

INDEX

page

Axles

25

Clutch

and

Brake Pedal

Bushings

............ 22

Clutch Master Cylinder

22

Drive Shafts

26

page

Front Axle U-Joint

and

Pivot Bearings

......... 26

Transfer

Case

(4WD

Vehicles)

. . ........ 24

Transmissions

. 22

CLUTCH

AND

BRAKE PEDAL

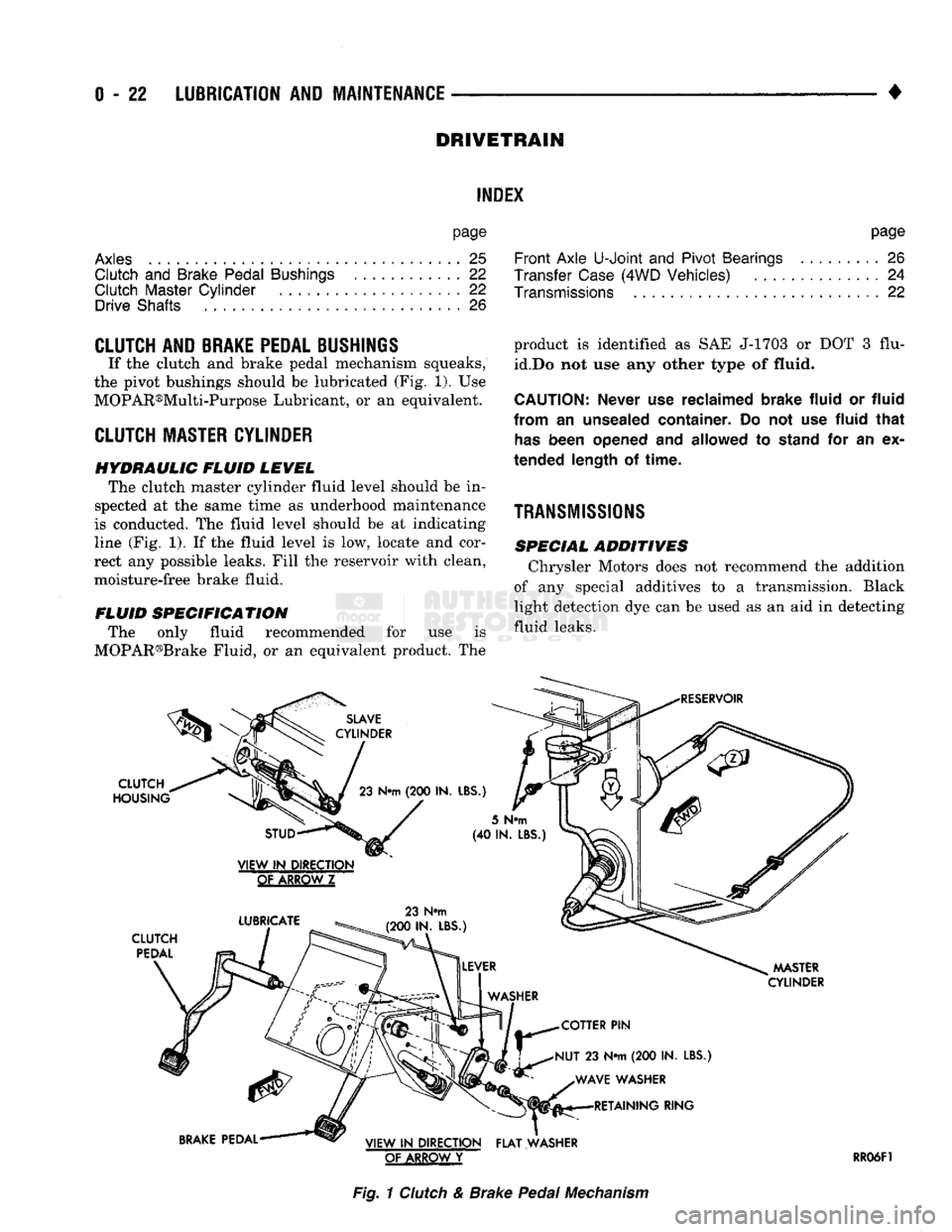

If the clutch and brake pedal mechanism squeaks,

the pivot bushings should be lubricated (Fig. 1). Use

MOPAR®Multi-Purpose Lubricant, or an equivalent.

CLUTCH

MASTER CYLINDER

HYDRAULIC FLUID LEVEL The clutch master cylinder fluid level should be in

spected at the same time as underhood maintenance

is conducted. The fluid level should be at indicating

line (Fig. 1). If the fluid level is low, locate and cor

rect any possible leaks. Fill the reservoir with clean,

moisture-free brake fluid.

FLUID SPECIFICATION The only fluid recommended for use is

MOPAR®Brake Fluid, or an equivalent product. The

SLAVE

CYLINDER

CLUTCH

HOUSING

23

N«m

(200 IN.

LBS.)

product is identified as SAE J-1703 or DOT 3 flu

id.Do not use any other type of

fluid.

CAUTION:

Never

use

reclaimed brake fluid

or

fluid

from

an

unsealed container.

Do not use

fluid that

has

been opened

and

allowed

to

stand

for an ex

tended length

of

time.

TRANSMISSIONS

SPECIAL ADDITIVES Chrysler Motors does not recommend the addition

of any special additives to a transmission. Black

light detection dye can be used as an aid in detecting

fluid leaks.

RESERVOIR

STUD

VIEW

IN

DIRECTION

GtAKBQWZ

LUBRICATE

CLUTCH

PEDAL

23 N#m

(200 IN. LBS.)

5

N«m

(40 IN.

LBS

MASTER

CYLINDER

COTTER

PIN

NUT

23 N*m (200 IN.

LBS.) WAVE WASHER RETAINING RING

BRAKE

PEDAL VIEW

IN

DIRECTION FLAT WASHER

OF ARROW

Y

RR06F1

Fig.

1

Clutch

& Brake

Pedal

Mechanism

Page 48 of 1502

•

LUBRICATION

AND

MAINTENANCE

0 - 29

POWER STEERING SYSTEM

SERVICE SCHEDULE

FLUID

LEWEL

WARNING.

THE

POWER

STEERING

FLUID LEVEL

SHOULD

ALWAYS

BE

CHECKED

WITH THE EN

GINE

OFF TO

PREVENT

PERSONAL

INJURY.

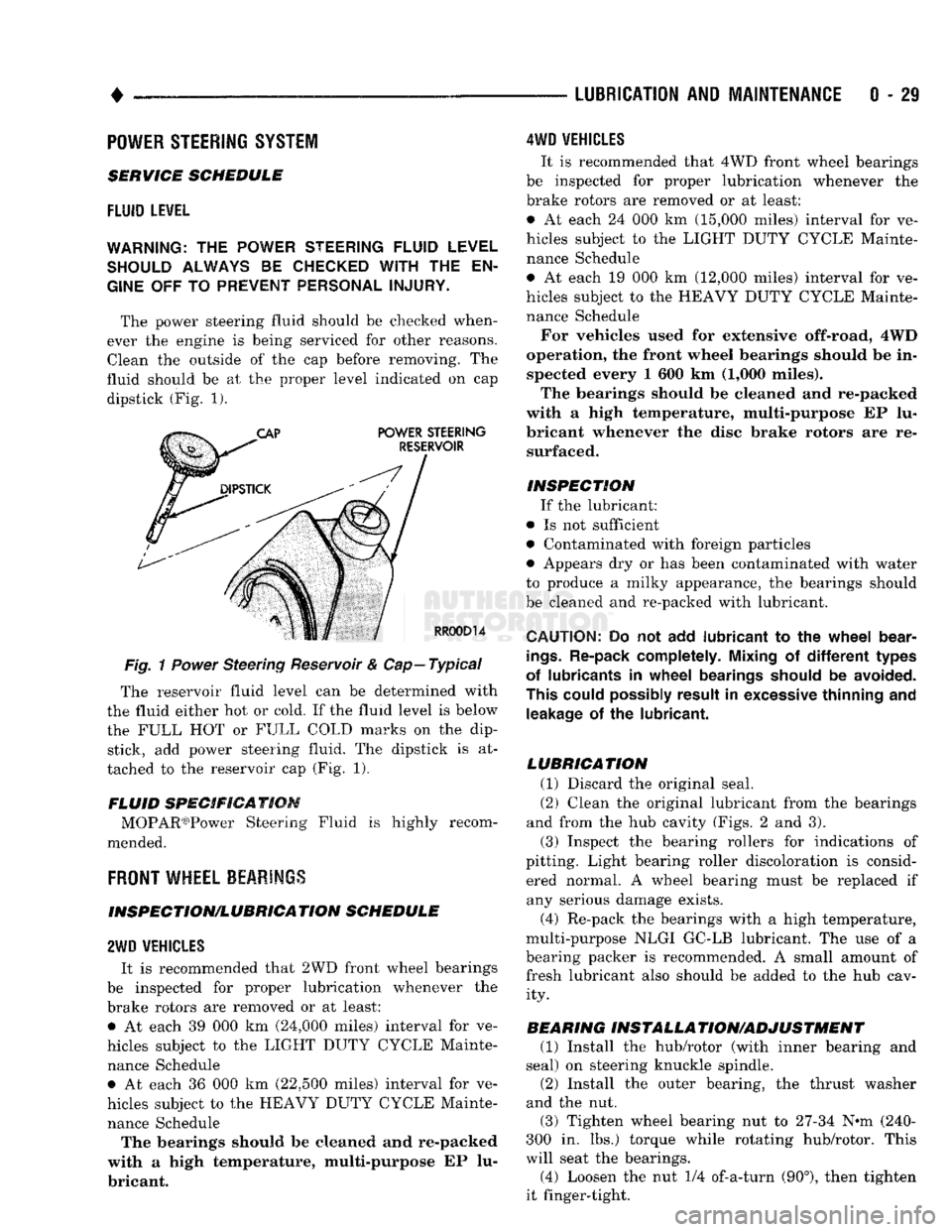

The power steering fluid should be checked when

ever the engine is being serviced for other reasons. Clean the outside of the cap before removing. The

fluid should be at the proper level indicated on cap dipstick (Fig. 1).

Fig.

1

Power

Steering Reservoir & Cap—Typical

The reservoir fluid level can be determined with

the fluid either hot or cold. If the fluid level is below

the FULL HOT or FULL COLD marks on the dip stick, add power steering fluid. The dipstick is at

tached to the reservoir cap (Fig. 1).

FLUID SPECIFICATION MOPAR03)Power Steering Fluid is highly recom

mended.

FRONT

WHEEL BEARINGS

INSPECTION/LUBRICATION SCHEDULE

2WD

VEHICLES

It is recommended that 2WD front wheel bearings

be inspected for proper lubrication whenever the

brake rotors are removed or at least: • At each 39 000 km (24,000 miles) interval for ve

hicles subject to the LIGHT DUTY CYCLE Mainte nance Schedule • At each 36 000 km (22,500 miles) interval for ve

hicles subject to the HEAVY DUTY CYCLE Mainte nance Schedule The bearings should be cleaned and re-packed

with a high temperature, multi-purpose EP lu

bricant.

4WD

VEHICLES

It is recommended that 4WD front wheel bearings

be inspected for proper lubrication whenever the

brake rotors are removed or at least:

• At each 24 000 km (15,000 miles) interval for ve

hicles subject to the LIGHT DUTY CYCLE Mainte nance Schedule

• At each 19 000 km (12,000 miles) interval for ve

hicles subject to the HEAVY DUTY CYCLE Mainte nance Schedule

For vehicles used for extensive off-road, 4WD

operation, the front wheel bearings should be in spected every 1 600 km (1,000 miles).

The bearings should be cleaned and re-packed

with a high temperature, multi-purpose EP lu

bricant whenever the disc brake rotors are re surfaced.

INSPECTION If the lubricant:

• Is not sufficient

• Contaminated with foreign particles

• Appears dry or has been contaminated with water

to produce a milky appearance, the bearings should

be cleaned and re-packed with lubricant.

CAUTION:

Do not add

lubricant

to the

wheel

bear

ings.

Re-pack completely. Mixing

of

different

types

of lubricants

in

wheel

bearings should

be

avoided.

This could possibly result

in

excessive thinning

and

leakage

of the

lubricant.

LUBRICATION (1) Discard the original seal.

(2) Clean the original lubricant from the bearings

and from the hub cavity (Figs. 2 and 3).

(3) Inspect the bearing rollers for indications of

pitting. Light bearing roller discoloration is consid ered normal. A wheel bearing must be replaced if any serious damage exists.

(4) Re-pack the bearings with a high temperature,

multi-purpose NLGI GC-LB lubricant. The use of a

bearing packer is recommended. A small amount of fresh lubricant also should be added to the hub cav ity.

BEARING INSTALLA TION/ADJUSTMENT (1) Install the hub/rotor (with inner bearing and

seal) on steering knuckle spindle.

(2) Install the outer bearing, the thrust washer

and the nut.

(3) Tighten wheel bearing nut to 27-34 N^m (240-

300 in. lbs.) torque while rotating hub/rotor. This

will seat the bearings.

(4) Loosen the nut 1/4 of-a-turn (90°), then tighten

it finger-tight.

Page 85 of 1502

2

- 32

FRONT

SUSPENSION

AND

AXLE

• (5) Disconnect flexible brake fluid hose fittings at

the frame crossmember. Plug the hoses at the fit

tings.

(6) Remove the shock absorber lower nut and stud

from the axle shaft tube bracket. Remove the nuts and disconnect the stabilizer bar links from the

spring brackets.

(7) Disconnect the vacuum hoses and wiring con

nections from the shift motor housing.

(8) Remove nuts and the washers from the spring

U-bolts. Remove the complete front axle from the ve

hicle.

INSTALLATION

(1) Position the front axle under the front of the

vehicle with the axle spring pads under the springs.

Place the spring brackets over the springs. Make sure the stabilizer bar link bolt holes face toward the

rear of the vehicle.

(2) Install the spring U-bolts, washers and nuts.

Refer to Front Suspension — 4WD Vehicles within

this group. (3) Install the shock absorber. Refer to Front Sus

pension — 4WD Vehicles within this group. (4) Connect the stabilizer bar links to the spring

brackets. Refer to Front Suspension-4WD Vehicles

within this group.

(5) Remove plugs and connect the brake hose fit

tings.

Refer to Group 5, Brakes. (6) Connect the drag-link ball stud to the steering

knuckle arm. Refer to Group 19, Steering. (7) Connect the drive shaft to the pinion yoke with

the installation reference marks aligned. Install the

washers and the nuts and tighten to 19 N*m (14 ft. lbs.) torque.

(8) Connect the vacuum hoses and wiring connec

tions to the shift motor housing. (9) Remove the supports, lower the vehicle and re

move the block from the brake pedal.

(10) Raise the vehicle.

• Bleed and adjust the brakes

• Lubricate all the ball stud fittings

• Inspect the differential housing lubricant level. Re

fer to Group 0, Lubrication and Maintenance. (11) Lower the vehicle and test the axle and sus

pension operation.

DIFFERENTIAL

DISASSEMBLY

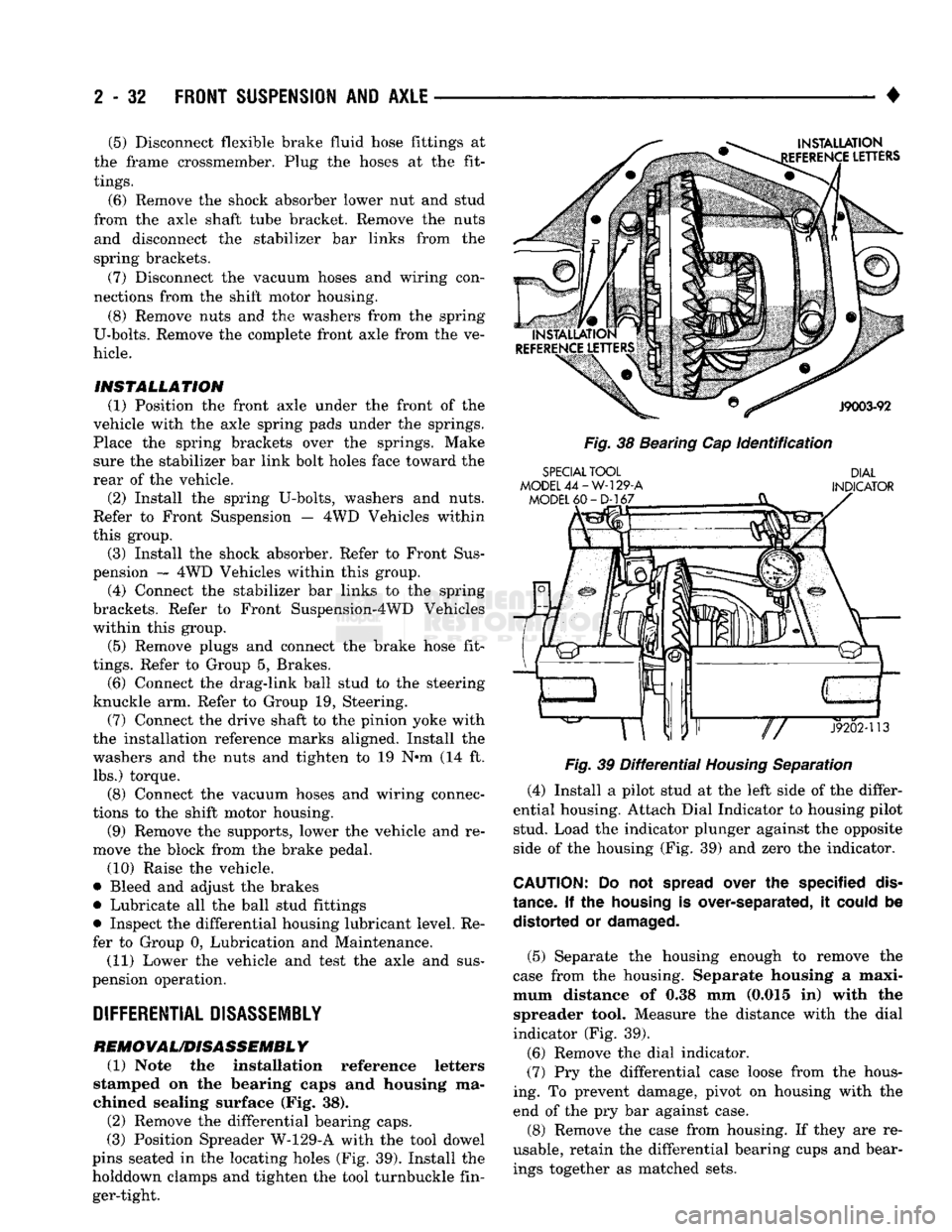

REMOVAL/DISASSEMBLY (1) Note the installation reference letters

stamped on the bearing caps and housing ma

chined sealing surface (Fig. 38). (2) Remove the differential bearing caps.

(3) Position Spreader W-129-A with the tool dowel

pins seated in the locating holes (Fig. 39). Install the

holddown clamps and tighten the tool turnbuckle fin ger-tight.

INSTALLATION

EFERENCE

LETTERS

J9003-92

Fig.

38 Bearing Cap

Identification

SPECIAL

TOOL

MODEL

44-W-129-A

MODEL

60-D-167

DIAL

INDICATOR

«ar"P—

J9202-113

Fig.

39

Differential

Housing

Separation

(4) Install a pilot stud at the left side of the differ

ential housing. Attach Dial Indicator to housing pilot stud. Load the indicator plunger against the opposite

side of the housing (Fig. 39) and zero the indicator.

CAUTION:

Do not

spread

over the specified

dis

tance.

If the

housing

is over-separated, it

could

be distorted or

damaged.

(5) Separate the housing enough to remove the

case from the housing. Separate housing a maxi

mum distance of 0.38 mm (0.015 in) with the spreader tool. Measure the distance with the dial

indicator (Fig. 39).

(6) Remove the dial indicator.

(7) Pry the differential case loose from the hous

ing. To prevent damage, pivot on housing with the end of the pry bar against case.

(8) Remove the case from housing. If they are re

usable, retain the differential bearing cups and bear ings together as matched sets.

Page 112 of 1502

•

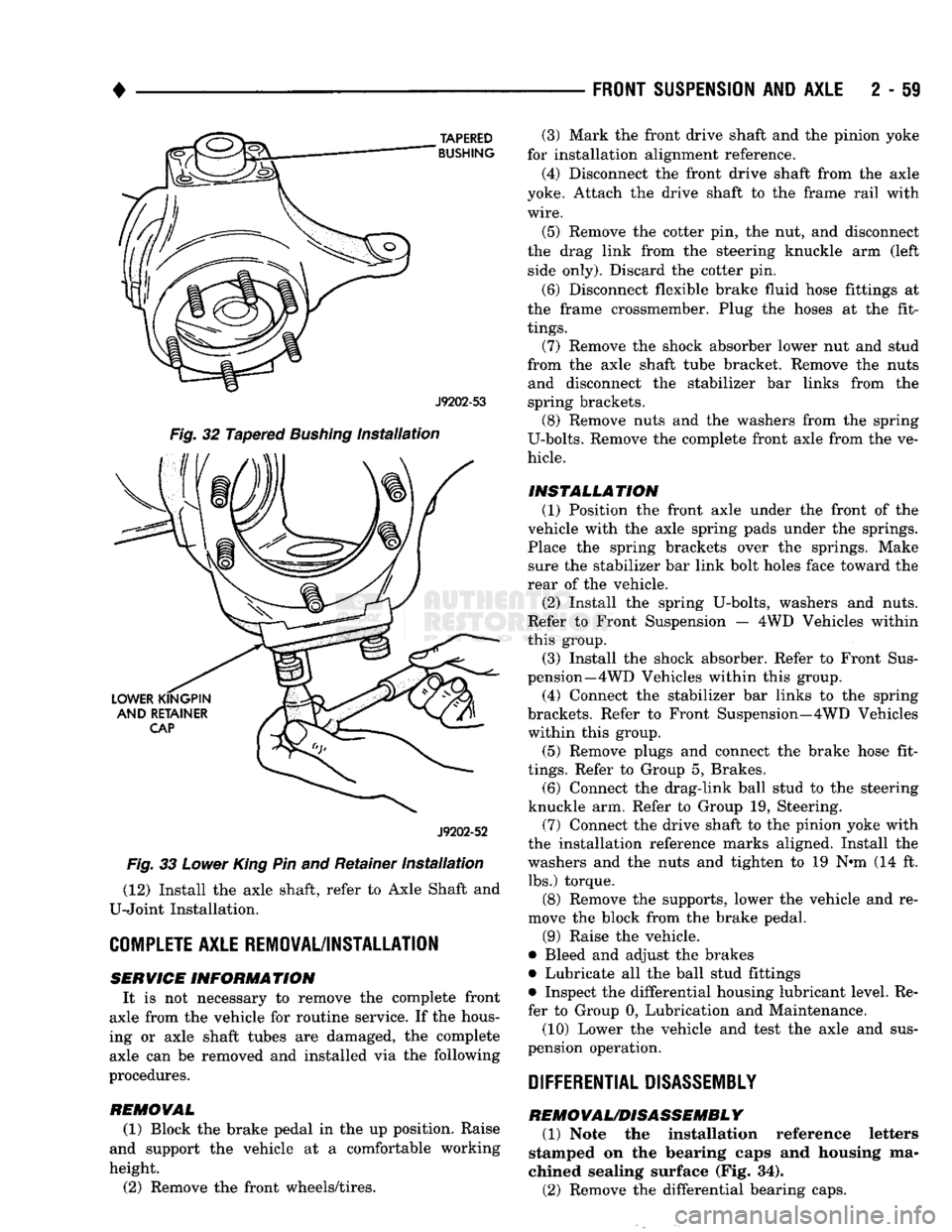

TAPERED

BUSHING

J9202-53

Fig.

32 Tapered

Bushing

Installation

J9202-52

Fig.

33

Lower

King

Pin and Retainer

Installation

(12) Install the axle shaft, refer to Axle Shaft and

U-Joint Installation.

COMPLETE

AXLE REMOVAL/INSTALLATION SERVICE

INFORMATION

It is not necessary to remove the complete front

axle from the vehicle for routine service. If the hous

ing or axle shaft tubes are damaged, the complete axle can be removed and installed via the following

procedures.

REMOVAL

(1) Block the brake pedal in the up position. Raise

and support the vehicle at a comfortable working

height.

(2) Remove the front wheels/tires.

FRONT SUSPENSION

AND

AXLE

2 - 59

(3) Mark the front drive shaft and the pinion yoke

for installation alignment reference.

(4) Disconnect the front drive shaft from the axle

yoke. Attach the drive shaft to the frame rail with

wire.

(5) Remove the cotter pin, the nut, and disconnect

the drag link from the steering knuckle arm (left side only). Discard the cotter pin.

(6) Disconnect flexible brake fluid hose fittings at

the frame crossmember. Plug the hoses at the fit

tings.

(7) Remove the shock absorber lower nut and stud

from the axle shaft tube bracket. Remove the nuts and disconnect the stabilizer bar links from the

spring brackets. (8) Remove nuts and the washers from the spring

U-bolts. Remove the complete front axle from the ve

hicle.

INSTALLATION (1) Position the front axle under the front of the

vehicle with the axle spring pads under the springs.

Place the spring brackets over the springs. Make sure the stabilizer bar link bolt holes face toward the

rear of the vehicle.

(2) Install the spring U-bolts, washers and nuts.

Refer to Front Suspension — 4WD Vehicles within

this group. (3) Install the shock absorber. Refer to Front Sus

pension—4 WD Vehicles within this group.

(4) Connect the stabilizer bar links to the spring

brackets. Refer to Front Suspension—4WD Vehicles within this group.

(5) Remove plugs and connect the brake hose fit

tings.

Refer to Group 5, Brakes. (6) Connect the drag-link ball stud to the steering

knuckle arm. Refer to Group 19, Steering. (7) Connect the drive shaft to the pinion yoke with

the installation reference marks aligned. Install the

washers and the nuts and tighten to 19 N-m (14 ft. lbs.) torque.

(8) Remove the supports, lower the vehicle and re

move the block from the brake pedal.

(9) Raise the vehicle.

• Bleed and adjust the brakes

• Lubricate all the ball stud fittings

• Inspect the differential housing lubricant level. Re

fer to Group 0, Lubrication and Maintenance.

(10) Lower the vehicle and test the axle and sus

pension operation.

DIFFERENTIAL DISASSEMBLY

REMOVAL/DISASSEMBLY

(1) Note the installation reference letters

stamped on the bearing caps and housing ma

chined sealing surface (Fig. 34).

(2) Remove the differential bearing caps.

Page 146 of 1502

•

REAR

SUSPENSION

AND

AXLE

3 - 11

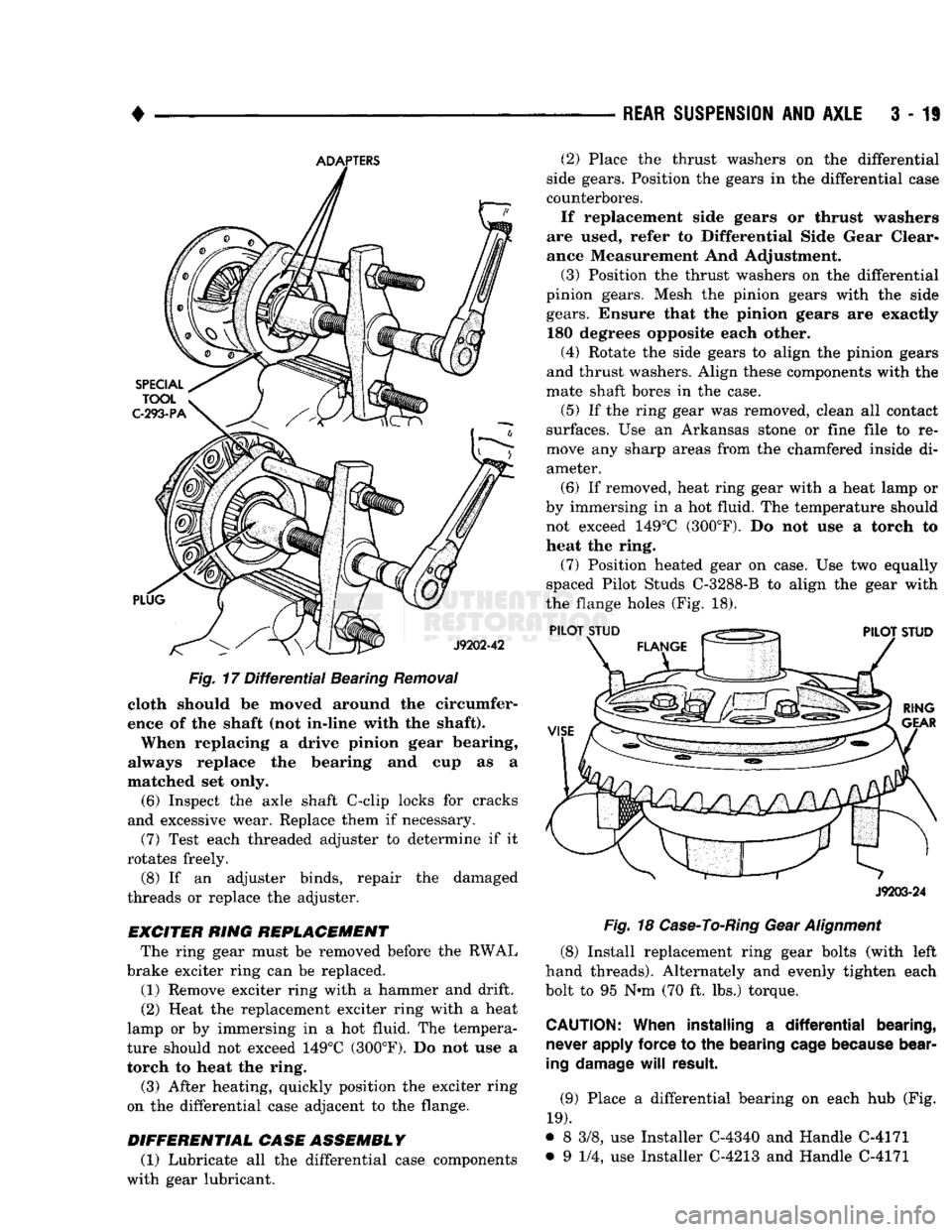

ADAPTERS

Fig.

17

Differential

Bearing

Removal

cloth should be moved around the circumfer

ence of the shaft (not in-line with the shaft).

When replacing a drive pinion gear bearing,

always replace the bearing and cup as a

matched set only.

(6) Inspect the axle shaft C-clip locks for cracks

and excessive wear. Replace them if necessary.

(7) Test each threaded adjuster to determine if it

rotates freely. (8) If an adjuster binds, repair the damaged

threads or replace the adjuster.

EXCITER

RING

REPLACEMENT

The ring gear must be removed before the RWAL

brake exciter ring can be replaced.

(1) Remove exciter ring with a hammer and drift.

(2) Heat the replacement exciter ring with a heat

lamp or by immersing in a hot fluid. The tempera

ture should not exceed 149°C (300°F). Do not use a

torch to heat the ring.

(3) After heating, quickly position the exciter ring

on the differential case adjacent to the flange.

DIFFERENTIAL

CASE ASSEMBLY

(1) Lubricate all the differential case components

with gear lubricant. (2) Place the thrust washers on the differential

side gears. Position the gears in the differential case

counterbores.

If replacement side gears or thrust washers

are used, refer to Differential Side Gear Clear ance Measurement And Adjustment.

(3) Position the thrust washers on the differential

pinion gears. Mesh the pinion gears with the side

gears.

Ensure that the pinion gears are exactly 180 degrees opposite each other.

(4) Rotate the side gears to align the pinion gears

and thrust washers. Align these components with the

mate shaft bores in the case.

(5) If the ring gear was removed, clean all contact

surfaces. Use an Arkansas stone or fine file to re

move any sharp areas from the chamfered inside di ameter.

(6) If removed, heat ring gear with a heat lamp or

by immersing in a hot fluid. The temperature should not exceed 149°C (300°F). Do not use a torch to

heat the ring.

(7) Position heated gear on case. Use two equally

spaced Pilot Studs C-3288-B to align the gear with

the flange holes (Fig. 18).

J9203-24

Fig.

18

Case-To-Ring

Gear

Alignment

(8) Install replacement ring gear bolts (with left

hand threads). Alternately and evenly tighten each

bolt to 95 N-m (70 ft. lbs.) torque.

CAUTION:

When

installing a

differential

bearing,

never apply force to the bearing

cage

because

bear

ing

damage

will

result.

(9) Place a differential bearing on each hub (Fig.

19).

• 8 3/8, use Installer C-4340 and Handle C-4171

• 9 1/4, use Installer C-4213 and Handle C-4171

Page 221 of 1502

5

- 34

BRAKES

•

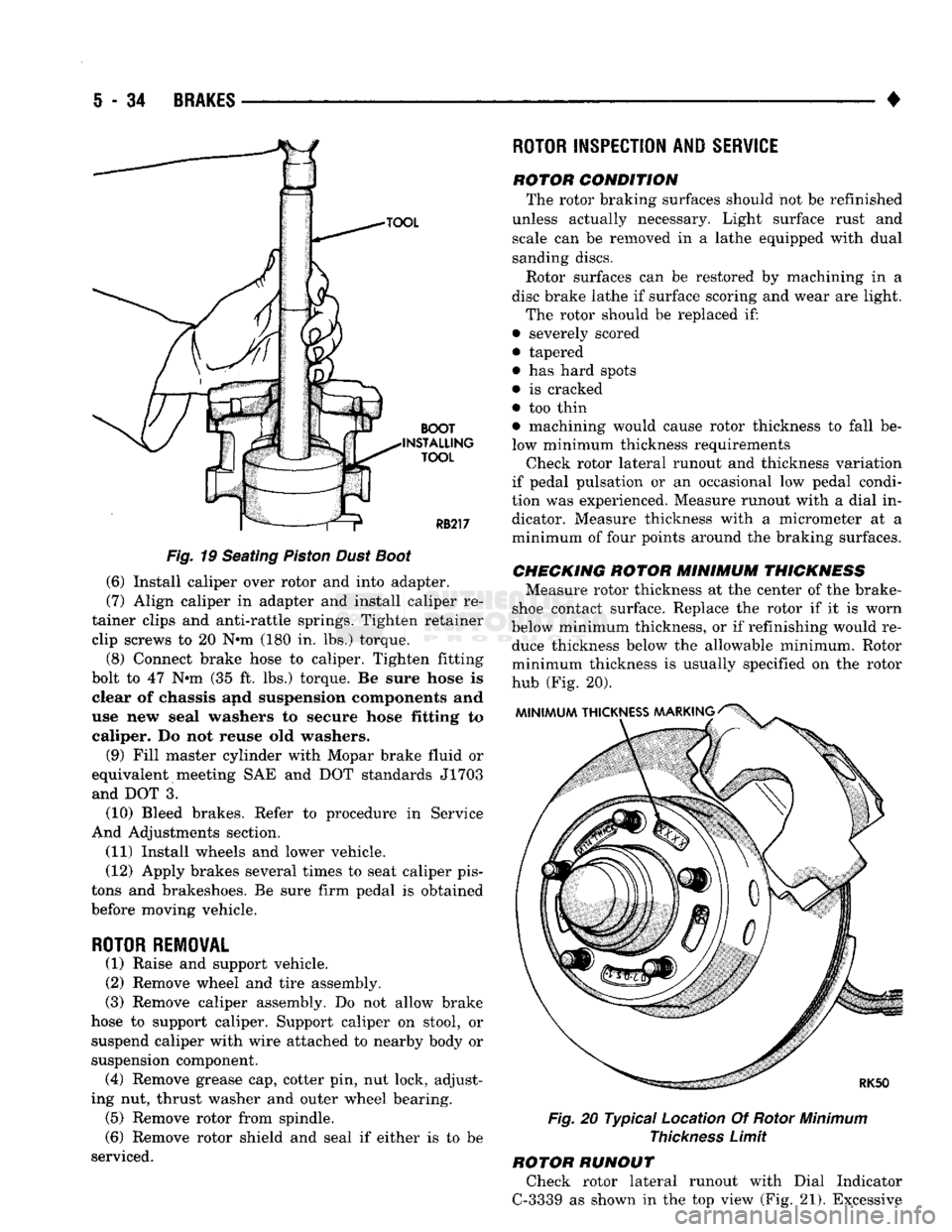

boot

>TALLir TOOL

Fig.

19 Seating

Piston

Dust

Boot

(6) Install caliper over rotor and into adapter.

(7) Align caliper in adapter and install caliper re

tainer clips and anti-rattle springs. Tighten retainer clip screws to 20 N*m (180 in. lbs.) torque.

(8) Connect brake hose to caliper. Tighten fitting

bolt to 47 N»m (35 ft. lbs.) torque. Be sure hose is clear of chassis and suspension components and

use new seal washers to secure hose fitting to caliper. Do not reuse old washers.

(9) Fill master cylinder with Mopar brake fluid or

equivalent meeting SAE and DOT standards J1703 and DOT 3.

(10) Bleed brakes. Refer to procedure in Service

And Adjustments section.

(11) Install wheels and lower vehicle.

(12) Apply brakes several times to seat caliper pis

tons and brakeshoes. Be sure firm pedal is obtained

before moving vehicle.

ROTOR REMOVAL

(1) Raise and support vehicle.

(2) Remove wheel and tire assembly.

(3) Remove caliper assembly. Do not allow brake

hose to support caliper. Support caliper on stool, or suspend caliper with wire attached to nearby body or

suspension component. (4) Remove grease cap, cotter pin, nut lock, adjust

ing nut, thrust washer and outer wheel bearing. (5) Remove rotor from spindle.

(6) Remove rotor shield and seal if either is to be

serviced.

ROTOR

INSPECTION AND

SERVICE

rotor condition The rotor braking surfaces should not be refinished

unless actually necessary. Light surface rust and scale can be removed in a lathe equipped with dual

sanding discs.

Rotor surfaces can be restored by machining in a

disc brake lathe if surface scoring and wear are light.

The rotor should be replaced if:

• severely scored

• tapered

• has hard spots

• is cracked

• too thin • machining would cause rotor thickness to fall be

low minimum thickness requirements Check rotor lateral runout and thickness variation

if pedal pulsation or an occasional low pedal condi

tion was experienced. Measure runout with a dial in dicator. Measure thickness with a micrometer at a

minimum of four points around the braking surfaces.

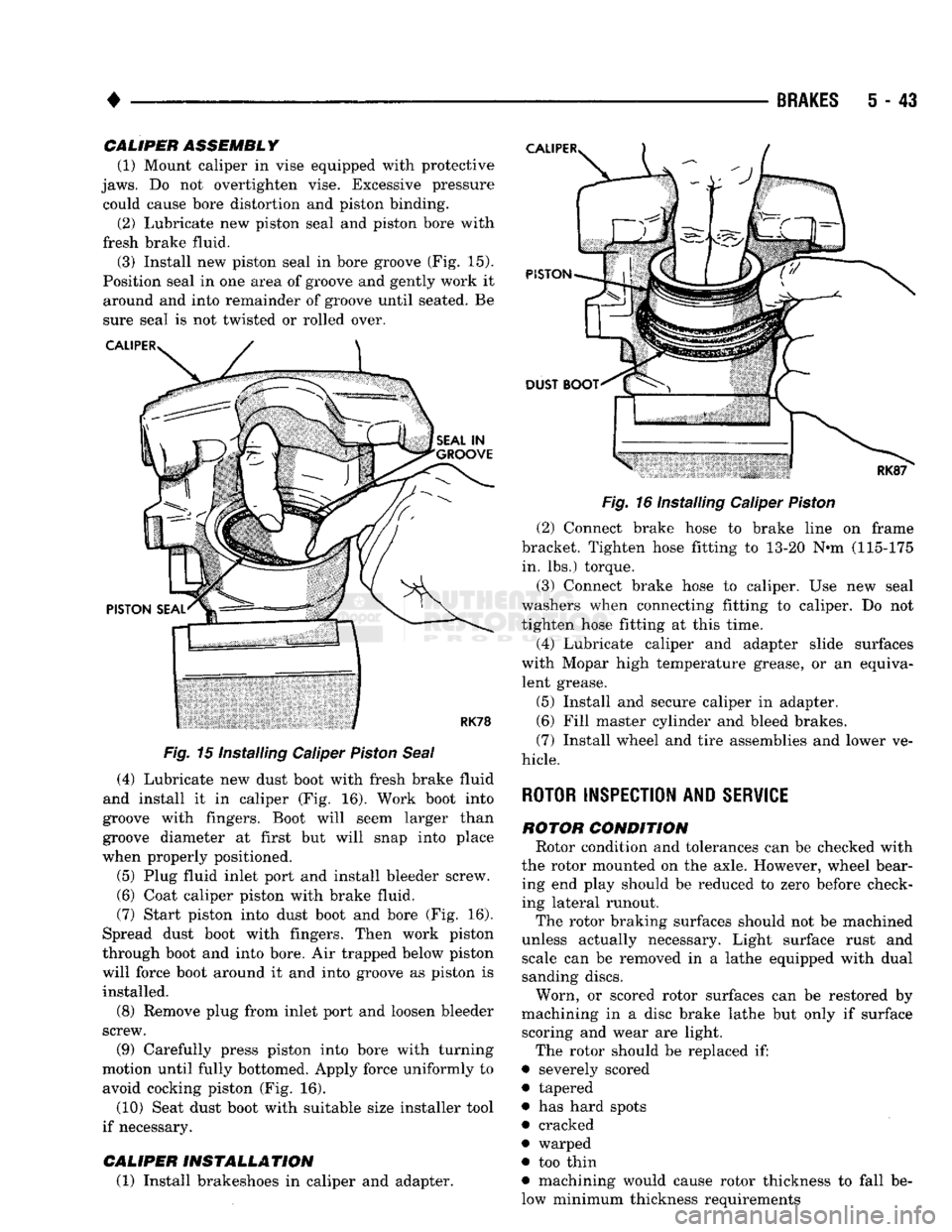

CHECKING

ROTOR

MINIMUM

THICKNESS

Measure rotor thickness at the center of the brake-

shoe contact surface. Replace the rotor if it is worn

below minimum thickness, or if refinishing would re duce thickness below the allowable minimum. Rotor

minimum thickness is usually specified on the rotor

hub (Fig. 20).

Fig.

20 Typical Location Of Rotor

Minimum

Thickness

Limit

ROTOR RUNOUT Check rotor lateral runout with Dial Indicator

C-3339 as shown in the top view (Fig. 21). Excessive

Page 230 of 1502

•

BRAKES

5 - 43

CAMPER

ASSEMBLY

(1) Mount caliper in vise equipped with protective

jaws.

Do not overtighten vise. Excessive pressure could cause bore distortion and piston binding. (2) Lubricate new piston seal and piston bore with

fresh brake fluid. (3) Install new piston seal in bore groove (Fig. 15).

Position seal in one area of groove and gently work it around and into remainder of groove until seated. Be

sure seal is not twisted or rolled over.

Fig.

15 Installing Caliper

Piston

Seal

(4) Lubricate new dust boot with fresh brake fluid

and install it in caliper (Fig. 16). Work boot into

groove with fingers. Boot will seem larger than

groove diameter at first but will snap into place

when properly positioned.

(5) Plug fluid inlet port and install bleeder screw. (6) Coat caliper piston with brake fluid.

(7) Start piston into dust boot and bore (Fig. 16).

Spread dust boot with fingers. Then work piston

through boot and into bore. Air trapped below piston

will force boot around it and into groove as piston is installed.

(8) Remove plug from inlet port and loosen bleeder

screw.

(9) Carefully press piston into bore with turning

motion until fully bottomed. Apply force uniformly to avoid cocking piston (Fig. 16).

(10) Seat dust boot with suitable size installer tool

if necessary.

CALIPER

INSTALLATION

(1) Install brakeshoes in caliper and adapter.

Fig.

16 Installing Caliper

Piston

(2) Connect brake hose to brake line on frame

bracket. Tighten hose fitting to 13-20 N«m (115-175 in. lbs.) torque.

(3) Connect brake hose to caliper. Use new seal

washers when connecting fitting to caliper. Do not

tighten hose fitting at this time.

(4) Lubricate caliper and adapter slide surfaces

with Mopar high temperature grease, or an equiva lent grease.

(5) Install and secure caliper in adapter.

(6) Fill master cylinder and bleed brakes.

(7) Install wheel and tire assemblies and lower ve

hicle.

ROTOR INSPECTION AND

SERVICE

ROTOR

CONDITION

Rotor condition and tolerances can be checked with

the rotor mounted on the axle. However, wheel bear ing end play should be reduced to zero before check

ing lateral runout.

The rotor braking surfaces should not be machined

unless actually necessary. Light surface rust and scale can be removed in a lathe equipped with dual

sanding discs.

Worn, or scored rotor surfaces can be restored by

machining in a disc brake lathe but only if surface scoring and wear are light.

The rotor should be replaced if:

• severely scored

• tapered

• has hard spots

• cracked

• warped

• too thin

• machining would cause rotor thickness to fall be

low minimum thickness requirements

Page 241 of 1502

5

- 54

BRAKES

• (11) Attach adjuster cable to adjuster lever. Be

sure cable is properly routed.

(12) Adjust brakeshoes to drum with brake gauge.

BRAKE

DRUM INSTALLATION

(1) Position drum on axle housing.

(2) Install bearing and inner nut. Adjust bearing

as described in Group 3. (3) Install locking washer and outer nut. Bend

locking washer to secure it. (4) Place new gasket on hub and install axle shaft,

cones,

lock washers and nuts. (5) Install wheel and tire assembly.

(6) Remove support stands and lower vehicle.

BRAKE

DRUM

SERVICE

BRAKE DRUM REFINISHING The brake drums can be resurfaced on a drum

lathe when necessary. Initial machining cuts should

be limited to 0.12 - 0.20 mm (0.005 - 0.008 in.) at a time as heavier feed rates can produce taper and sur

face variation. Final finish cuts of 0.025 to 0.38 mm (0.001 to 0.0015 in) are recommended and will gen

erally provide the best surface finish.

Be sure the drum is securely mounted in the lathe

before machining operations. A damper strap should always be used around the drum to reduce vibration

and avoid chatter marks.

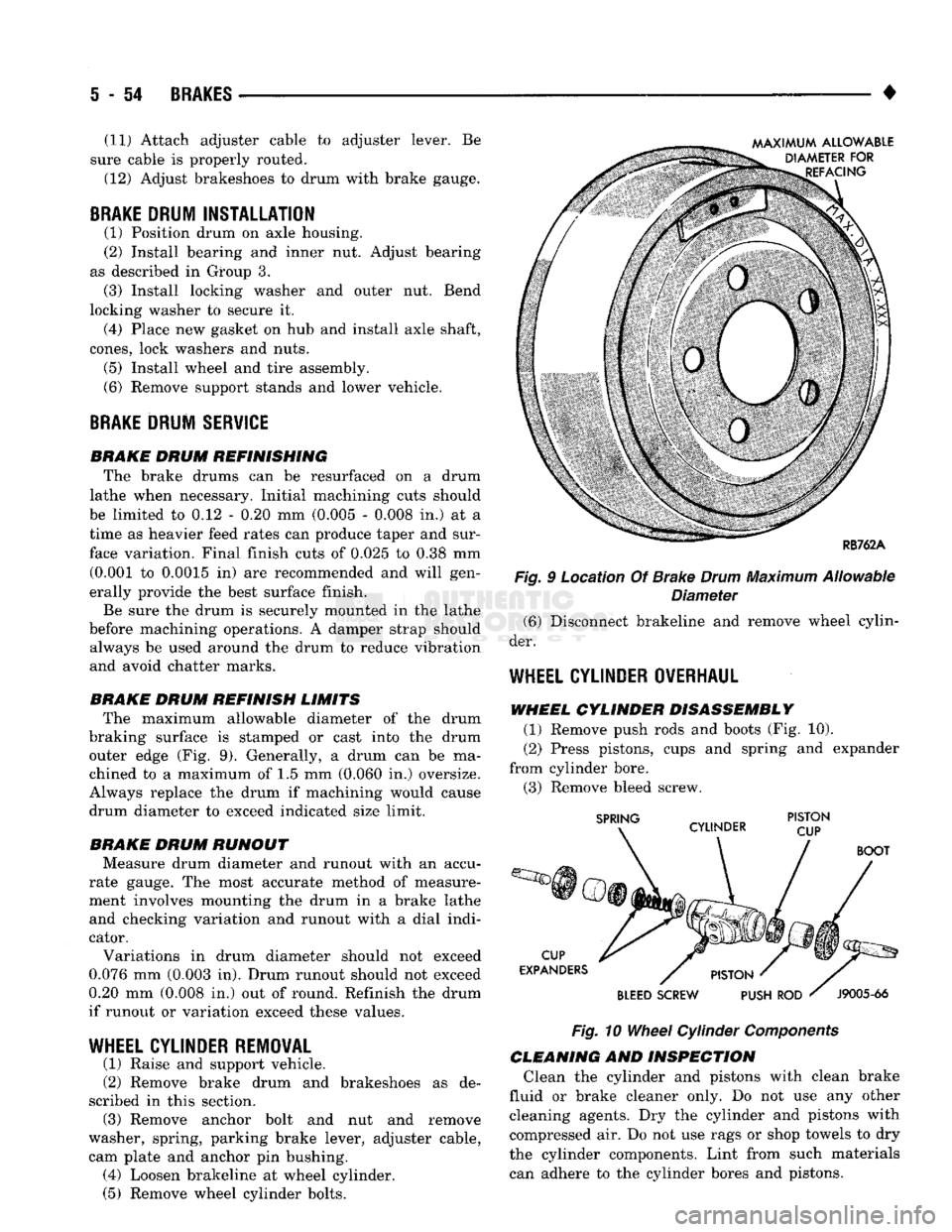

BRAKE DRUM REFINISH LIMITS The maximum allowable diameter of the drum

braking surface is stamped or cast into the drum outer edge (Fig. 9). Generally, a drum can be ma

chined to a maximum of 1.5 mm (0.060 in.) oversize.

Always replace the drum if machining would cause

drum diameter to exceed indicated size limit.

BRAKE DRUM RUNOUT Measure drum diameter and runout with an accu

rate gauge. The most accurate method of measure

ment involves mounting the drum in a brake lathe and checking variation and runout with a dial indi

cator.

Variations in drum diameter should not exceed

0.076 mm (0.003 in). Drum runout should not exceed

0.20 mm (0.008 in.) out of round. Refinish the drum

if runout or variation exceed these values.

WHEEL

CYLINDER REMOVAL

(1) Raise and support vehicle.

(2) Remove brake drum and brakeshoes as de

scribed in this section. (3) Remove anchor bolt and nut and remove

washer, spring, parking brake lever, adjuster cable, cam plate and anchor pin bushing. (4) Loosen brakeline at wheel cylinder.

(5) Remove wheel cylinder bolts. Fig. 9 Location Of Brake

Drum

Maximum Allowable

Diameter (6) Disconnect brakeline and remove wheel cylin

der.

WHEEL

CYLINDER OVERHAUL

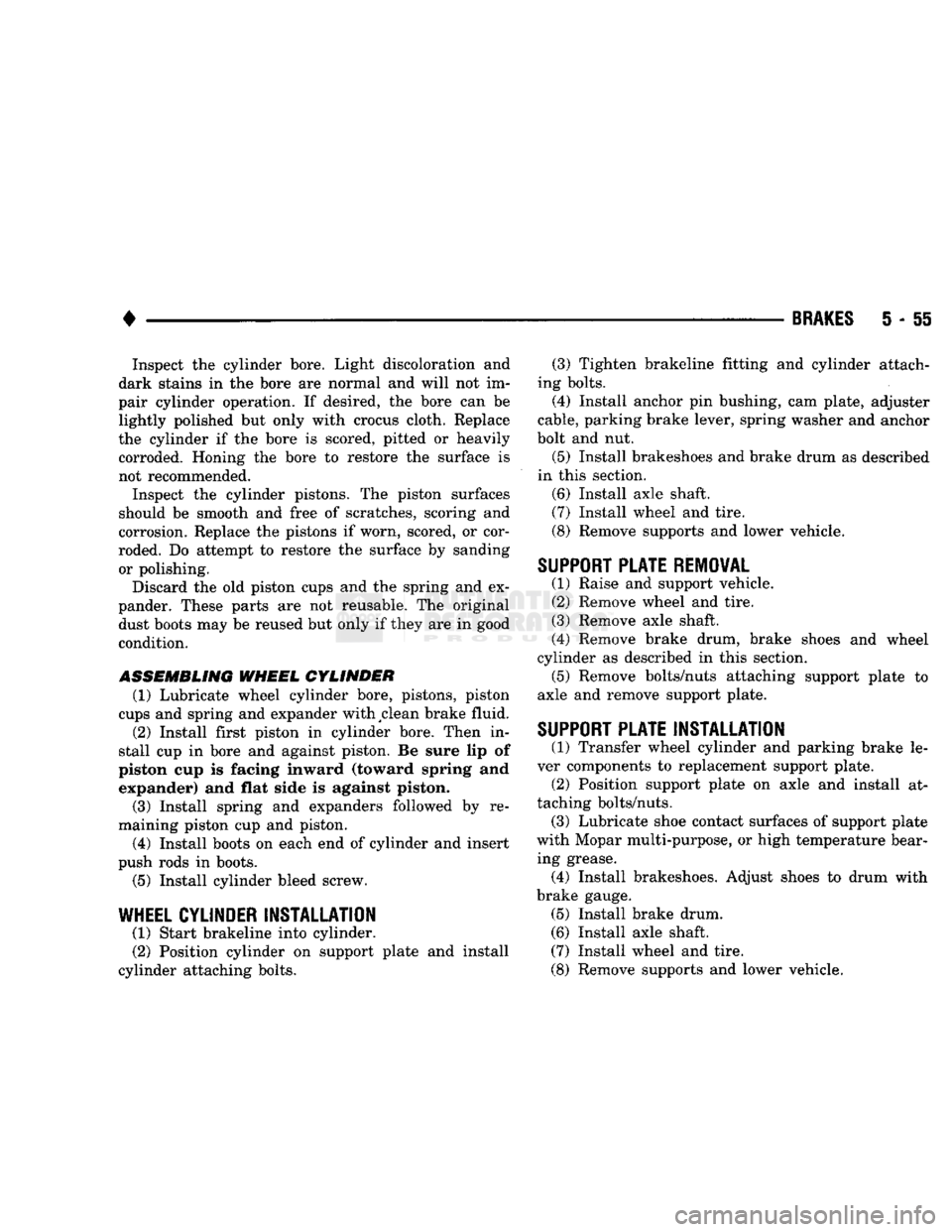

WHEEL CYLINDER DISASSEMBLY (1) Remove push rods and boots (Fig. 10).

(2) Press pistons, cups and spring and expander

from cylinder bore. (3) Remove bleed screw.

Fig.

10

Wheel

Cylinder

Components

CLEANING AND INSPECTION Clean the cylinder and pistons with clean brake

fluid or brake cleaner only. Do not use any other cleaning agents. Dry the cylinder and pistons with

compressed air. Do not use rags or shop towels to dry

the cylinder components. Lint from such materials can adhere to the cylinder bores and pistons.

Page 242 of 1502

•

BRAKES

5 - 55 Inspect the cylinder bore. Light discoloration and

dark stains in the bore are normal and will not im

pair cylinder operation. If desired, the bore can be lightly polished but only with crocus cloth. Replace

the cylinder if the bore is scored, pitted or heavily corroded. Honing the bore to restore the surface is not recommended.

Inspect the cylinder pistons. The piston surfaces

should be smooth and free of scratches, scoring and

corrosion. Replace the pistons if worn, scored, or cor

roded. Do attempt to restore the surface by sanding or polishing.

Discard the old piston cups and the spring and ex

pander. These parts are not reusable. The original

dust boots may be reused but only if they are in good condition.

ASSEMBLING

WHEEL CYLINDER

(1) Lubricate wheel cylinder bore, pistons, piston

cups and spring and expander with ^clean brake fluid. (2) Install first piston in cylinder bore. Then in

stall cup in bore and against piston. Be sure lip of

piston cup is facing inward (toward spring and

expander) and flat side is against piston.

(3) Install spring and expanders followed by re

maining piston cup and piston.

(4) Install boots on each end of cylinder and insert

push rods in boots.

(5)

Install cylinder bleed screw.

WHEEL

CYLINDER INSTALLATION

(1) Start brakeline into cylinder.

(2) Position cylinder on support plate and install

cylinder attaching bolts. (3) Tighten brakeline fitting and cylinder attach

ing bolts. (4) Install anchor pin bushing, cam plate, adjuster

cable, parking brake lever, spring washer and anchor

bolt and nut.

(5) Install brakeshoes and brake drum as described

in this section. (6) Install axle shaft.

(7) Install wheel and tire.

(8) Remove supports and lower vehicle.

SUPPORT

PLATE REMOVAL

(1) Raise and support vehicle.

(2) Remove wheel and tire.

(3) Remove axle shaft.

(4) Remove brake drum, brake shoes and wheel

cylinder as described in this section. (5) Remove bolts/nuts attaching support plate to

axle and remove support plate.

SUPPORT PLATE INSTALLATION

(1) Transfer wheel cylinder and parking brake le

ver components to replacement support plate. (2) Position support plate on axle and install at

taching bolts/nuts. (3) Lubricate shoe contact surfaces of support plate

with Mopar multi-purpose, or high temperature bear ing grease. (4) Install brakeshoes. Adjust shoes to drum with

brake gauge. (5) Install brake drum.

(6) Install axle shaft.

(7) Install wheel and tire.

(8) Remove supports and lower vehicle.