bulb DODGE TRUCK 1993 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 454 of 1502

•

LAMPS

8L - 11

BULB

APPLICATION

GENERAL

INFORMATION

The following Bulb Application Table lists

the

lamp title

on the

left side

of the

column

and

part

number

on the

right.

CAUTION:

Do not use

bulbs

that

have

a

higher

can

dle power than

the

bulb

listed

in the

Bulb

Applica

tion Table.

Damage

to

lamp

can

result.

EXTERIOR LAMPS

Auxiliary Turn Signal (Snow Plow) 2057

Auxiliary Headlamps (Snow Plow) .6054

Back-up....................... .......1156 Cargo Lamp..

922

Clearance Lamps

194

Front Side Marker

168

Headlamp/Sealed Beam .6052

License Plate

168

Park/Turn Signal 2057

TaiyStop/Turn Signal ...2057

INTERIOR LAMPS

DIMMER CONTROLLED LAMPS Service procedures

for

most

of the

lamps

in the in

strument panel

are

located

in

Group

8E,

Instrument

Panel

and

Gauges. Some components have lamps

that

can

only

be

serviced

by an

Authorized Service Center (ASC). These components must

be

removed

from

the

vehicle

for

service. Contact local dealer

for

location

of

nearest

ASC.

A/C Heater Control

158

Ash Receiver

..158

Gear Shift Selector...........................................PC194

Heater Control

158

Instrument Cluster.. PC 194

Radio

ASC

Snow Plow Control

.158

INDICATOR LAMPS Service procedures

for

most

of the

lamps

in the in

strument panel,

and

switches

are

located

in

Group

8E,

Instrument Panel

and

Gauges. Anti-lock Brake PC194

Brake Warning PC194 Check Engine PC194

Engine

Oil

Pressure

158

Fasten Seat Belts.. PC 194 Four Wheel Drive ....158

Hazard Flasher

194

High Beam PC194

Low Fuel....... JPC194

Maintenance Required PC 194

Transmission Temperature ..PC 194 Turn Signal PC194

NON-DIMMING LAMPS Service procedures

for

most

of the

lamps

in the

fol

lowing list

can be

found

in

Group

23,

Body.

Dome

1004

Engine Compartment ...105 Glove Compartment....

1891

Ignition Lock

ASC

Reading Lamp

912

Page 457 of 1502

8N

- 2

REAR WINDOW DEFOGGER

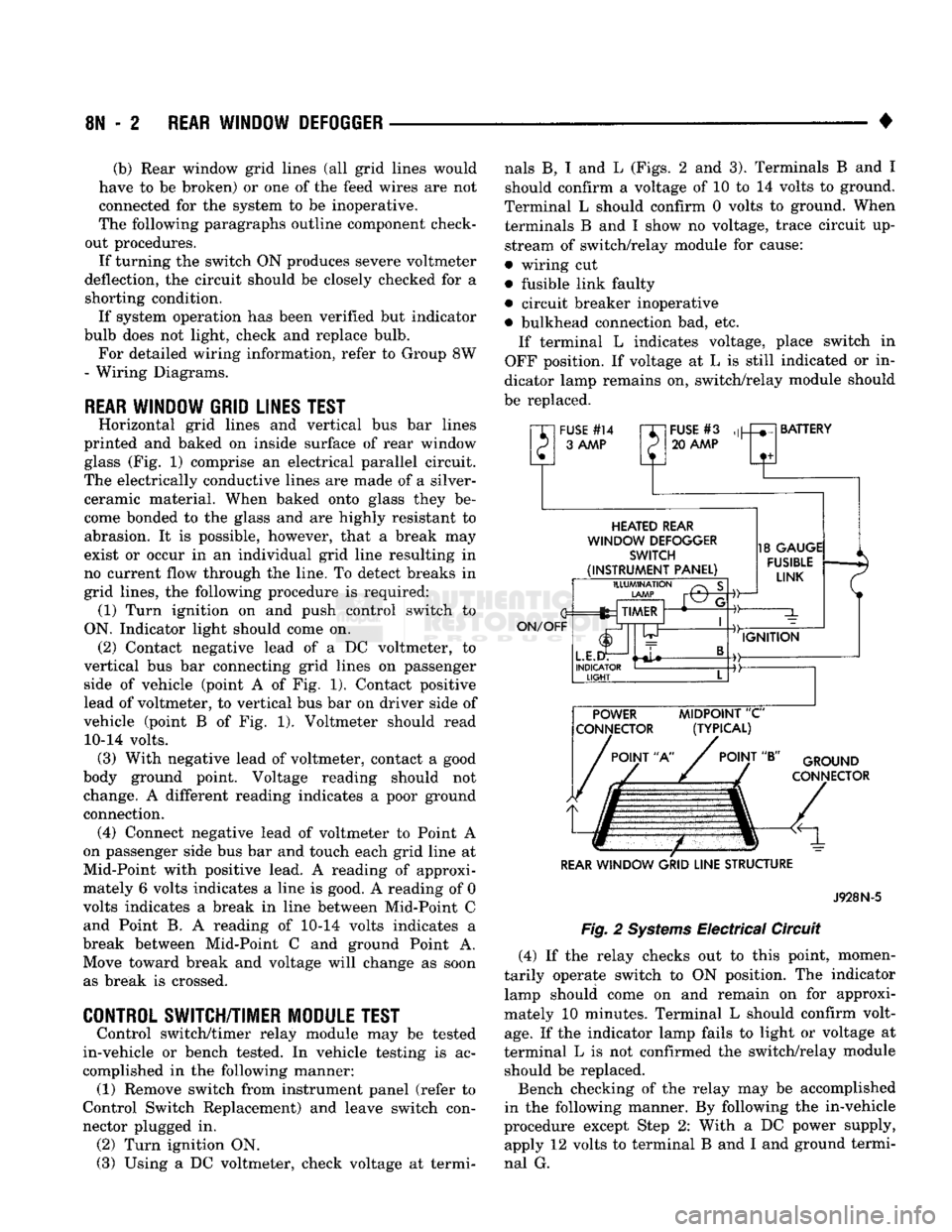

• (b) Rear window grid lines (all grid lines would

have to be broken) or one of the feed wires are not

connected for the system to be inoperative.

The following paragraphs outline component check

out procedures.

If turning the switch ON produces severe voltmeter

deflection, the circuit should be closely checked for a shorting condition. If system operation has been verified but indicator

bulb does not light, check and replace bulb.

For detailed wiring information, refer to Group 8W

- Wiring Diagrams.

REAR

WINDOW GRID LINES TEST

Horizontal grid lines and vertical bus bar lines

printed and baked on inside surface of rear window glass (Fig. 1) comprise an electrical parallel circuit.

The electrically conductive lines are made of a silver- ceramic material. When baked onto glass they be

come bonded to the glass and are highly resistant to abrasion. It is possible, however, that a break may

exist or occur in an individual grid line resulting in

no current flow through the line. To detect breaks in

grid lines, the following procedure is required: (1) Turn ignition on and push control switch to

ON. Indicator light should come on. (2) Contact negative lead of a DC voltmeter, to

vertical bus bar connecting grid lines on passenger side of vehicle (point A of Fig. 1). Contact positive

lead of voltmeter, to vertical bus bar on driver side of

vehicle (point B of Fig. 1). Voltmeter should read 10-14 volts. (3) With negative lead of voltmeter, contact a good

body ground point. Voltage reading should not change. A different reading indicates a poor ground connection. (4) Connect negative lead of voltmeter to Point A

on passenger side bus bar and touch each grid line at

Mid-Point with positive lead. A reading of approxi mately 6 volts indicates a line is good. A reading of 0

volts indicates a break in line between Mid-Point C and Point B. A reading of 10-14 volts indicates a

break between Mid-Point C and ground Point A. Move toward break and voltage will change as soon as break is crossed.

CONTROL SWITCH/TIMER MODULE TEST

Control switch/timer relay module may be tested

in-vehicle or bench tested. In vehicle testing is ac

complished in the following manner: (1) Remove switch from instrument panel (refer to

Control Switch Replacement) and leave switch con

nector plugged in. (2) Turn ignition ON.

(3) Using a DC voltmeter, check voltage at termi nals B, I and L (Figs. 2 and 3). Terminals B and I

should confirm a voltage of 10 to 14 volts to ground.

Terminal L should confirm 0 volts to ground. When terminals B and I show no voltage, trace circuit up

stream of switch/relay module for cause:

• wiring cut

• fusible link faulty

• circuit breaker inoperative

• bulkhead connection bad, etc. If terminal L indicates voltage, place switch in

OFF position. If voltage at L is still indicated or in

dicator lamp remains on, switch/relay module should

be replaced.

"XI

FUSE

#14

rr~

P 3

AAAP

P

FUSE

#3

20

AAAP

BATTERY

HEATED

REAR

WINDOW

DEFOGGER

SWITCH

(INSTRUMENT

PANEL)

ON/OFF

ILLUMINATION

LAMP

fez TIMER

L.E.I

INDICATOR

LIGHT

-©-

18

GAUGE

FUSIBLE

LINK

IGNITION POWER

MIDPOINT

"C"

CONNECTOR (TYPICAL)

POINT

"A"

POINT

"B"

GROUND

CONNECTOR

REAR

WINDOW

GRID

LINE

STRUCTURE

Fig.

2

Systems

Electrical Circuit

J928N-5

(4) If the relay checks out to this point, momen

tarily operate switch to ON position. The indicator lamp should come on and remain on for approxi

mately 10 minutes. Terminal L should confirm volt

age.

If the indicator lamp fails to light or voltage at

terminal L is not confirmed the switch/relay module should be replaced.

Bench checking of the relay may be accomplished

in the following manner. By following the in-vehicle

procedure except Step 2: With a DC power supply, apply 12 volts to terminal B and I and ground termi

nal G.

Page 469 of 1502

8T - 2

POWER MIRRORS

•

MIRROR

SWITCH TEST PROCEDURE

(1) Remove power mirror switch from mounting

position (refer to Service Procedures). (2) Disconnect wiring harness at switch connector.

(3) Test for continuity (no resistance) between the

terminals of the switch as shown in the MIRROR SWITCH CONTINUITY CHART. (4) If results shown in the chart are not obtained,

replace the switch.

MIRROR

SWITCH

CONTINUITY

CHART

MIRROR SELECTOR KNOB

IN

"L"

POSITION Move

Lever Continuity Between

WT

and BK

YL

and

PK

and

YL/BK

and PK

WT

and

PK,

DB/WT

and

BK

and

DB

&

BK

YL/BK

and

BK, YL

and

BK WT and PK

WT

and

BK, DB/WT

and PK

DB

and

PK

MIRROR SELECTOR KNOB

IN "R"

POSITION Move

Lever Continuity Between

WT/BK

and

BK,

YL and PK

YL/BK

and PK

•

WT/BK

and

PK, DB

and

BK

DB/WT

and

BK

WT/BK

and

PK, YL

and

BK

YL/BK

and

BK

«

WT/BK

and

BK, DB

and PK

DB/WT

and PK

J928T-6

SERVICE PROCEDURES

MIRROR

SWITCH REMOVAL AND INSTALLATION

(1) Disconnect negative cable from battery.

(2) Remove 2 screws holding map lamp and re

move map lamp. (3) Remove 6 screws which attach instrument clus

ter bezel to instrument panel (Fig. 2). Make sure the screw below the Heater/C control is removed.

INSTRUMENT

CLUSTER

BEZEL

J938E-51

Fig.

2 Instrument

Cluster

Bezel

(4) Place column shift lever in Position 1. (5) Remove bezel by pulling top edge rearward to

clear brow. Disengage attaching clips around bottom

of bezel and complete removal of bezel.

(6) If the bezel has a four wheel drive indicator, re

move bulb socket as bezel is removed. (7) Disconnect message center wires.

(8) Remove instrument cluster bezel assembly.

(9) Pull headlamp switch to ON position.

(10) Reach under instrument panel and depress

button on side of switch while pulling stem out.

(11) Remove switch bezel retaining screws and pull

bezel out of instrument panel (Fig. 1). (12) Pull harness out through opening in instru

ment panel and disconnect mirror switch connector.

(13) Remove 2 switch mounting-plate-to-bezel re

taining screws.

(14) Remove switch-to-mounting-plate nut.

For Installation, reverse removal procedures.

MIRROR

ASSEMBLY

REMOVAL

AND

INSTALLATION

(1) Remove remote control handle (Fig. 3).

(2) Remove power window/lock switch by inserting

a standard blade screwdriver into notch on forward

end of switch housing and push to depress locking

tab.

Pull out and forward to remove switch bezel

from door panel.

Page 473 of 1502

8U

- 2

CHIME/BUZZER

WARNING SYSTEMS

•

TERMINAL

7

TO

B

+

TERMINAL

6

TO DOOR SWITCH

KEY

IN

SWITCH

AND

HEADLAMP

ON

SWITCH

!cO=f

Mi c£K

*£h

• CZ3

EZZ3

EZI 1

TERMINAL

4

TO SEAT BELT

BUCKLE SWITCH TERMINAL

1

TO

IGNITION

SWITCH

TERMINAL

3

TO GROUND TERMINAL

2

TO SEAT BELT

WARNING

LIGHT

J928U-12

Fig.

2

Buzzer

Module

Connector

Terminal

Identification—Front

View

LIGHTS-ON/KEY-IN-IGNITION

WARNING

BATTERY

(+)

IS SI S K|

IGNITION

SEAT BELT

WARNING

LIGHT

GROUND SEAT BELT

SWITCH

J928U-9

Fig.

3

Buzzer

Module

Terminal

Identification—Front

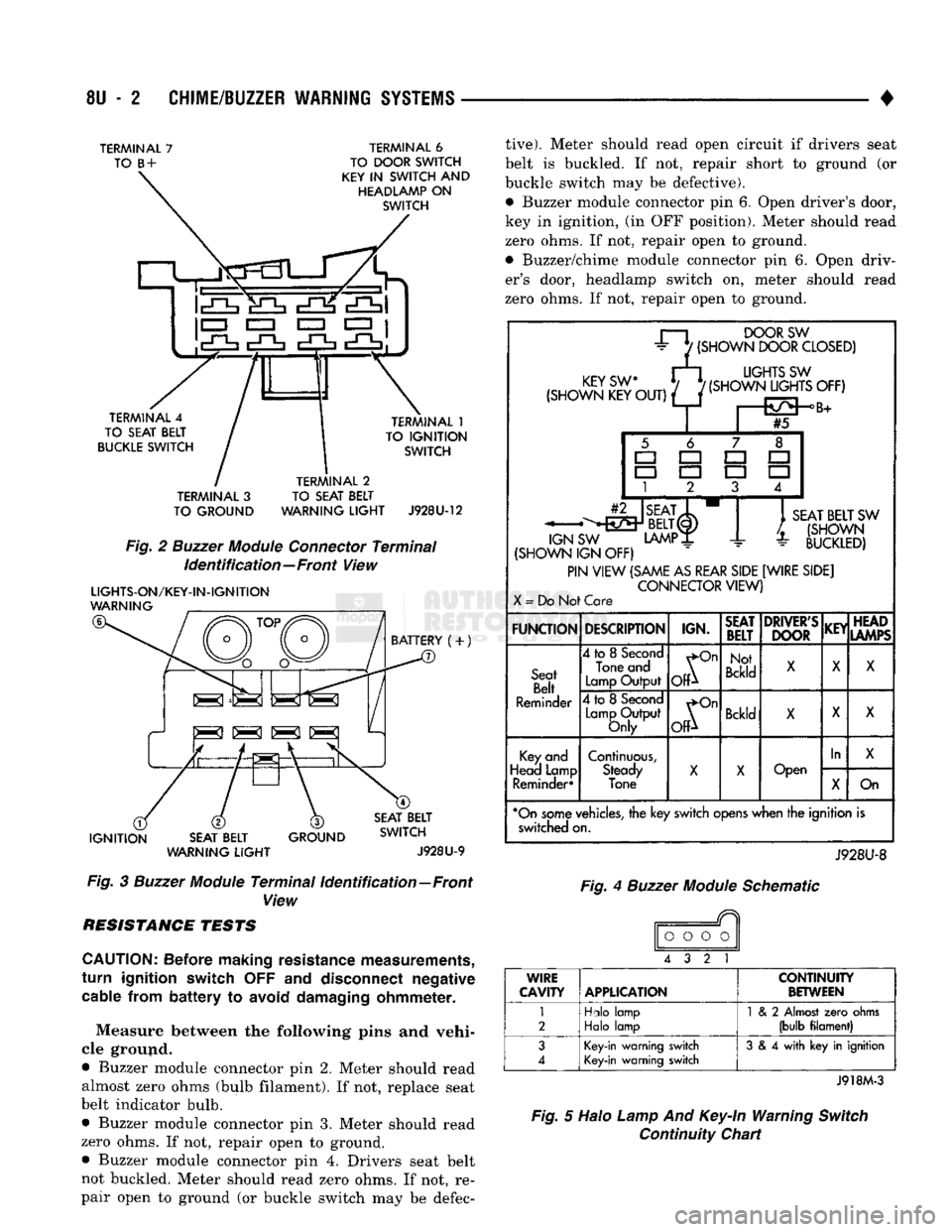

View RESISTANCE TESTS

CAUTION:

Before making resistance measurements,

turn

ignition switch

OFF and

disconnect negative cable from

battery

to

avoid damaging ohmmeter.

Measure between the following pins and vehi

cle ground.

• Buzzer module connector pin 2. Meter should read almost zero ohms (bulb filament). If not, replace seat

belt indicator bulb.

• Buzzer module connector pin 3. Meter should read

zero ohms. If not, repair open to ground. • Buzzer module connector pin 4. Drivers seat belt

not buckled. Meter should read zero ohms. If not, re

pair open to ground (or buckle switch may be defec

tive).

Meter should read open circuit if drivers seat

belt is buckled. If not, repair short to ground (or buckle switch may be defective).

• Buzzer module connector pin 6. Open driver's door,

key in ignition, (in OFF position). Meter should read

zero ohms. If not, repair open to ground.

• Buzzer/chime module connector pin 6. Open driv

er's door, headlamp switch on, meter should read

zero ohms. If not, repair open to ground.

r—i

DOORSW

±

7

(SHOWN

DOOR

CLOSED)

rFY<;w M

UGHTS

SW

(SHOWN

KEW/

f(SHOWN^JGHTS

OFF)

#5 -^•^Y

BELT(I)

SW

LAMP

JL

SEAT

BELT

SW

/.

(SHOWN

-

BUCKLED)

IGN

SW

(SHOWN

IGN OFF)

PIN

VIEW

(SAME

AS

REAR

SIDE

[WIRE

SIDE]

CONNECTOR

VIEW)

X

=

Do Not Care

FUNCTION

DESCRIPTION

IGN.

SEAT

BELT

DRIVER'S

DOOR

KEY

HEAD

LAMPS

Seat

Belt

Reminder

4

to

8

Second

Tone and

Lamp

Output

^On

OP

Not

Bckld

X

X

X

Seat

Belt

Reminder

4

to

8

Second

Lamp

Output

Only

^On

OfP

Bckld

X X

X

Key

and

Head Lamp Reminder*

Continuous,

Steady

Tone

X

X

Open

In

X

Key

and

Head Lamp Reminder*

Continuous,

Steady

Tone

X

X

Open

X

On

*On

some

vehicles,

the key

switch

opens

when the ignition is switched on.

J928U-8

Fig.

4

Buzzer

Module

Schematic

o

o o o

4 3 2 1

WIRE

CAVITY APPLICATION

CONTINUITY

BETWEEN

1

2

Hdo

lamp

Halo

lamp

1

& 2

Almost

zero

ohms

(bulb

filament)

3

4

Key-in

warning switch

Key-in

warning switch

3

& 4

with

key in ignition

J918M-3

Fig.

5 Halo

Lamp

And

Key-In

Warning

Switch

Continuity Chart

Page 573 of 1502

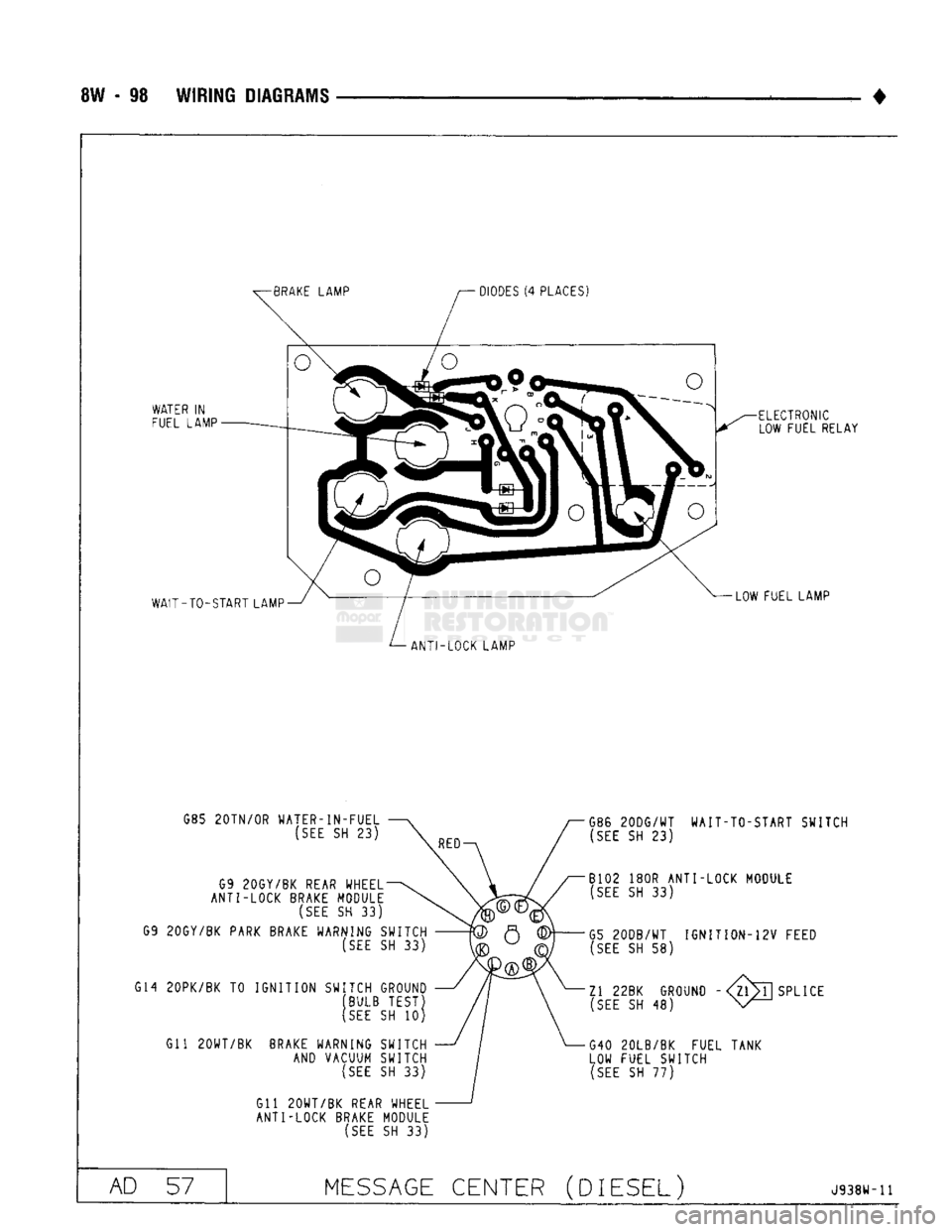

G85 20TN/0R WATER-IN-FUEL

(SEE

SH 23) G9 20GY/BK REAR WHEEL

ANTI-LOCK BRAKE MODULE

(SEE

SH 33)

G9 20GY/BK PARK BRAKE WARNING SWITCH

(SEE

SH 33

G14 20PK/BK TO IGNITION SWITCH GROUND BULB TEST)

(SEE

SH 10)

Gil 20WT/BK

BRAKE

WARNING SWITCH

AND VACUUM SWITCH

(SEE

SH 33)

Gil 20WT/BK REAR WHEEL

ANTI-LOCK BRAKE MODULE

(SEE

SH 33) G86 20DG/WT WAIT-TO-START SWITCH

(SEE

SH 23)

B102 180R ANTI-LOCK MODULE

(SEE

SH 33)

G5 20DB/WT IGNITION-12V FEED

(SEE

SH 58)

Zl 22BK GROUND -

SEE

SH 48)

G40 20LB/BK FUEL TANK

LOW FUEL SWITCH

(SEE

SH 77) AD 57

MESSAGE

CENTER

(DIESEL)

J938W-11

Page 789 of 1502

13 - 2

FRAME

AND

BUMPERS

•

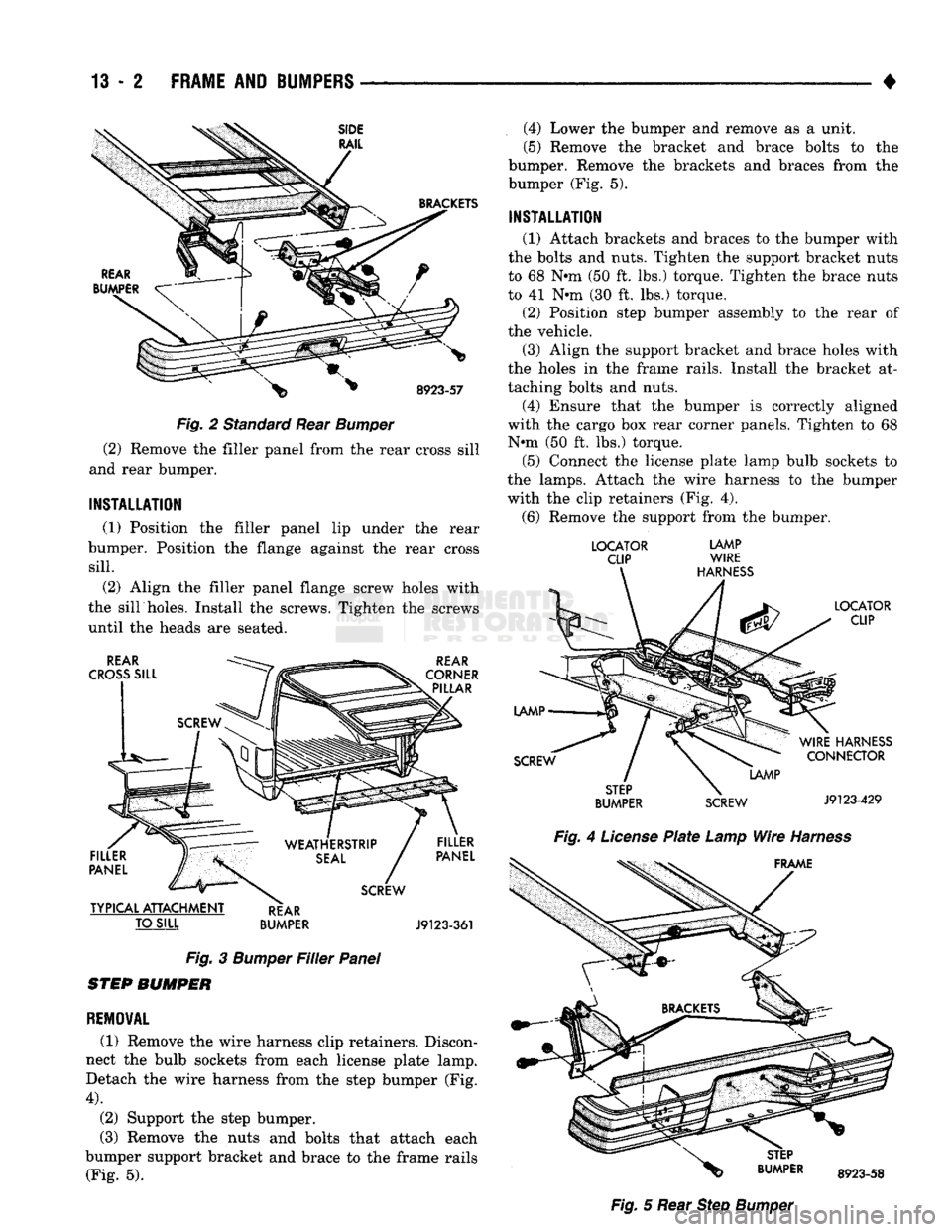

Fig. 2 Standard Rear Bumper

(2) Remove the filler panel from the rear cross sill

and rear bumper.

INSTALLATION

(1) Position the filler panel lip under the rear

bumper. Position the flange against the rear cross

sill.

(2) Align the filler panel flange screw holes with

the sill holes. Install the screws. Tighten the screws

until the heads are seated.

TO SILL

BUMPER J9123-361

Fig. 3 Bumper Filler Panel

STEP BUMPER

REMOVAL

(1) Remove the wire harness clip retainers. Discon

nect the bulb sockets from each license plate lamp.

Detach the wire harness from the step bumper (Fig.

4).

(2) Support the step bumper.

(3) Remove the nuts and bolts that attach each

bumper support bracket and brace to the frame rails (Fig. 5). (4) Lower the bumper and remove as a unit.

(5) Remove the bracket and brace bolts to the

bumper. Remove the brackets and braces from the

bumper (Fig. 5).

INSTALLATION

(1) Attach brackets and braces to the bumper with

the bolts and nuts. Tighten the support bracket nuts

to 68 N*m (50 ft. lbs.) torque. Tighten the brace nuts

to 41 N»m (30 ft. lbs.) torque.

(2) Position step bumper assembly to the rear of

the vehicle.

(3) Align the support bracket and brace holes with

the holes in the frame rails. Install the bracket at

taching bolts and nuts. (4) Ensure that the bumper is correctly aligned

with the cargo box rear corner panels. Tighten to 68 N«m (50 ft. lbs.) torque.

(5) Connect the license plate lamp bulb sockets to

the lamps. Attach the wire harness to the bumper

with the clip retainers (Fig. 4). (6) Remove the support from the bumper.

LOCATOR

LAMP

CLIP WIRE

BUMPER SCREW J9123429

Fig. 4 License Plate Lamp Wire Harness Fig. 5 Rear Step Bumper

Page 856 of 1502

•

FUEL SYSTEM

14 - 37 used only on vehicles equipped with the 5.9L heavy

duty cycle (HDC) engine. Refer to Group 25, Emis

sion Control System for information.

EVAP CANISTER PURGE SOLENOID-PCM

OUTPUT

Refer to Group 25, Emission Control System. See

EVAP Canister Purge Solenoid.

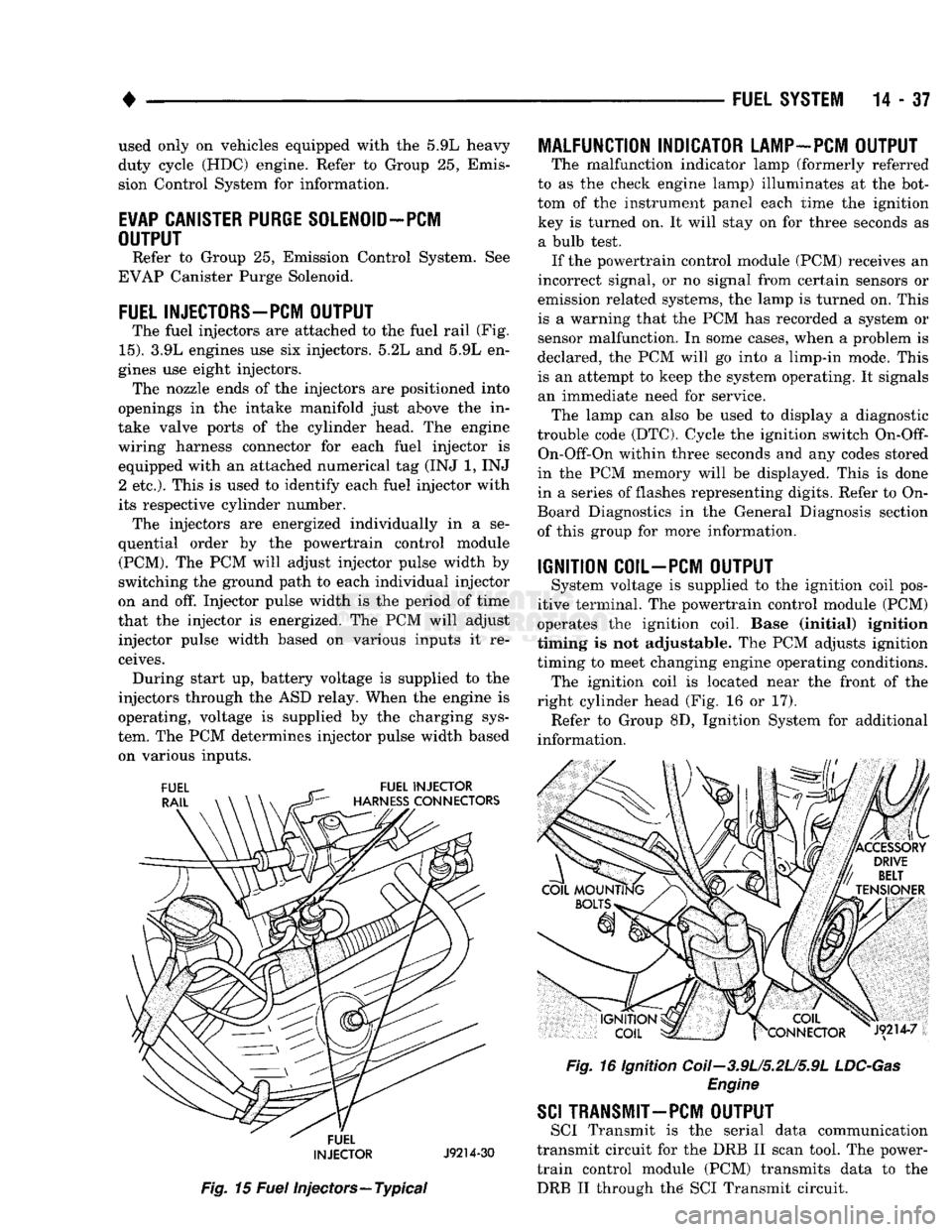

FUEL INJECTORS-PCM

OUTPUT

The fuel injectors are attached to the fuel rail (Fig.

15).

3.9L engines use six injectors. 5.2L and 5.9L en

gines use eight injectors. The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the in

take valve ports of the cylinder head. The engine

wiring harness connector for each fuel injector is equipped with an attached numerical tag (INJ 1, INJ 2 etc.). This is used to identify each fuel injector with

its respective cylinder number. The injectors are energized individually in a se

quential order by the powertrain control module (PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust injector pulse width based on various inputs it re

ceives. During start up, battery voltage is supplied to the

injectors through the ASD relay. When the engine is

operating, voltage is supplied by the charging sys

tem. The PCM determines injector pulse width based on various inputs.

FUEL

INJECTOR

J9214-30

Fig.

15

Fuel

injectors—Typical

MALFUNCTION INDICATOR LAMP-PCM OUTPUT

The malfunction indicator lamp (formerly referred

to as the check engine lamp) illuminates at the bot

tom of the instrument panel each time the ignition key is turned on. It will stay on for three seconds as a bulb test. If the powertrain control module (PCM) receives an

incorrect signal, or no signal from certain sensors or

emission related systems, the lamp is turned on. This

is a warning that the PCM has recorded a system or

sensor malfunction. In some cases, when a problem is

declared, the PCM will go into a limp-in mode. This

is an attempt to keep the system operating. It signals an immediate need for service. The lamp can also be used to display a diagnostic

trouble code (DTC). Cycle the ignition switch

On-Off-

On-Off-On within three seconds and any codes stored

in the PCM memory will be displayed. This is done

in a series of flashes representing digits. Refer to On-

Board Diagnostics in the General Diagnosis section

of this group for more information.

IGNITION COIL-PCM OUTPUT

System voltage is supplied to the ignition coil pos

itive terminal. The powertrain control module (PCM)

operates the ignition coil. Base (initial) ignition

timing is not adjustable. The PCM adjusts ignition

timing to meet changing engine operating conditions. The ignition coil is located near the front of the

right cylinder head (Fig. 16 or 17). Refer to Group 8D, Ignition System for additional

information.

Fig.

16 Ignition Coii-3.9U5.2U5.9L

LDC-Gas

Engine

SCI

TRANSMIT—PCM OUTPUT

SCI Transmit is the serial data communication

transmit circuit for the DRB II scan tool. The power- train control module (PCM) transmits data to the DRB II through the SCI Transmit circuit.

Page 901 of 1502

14 - 82

FUEL 'SYSTEM

—. — ~—— — «

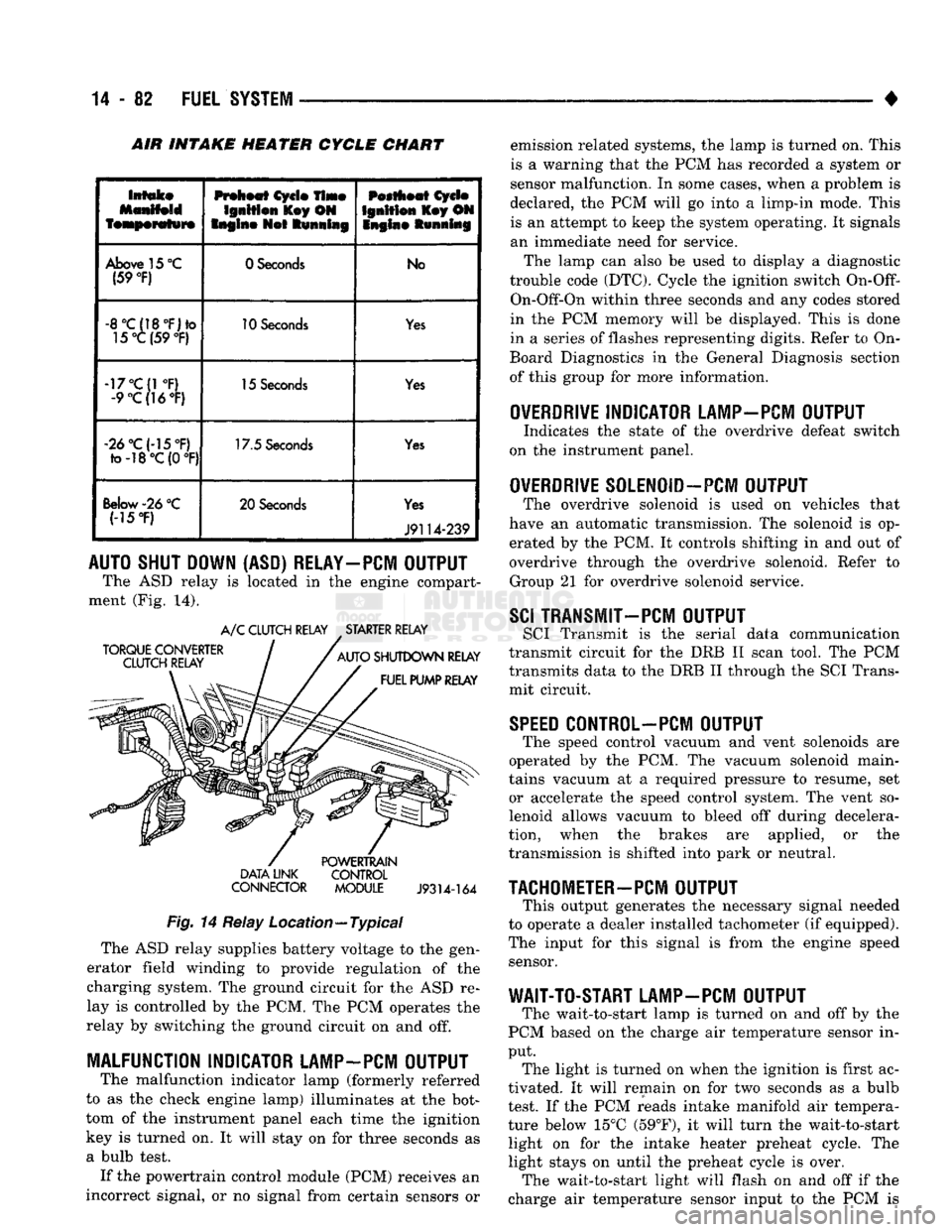

INTAKE HEATER CYCLE CHART

Intake

featperafwre

Preheat

Cycle

Time

Ignition

l£ey ON

Engine

Not

Running

Pestheat

Cycle

Ignition

Key ON

Snglne Running

Above

15

°C

(59

°F)

0 Seconds

No

-8°C(18°F)to

15°C (59

°F)

10

Seconds

Yes

-17°C(1

°F)

-9

°C(]6°F)

15

Seconds

Yes

«2d°C(-15°F)

to-18°C(0

°F) 17.5

Seconds

Yes

Below-26

°C (-15

*F)

20 Seconds

Yes

J9114-239

AUTO SHUT DOWN (ASD) RELAY-PCM OUTPUT

The ASD relay is located in the engine compart

ment (Fig. 14).

TORQUE CONVERTER

CLUTCH RELAY A/C CLUTCH RELAY STARTER RELAY

AUTO SHUTDOWN RELAY FUEL PUMP RELAY DATA LINK

CONNECTOR

POWERTRAIN

CONTROL MODULE

J9314-164

Fig.

14 Relay Location—Typical The ASD relay supplies battery voltage to the gen

erator field winding to provide regulation of the

charging system. The ground circuit for the ASD re

lay is controlled by the PCM. The PCM operates the

relay by switching the ground circuit on and off.

MALFUNCTION INDICATOR LAMP-PCM OUTPUT

The malfunction indicator lamp (formerly referred

to as the check engine lamp) illuminates at the bot

tom of the instrument panel each time the ignition

key is turned on. It will stay on for three seconds as

a bulb test. If the powertrain control module (PCM) receives an

incorrect signal, or no signal from certain sensors or emission related systems, the lamp is turned on. This

is a warning that the PCM has recorded a system or

sensor malfunction. In some cases, when a problem is

declared, the PCM will go into a limp-in mode. This is an attempt to keep the system operating. It signals

an immediate need for service.

The lamp can also be used to display a diagnostic

trouble code (DTC). Cycle the ignition switch

On-Off-

On-Off-On within three seconds and any codes stored

in the PCM memory will be displayed. This is done

in a series of flashes representing digits. Refer to On-

Board Diagnostics in the General Diagnosis section

of this group for more information.

OVERDRIVE

INDICATOR LAMP-PCM OUTPUT

Indicates the state of the overdrive defeat switch

on the instrument panel.

OVERDRIVE

S0LEN0ID-PCM OUTPUT

The overdrive solenoid is used on vehicles that

have an automatic transmission. The solenoid is op erated by the PCM. It controls shifting in and out of

overdrive through the overdrive solenoid. Refer to Group 21 for overdrive solenoid service.

SCI

TRANSMIT—PCM OUTPUT

SCI Transmit is the serial data communication

transmit circuit for the DRB II scan tool. The PCM

transmits data to the DRB II through the SCI Trans

mit circuit.

SPEED

C0NTR0L-PCM OUTPUT

The speed control vacuum and vent solenoids are

operated by the PCM. The vacuum solenoid main

tains vacuum at a required pressure to resume, set or accelerate the speed control system. The vent so

lenoid allows vacuum to bleed off during decelera

tion, when the brakes are applied, or the

transmission is shifted into park or neutral.

TACHOMETER-PCM

OUTPUT

This output generates the necessary signal needed

to operate a dealer installed tachometer (if equipped).

The input for this signal is from the engine speed sensor.

WAIT-TO-START LAMP-PCM OUTPUT

The wait-to-start lamp is turned on and off by the

PCM based on the charge air temperature sensor in

put. The light is turned on when the ignition is first ac

tivated. It will remain on for two seconds as a bulb

test. If the PCM reads intake manifold air tempera

ture below 15°C (59°F), it will turn the wait-to-start light on for the intake heater preheat cycle. The

light stays on until the preheat cycle is over. The wait-to-start light will flash on and off if the

charge air temperature sensor input to the PCM is

Page 905 of 1502

14-86

FUEL

SYSTEM

WARNING:

USE

EXTREME CAUTION WHEN

IN

SPECTING

FOR

HIGH

PRESSURE

FUEL

LEAKS.

IN

SPECT

FOR

HIGH

PRESSURE

FUEL

LEAKS

WITH

A

SHEET

OF

CARDBOARD. HIGH FUEL INJECTION

PRESSURE

CAN

CAUSE PERSONAL INJURY

IF

CONTACT

IS

MADE

WITH

THE

SKIN.

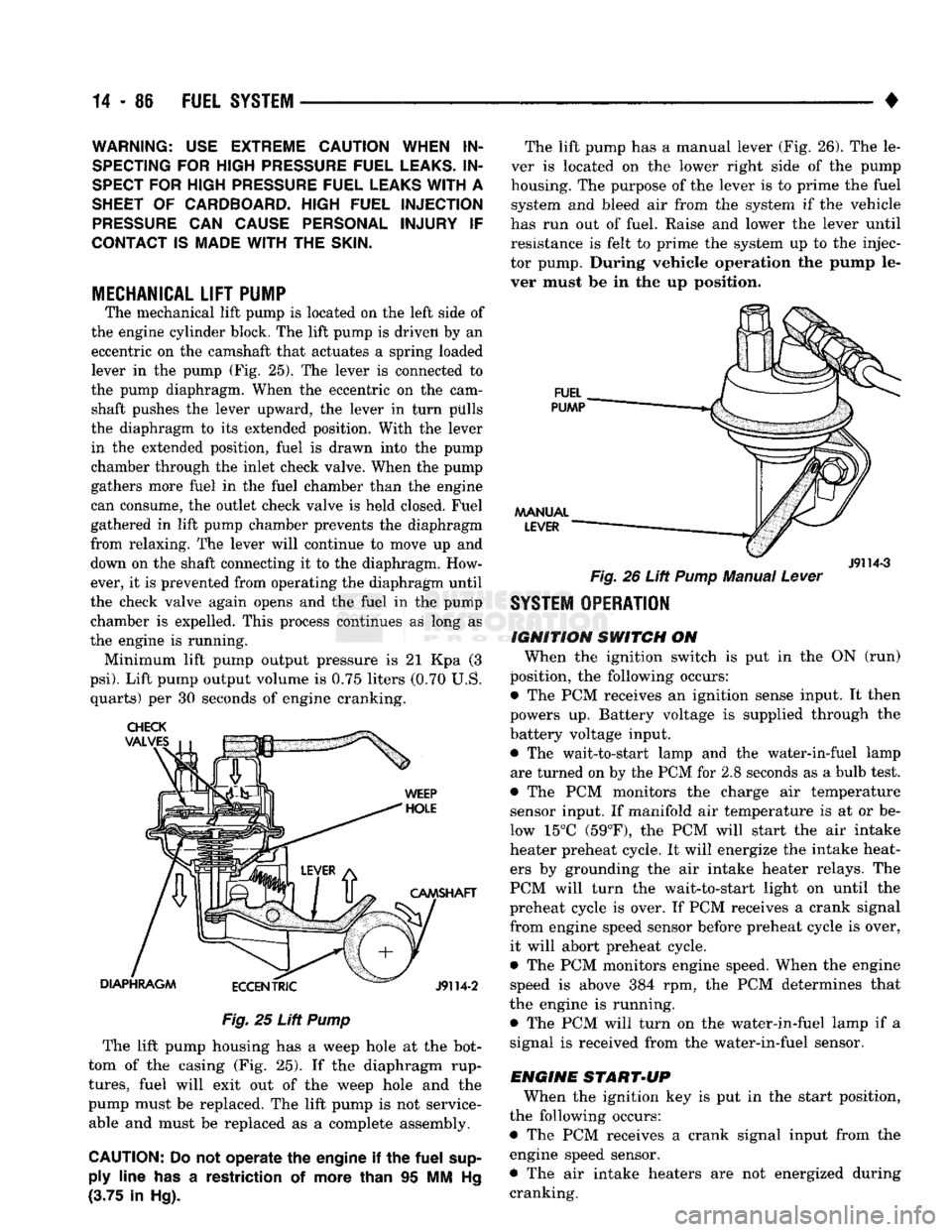

MECHANICAL

LIFT

PUMP

The mechanical lift pump

is

located

on the

left side

of

the engine cylinder block.

The

lift pump

is

driven

by an

eccentric

on the

camshaft that actuates

a

spring loaded lever

in the

pump

(Fig. 25). The

lever

is

connected

to

the pump diaphragm. When

the

eccentric

on the

cam shaft pushes

the

lever upward,

the

lever

in

turn pulls

the diaphragm

to its

extended position. With

the

lever in

the

extended position, fuel

is

drawn into

the

pump

chamber through

the

inlet check valve. When

the

pump

gathers more fuel

in the

fuel chamber than

the

engine

can consume,

the

outlet check valve

is

held closed. Fuel

gathered

in

lift pump chamber prevents

the

diaphragm

from relaxing.

The

lever will continue

to

move

up and

down

on the

shaft connecting

it to the

diaphragm. How ever,

it is

prevented from operating

the

diaphragm until

the check valve again opens

and the

fuel

in the

pump chamber

is

expelled. This process continues

as

long

as

the engine

is

running. Minimum lift pump output pressure

is 21 Kpa (3

psi).

Lift pump output volume

is 0.75

liters

(0.70 U.S.

quarts)

per 30

seconds

of

engine cranking.

Fig.

25 Lift

Pump

The lift pump housing

has a

weep hole

at the

bot

tom

of the

casing

(Fig. 25). If the

diaphragm rup

tures,

fuel will exit

out of the

weep hole

and the

pump must

be

replaced.

The

lift pump

is not

service able

and

must

be

replaced

as a

complete assembly.

CAUTION:

Do not

operate

the

engine

if the

fuel

sup

ply

line

has a

restriction

of

more than

95 MM Hg

(3.75

in Hg).

The lift pump

has a

manual lever

(Fig. 26). The le

ver

is

located

on the

lower right side

of the

pump

housing.

The

purpose

of the

lever

is to

prime

the

fuel system

and

bleed

air

from

the

system

if the

vehicle

has

run out of

fuel. Raise

and

lower

the

lever until

resistance

is

felt

to

prime

the

system

up to the

injec

tor pump. During vehicle operation

the

pump

le

ver must

be in the up

position.

FUEL

PUMP

MANUAL

JKT /

LEVER

——-—•

.

LJ*y^"^^

J9114-3

Fig.

26 Lift

Pump

Manual

Lever

SYSTEM

OPERATION

IGNITION

SWITCH

ON

When

the

ignition switch

is put in the ON (run)

position,

the

following occurs: •

The PCM

receives

an

ignition sense input.

It

then

powers

up.

Battery voltage

is

supplied through

the

battery voltage input. •

The

wait-to-start lamp

and the

water-in-fuel lamp are turned

on by the PCM for 2.8

seconds

as a

bulb test.

•

The PCM

monitors

the

charge

air

temperature

sensor input.

If

manifold

air

temperature

is at or be

low

15°C

(59°F),

the PCM

will start

the air

intake

heater preheat cycle.

It

will energize

the

intake heat

ers

by

grounding

the air

intake heater relays.

The

PCM will turn

the

wait-to-start light

on

until

the

preheat cycle

is

over.

If PCM

receives

a

crank signal

from engine speed sensor before preheat cycle

is

over, it will abort preheat cycle.

•

The PCM

monitors engine speed. When

the

engine speed

is

above

384 rpm, the PCM

determines that

the engine

is

running.

•

The PCM

will turn

on the

water-in-fuel lamp

if a

signal

is

received from

the

water-in-fuel sensor.

ENGINE

START-UP

When

the

ignition

key is put in the

start position,

the following occurs: •

The PCM

receives

a

crank signal input from

the

engine speed sensor.

•

The air

intake heaters

are not

energized during cranking.

Page 1432 of 1502

•

^ ^ —

BODY COMPONENTS

23 - 49

HEADLINER ROOF

INNER PANEL

ROOF

INNER PANEL

SCREW

ROOF

RAIL

HEADER

TRIM

PANEL HEADLINER

J9123-353

Fig.

40

Cloth-Covered

Molded

Cab Headliner

ROOF

INNER PANEL RETAINER RAIL

CENTERING HOLE

REAR

HEADLINER

RETAINER PERIMETER

RETAINER

INSTALLATION

TRIM

'MOULDING

J9123-358

Fig.

41

Ramcharger

Headliner

INNER

BACK

PANEL

ROOF

—

INNER

PANEL

REAR

WINDOW

UPPER

TRIM

SUNVISOR SUNVISOR

AND WINDSHIELD HEADER

TRIM

DOME LAMP LENSE

DOME AND

WINDOW

TRIM

LAMP

LENSE

J9l

23-352

Fig.

42 Ram

Truck/Chassis

Cab

Sunvisor

&

Dome

Lamp

ROOF

INNER

v

PANEL

SIDE

TRIM

MOULDING

HEADLINER

RETAINER

RAIL

FRONT

HEADLINER

SCREW

SIDE

OF VEHICLE ROOF INNER PANEL

WINDSHIELD

WEATHERSTRIP

SEAL

ROOF

INNER PANEL

REAR

HEADLINER

SCREW

RETAINER SNAP-ON

TRIM

MOULDING

ENDCAP CENTER OF VEHICLE

FRONT

HEADLINER

REAR

HEADLINER ROOF INNER

PANEL WINDSHIELD

HEADER

TRIM

MOULDING

FRONT

OF VEHICLE

SCREW

SCREW

SUN VISOR SCREW

REAR

TRIM

ARM

MOULDING

REAR

OF VEHICLE

J9123-359

Fig.

43

Ramcharger

Sunvisor

& Headliner

Trim

Moulding

ROOF

INNER PANEL

BRACKET

BULB

HOLDER DOME

LAMP

BRACKET

HEADLINER

LENSE

DOME LAMP

WITH

HEADLINER

SCREW

DOME LAMP CLUB CAB

BULB

HOLDER

J9123-401

Fig.

44 Ram

Truck/Chassis

Cab

Dome

Lamps

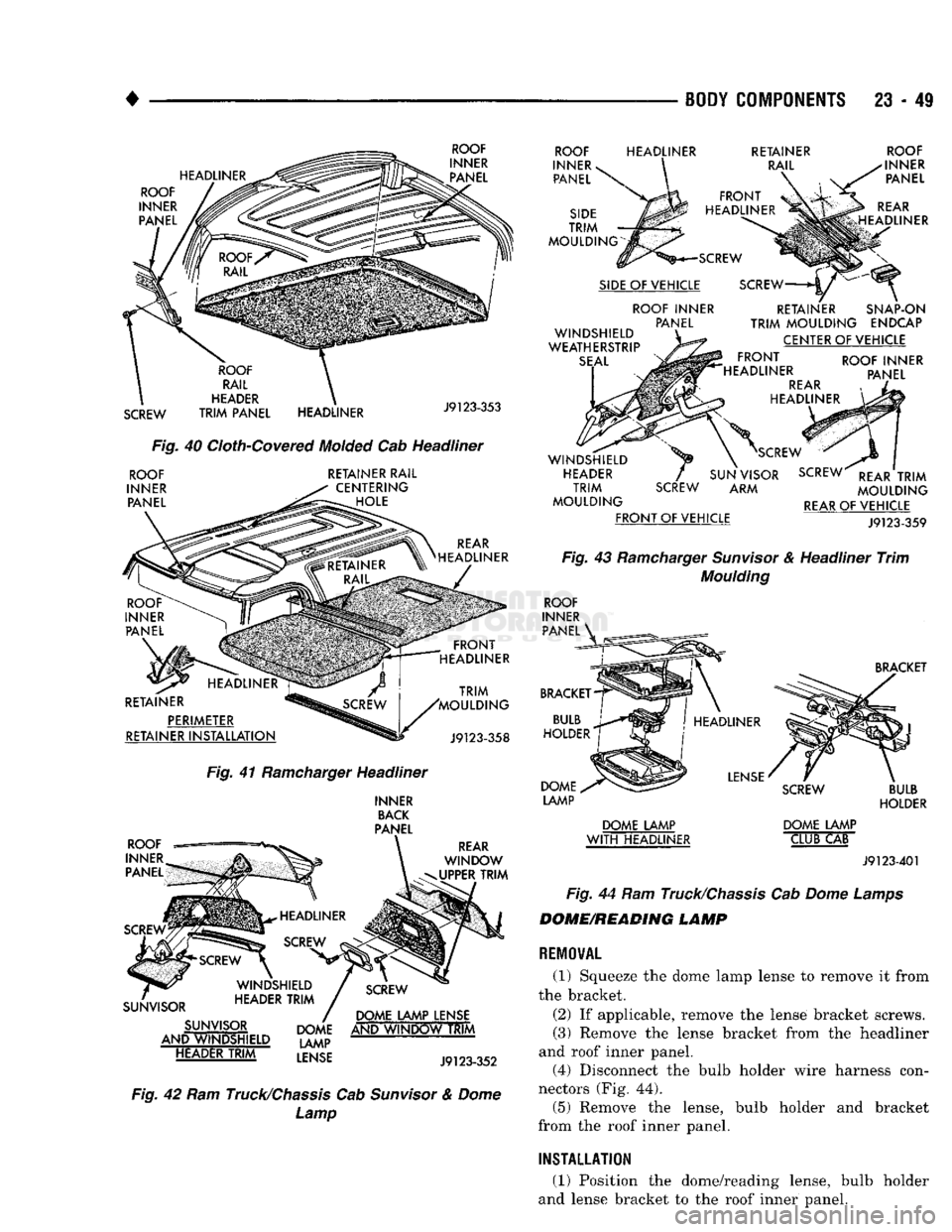

DOME/READING LAMP

REMOVAL

(1) Squeeze the dome lamp lense to remove it from

the bracket.

(2) If applicable, remove the lense bracket screws.

(3) Remove the lense bracket from the headliner

and roof inner panel. (4) Disconnect the bulb holder wire harness con

nectors (Fig. 44). (5) Remove the lense, bulb holder and bracket

from the roof inner panel.

INSTALLATION

(1) Position the dome/reading lense, bulb holder

and lense bracket to the roof inner panel.