high beam DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 15 of 1502

10 INTRODUCTION

•

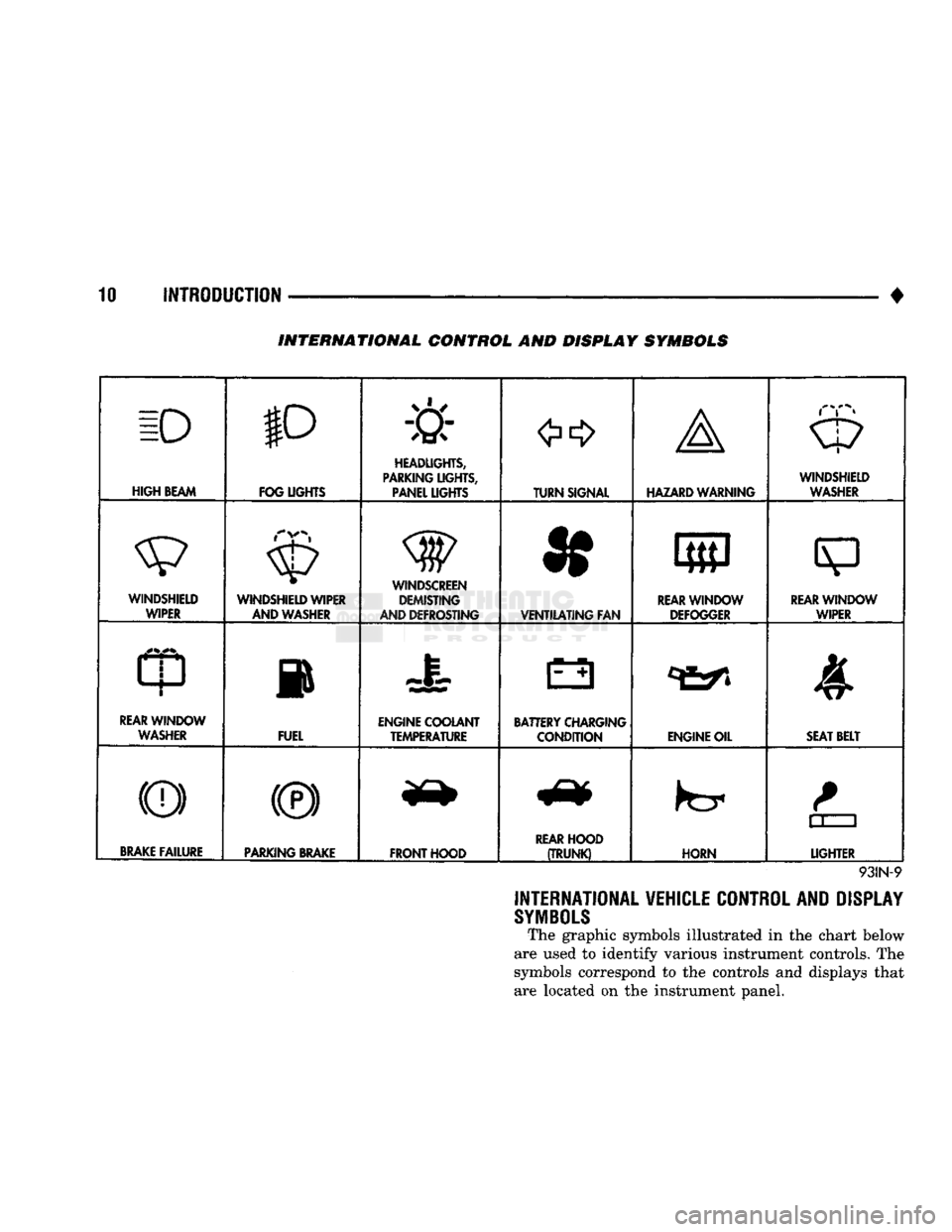

INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

ID

HIGH

BEAM P

FOG UGHTS -&

HEADLIGHTS,

PARKING UGHTS, PANEL UGHTS TURN SIGNAL A

HAZARD WARNING WINDSHIELD

WASHER

WINDSHIELD WIPER WINDSHIELD WIPER

AND WASHER

AND DEFROSTING *

VENTILATING

FAN 8

M f

REAR

WINDOW DEFOGGER

sp

REARWINLX)W WIPER

CD

l

m

REAR

WINDOW WASHER FUEL ENGINE COOLANT

TEMPERATURE BATTERY CHARGING

CONDITION ENGINE OIL

SEAT

BELT

(©) (®) ky

11 J

LIGHTER

BRAKE

FAILURE

PARKING

BRAKE

FRONT HOOD

REAR

HOOD

(TRUNK)

HORN

11 J

LIGHTER

93IN-9

INTERNATIONAL VEHICLE CONTROL AND DISPLAY

SYMBOLS

The graphic symbols illustrated in the chart below

are used to identify various instrument controls. The

symbols correspond to the controls and displays that are located on the instrument panel.

Page 382 of 1502

• • ^ ^ ^ INSTRUMENT PANEL AND GAUGES 8E - 1

CONTENTS

page

CLUSTER AND GAUGE SERVICE PROCEDURES . 12

CLUSTER AND GAUGE TEST PROCEDURES .. i

GENERAL INFORMATION . 1

page

MESSAGE CENTER-DIESEL ENGINE ........ 4

MESSAGE CENTER-GAS ENGINE .......... 3

SWITCH

AND PANEL COMPONENT SERVICE . 16

GENERAL

INFORMATION

INDEX

page

Generator

Indicating

System

2

Distance

Sensor

2

Electronic

Digital

Clock

3

Fuel

Level

Indicating

System

1

page

Malfunction

Indicator

(Check

Engine)

3

Oil

Pressure

Warning

Lamp

................. 2

Speedometer/Odometer

System

2

Temperature

and Oil

Indicating

System

......... 2

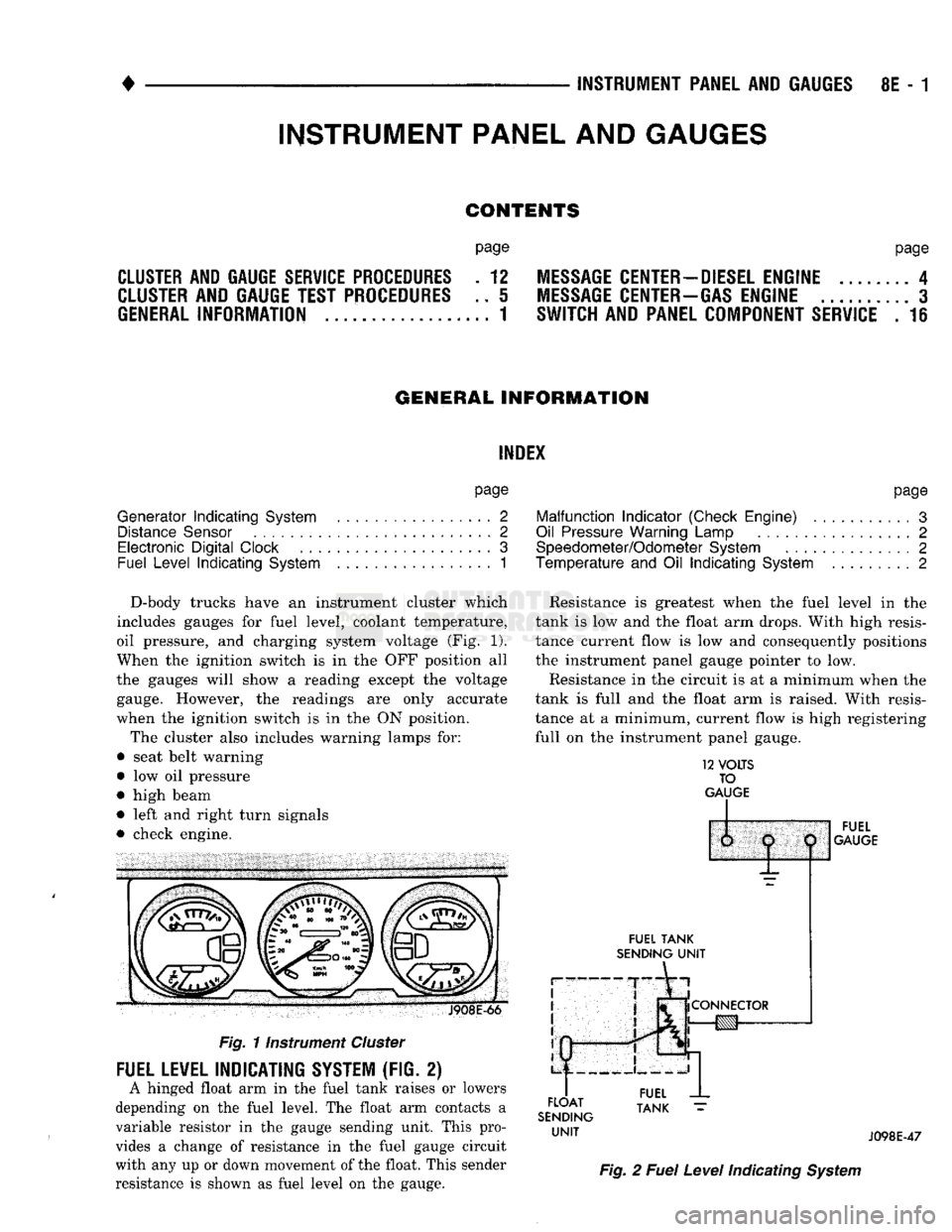

D-body trucks have an instrument cluster which

includes gauges for fuel level, coolant temperature,

oil pressure, and charging system voltage (Fig. 1).

When the ignition switch is in the OFF position all

the gauges will show a reading except the voltage gauge. However, the readings are only accurate

when the ignition switch is in the ON position.

The cluster also includes warning lamps for:

• seat belt warning

• low oil pressure

• high beam

• left and right turn signals

• check engine. J908E-66

Fig.

11nstrument

Cluster

FUEL LEVEL INDICATING SYSTEM (FIG. 2)

A hinged float arm in the fuel tank raises or lowers

depending on the fuel level. The float arm contacts a

variable resistor in the gauge sending unit. This pro

vides a change of resistance in the fuel gauge circuit

with any up or down movement of the float. This sender

resistance is shown as fuel level on the gauge. Resistance is greatest when the fuel level in the

tank is low and the float arm drops. With high resis

tance current flow is low and consequently positions

the instrument panel gauge pointer to low.

Resistance in the circuit is at a minimum when the

tank is full and the float arm is raised. With resis

tance at a minimum, current flow is high registering

full on the instrument panel gauge.

12

VOLTS

TO

GAUGE

IP

FUEL

TANK

SENDING

UNIT

FLOAT

SENDING

UNIT

1:

1

j

^

fCONNECTOR

!g|yj-»—

FUEL

GAUGE

FUEL

TANK

J098E-47

Fig.

2

Fuel

Level

Indicating

System

INSTRUMENT PANEL AND GAUGES

Page 396 of 1502

•

INSTRUMENT PANEL

AND

GAUGES

8E - 15

PRND21 INDICATOR

REMOVAL

(1) Remove bezel. Refer to Cluster Bezel Removal.

(2)

Remove cluster mask and lens. Refer to Cluster

Mask and Lens Removal. (3) Remove cluster assembly. Refer to Instrument

Cluster Removal. (4) Remove screws attaching PRND21 mechanism

to cluster housing.

(5)

Remove PRND21 mechanism.

INSTALLATION (1) Position PRND21 mechanism to cluster hous

ing. (2) Install mounting screws.

(3)

Install cluster assembly. (4) Install mask-lens.

(5)

Install bezel.

LAMP BULBS

CLUSTER ILLUMINATION LAMPS TURN SIGNAL INDICATOR LAMPS

LOW OIL PRESSURE INDICATOR LAMP

HIGH BEAM INDICATOR LAMP CHECK ENGINE LAMP

SEAT BELT WARNING LAMP

REMOVAL (1) Disconnect negative cable from battery.

(2) Remove instrument cluster. See cluster re

moval.

(3)

Twist lamp socket assembly and remove from

printed circuit board. (4) Remove bulb from socket.

INSTALLATION (1) Install bulb into socket.

(2) Install socket assembly into printed circuit

board.

(3)

Position cluster into place in panel. See cluster

installation. (4) Connect battery negative cable.

LAMP BULB REPLACEMENT—MESSAGE CENTER

REMOVAL (1) Disconnect battery negative cable.

(2) Remove instrument cluster bezel assembly. Re

fer to Instrument Cluster removal.

(3)

Twist lamp socket assembly and remove from

printed circuit board. (4) Remove bulb from socket.

INSTALLATION (1) Install bulb into socket assembly. (2) Install lamp socket assembly into printed cir

cuit board.

(3)

Install Instrument Cluster bezel assembly to

instrument panel. Refer to Instrument Cluster instal

lation.

(4) Connect negative cable from battery.

FOUR WHEEL DRIVE INDICATOR LAMP (1) Pull bulb and socket assembly from rear of

housing. (2) Remove bulb from socket.

(3)

Reverse removal procedures to install.

SPECIFICATIONS

Fuel

Gauge Calibration

Mntar Position Resistance

Empty Graduation 90

ohms

± 3

ohms

Empty Stop

Greater

than

96.5 ohms

Full

Graduation 12 ohm

± 3

ohms

Full

Stop

Less

than

8

ohms

1/2

45.3 ohms

± 3

ohms

Temperature

Gauge

Calibration

Pointer

Position Resistance

Cold Graduation 655 ohms

Hot Graduation 64 ohms

Oil Pressure Gauge Calibration

Pointer

Position Resistance

Low Graduation 100 ohms

High Graduation 12 ohms

J908E-58

Page 444 of 1502

•

LAMPS

LAMPS

8L - 1

CONTENTS

page page

BULB

APPLICATION 11 EXTERIOR

LAMPS

SERVICE

PROCEDURES

... 3

EXTERIOR

LAMPS

1 INTERIOR

LAMPS

10

EXTERIOR LAMPS

GENERAL

INFORMATION Each vehicle is equipped with various lamp assem

blies.

A good ground is necessary for proper lighting operation. When changing lamp bulbs check the socket for

corrosion. Clean corrosion with a wire brush. Coat

the inside of the socket lightly with Mopar® Multi- Purpose Grease or equivalent.

DIAGNOSTIC

PROCEDURES

Always begin any diagnosis by testing all of the

fuses and circuit breakers in the system. Refer to Group 8W, Wiring Diagrams. Conventional and halogen headlamps are inter

changeable. It is recommended that they not be in

termixed on a given vehicle.

MULTI-FUNCTION

SWITCH TESTING

PROCEDURES

The multi-function switch contains electrical cir

cuitry for:

• Headlamp Dimmer Switch

• Passing Lights

• Turn Signals

• Hazard Warning • Windshield Wiper

• Pulse Wiper

• Windshield Washer

HEADLAMPS

HIM

ENGINE

IDLING

OR

IGNITION

OFF

TEST CHARGING

SYSTEM

HEADLAMP

DIAGNOSIS

SEALED

BEAM

OR

BULB

BURNS

OUT

FREQUENTLY

][

TEST CHARGING SYSTEM

HEADLAMPS

DIM

ENGINE

RUNNING

ABOVE

IDLE

][

TEST CHARGING SYSTEM

HEADLAMPS

RANDOM

FLASH

[

HEADLAMPS

WILL

NOT

LIGHT

POORLY GROUNDED HEADLAMP CIRCUIT

LOOSE

CONNECTION

IN HEADLAMP CIRCUIT

HIGH RESISTANCE IN HEADLAMP CIRCUIT

LOOSE

CONNECTION

IN HEADLAMP CIRCUIT HIGH RESISTANCE

IN HEADLAMP CIRCUIT

LOOSE

CONNECTION

IN HEADLAMP CIRCUIT OPEN OR CORRODED

CONTACT

IN

HEADLAMP SWITCH

CRACKED

LENS ON HALOGEN SEALED BEAM ONLY

FAULTY

SEALED

BEAMS

OR BULBS OPEN OR CORRODED

CONTACT IN DIMMER SWITCH

FAULTY

SEALED

BEAMS

OR BULBS

FAULTY

SEALED

BEAMS

OR BULBS

RR8LD21

Page 445 of 1502

8L

- 2

LAMPS

• This switch is mounted to the left hand side of the

steering column. Should any function of the switch

fail,

the entire switch must be replaced.

SWITCH

TEST

(1) Disconnect battery negative cable.

(2) Remove tilt lever.

(3) Remove upper and lower column covers to gain

access to the switch connector (Fig. 1).

(4) Remove lower fixed column cover.

(5) Loosen steering column upper bracket nuts. Do

not remove nuts.

(6) Move upper fixed column cover to gain access

to rear of multi-function switch.

(7) Remove switch connector (Figs. 2 and 3). (8) Use an ohmmeter to test for continuity. Check

between the terminals of the switch as shown in the continuity chart (Fig. 4).

(9) Refer to Service Procedures for assembly.

UPPER SHROUD GROUND

CLIP UPPER

FIXED SHROUD

SUPPORT BRACKET

LOWER

SHROUD LOWER

FIXED

SHROUD

J9119-22

Fig.

1 Steering

Column

Covers

STEERING

COLUMN

ASSY.

J918J-1

TURN

SIGNAL

MULT

I

SWITCH

AND

*® FUNCTION

LEVER

SWITCH

CONNECTOR

Fig.

2 Multi-function

Switch

Connector

KEY-IN

SWITCH

&

HALO

LIGHT

MULTIFUNCTION

SWITCH

IGNITION

SWITCH

TURN

SIGNAL

SWITCH

&

LEVER

SPEED

CONTROL

J918J-2

Fig.

3 Steering

Column

Connectors

24 23 22 21 20 19 18

EZJ

C=3 C=3 E=3

CZZJ

E=3 E=3

17 16 15 14 13 12 11 10

a a a 8=3 ( ( ) ) 1=3 1=3 1=3 9 8 7 6 \5_y4 3 2 1

VIEW

FROM

TERMINAL

SIDE

SWITCH POSITION CONTINUITY BETWEEN

LOW

BEAM

HIGH

BEAM

OPTICAL

HORN

18 AND 19

19 AND 20

20

AND

21

908J-5

Fig.

4

Beam

Select

Switch

Continuity Chart

Page 446 of 1502

•

LAMPS

8L - 3

EXTERIOR

LAMPS

SERWICE PROCEDURES

INDEX

page

Cargo

Lamp

7

Clearance Lamps

for

Dual Wheel Model

........

5

Daytime Running

Light

Module (Canada Only)

... 8

Front

Park

and

Turn Signal Lamp Bulb

4

Headlamp

Adjustment

Using

Alignment

Screen

... 3

Headlamp

Alignment

3

Headlamp

Alignment

Preparation

3

page

Headlamp Switch

4

License

Lamp

............................

7

Sealed

Beam Replacement

4

Side

Marker Lamp

and

Bulb

. 5

Tail,

Stop, Turn Signal, Rear Side Marker

and

Back-Up

Lamps

5

Underhood Lamp

8

HEADLAMP

ALIGNMENT

Headlamps

can be

aligned using

the

screen method

provided

in

this section. Alignment Tool C4466-A

or

equivalent

can

also

be

used. Refer

to

instructions

provided with

the

tool

for

proper procedures.

The

preferred headlamp alignment setting

is 0 for

the left/right adjustment

and

1" down

for the up/

down adjustment.

HEADLAMP

ALIGNMENT PREPARATION

(1) Verify headlamp dimmer switch

and

high beam

indicator operation. (2) Correct defective components that could hinder

proper headlamp alignment. (3) Verify proper tire inflation. (4) Clean headlamp lenses.

(5) Verify that luggage area

is not

heavily loaded.

(6) Fuel tank should

be

FULL.

Add 2.94 kg (6.5

lbs.)

of

weight over

the

fuel tank

for

each estimated

gallon

of

missing fuel.

HEADLAMP

ADJUSTMENT USING ALIGNMENT

SCREEN

ALIGNMENT SCREEN PREPARATION (1) Position vehicle

on a

level surface perpendicu

lar

to a

flat wall

7.62

meters

(25 ft)

away from front

of headlamp lens.

(2)

If

necessary, tape

a

line

on the

floor

7.62

meters

(25 ft)

away from

and

parallel

to the

wall.

CENTER

OF

VEHICLE

TO

CENTER

OF

HEADLAMP

LENS

VEHICLE

CENTERLINE" LOW BEAM

HOT

SPOT AREA FLOOR

TO

CENTER

OF

HEADLAMP

LENS

PREFERRED

HOT SPOT

LOCATION

7.62

METERS

(25

FEET)

FRONT

OF

HEADLAMP

938L-25X

Fig.

1 Headlamp

Alignment

Screen

—Typical

Page 447 of 1502

8L

- 4

LAMPS

• (3) Up 1.27 meters (5 feet) from the floor, tape a

line on the wall at the centerline of the vehicle.

Sight along the centerline of the vehicle (from rear of

vehicle forward) to verify accuracy of the line place

ment.

(4) Rock vehicle side-to-side three times to allow

suspension to stabilize. (5) Jounce front suspension three times by pushing

downward on front bumper and releasing. (6) Measure the distance from the center of head

lamp lens to the floor. Transfer measurement to the alignment screen (with tape). Use this line for up/

down adjustment reference.

(7) Measure distance from the centerline of the ve

hicle to the center of each headlamp being aligned. Transfer measurements to screen (with tape) to each side of vehicle centerline. Use these lines for left/

right adjustment reference.

HEADLAMP

ADJUSTMENT

A properly aimed low beam headlamp will project

top edge of high intensity pattern on screen from 50 mm (2 in.) above to 50 mm (2 in.) below headlamp

centerline. The side-to-side outboard edge of high in

tensity pattern should be from 50 mm (2 in.) left to 50 mm (2 in.) right of headlamp centerline (Fig. 1).

The preferred headlamp alignment is 0 for the

up/down adjustment and 1" down for the left/

right adjustment. The high beam pattern should be correct when the iow beams are aligned properly (Fig. 2).

To adjust headlamp aim, rotate alignment screws

to achieve the specified high intensity pattern.

1.

HORIZONTAL

ADJ. SCREW

- RH

2.

VERTICAL

ADJ. SCREW

3.

HORIZONTAL

ADJ. SCREW

- LH

J908L-24

Fig.

2

Sealed

Beam

Headlamp

Alignment

SEALED

BEAM REPLACEMENT

(1) Remove the headlamp bezel (Fig. 3).

(2) Remove four screws from retaining ring (Fig.

4).

(3) Separate sealed beam from seat and disconnect

from the socket. To install, reverse the removal procedures.

HEADLAMP

BEZEL

: ') J918L-29

Fig.

3 Headlamp

Bezel

RETAINING

RING

SCREWS

J918L-28

Fig.

4

Sealed

Beam

Replacement

HEADLAMP SWITCH

To remove or replace the headlamp switch see in

structions in Group 8E - Instrument Panel and

Gauges.

FRONT

PARK AND

TURN

SIGNAL LAMP BULB

(1) Remove 2 screws securing the Park/Turn signal

lamp (Fig. 5) (2) Twist out lamp socket from back of lamp hous

ing. (3) Replace bulb.

To install, reverse removal procedures.

Page 454 of 1502

•

LAMPS

8L - 11

BULB

APPLICATION

GENERAL

INFORMATION

The following Bulb Application Table lists

the

lamp title

on the

left side

of the

column

and

part

number

on the

right.

CAUTION:

Do not use

bulbs

that

have

a

higher

can

dle power than

the

bulb

listed

in the

Bulb

Applica

tion Table.

Damage

to

lamp

can

result.

EXTERIOR LAMPS

Auxiliary Turn Signal (Snow Plow) 2057

Auxiliary Headlamps (Snow Plow) .6054

Back-up....................... .......1156 Cargo Lamp..

922

Clearance Lamps

194

Front Side Marker

168

Headlamp/Sealed Beam .6052

License Plate

168

Park/Turn Signal 2057

TaiyStop/Turn Signal ...2057

INTERIOR LAMPS

DIMMER CONTROLLED LAMPS Service procedures

for

most

of the

lamps

in the in

strument panel

are

located

in

Group

8E,

Instrument

Panel

and

Gauges. Some components have lamps

that

can

only

be

serviced

by an

Authorized Service Center (ASC). These components must

be

removed

from

the

vehicle

for

service. Contact local dealer

for

location

of

nearest

ASC.

A/C Heater Control

158

Ash Receiver

..158

Gear Shift Selector...........................................PC194

Heater Control

158

Instrument Cluster.. PC 194

Radio

ASC

Snow Plow Control

.158

INDICATOR LAMPS Service procedures

for

most

of the

lamps

in the in

strument panel,

and

switches

are

located

in

Group

8E,

Instrument Panel

and

Gauges. Anti-lock Brake PC194

Brake Warning PC194 Check Engine PC194

Engine

Oil

Pressure

158

Fasten Seat Belts.. PC 194 Four Wheel Drive ....158

Hazard Flasher

194

High Beam PC194

Low Fuel....... JPC194

Maintenance Required PC 194

Transmission Temperature ..PC 194 Turn Signal PC194

NON-DIMMING LAMPS Service procedures

for

most

of the

lamps

in the

fol

lowing list

can be

found

in

Group

23,

Body.

Dome

1004

Engine Compartment ...105 Glove Compartment....

1891

Ignition Lock

ASC

Reading Lamp

912

Page 513 of 1502

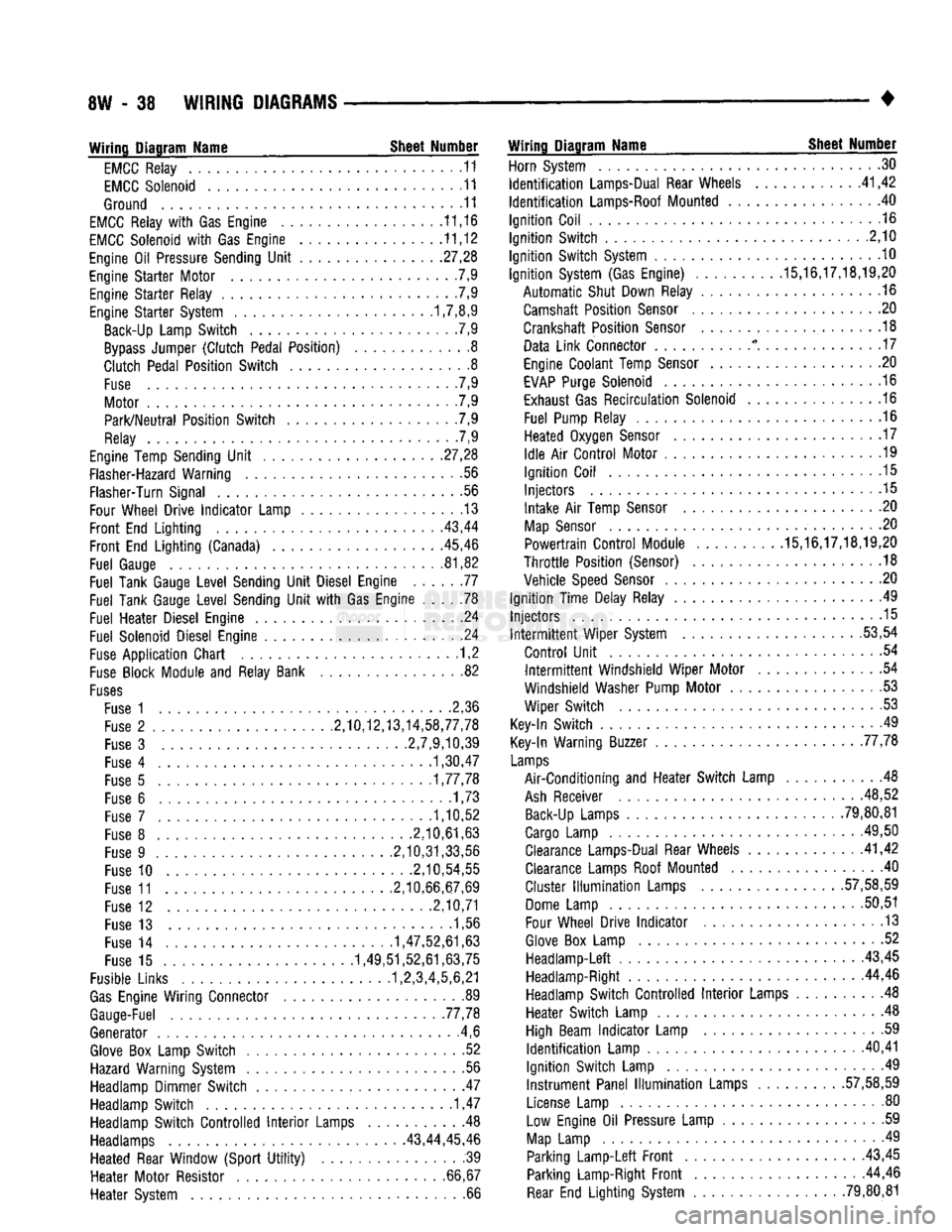

8W

- 38

WIRING

DIAGRAMS

• Wiring Diagram Name Sheet Number

EMCC

Relay

11

EMCC

Solenoid

11

Ground

11

EMCC

Relay

with Gas

Engine

11,16

EMCC

Solenoid

with Gas

Engine

11,12

Engine

Oil

Pressure Sending

Unit

.27,28

Engine

Starter

Motor

7,9

Engine

Starter

Relay

.7,9

Engine

Starter

System 1,7,8,9 Back-Up Lamp

Switch

.7,9

Bypass

Jumper

(Clutch

Pedal

Position)

8

Clutch

Pedal

Position

Switch

8

Fuse

. 7,9

Motor

7,9

Park/Neutral

Position

Switch

. .7,9

Relay

7,9

Engine Temp Sending

Unit

.

.27,28

Flasher-Hazard Warning

.56

Flasher-Turn Signal

56

Four Wheel

Drive

Indicator

Lamp

13

Front

End

Lighting

. .

.43,44

Front

End

Lighting

(Canada) 45,46

Fuel

Gauge

81,82

Fuel

Tank Gauge

Level

Sending

Unit

Diesel Engine

77

Fuel

Tank Gauge

Level

Sending

Unit

with Gas

Engine

78

Fuel

Heater

Diesel Engine

24

Fuel

Solenoid Diesel Engine

.24

Fuse

Application

Chart

1,2

Fuse

Block Module

and

Relay Bank

82

Fuses

Fuse

1 2,36

Fuse

2

.........

2,10,12,13,14,58,77,78

Fuse

3

2,7,9,10,39

Fuse

4

1,30,47

Fuse

5

1,77,78

Fuse

6

......

.1,73

Fuse

7

1,10,52

Fuse

8

.2,10,61,63

Fuse

9

.2,10,31,33,56

Fuse

10

.2,10,54,55

Fuse

11

2,10,66,67,69

Fuse

12

2,10,71

Fuse

13 1,56

Fuse

14

1,47,52,61,63

Fuse

15

1,49,51,52,61,63,75

Fusible Links 1,2,3,4,5,6,21

Gas

Engine

Wiring

Connector

89

Gauge-Fuel .77,78

Generator

.4,6

Glove

Box

Lamp

Switch

52

Hazard Warning System

. .56

Headlamp Dimmer

Switch

47

Headlamp

Switch

1,47

Headlamp

Switch

Controlled

Interior

Lamps

Headlamps 43,44,

Heated

Rear Window

(Sport

Utility)

Heater

Motor

Resistor

Heater

System Wiring Diagram Name Sheet Number

Horn System

30

Identification

Lamps-Dual Rear Wheels

41,42

Identification

Lamps-Roof Mounted

. 40

Ignition

Coil

.16

Ignition

Switch

.2,10

Ignition

Switch

System

10

Ignition

System (Gas Engine)

.........

.15,16,17,18,19,20

Automatic

Shut Down Relay

.16

Camshaft

Position

Sensor

20

Crankshaft

Position

Sensor

.18

Data

Link

Connector

* . . .17

Engine Coolant Temp

Sensor

20

EVAP

Purge Solenoid

16

Exhaust Gas

Recirculation

Solenoid

16

Fuel

Pump Relay

.16

Heated

Oxygen

Sensor

. . . 17

Idle

Air

Control

Motor

.19

Ignition

Coil

.15

Injectors

.15

Intake

Air

Temp

Sensor

. .20

Map

Sensor

. .20

Powertrain

Control

Module .15,16,17,18,19,20

Throttle

Position

(Sensor)

.18

Vehicle

Speed

Sensor

.20

Ignition

Time

Delay Relay

49

Injectors

.15 Intermittent

Wiper

System .53,54

Control

Unit

.54 Intermittent

Windshield

Wiper

Motor

54

Windshield

Washer Pump

Motor

53

Wiper

Switch

53

Key-In

Switch

49

Key-In Warning Buzzer 77,78

Lamps

Air-Conditioning

and

Heater

Switch

Lamp

48

Ash

Receiver .48,52 Back-Up Lamps

......

79,80,81

Cargo Lamp

.

.49,50 Clearance Lamps-Dual Rear Wheels .41,42

Clearance Lamps Roof Mounted

.40

Cluster

Illumination

Lamps

.

.57,58,59

Dome Lamp

50,51

Four Wheel

Drive

Indicator

.13

Glove

Box

Lamp

52

Headlamp-Left

43,45 Headlamp-Right 44,46

Headlamp

Switch

Controlled

Interior

Lamps

. 48

Heater

Switch

Lamp

.48

High Beam

Indicator

Lamp

.59

Identification

Lamp

.

.40,41

Ignition

Switch

Lamp

.49

Instrument

Panel

Illumination

Lamps

.

.57,58,59

License Lamp

. . . 80

.

.48 Low

Engine

Oil

Pressure Lamp

59

45,46

Map

Lamp

49

.

.39

Parking

Lamp-Left

Front

43,45

66,67 Parking Lamp-Right

Front

44,46 .

.66

Rear

End

Lighting

System .79,80,81

Page 575 of 1502

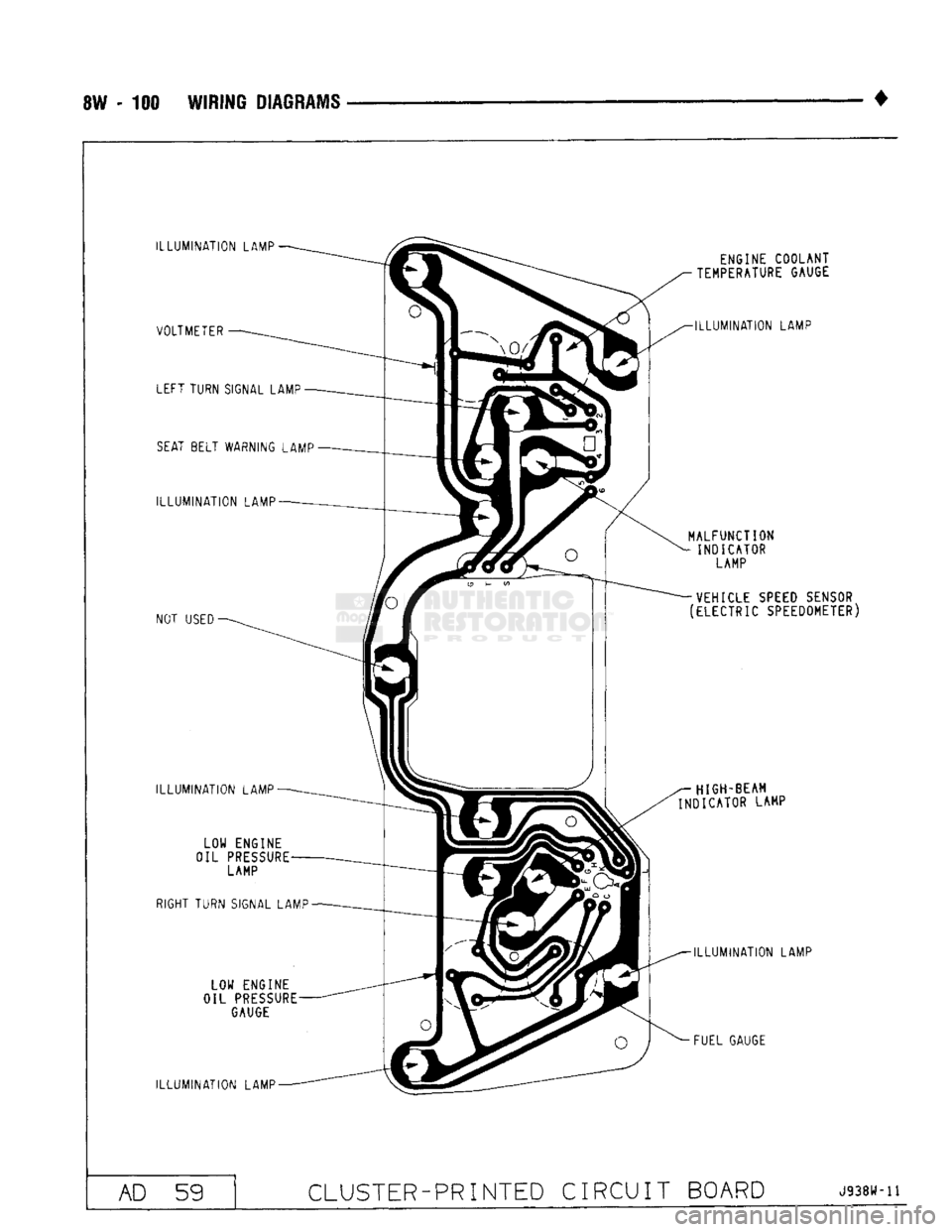

8W - 100 WIRING DIAGRAMS

ILLUMINATION

LAMP VOLTMETER LEFT TURN SIGNAL LAMP

SEAT

BELT WARNING LAMP

ILLUMINATION

LAMP

NOT

USED

ILLUMINATION

LAMP LOW ENGINE

OIL

PRESSURE

LAMP

RIGHT TURN SIGNAL LAMP

LOW ENGINE

OIL

PRESSURE

GAUGE

ILLUMINATION

LAMP ENGINE COOLANT

TEMPERATURE GAUGE

ILLUMINATION

LAMP

MALFUNCTION

INDICATOR LAMP

VEHICLE SPEED SENSOR

(ELECTRIC SPEEDOMETER)

HIGH-BEAM

INDICATOR LAMP

ILLUMINATION

LAMP

FUEL GAUGE AD 59

CLUSTER-PRINTED

CIRCUIT BOARD

J938W-11