open hood DODGE TRUCK 1993 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1384 of 1502

•

BODY

COMPONENTS

23 - 1

CONTENTS

page

page

CAB/BODY

INTERIOR COMPONENTS

35

FIXED

GLASS

. 29

DOORS

21

PAINT

CODE

CHART

54

EXTERIOR

COMPONENTS

1

REFINISHING

PROCEDURES

54

EXTERIOR COMPONENTS

INDEX

page

Battery

Tray

7

Blower Motor Housing

Insulation

Panel—Diesel

Engine

Only

7

Body

Mouldings, Nameplates

and

Decals .......

9

Cab

. 14

Cab/Body

and

Cargo

Box

Stripes

11

Cargo

Box

19

Cowl

Grille

7

Front

Fenders

8

Fuel

Filler

Door

and

Nozzle/Tubes

12

Grille

and

Grille

Extension Panel

1

Grille

Extension Panel Support Bracket

(With

Diesel Engine Only)

3

page

Grille

Opening Panel (GOP)

and

Radiator Support Panel

3

Hatchgate

and

Components

16

Hood

5

Hood

Inside Release Cable

5

Hood

Latch

4

Labels/Decals/Plates

1

Outside Mirrors

13

Roof

Vent—Ramcharger

. 20

Splash

Shields—Front Fender

9

Sport

Bar

18

Tailgate

14

LABELS/DECALS/PLATES

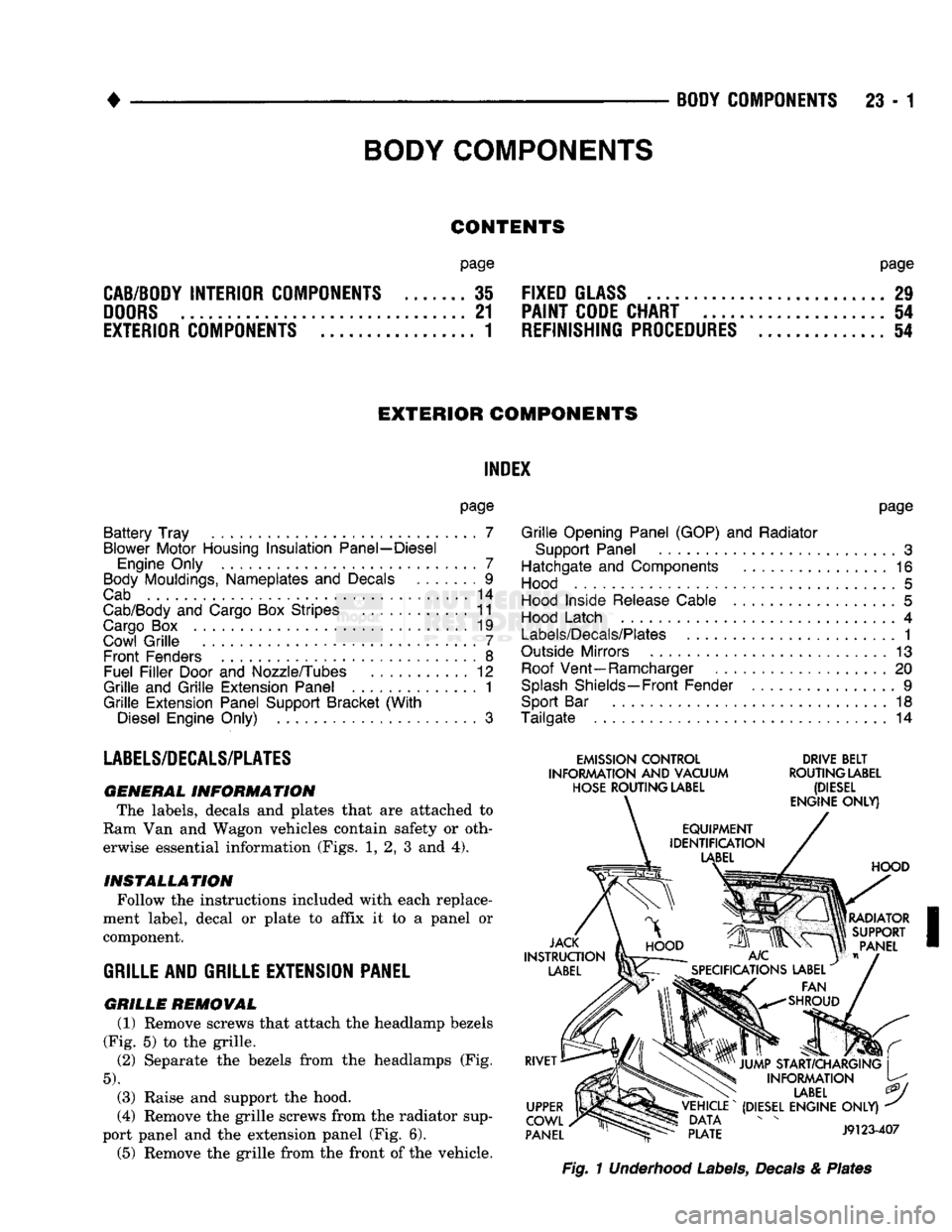

GENERAL

INFORMATION The labels, decals

and

plates that

are

attached

to

Ram Van

and

Wagon vehicles contain safety

or

oth erwise essential information (Figs.

1, 2, 3 and 4).

INSTALLATION

Follow the instructions included with each replace

ment label, decal

or

plate

to

affix

it to a

panel

or

component.

GRILLE

AND GRILLE EXTENSION PANEL

GRILLE

REMOVAL (1) Remove screws that attach the headlamp bezels

(Fig.

5) to the

grille.

(2)

Separate

the

bezels from

the

headlamps

(Fig.

5).

(3) Raise

and

support

the

hood.

(4) Remove the grille screws from the radiator sup

port panel

and the

extension panel (Fig.

6).

(5) Remove

the

grille from the front

of

the vehicle.

EMISSION

CONTROL

DRIVE

BELT

INFORMATION

AND

VACUUM

ROUTING

LABEL

HOSE

ROUTING

LABEL

(DIESEL

Fig.

1 Underhood Labels, Decals & Plates

BODY

COMPONENTS

Page 1386 of 1502

•

BODY

COMPONENTS

23 - 3

GRILLE

EXTENSION

PANEL

INSTALLATION

(1) Position the grille extension panel at the fender

panels and the support bracket. (2) Install the panel screws. Tighten the screws to

23 N*m (200 in. lbs.) torque.

(3) Install the grille. If necessary, refer to the in

stallation procedure. (4) Remove the support and close the hood.

U-NUT

RADIATOR GRILLE

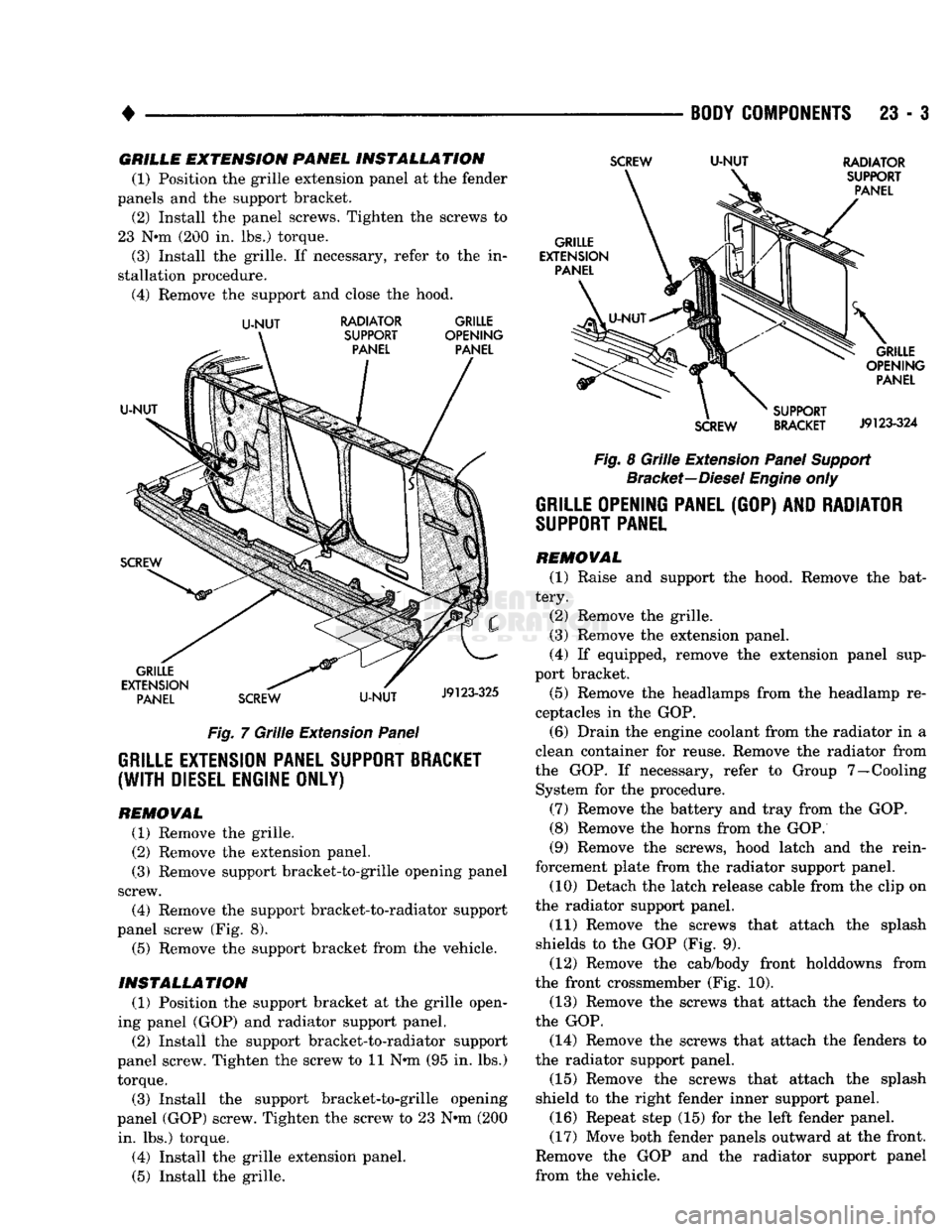

Fig. 7 Grille Extension Panel

GRILLE EXTENSION PANEL SUPPORT BRACKET

(WITH

DIESEL ENGINE ONLY)

REMOWAL

(1) Remove the grille.

(2) Remove the extension panel.

(3) Remove support bracket-to-grille opening panel

screw. (4) Remove the support bracket-to-radiator support

panel screw (Fig. 8). (5) Remove the support bracket from the vehicle.

INSTALLATION

(1) Position the support bracket at the grille open

ing panel (GOP) and radiator support panel. (2) Install the support bracket-to-radiator support

panel screw. Tighten the screw to 11 N*m (95 in. lbs.) torque.

(3) Install the support bracket-to-grille opening

panel (GOP) screw. Tighten the screw to 23 N-m (200 in. lbs.) torque.

(4) Install the grille extension panel.

(5) Install the grille.

SCREW

U-NUT

RADIATOR

Fig. 8 Grille Extension Panel Support Bracket—Diesel Engine only

GRILLE OPENING PANEL

(GOP) AND

RADIATOR

SUPPORT

PANEL

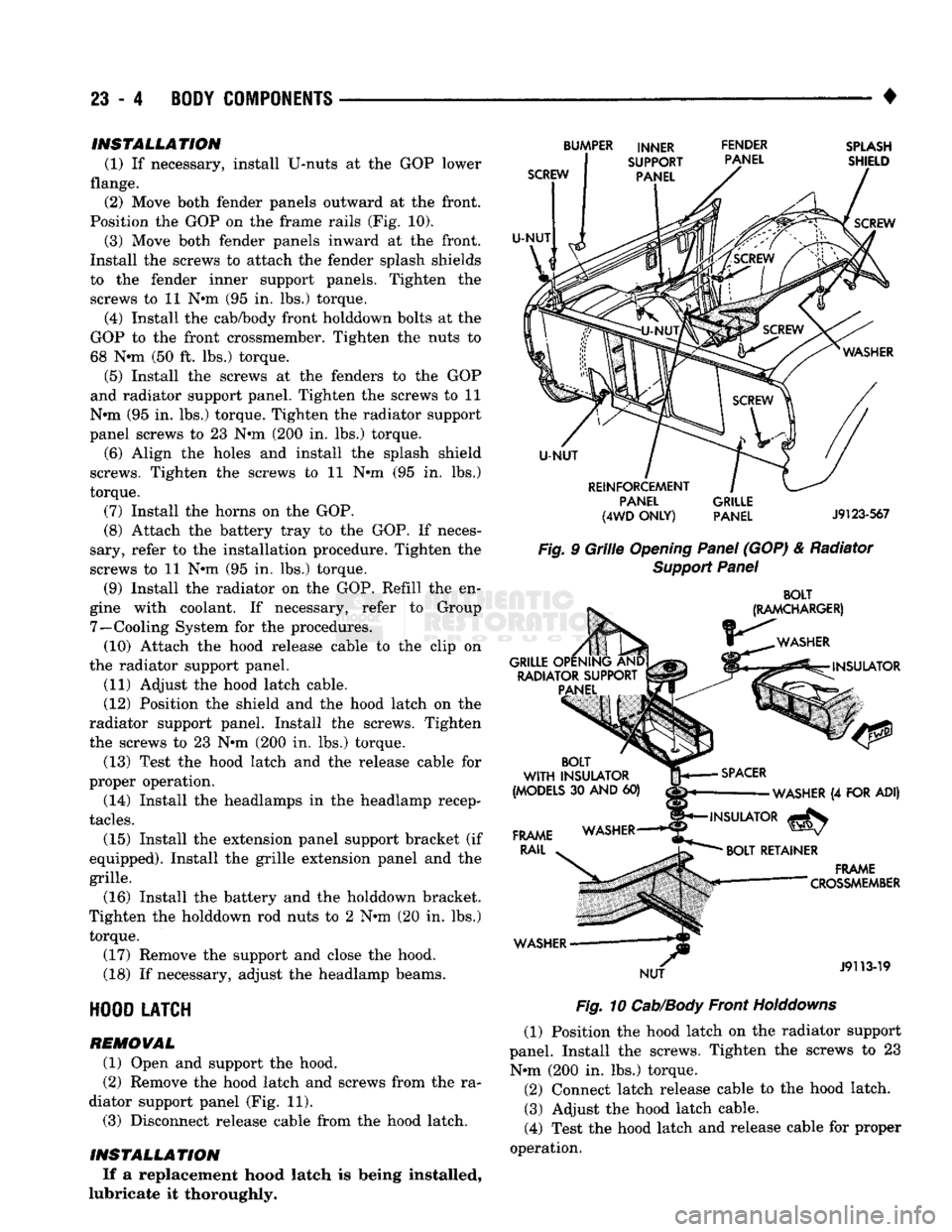

REMOVAL

(1) Raise and support the hood. Remove the bat

tery. (2) Remove the grille.

(3) Remove the extension panel.

(4) If equipped, remove the extension panel sup

port bracket.

(5) Remove the headlamps from the headlamp re

ceptacles in the GOP.

(6) Drain the engine coolant from the radiator in a

clean container for reuse. Remove the radiator from

the GOP. If necessary, refer to Group 7—Cooling System for the procedure.

(7) Remove the battery and tray from the GOP.

(8) Remove the horns from the GOP.

(9) Remove the screws, hood latch and the rein

forcement plate from the radiator support panel. (10) Detach the latch release cable from the clip on

the radiator support panel.

(11) Remove the screws that attach the splash

shields to the GOP (Fig. 9). (12) Remove the cab/body front holddowns from

the front crossmember (Fig. 10). (13) Remove the screws that attach the fenders to

the GOP.

(14) Remove the screws that attach the fenders to

the radiator support panel.

(15) Remove the screws that attach the splash

shield to the right fender inner support panel.

(16) Repeat step (15) for the left fender panel.

(17) Move both fender panels outward at the front.

Remove the GOP and the radiator support panel

from the vehicle.

Page 1387 of 1502

23

- 4

BODY

COMPONENTS

• INSTALLATION

(1) If necessary, install U-nuts at the GOP lower

flange. (2) Move both fender panels outward at the front.

Position the GOP on the frame rails (Fig. 10).

(3) Move both fender panels inward at the front.

Install the screws to attach the fender splash shields

to the fender inner support panels. Tighten the

screws to 11 N#m (95 in. lbs.) torque.

(4) Install the cab/body front holddown bolts at the

GOP to the front crossmember. Tighten the nuts to

68 Nnn (50 ft. lbs.) torque.

(5) Install the screws at the fenders to the GOP

and radiator support panel. Tighten the screws to 11

N»m (95 in. lbs.) torque. Tighten the radiator support

panel screws to 23 Nnn (200 in. lbs.) torque.

(6) Align the holes and install the splash shield

screws. Tighten the screws to 11 N»m (95 in. lbs.)

torque.

(7) Install the horns on the GOP.

(8) Attach the battery tray to the GOP. If neces

sary, refer to the installation procedure. Tighten the

screws to 11 Nnn (95 in. lbs.) torque.

(9) Install the radiator on the GOP. Refill the en

gine with coolant. If necessary, refer to Group 7—Cooling System for the procedures. (10) Attach the hood release cable to the clip on

the radiator support panel.

(11) Adjust the hood latch cable.

(12) Position the shield and the hood latch on the

radiator support panel. Install the screws. Tighten

the screws to 23 Nnn (200 in. lbs.) torque.

(13) Test the hood latch and the release cable for

proper operation.

(14) Install the headlamps in the headlamp recep

tacles.

(15) Install the extension panel support bracket (if

equipped). Install the grille extension panel and the

grille.

(16) Install the battery and the holddown bracket.

Tighten the holddown rod nuts to 2 Nnn (20 in. lbs.) torque.

(17) Remove the support and close the hood.

(18) If necessary, adjust the headlamp beams.

HOOD

LATCH

REMOVAL

(1) Open and support the hood.

(2) Remove the hood latch and screws from the ra

diator support panel (Fig. 11). (3) Disconnect release cable from the hood latch.

INSTALLATION If a replacement hood latch is being installed,

lubricate it thoroughly.

SCREW

U-NUT

BUMPER INNER FENDER

SUPPORT PANEL

PANEL

SPLASH

SHIELD

SCREW

U-NUT

REINFORCEMENT PANEL

(4WD

ONLY)

GRILLE

PANEL

J9123-567

Fig.

9

Grille

Opening

Panel

(GOP) & Radiator

Support

Panel

BOLT

(RAMCHARGER)

WASHER

GRILLE OPENING AND RADIATOR SUPPORT PANEL INSULATOR

BOLT

WITH

INSULATOR

(MODELS

30

AND

60)

FRAME

RAIL

WASHER NUT

SPACER

WASHER

(4

FOR ADI)

INSULATOR

^

BOLT

RETAINER

.

FRAME

— "

"

CROSSMEMBER

J9113-19

Fig.

10

Cab/Body

Front

Holddowns

(1) Position the hood latch on the radiator support

panel. Install the screws. Tighten the screws to 23 Nnn (200 in. lbs.) torque. (2) Connect latch release cable to the hood latch. (3) Adjust the hood latch cable.

(4) Test the hood latch and release cable for proper

operation.

Page 1388 of 1502

•

BODY

COMPONENTS

23 - 5

(5)

If

necessary, align

the

hood,

the

latch,

and the

striker. Refer

to

Fore/Aft

And

Latch/Striker Adjust

ment.

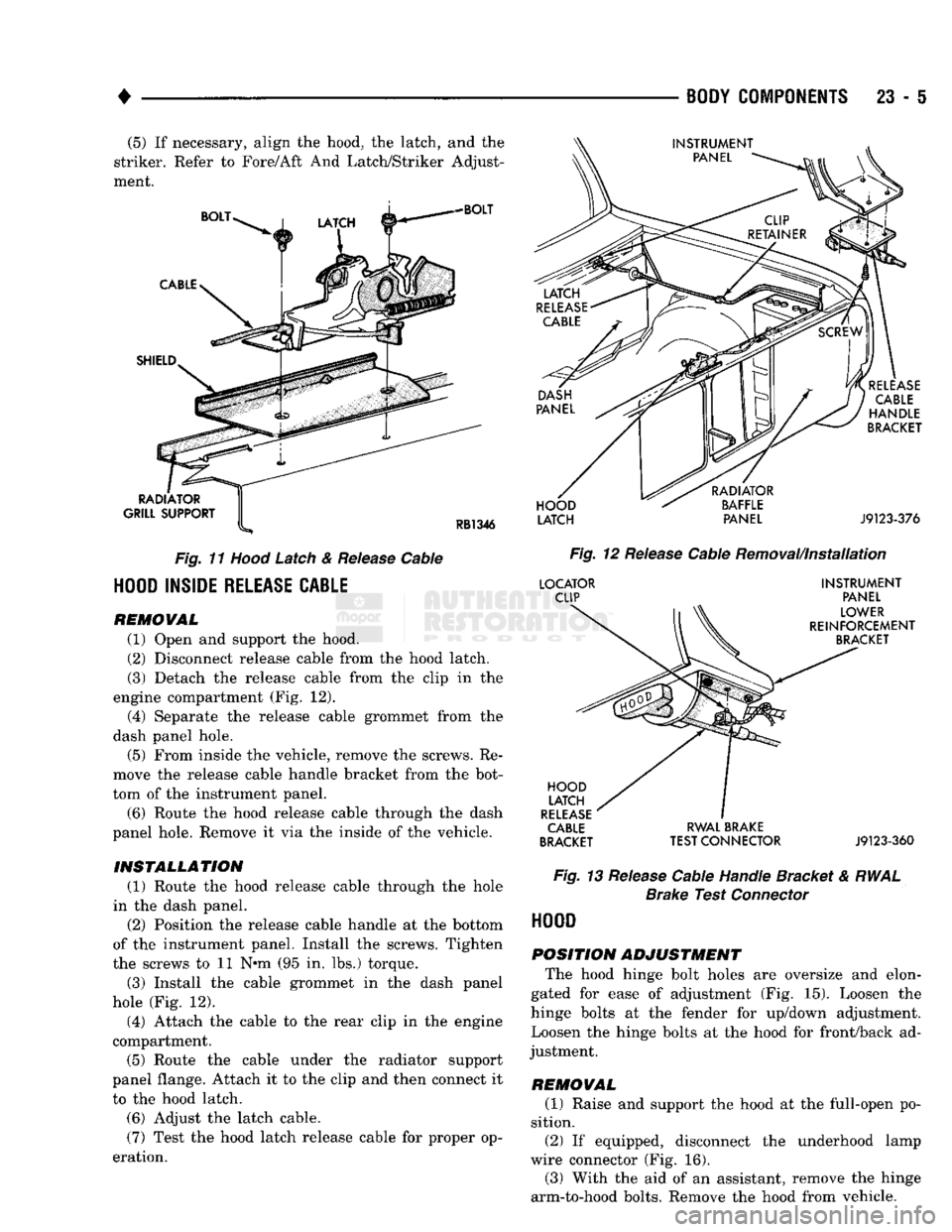

BOLT

CABLE

SHIELD

RADIATOR

GRILL SUPPORT

RB1346

Fig.

11

Hood

Latch

&

Release

Cable

HOOD

INSIDE

RELEASE

CABLE

REMOWAL

(1) Open

and

support

the

hood.

(2) Disconnect release cable from

the

hood latch.

(3) Detach

the

release cable from

the

clip

in the

engine compartment

(Fig. 12).

(4)

Separate

the

release cable grommet from

the

dash panel hole.

(5) From inside

the

vehicle, remove

the

screws.

Re

move

the

release cable handle bracket from

the

bot

tom

of the

instrument panel.

(6) Route

the

hood release cable through

the

dash

panel hole. Remove

it via the

inside

of the

vehicle.

INSTALLATION (1) Route

the

hood release cable through

the

hole

in

the

dash panel.

(2) Position

the

release cable handle

at the

bottom

of

the

instrument panel. Install

the

screws. Tighten

the screws

to 11 Nem (95 in. lbs.)

torque.

(3) Install

the

cable grommet

in the

dash panel

hole

(Fig. 12).

(4)

Attach

the

cable

to the

rear clip

in the

engine

compartment. (5) Route

the

cable under

the

radiator support

panel flange. Attach

it to the

clip

and

then connect

it

to

the

hood latch.

(6) Adjust

the

latch cable.

(7) Test

the

hood latch release cable

for

proper

op

eration.

RELEASE

CABLE

HANDLE

BRACKET

HOOD

LATCH

RADIATOR

BAFFLE PANEL

J9123-376

Fig.

12

Release

Cable Removal/Installation

LOCATOR

CLIP

HOOD

LATCH

RELEASE

CABLE

BRACKET

INSTRUMENT

PANEL

LOWER

REINFORCEMENT

BRACKET

RWAL BRAKE

TEST CONNECTOR

J9123-360

Fig.

13

Release

Cable Handle Bracket

&

RWAL

Brake

Test

Connector

HOOD

POSITION ADJUSTMENT The hood hinge bolt holes

are

oversize

and

elon

gated

for

ease

of

adjustment

(Fig. 15).

Loosen

the

hinge bolts

at the

fender

for

up/down adjustment.

Loosen

the

hinge bolts

at the

hood

for

front/back

ad

justment.

REMOVAL (1) Raise

and

support

the

hood

at the

full-open

po

sition. (2)

If

equipped, disconnect

the

underhood lamp

wire connector

(Fig. 16).

(3) With

the aid of an

assistant, remove

the

hinge

arm-to-hood bolts. Remove

the

hood from vehicle.

Page 1389 of 1502

23

- 6

BODY

COMPONENTS

•

INSTRUMENT

PANEL

COWL

PANEL

REGULATOR

BRACKET

J9123-437

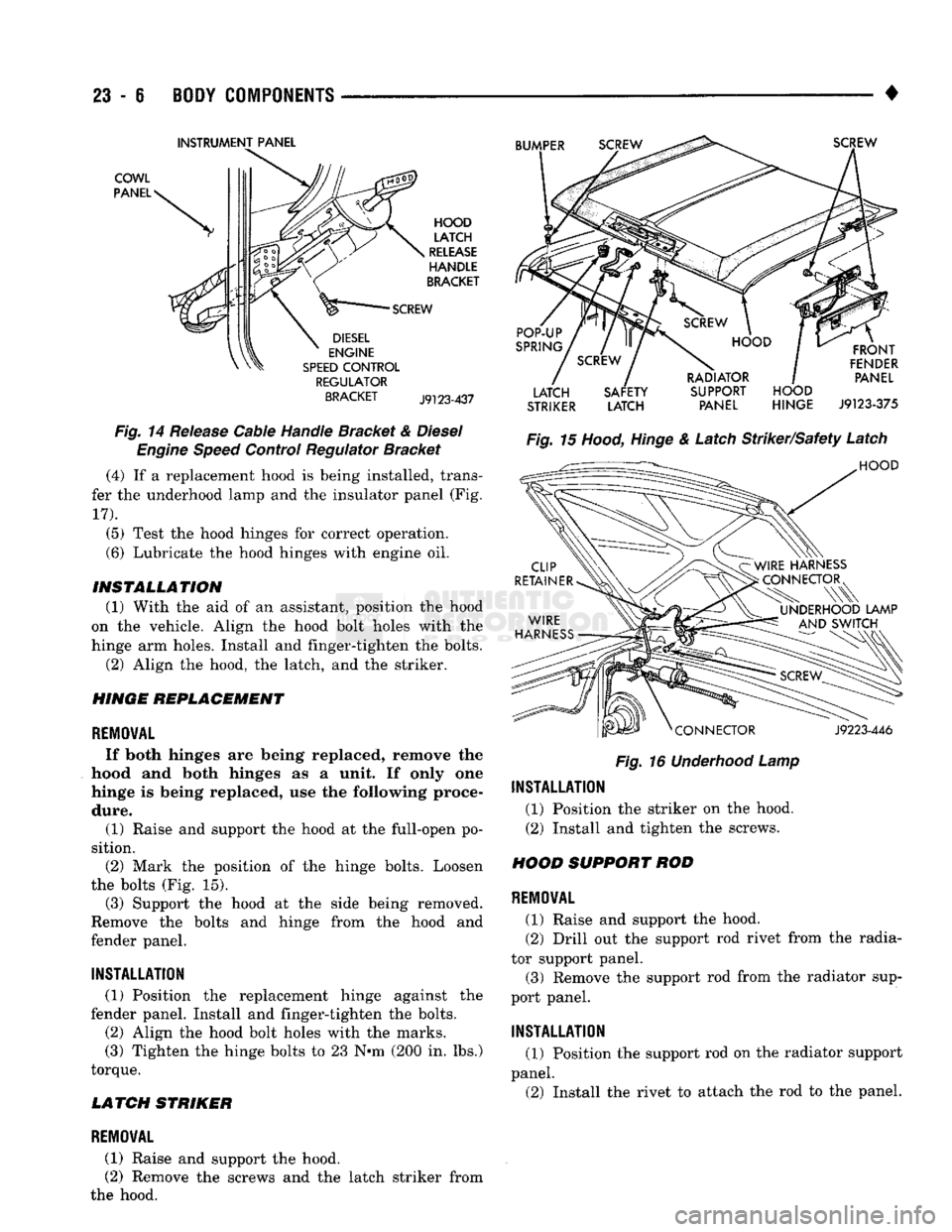

Fig.

14 Release Cable Handle Bracket &

Diesel

Engine

Speed

Control Regulator Bracket (4) If a replacement hood is being installed, trans

fer the underhood lamp and the insulator panel (Fig.

17).

(5) Test the hood hinges for correct operation.

(6) Lubricate the hood hinges with engine oil.

INSTALLATION

(1) With the aid of an assistant, position the hood

on the vehicle. Align the hood bolt holes with the

hinge arm holes. Install and finger-tighten the bolts. (2) Align the hood, the latch, and the striker.

HINGE

REPLACEMENT

REMOVAL

If both hinges are being replaced, remove the

hood and both hinges as a unit. If only one

hinge is being replaced, use the following proce dure. (1) Raise and support the hood at the full-open po

sition. (2) Mark the position of the hinge bolts. Loosen

the bolts (Fig. 15). (3) Support the hood at the side being removed.

Remove the bolts and hinge from the hood and

fender panel.

INSTALLATION

(1) Position the replacement hinge against the

fender panel. Install and finger-tighten the bolts. (2) Align the hood bolt holes with the marks.

(3) Tighten the hinge bolts to 23 N-m (200 in. lbs.)

torque.

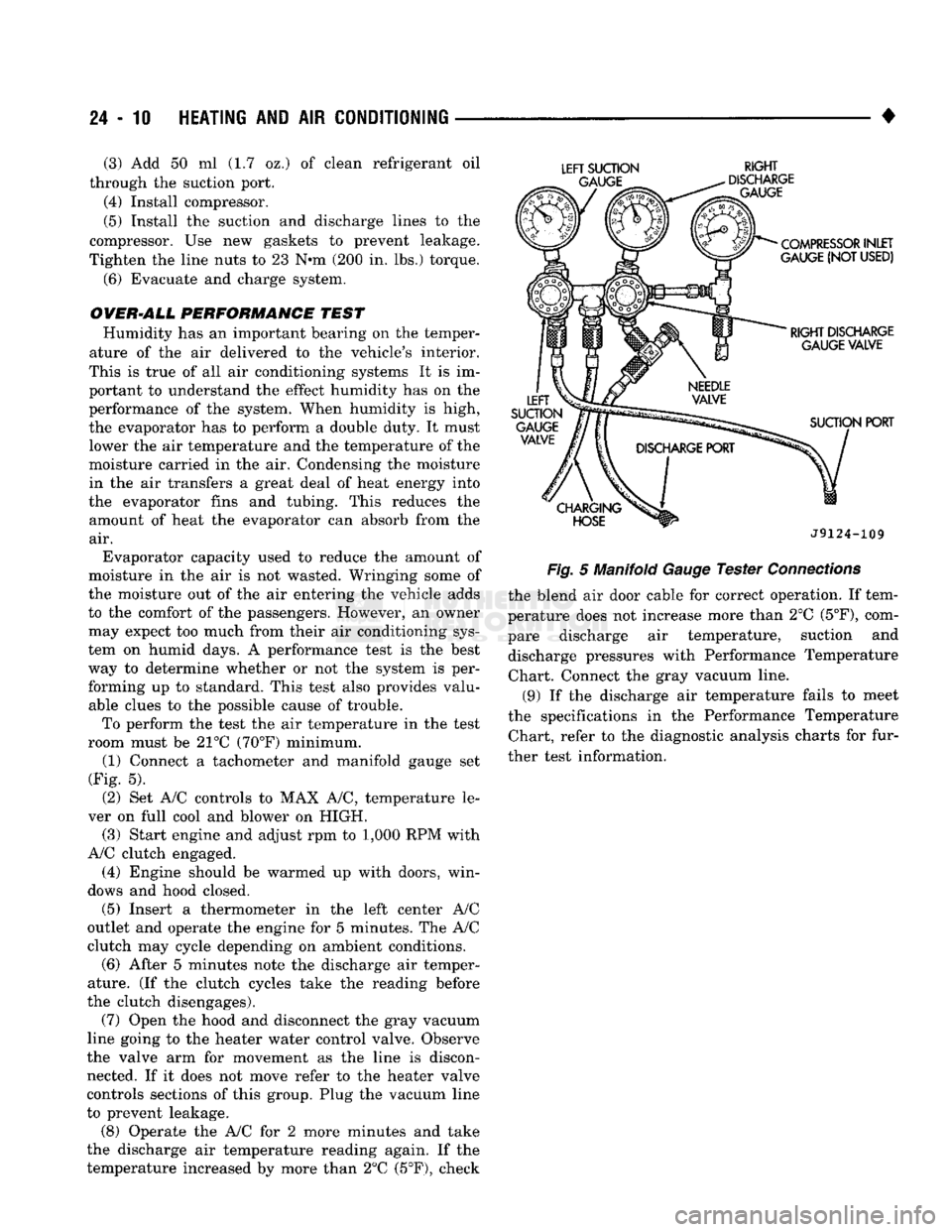

LATCH STRIKER

LATCH SAFETY SUPPORT HOOD

STRIKER

LATCH PANEL HINGE

J9123-375

Fig.

16

Underhood

Lamp

INSTALLATION

(1) Position the striker on the hood.

(2) Install and tighten the screws.

HOOD SUPPORT ROD

REMOVAL

(1) Raise and support the hood.

(2) Drill out the support rod rivet from the radia

tor support panel. (3) Remove the support rod from the radiator sup

port panel.

INSTALLATION

(1) Position the support rod on the radiator support

panel. (2) Install the rivet to attach the rod to the panel.

REMOVAL

(1) Raise and support the hood.

(2) Remove the screws and the latch striker from

the hood.

Page 1447 of 1502

24 - 10

HEATING

AND AIR

CONDITIONING

•

(3) Add 50 ml (1.7 oz.) of clean refrigerant oil

through the suction port.

(4) Install compressor.

(5) Install the suction and discharge lines to the

compressor. Use new gaskets to prevent leakage.

Tighten the line nuts to 23 N*m (200 in. lbs.) torque.

(6)

Evacuate and charge system.

OVER-ALL

PERFORMANCE

TEST

Humidity has an important bearing on the temper

ature of the air delivered to the vehicle's interior.

This is true of all air conditioning systems It is im

portant to understand the effect humidity has on the

performance of the system. When humidity is high,

the evaporator has to perform a double duty. It must lower the air temperature and the temperature of the

moisture carried in the air. Condensing the moisture

in the air transfers a great deal of heat energy into

the evaporator fins and tubing. This reduces the amount of heat the evaporator can absorb from the

air.

Evaporator capacity used to reduce the amount of

moisture in the air is not wasted. Wringing some of

the moisture out of the air entering the vehicle adds

to the comfort of the passengers. However, an owner may expect too much from their air conditioning sys

tem on humid days. A performance test is the best

way to determine whether or not the system is per

forming up to standard. This test also provides valu able clues to the possible cause of trouble.

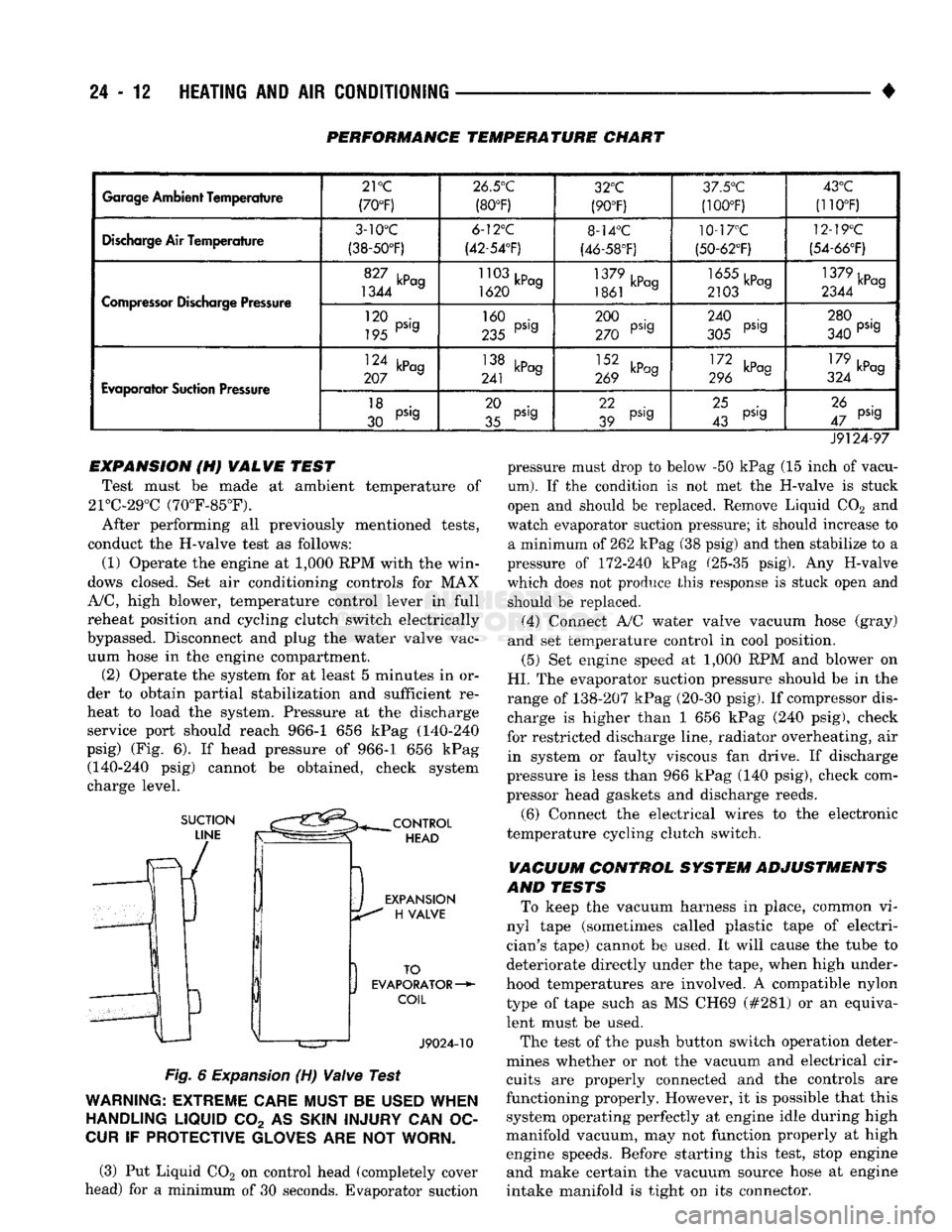

To perform the test the air temperature in the test

room must be 21°C (70°F) minimum. (1) Connect a tachometer and manifold gauge set

(Fig. 5).

(2) Set A/C controls to MAX A/C, temperature le

ver on full cool and blower on HIGH. (3) Start engine and adjust rpm to 1,000 RPM with

A/C clutch engaged.

(4) Engine should be warmed up with doors, win

dows and hood closed.

(5)

Insert a thermometer in the left center A/C

outlet and operate the engine for 5 minutes. The A/C

clutch may cycle depending on ambient conditions.

(6)

After 5 minutes note the discharge air temper

ature. (If the clutch cycles take the reading before

the clutch disengages).

(7) Open the hood and disconnect the gray vacuum

line going to the heater water control valve. Observe

the valve arm for movement as the line is discon nected. If it does not move refer to the heater valve

controls sections of this group. Plug the vacuum line

to prevent leakage.

(8) Operate the A/C for 2 more minutes and take

the discharge air temperature reading again. If the

temperature increased by more than 2°C (5°F), check

LEFT

SUCTION

RIGHT

J9124-109

Fig.

5 Manifold

Gauge

Tester

Connections

the blend air door cable for correct operation. If tem

perature does not increase more than 2°C

(5°F),

com

pare discharge air temperature, suction and discharge pressures with Performance Temperature Chart. Connect the gray vacuum line.

(9) If the discharge air temperature fails to meet

the specifications in the Performance Temperature Chart, refer to the diagnostic analysis charts for fur

ther test information.

Page 1449 of 1502

24-12

HEATING

AND AIR

CONDITIONING

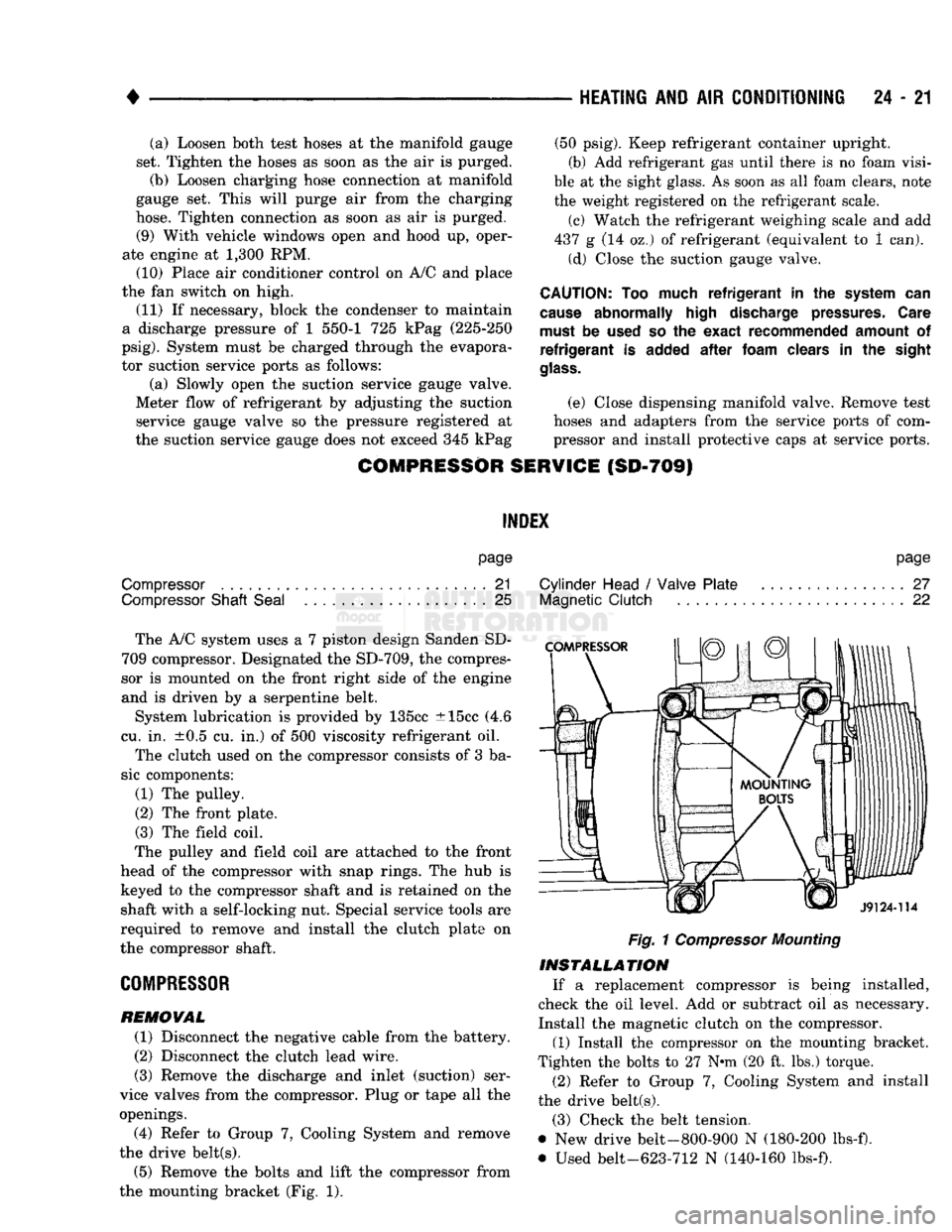

PERFORMANCE TEMPERATURE CHART

Garage

Ambient

Temperature

21

°C

(70°F) 26.5°C

(80°F) 32°C

(90°F) 3/.5°'J

(100T) 43°C

(110°F)

Discharge

Air Temperature

3-10°C

(38-50°F) 6-12°C

(42-54'F) 8-14°C

(46-58°F) 10-17°C

(50-62°F) 12-19°C

(54-66°F)

Compressor

Discharge Pressure

1344 a

1620 a

1861 kPag 2103 a 1379kPcg

2344 a

Compressor

Discharge Pressure

120 •

195 PS'9 160 .

235 PS'9 200 .

270 PS'9 240 .

305 PS'9 280 .

340 PS'9

Evaporator

Suction Pressure

124 kPag

207 a 138 kPag

241 J 269 kPag III kP°9

296 179 ,D

324 kPag

Evaporator

Suction Pressure

18 .

30 PS'9 20 .

35 pS'g 22

39 pS,g

25 .

43 pS'g 26 .

47 pS'9

J9124-97 pressure must drop to below -50 kPag (15 inch of vacu

um).

If the condition is not met the H-valve is stuck

open and should be replaced. Remove Liquid C02 and

watch evaporator suction pressure; it should increase to a minimum of 262 kPag (38 psig) and then stabilize to a

pressure of 172-240 kPag (25-35 psig). Any H-valve

which does not produce this response is stuck open and should be replaced.

(4) Connect A/C water valve vacuum hose (gray)

and set temperature control in cool position.

(5) Set engine speed at 1,000 RPM and blower on

HI.

The evaporator suction pressure should be in the

range of 138-207 kPag (20-30 psig). If compressor dis charge is higher than 1 656 kPag (240 psig), check

for restricted discharge line, radiator overheating, air in system or faulty viscous fan drive. If discharge

pressure is less than 966 kPag (140 psig), check com

pressor head gaskets and discharge reeds.

(6) Connect the electrical wires to the electronic

temperature cycling clutch switch.

VACUUM CONTROL SYSTEM ADJUSTMENTS

AND TESTS To keep the vacuum harness in place, common vi

nyl tape (sometimes called plastic tape of electri

cian's tape) cannot be used. It will cause the tube to

deteriorate directly under the tape, when high under

hood temperatures are involved. A compatible nylon type of tape such as MS CH69 (#281) or an equivalent must be used.

The test of the push button switch operation deter

mines whether or not the vacuum and electrical cir cuits are properly connected and the controls are

functioning properly. However, it is possible that this system operating perfectly at engine idle during high

manifold vacuum, may not function properly at high engine speeds. Before starting this test, stop engine and make certain the vacuum source hose at engine

intake manifold is tight on its connector.

EXPANSION (H) VALVE TEST

Test must be made at ambient temperature of

21°C-29°C (70°F-85°F).

After performing all previously mentioned tests,

conduct the H-valve test as follows:

(1) Operate the engine at 1,000 RPM with the win

dows closed. Set air conditioning controls for MAX

A/C,

high blower, temperature control lever in full

reheat position and cycling clutch switch electrically

bypassed. Disconnect and plug the water valve vac uum hose in the engine compartment. (2) Operate the system for at least 5 minutes in or

der to obtain partial stabilization and sufficient re

heat to load the system. Pressure at the discharge service port should reach 966-1 656 kPag (140-240

psig) (Fig. 6). If head pressure of 966-1 656 kPag (140-240 psig) cannot be obtained, check system

charge level.

Fig.

6

Expansion

(H)

Valve

Test

WARNING:

EXTREME

CARE

MUST

BE

USED

WHEN

HANDLING

LIQUID

C02 AS

SKIN

INJURY

CAN OC

CUR

IF

PROTECTIVE

GLOVES

ARE NOT

WORN.

(3) Put Liquid C02 on control head (completely cover

head) for a minimum of 30 seconds. Evaporator suction

Page 1458 of 1502

•

HEATING

AND AIR

CONDITIONING

24 - 21 (a) Loosen both test hoses at the manifold gauge

set. Tighten the hoses as soon as the air is purged. (b) Loosen charging hose connection at manifold

gauge set. This will purge air from the charging

hose.

Tighten connection as soon as air is purged.

(9) With vehicle windows open and hood up, oper

ate engine at 1,300 RPM. (10) Place air conditioner control on A/C and place

the fan switch on high. (11) If necessary, block the condenser to maintain

a discharge pressure of 1 550-1 725 kPag (225-250

psig).

System must be charged through the evapora

tor suction service ports as follows:

(a) Slowly open the suction service gauge valve.

Meter flow of refrigerant by adjusting the suction service gauge valve so the pressure registered at

the suction service gauge does not exceed 345 kPag

COMPRESSOR

J

(50

psig). Keep refrigerant container upright.

(b) Add refrigerant gas until there is no foam visi

ble at the sight glass. As soon as all foam clears, note the weight registered on the refrigerant scale.

(c) Watch the refrigerant weighing scale and add

437 g (14 oz.) of refrigerant (equivalent to 1 can).

(d) Close the suction gauge valve.

CAUTION:

TOO

much

refrigerant

in the

system

can

cause

abnormally high discharge pressures. Care

must

be

used

so the

exact recommended amount

of

refrigerant

is

added

after

foam clears

in the

sight

glass.

(e) Close dispensing manifold valve. Remove test

hoses and adapters from the service ports of com

pressor and install protective caps at service ports.

RVICE (SD-709)

INDEX

page

Compressor

21

Compressor

Shaft Seal

.................... 25

The A/C system uses a 7 piston design Sanden SD-

709 compressor. Designated the SD-709, the compres

sor is mounted on the front right side of the engine

and is driven by a serpentine belt.

System lubrication is provided by 135cc ±15cc (4.6

cu. in. ±0.5 cu. in.) of 500 viscosity refrigerant oil.

The clutch used on the compressor consists of 3 ba

sic components:

(1) The pulley.

(2) The front plate. (3) The field coil.

The pulley and field coil are attached to the front

head of the compressor with snap rings. The hub is keyed to the compressor shaft and is retained on the

shaft with a self-locking nut. Special service tools are

required to remove and install the clutch plate on

the compressor shaft.

COMPRESSOR

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Disconnect the clutch lead wire.

(3) Remove the discharge and inlet (suction) ser

vice valves from the compressor. Plug or tape all the

openings.

(4) Refer to Group 7, Cooling System and remove

the drive belt(s). (5) Remove the bolts and lift the compressor from

the mounting bracket (Fig. 1).

page

Cylinder Head

/

Valve Plate

27

Magnetic

Clutch

22

Fig.

1

Compressor

Mounting

INSTALLATION

If a replacement compressor is being installed,

check the oil level. Add or subtract oil as necessary.

Install the magnetic clutch on the compressor.

(1) Install the compressor on the mounting bracket.

Tighten the bolts to 27 N*m (20 ft. lbs.) torque.

(2) Refer to Group 7, Cooling System and install

the drive belt(s).

(3) Check the belt tension.

@ New drive belt-800-900 N (180-200 lbs-f).

• Used belt-623-712 N (140-160 lbs-f).